Tailoring a Refractory High Entropy Alloy by Powder Metallurgy Process Optimization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mechanical Alloying and Sintering

2.2. Characterization

3. Results

3.1. Phase Prediction

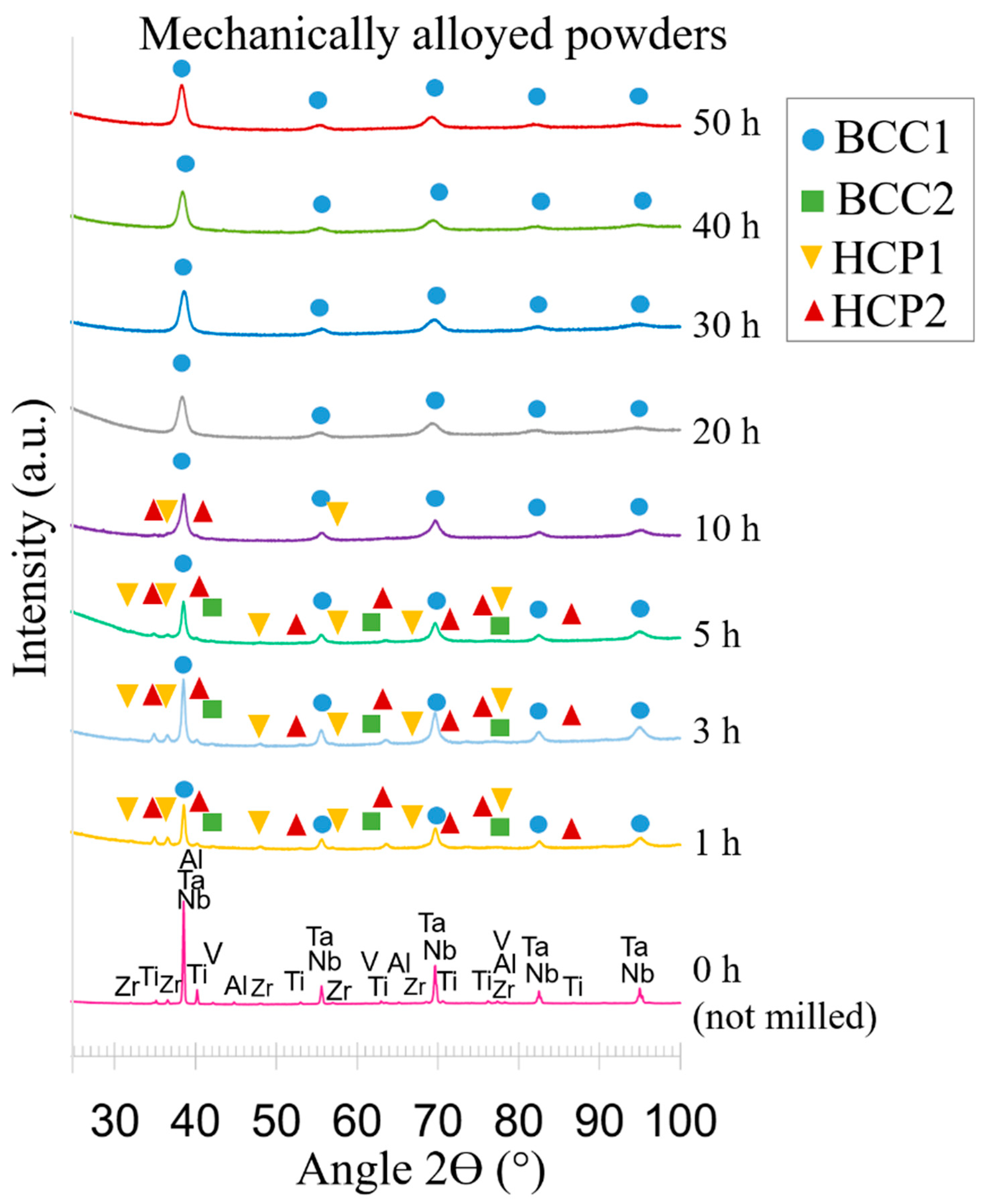

3.2. Microstructural and Morphological Characterization of the Powders

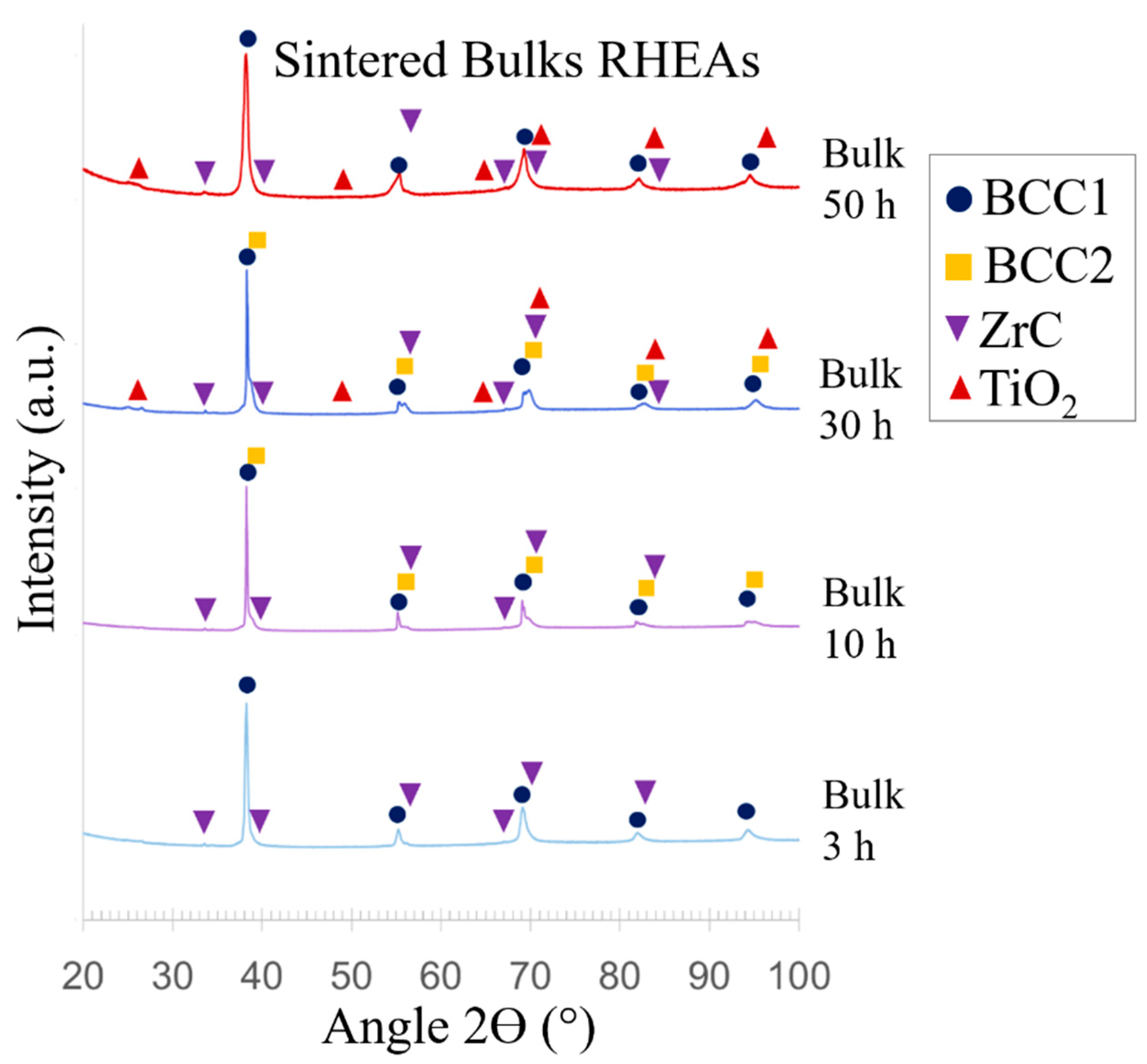

