A Study on the Heat Transfer Characteristics of Steel Plate in the Matrix Laminar Cooling Process

Abstract

:1. Introduction

2. Experiment

2.1. Experimental Raw Material

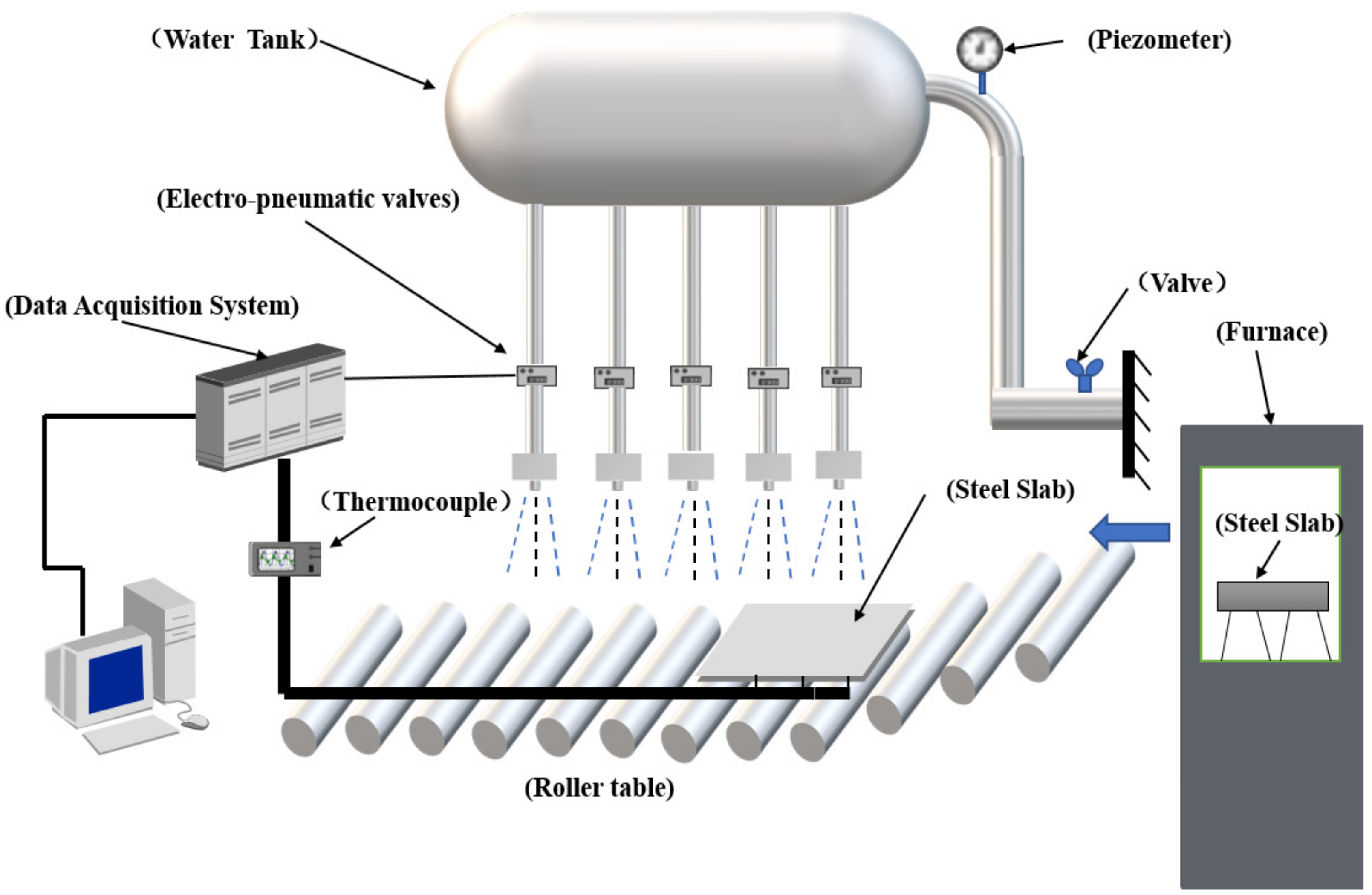

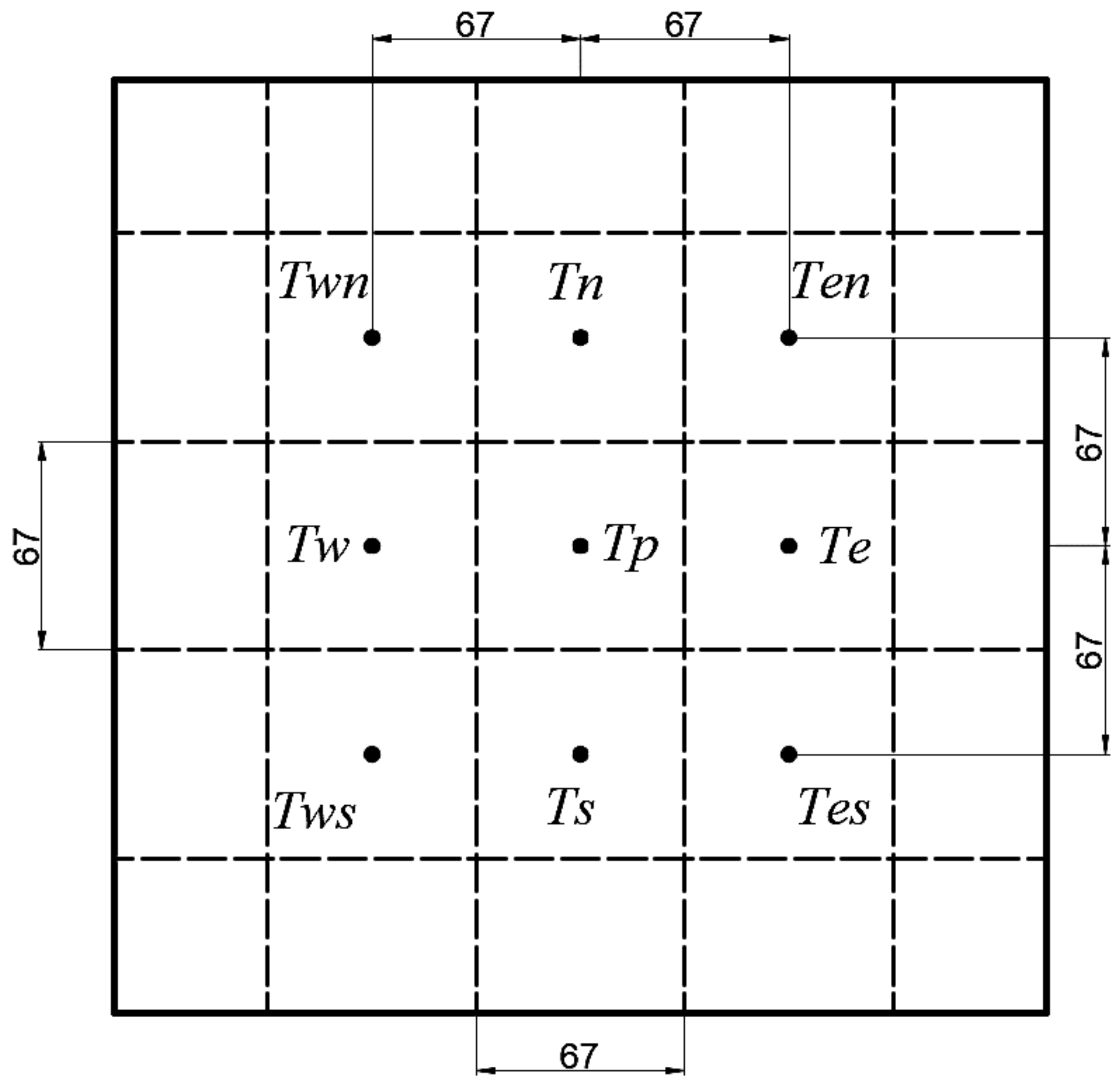

2.2. Experimental Apparatus

2.3. Experimental Method

3. Experimental Results and Analysis

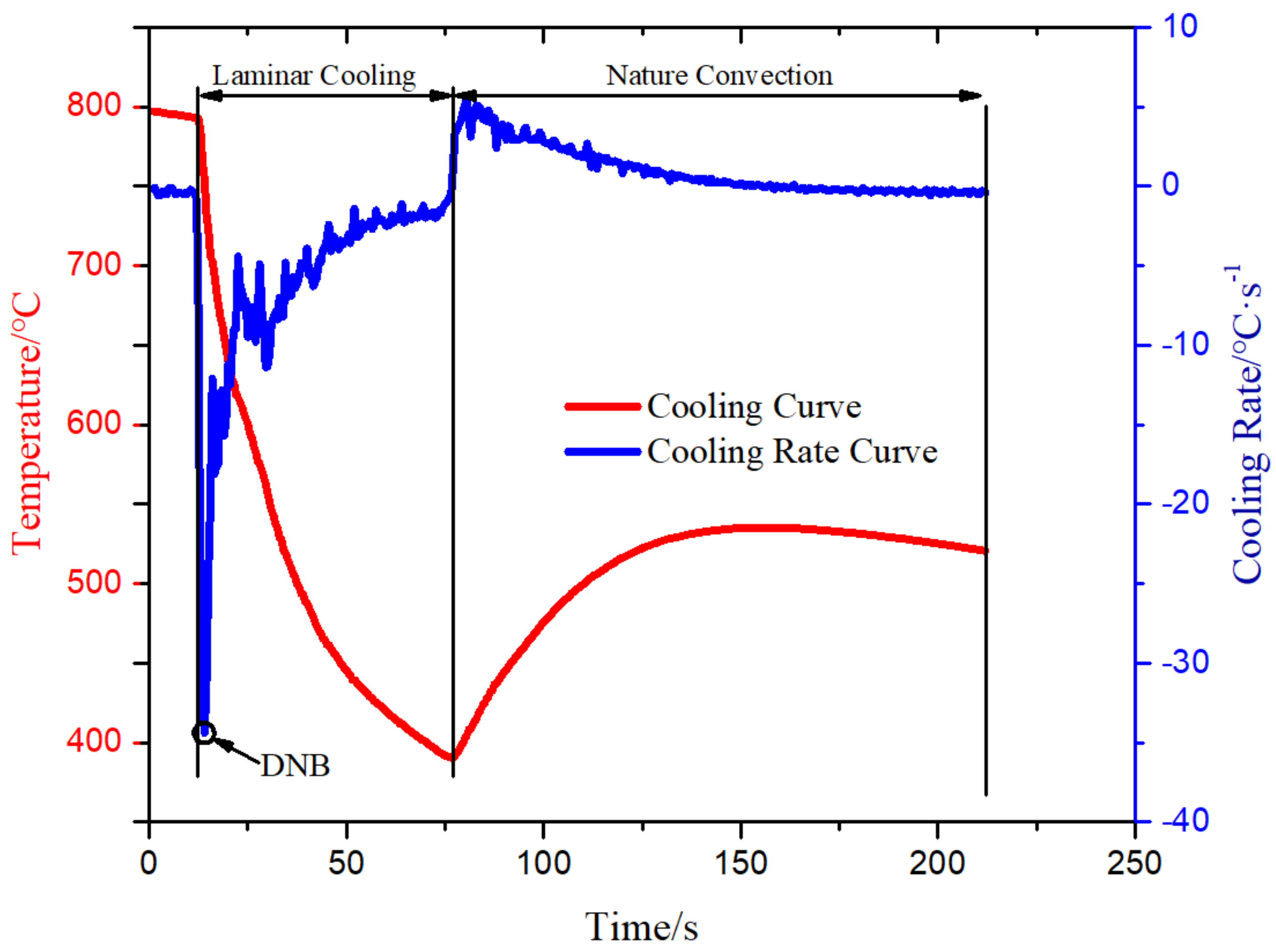

3.1. The Rule of Temperature Changing with Time at the Tp Position in the Whole Cooling Process

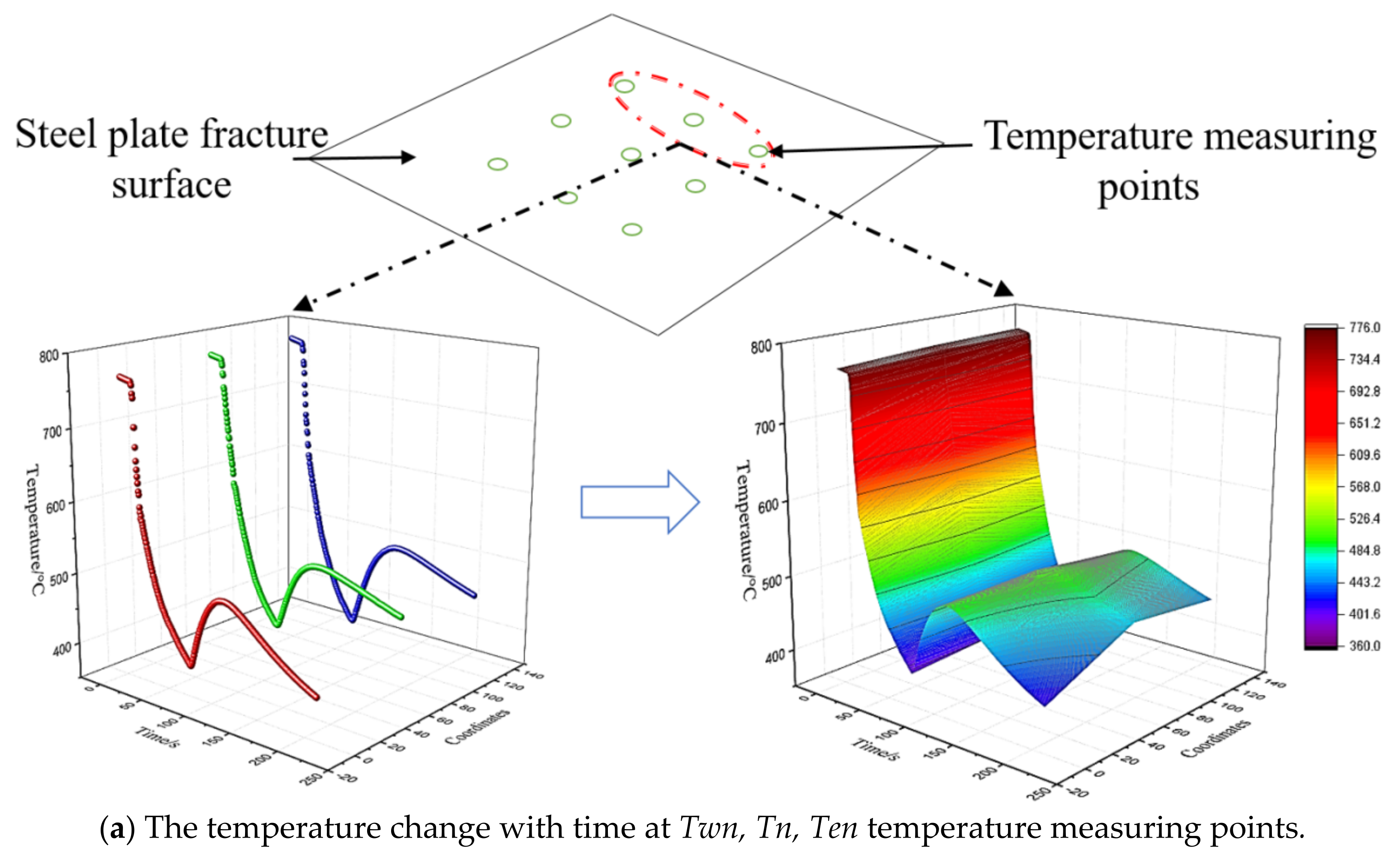

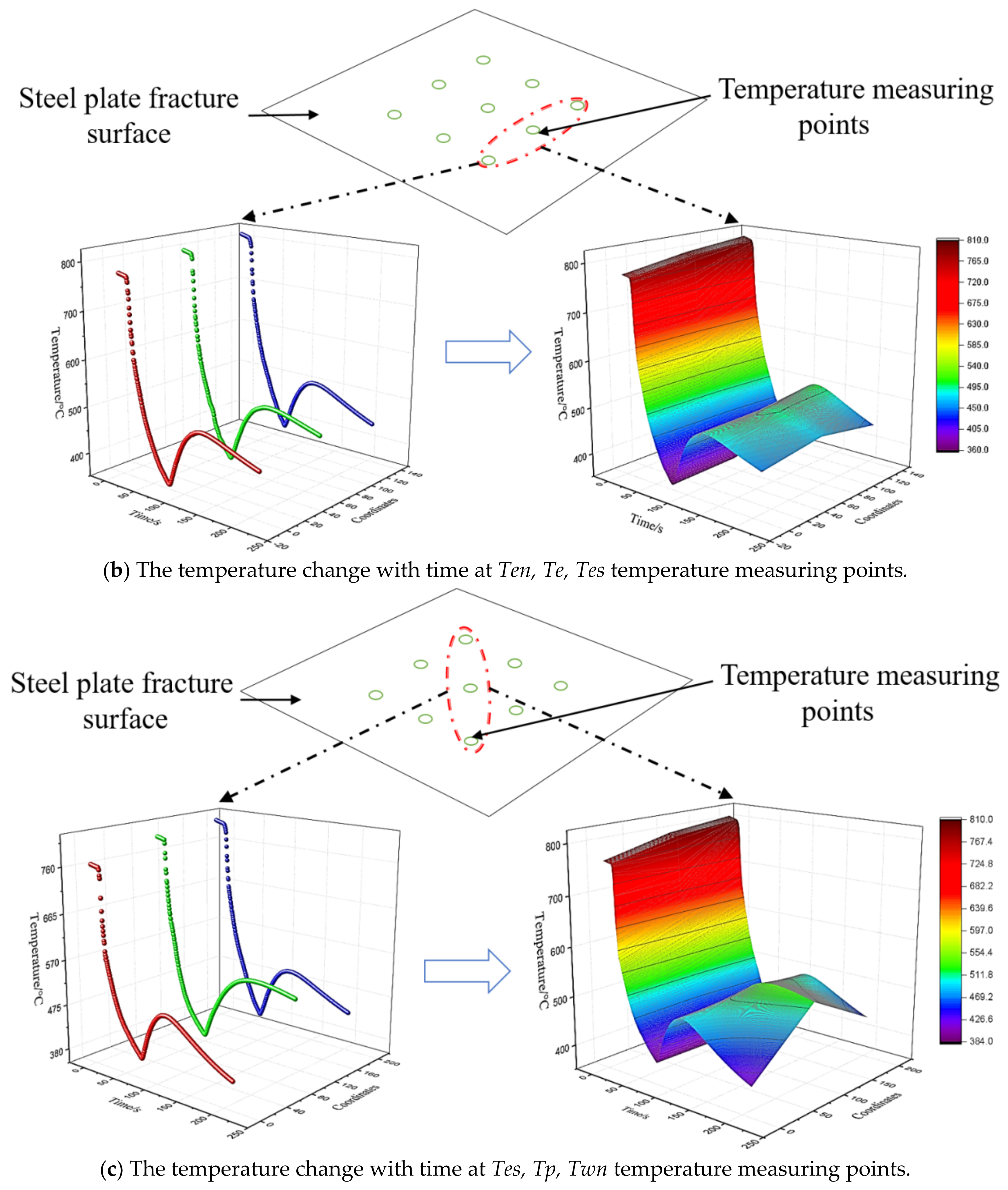

