Exploring the Influence Factors of Early Hydration of Ultrafine Cement

Abstract

:1. Introduction

2. Materials and Methods

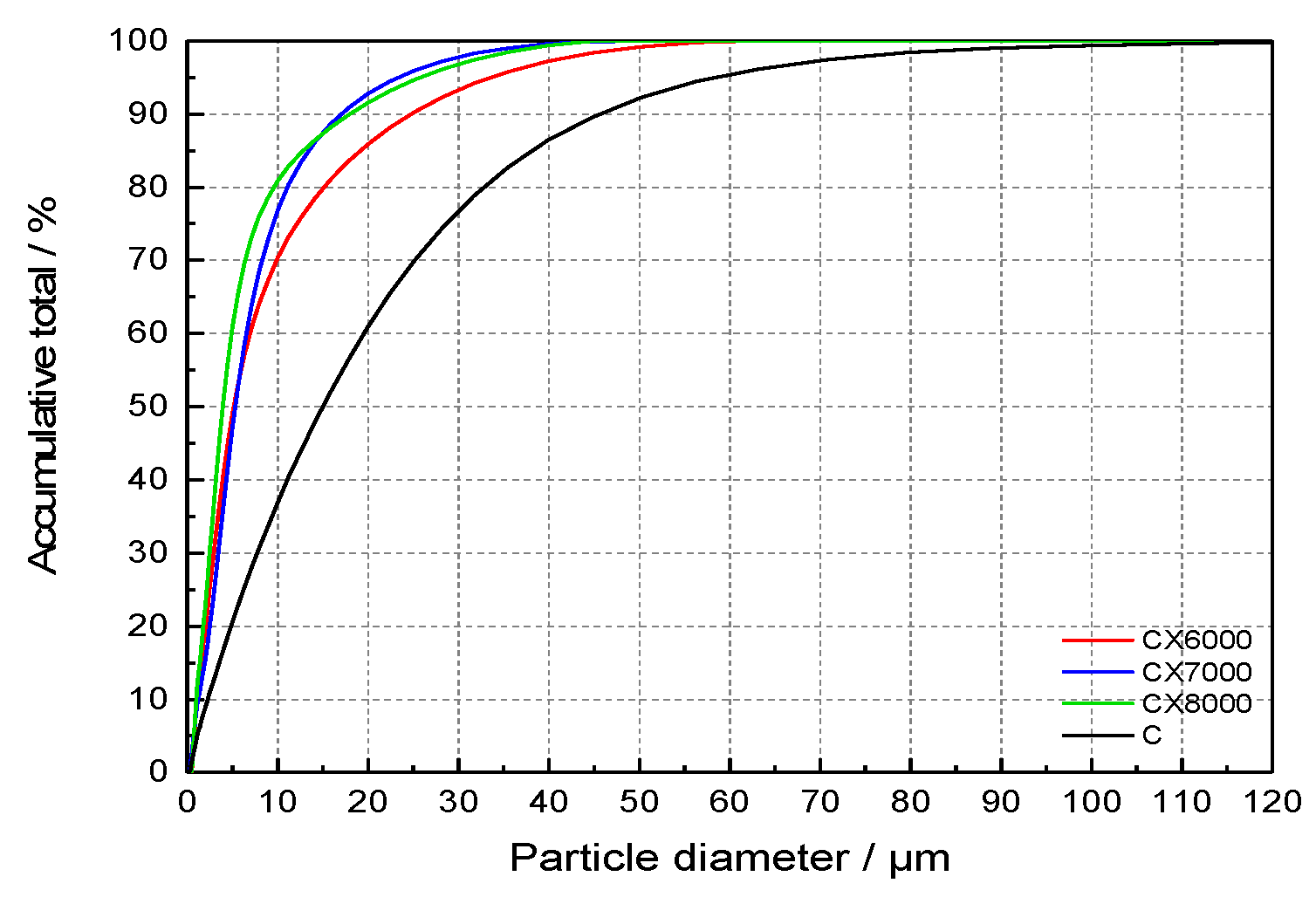

2.1. Materials

2.2. Methods

- (1)

