Evaluation of Critical Dynamic Stress and Accumulative Plastic Strain of an Unbound Granular Material Based on Cyclic Triaxial Tests

Abstract

:1. Introduction

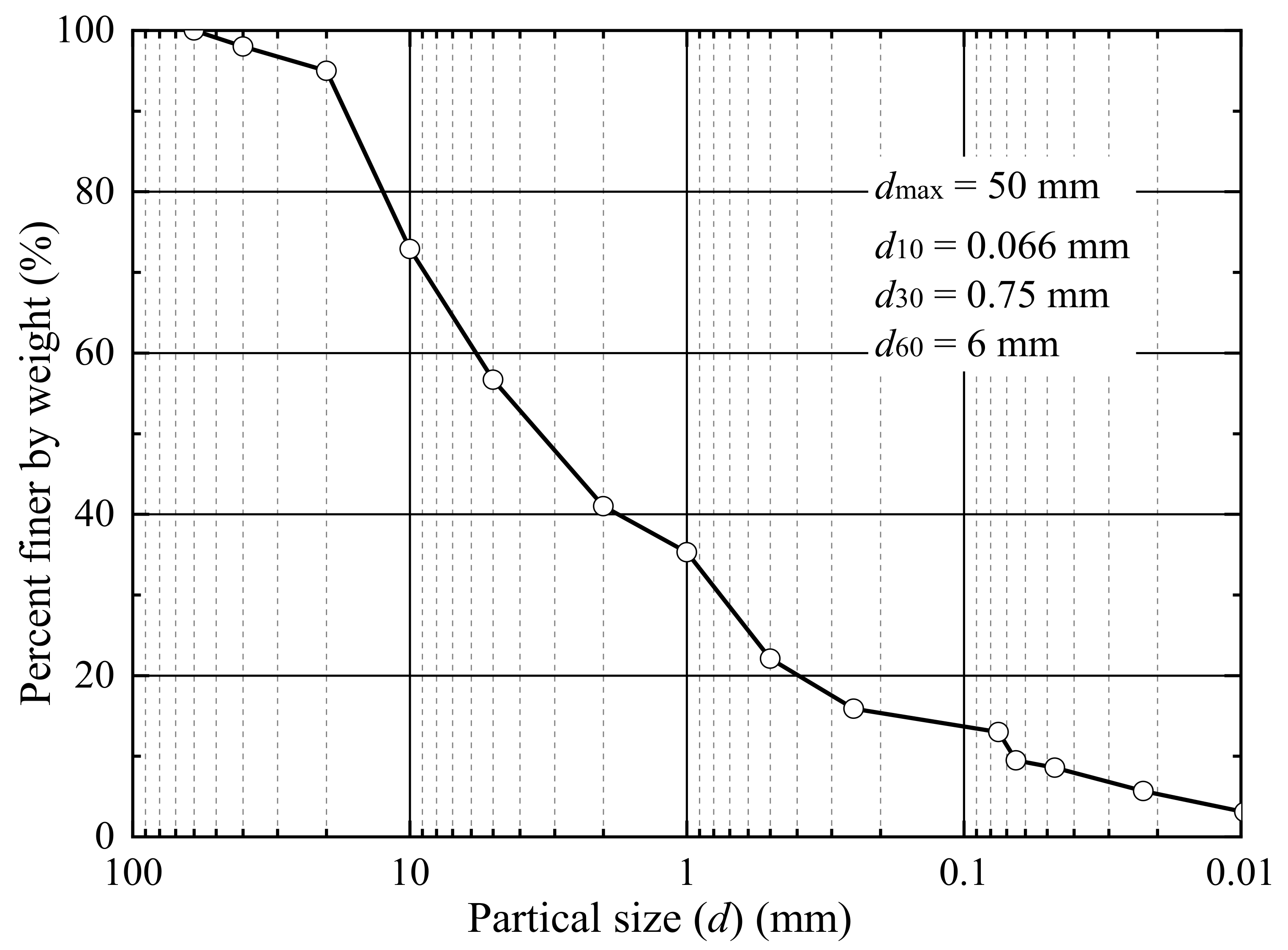

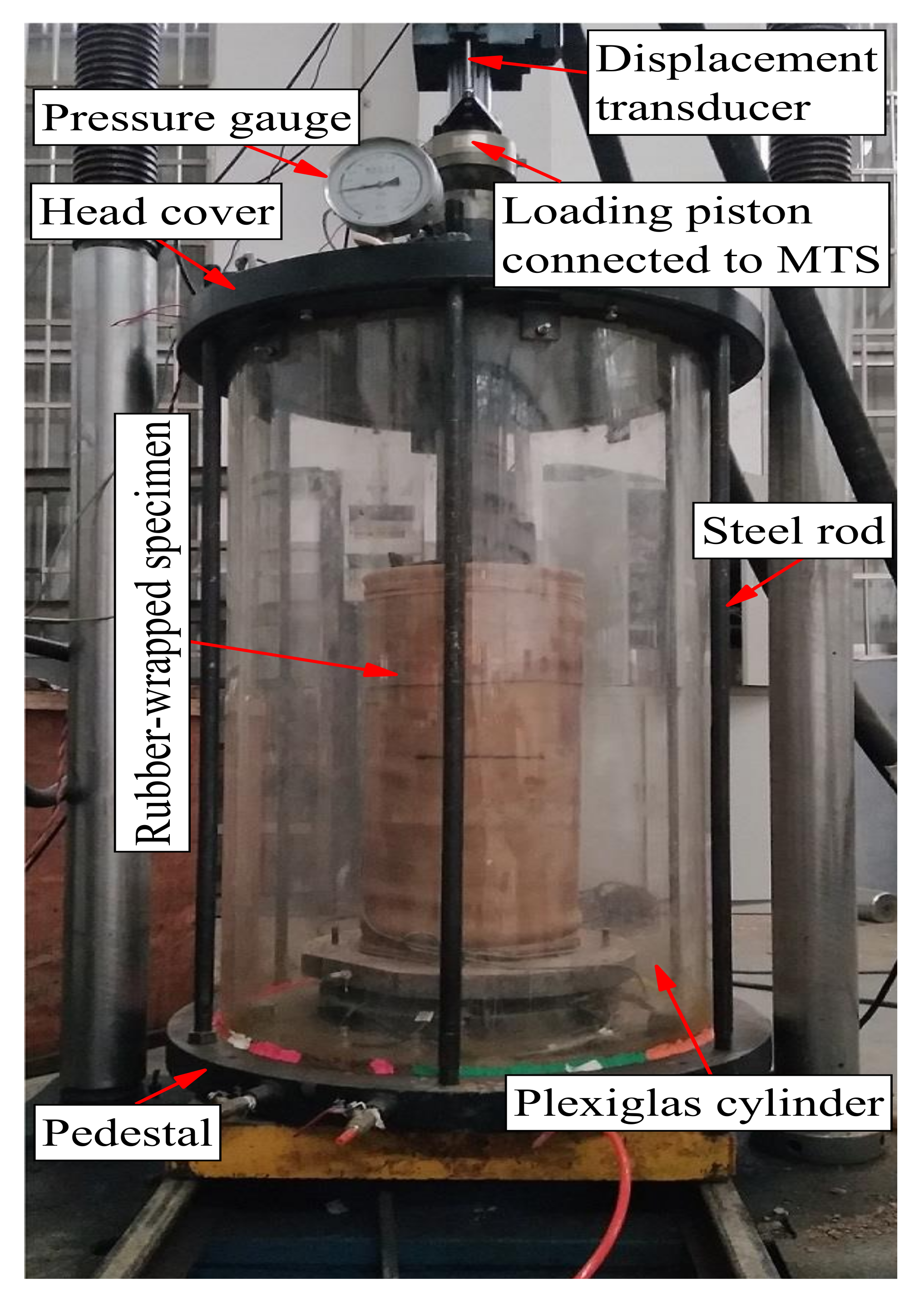

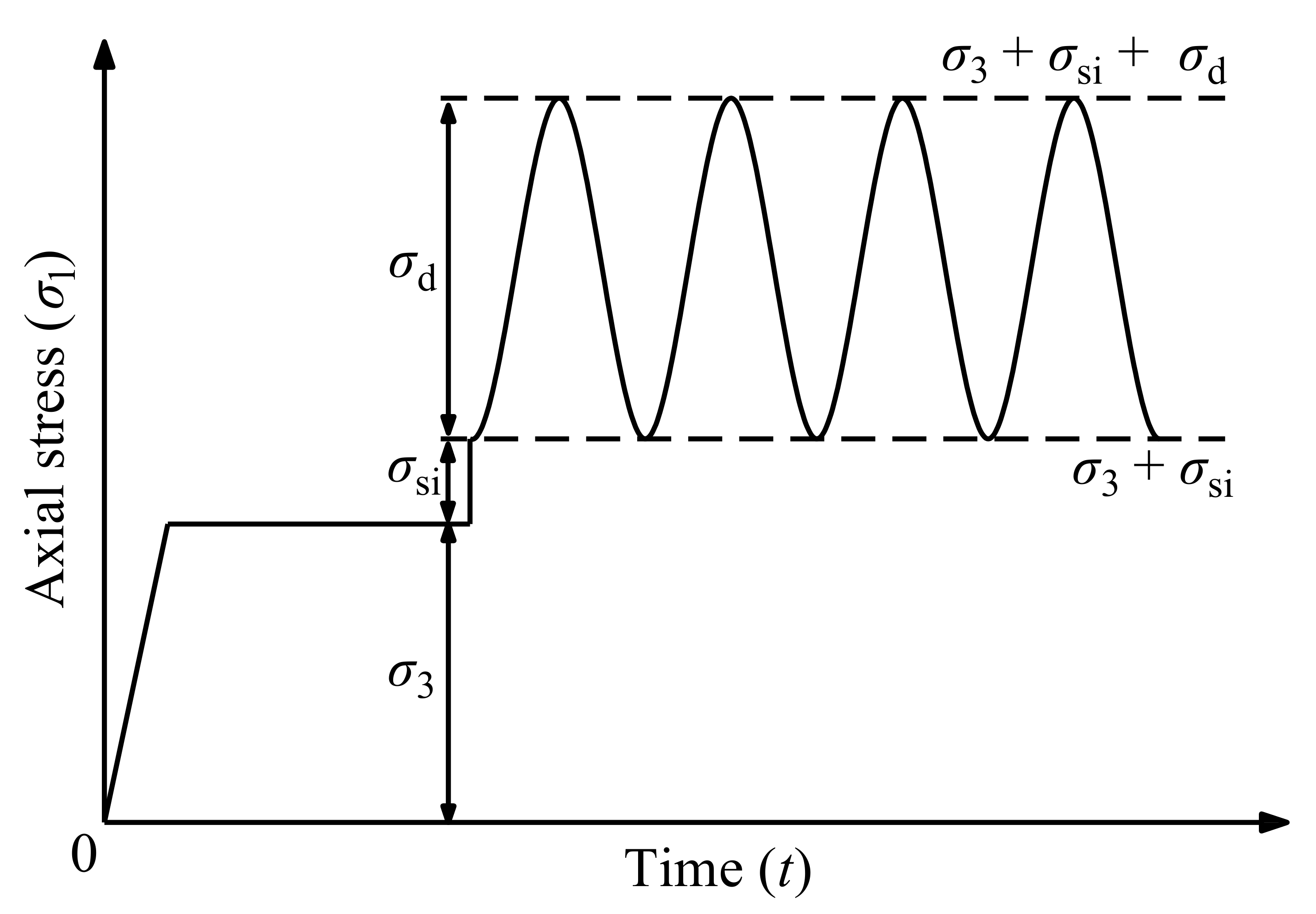

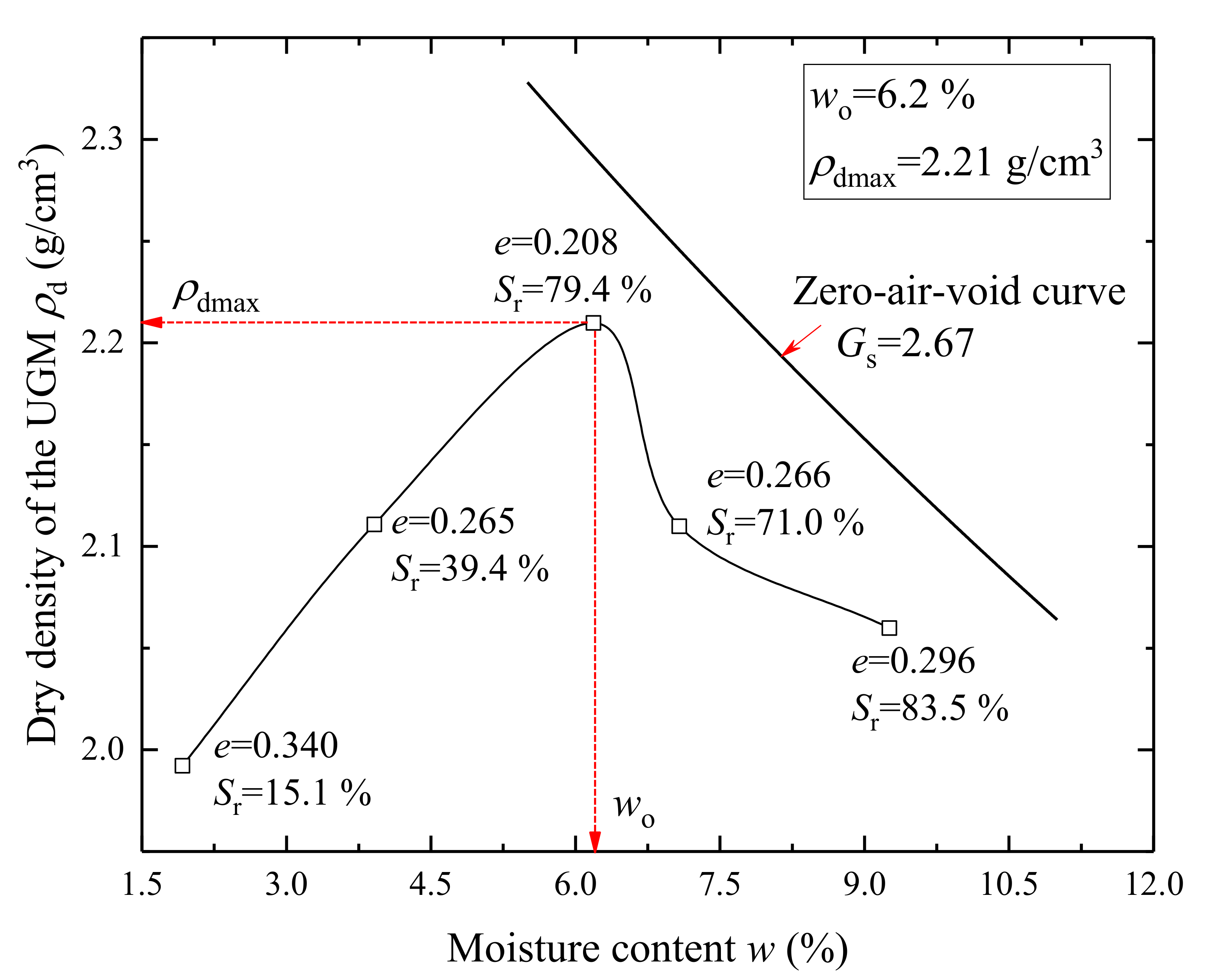

2. Test Materials and Methods

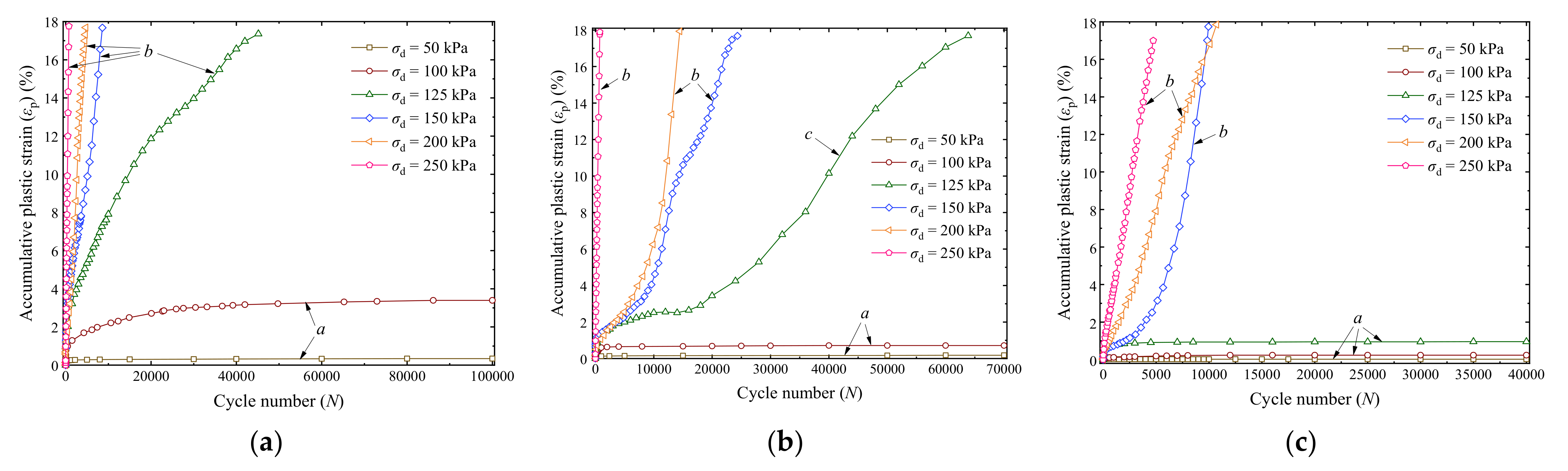

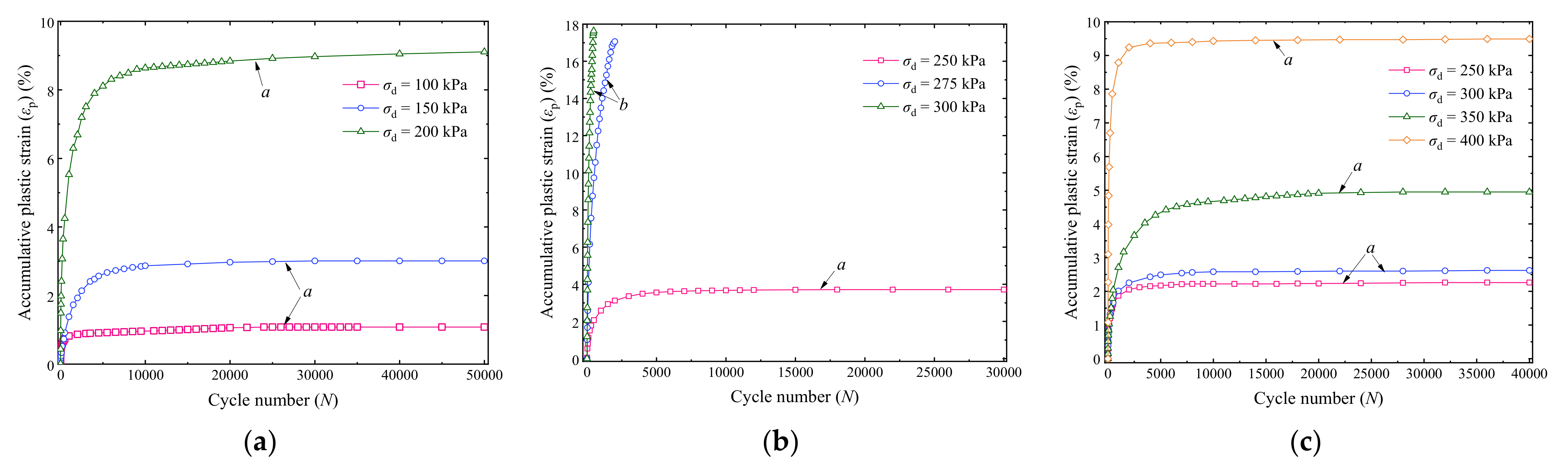

3. Results and Discussion of Accumulative Plastic Strain Curves

4. Evaluation of Critical Dynamic Stress and Final Accumulative Plastic Strain

4.1. Evaluation of Critical Dynamic Stress

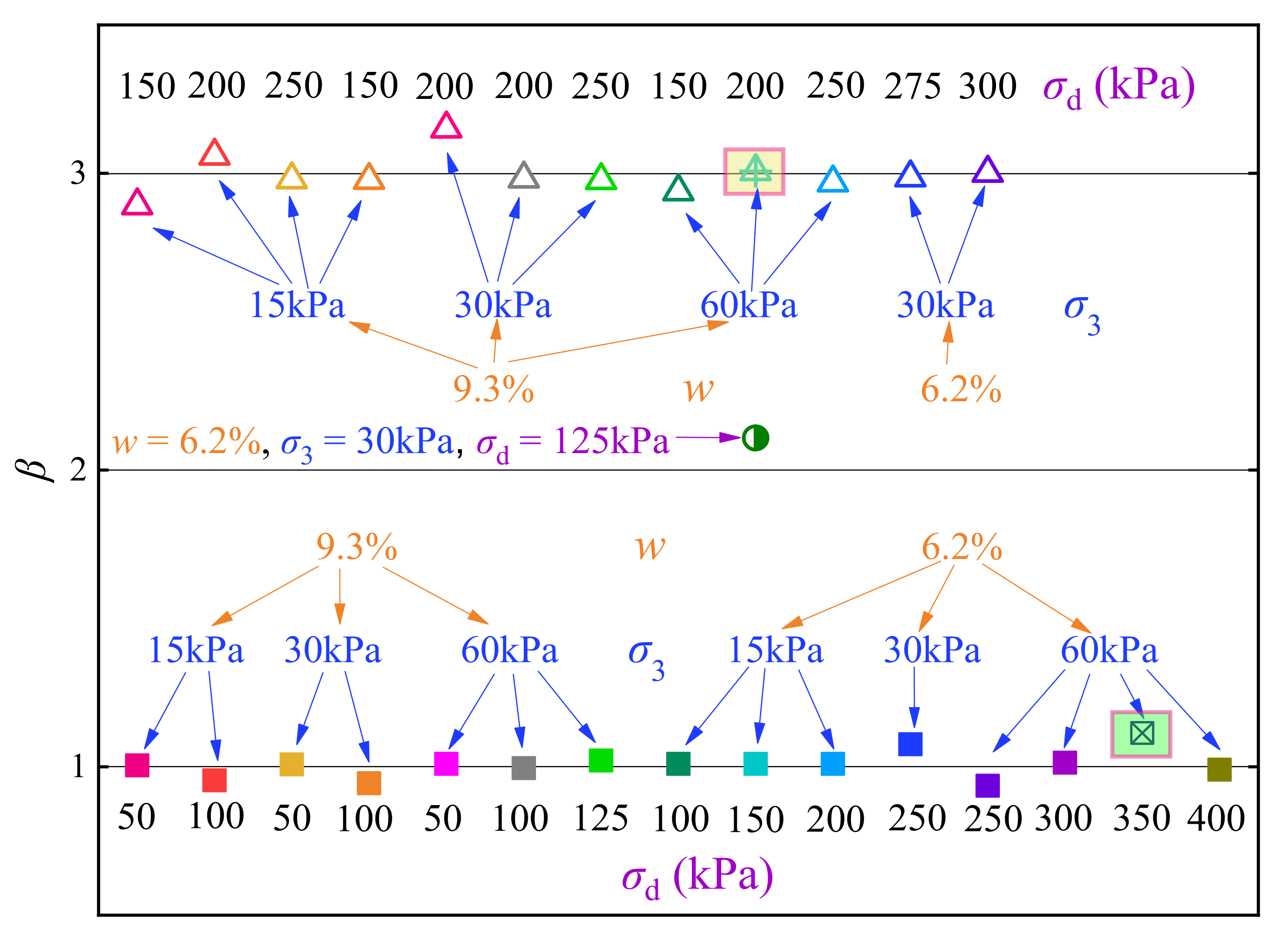

4.1.1. Grey Relation of εp–N Curve Pattern Regarding w, σ3, and σd

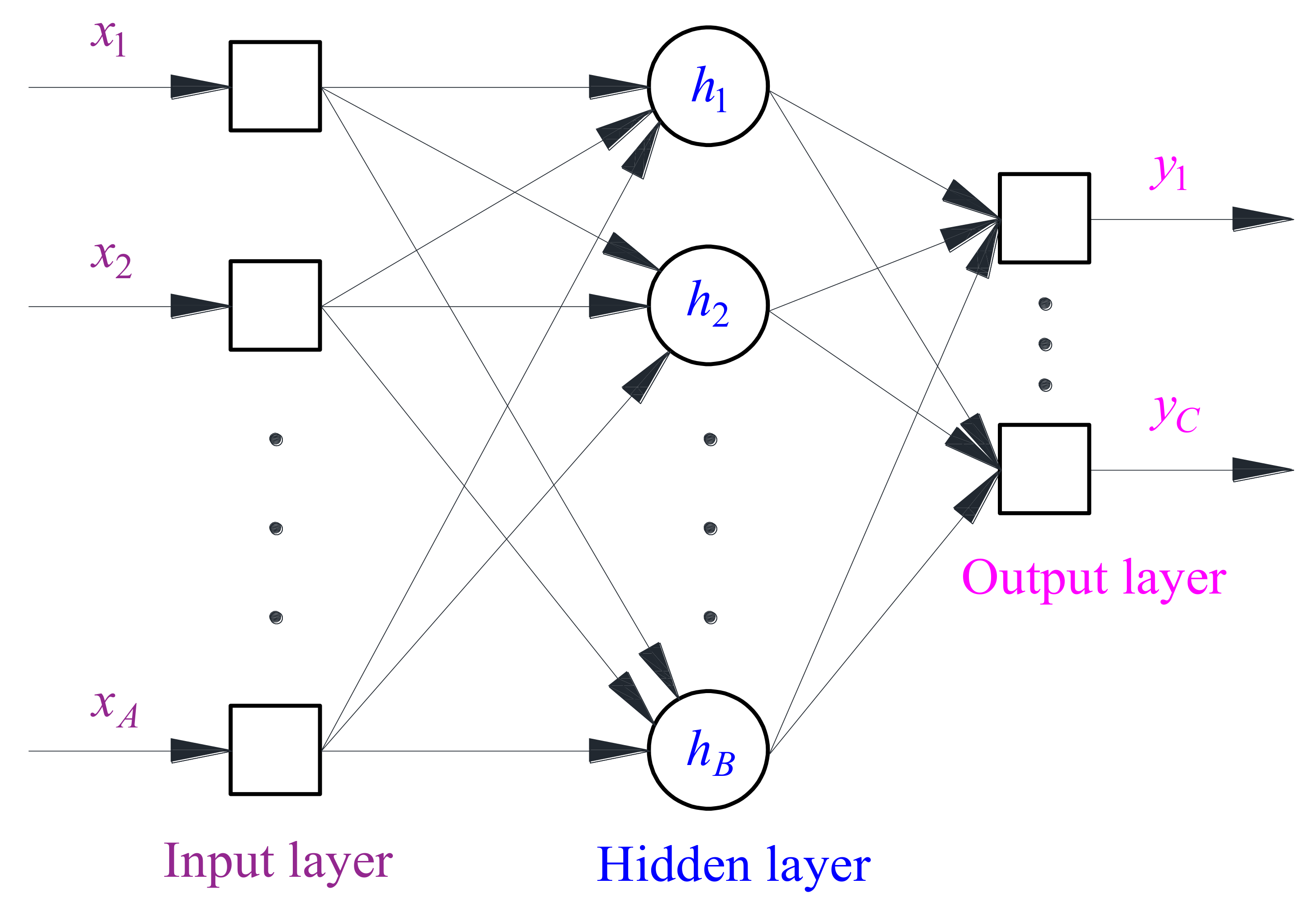

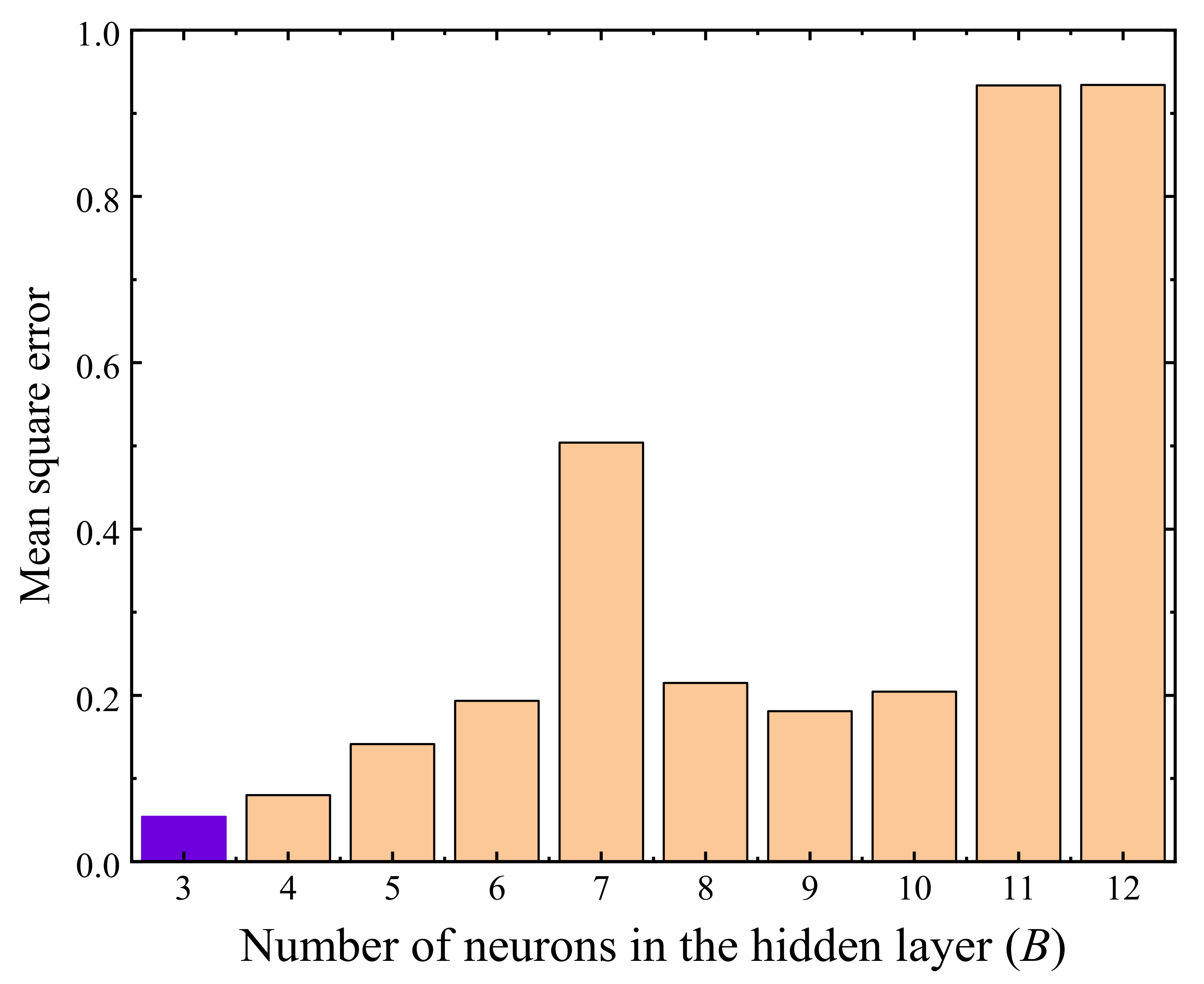

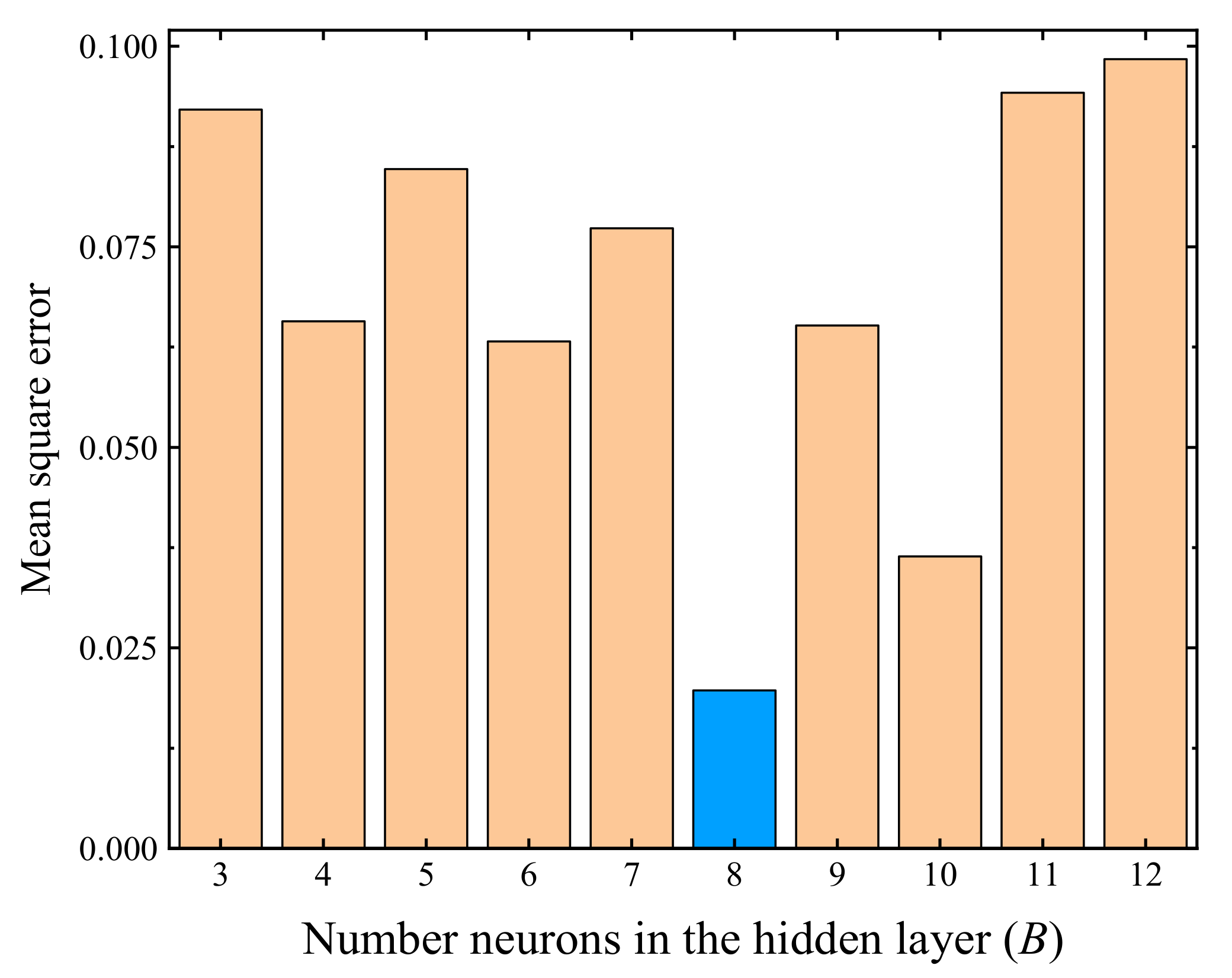

4.1.2. Analysis of Specimen Pattern using the BP Neural Network

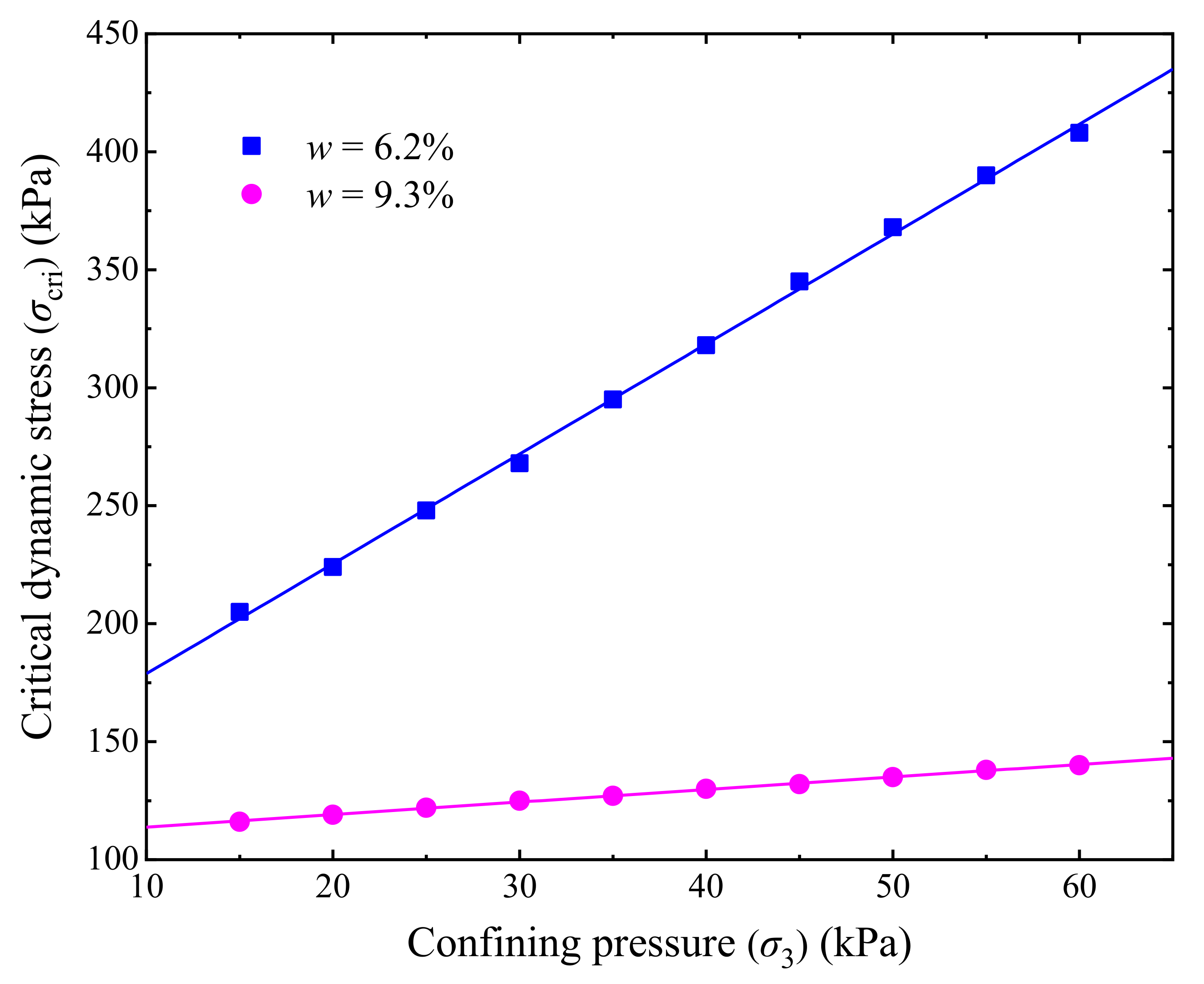

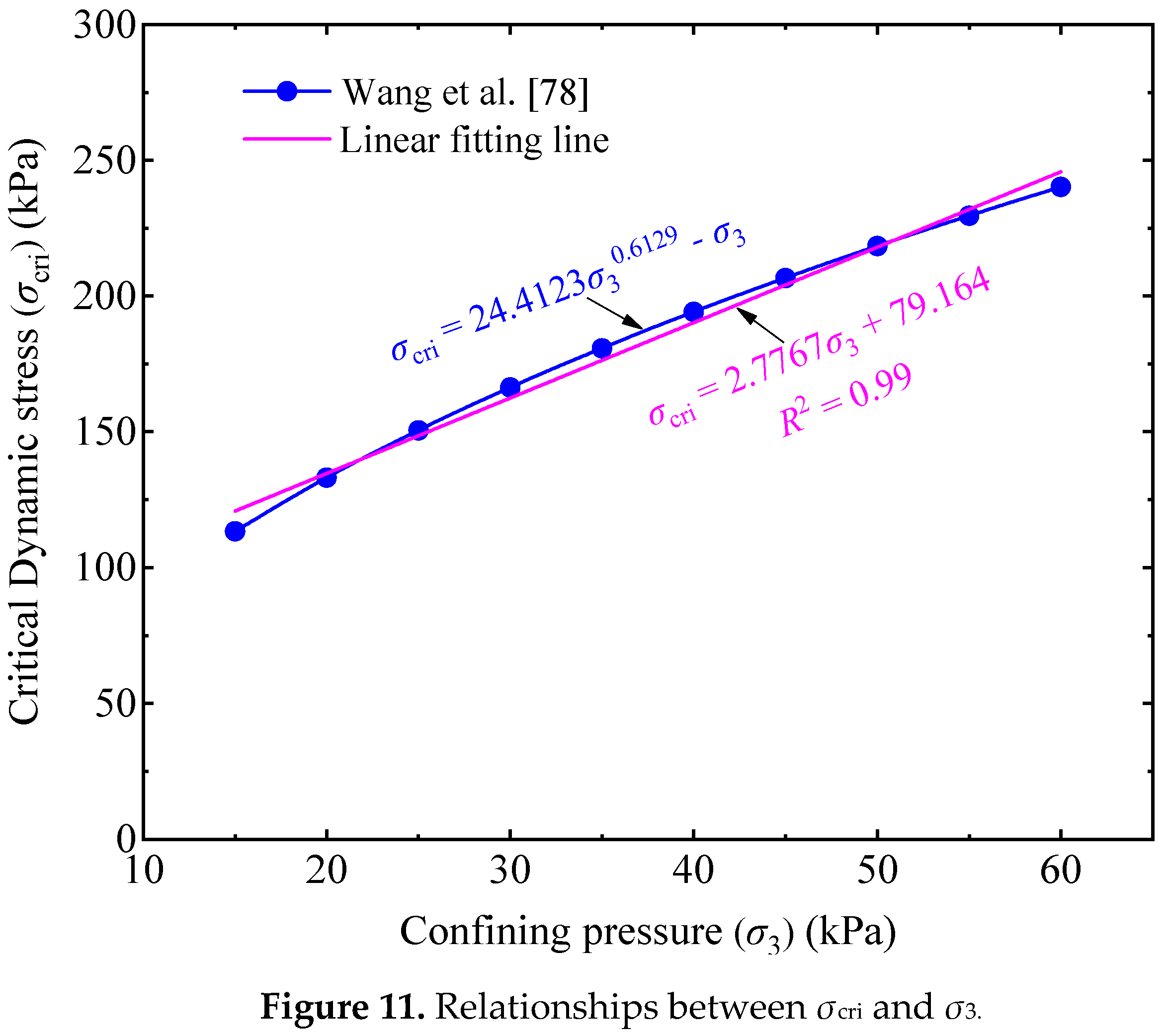

4.1.3. Evaluation of Critical Dynamic Stress Using the Trained BP Neural Network

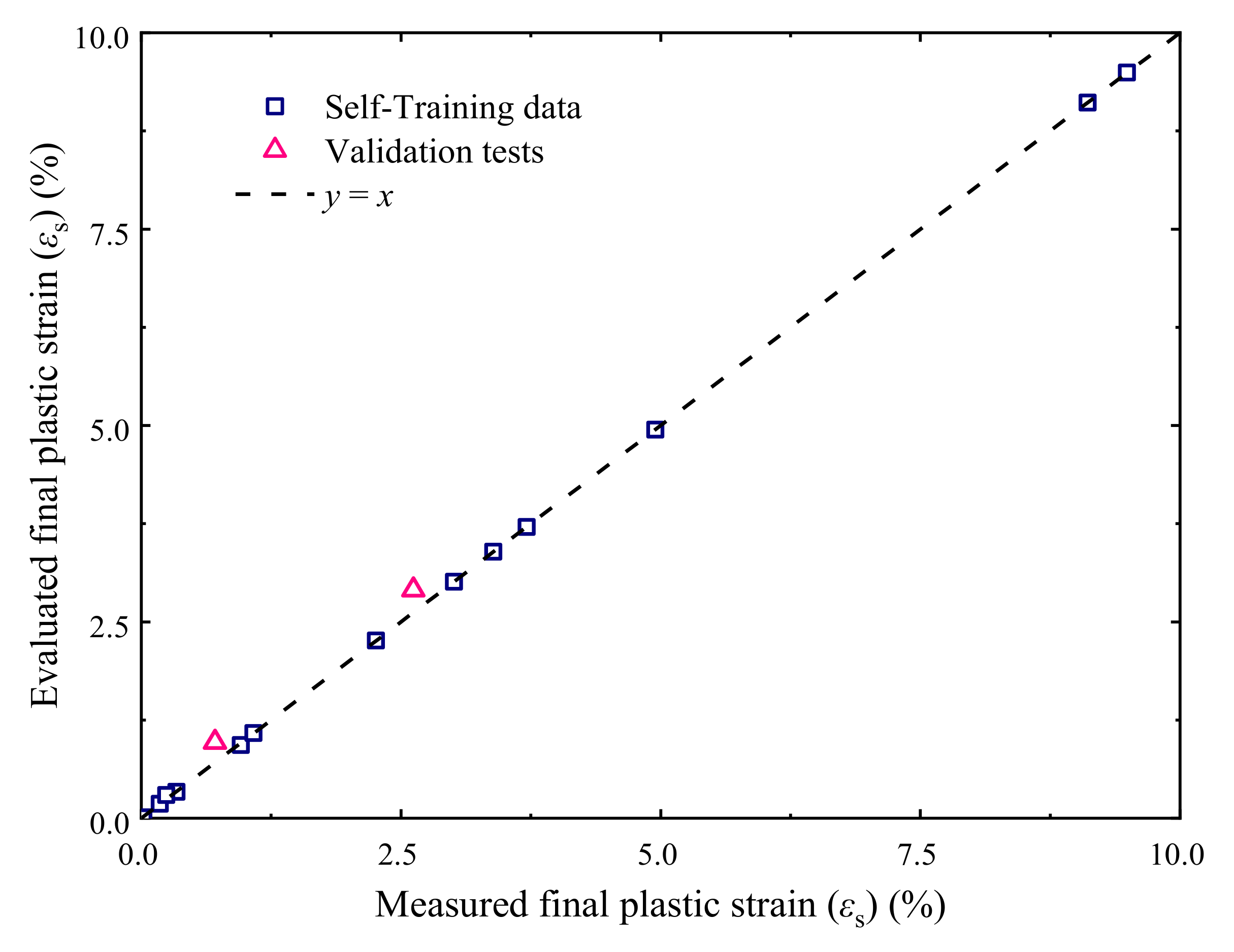

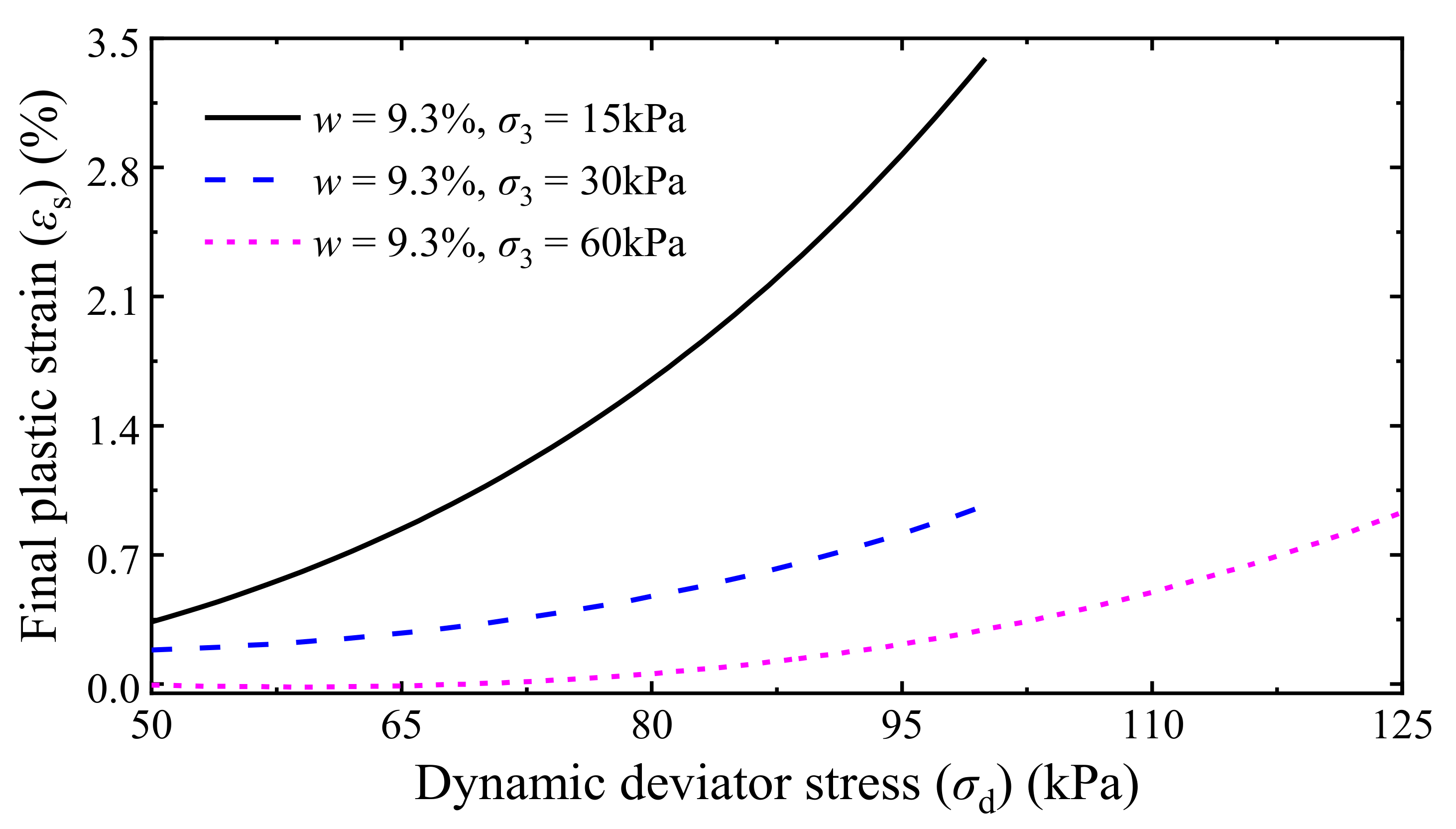

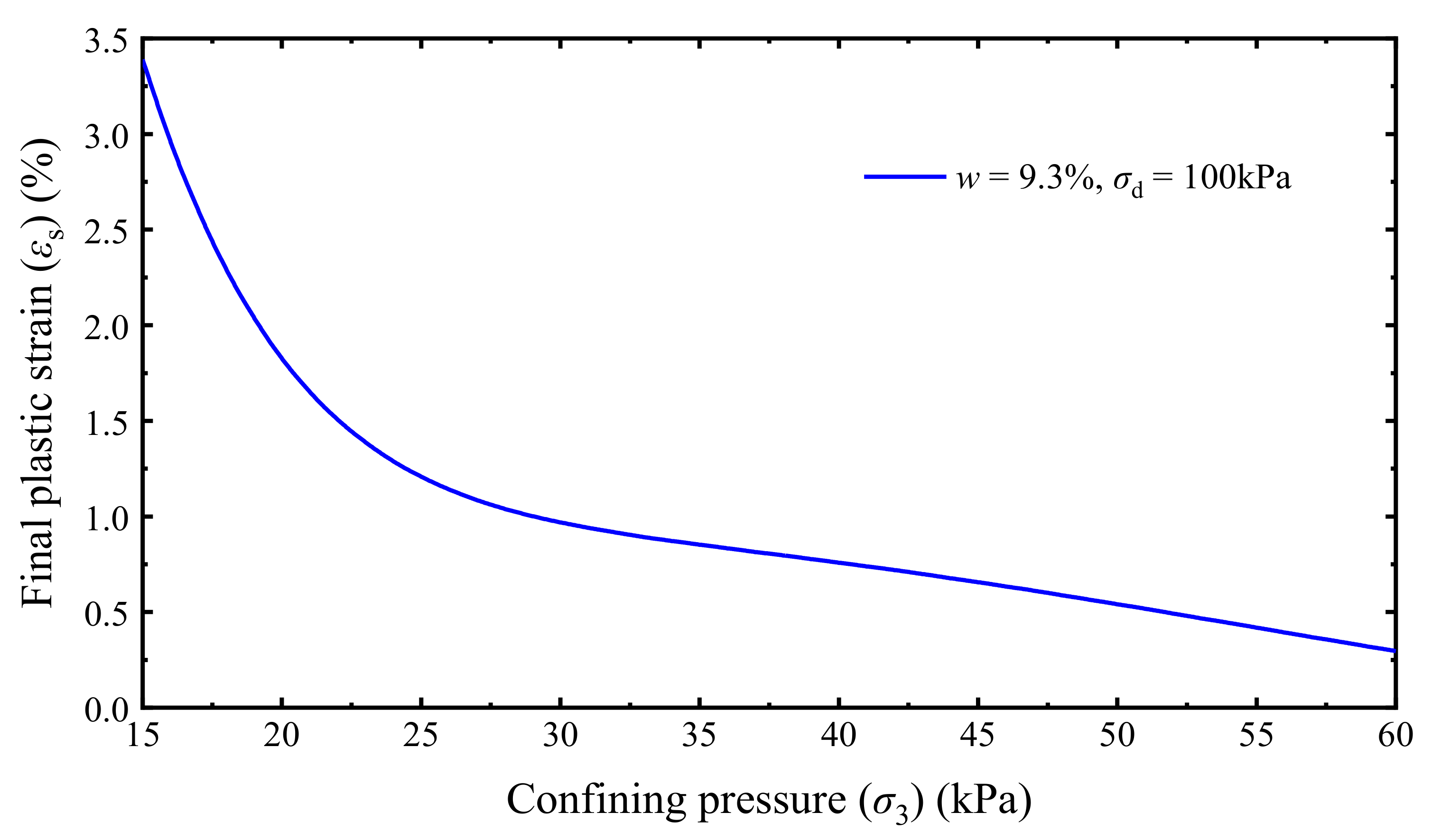

4.2. Evaluation of Final Accumulative Plastic Strain