3.2. The Temperature Change with Time at Other Positions in the Whole Cooling Process

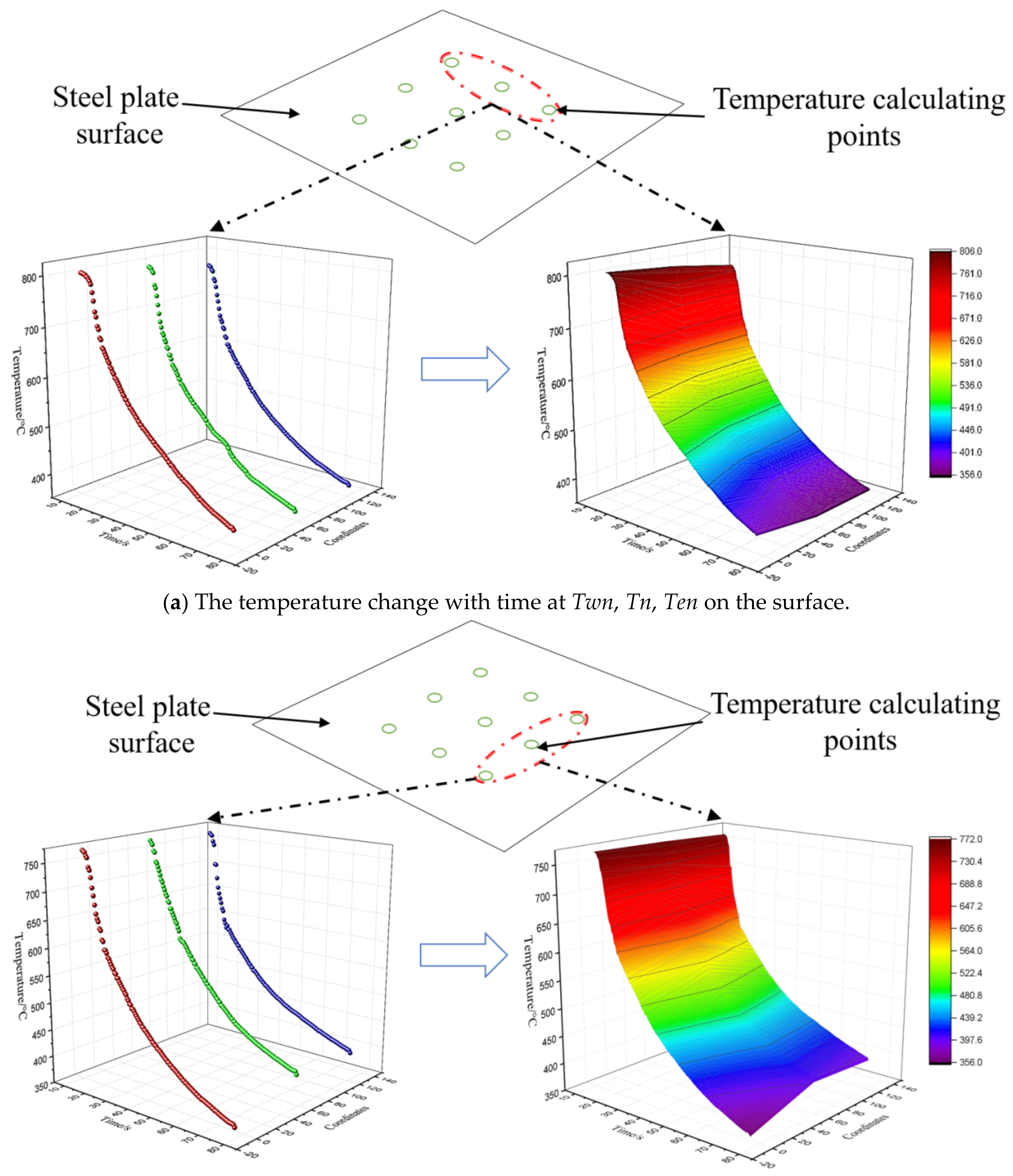

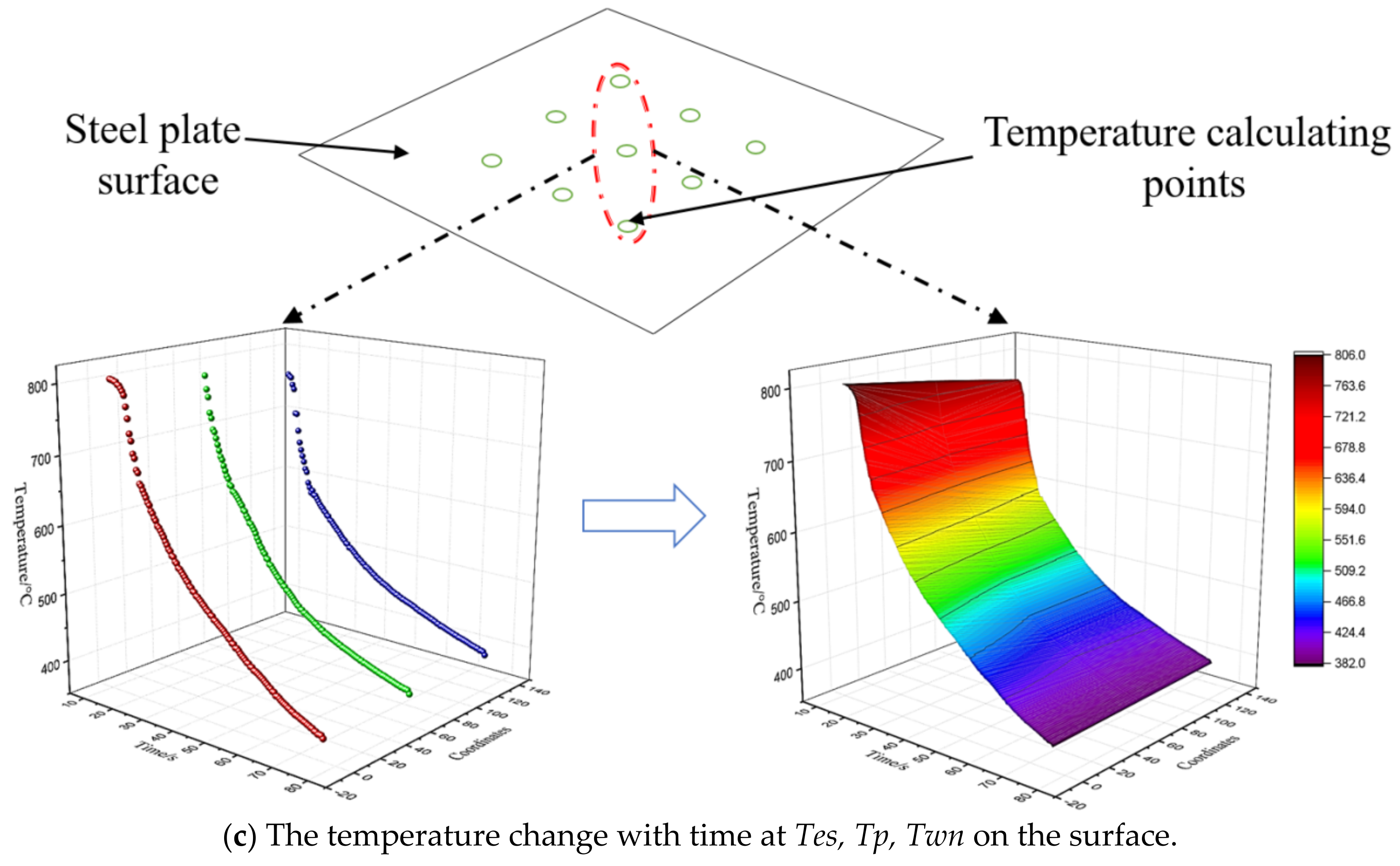

4. Solution of Temperature and Integrated Convection Heat Transfer at the Center of the Surface by TSFM

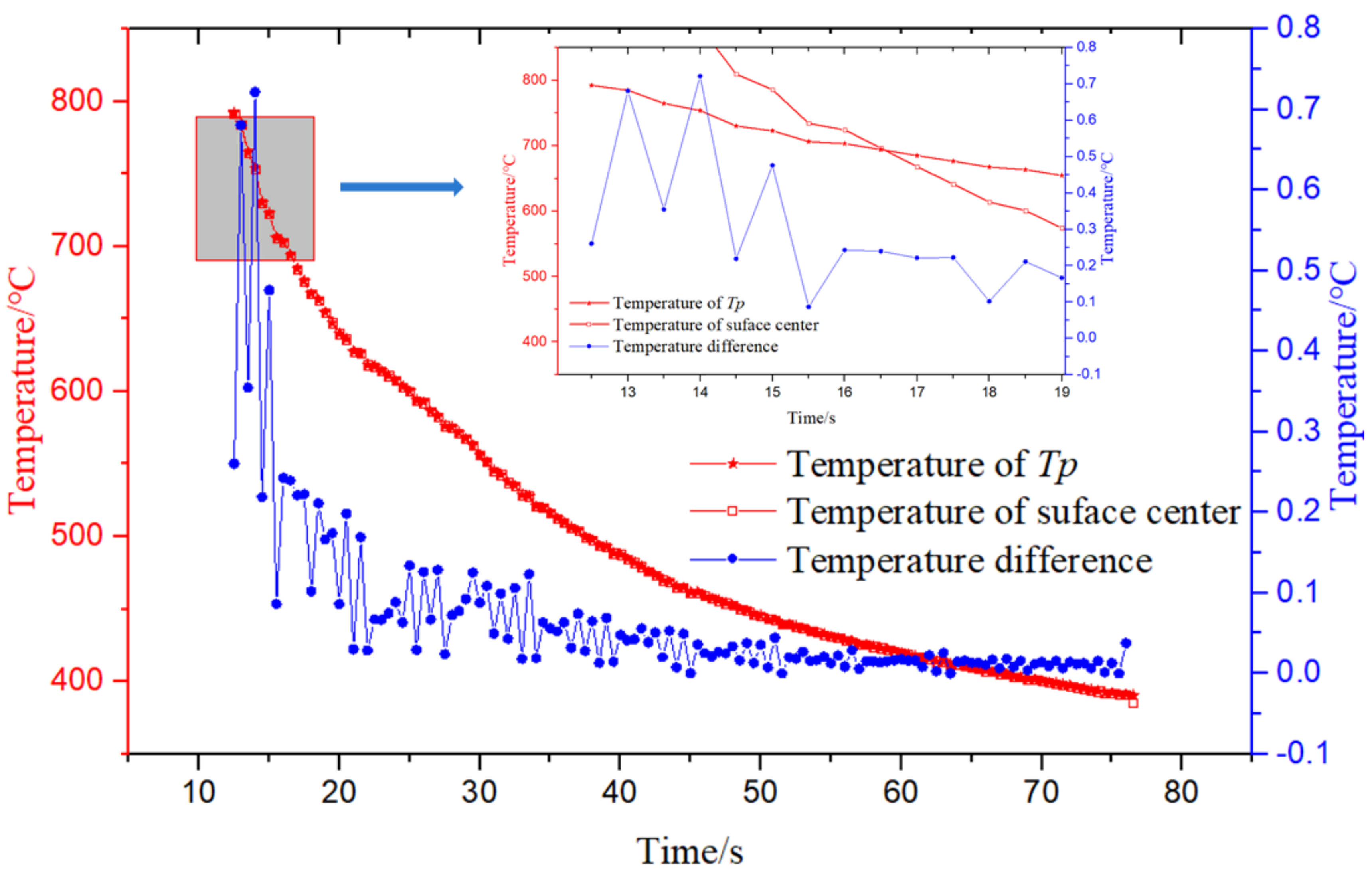

4.1. Solution of Temperature at the Center of the Laminar Cooling Surface

- (1)

- The temperature distribution of the steel plate is mainly along its thickness direction, so the cooling process is simplified as a one-dimensional unsteady heat transfer process, that is, from Tp to the center of the steel plate surface, the thickness is 1 mm;

- (2)

- The time and space are dispersed from the Tp position to the center of the steel plate surface. The time step is ∆t = 0.5 s according to the thermocouple response time. The calculation time is 12.5–77 s, i.e., the laminar spray cooling process, yielding N = 54/∆t = 109;

- (3)

- The heat transfer process of the steel plate includes only the heat conduction and the surface convection heat transfer, ignoring the radiation heat transfer;

- (4)

- There is no internal heat source;

- (5)

- The bottom of Tp is filled with cotton, which can be considered as insulation. The heat is transmitted along the direction perpendicular to the upper surface, so the temperature change at each time step is caused by the temperature difference in the center of the surface, namely:

- (1)

- The heat transfer process of the steel plate includes only the heat conduction and the surface convection heat transfer, ignoring the radiation heat transfer;

- (2)

- There is no internal heat source;