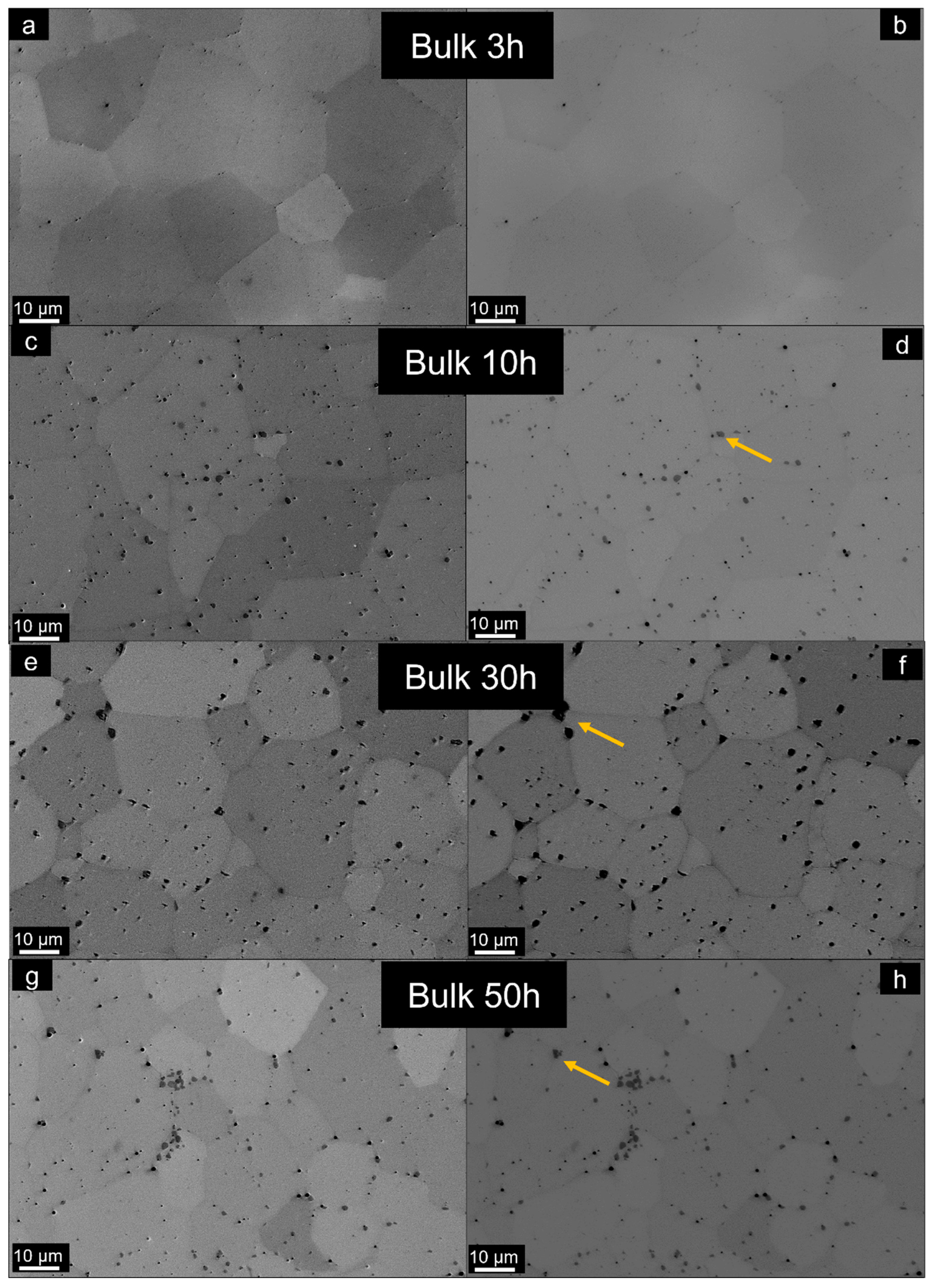

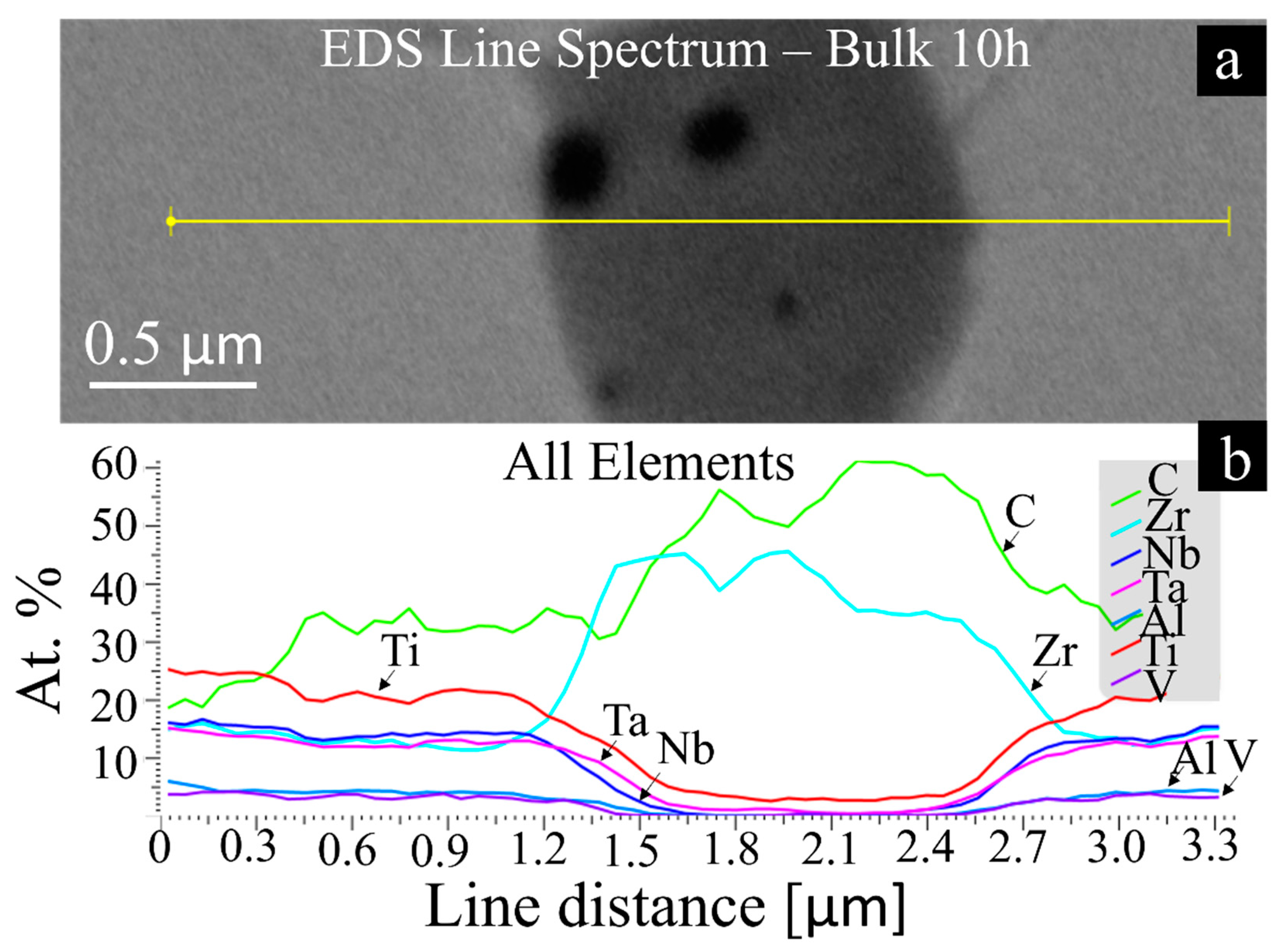

3.3. Microstructural Characterization of Refractory High-Entropy Alloy Bulks

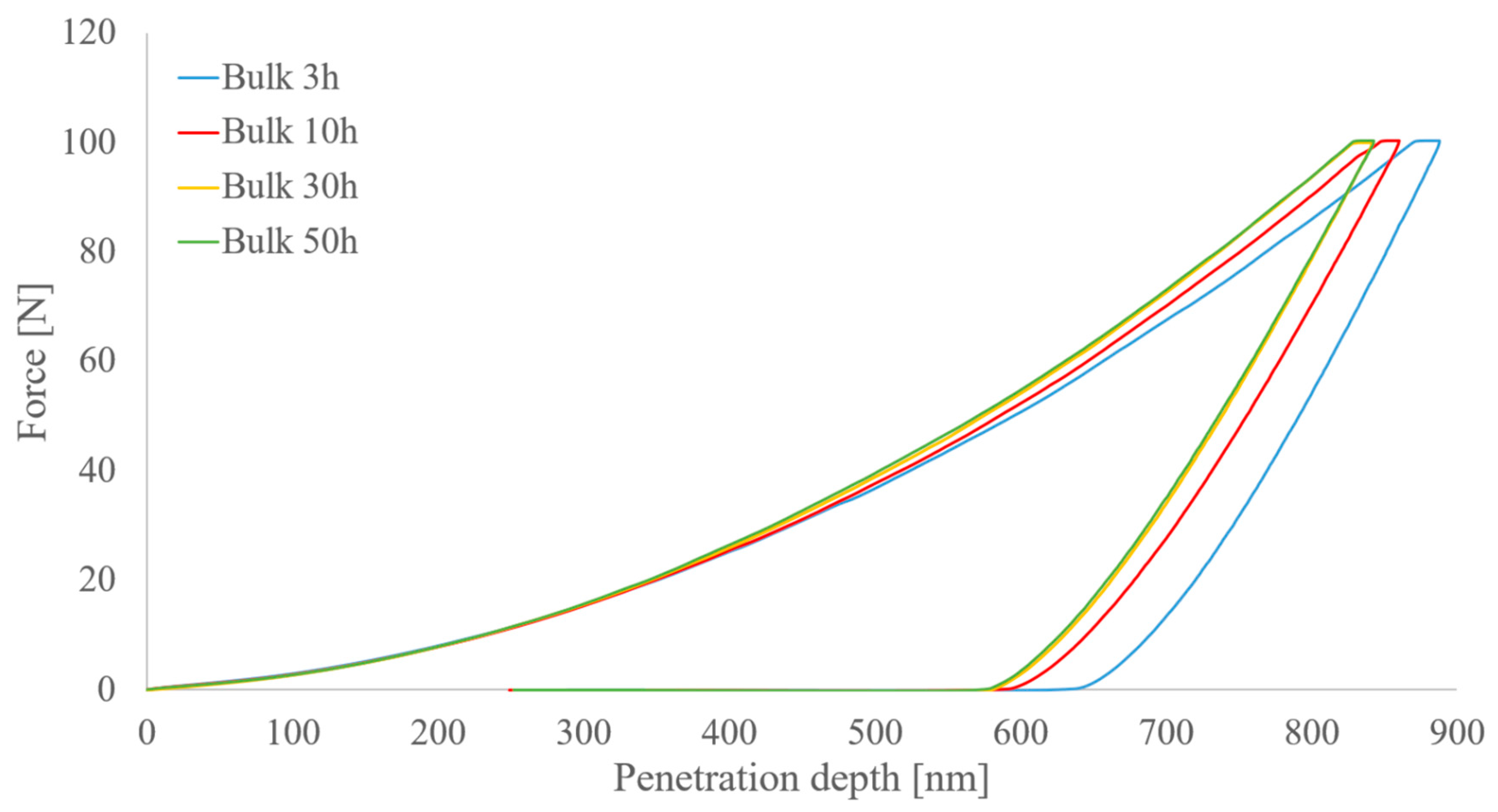

3.4. Mechanical Properties

4. Discussion

4.1. Influence of the Milling Time on the Properties of the Powders

4.2. Characterization of the RHEA Bulks

4.3. Mechanical Properties

5. Conclusions

- Longer milling times used for powder preparation for mechanical alloying produce more refined microstructures in the bulks.

- Powder homogeneity increases with the milling time, while a sufficient state is achieved after 10h of milling.

- Longer milling times lead to an increase in the total amount of oxides, carbides dispersed and iron in the matrix, compared to the non-milled state due to contamination.

- Carbide formation in the sintered RHEAs was observed after 3 h of powder milling, while oxides were detected after 30 h despite the fact that the fabrication was entirely performed using protective atmospheres. These could potentially positively contribute to the strength of the material.

- The extent of contamination is a function of the powder milling time, positively increasing with increasing milling time.

