A Comparative Study of Corrosion AA6061 and AlSi10Mg Alloys Produced by Extruded and Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Microstructural Characterization

2.3. Corrosion Test

3. Results

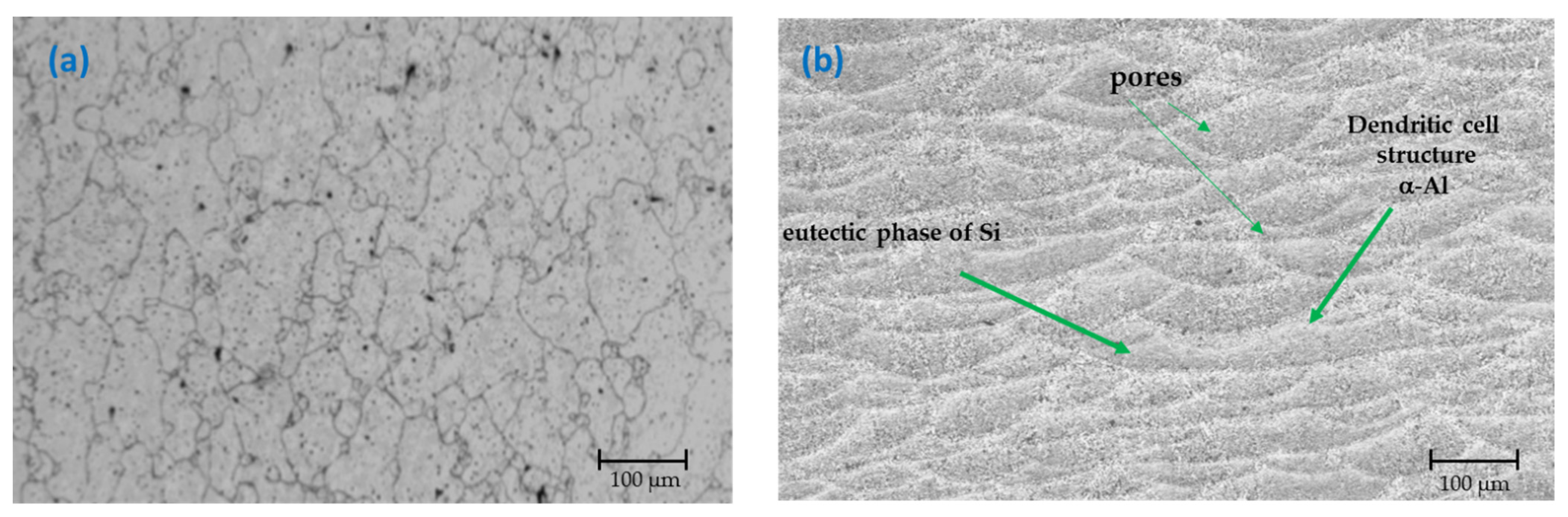

3.1. Microstructural Analysis

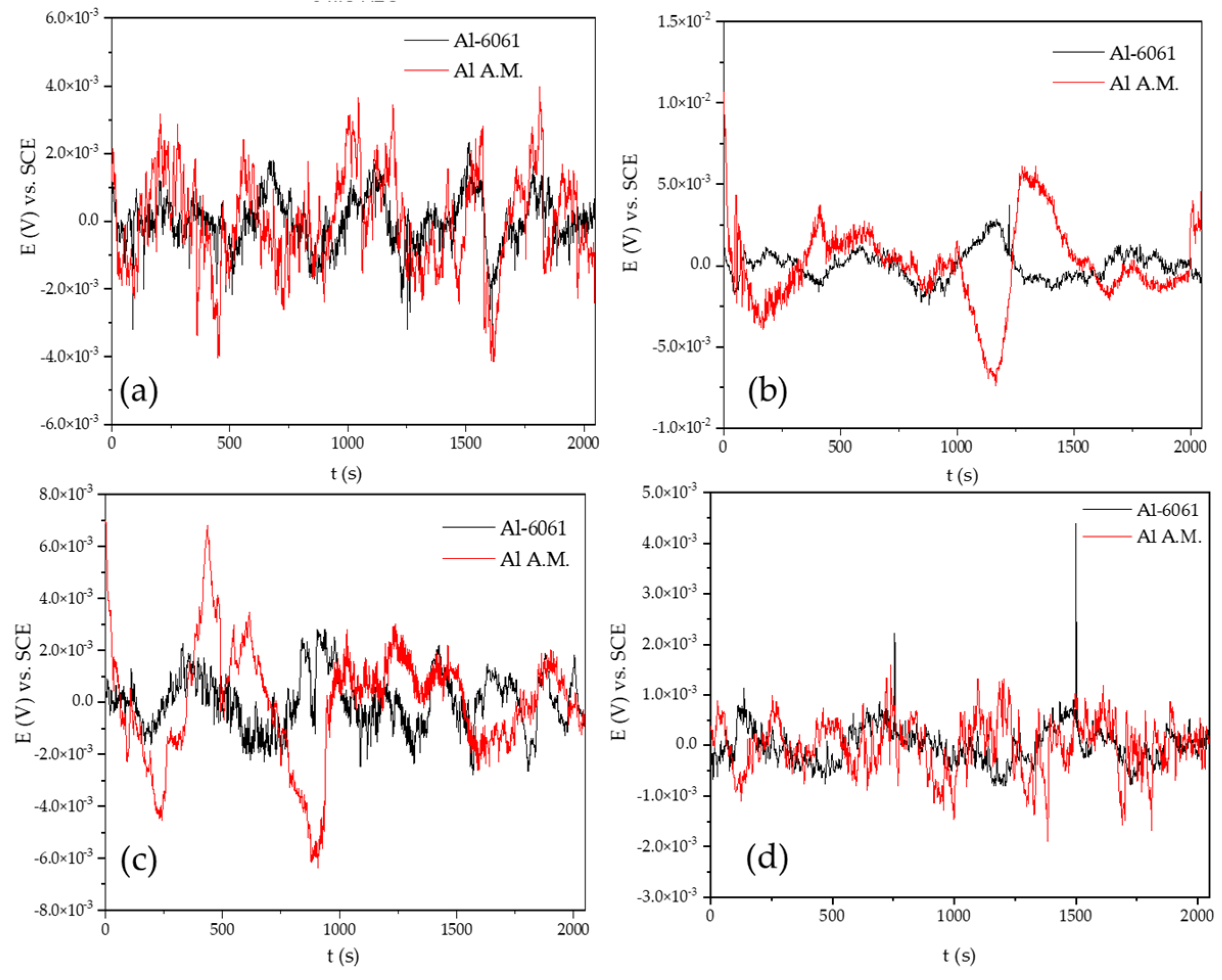

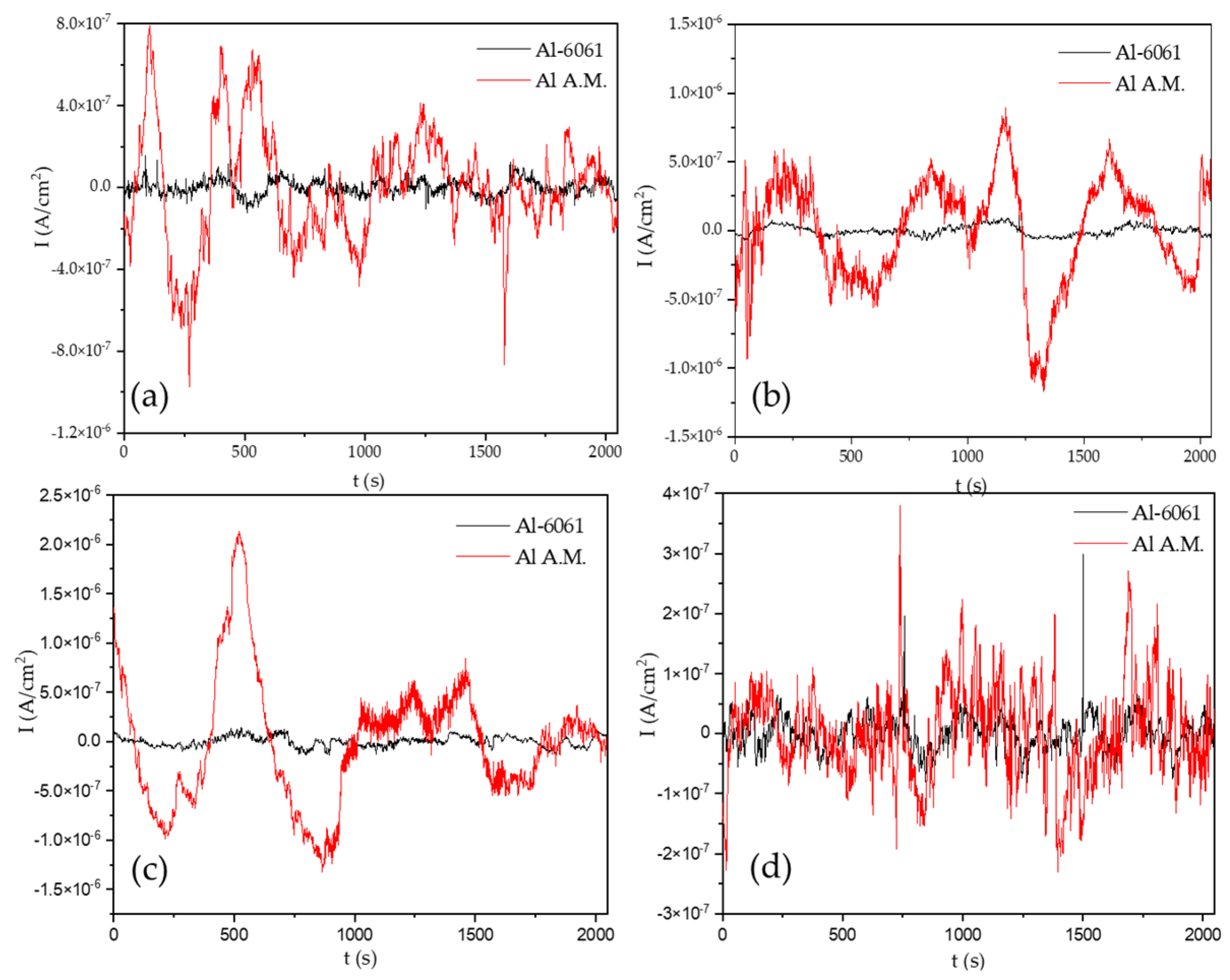

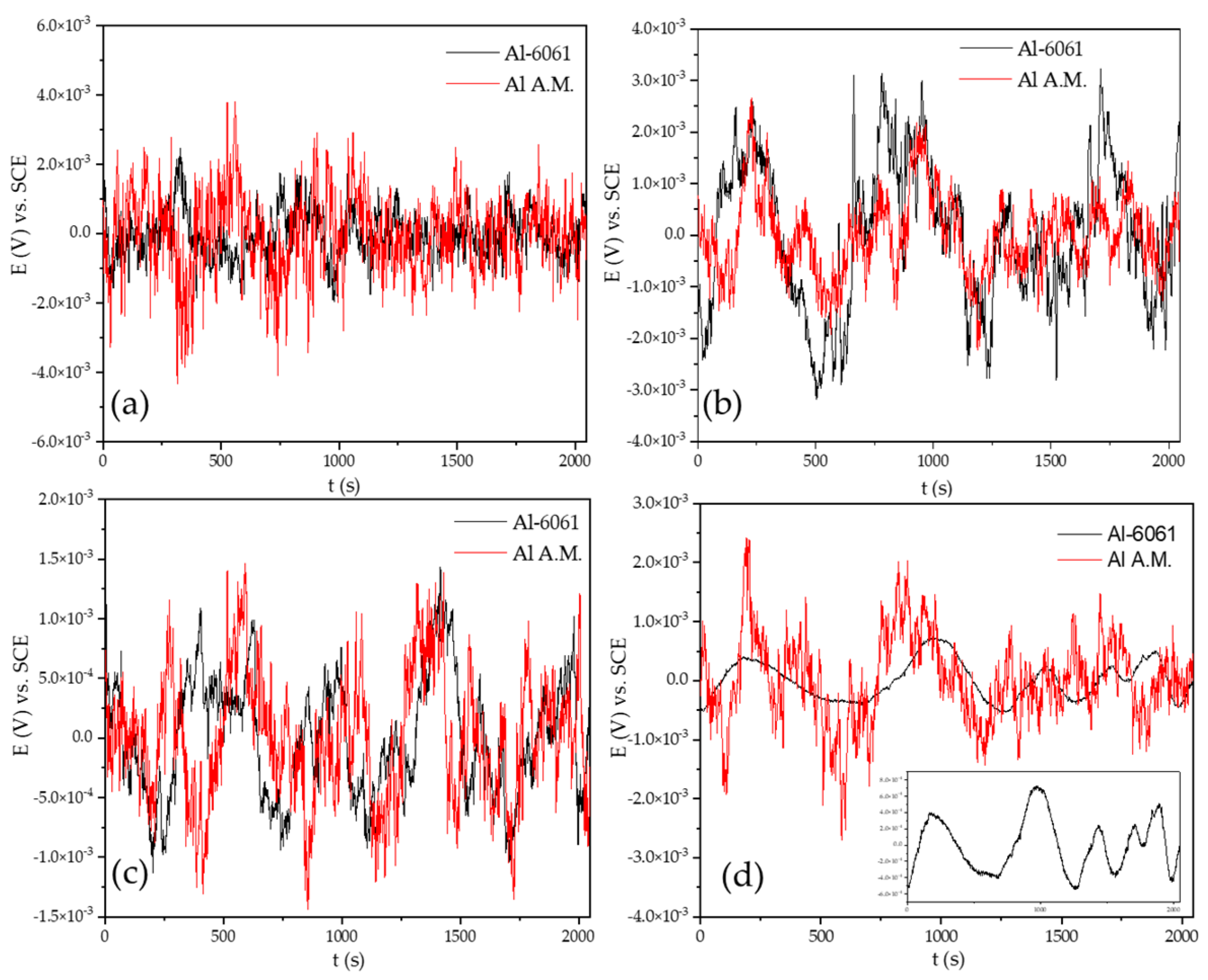

3.2. Electrochemical Noise

3.2.1. Statistical Analysis

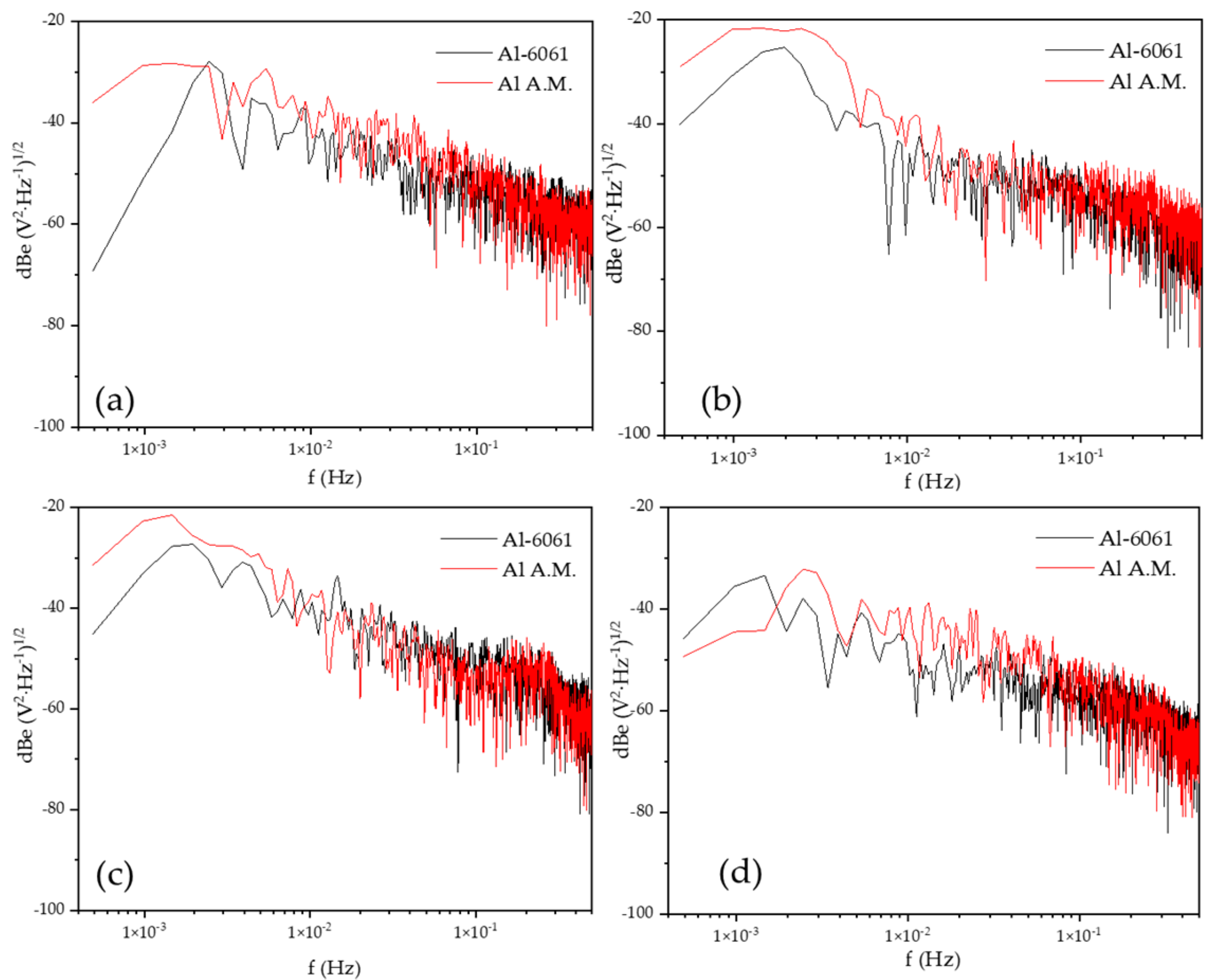

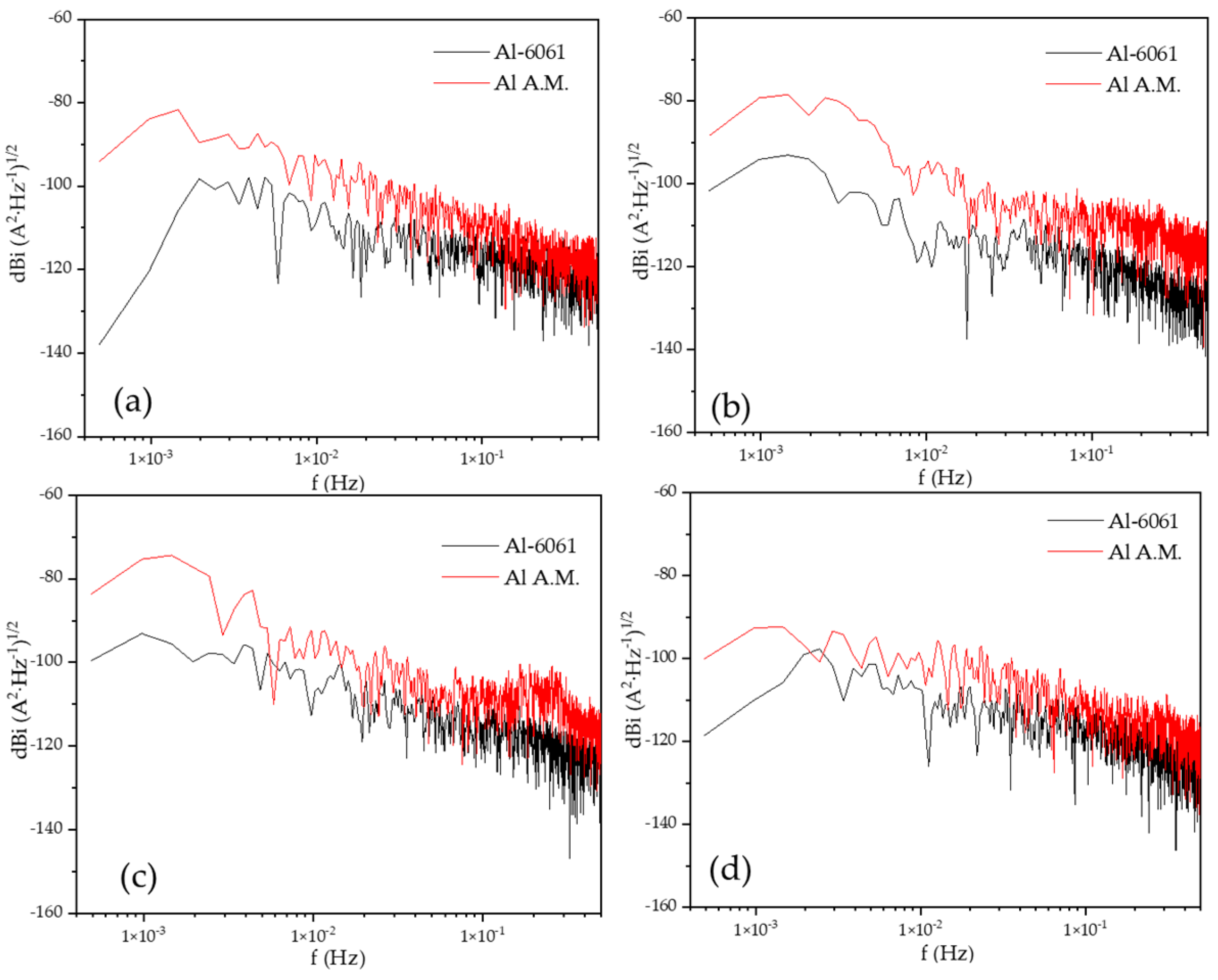

3.2.2. Power Spectral Density

3.2.3. Noise Impedance (Zn)

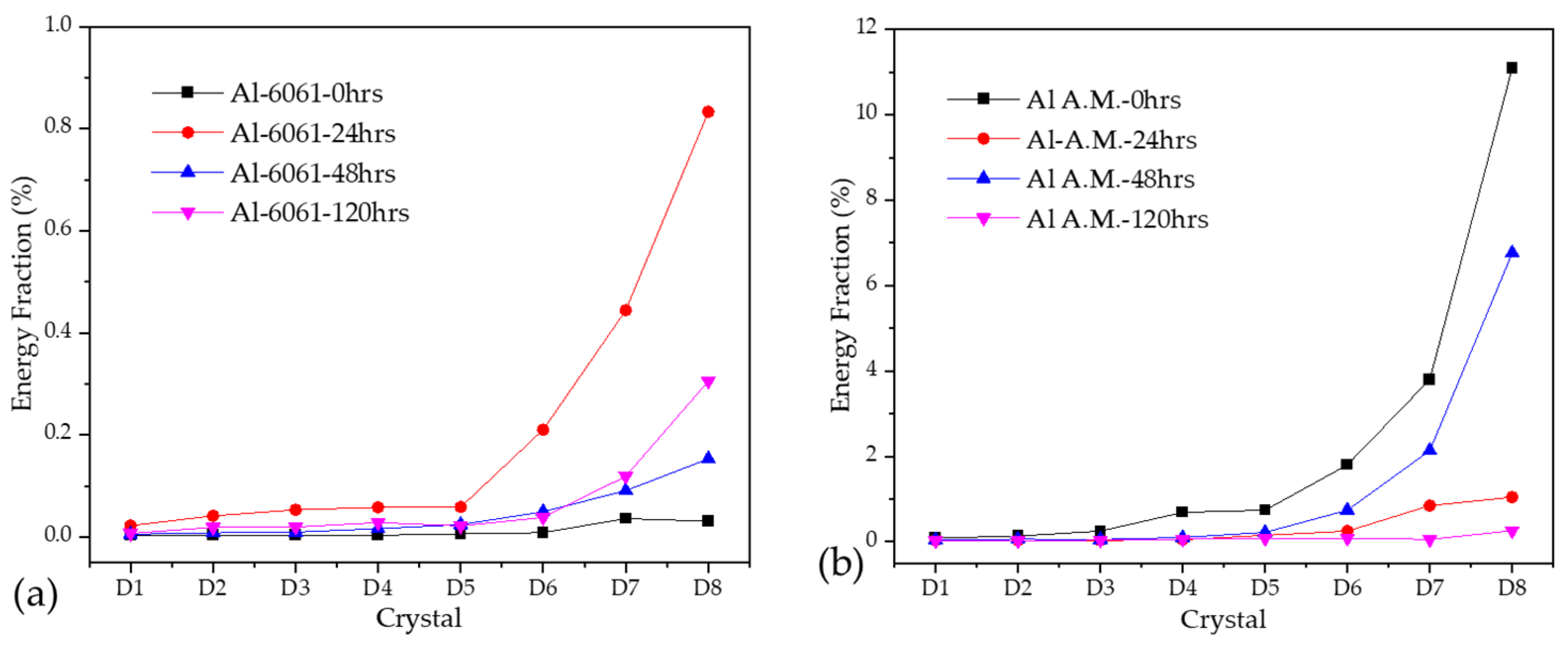

3.2.4. Wavelet Method

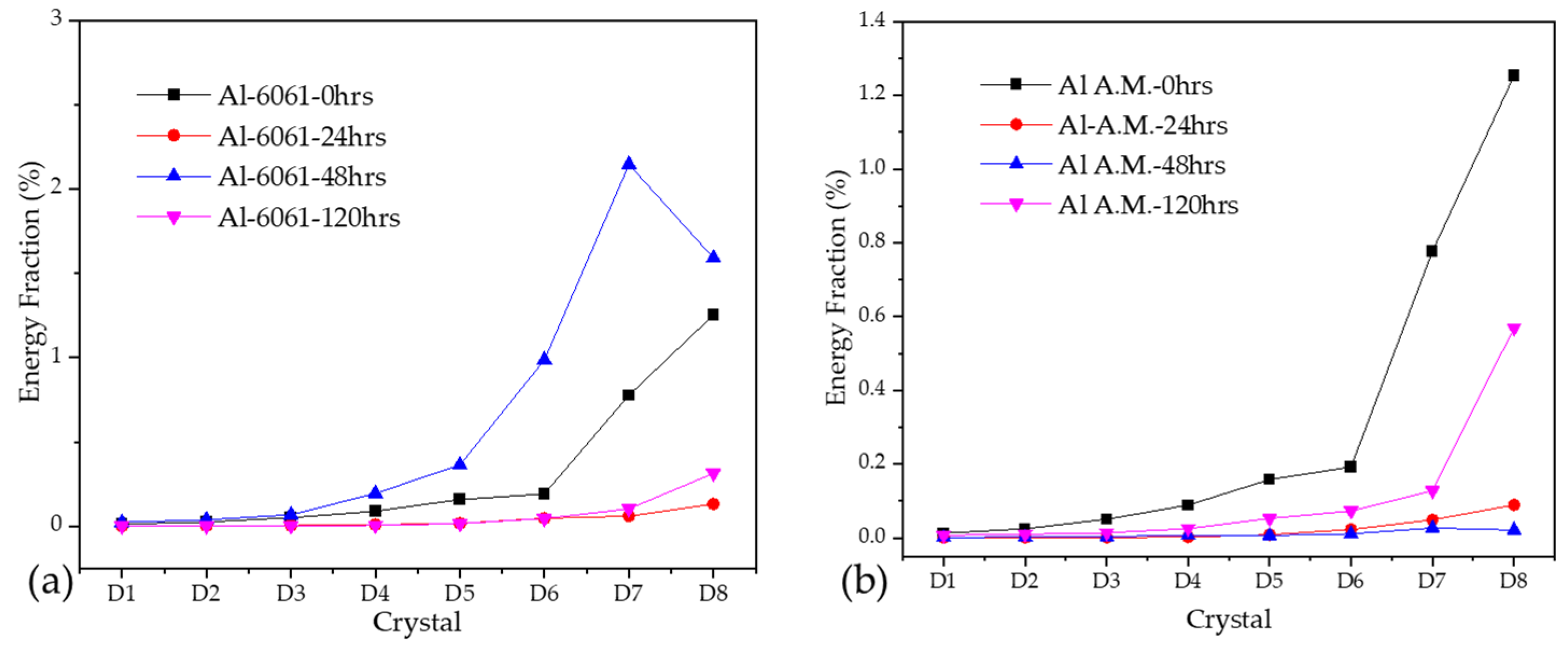

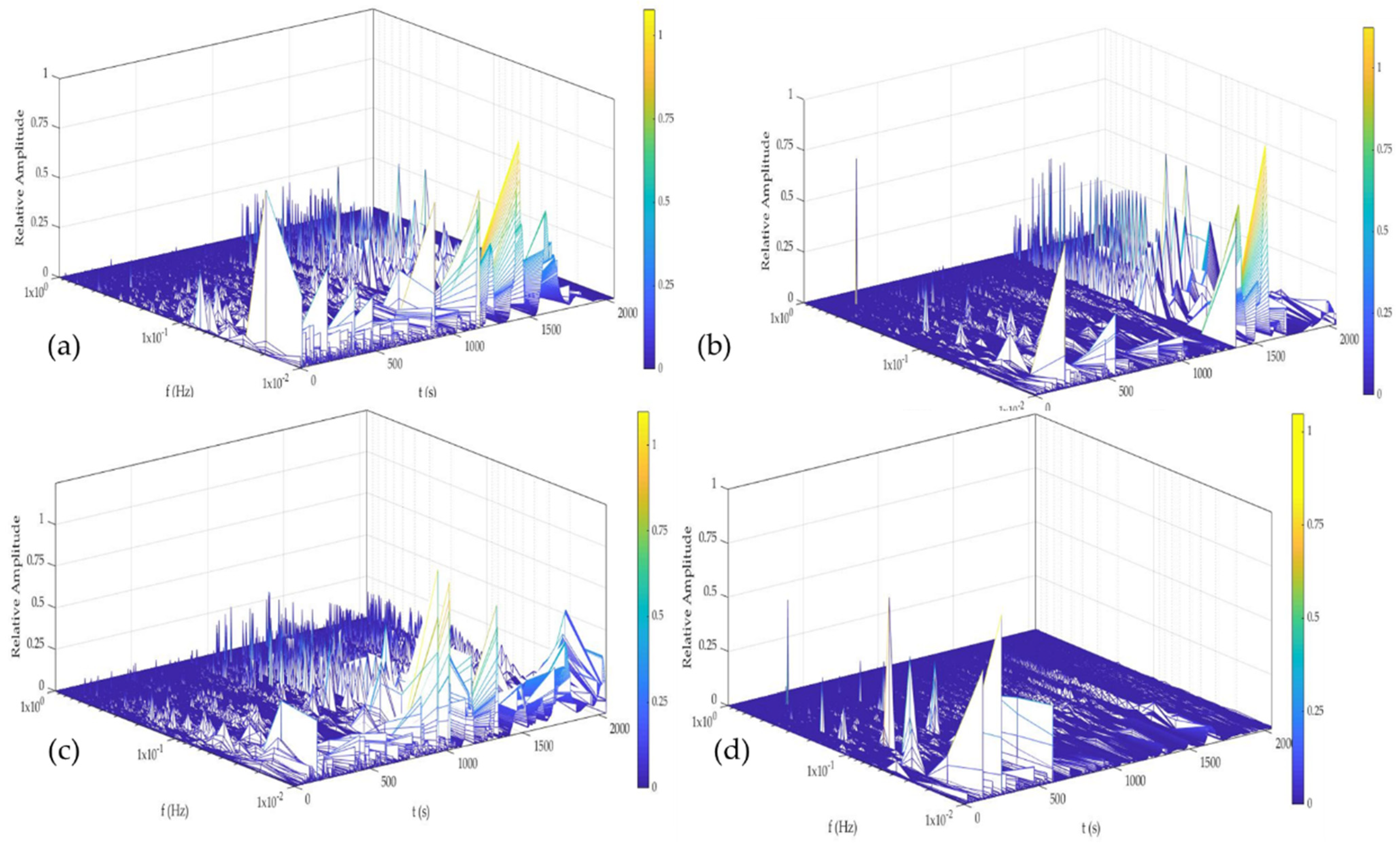

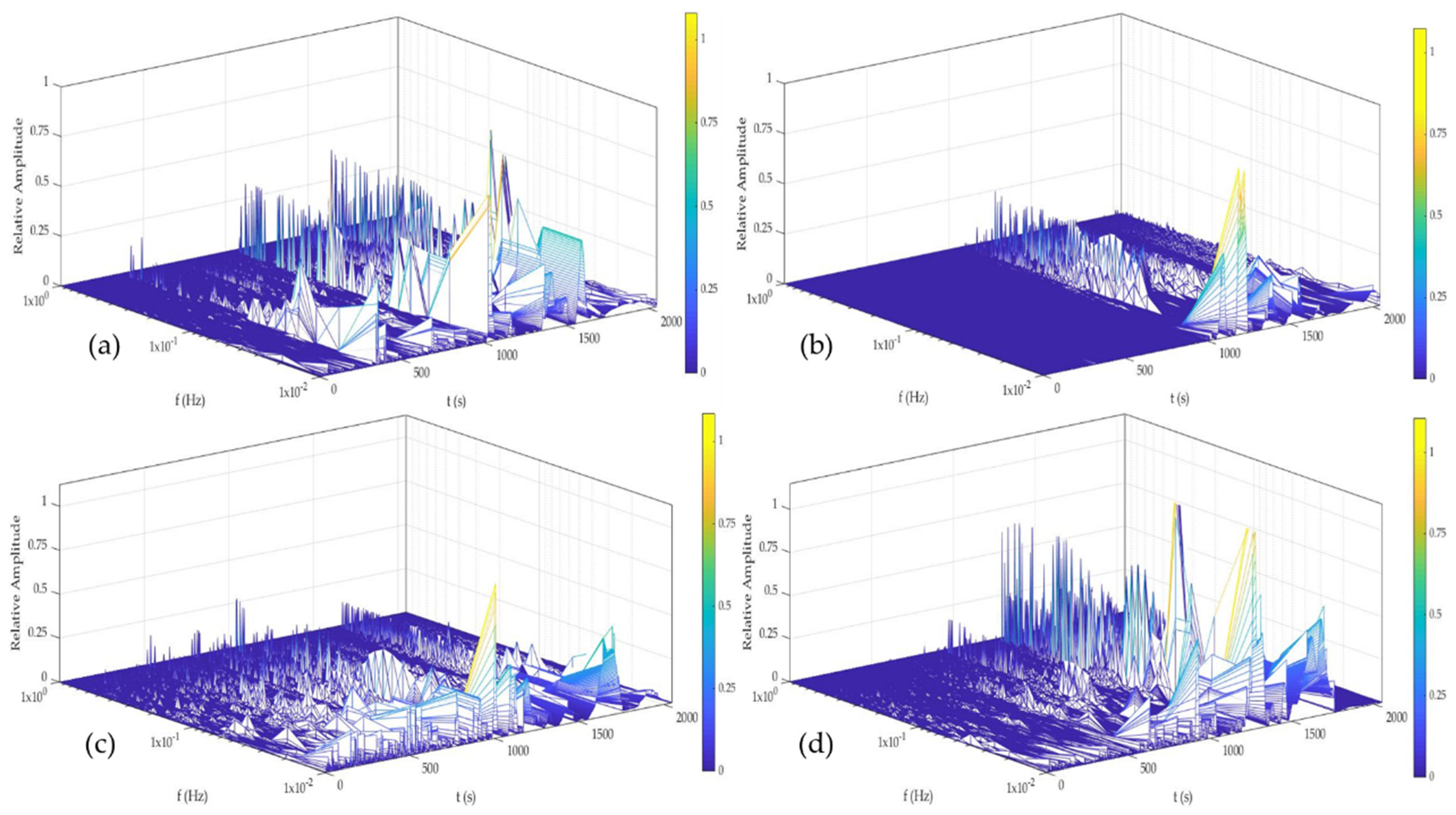