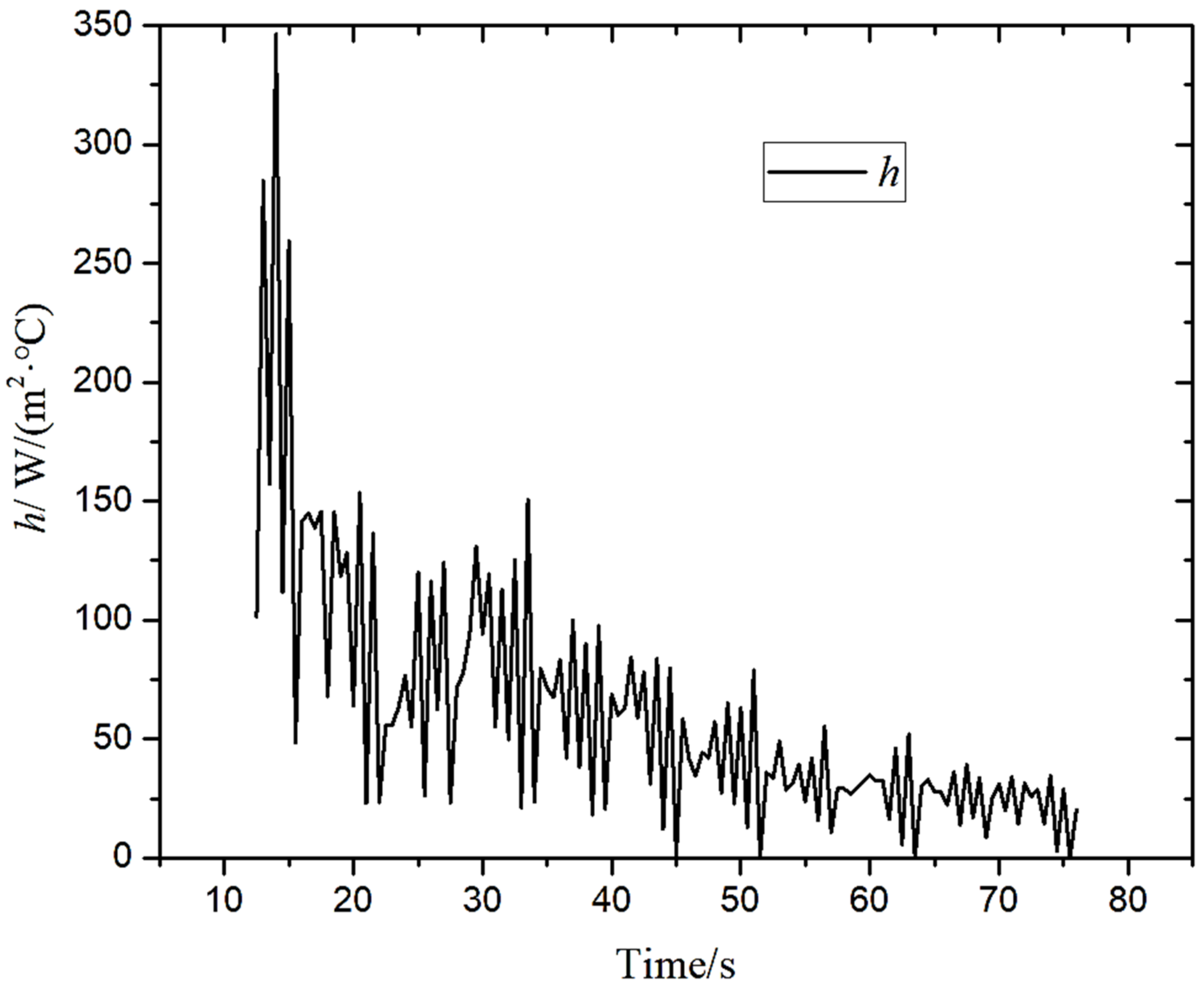

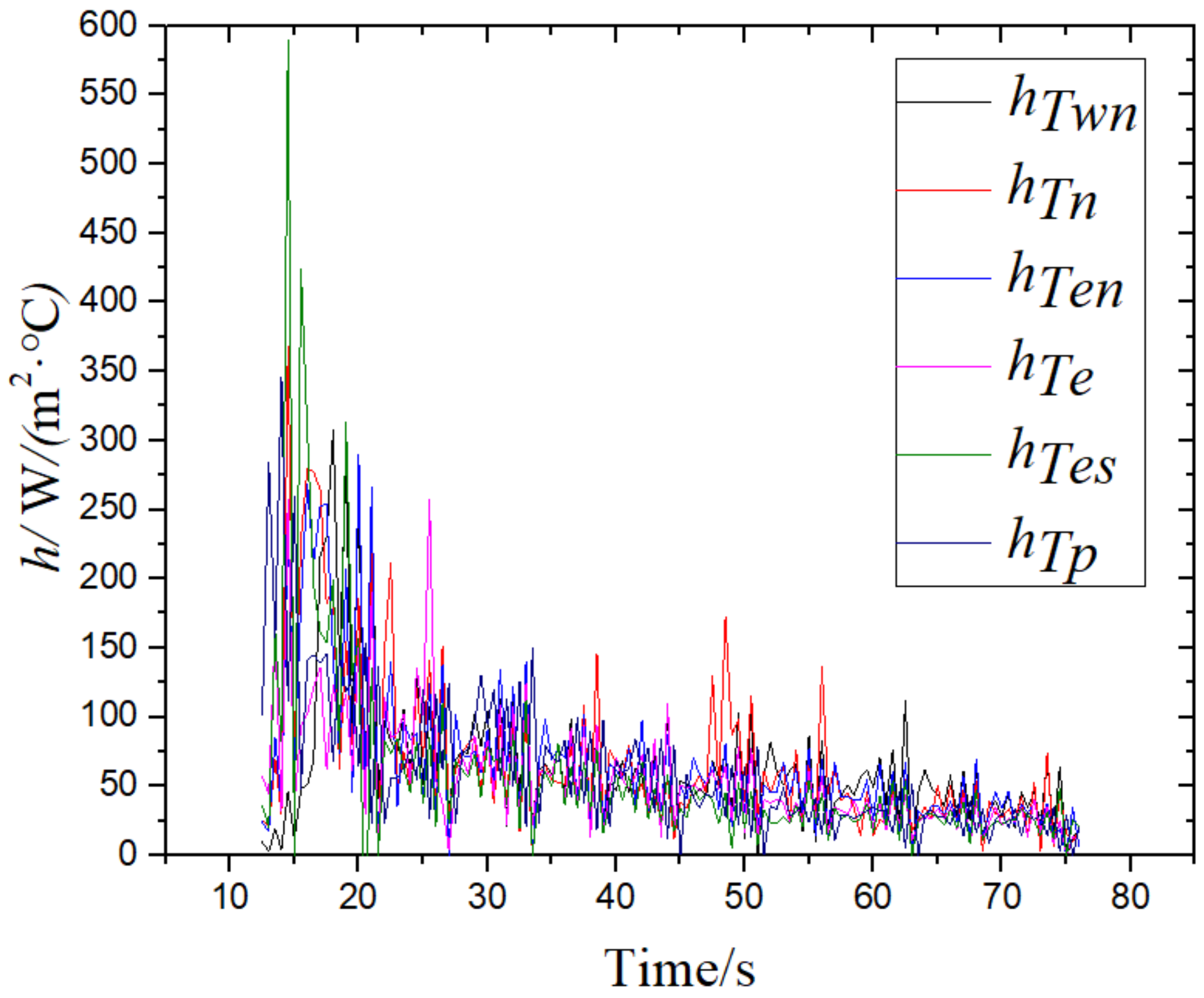

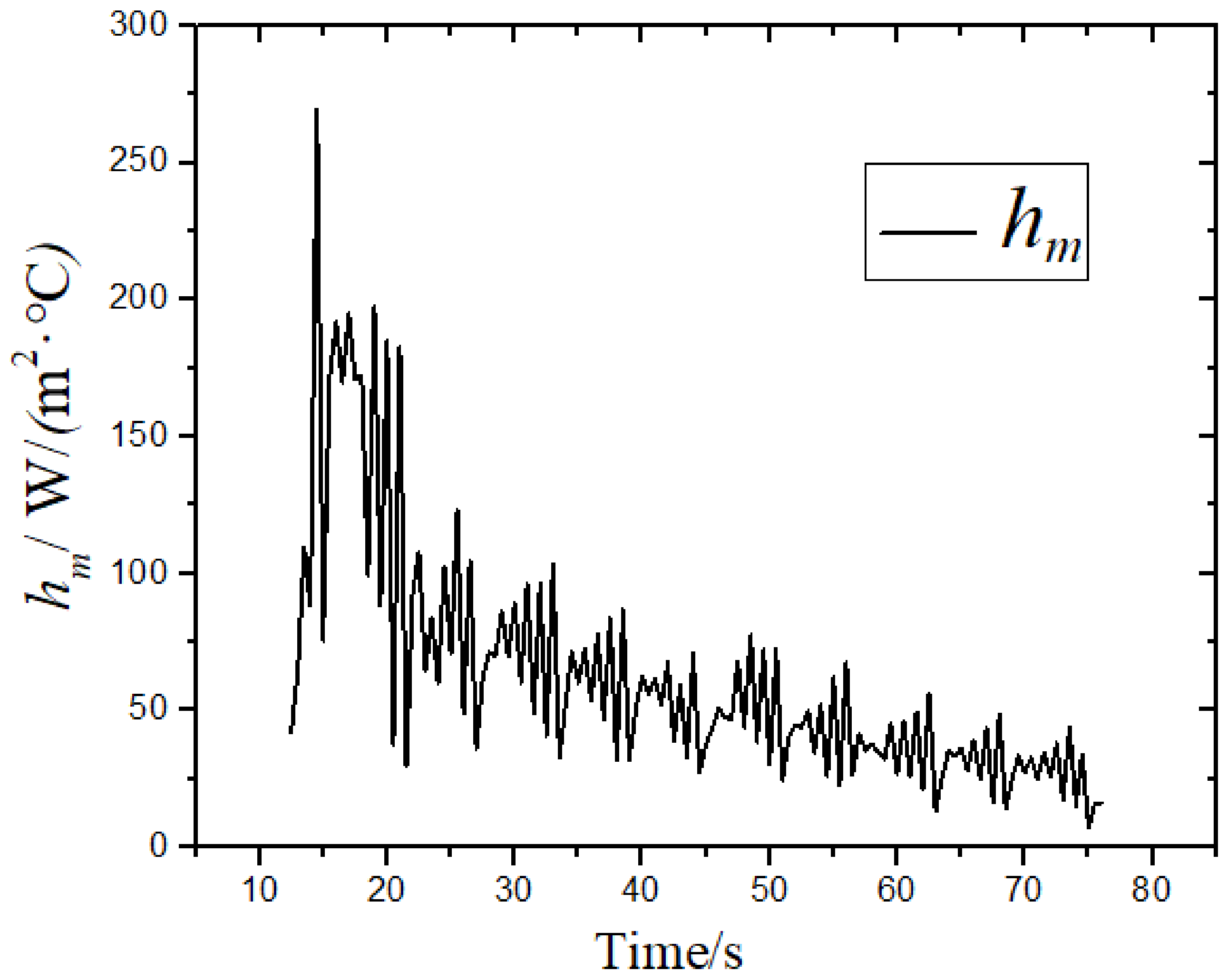

4.2. Solution of the Integrated Convection Heat Transfer at the Center of the Laminar Cooling Surface

4.3. Solution of the Temperature and the Integrated Convection Heat Transfer Coefficient at Other Positions of the Laminar Cooling Surface