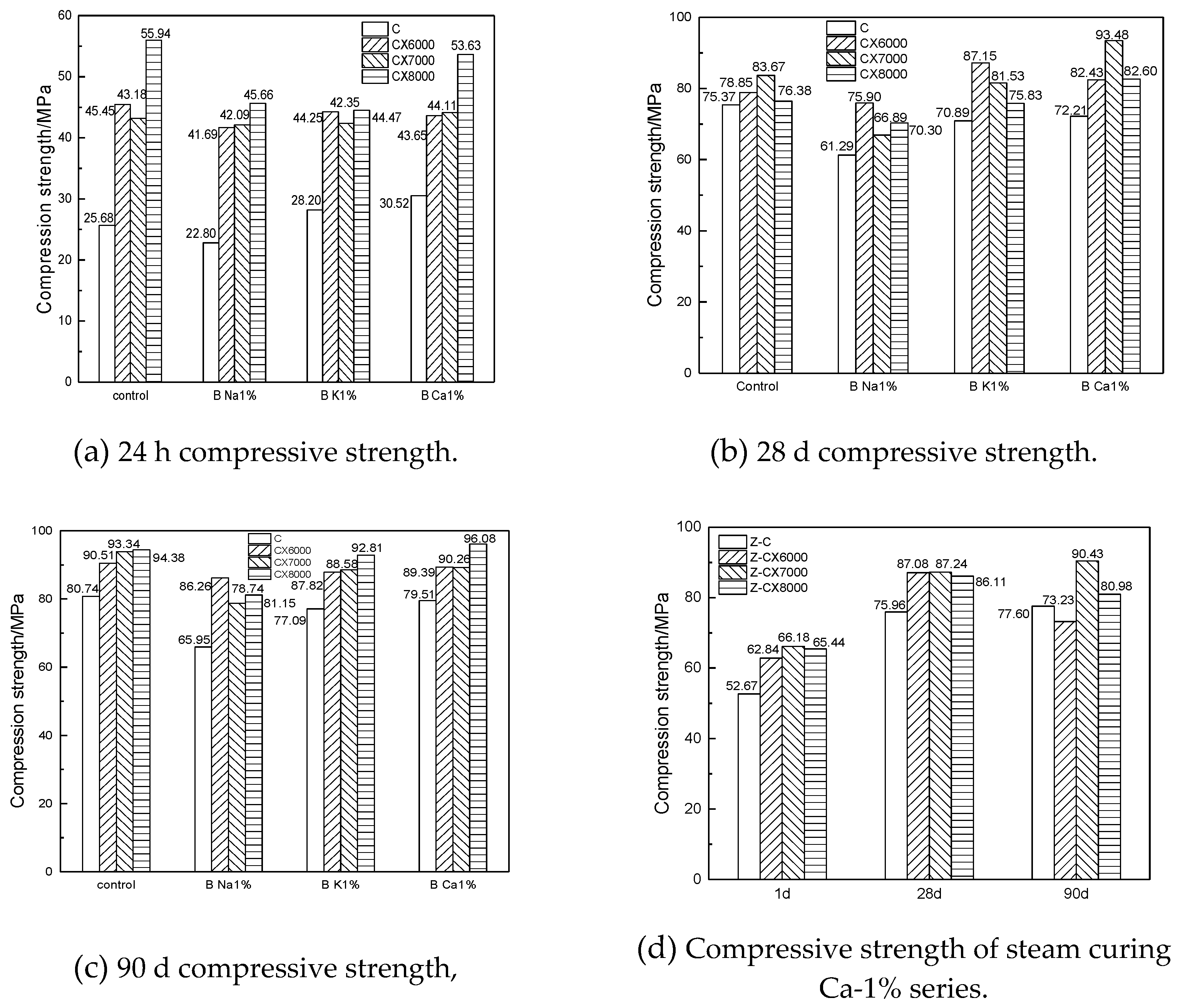

- Compressive strength: Cement, river sand, water, and additives were mixed according to ratio. Cement mortar mixer (Wuxi Jian Gong Test Equipment Co., Ltd., Wuxi, China) was used: slow mixing 120 s, fast mixing 180 s before molding. The grouted specimens (40 mm × 40 mm × 160 mm) were kept in a horizontal position in molds for 24 h at different temperatures. They were then extracted and moved to a standard curing room until testing time. The compressive strength tests were conducted on the specimens cured for 1, 28, and 90 days according to GB/T 17671–1999 [25]. Three identical samples were tested for each test, and the values were averaged.