- Milling for 10 h provides the best balance between sufficient microstructural refinement, homogeneity, high hardness and minimal contamination.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Senkov, O.N.; Miracle, D.B.; Chaput, K.J.; Couzinie, J.-P. Development and exploration of refractory high entropy alloys—A review. J. Mater. Res. 2018, 33, 3092–3128. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Zhou, X.; Wang, W.; Liu, B.; Lv, Y.; Yang, W.; Xu, D.; Liu, Y. A review on fundamental of high entropy alloys with promising high–temperature properties. J. Alloys Compd. 2018, 760, 15–30. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Sheikh, S.; Shafeie, S.; Hu, Q.; Ahlström, J.; Persson, C.; Veselý, J.; Zýka, J.; Klement, U.; Guo, S. Alloy design for intrinsically ductile refractory high-entropy alloys. J. Appl. Phys. 2016, 120, 164902. [Google Scholar] [CrossRef] [Green Version]

- Borg, C.K.H.; Frey, C.; Moh, J.; Pollock, T.M.; Gorsse, S.; Miracle, D.B.; Senkov, O.N.; Meredig, B.; Saal, J.E. Expanded dataset of mechanical properties and observed phases of multi-principal element alloys. Sci. Data 2020, 7, 430. [Google Scholar] [CrossRef] [PubMed]

- Senkov, O.N.; Miracle, D.B.; Rao, S.I. Correlations to improve room temperature ductility of refractory complex concentrated alloys. Mater. Sci. Eng. A 2021, 820, 141512. [Google Scholar] [CrossRef]

- Mareska, F.; Curtin, W.A. Mechanistic origin of high strength in refractory BCC high entropy alloys up to 1900 K. Acta Mater. 2020, 182, 235–249. [Google Scholar] [CrossRef]

- Senkov, N.O.; Isheim, D.; Seidman, N.D.; Pilchak, L.A. Development of a Refractory High Entropy Superalloy. Entropy 2016, 18, 102. [Google Scholar] [CrossRef]

- Chen, H.; Kauffmann, A.; Seils, S.; Boll, T.; Liebscher, C.H.; Harding, I.; Kumar, K.S.; Szabó, D.V.; Schlabach, S.; Kauffmann-Weiss, S.; et al. Crystallographic ordering in a series of Al-containing refractory high entropy alloys Ta–Nb–Mo–Cr–Ti–Al. Acta Mater. 2019, 176, 123–133. [Google Scholar] [CrossRef]

- Miracle, D.B.; Tsai, M.-H.; Senkov, O.N.; Soni, V.; Banerjee, R. Refractory high entropy superalloys (RSAs). Scr. Mater. 2020, 187, 445–452. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications, 1st ed.; Cambridge University Press: Cambridge, UK, 2008; ISBN 0521070112. [Google Scholar]

- De Almeida Gouvea, L.M. Metal Matrix Composites Prepared by Powder Metallurgy Route. Ph.D. Thesis, Brno University of Technology, Brno, Czech Republic, 2021. [Google Scholar]

- Senkov, O.N.; Jensen, J.K.; Pilchak, A.L.; Miracle, D.B.; Fraser, H.L. Compositional variation effects on the microstructure and properties of a refractory high-entropy superalloy AlMo0.5NbTa0.5TiZr. Mater. Des. 2018, 139, 498–511. [Google Scholar] [CrossRef]

- Qi, L.; Chrzan, D.C. Tuning Ideal Tensile Strengths and Intrinsic Ductility of bcc Refractory Alloys. Phys. Rev. Lett. 2014, 112, 115503. [Google Scholar] [CrossRef] [PubMed]

- Soni, V.; Senkov, O.N.; Gwalani, B.; Miracle, D.B.; Banerjee, R. Microstructural Design for Improving Ductility of An Initially Brittle Refractory High Entropy Alloy. Sci. Rep. 2018, 8, 8816. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Soni, V.; Gwalani, B.; Alam, T.; Dasari, S.; Zheng, Y.; Senkov, O.N.; Miracle, D.; Banerjee, R. Phase Inversion in a Two-phase, BCC+B2, Refractory High Entropy Alloy. Acta Mater. 2019, 185, 89–97. [Google Scholar] [CrossRef]

- Soni, V.; Senkov, O.N.; Couzinie, J.-P.; Zheng, Y.; Gwalani, B.; Banerjee, R. Phase stability and microstructure evolution in a ductile refractory high entropy alloy Al10Nb15Ta5Ti30Zr40. Materialia 2020, 9, 100569. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Praveen, S.; Kim, H.S. High-Entropy Alloys: Potential Candidates for High-Temperature Applications—An Overview. Adv. Eng. Mater. 2018, 20, 1700645. [Google Scholar] [CrossRef]

- Moravcikova-Gouvea, L.; Moravcik, I.; Omasta, M.; Veselý, J.; Cizek, J.; Minárik, P.; Cupera, J.; Záděra, A.; Jan, V.; Dlouhy, I. High-strength Al0.2Co1.5CrFeNi1.5Ti high-entropy alloy produced by powder metallurgy and casting: A comparison of microstructures, mechanical and tribological properties. Mater. Charact. 2020, 159, 110046. [Google Scholar] [CrossRef]

- Waseem, O.A.; Ryu, H.J. Powder Metallurgy Processing of a W(x)TaTiVCr High-Entropy Alloy and Its Derivative Alloys for Fusion Material Applications. Sci. Rep. 2017, 7, 1926. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- De, J.; Umarji, A.M.; Chattopadhyay, K. Origin of contamination and role of mechanochemistry during mechanical alloying: The case of Ag–Te alloys. Mater. Sci. Eng. A 2007, 449–451, 1062–1066. [Google Scholar] [CrossRef]