3.2.5. Hilbert–Huang Transform Analysis

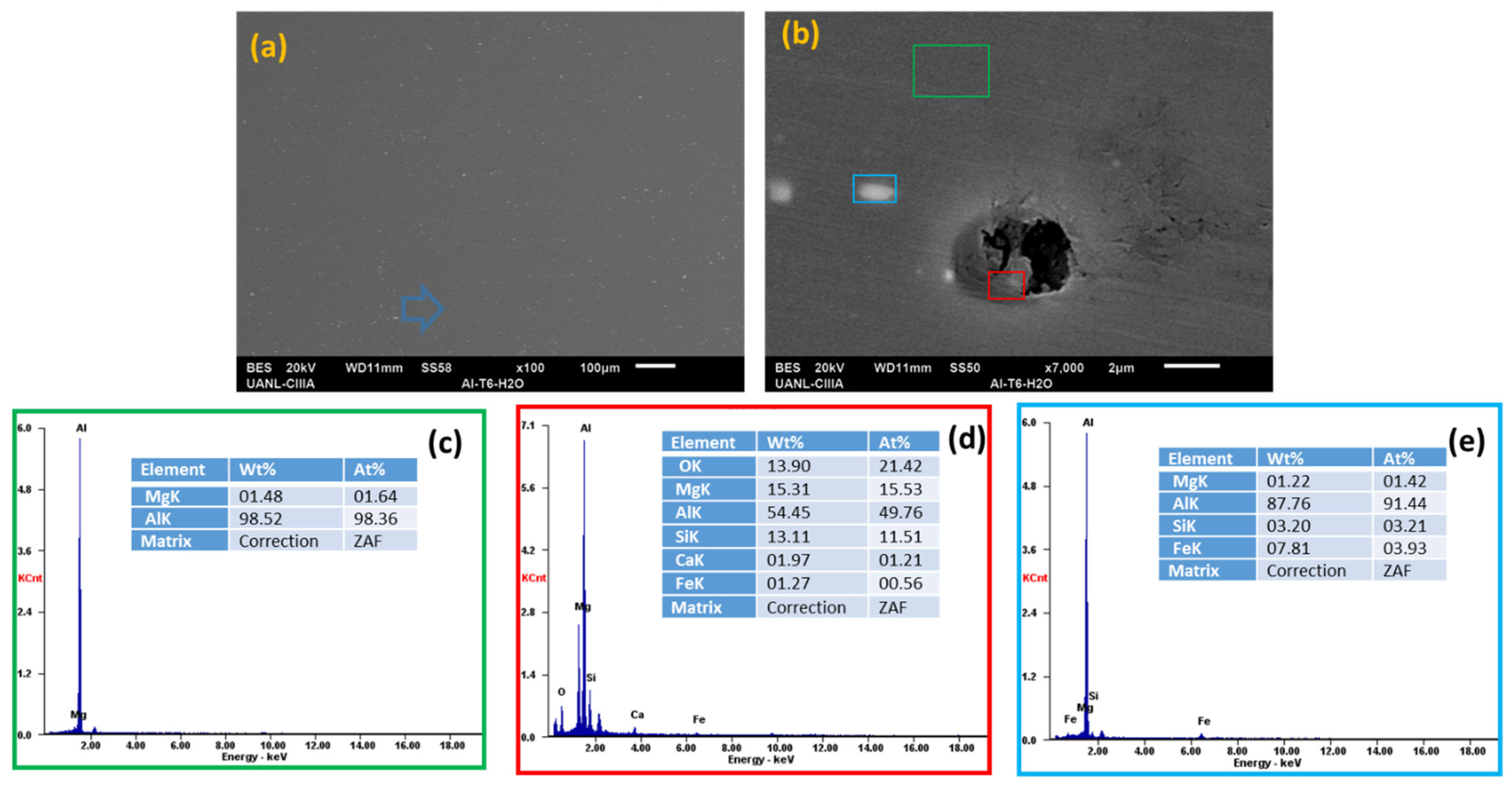

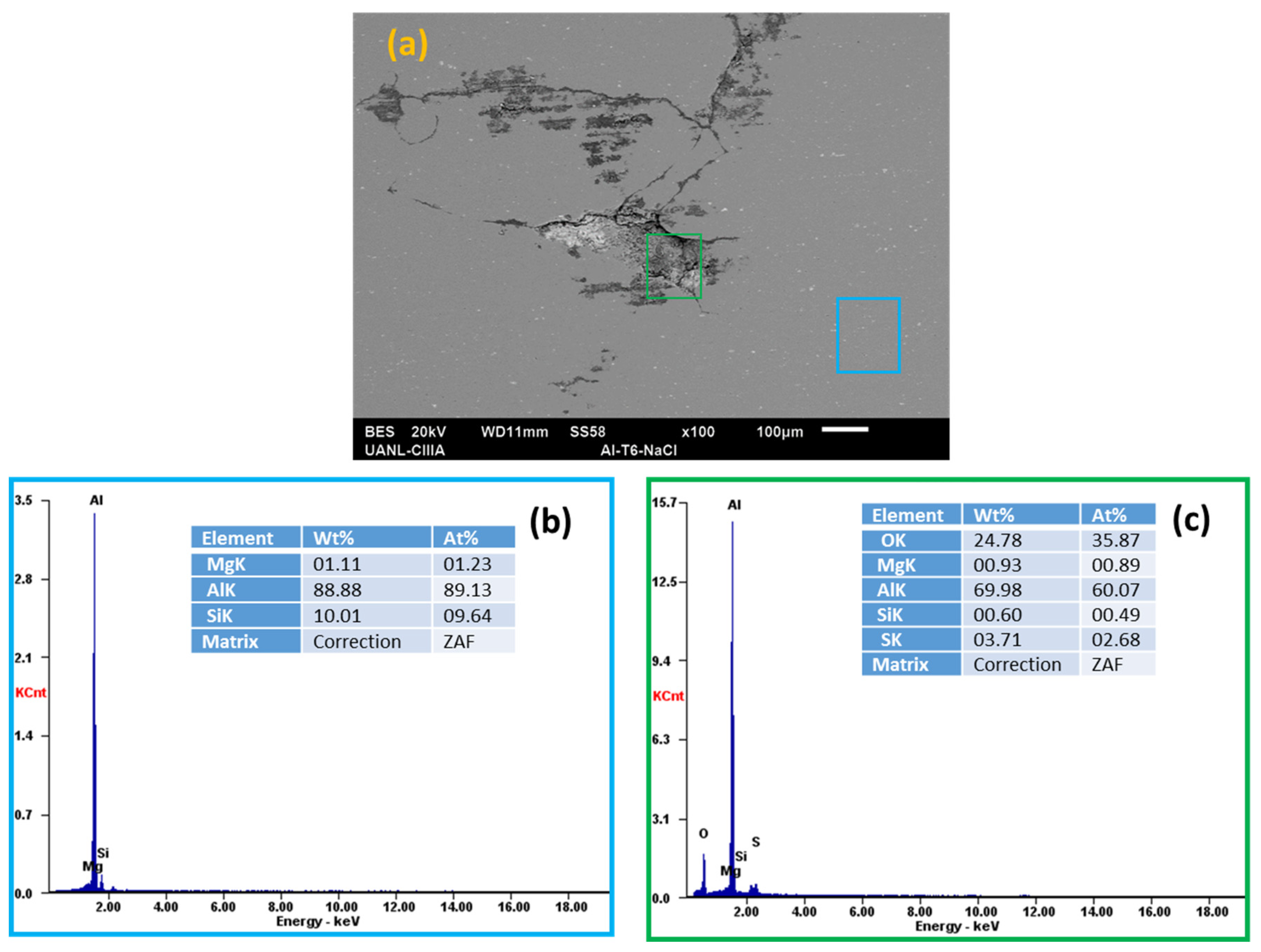

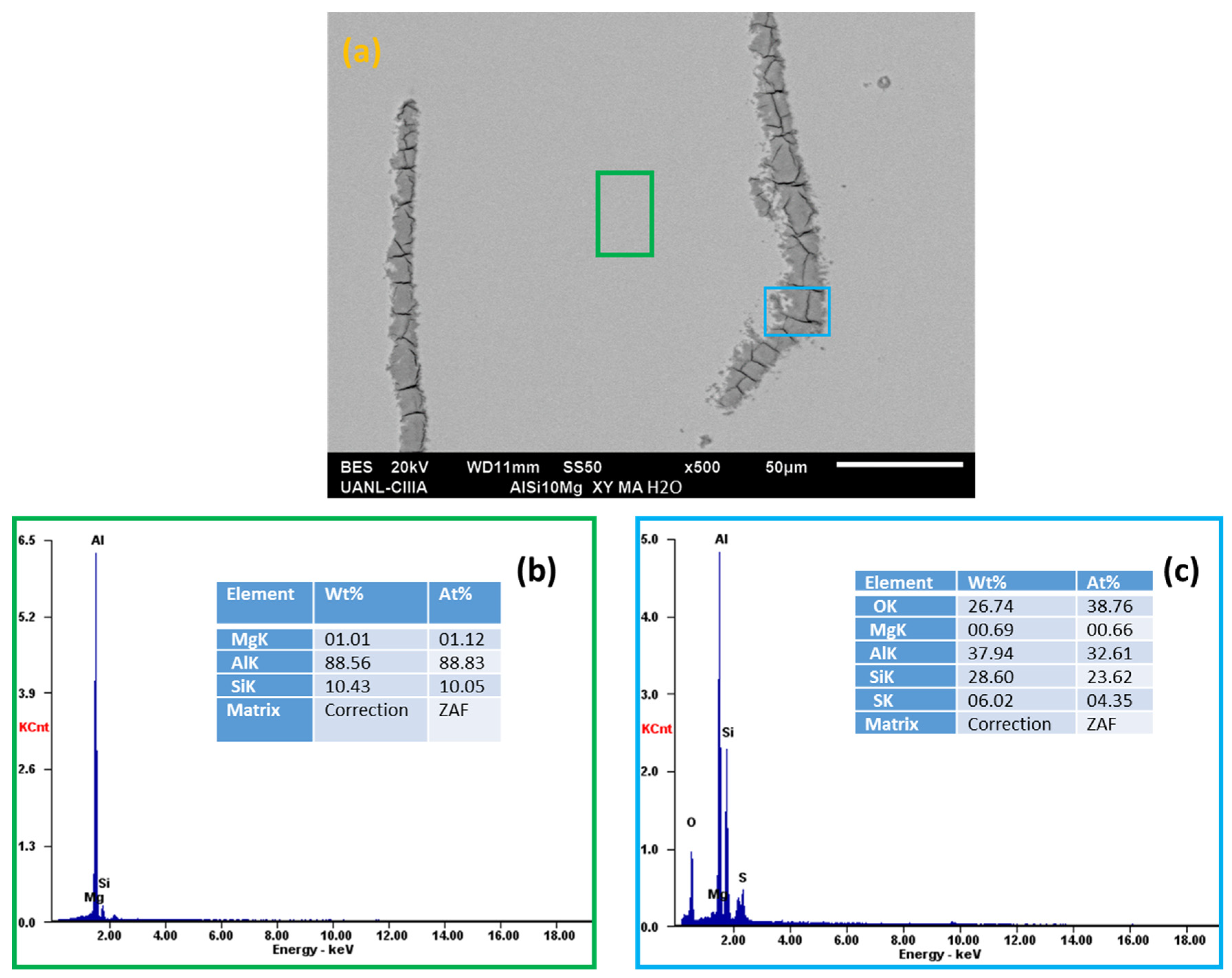

3.2.6. SEM Corrosion Product Analysis

4. Discussion

5. Conclusions

- Microstructural analysis indicated that alloys produced by additive manufacturing- SLM were more susceptible to localized corrosion due to porosity.

- EN results showed that the amplitude of the transients in both the potential and current time series was greater in the AlSi10Mg (Al-A.M.) alloy manufactured by additive manufacturing.

- The localization index, skewness, and Kurtosis results showed that they must be interpreted to measure the disorder and distribution of transients and not as a mechanistic method for aluminum alloys.