4.2.1. Grey Relation of εs Regarding w, σ3, and σd

4.2.2. Evaluation of Final Accumulative Plastic Strain Using the BP Neural Network

5. Conclusions

- The variation curves of εp with cyclic number (N) can be categorized into stable, failure, and critical patterns, and the grey relational analyses shown that the curve patterns and final accumulative plastic strain εs of stable specimens are closely related to the w, σ3, and σd. In addition, the analyzed grey relational grades were in a narrow range of 0.72 to 0.81, demonstrating that the w, σ3, and σd have similar importance degrees in determining the εp versus N curve patterns and the values of εp of the UGM.

- The developed evaluation method indicates that the σcri approximately linearly increases with increasing σ3, and a simple linear empirical equation is proposed for the σcri. In addition, εs and its variation rate non-linearly increases with increasing σd but non-linearly decreases as σ3 increases; therefore, an increase in σ3 can effectively reduce the εs, especially in low confining pressure conditions.

- The εs of saturation specimens with a low confining pressure of 15 kPa started to increase rapidly when the σd was greater than 60 kPa which is generally less than the dynamic deviator stress on subgrade surfaces imposed by freight trains operated in heavy-haul railway lines. Therefore, keeping sufficient drainage capacity, preventing the subgrade approaching saturation, and raising the confining pressure of the subgrade by appropriate reinforcement techniques are effective ways to enhance the railway dynamic stability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, P.Y.; Tang, L.S.; Ni, P.P. Field evaluation of subgrade soils under dynamic loads using orthogonal earth pressure transducers. Soil Dyn. Earthq. Eng. 2019, 121, 12–14. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Setunge, J. Evaluation of permanent deformation of a new pavement base and subbase containing unbound granular materials, crumb rubber and crushed glass. J. Clean. Prod. 2019, 230, 38–45. [Google Scholar] [CrossRef]

- Xiao, Y.J.; Zheng, K.Y.; Chen, L.X.; Mao, J.F. Shakedown analysis of cyclic plastic deformation characteristics of unbound granular materials under moving wheel loads. Constr. Build. Mater. 2018, 167, 457–472. [Google Scholar] [CrossRef]

- Li, L.H.; Fang, Y.N.; Cheng, B.W.; Chen, N.; Tian, M.; Liu, Y.M. Characterisation of Geogrid and Waste Tyres as Reinforcement Materials in Railway Track Beds. Materials 2021, 14, 4162. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.H.; Zhang, A.S.; Li, J.; Li, F.; Peng, J.H. Gray Correlation Analysis and Prediction on Permanent Deformation of Subgrade Filled with Construction and Demolition Materials. Materials 2019, 12, 3035. [Google Scholar] [CrossRef] [Green Version]

- Xu, F.; Leng, W.M.; Nie, R.S.; Zhang, Q.S.; Yang, Q. New structure for strengthening soil embankments. Adv. Civ. Eng. 2018, 2018, 4809034. [Google Scholar] [CrossRef]

- Ju, S.H.; Leong, C.C.; Ho, Y.S. Safety of maglev trains moving on bridges subject to foundation settlements and earthquakes. J. Bridge Eng. 2014, 19, 91–100. [Google Scholar] [CrossRef]

- Remennikov, A.M.; Kaewunruen, S. A review of loading conditions for railway track structures due to train and track vertical interaction. Struct. Control Health 2008, 15, 207–234. [Google Scholar] [CrossRef]

- Lyu, Z.; Qian, J.G.; Shi, Z.H.; Gao, Q. Dynamic responses of layered poroelastic ground under moving traffic loads considering effects of pavement roughness. Soil. Dyn. Earthq. Eng. 2020, 130, 105996. [Google Scholar] [CrossRef]

- Dong, K.; Con1nolly, D.P.; Laghrouche, O.; Woodward, P.K.; Alves, C.P. The stiffening of soft soils on railway lines. Transp. Geotech. 2018, 17, 179–191. [Google Scholar] [CrossRef]