- Moravcik, I.; Kubicek, A.; Moravcikova-Gouvea, L.; Adam, O.; Kana, V.; Pouchly, V.; Zadera, A.; Dlouhy, I. The Origins of High-Entropy Alloy Contamination Induced by Mechanical Alloying and Sintering. Metals 2020, 10, 1186. [Google Scholar] [CrossRef]

- Nganbe, M.; Heilmaier, M. High temperature strength and failure of the Ni-base superalloy PM 3030. Int. J. Plast. 2009, 25, 822–837. [Google Scholar] [CrossRef]

- Eiselt, C.C.; Schendzielorz, H.; Seubert, A.; Hary, B.; de Carlan, Y.; Diano, P.; Perrin, B.; Cedat, D. ODS-materials for high temperature applications in advanced nuclear systems. Nucl. Mater. Energy 2016, 9, 22–28. [Google Scholar] [CrossRef] [Green Version]

- Ukai, S.; Ohtsuka, S.; Kaito, T.; de Carlan, Y.; Ribis, J.; Malaplate, J. 10—Oxide Dispersion-Strengthened/Ferrite-Martensite Steels as Core Materials for Generation IV Nuclear Reactors; Yvon, P., Ed.; Woodhead Publishing: Cambridge, UK, 2017; ISBN 978-0-08-100906-2. [Google Scholar]

- Hadraba, H.; Chlup, Z.; Dlouhy, A.; Dobes, F.; Roupcova, P.; Vilemova, M.; Matejicek, J. Oxide dispersion strengthened CoCrFeNiMn high-entropy alloy. Mater. Sci. Eng. A 2017, 689, 252–256. [Google Scholar] [CrossRef]

- Moravcik, I.; Gouvea, L.; Hornik, V.; Kovacova, Z.; Kitzmantel, M.; Neubauer, E.; Dlouhy, I. Synergic strengthening by oxide and coherent precipitate dispersions in high-entropy alloy prepared by powder metallurgy. Scr. Mater. 2018, 157, 24–29. [Google Scholar] [CrossRef]

- Moravcik, I. Metal Matrix Composites Prepared by Powder Metallurgy Route. Ph.D. Thesis, Brno University of Technology, Brno, Czech Republic, 2017. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Shuman, D.J.; Costa, A.L.M.; Andrade, M.S. Calculating the elastic modulus from nanoindentation and microindentation reload curves. Mater. Charact. 2007, 58, 380–389. [Google Scholar] [CrossRef]

- Battu, A.K.; Ramana, C.V. Mechanical Properties of Nanocrystalline and Amorphous Gallium Oxide Thin Films. Adv. Eng. Mater. 2018, 20, 1701033. [Google Scholar] [CrossRef]

- Battu, A.K.; Zade, V.B.; Deemer, E.; Ramana, C.V. Microstructure-Mechanical Property Correlation in Size Controlled Nanocrystalline Molybdenum Films. Adv. Eng. Mater. 2018, 20, 1800496. [Google Scholar] [CrossRef]

- Fu, Z.; Chen, W.; Xiao, H.; Zhou, L.; Zhu, D.; Yang, S. Fabrication and properties of nanocrystalline Co0.5FeNiCrTi0.5 high entropy alloy by MA–SPS technique. Mater. Des. 2013, 44, 535–539. [Google Scholar] [CrossRef]

- Chen, W.; Fu, Z.; Fang, S.; Xiao, H.; Zhu, D. Alloying behavior, microstructure and mechanical properties in a FeNiCrCo0.3Al0.7 high entropy alloy. Mater. Des. 2013, 51, 854–860. [Google Scholar] [CrossRef]

- Shkodich, N.; Sedegov, A.; Kuskov, K.; Busurin, S.; Scheck, Y.; Vadchenko, S.; Moskovskikh, D. Refractory High-Entropy HfTaTiNbZr-Based Alloys by Combined Use of Ball Milling and Spark Plasma Sintering: Effect of Milling Intensity. Metals 2020, 10, 1268. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, W.; Wu, B.; Cao, X.; Liu, L.; Fu, Z. Effects of Co and Ti on microstructure and mechanical behavior of Al0.75FeNiCrCo high entropy alloy prepared by mechanical alloying and spark plasma sintering. Mater. Sci. Eng. A 2015, 648, 217–224. [Google Scholar] [CrossRef]

- Gao, M.C.; Zhang, B.; Yang, S.; Guo, S.M. Senary Refractory High-Entropy Alloy HfNbTaTiVZr. Metall. Mater. Trans. A 2016, 47, 3333–3345. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Yao, H.W.; Qiao, J.W.; Gao, M.C.; Hawk, J.A.; Ma, S.G.; Zhou, H.F.; Zhang, Y. NbTaV-(Ti, W) refractory high-entropy alloys: Experiments and modeling. Mater. Sci. Eng. A 2016, 674, 203–211. [Google Scholar] [CrossRef]

- Fu, Z.; Chen, W.; Wen, H.; Chen, Z.; Lavernia, E.J. Effects of Co and sintering method on microstructure and mechanical behavior of a high-entropy Al0.6NiFeCrCo alloy prepared by powder metallurgy. J. Alloys Compd. 2015, 646, 175–182. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Miracle, D.B.; Woodward, C.F. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy. J. Alloys Compd. 2011, 509, 6043–6048. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodward, C.; Miracle, D.B. Low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system: Microstructure and phase analysis. Acta Mater. 2013, 61, 1545–1557. [Google Scholar] [CrossRef]