- EN results showed that Zn and Ψ0 parameters should be considered a counterpart to calculate the corrosion resistance of materials.

- Wavelets and HHT methods were more reliable in determining the corrosion type for Al-6061 and Al-A.M. alloys than statistical methods. In H2O and NaCl, wavelets and HHT presented similar results. For NaCl, the behavior was associated with a slow process, but the energy presence at middle frequencies was significant, and an unstable passive layer was attributed to Cl− ions.

- SEM-EDS observations indicated that Al-6061 and Al-A.M. alloys exposed to sodium chloride presented corrosion products with more severe corrosion, having a greater presence of oxygen in the grain boundary zones for Al-A.M. alloys.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sames, J.W.; List, A.F.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Fathi, P.; Rafieazad, M.; Duan, X.; Mohammadi, M.; Nasiri, M.A. On microstructure and corrosion behaviour of AlSi10Mg alloy with low surface roughness fabricated by direct metal laser sintering. Corros. Sci. 2019, 57, 126–145. [Google Scholar] [CrossRef]

- Gu, X.; Zhang, J.; Fan, X.; Dai, N.; Xiao, Y.; Zhang, C.L. Abnormal corrosion behavior of selective laser melted AlSi10Mg alloy induced by heat treatment at 300 °C. J. Alloy. Compd. 2019, 803, 314–324. [Google Scholar] [CrossRef]

- Buchbinder, D.; Schleifenbaum, H.; Heidrich, S.; Meiners, W.; Bültmann, J. High power selective laser melting (HP SLM) of aluminum parts. Phys. Procedia 2017, 12, 271–278. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Ahn, G.-D. Direct metal additive manufacturing processes and their sustainable applications for green technology: A review. Int. J. Precis. Eng. Manuf. 2016, 3, 381–395. [Google Scholar] [CrossRef]

- Frazier, E.W. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.P.; Humbeeck, J.V. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Li, P.X.; Kang, W.C.; Huang, H.; Zhang, C.L.; Sercombe, B.T. Selective laser melting of an Al86Ni6Y4.5Co2La1.5 metallic glass: Processing, microstructure evolution and mechanical properties. Mater. Sci. Eng. 2017, 606, 370–379. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhang, J.; Gu, X.; Qin, P.; Zhang, C.L. Distinction of corrosion resistance of selective laser melted Al-12Si alloy on different planes. J. Alloy. Comp. 2018, 747, 648–658. [Google Scholar] [CrossRef]