4.4. Verification of the Calculation Results

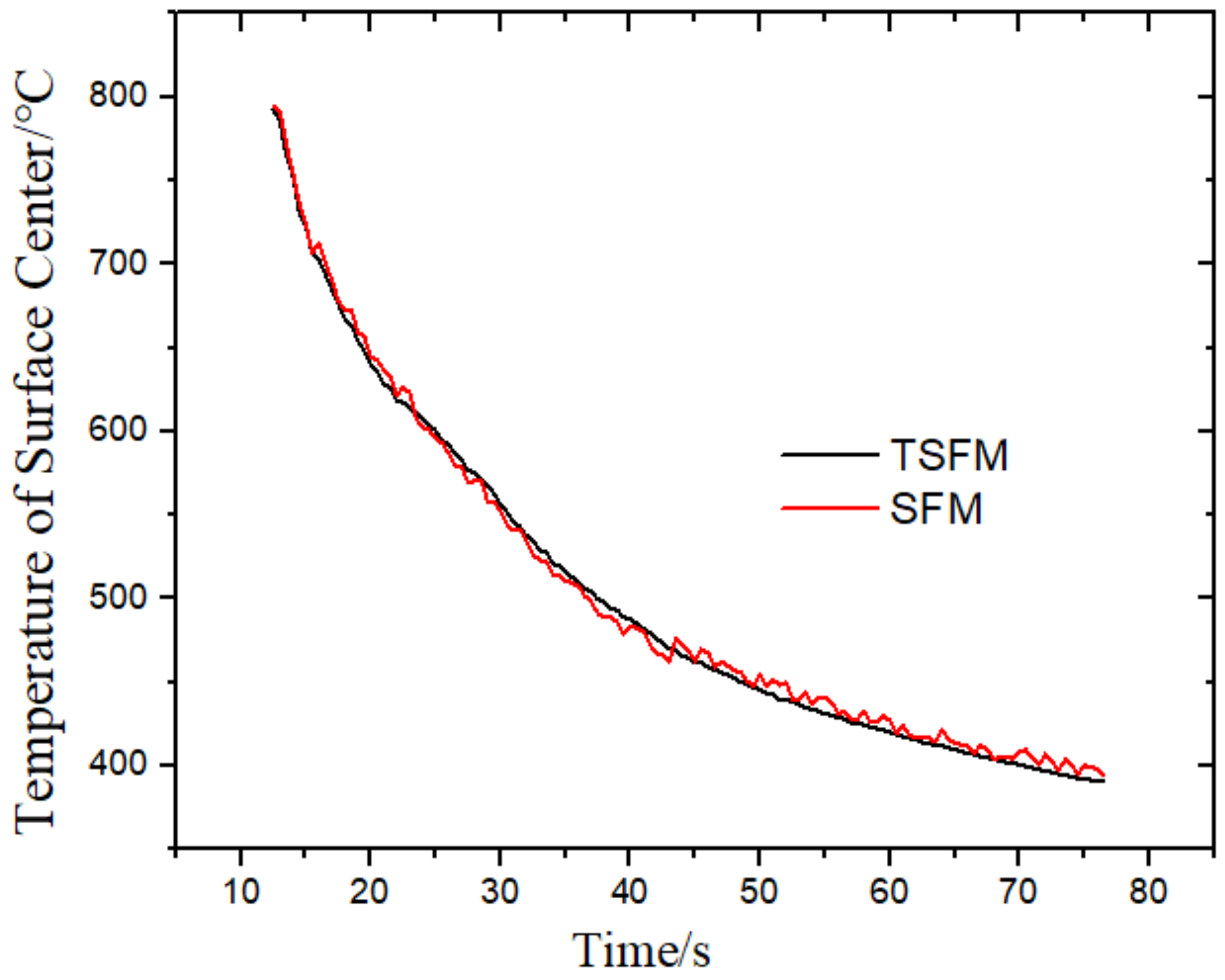

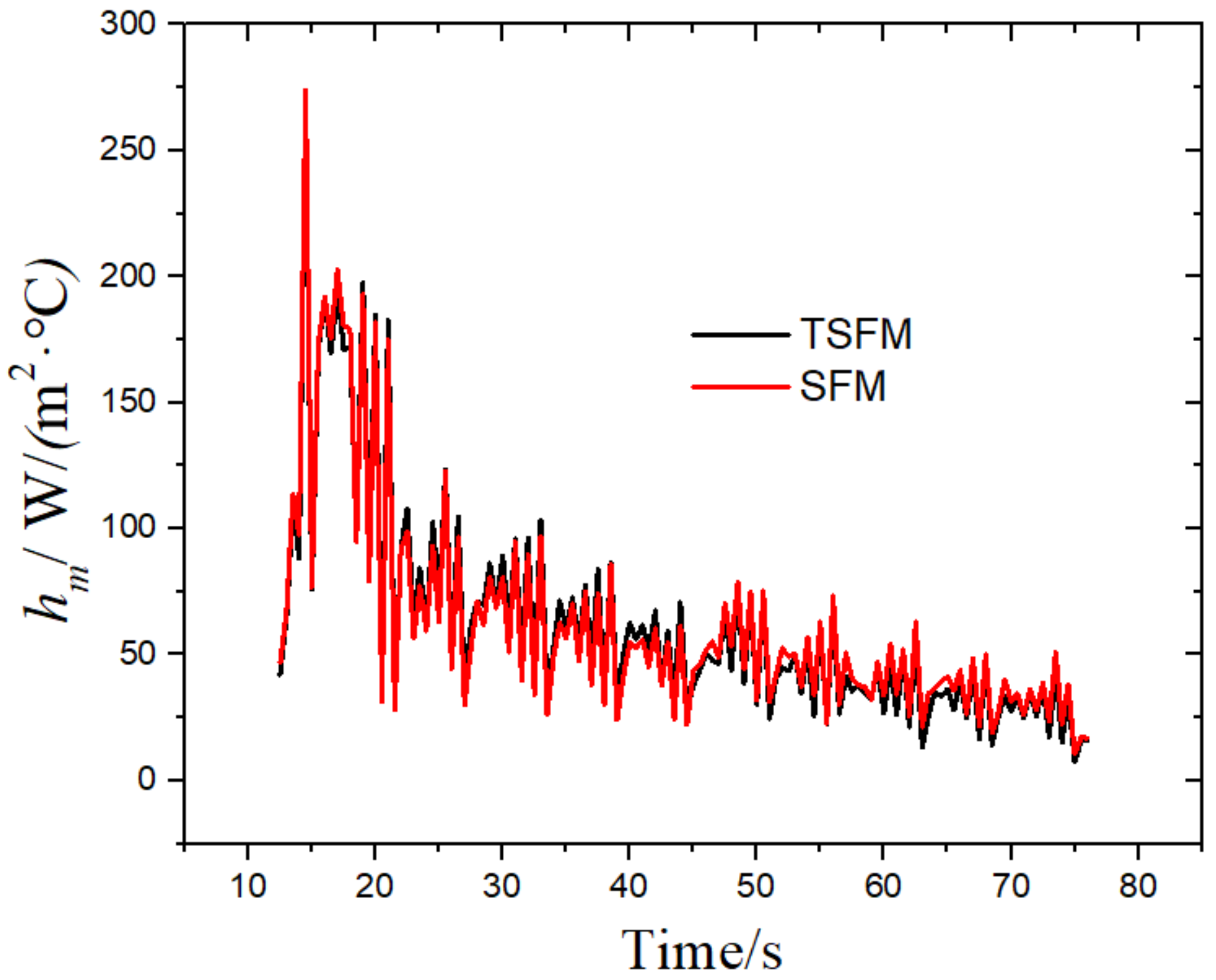

4.4.1. Verification Using SFM

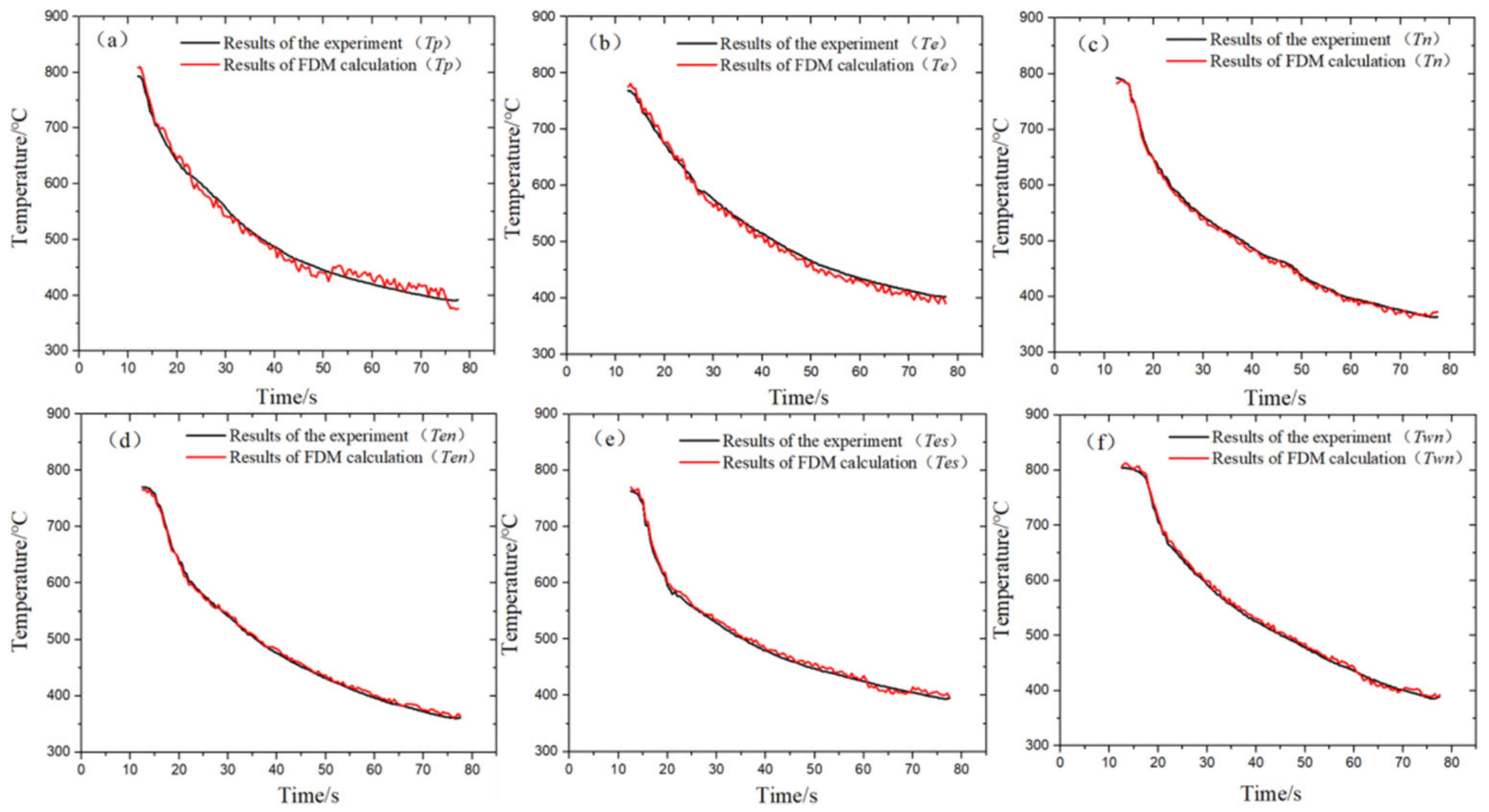

4.4.2. Verification Using FDM

5. Conclusions

- (1)

- At the beginning of water cooling, the temperature of the measuring point dropped sharply, with a drop rate of 8% and a drop multiplying power of 36%; at the stage of air cooling, the temperature of the measuring point ascended, with an increase of 35%, showing the phenomenon of “re-reddening”.

- (2)

- In the laminar cooling process of the hot-rolled steel plate, the surface temperature and the integrated convection heat transfer coefficient of the surface exhibited non-linear behavior with time. When the cooling time was 12.5–14 s, the surface temperature decreased sharply, while the integrated convection heat transfer coefficient increased periodically with time. When the time was more than 14 s, the surface temperature dropping rate decreased, and the integrated convection heat transfer coefficient declined periodically, finally approaching slight changes;

- (3)

- The SFM was used to verify the calculated results. The relative average errors of the surface temperature and the comprehensive convective heat transfer coefficient were 0.39 and 0.18%, respectively, which proved that the TSFM was a successful approach.

- (4)

- The FDM was used to verify the correctness of the calculated results indirectly. The results show that when the boundary conditions calculated by TSFM were brought back to the governing equation for solving, the calculated results were in good agreement with the experimental results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, H.M.; Wei, Y.; Cai, Q.W. Experimental Study of Heat Transfer Coefficient on Hot Steel Plate During Water Jet Impingement Cooling. J. Mater. Process. Tech. 2012, 212, 1825–1831. [Google Scholar] [CrossRef]

- Liu, W.H.; Zhang, S.Y.; Wang, J.L. Experimental Study of Laminar Cooling Process on Temperature Field of the Heavy Plate. IOP Conf. Ser. Mater. Sci. Eng. 2018, 452, 022034. [Google Scholar] [CrossRef]