- Kubicek, A. Vliv Podmínek Mechanického Legování na Kontaminaci Práškových Směsí a Bulk Materiálů. Master’s Thesis, Brno University of Technology, Brno, Czech Republic, 2020. [Google Scholar]

- Premkumar, M.; Prasad, K.S.; Singh, A.K. Structure and stability of the B2 phase in Ti–25Al–25Zr alloy. Intermetallics 2009, 17, 142–145. [Google Scholar] [CrossRef]

- Senkov, O.N.; Couzinie, J.-P.; Rao, S.I.; Soni, V.; Banerjee, R. Temperature dependent deformation behavior and strengthening mechanisms in a low density refractory high entropy alloy Al10Nb15Ta5Ti30Zr40. Materialia 2020, 9, 100627. [Google Scholar] [CrossRef]

- Mackie, A.J.; Hatton, G.D.; Hamilton, H.G.C.; Dean, J.S.; Goodall, R. Carbon uptake and distribution in Spark Plasma Sintering (SPS) processed Sm(Co, Fe, Cu, Zr)z. Mater. Lett. 2016, 171, 14–17. [Google Scholar] [CrossRef]

- Bar-Cohen, Y. High Temperature Materials and Mechanisms, 1st ed.; Bar-Cohen, Y., Ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Guo, Y.; Li, M.; Li, P.; Chen, C.; Zhan, Q.; Chang, Y.; Zhang, Y. Microstructure and mechanical properties of oxide dispersion strengthened FeCoNi concentrated solid solution alloys. J. Alloys Compd. 2020, 820, 153104. [Google Scholar] [CrossRef]

- Moravcik, I.; Gamanov, S.; Moravcikova-Gouvea, L.; Kovacova, Z.; Kitzmantel, M.; Neubauer, E.; Dlouhy, I. Influence of Ti on the tensile properties of the high-strength powder metallurgy high entropy alloys. Materials 2020, 13, 578. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rao, K.R.; Sinha, S.K. Effect of sintering temperature on microstructural and mechanical properties of SPS processed CoCrCuFeNi based ODS high entropy alloy. Mater. Chem. Phys. 2020, 256, 123709. [Google Scholar] [CrossRef]

- Li, M.; Guo, Y.; Wang, H.; Shan, J.; Chang, Y. Microstructures and mechanical properties of oxide dispersion strengthened CoCrFeNi high-entropy alloy produced by mechanical alloying and spark plasma sintering. Intermetallics 2020, 123, 106819. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Ivanov, E.; Boldyrev, V.V. The science and technology of mechanical alloying. Mater. Sci. Eng. A 2001, 304–306, 151–158. [Google Scholar] [CrossRef]

- Briant, C.L. Refractory Metals and Alloys; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P.B.T.-E., Eds.; Elsevier: Oxford, UK, 2001; pp. 8088–8095. ISBN 978-0-08-043152-9. [Google Scholar]

| 1 h | 3 h | 5 h | |||||||

|---|---|---|---|---|---|---|---|---|---|

| a [Å] | c [Å] | wt.% | a [Å] | c [Å] | wt.% | a [Å] | c [Å] | wt.% | |

| BCC1 | 3.30 | - | 56.2 | 3.31 | - | 58.6 | 3.31 | - | 87.7 |

| BCC2 | 3.03 | - | 2.9 | 3.03 | - | 3.3 | 3.03 | - | 0.4 |

| HCP1 | 3.23 | 5.14 | 23.1 | 3.24 | 5.14 | 20.7 | 3.24 | 5.13 | 10.8 |

| HCP2 | 2.95 | 4.68 | 17.8 | 2.95 | 4.68 | 17.4 | 2.94 | 4.68 | 1.1 |

| 10 h | 20 h | 30 h | |||||||

| BCC1 | 3.31 | - | 94.3 | 3.31 | - | 100.0 | 3.32 | - | 100.0 |

| HCP1 | 3.24 | 5.13 | 4.9 | - | - | - | - | - | - |

| HCP2 | 2.95 | 4.68 | 0.8 | - | - | - | - | - | - |

| 40 h | 50 h | ||||||||

| BCC1 | 3.32 | - | 100.0 | 3.33 | - | 100.0 | |||

| BCC1 | BCC2 | ZrC (Fm-3m) | TiO2 (I41/amd) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| a | wt.% | A | wt.% | a | wt.% | a | c | wt.% | |

| Bulk 3 h | 3.32 | 98.0 | - | - | 4.62 | 2.0 | - | - | - |

| Bulk 10 h | 3.32 | 52.7 | 3.30 | 43.3 | 4.62 | 4.0 | - | - | - |

| Bulk 30 h | 3.32 | 74.6 | 3.29 | 20.7 | 4.61 | 4.3 | 3.80 | 9.56 | 0.4 |

| Bulk 50 h | 3.31 | 88.7 | - | - | 4.60 | 6.8 | 3.79 | 9.55 | 4.5 |

| (at.%) | Bulk 3 h (BCC1) | Bulk 10 h (BCC1) | Bulk 30 h (BCC1) | Bulk 50 h (BCC1) |

