A New Approach for Modeling Mixed Lubricated Piston-Cylinder Pairs of Variable Lengths in Swash-Plate Axial Piston Pumps

(This article belongs to the Section Manufacturing Processes and Systems)

Abstract

:1. Introduction

2. The Mixed Lubrication Model of a Piston-Cylinder Tribo-Pair

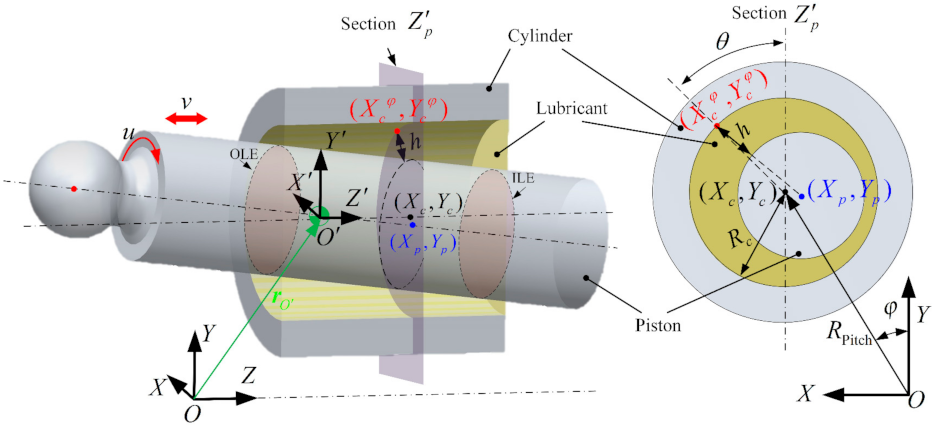

2.1. The Hydrodynamic Mixed Lubrication Model

2.2. The FEM-Based Model for Solving the Reynolds Equation

2.3. Forces and Moments Acting on the Piston

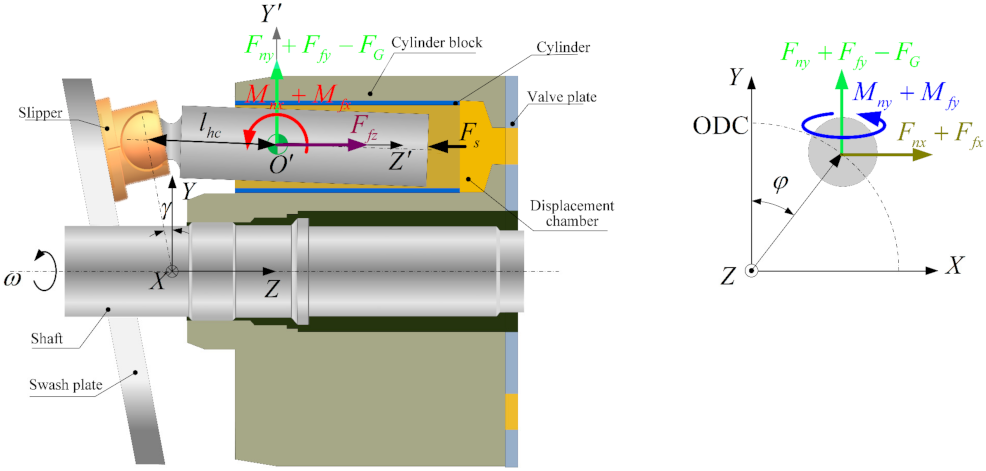

3. Multibody Dynamics Model of a Swash-Plate Axial Piston Pump

3.1. Multibody Dynamics Model of the Pump Based on the Lagrangian Formalism

3.2. Computational Algorithm

4. Model Validation

5. Results and Discussion

5.1. The Performance of the Piston-Cylinder Interface with Variable Lengths

5.2. The Influence of the Cylinder Length

5.3. The Influence of the Tilt Angle of the Swash-Plate

6. Conclusions

- (1)

- Increasing the cylinder length can enlarge the lubrication interface. This can improve the stability of the piston by reducing the misalignment and eccentricity of the piston, especially in the pumping stroke.