- Yang, T.; Chen, Y.; Zhang, J.; Gu, X.; Qin, P.; Dai, N.; Li, X.; Kruth, P.J.; Zhang, C.L. Improved corrosion behavior of ultrafine-grained eutectic Al-12Si alloy produced by selective laser melting. Mater. Des. 2018, 146, 239–248. [Google Scholar] [CrossRef]

- Prasad, V.S.; Asthana, R. Aluminum metal-matrix composites for automotive applications: Tribological considerations. Tribol. Lett. 2004, 17, 445–453. [Google Scholar] [CrossRef]

- Lu, K.; Hansen, N. Structural refinement and deformation mechanisms in nanostructured metals. Scripta Mater. 2009, 60, 1033–1038. [Google Scholar] [CrossRef]

- Lu, K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat. Rev. Mater. 2016, 1, 16019. [Google Scholar] [CrossRef]

- Leon, A.; Aghion, E. Effect of surface roughness on corrosion fatigue performance of AlSi10Mg alloy produced by Selective Laser Melting. Mater. Charact. 2017, 131, 188–194. [Google Scholar] [CrossRef]

- Guzmán-Nogales, R.; Estupiñán-López, F.; Gaona-Tiburcio, C.; Lopez-Botello, O.E.; Ramírez-Rodríguez, J.G.; Zambrano-Robledo, P.C. Corrosion Resistance Measurement of 316L Stainless Steel Manufactured by Selective Laser Melting. Materials 2021, 14, 4509. [Google Scholar] [CrossRef]

- Almeraya-Calderón, F.; Estupiñán, F.; Zambrano, R.P.; Martínez-Villafañe, A.; Borunda, T.A.; Colás, O.R.; Gaona-Tiburcio, C. Análisis de los transitorios de ruido electroquímico para aceros inoxidables 316 y -DUPLEX 2205 en NaCl y FeCl. Rev. Metal. 2012, 4, 147–156. [Google Scholar] [CrossRef]

- Gaona-Tiburcio, C.; Aguilar, L.M.R.; Zambrano-Robledo, P.; Estupiñán-López, F.; Cabral-Miramontes, J.A.; Nieves-Mendoza, D.; Castillo-González, E.; Almeraya-Calderón, F. Electrochemical Noise Analysis of Nickel Based Superalloys in Acid Solutions. Int. J. Electrochem. Sci. 2014, 9, 523–533. [Google Scholar]

- Mehdipour, M.; Naderi, R.; Markhali, B.P. Electrochemical study of effect of the concentration of azole derivatives on corrosion behavior of stainless steel in H2SO4. Prog. Org. Coat. 2014, 77, 1761–1767. [Google Scholar] [CrossRef]

- Kelly, R.G.; Scully, J.R.; Shoesmith, D.W.; Buchheit, G. Electrochemical Techniques in Corrosion Science and Engineering; Taylor & Francis: Boca Raton, FL, USA, 2002; pp. 54–123. [Google Scholar]

- Kearns, J.R.; Eden, D.A.; Yaffe, M.R.; Fahey, J.V.; Reichert, D.L.; Silverman, D.C. ASTM Standardization of Electrochemical Noise Measurement. In Electrochemical Noise Measurement for Corrosion Applications; Kearns, J.R., Scully, J.R., Roberge, P.R., Reirchert, D.L., Dawson, L., Eds.; ASTM International, Materials Park: Russell, OH, USA, 1996; pp. 446–471. [Google Scholar]

- Ma, C.; Song, S.; Gao, Z.; Wang, J.; Hu, W.; Behnamian, Y.; Xia, D.H. Electrochemical noise monitoring of the atmospheric corrosion of steels: Identifying corrosion form using wavelet analysis. Corros. Eng. Sci. Technol. 2017, 5, 1–9. [Google Scholar] [CrossRef]

- Ma, C.; Wang, Z.; Behnamian, Y.; Gao, Z.; Wu, Z.; Qin, Z.; Xia, D.H. Measuring atmospheric corrosion with electrochemical noise: A review of contemporary methods. Measurement 2019, 138, 54–79. [Google Scholar] [CrossRef]

- Xia, D.H.; Song, S.; Behnamian, Y.; Hu, W.; Cheng, F.; Luo, J.L.; Huet, F. Review—Electrochemical Noise Applied in Corrosion Science: Theoretical and Mathematical Models towards Quantitative Analysis. J. Electrochem. Soc. 2020, 167, 081507. [Google Scholar] [CrossRef]

- Botana, P.J.; Bárcena, M.M.; Villero, Á.A. Ruido Electroquímico: Métodos de Análisis; Septem Ediciones: Cadiz, Spain, 2002; pp. 50–70. [Google Scholar]

- Montoya-Rangel, M.; de Garza-Montes, O.N.; Gaona-Tiburcio, C.; Colás, R.; Cabral-Miramontes, J.; Nieves-Mendoza, D.; Maldonado-Bandala, E.; Chacón-Nava, J.; Almeraya-Calderón, F. Electrochemical Noise Measurements of Advanced High-Strength Steels in Different Solutions. Metals 2020, 10, 1232. [Google Scholar] [CrossRef]

- Monticelli, C. Evaluation of Corrosion Inhibitors by Electrochemical Noise Analysis. J. Electrochem. Soc. 1992, 139, 706–711. [Google Scholar] [CrossRef]

- Park, C.J.; Kwon, H.S. Electrochemical noise analysis of localized corrosion of duplex stainless steel aged at 475 °C. Mater. Chem. Phys. 2005, 91, 355–360. [Google Scholar] [CrossRef]

- Suresh, G.U.; Kamachi, M.S. Electrochemical Noise Analysis of Pitting Corrosion of Type 304L Stainless Steel. Corrosion 2014, 70, 283–293. [Google Scholar] [CrossRef]

- Núñez-Jaquez, R.E.; Buelna-Rodríguez, J.E.; Barrios-Durstewitz, C.P.; Gaona-Tiburcio, C.; Almeraya-Calderón, F. Corrosion of modified concrete with sugar cane bagasse Ash. Int. J. Corros. 2012, 2012, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Nagiub, A.M. Electrochemical Noise Analysis for Different Green Corrosion Inhibitors for Copper Exposed to Chloride Media. Port. Electrochim. Acta 2017, 35, 201–210. [Google Scholar] [CrossRef]

- Dawson, D.L. Electrochemical Noise Measurement: The definitive In-Situ Technique for Corrosion Applications? In Electrochemical Noise Measurement for Corrosion Applications STP 1277; Kearns, J.R., Scully, J.R., Roberge, P.R., Reirchert, D.L., Dawson, L., Eds.; ASTM International, Materials Park: Russell, OH, USA, 1996; pp. 3–39. [Google Scholar]

- Jáquez-Muñoz, J.M.; Gaona-Tiburcio, C.; Cabral-Miramontes, J.; Nieves-Mendoza, D.; Maldonado-Bandala, E.; Olguín-Coca, J.; López-León, L.D.; Flores-De los Rios, J.P.; Almeraya-Calderón, F. Electrochemical Noise Analysis of the Corrosion of Titanium Alloys in NaCl and H2SO4 Solutions. Metals 2021, 11, 105. [Google Scholar] [CrossRef]

- Cottis, R.; Turgoose, S.; Mendoza-Flores, J. The Effects of Solution Resistance on Electrochemical Noise Resistance Measurements: A Theorical Analysis. In Electrochemical Noise Measurement for Corrosion Applications STP 1277; Kearns, J.R., Scully, J.R., Roberge, P.R., Reirchert, D.L., Dawson, L., Eds.; ASTM International, Materials Park: Russell, OH, USA, 1996; pp. 93–100. [Google Scholar]

- Lara-Banda, M.; Gaona-Tiburcio, C.; Zambrano-Robledo, P.; Delgado-E, M.; Cabral-Miramontes, J.A.; Nieves-Mendoza, D.; Maldonado-Bandala, E.; Estupiñan-López, F.; Chacón-Nava, J.G.; Almeraya-Calderón, F. Alternative to Nitric Acid Passivation of 15-5 and 17-4PH Stainless Steel Using Electrochemical Techniques. Materials 2020, 13, 2836. [Google Scholar] [CrossRef] [PubMed]

- ASTM E3-95. Standard Practice for Preparation of Metallographic Specimens; ASTM International: West Conshohocken, PA, USA, 1995. [Google Scholar]

- ASTM E407-07. Standard Practice for Microetching Metals and Alloys; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM G199-09. Standard Guide for Electrochemical Noise Measurement; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Chen, Z.; Li, S.; Hihara, H.L. Microstructure, mechanical properties and corrosion of friction stir welded 6061 Aluminum Alloy. arXiv 2015, arXiv:1511.05507. [Google Scholar]

- Cabral-Miramontes, J.A.; Gaona-Tiburcio, C.; Almeraya-Calderón, F.; Estupiñan-Lopez, H.F.; Pedraza-Basulto, G.; Poblano-Salas, C. Parameter Studies on High-Velocity Oxy-Fuel Spraying of CoNiCrAlY Coatings Used in the Aeronautical Industry. Int. J. Corros. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Cottis, R.A.; Turgoose, S. Electrochemical Impedance and Noise, Corrosion Testing Made Easy; Syrett, B.C., Ed.; NACE International: Houston, TX, USA, 1999; Volume 7. [Google Scholar]

- Corral, H.R.; Arredondo, R.S.P.; Neri, F.M.; Gómez, S.J.M.; Almeraya, C.F.; Castorena, G.J.H.; Almaral, S.J. Sulfate attack and reinforcement corrosion in concrete with recycled concrete aggregates and supplementary cementing materials. Int. J. Electrochem. Sci. 2011, 6, 613–621. [Google Scholar]

- Cottis, R.A.; Homborg, A.M.; Mol, J.M.C. The relationship between spectral and wavelet techniques for noise analysis. Electrochimica Acta 2016, 202, 277–287. [Google Scholar] [CrossRef]

- Martínez-Villafañe, A.; Almeraya-Calderón, M.F.; Gaona-Tiburcio, C.; Gonzalez-Rodriguez, J.G.; Porcayo-Calderón, J. High-Temperature Degradation and Protection of Ferritic and Austenitic Steels in Steam Generators. J. Mater. Eng. Perform 1998, 7, 108–113. [Google Scholar] [CrossRef]

- Stern, M.; Geary, A.L. Electrochemical polarization. I. A theoretical analysis of the shape of the polarization curves. J. Electrochem. Soc. 1957, 104, 56–63. [Google Scholar] [CrossRef]

- Eden, D.A.; John, D.G.; Dawson, J.L. Corrosion Monitoring. International Patent WO 87/07022, 19 November 1997. Available online: https://patentimages.storage.googleapis.com/19/ca/d4/c180ce2c0b9dfe/WO1987007022A1.pdf (accessed on 15 March 2021).