- Puppala, A.J.; Saride, S.; Chomtid, S. Experimental and modeling studies of permanent strains of subgrade soils. J. Geotech. Geoenviron. 2009, 135, 1379–1389. [Google Scholar] [CrossRef]

- Aw, E.S. Low Cost Monitoring System to Diagnose Problematic Rail Bed: Case Study at a Mud Pumping Site. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2007. [Google Scholar]

- Kang, X.; Ge, L.; Chang, K.T.; Kwok, A.O. Strain-controlled cyclic simple shear tests on sand with radial strain measurements. J. Mater. Civil. Eng. 2016, 28, 0405169. [Google Scholar] [CrossRef]

- Zhang, Q.S.; Leng, W.M.; Xu, F.; Yang, Q.; Ai, X. Additional stress in soil embankments subjected to a new prestressed reinforcement device. J. Civ. Eng. Manag. 2019, 25, 700–714. [Google Scholar] [CrossRef]

- Xiao, J.H.; Juang, C.H.; Xu, C.J.; Li, X.W.; Wang, L. Strength and deformation characteristics of compacted silt from the lower reaches of the Yellow River of China under monotonic and repeated loading. Eng. Geol. 2014, 178, 49–57. [Google Scholar] [CrossRef]

- Zhai, B.; Leng, W.M.; Xu, F.; Zhang, S.; Ye, X.Y.; Leng, H.K. Critical dynamic stress and shakedown limit criterion of coarse-grained subgrade soil. Transp. Geotech. 2020, 23, 100354. [Google Scholar] [CrossRef]