- (2)

- Increasing the cylinder is conducive to improving the wear-resistance of the piston by raising the minimum oil film thickness and reducing the duration of the mixed lubrication, but it can aggravate the friction force and thus the frictional power loss.

- (3)

- In practical applications, although enlarging the tilt angle of the swash plate can effectively increase the pump displacement, it can easily lead to serious friction, wear, and leakage problems. Consequently, the tilt angle of the swash plate should be carefully selected.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Radial clearance | |

| Total normal force | |

| Total friction force | |

| The gravity of the piston | |

| Supply pressure force | |

| Oil film thickness | |

| Distance between the head to the COM of the piston | |

| Piston Length | |

| Cylinder length | |

| The time | |

| , | The axial and circumferential sliding velocity of the piston relative to the cylinder |

| Leakage flow | |

| Supply pressure from the displacement chamber | |

| The inner radius of the cylinder | |

| The radius of the piston | |

| The pitch radius | |

| The position of the COM of the piston in the global coordinate system | |

| Stiff matrix of the Reynold equation with FEM | |

| System mass matrix | |

| The total moments from the normal pressure | |

| The total moments from the shear stress | |

| Shape function of discrete elements | |

| Oil film pressure | |

| Asperity contact pressure | |

| Generalized force vector | |

| Generalized Cartesian coordinates of the system | |

| Mass of the piston | |

| , | Inertia moments of the piston corresponding to its com |

| , | Local coordinate axis along the circumferential direction and axial direction of the unwrapped fluid film thickness |

| The shaft speed | |

| Convergence criterion | |

| Dynamic viscosity of oil | |

| , | Pressure flow factors |

| Hydrodynamic shear stress, in both axial and circumferential directions | |

| Shear flow factor | |

| , | Shear stress factors |

| Contact factor | |

| Term to average the sliding velocity component of the shear stress | |

| Composite roughness of the surface | |

| , | The roughness of the piston and cylinder, respectively. |

| Angular coordinate in | |

| , | The inclination angle of the piston axis in . |

| Shaft angle of the pump | |

| The lubrication domain | |

| The boundary of an integral domain | |

| The friction coefficient of the asperity contact | |

| Kinematic constraints | |

| Lagrange multipliers | |

| , | Feedback parameters in Baumgarte’s approach |

| The tilt angle of the swash plate | |

| Coordinate systems | |

| The global coordinate system of the multibody system | |

| The local coordinate system fixed on the COM of the piston and parallel to the global coordinate system | |

References

- Wang, D.; Song, Y.; Tian, J.; E, S.; Haidak, G. Research on the fluid film lubrication between the piston-cylinder interface. AIP Adv. 2018, 8, 105330. [Google Scholar] [CrossRef]

- Sun, S.Q.; Sun, N.; Wang, X.L. Study on mixed lubrication characteristics of piston/cylinder interface of variable length. AIP Adv. 2019, 9, 075303. [Google Scholar] [CrossRef] [Green Version]

- Yi, F.; Shirakashi, M. Mixed Lubrication Characteristics Between the Piston and Cylinder in Hydraulic Piston Pump-Motor. Psychiatry Res. 1995, 117, 658–666. [Google Scholar]

- Manring, N.D. Friction Forces Within the Cylinder Bores of SwashPlate Type Axial-Piston Pumps and Motors. J. Dyn. Syst. Meas. Control 1999, 121, 531–537. [Google Scholar] [CrossRef]

- Pelosi, M.; Ivantysynova, M. Heat Transfer and Thermal Elastic Deformation Analysis on the Piston/Cylinder Interface of Axial Piston Machines. J. Tribol. 2012, 134, 041101. [Google Scholar] [CrossRef]