- (2)

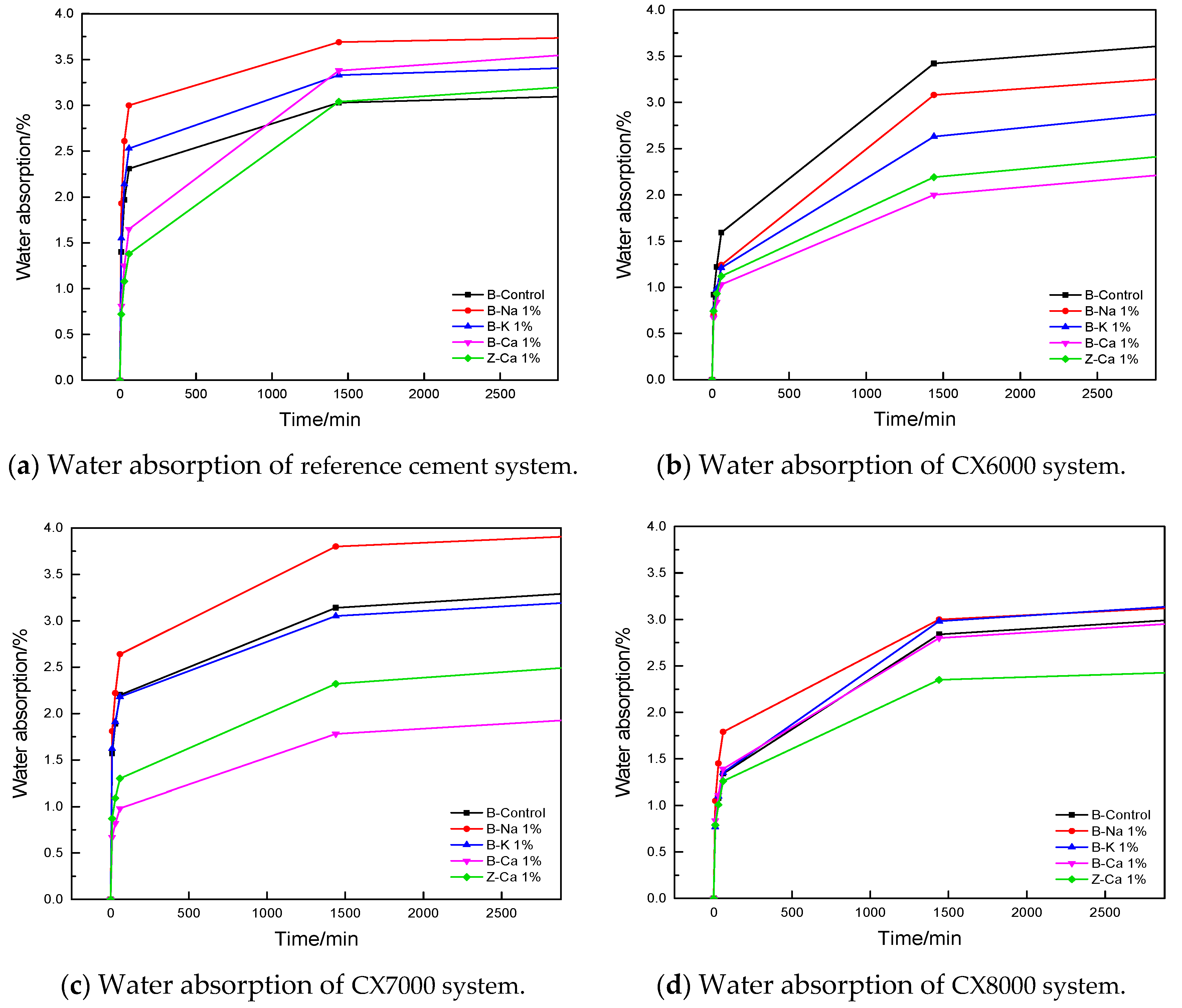

- Water absorption: Each group prepared three mortars (70.7 mm × 70.7 mm × 70.7 mm), cured for 28 d, then placed in the vacuum drying oven at 105 °C for 48 h. The temperature was lowered to the standard curing temperature, and then the specimens were taken out and immersed in water. It was ensured that the bottoms of mortars were fully in contact with water, with the surface below the water surface of at least 2 cm. The mortars were immersed in water for 48 h. We set the measurement time point during the period according to DL/T 5148-2012 [26] and finally obtained the water absorption curve.