- Serajzadeh, S. Modelling of Temperature History and Phase Transformations During Cooling of Steel. J. Mater. Process. Tech. 2003, 146, 311–317. [Google Scholar] [CrossRef]

- Chen, S.X.; Zou, J.; Fu, X. Coupled Models of Heat Transfer and Phase Transformation for the Run-Out Table in Hot Rolling. J. Zhejiang Univ.-Sci. A 2008, 9, 932–939. [Google Scholar] [CrossRef]

- Munshi, L.B.; Barik, K.; Mohapatra, S.S. The role of surface tension and viscosity of the coolant on spray cooling performance of red-hot inclined steel plate. Int. J. Heat Mass Transf. 2019, 130, 496–513. [Google Scholar] [CrossRef]

- Hou, Y.; Liu, X.F.; Liu, J.H.; Li, M.J.; Pu, L. Experimental Study on Phase Change Spray Cooling. Exp. Therm. Fluid Sci. 2013, 46, 84–88. [Google Scholar] [CrossRef]

- Gulati, P.; Katti, V.; Prabhu, S.V. Influence of the Shape of the Nozzle on the Local Heat Transfer Distribution Between Smooth Flat Surface and Impinging Air Jet. Int. J. Therm. Sci. 2009, 48, 602–617. [Google Scholar] [CrossRef]

- Ndao, S.; Joon Lee, H.; Peles, Y.; Jensen, M.K. Heat Transfer Enhancement from Micro Pin Fins Subjected to an Impinging Jet. Int. J. Heat Mass Transf. 2011, 55, 413–421. [Google Scholar] [CrossRef]

- Hammad, J.; Mitsutake, Y.; Monde, M. Movement of Maximum Heat Flux and Wetting front During Quenching of Hot Cylindrical Block. Int. J. Therm Sci. 2004, 43, 743–752. [Google Scholar] [CrossRef]

- Holappa, L.; Ollilainen, V.; Kasprzak, W. The Effect of Silicon and Vanadium Alloying on the Microstructure of Air Cooled Forged HSLA Steels. J. Mater. Process. Tech. 2001, 109, 78–82. [Google Scholar] [CrossRef]

- Mudawar, I.; Estes, K.A. Optimizing and Predicting CHF in Spray Cooling of a Square Surface. J. Heat Transf. 1996, 118, 672–680. [Google Scholar] [CrossRef]

- Fernández-Seara, J.; Pardiñas, Á.Á. Refrigerant Falling Film Evaporation Review: Description, Fluid Dynamics and Heat Transfer. Appl. Therm. Eng. 2014, 64, 155–171. [Google Scholar] [CrossRef]