- Pelosi, M.; Ivantysynova, M. The Impact of Axial Piston Machines Mechanical Parts Constraint Conditions on The Thermo-Elastohydrodynamic Lubrication Analysis of The Fluid Film Interfaces. Int. J. Fluid Power 2013, 14, 35–51. [Google Scholar] [CrossRef]

- Pelosi, M.; Ivantysynova, M. A Geometric Multigrid Solver for the Piston-Cylinder Interface of Axial Piston Machines. Tribol. Trans. 2012, 55, 163–174. [Google Scholar] [CrossRef]

- Ernst, M.; Ivantysynova, M. Axial Piston Machine Cylinder Block Bore Surface Profile for High-Pressure Operating Conditions with Water as Working Fluid. In Proceedings of the 2018 Global Fluid Power Society PhD Symposium (GFPS), Samara, Russia, 18–20 July 2018. [Google Scholar]

- Ma, X.; Wang, Q.J.; Lu, X.; Mehta, V.S. A transient hydrodynamic lubrication model for piston/cylinder interface of variable length. Tribol. Int. 2018, 118, 227–239. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, K.; Yan, W.; Sun, Y. A novel fluid structure interaction model for the grooved piston-cylinder interface in axial piston pump. AIP Adv. 2019, 9, 055013. [Google Scholar] [CrossRef] [Green Version]

- Li, F.; Wang, D.; Lv, Q.; Haidak, G.; Zheng, S. Prediction on the lubrication and leakage performance of the piston-cylinder interface for axial piston pumps. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5887–5896. [Google Scholar] [CrossRef]

- Chen, X.; Li, F.; Haidak, G.; Wang, D.; Li, S. Characterizations of the oil film considering the elastohydrodynamic lubrication effect of the piston-cylinder interface. AIP Adv. 2020, 10, 095017. [Google Scholar] [CrossRef]

- Nie, S.; Guo, M.; Yin, F.; Ji, H.; Ma, Z.; Hu, Z.; Zhou, X. Research on fluid-structure interaction for piston/cylinder tribo-pair of seawater hydraulic axial piston pump in deep-sea environment. Ocean Eng. 2021, 219, 108222. [Google Scholar] [CrossRef]

- Flores, P.; Ambrósio, J.; Claro, J.P. Dynamic analysis for planar multibody mechanical systems with lubricated joints. Multibody Syst. Dyn. 2004, 12, 47–74. [Google Scholar] [CrossRef] [Green Version]

- Flores, P.; Machado, M.; Seabra, E.; da Silva, M.T. A parametric study on the Baumgarte stabilization method for forward dynamics of constrained multibody systems. J. Comput. Nonlinear Dyn. 2011, 6, 011019. [Google Scholar] [CrossRef]

- Bo, Z.; Fei, S. A numerical coupling model for a multibody system with multiple lubricated clearance joints. MATEC Web Conf. 2017, 108, 15006. [Google Scholar] [CrossRef] [Green Version]

- Zhao, B.; Dai, X.-D.; Zhang, Z.-N.; Xie, Y.-B. A new numerical method for piston dynamics and lubrication analysis. Tribol. Int. 2016, 94, 395–408. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, Z.-N.; Fang, C.-C.; Dai, X.-D.; Xie, Y.-B. Modeling and analysis of planar multibody system with mixed lubricated revolute joint. Tribol. Int. 2016, 98, 229–241. [Google Scholar] [CrossRef]

- Zhao, B.; Cui, Y.; Xie, Y.; Zhou, K. Dynamics and lubrication analyses of a planar multibody system with multiple lubricated joints. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 326–346. [Google Scholar] [CrossRef]

- Zhao, B.; Zhou, K.; Xie, Y.-B. A new numerical method for planar multibody system with mixed lubricated revolute joint. Int. J. Mech. Sci. 2016, 113, 105–119. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. J. Tribol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Schmid, S.R.; Jacobson, B.O. Fundamentals of Fluid Film Lubrication; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Wróblewski, P.; Iskra, A. Problems of Reducing Friction Losses of a Piston-Ring-Cylinder Configuration in a Combustion Piston Engine with an Increased Isochoric Pressure Gain; Society of Automotive Engineers (SAE): Warrendale, PA, USA, 2020; ISSN 0148-7191. [Google Scholar]