|---|---|---|---|---|

| Al | 5.4 ± 0.2 | 6.1 ± 0.1 | 6.0 ± 0.2 | 6.1 ± 0.1 |

| Ti | 29.4 ± 1.2 | 31.0 ± 0.2 | 30.3 ± 0.1 | 29.8 ± 0.3 |

| V | 3.9 ± 0.6 | 4.0 ± 0.4 | 4.5 ± 0.1 | 4.8 ± 0.1 |

| Zr | 18.9 ± 1.2 | 20.5 ± 0.3 | 19.3 ± 0.3 | 20.5 ± 0.1 |

| Nb | 23.0 ± 0.8 | 20.2 ± 0.1 | 19.9 ± 0.1 | 19.7 ± 0.3 |

| Ta | 19.4 ± 1.2 | 18.3 ± 0.1 | 18.3 ± 0.1 | 18.0 ± 0.3 |

| Fe | - | - | 1.8 ± 0.1 | 2.2 ± 0.1 |

| Sample | Hardness (HV 0.2) | Elastic Modulus (NHT) (GPa) | Penetration Depth (NHT) (nm) |

|---|---|---|---|

| Bulk 3 h | 592.9 ± 21.0 | 134.7 ± 1.0 | 911.9 ± 5.2 |

| Bulk 10 h | 641.8 ± 9.4 | 136.6 ± 1.2 | 861.3 ± 4.9 |

| Bulk 30 h | 670.3 ± 12.3 | 137.2 ± 0.7 | 843.4 ± 6.3 |

| Bulk 50 h | 675.7 ± 9.8 | 138.7 ± 0.8 | 842.6 ± 3.6 |

| Elastic Modulus (NHT) (GPa) | Elastic Modulus (US) (GPa) | Poisson Ratio (US) [-] | Shear Modulus (US) (GPa) |

|---|---|---|---|

| 136.6 | 136.0 | 0.326 | 53 |

| Composition | Vickers Hardness (HV) | Preparation | Reference |

|---|---|---|---|

| Al0.3NbTa0.8Ti1.5V0.2Zr | 676 | PM—as-sintered: Milling 50 h SPS: 1200 °C—15 min | This work |

| W0.7(TaTiCrV)0.3 | 671 | PM—as-sintered: Milling 3 h SPS: 1600 °C—10 min | [21] |

| Al0.3NbTa0.8Ti1.5V0.2Zr | 670 | PM—as-sintered: Milling 30 h SPS: 1200 °C—15 min | This work |

| Al0.3NbTa0.8Ti1.5V0.2Zr | 642 | PM—as-sintered: Milling 10 h SPS: 1200 °C—15 min | This work |

| FeNiCrCo0.3Al0.7 | 624 | PM: as-sintered: Milling 45 h SPS: 1000 °C—8 min | [36] |

| Al0.3NbTa0.8Ti1.5V0.2Zr | 593 | PM—as-sintered: Milling 3 h SPS: 1200 °C—15 min | This work |

| HfTaTiNbZr | 592 | PM—as-sintered: Milling 1 h SPS: 1300 °C—10 min | [1,37] |

| Al0.75FeNiCrCo | 577 | PM—as-sintered: Milling 45 h SPS: 1000 °C—8 min | [38] |

| HfNbTaTiVZr | 558 | As-cast (Arc melting) | [1,39] |

| MoNbTaVW | 535 | As-cast (Arc melting) | [40] |

| W0.9(TaTiCrV)0.1 | 480 | PM—as-sintered: Milling 3 h SPS: 1600 °C—10 min | [21] |

| NbTaTiVW | 447 | As-cast (Arc melting) | [41] |

| Al0.6NiFeCr | 431 | PM—as-sintered: Milling 38 h SPS: 1000 °C—1 h | [42] |

| HfNbTaTiZr | 390 | As-cast (Arc melting) | [43] |

| NbTiVZr | 335 | Annealed (Arc melting) | [1,44] |

| NbTaTiV | 298 | As-cast (Arc melting) | [41] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moravcikova-Gouvea, L.; Moravcik, I.; Pouchly, V.; Kovacova, Z.; Kitzmantel, M.; Neubauer, E.; Dlouhy, I. Tailoring a Refractory High Entropy Alloy by Powder Metallurgy Process Optimization. Materials 2021, 14, 5796. https://doi.org/10.3390/ma14195796

Moravcikova-Gouvea L, Moravcik I, Pouchly V, Kovacova Z, Kitzmantel M, Neubauer E, Dlouhy I. Tailoring a Refractory High Entropy Alloy by Powder Metallurgy Process Optimization. Materials. 2021; 14(19):5796. https://doi.org/10.3390/ma14195796

Chicago/Turabian StyleMoravcikova-Gouvea, Larissa, Igor Moravcik, Vaclav Pouchly, Zuzana Kovacova, Michael Kitzmantel, Erich Neubauer, and Ivo Dlouhy. 2021. "Tailoring a Refractory High Entropy Alloy by Powder Metallurgy Process Optimization" Materials 14, no. 19: 5796. https://doi.org/10.3390/ma14195796

APA StyleMoravcikova-Gouvea, L., Moravcik, I., Pouchly, V., Kovacova, Z., Kitzmantel, M., Neubauer, E., & Dlouhy, I. (2021). Tailoring a Refractory High Entropy Alloy by Powder Metallurgy Process Optimization. Materials, 14(19), 5796. https://doi.org/10.3390/ma14195796