- Guo, Y.; Zhai, W.M. Long-term prediction of track geometry degradation in high-speed vehicle–ballastless track system due to differential subgrade settlement. Soil Dyn. Earthq. Eng. 2018, 113, 1–11. [Google Scholar] [CrossRef]

- Nie, R.S.; Chen, Y.F.; Leng, W.M.; Yang, Q. Experimental measurement of dynamic load parameters for pier pile caps of high-speed railway bridges. Proc. Inst. Mech. Eng. Part F 2017, 231, 162–174. [Google Scholar] [CrossRef]

- NRA (TB10621-2014). Code for Design of High Speed Railway; China Railway Publishing House: Beijing, China, 2014. [Google Scholar]

- Atilla, M.A.; Afer, E. Undrained behavior of clay under cyclic shear stresses. J. Geotech. Eng. 1989, 115, 968–983. [Google Scholar]

- Liu, J.K.; Xiao, J.H. Experimental study on the stability of railroad silt subgrade with increasing train speed. J. Geotech. Geoenviron. 2010, 136, 833–841. [Google Scholar] [CrossRef]

- Sabine, W.; Dawson, A.R.; Frohmut, W. Permanent deformation behavior of granular materials and the shakedown concept. Transp. Res. Rec. 2001, 1757, 75–81. [Google Scholar]

- Wang, T.L.; Liu, J.K.; Tian, Y.H. Dynamic properties of cement- and lime-improved soil subjected to freeze-thaw cycles. Chin. J. Geotech. Eng. 2010, 32, 1733–1737. [Google Scholar]

- David, C.P.; Jalal, H.K. dynamic triaxial tests on remoulded clays. J. Geotech. Eng. 1984, 110, 1431–1445. [Google Scholar]