- Mansfeld, F.; Sun, Z. Technical Note: Localization Index Obtained from Electrochemical Noise Analysis. Corrosion 1999, 55, 915–918. [Google Scholar] [CrossRef]

- Reid, S.A.; Eden, D.A. Assessment of Corrosion. US 6,264,824 B1, 24 July 2001. Available online: http://www.khdesign.co.uk/Patents/US6264824.Eden%20AI.pdf (accessed on 15 March 2021).

- Cottis, R. Interpretation of Electrochemical Noise Data. Corrosion 2001, 57, 265–285. [Google Scholar] [CrossRef]

- Bertocci, U.; Huet, F. Noise Analysis Applied to Electrochemical Systems. Corrosion 1995, 51, 131–144. [Google Scholar] [CrossRef]

- Coakley, J.; Vorontsov, V.A.; Littlell, K.C.; Heenan, R.K.; Ohnuma, G.; Jones, N.G.; Dye, D. Nanoprecipitation in a beta-titanium alloy. J. Alloy. Compd. 2015, 623, 146–156. [Google Scholar] [CrossRef] [Green Version]

- Martinez-Villafañe, A.; Chacon-Nava, J.G.; Gaona-Tiburcio, C.; Almeraya-Calderon, F.; Domínguez-Patiño, G.; Gonzalez-Rodríguez, J.G. Oxidation performance of a Fe–13Cr alloy with additions of rare earth elements. Mater. Sci. Eng. A 2003, 363, 1–2, 15–19. [Google Scholar] [CrossRef]

- Cabral-Miramontes, J.A.; Barceinas-Sánchez, J.D.O.; Poblano-Salas, C.A.; Pedraza-Basulto, G.K.; Nieves-Mendoza, D.; Zambrano-Robledo, P.C.; Almeraya-Calderón, F.; Chacón-Nava, J.G. Corrosion Behavior of AISI 409Nb Stainless Steel Manufactured by Powder Metallurgy Exposed in H2SO4 and NaCl Solutions. Int. J. Electrochem. Sci. 2013, 8, 564–577. [Google Scholar]

- Froes, F.; Quian, M.; Niinomi, M. Titanium for Consumer Applications. Real World Use of Titanium; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 27–65. [Google Scholar] [CrossRef]

- Xia, D.-H.; Song, S.-Z.; Behnamian, Y. Detection of corrosion degradation using electrochemical noise (EN): Review of signal processing methods for identifying corrosion forms. Corros. Eng. Sci. Technol. 2016, 51, 527–544. [Google Scholar] [CrossRef]

- Galvan-Martinez, R.; Orozco-Cruz, R.; Torres-Sanchez, R.; Martinez, E.A. Corrosion study of the X52 steel immersed in seawaterwith a corrosion inhibitor using a rotating cylinder electrode. Mater. Corros. 2010, 61, 872–876. [Google Scholar] [CrossRef]

- Lentka, L.; Smulko, J. Methods of trend removal in electrochemical noise data-overview. Measurement 2019, 131, 569–581. [Google Scholar] [CrossRef]

- Lafront, A.M.; Safizadeha, F.; Ghali, E.; Houlachi, G. Study of the cupper anode passivation by electrochemical noise analysis using spectral and wavelet transform. Electrochim. Acta. 2010, 55, 2505–2512. [Google Scholar] [CrossRef]

- Eden, D.A. Electrochemical Noise—The First Two Octaves; NACE International Corrosion/98: San Diego, FL, USA, 1998; pp. 1–31. [Google Scholar]

- Homborg, A.M.; Tinga, T.; Zhang, X.; Van Westing, E.P.M.; Ferrari, G.M.; Wit, J.H.W.; Mol, J.M.W. A Critical Appraisal of the Interpretation of Electrochemical Noise for Corrosion Studies. Corrosion 2017, 70, 971–987. [Google Scholar] [CrossRef]

- Dubent, S.; Mazard, A. Characterization and corrosion behaviour of grade 2 titanium used in electrolyzers for hydrogen production. Int. J. Hydrogen Energy 2019, 44, 15622–15633. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, Z.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, T.; Shao, Y.; Meng, G.; Wang, F. In-situ study of the formation process of stannate conversion coatings on AZ91D magnesium alloy using electrochemical noise. Corros. Sci. 2010, 52, 892–900. [Google Scholar] [CrossRef]

- Uruchurtu, J.C.; Dawson, J.L. Noise Analysis of Pure Aluminum under Different Pitting Conditions. Corrosion 1987, 43, 19–26. [Google Scholar] [CrossRef]

- Corral-Higuera, R.; Arredondo-Rea, P.; Neri-Flores, M.A.; Gómez-Soberón, J.M.; Almaral-Sánchez, J.L.; Castorena-González, J.C.; Almeraya-Calderón, F. Chloride ion penetrability and Corrosion Behavior of Steel in Concrete with Sustainability Characteristics. Int. J. Electrochem. Sci. 2011, 6, 958–970. [Google Scholar]

- Lohrberg, K.; Kohl, P. Preparation and use of Raney-Ni activated cathodes for large scale hydrogen production. Electrochem. Acta 1984, 29, 1557–1561. [Google Scholar] [CrossRef]

- Cabral Miramontes, J.A.; Barceinas Sánchez, J.D.O.; Almeraya Calderón, F.; Martínez Villafañe, A.; Chacón Nava, J.G. Effect of Boron Additions on Sintering and Densification of a Ferritic Stainless Steel. J. Mater. Eng. Perform. 2010, 19, 880–884. [Google Scholar] [CrossRef]

- Huet, F.; Musiani, M.; Nogueira, P. Oxygen evolution on electrodes of different roughness an electrochemical noise study. J. Solid State Electrochem. 2004, 786–793. [Google Scholar] [CrossRef]

- Seah, K.H.W.; Thampuran, R.; Teoh, S.H. The influence of pore morphology on corrosion. Corros. Sci. 1998, 40, 547–556. [Google Scholar] [CrossRef]

- Kwok, C.T.; Fong, S.L.; Cheng, F.T.; Man, H.C. Pitting and galvanic corrosion behavior of laser-welded stainless steels. J. Mater. Process. Technol. 2006, 176, 168–178. [Google Scholar] [CrossRef]

- Cem, Ö. Additive manufacturing—A general corrosion perspective. Corr. Eng. Sci and Tech. 2018, 53, 531–535. [Google Scholar] [CrossRef]

- Lin, Y.C.; Zhang, J.-L.; Liu, G.; Liang, Y.-J. Effects of pre-treatments on aging precipitates and corrosion resistance of a creep-aged Al–Zn–Mg–Cu alloy. Mater. Des. 2015, 83, 866–875. [Google Scholar] [CrossRef]

- Tian, Q.; Yang, Q.-M.; Lin, Y.-C.; Wang, J.-Q.; Zhu, X.-H. Effects of Aging Treatment on Corrosion Behavior of a Tensile Deformed Al-Cu-Mn-Fe-Zr Alloy in 3.5% NaCl Solution. Materials 2021, 14, 5062. [Google Scholar] [CrossRef]

- Chiu, T.; Mahmoudi, M.; Dai, W.; Elwany, A.; Liang, H.; Castaneda, H. Corrosion assessment of Ti-6Al-4V fabricated using laser power-bed fusion additive manufacturing. Electrochem. Acta. 2018, 279, 143–151. [Google Scholar] [CrossRef]

- Azar, A.S.; Lekatou, A.; Sunding, M.F.; Graff, J.S.; Tzima, N.; Diplas, S. Corrosion performance and degradation mechanism of a bimetallic aluminum structure processed by wire-arc additive manufacturing. Mater. Degrad. 2021, 5, 26. [Google Scholar] [CrossRef]

- Melia, M.A.; Nguyen, H.A.; Rodelas, J.M.; Schindelholz, E.J. Corrosion properties of 304L stainless made by directed energy deposition additive manufacturing. Corr. Sci. 2019, 152, 20–30. [Google Scholar] [CrossRef]

- Kubacki, G.; Brownhill, J.P.; Kelly, R.G. Comparison of Atmospheric Corrosion of Additively Manufactured and Cast Al-10Si-Mg Over a Range of Heat Treatments. Corrosion 2019, 75, 1527–1540. [Google Scholar] [CrossRef]

- Revilla, R.I.; Liang, J.; Godet, S.; De Graeve, I. Local Corrosion Behavior of Additive Manufactured AlSiMg Alloy Assessed by SEM and SKPFM. J. Electrochem. Soc. 2016, 164, C27–C35. [Google Scholar] [CrossRef]

- Xu, Z.; Hui, Z.; Du, X.; He, Y.; Luo, H.; Song, G.; Mao, L.; Zhou, T.; Wang, L. Corrosion resistance enhancement of CoCrFeMnNi high-entropy alloy fabricated by additive manufacturing. Corr. Sci. 2020, 177, 108954. [Google Scholar] [CrossRef]

- Ramirez-Arteaga, A.M.; Gonzalez-Rodriguez, J.G.; Campillo, B.; Gaona-Tiburcio, C.; Dominguez-Patiño, G.; Leduc Lezama, L.; Chacon-Nava, J.G.; Neri-Flores, M.A.; Martinez-Villafañe, A. An Electrochemical Study of the Corrosion Behavior of a Dual Phase Steel in 0.5m H2SO4. Int. J. Electrochem. Sci. 2010, 5, 1786–1798. [Google Scholar]