- Jiang, X.; Hua, D.; Cheng, H.; Ai, X.; Lee, S.C. A mixed elastohydrodynamic lubrication model with asperity contact. J. Tribol. 1999, 121, 481–491. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H. Application of average flow model to lubrication between rough sliding surfaces. J. Tribol. 1979, 101, 220–229. [Google Scholar] [CrossRef]

- Wu, C.; Zheng, L. An Average Reynolds Equation for Partial Film Lubrication With a Contact Factor. J. Tribol. 1989, 111, 188–191. [Google Scholar] [CrossRef]

- He, Z.; Xie, W.; Zhang, G.; Hong, Z.; Zhang, J. Piston dynamic characteristics analyses based on FEM method Part I: Effected by piston skirt parameters. Adv. Eng. Softw. 2014, 75, 68–85. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, B.; Zhang, K. Modelling three-dimensional soft elastohydrodynamic lubrication contact of heterogeneous materials. Tribol. Int. 2018, 129, 377–389. [Google Scholar] [CrossRef]

- Wang, N.; Chang, C. An application of Newton’s method to the lubrication analysis of air-lubricated bearings. Tribol. Trans. 1999, 42, 419–424. [Google Scholar] [CrossRef]

- Lyu, B.; Meng, X.; Zhang, R.; Wen, C. A deterministic contact evolution and scuffing failure analysis considering lubrication deterioration due to temperature rise under heavy loads. Eng. Fail. Anal. 2021, 123, 105276. [Google Scholar] [CrossRef]

- Greenwood, J.; Tripp, J. The contact of two nominally flat rough surfaces. Proc. Inst. Mech. Eng. 1970, 185, 625–633. [Google Scholar] [CrossRef]

- Akalin, O.; Newaz, G.M. Piston ring-cylinder bore friction modeling in mixed lubrication regime: Part I—Analytical results. J. Tribol. 2001, 123, 211–218. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, H.S.; Arai, T.; Kobayashiy; Aoyama, S. Numerical Simulation of Piston Ring in Mixed Lubrication—A Nonaxisymmetrical Analysis. Trans. ASME 1994, 116, 470–478. [Google Scholar] [CrossRef]

- Masjedi, M.; Khonsari, M.M. Theoretical and experimental investigation of traction coefficient in line-contact EHL of rough surfaces. Tribol. Int. 2014, 70, 179–189. [Google Scholar] [CrossRef]

- Shabana, A.A. Dynamics of Multibody Systems; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Nikravesh, P.E. Computer-Aided Analysis of Mechanical Systems; Prentice-Hall Englewood Cliffs: Hoboken, NJ, USA, 1988; Volume 186. [Google Scholar]

- de Jalón, J.G.; Bayo, E. Kinematic and dynamic simulation of multibody systems. In Mechanical Engineering Series; Springer: New York, NY, USA, 1994. [Google Scholar]

- Ravn, P. A Continuous Analysis Method for Planar Multibody Systems with Joint Clearance. Multibody Syst. Dyn. 1998, 2, 1–24. [Google Scholar] [CrossRef]

- Muvengei, O.; Kihiu, J.; Ikua, B. Numerical study of parametric effects on the dynamic response of planar multi-body systems with differently located frictionless revolute clearance joints. Mech. Mach. Theory 2012, 53, 30–49. [Google Scholar] [CrossRef]

- Machado, M.; Costa, J.; Seabra, E.; Flores, P. The effect of the lubricated revolute joint parameters and hydrodynamic force models on the dynamic response of planar multibody systems. Nonlinear Dyn. 2012, 69, 635–654. [Google Scholar] [CrossRef] [Green Version]