- Cheung, L.W. Laboratory Assessment of Pavement Foundation Materials. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 1994. [Google Scholar]

- Frost, M.W.; Fleming, P.R.; Rogers, D.F. dynamic triaxial tests on clay subgrades for analytical pavement design. J. Transp. Eng. 2004, 130, 378–386. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.H.; Ling, X.Z.; Li, Q.L.; Zhang, F.; Li, Y. Accumulated permanent strain and critical dynamic stress of frozen silty clay under cyclic loading. Cold. Reg. Sci. Technol. 2018, 153, 130–143. [Google Scholar] [CrossRef]

- Zhang, X.; Ren, K. Experimental study on dynamic elastic modulus and critical dynamic stress of cinder-improved soil subgrade. J. Highw. Transp. R. Dev. 2018, 12, 25–32. [Google Scholar] [CrossRef]

- Monismith, C.L.; Ogawa, N.; Freeme, C.R. Permanent deformation characteristics of subgrade soils due to repeated load. Transp. Res. Rec. 1975, 537, 1–17. [Google Scholar]

- Barksdale, R.D. Laboratory evaluation of rutting in base course material. In Proceedings of the 3rd International Conference on Structural Design of Asphalt Pavement, London, UK, 11–15 September 1972; pp. 161–174. [Google Scholar]

- Hornych, P.; Piau, J.M. Towards computation tools for the assessment of rutting of flexible pavements. In Proceedings of the 6th International Conference on the Bearing Capacity of Roads, Railways and Airfields, Lisbon, Portugal, 24–26 June 2002; pp. 57–74. [Google Scholar]

- Li, D.Q.; Selig, E.T. Cumulative plastic deformation for fine-grained subgrade soils. J. Geotech. Eng. 1996, 122, 1006–1013. [Google Scholar] [CrossRef]

- Chai, J.C.; Miura, N. Traffic-load-induced permanent deformation of road on soft subsoil. J. Geotech. Geoenviron. 2002, 128, 907–916. [Google Scholar] [CrossRef]

- Wu, T.Y.; Cai, Y.Q.; Guo, Y.; Ling, D.S.; Wang, J. Influence of shear stress level on cyclic deformation behaviour of intact Wenzhou soft clay under traffic loading. Eng. Geol. 2017, 228, 61–70. [Google Scholar] [CrossRef]

- Moghaddas-Nejad, F.; Small, J. Resilient and permanent characteristics of reinforced granular materials by repeated load triaxial tests. Geotech. Test. J. 2003, 26, 152–166. [Google Scholar]

- Stewart, H.E. Permanent strains from cyclic variable-amplitude loadings. J. Geotech. Eng. 1986, 112, 646–660. [Google Scholar] [CrossRef]

- Xu, F.; Zhai, B.; Leng, W.M.; Yang, Q.; Leng, H.K.; Nie, R.S. Probabilistic method for evaluating the permanent strain of unbound granular materials under cyclic traffic loading. Constr. Build. Mater. 2020, 251, 118975. [Google Scholar] [CrossRef]

- Lekarp, F.; Dawson, A. Modelling permanent deformation behaviour of unbound granular materials. Constr. Build. Mater. 1998, 12, 9–18. [Google Scholar] [CrossRef]

- El-Badawy, S.M.; Witczak, M. Development of a universal permanent strain model for subgrade pavement materials. In Proceedings of the 86th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 21–25 January 2007; p. 07-2318. [Google Scholar]

- Xiao, Y.J.; Tutumluer, E.; Mishra, D. Performance evaluations of unbound aggregate permanent deformation models for various aggregate physical properties. Transp. Res. Rec. 2015, 2525, 20–30. [Google Scholar] [CrossRef]

- Romanoschi, S.A. Empirical models for permanent deformation of subgrade soils from the data collected at the pavement subgrade performance study. J. Mater. Civ. Eng. 2017, 29, 04016236. [Google Scholar] [CrossRef]

- NRA (TB 10001-2016). Code for Design of Railway Earth Structure; China Railway Publishing House: Beijing, China, 2016. [Google Scholar]

- ASTM (ASTM D2487–17e1). Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM (ASTM D1557–12). Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM (ASTM D7181–20). Standard Test Method for Consolidated Drained Triaxial Compression Test for Soils; ASTM: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Yan, C.B.; Wang, H.J.; Xu, X.; Zhang, Y.C. Identifying fatigue damage of mudded intercalations based on dynamic triaxial test. Eng. Geol. 2021, 280, 105933. [Google Scholar] [CrossRef]

- Karg, C.; Haegeman, W. Elasto-plastic long-term behavior of granular soils: Experimental investigation. Soil. Dyn. Earthq. Eng. 2009, 29, 155–172. [Google Scholar] [CrossRef]

- Cerni, G.; Cardone, F.; Virgili, A.; Camilli, S. Characterisation of permanent deformation behaviour of unbound granular materials under repeated triaxial loading. Constr. Build. Mater. 2012, 28, 79–87. [Google Scholar] [CrossRef]

- Tang, L.; Yan, M.H.; Ling, X.Z.; Tian, S. Dynamic behaviours of railway’s base course materials subjected to long-term low-level cyclic loading: Experimental study and empirical model. Géotechnique 2017, 67, 537–545. [Google Scholar] [CrossRef]

- Mehdizadeh, A.; Disfani, M.M.; Evans, R.; Arulrajah, A.; Ong, D. Mechanical consequences of suffusion on undrained behaviour of a gap-graded cohesionless soil—An experimental approach. Geotech. Test. J. 2017, 40, 20160145. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.C. Study on the Vertical Load Transmission through the Track Structure and the Characteristics of Subgrade Dynamic Stress; China Academy of Railway Science: Beijing, China, 2000; pp. 4–5. [Google Scholar]

- Xiao, H.; Liu, G.P.; Yan, D.W.; Zhao, Y.; Wang, J.Q.; Wang, H.Y. Field test and numerical analysis of insulated rail joints in heavy-haul railway. Constr. Build. Mater. 2021, 298, 123905. [Google Scholar] [CrossRef]

- Shi, Z.Y.; Wang, K.Y.; Zhang, D.W.; Chen, Z.G.; Zhai, G.H.; Huang, D.X. Experimental investigation on dynamic behaviour of heavy-haul railway track induced by heavy axle load. Transport 2019, 34, 351–362. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Ling, C.X.; Zhang, F.; Li, Y.; Zhao, Y.Y. Field testing and analysis of embankment vibrations induced by heavy haul trains. Shock. Vib. 2017, 7410836, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Thevakumar, K.; Indraratna, B.; Ferreira, F.B.; Carter, J.; Rujikiatkamjorn, C. The influence of cyclic loading on the response of soft subgrade soil in relation to heavy haul railways. Transp. Geotech. 2021, 29, 100571. [Google Scholar] [CrossRef]

- Indraratna, B.; Ngo, T.; Ferreira, F.B.; Rujikiatkamjorn, C.; Tucho, A. Large-scale testing facility for heavy haul track. Transp. Geotech. 2021, 28, 100517. [Google Scholar] [CrossRef]

- Mei, H.H.; Leng, W.M.; Nie, R.S.; Liu, W.J.; Chen, C.; Wu, X.W. Random distribution characteristics of peak dynamic stress on the subgrade surface of heavy-haul railways considering track irregularities. Soil. Dyn. Earthq. Eng. 2019, 116, 205–214. [Google Scholar] [CrossRef]

- Hu, Z.X. Soil Mechanics and Environmental Geotechnology; Tongji University Press: Shanghai, China, 1997. [Google Scholar]

- Mehdizadeh, A.; Disfani, M.M.; Evans, R.; Arulrajah, A.; Ong, D. Discussion of ‘Development of an Internal Camera-Based Volume Determination System for Triaxial Testing’ by S.E. Salazar, A. Barnes and R.A. Coffman. Geotech. Test. J. 2016, 39, 165–168. [Google Scholar]

- Liu, S.F.; Yang, Y.J.; Forrest, J. Grey Data Analysis: Methods, Models, and Applications; Springer: Singapore, 2017. [Google Scholar]

- Cui, K.; Jing, X. Research on prediction model of geotechnical parameters based on bp neural network. Neural Comput. Appl. 2018, 31, 8205–8215. [Google Scholar] [CrossRef]

- Prusty, J.K.; Pradhan, B. Multi-response optimization using Taguchi-Grey relational analysis for composition of fly ash-ground granulated blast furnace slag based geopolymer concrete. Constr. Build. Mater. 2020, 241, 118049. [Google Scholar] [CrossRef]

- Rajeswari, B.; Amirthagadeswaran, K.S. Experimental investigation of machinability characteristics and multi-response optimization of end milling in aluminium composites using RSM based grey relational analysis. Measurement 2017, 105, 78–86. [Google Scholar] [CrossRef]

- Shi, S.X.; Fei, H.Y.; Xu, X.G. Application of a FMEA method combining interval 2-tuple linguistic variables and grey relational analysis in preoperative medical service process. IFAC-PapersOnLine 2019, 52, 1242–1247. [Google Scholar] [CrossRef]

- Javed, S.A.; Mahmoudi, A.; Khan, A.M.; Javed, A.M.; Javed, S.; Liu, S.F. A critical review: Shape optimization of welded plate heat exchangers based on grey correlation theory. Appl. Therm. Eng. 2018, 144, 593–599. [Google Scholar] [CrossRef]

- Wu, L.Z.; Li, S.H.; Huang, R.Q.; Xu, Q. A new grey prediction model and its application to predicting landslide displacement. Appl. Soft Comput. J. 2020, 95, 106543. [Google Scholar] [CrossRef]

- Liu, D.; Li, M.X.; Ji, Y.; Fu, Q.; Li, M.; Faiz, M.A.; Ali, S.; Li, T.X.; Cui, S.; Khan, M.I. Spatial-temporal characteristics analysis of water resource system resilience in irrigation areas based on a support vector machine model optimized by the modifed gray wolf algorithm. J. Hydrol. 2020, 2020, 125758. [Google Scholar] [CrossRef]

- Liu, W.J.; Zhang, J.; Jin, M.Z.; Liu, S.F.; Chang, X.Y.; Xie, N.M.; Wang, Y.T. Key indices of the remanufacturing industry in China using a combined method of grey incidence analysis and grey clustering. J. Clean. Prod. 2017, 168, 1348–1357. [Google Scholar] [CrossRef]

- Mathworks. MATLAB Version 8.6.0; The Mathworks Inc.: Natick, MA, USA, 2015. [Google Scholar]