- Sander, G.; Thomas, S.; Cruz, V.; Jurg, M.; Birbilis, N.; Gao, X.; Brameld, M.; Hutchinson, C.R. On the corrosion and metastable pitting characteristics of 316L stainless steel produced by selective laser melting. J. Electrochem. Soc. 2017, 164, C250–C257. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Cheng, X.; Wang, H.; Huang, Z. Effect of heat treatment on microstructure, mechanical and corrosion properties of austenitic stainless steel 316L using arc additive manufacturing. Mater. Sci. Eng. A 2018, 715, 307–314. [Google Scholar] [CrossRef]

- Zakay, A.; Aghion, E. Effect of Post-heat Treatment on the Corrosion Behavior of AlSi10Mg Alloy Produced by Additive Manufacturing. JOM 2019, 71, 1050–1057. [Google Scholar] [CrossRef]

- Longhitano, G.A.; Arenas, M.A.; Conde, C.; Karisam, M.A.; Jardini, A.L.; Avaglia, C.A.C.; Damborenea, J.J. Heat treatments effects on functionalization and corrosion behavior of Ti-6Al-4VmELI alloy made by additive manufacturing. J. Alloys. Comp. 2018, 765, 961–968. [Google Scholar] [CrossRef]

- Leon, A.; Shirizly, A.; Aghion, E. Corrosion Behavior of AlSi10Mg Alloy Produced by Additive Manufacturing (AM) vs. Its Counterpart Gravity Cast Alloy. Metals 2016, 6, 148. [Google Scholar] [CrossRef]

- Revilla, R.I.; Van Calster, M.; Raes, M.; Arroud, G.; Andreatta, F.; Pyl, L.; Guillaume, P.; De Graeve, I. Microstructure and corrosion behavior of 316L stainless steel prepared using different additive manufacturing methods; A comparative study bringing insights into the impact of microstructure on their passivity. Corr. Sci. 2020, 176, 108914. [Google Scholar] [CrossRef]

| Alloy | Si | Fe | Cu | Mg | Zn | Ti | Cr | Mn | Al |

|---|---|---|---|---|---|---|---|---|---|

| AA6061-T6 | 0.6 ± 0.03 | 0.7 ± 0.35 | 0.18 ± 0.01 | 0.9 ± 0.045 | 0.25 ± 0.013 | 0.015 ± 7.5 × 10−4 | 0.35 ± 0.018 | - | Bal. |

| AlSi10Mg (A.M) | 10.1 ± 0.5 | 0.16 ± 0.008 | 0.001 ± 5 × 10−5 | 0.35 ± 18 × 10−4 | 0.002 ± 1 × 10−4 | 0.01 ± 5 × 10−4 | - | 0.002 ± 1 × 10−4 | Bal. |

| Parameter | Value |

|---|---|

| Laser power, W | 400 |

| Scanning speed, mm/s | 230 |

| Layer thickness, µm | 30 |

| Hatch spacing, µm | 110 |

| Energy density, J/mm3 | 527 |

| Scan rotation between successive layers | 90° |

| H2O Solution | ||||||||

|---|---|---|---|---|---|---|---|---|

| Time (h) | Rn (Ω·cm2) | icorr (mA/cm2) | LI | Corrosion Type | Skewness | Corrosion Type | Kurtosis | Corrosion Type |

| 0 | 19,405.77± 970 | 1.3 × 10−6 ± 6.5 × 10−8 | 0.032 | Mix | 0.17 | Uniform | 2.67 | Uniform |

| 24 | 25,422.38 ± 1271 | 1.0 × 10−6 ± 5.0 × 10−8 | 0.131 | Localized | 0.27 | Uniform | 2.33 | Uniform |

| 48 | 20,344.82 ± 1017 | 1.2 × 10−6 ± 6.0 × 10−8 | 0.051 | Mix | −0.008 | Uniform | 2.55 | Uniform |

| 120 | 13,476.44 ± 674 | 1.9 × 10−6 ± 9.5 × 10−8 | 0.044 | Mix | 0.81 | Uniform | 11.31 | Uniform |

| NaCl Solution | ||||||||

| 0 | 1810 ± 90 | 14.4 × 10−6 ± 7.2 × 10−7 | 0.044 | Mix | −0.002 | Uniform | 2.23 | Uniform |

| 24 | 4881.08 ± 244 | 9.1 × 10−6 ± 4.5 × 10−7 | 0.056 | Mix | 0.037 | Uniform | 3.00 | Uniform |

| 48 | 3021.06 ± 151 | 8.6 × 10−6 ± 4.3 × 10−7 | 0.27 | Localized | −0.3 | Uniform | 2.93 | Uniform |

| 120 | 5277.3 ± 263 | 4.9 × 10−6 ± 2.5 × 10−7 | 0.055 | Mix | −0.45 | Uniform | 3.82 | Mix |

| H2O Solution | ||||||||

|---|---|---|---|---|---|---|---|---|

| Time (h) | Rn (Ω·cm2) | icorr (mA/cm2) | LI | Corrosion Type | Skewness | Corrosion Type | Kurtosis | Corrosion Type |

| 0 | 5145.31 ± 257 | 5.1 × 10−6 ± 2.6 × 10−7 | 0.344 | Localized | 0.046 | Uniform | 3.39 | Localized |

| 24 | 6547.6 ± 327 | 4.0 × 10−6 ± 2.0 × 10−7 | 0.17 | Localized | −0.46 | Uniform | 2.99 | Uniform |

| 48 | 3358.78 ± 168 | 7.7 × 10−6 ± 3.9 × 10−7 | 0.051 | Mix | 0.71 | Uniform | 2.55 | Localized |

| 120 | 6800.02 ± 340 | 5.7 × 10−6 ± 2.9 × 10−7 | 0.26 | Localized | 0.26 | Uniform | 4.02 | Uniform |

| NaCl Solution | ||||||||

| 0 | 1810 ± 90 | 14.4 × 10−6 ± 7.2 × 10−7 | 0.044 | Mix | −0.002 | Uniform | 2.23 | Uniform |

| 24 | 4881.08 ± 244 | 9.1 × 10−6 ± 4.5 × 10−7 | 0.056 | Mix | 0.037 | Uniform | 3.00 | Uniform |

| 48 | 3021.06 ± 151 | 8.6 × 10−6 ± 4.3 × 10−7 | 0.27 | Localized | −0.3 | Uniform | 2.93 | Uniform |

| 120 | 5277.3 ± 263 | 4.9 × 10−6 ± 2.5 × 10−7 | 0.055 | Mix | −0.45 | Uniform | 3.82 | Mix |

| Al-6061 Alloy | ||||

|---|---|---|---|---|

| Time (h) | Ψ0 (dBi) | Zn0 (Ω·cm2) | Β (dB (V)) | Β (dB (A)) |

| H2O | ||||

| 0 | −138.01 | 38,612.3 | −9.5 | −8.4 |

| 24 | −101.59 | 12,627.58 | −11.4 | −11.1 |

| 48 | −99.61 | 4252.54 | −11.7 | −10.8 |

| 120 | −118.61 | 70,334.05 | −9.4 | −9.5 |

| NaCl | ||||

| 0 | −86.81 | 363.47 | −9.7 | −14.8 |

| 24 | −90.53 | 6027.83 | −14.8 | −15.3 |

| 48 | −93.04 | 2217.93 | −12.6 | −14.2 |

| 120 | −103.81 | 13,962.53 | −8.7 | −10 |

| Al-A.M.—Alloy | ||||

|---|---|---|---|---|

| Time (h) | Ψ0 (dBi) | Zn0 (Ω·cm2) | Β (dB (V)) | Β (dB (A)) |

| H2O | ||||

| 0 | −94.11 | 7473.53 | −13.1 | −13.1 |

| 24 | −88.42 | 9077.61 | −10.6 | −10.2 |

| 48 | −83.69 | 3030.07 | −12.1 | −10.3 |

| 120 | −100.11 | 2410.34 | −13.8 | −10.8 |

| NaCl | ||||

| 0 | −95.09 | 1320.19 | −9.5 | −13.5 |

| 24 | −100.81 | 10,368.45 | −10.2 | −11.4 |

| 48 | −94.37 | 1609.84 | −10.6 | −12.1 |

| 120 | −90.08 | 1629.51 | −11.9 | −11.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Estupiñan-López, F.; Gaona-Tiburcio, C.; Jáquez-Muñoz, J.; Zambrano-Robledo, P.; Maldonado-Bandala, E.; Cabral-Miramontes, J.; Nieves-Mendoza, D.; D. Delgado, A.; Flores-De los Rios, J.P.; Almeraya-Calderón, F. A Comparative Study of Corrosion AA6061 and AlSi10Mg Alloys Produced by Extruded and Additive Manufacturing. Materials 2021, 14, 5793. https://doi.org/10.3390/ma14195793

Estupiñan-López F, Gaona-Tiburcio C, Jáquez-Muñoz J, Zambrano-Robledo P, Maldonado-Bandala E, Cabral-Miramontes J, Nieves-Mendoza D, D. Delgado A, Flores-De los Rios JP, Almeraya-Calderón F. A Comparative Study of Corrosion AA6061 and AlSi10Mg Alloys Produced by Extruded and Additive Manufacturing. Materials. 2021; 14(19):5793. https://doi.org/10.3390/ma14195793

Chicago/Turabian StyleEstupiñan-López, Francisco, Citlalli Gaona-Tiburcio, Jesús Jáquez-Muñoz, Patricia Zambrano-Robledo, Erick Maldonado-Bandala, José Cabral-Miramontes, Demetrio Nieves-Mendoza, Anabel D. Delgado, Juan Pablo Flores-De los Rios, and Facundo Almeraya-Calderón. 2021. "A Comparative Study of Corrosion AA6061 and AlSi10Mg Alloys Produced by Extruded and Additive Manufacturing" Materials 14, no. 19: 5793. https://doi.org/10.3390/ma14195793

APA StyleEstupiñan-López, F., Gaona-Tiburcio, C., Jáquez-Muñoz, J., Zambrano-Robledo, P., Maldonado-Bandala, E., Cabral-Miramontes, J., Nieves-Mendoza, D., D. Delgado, A., Flores-De los Rios, J. P., & Almeraya-Calderón, F. (2021). A Comparative Study of Corrosion AA6061 and AlSi10Mg Alloys Produced by Extruded and Additive Manufacturing. Materials, 14(19), 5793. https://doi.org/10.3390/ma14195793