- Muvengei, O.; Kihiu, J.; Ikua, B. Dynamic analysis of planar rigid-body mechanical systems with two-clearance revolute joints. Nonlinear Dyn. 2013, 73, 259–273. [Google Scholar] [CrossRef]

- Kim, J.; Chung, I.; Lee, B. Determination of the feedback coefficients for the constraint violation stabilization method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1990, 204, 233–242. [Google Scholar] [CrossRef]

- Baumgarte, J. Stabilization of constraints and integrals of motion in dynamical systems. Comput. Methods Appl. Mech. Eng. 1972, 1, 1–16. [Google Scholar] [CrossRef]

- Cash, J.R. Modified extended backward differentiation formulae for the numerical solution of stiff initial value problems in ODEs and DAEs. J. Comput. Appl. Math. 2000, 125, 117–130. [Google Scholar] [CrossRef] [Green Version]

- Ivantysynova, M.; Lasaar, R. An Investigation into Micro- and Macrogeometric Design of Piston/Cylinder Assembly of Swash Plate Machines. Int. J. Fluid Power 2004, 5, 23–36. [Google Scholar] [CrossRef]

- Ernst, M.H.; Ivantysynova, M. Micro Surface Shaping for the High-Pressure Operation of Piston Machines with Water as a Working Fluid. In Proceedings of the ASME/bath Symposium on Fluid Power & Motion Control, Chicago, IL, USA, 12–14 October 2015. [Google Scholar]

- Ma, X.; Wang, Q.J.; Lu, X.; Mehta, V.S. Piston surface design to improve the lubrication performance of a swash plate pump. Tribol. Int. 2019, 132, 275–285. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Piston radius, | 8 mm |

| Clearance, | 0.015 mm |

| Piston Length, | 66 mm |

| Cylinder length, | 66 mm |

| Distance between the head to the COM of the piston, | 33 mm |

| Fluid viscosity, | 0.03 Pas |

| Shaft speed, | 1500 r/min |

| The tilt angle of the swash plate, | 12° |

| Piston mass, | 7.05 × 10−2 kg |

| Cylinder block pitch radius, | 40 mm |

| The roughness of the piston, | 1.65 × 10−7 m |

| The roughness of the cylinder, | 8.15 × 10−7 m |

| Baumgarte coefficients, , | 1500 |

| Minimum time step size for integration in MEBDF | 1.0 × 10−7 s |

| Maximum order for integration in MEBDF | 6 |

| Number of elements in the lubrication domains, | 40 × 40 |

| Convergence criterion, | 1% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, B.; Hu, X.; Li, H.; Liu, Y.; Zhang, B.; Dong, Q. A New Approach for Modeling Mixed Lubricated Piston-Cylinder Pairs of Variable Lengths in Swash-Plate Axial Piston Pumps. Materials 2021, 14, 5836. https://doi.org/10.3390/ma14195836

Zhao B, Hu X, Li H, Liu Y, Zhang B, Dong Q. A New Approach for Modeling Mixed Lubricated Piston-Cylinder Pairs of Variable Lengths in Swash-Plate Axial Piston Pumps. Materials. 2021; 14(19):5836. https://doi.org/10.3390/ma14195836

Chicago/Turabian StyleZhao, Bo, Xinqing Hu, Haifeng Li, Yonghui Liu, Baocheng Zhang, and Qingbing Dong. 2021. "A New Approach for Modeling Mixed Lubricated Piston-Cylinder Pairs of Variable Lengths in Swash-Plate Axial Piston Pumps" Materials 14, no. 19: 5836. https://doi.org/10.3390/ma14195836

APA StyleZhao, B., Hu, X., Li, H., Liu, Y., Zhang, B., & Dong, Q. (2021). A New Approach for Modeling Mixed Lubricated Piston-Cylinder Pairs of Variable Lengths in Swash-Plate Axial Piston Pumps. Materials, 14(19), 5836. https://doi.org/10.3390/ma14195836