- (3)

- Thermal analysis: The TAM Air eight-channel isothermal calorimeter produced by the American TA Company (New Castle, DE, USA) was used to measure the specific heat flow released during hydration at 20 °C. The samples were temperature-equilibrated for 72 h prior to the measurements. Mixing was performed for 1 min at 860 rpm. Afterwards, approximately 1.8 g of paste was cast into ampoules and inserted into the calorimeter [27].

- (4)

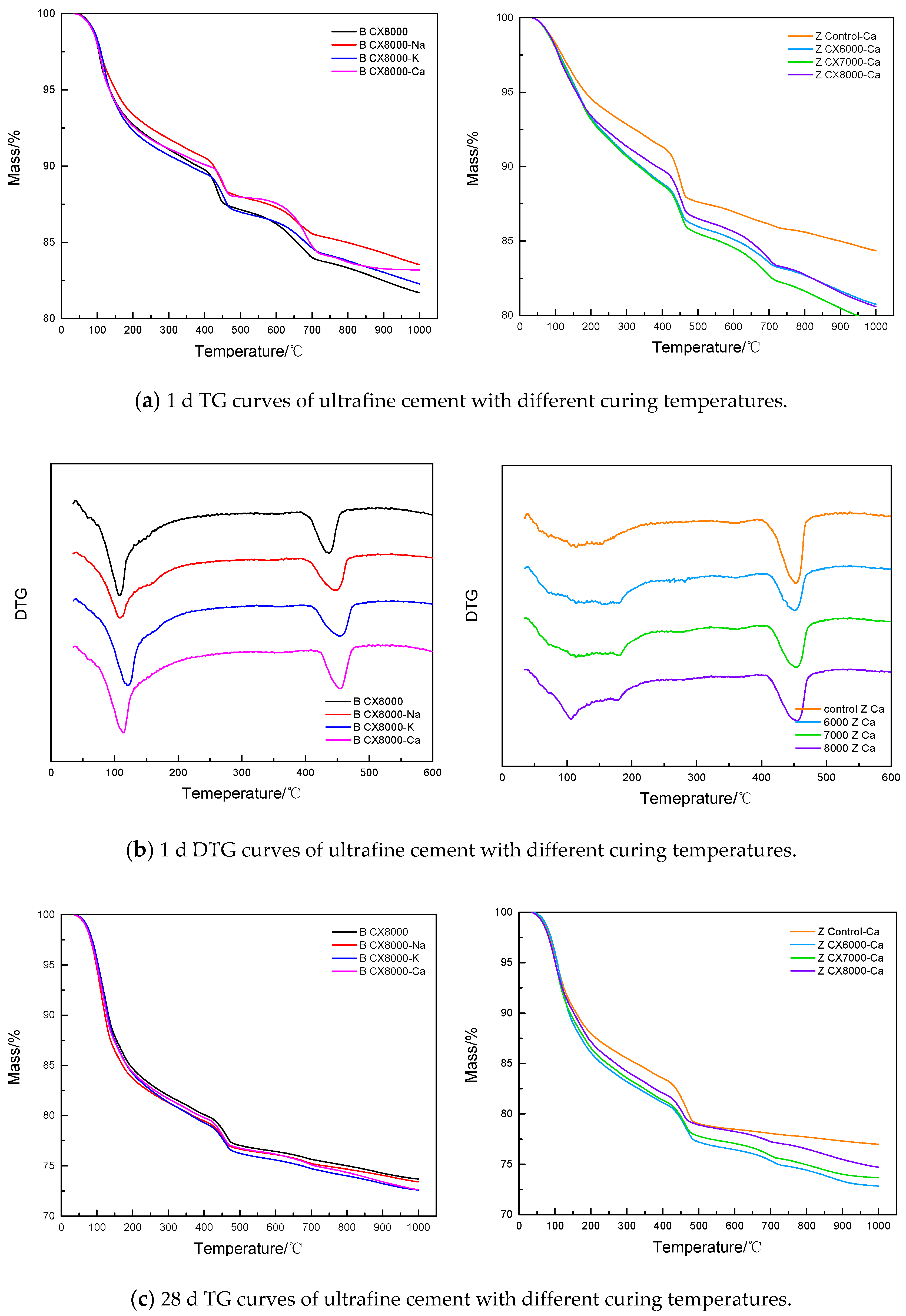

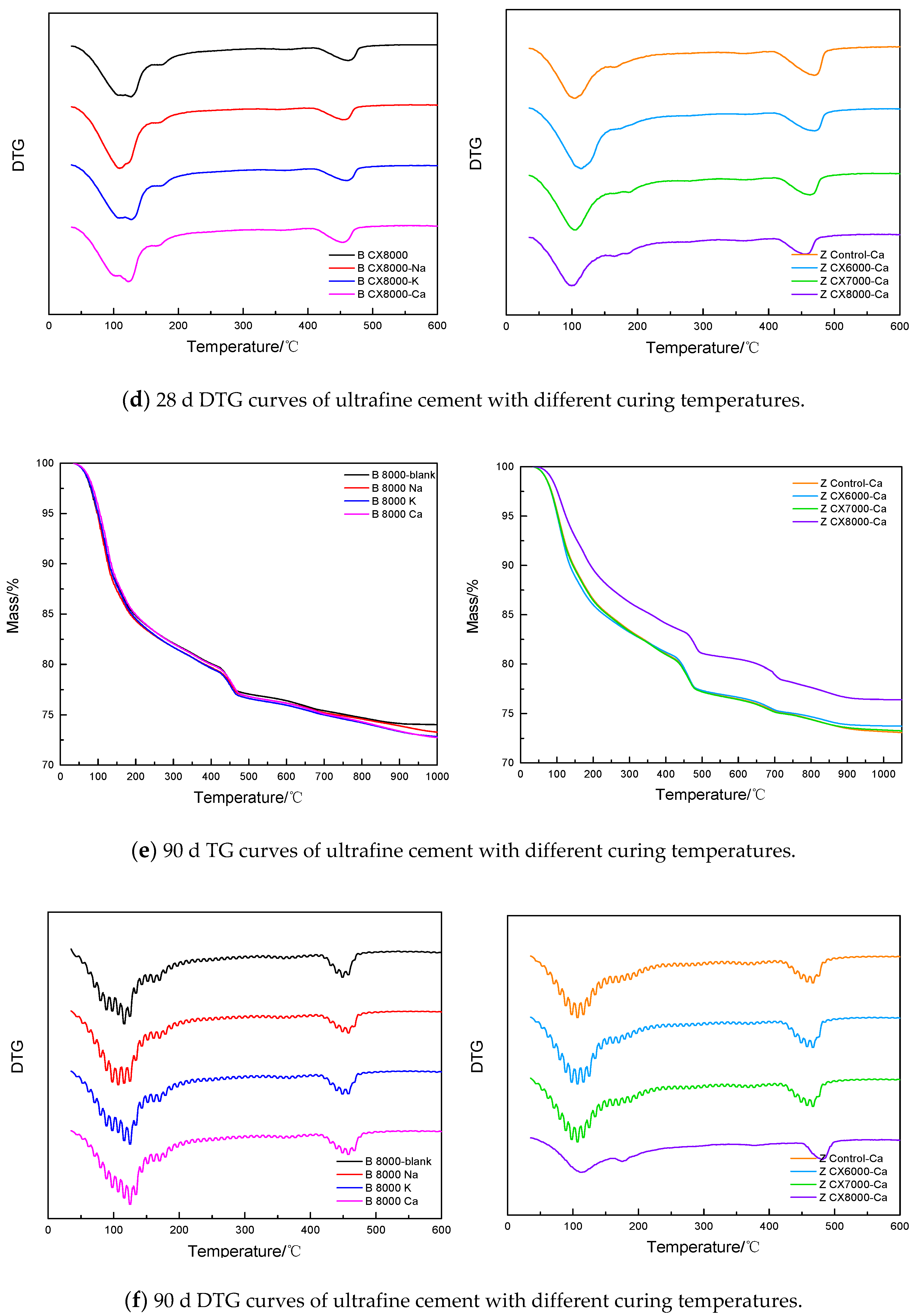

- Thermogravimetric analysis: TG/DTG was done by used METTLER TOLEDO TGA 2 thermal analyzer (METTLER TOLEDO, Zurich, Switzerland). Dried cement paste was taken in a ceramic crucible and heated from room temperature to 1050 °C at a heating rate of 10 °C/min under a nitrogen flow of 70 mL/min [28,29,30,31,32,33,34].