- Wang, L.; Bi, X.H. Risk assessment of knowledge fusion in an innovation ecosystem based on a GA-BP neural network. Cogn. Syst. Res. 2021, 66, 201–210. [Google Scholar] [CrossRef]

- Jiang, C.; Wen, J.W.; Li, M.Z.; You, T.P. Calculation on enantiomeric excess of catalytic asymmetric reactions of diethylzinc addition to aldehydes with topological indices and artificial neural network. J. Mol. Catal. 2006, 258, 191–197. [Google Scholar]

- Costanza, G.; Tata, M.E.; Ucciardello, N. Superplasticity in PbSn60: Experimental and neural network implementation. Comp. Mater. Sci. 2006, 37, 226–233. [Google Scholar] [CrossRef]

- Xu, L.J.; Xing, J.D.; Wei, S.Z.; Zhang, Y.Z.; Long, R. Artificial neural network prediction of retained austenite content and impact toughness of high-vanadium high-speed steel (HVHSS). Mater. Sci. Eng. 2006, 433, 251–256. [Google Scholar] [CrossRef]

- Chakraverty, S.; Sigh, V.P.; Sharma, R.K. Regression based weight generation algorithm in neural network for estimation of frequencies of vibrating plates. Comput. Methods Appl. Mech. Eng. 2006, 195, 4194–4202. [Google Scholar] [CrossRef]

- Rumelhart, D.W.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1989, 323, 533–536. [Google Scholar] [CrossRef]

- Chen, M. Principle and Example of MATLAB Neural Network; Tsinghua University Press: Beijing, China, 2013. [Google Scholar]

- Dawson, A.; Mundy, M.; Huhtala, M. European research into granular material for pavement bases and subbases. Transp. Res. Rec. 2000, 1721, 91–99. [Google Scholar] [CrossRef]

- Wang, K.Y.; Zhuang, Y.; Geng, X.Y. Experimental research on critical dynamic Stress of coarse-grained soil in railway subgrade. Rock. Soil Mech. 2020, 41, 1865–1873. [Google Scholar]

- Xu, F.; Yang, Q.; Liu, W.J.; Leng, W.M.; Nie, R.S.; Mei, H.H. Dynamic stress of subgrade bed layers subjected to train vehicles with large axle loads. Shock. Vib. 2018, 2018, 2916096. [Google Scholar] [CrossRef]

- Shan, Y.; Albers, B.; Savidis, S.A. Influence of different transition zones on the dynamic response of track–subgrade systems. Comput. Geotech. 2013, 48, 21–28. [Google Scholar] [CrossRef]

| Group | w (%) | σ3 (kPa) | σd (kPa) |

|---|---|---|---|

| 1 | 9.3 (Sr = 100%) | 15 | 50, 100, 125, 150, 200, 250 |

| 2 | 9.3 (Sr = 100%) | 30 | 50, 100, 125, 150, 200, 250 |

| 3 | 9.3 (Sr = 100%) | 60 | 50, 100, 125, 150, 200, 250 |

| 4 | 6.2 (Sr = 79.4%) | 15 | 100, 150, 200 |

| 5 | 6.2 (Sr = 79.4%) | 30 | 250, 275, 300 |

| 6 | 6.2 (Sr = 79.4%) | 60 | 250, 300, 350, 400 |

| Β | σ3 (kPa) | σd (kPa) | w (%) | γ1j | γ2j | γ3j |

|---|---|---|---|---|---|---|

| 1 | 15 | 50 | 9.3 | 1.000 | 1.000 | 1.000 |

| 1 | 15 | 100 | 9.3 | 1.000 | 1.000 | 0.778 |

| 3 | 15 | 125 | 9.3 | 0.636 | 0.636 | 0.875 |

| 3 | 15 | 150 | 9.3 | 0.636 | 0.636 | 1.000 |

| 3 | 15 | 200 | 9.3 | 0.636 | 0.636 | 0.778 |

| 3 | 15 | 250 | 9.3 | 0.636 | 0.636 | 0.636 |

| 1 | 30 | 50 | 9.3 | 1.000 | 0.778 | 1.000 |

| 1 | 30 | 100 | 9.3 | 1.000 | 0.778 | 0.778 |

| 2 | 30 | 125 | 9.3 | 0.778 | 1.000 | 0.875 |

| 3 | 30 | 150 | 9.3 | 0.636 | 0.778 | 1.000 |

| 3 | 30 | 200 | 9.3 | 0.636 | 0.778 | 0.778 |

| 3 | 30 | 250 | 9.3 | 0.636 | 0.778 | 0.636 |

| 1 | 60 | 50 | 9.3 | 1.000 | 0.538 | 1.000 |

| 1 | 60 | 100 | 9.3 | 1.000 | 0.538 | 0.778 |

| 1 | 60 | 125 | 9.3 | 1.000 | 0.538 | 0.700 |

| 3 | 60 | 150 | 9.3 | 0.636 | 0.778 | 1.000 |

| 3 | 60 | 200 | 9.3 | 0.636 | 0.778 | 0.778 |

| 3 | 60 | 250 | 9.3 | 0.636 | 0.778 | 0.636 |

| 1 | 15 | 100 | 6.2 | 0.913 | 1.000 | 0.778 |

| 1 | 15 | 150 | 6.2 | 0.913 | 1.000 | 0.636 |

| 1 | 15 | 200 | 6.2 | 0.913 | 1.000 | 0.538 |

| 1 | 30 | 250 | 6.2 | 0.913 | 0.778 | 0.467 |

| 3 | 30 | 275 | 6.2 | 0.600 | 0.778 | 0.583 |

| 3 | 30 | 300 | 6.2 | 0.600 | 0.778 | 0.538 |

| 1 | 60 | 250 | 6.2 | 0.913 | 0.538 | 0.467 |

| 1 | 60 | 300 | 6.2 | 0.913 | 0.538 | 0.412 |

| 1 | 60 | 350 | 6.2 | 0.913 | 0.538 | 0.368 |

| 1 | 60 | 400 | 6.2 | 0.913 | 0.538 | 0.333 |

| 1 | 15 | 50 | 9.3 | 1.000 | 1.000 | 1.000 |

| 1 | 15 | 100 | 9.3 | 1.000 | 1.000 | 0.778 |

| w (%) | σ3 (kPa) | σcri (kPa) | w (%) | σ3 (kPa) | σcri (kPa) | w (%) | σ3 (kPa) | σcri (kPa) | w (%) | σ3 (kPa) | σcri (kPa) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6.2 | 15 | 205 | 7.5 | 15 | 186 | 8.5 | 15 | 147 | 9.3 | 15 | 116 |

| 20 | 224 | 20 | 203 | 20 | 155 | 20 | 119 | ||||

| 25 | 248 | 25 | 222 | 25 | 165 | 25 | 122 | ||||

| 30 | 268 | 30 | 242 | 30 | 177 | 30 | 125 | ||||

| 35 | 295 | 35 | 259 | 35 | 185 | 35 | 127 | ||||

| 40 | 318 | 40 | 277 | 40 | 194 | 40 | 130 | ||||

| 45 | 345 | 45 | 299 | 45 | 204 | 45 | 132 | ||||

| 50 | 368 | 50 | 319 | 50 | 214 | 50 | 135 | ||||

| 55 | 390 | 55 | 337 | 55 | 223 | 55 | 138 | ||||

| 60 | 408 | 60 | 357 | 60 | 235 | 60 | 140 |

| εs (%) | σ3 (kPa) | σd (kPa) | w (%) | γ′1j | γ′2j | γ′3j |

|---|---|---|---|---|---|---|

| 0.34 | 15 | 50 | 9.3 | 1.000 | 1.000 | 1.000 |

| 3.39 | 15 | 100 | 9.3 | 0.603 | 0.603 | 0.631 |

| 0.18 | 30 | 50 | 9.3 | 0.967 | 0.903 | 0.967 |

| 0.71 | 30 | 100 | 9.3 | 0.926 | 0.994 | 0.994 |

| 0.02 | 60 | 50 | 9.3 | 0.935 | 0.776 | 0.935 |

| 0.24 | 60 | 100 | 9.3 | 0.979 | 0.805 | 0.913 |

| 0.96 | 60 | 125 | 9.3 | 0.882 | 0.921 | 0.977 |

| 1.08 | 15 | 100 | 6.2 | 0.844 | 0.862 | 0.921 |

| 3.01 | 15 | 150 | 6.2 | 0.625 | 0.634 | 0.699 |

| 9.11 | 15 | 200 | 6.2 | 0.343 | 0.346 | 0.374 |

| 3.71 | 30 | 250 | 6.2 | 0.571 | 0.605 | 0.697 |

| 2.26 | 60 | 250 | 6.2 | 0.695 | 0.837 | 0.892 |

| 2.62 | 60 | 300 | 6.2 | 0.659 | 0.786 | 0.889 |

| 4.95 | 60 | 350 | 6.2 | 0.495 | 0.563 | 0.643 |

| 9.49 | 60 | 400 | 6.2 | 0.333 | 0.363 | 0.406 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Leng, W.; Zhai, B.; Xu, F.; Dong, J.; Yang, Q. Evaluation of Critical Dynamic Stress and Accumulative Plastic Strain of an Unbound Granular Material Based on Cyclic Triaxial Tests. Materials 2021, 14, 5722. https://doi.org/10.3390/ma14195722

Zhang Q, Leng W, Zhai B, Xu F, Dong J, Yang Q. Evaluation of Critical Dynamic Stress and Accumulative Plastic Strain of an Unbound Granular Material Based on Cyclic Triaxial Tests. Materials. 2021; 14(19):5722. https://doi.org/10.3390/ma14195722

Chicago/Turabian StyleZhang, Qishu, Wuming Leng, Bin Zhai, Fang Xu, Junli Dong, and Qi Yang. 2021. "Evaluation of Critical Dynamic Stress and Accumulative Plastic Strain of an Unbound Granular Material Based on Cyclic Triaxial Tests" Materials 14, no. 19: 5722. https://doi.org/10.3390/ma14195722

APA StyleZhang, Q., Leng, W., Zhai, B., Xu, F., Dong, J., & Yang, Q. (2021). Evaluation of Critical Dynamic Stress and Accumulative Plastic Strain of an Unbound Granular Material Based on Cyclic Triaxial Tests. Materials, 14(19), 5722. https://doi.org/10.3390/ma14195722