- Thiagarajan, S.J.; Narumanchi, S.; Yang, R. Effect of flow Rate and Sub-Cooling on Sprayheat Transfer on Microporous Copper Surfaces. Int. J. Heat Mass Transf. 2014, 69, 493–505. [Google Scholar] [CrossRef]

- Abd, H.M.; Alomar, O.R.; Mohamed, I.A. Effects of Varying Orifice Diameter and Reynolds Number on Discharge Coefficient and Wall Pressure. Flow Meas. Instrum. 2019, 65, 219–226. [Google Scholar] [CrossRef]

- Şahin, A.Z. Thermodynamics of Laminar Viscous Flow Through a Duct Subjected to Constant Heat Flux. Energy 1996, 21, 1179–1187. [Google Scholar] [CrossRef]

- Pautsch, A.G.; Shedd, T.A. Spray Impingement Cooling with Single-and Multiple-Nozzle Arrays. Part I: Heat Transfer Data Using FC-72. Int. J. Heat Mass Transf. 2005, 48, 3167–3175. [Google Scholar] [CrossRef]

- Wang, B.X.; Guo, X.T.; Xie, Q.; Wang, Z.D.; Wang, G.D. Heat Transfer Characteristic Research During Jet Impinging on Top/Bottom Hot Steel Plate. Int. J. Heat Mass Transf. 2016, 101, 844–851. [Google Scholar] [CrossRef]

- Yang, J.; Chow, L.C.; Pais, M.R.; Ito, A. Liquid Film Thickness and Topography Determination Using Fresnel Diffraction And Holography. Exp. Heat Transf. 1992, 5, 239–252. [Google Scholar] [CrossRef]

- Zhang, P.; Ruan, L. Theoretical Study of the Effect of Spray Inclination on Spray Cooling for Large-scale Electronic Equipment. IERI Procedia 2013, 4, 118–125. [Google Scholar] [CrossRef] [Green Version]

- Mohapatra, S.S.; Ravikumar, S.V.; Andhare, S.; Chakraborty, S.; Pal, S.K. Experimentalstudy and Optimization of Air Atomized Spray with Surfactant Added Water to Produce Highcooling Rate. J. Enhanc. Heat Transf. 2012, 19, 397–408. [Google Scholar] [CrossRef]

- Wang, B.X.; Lin, D.; Xie, Q.; Wang, Z.D.; Wang, G.D. Heat Transfer Characteristics During Jet Impingement on a High—Temperature Plate Surface. Appl. Therm. Eng. 2016, 100, 902–910. [Google Scholar] [CrossRef]

- Lim, H.S.; Kang, Y.T. Optimization of Influence Factors for Water Cooling of High Temperature Plate by Accelerated Control Cooling Process. Int. J. Heat Mass Transf. 2019, 128, 526–535. [Google Scholar] [CrossRef]

- Chen, R.H.; Chow, L.C.; Navedo, E. Effects of Spray Characteristics on Critical Heat Flux in Subcooled Water Spray Cooling. Int. J. Heat Mass Transf. 2002, 45, 4033–4043. [Google Scholar] [CrossRef]

- Zhu, F.; Chen, J.; Han, Y. A Multiple Regression Convolutional Neural Network for Estimating Multi-parameters Based on Overall Data in the Inverse Heat Transfer Problem. J. Thermal Sci. Eng. Appl. 2021, 14, 051003. [Google Scholar] [CrossRef]

- Park, H.M.; Lee, J.H. A method of Solving Inverse Convection Problems by Means of Mode Reduction. Chem. Eng. Sci. 1998, 53, 1731–1744. [Google Scholar] [CrossRef]

- Jing, L.; Lisa, X. Boundary Information based Diagnostics on The Thermal States of Biological Bodies. Int. J. Heat Mass Tran. 2000, 43, 2827–2839. [Google Scholar] [CrossRef]

- Yun, K.H.; Seung, W.B. Inverse Analysis for Estimating The Unsteady Inlet Temperature Distribution for Two-phase Laminar Flow in a Channel. Int. J. Heat Mass Tran. 2005, 49, 1137–1147. [Google Scholar] [CrossRef]

- Cheng, H.; His, C.; Chia, L. A Shape Identification Problem in Estimating the Unknown Interfacial Surface for a Multiple Region Domain. J. Hydrodyn 2010, 22, 101–105. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the Uncertainties in Experimental Results. Exp. Therm. Fluid. Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef] [Green Version]

- Zumbrunnen, D.A. Method and Apparatus for Measuring Heat Transfer Distributions on Moving and Stationary Plates Cooled by a Planar Liquid Jet. Exp. Therm Fluid Sci. 1990, 3, 202–213. [Google Scholar] [CrossRef]

- Farzan, H.; Loulou, T.; Sarvari, S.M.H. Estimation of Applied Heat Flux at the Surface of Ablating Materials by Using Sequential Function Specification Method. J. Mech. Sci. Technol. 2017, 31, 3969–3979. [Google Scholar] [CrossRef]

- Huang, C.H.; Ju, T.M.; Tseng, A.A. The Estimation of Surface Thermal Behavior of the Working Roll in Hot Rolling Process. Int. J. Heat Mass Tran. 1995, 38, 1019–1031. [Google Scholar] [CrossRef]

- Keanini, R.G. Inverse Estimation of Surface Heat Flux Distributions During High Speed Rolling Using Remote Thermal Measurements. Int. J. Heat Mass Tran. 1998, 41, 275–285. [Google Scholar] [CrossRef]

- Jacobi, H.; Kaestle, G.; Wuennenberg, K. Heat Transfer in Cyclic Secondary Cooling During Solidification of Steel. Ironmak. Steelmak. 1984, 11, 132–145. [Google Scholar]

- Prieto, M.M.; Ruíz, L.S.; Menéndez, J.A. Thermal Performance of Numerical Model of Hot Strip Mill Runout Table. Ironmak. Steelmak. 2013, 28, 474–480. [Google Scholar] [CrossRef]

- Funk, G.; Boehmer, J.R.; Fett., F.N. A coupled FDM/FEM model for the continuous casting process. Int. J. Comput. Appl. Technol. 1994, 7, 214–228. [Google Scholar] [CrossRef]

- Suman, S. Heatline Based Thermal Behaviour during Cooling of a Hot Moving Steel Plate Using Single Jet. Appl. Mech. Mater. 2014, 3304, 1622–1626. [Google Scholar] [CrossRef]

| Types | Process Parameters | Fluid Properties | Steel Plate Properties | Environmental Properties |

|---|---|---|---|---|

| Nozzle types [7] | Thermal properties of fluid [8] | Thermal properties of steel plate [9] | Air properties [10] | |

| Nozzle height [11] | Fluid viscosity [12] | Surface roughness [13] | ||

| Nozzle caliber [14] | Surface tension [15] | Undercooling [16] | ||

| Jet volocity [17] | Surfactant [18] | |||

| Nozzle angle [19] | Latent heat of vaporization [20] | |||

| Jet flow rate [21] | ||||

| Fluid temperature [22] | ||||

| Droplet size [23] |

| Experimental Condition | Water Temperature | Nozzle Height | Nozzle Diameter | Nozzle Water Flow | Steel Plate Speed |

|---|---|---|---|---|---|

| Case1 | 25 °C | 465 mm | 3 mm | 0.125 m3/h | 3 m/min |

| Experimental Parameter | Uncertainty |

|---|---|

| Thermocouple response time/s | ±0.01 |

| Plate speed/m/min | ±0.03 |

| Water temperture/°C | ±0.5 |

| Nozzle height/mm | ±0.1 |

| Water flow/m3/h | ±0.001 |

| Thermocouple accuracy/°C | ±0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Chen, G.; Bao, X.; He, X.; Duan, Q. A Study on the Heat Transfer Characteristics of Steel Plate in the Matrix Laminar Cooling Process. Materials 2021, 14, 5680. https://doi.org/10.3390/ma14195680

Xu J, Chen G, Bao X, He X, Duan Q. A Study on the Heat Transfer Characteristics of Steel Plate in the Matrix Laminar Cooling Process. Materials. 2021; 14(19):5680. https://doi.org/10.3390/ma14195680

Chicago/Turabian StyleXu, Jing, Guang Chen, Xiangjun Bao, Xin He, and Qingyue Duan. 2021. "A Study on the Heat Transfer Characteristics of Steel Plate in the Matrix Laminar Cooling Process" Materials 14, no. 19: 5680. https://doi.org/10.3390/ma14195680

APA StyleXu, J., Chen, G., Bao, X., He, X., & Duan, Q. (2021). A Study on the Heat Transfer Characteristics of Steel Plate in the Matrix Laminar Cooling Process. Materials, 14(19), 5680. https://doi.org/10.3390/ma14195680