- (5)

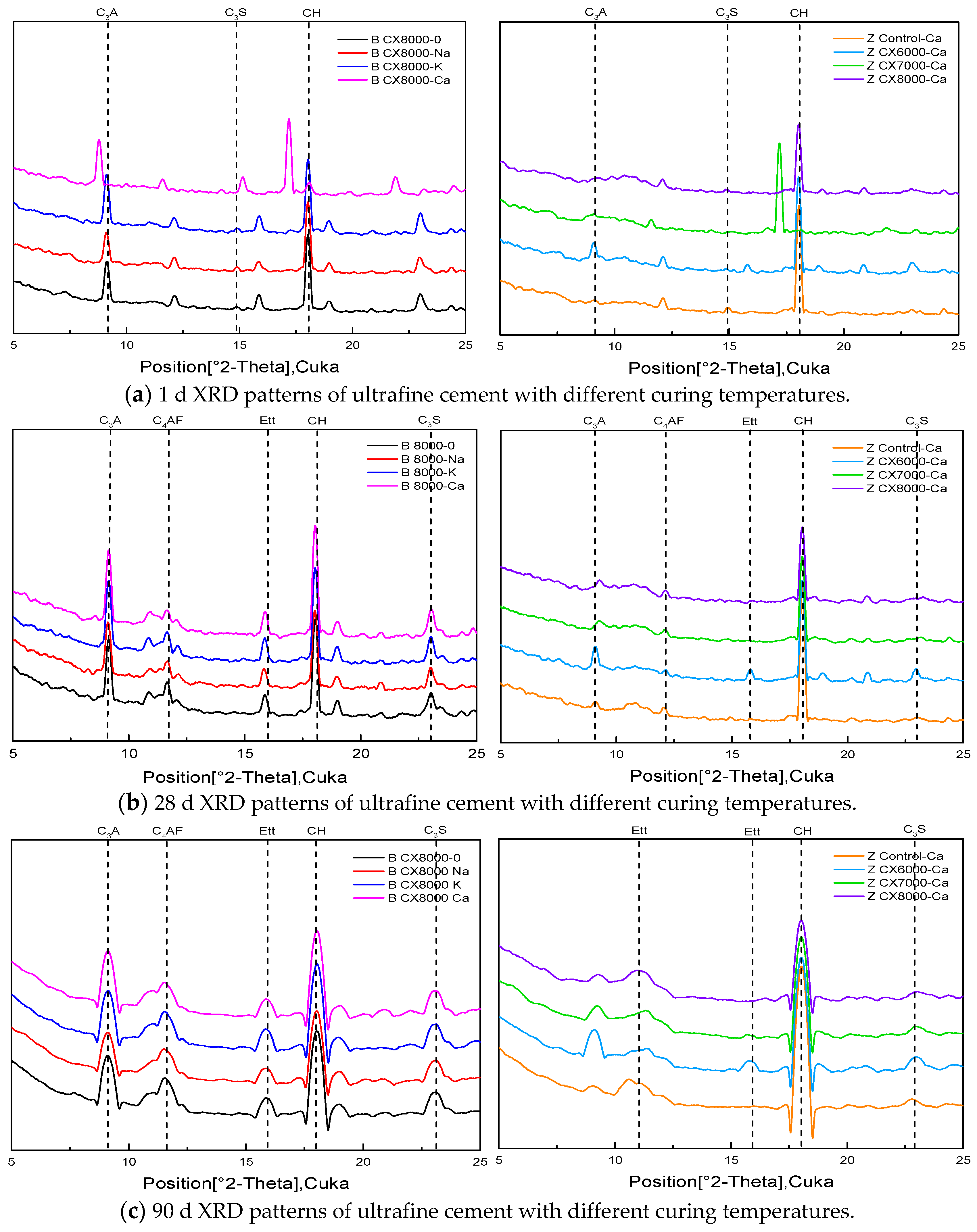

- X-ray diffraction: XRD was conducted using PANalytical X’Pert PRO (PANalytical, Almelo, Netherlands) using a Cu Kα radiation nickel (PANalytical, Almelo, Netherlands) foil filter. Dried cement paste was placed on a flat plate sample geometry. A fixed divergence slit of 1/16 degree was chosen to limit beam overflow on the samples at small angles of 2θ. The X’Celerator high-speed linear detector was used for the XRD experiment, and scans ranged from 5 to 70 degrees [27,35].

3. Results and Discussions

3.1. Compressive Strength

3.2. Water Absorption

3.3. Thermal Analysis

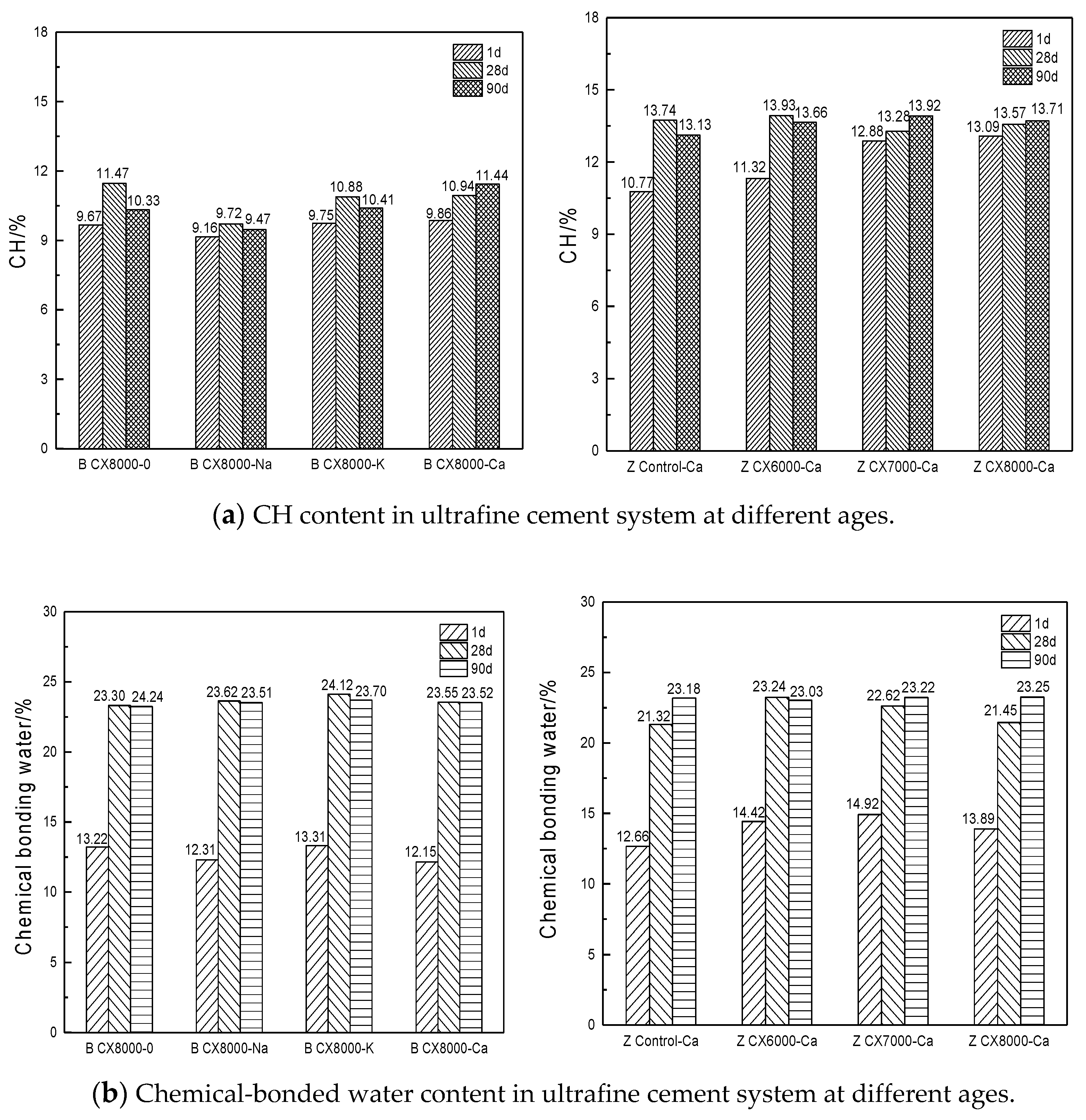

3.4. Thermogravimetric Analysis

3.5. X-ray Diffraction

4. Conclusions

- Under the standard curing condition, ultrafine cement can reach high strength in 24 h without adding an early strength agent, and the CX8000 ultrafine cement can reach 55.94 MPa, which is 118% higher than the reference cement. Adding 1% Ca(HCOO)2 can effectively reduce the water absorption rate of ultrafine cement.

- The hydration heat test results showed that with the decrease of cement particle size, the early hydration speed was accelerated, and the hydration process was significantly accelerated compared with the reference cement. The maximum hydration heat release of ultrafine cement in 72 h was 262.55 J/g, which was 12% higher than that of reference cement.

- The results of thermogravimetric analysis and XRD analysis showed that the hydration products of ultrafine cement paste were the same as those of the reference cement. Under steam curing conditions, the CH content of ultrafine cement could reach 13.09% in 1 day, which was 22% higher than that of reference cement and 33% higher than that of ultrafine cement under standard curing conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, D.; Shi, X.; Zhong, X.; Zhao, H.; Pei, C.; Zhu, T.; Zhang, F.; Shao, M.; Huo, G. Properties and plugging behaviors of smectite-superfine cement dispersion using as water shutoff in heavy oil reservoir. Appl. Clay Sci. 2017, 147, 160–167. [Google Scholar] [CrossRef]

- Akbulut, S.; Sehhatigdiri, A.; Eroglu, H.; Çelik, S. A research on the radiation shielding effects of clay, silica fume and cement samples. Radiat. Phys. Chem. 2015, 117, 88–92. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Ren, Q.; Guo, M.; Wang, Q.; Yang, Y.; Zhao, Q.; Zhang, L. Study and application of super-fine cement plugging slurry. Petrochem. Ind. Appl. 2020, 39, 24–27. [Google Scholar]

- Kang, R.X.; A, X.Q.; Xing, Z.; Feng, S. Analysis of Blocking Construction of Se 4-9 Well in Sebei Gas Field. Qinghai Shiyou 2009, 27, 69–72. [Google Scholar]

- Li, H.; Liu, C.; Zhang, J.; Zhang, Y.; Xia, Z.; Yu, J.; Pu, L. Application of old well plugging to the construction of underground gas storage in the eastern Sichuan Basin. Nat. Gas Ind. 2013, 33, 63–67. [Google Scholar]

- Ba, M.F.; Qian, C.; Guo, X.J. Effects of stem curing on strength and pore structure of concrete with low water/binder ratio. Constr. Build. Mater. 2011, 25, 123–128. [Google Scholar] [CrossRef]

- Li, W.; Shaikh, F.U.A.; Wang, L.; Lu, Y.; Wang, B.; Jiang, C.; Su, Y. Experimental study on shear property and rheological characteristic of superfine cement grouts with nano-SiO2 addition. Constr. Build. Mater. 2019, 228, 117046. [Google Scholar] [CrossRef]

- Schulze, M. Recent investigation on the groutability of microcement-suspensions. In Grouting in Rock and Concrete; AA Balkema: Rotterdam, The Netherlands, 1993; pp. 107–116. [Google Scholar]

- Huang, Z.C.; Chen, M.X.; Chen, X.R. A developed technology for wet-ground finecement slurry with its applications. Cem. Concr. Res. 2003, 33, 729–732. [Google Scholar] [CrossRef]

- He, Z.; Long, G.; Xie, Y.; Liu, J. Surface Layer Degradation Effect of Steam-Cured Concrete. J. Build. Mater. 2014, 17, 994–1008. [Google Scholar]

- Xu, J.; Zhang, B. Ultrafine cement. Guangdong Build. Mater. 1998, 9, 32–35. [Google Scholar]

- Wei, R.; Zeng, Y. The relationship between fineness and strength of different types of cement. Cem. Eng. 1998, 4, 5. [Google Scholar]

- Fan, L. Research on the Hydration Characteristics of Superfine Cement and the Preparation Technology of High Early Strength Concrete; Central South University: Changsha, China, 2008. [Google Scholar]

- Kaufmann, J.; Winnefeld, F.; Hesselbarth, D. Effect of the addition of ultrafine cement and short fiber reinforcement on shrinkage, rheological and mechanical properties of Portland cement pastes. Cem. Concr. Compos. 2004, 26, 541–549. [Google Scholar] [CrossRef]

- Sarkar, S.L.; Wheeler, J. Important properties of an ultrafine cement—Part I. Cem. Concr. Res. 2001, 31, 119–123. [Google Scholar] [CrossRef]

- Gil, N.P. Grouting as a repair and strengthening technique. Constr. Repair. 1996, 10, 24–26. [Google Scholar]

- Jiang, M.; Lv, X. Research and Application Progresses of Concrete Early Strength Agent. Bull. Chin. Ceram. Soc. 2014, 33, 2527–2533. [Google Scholar]

- Mollamahmutoglu, M.; Avci, E. Strength and permeability of boric acid-tempered ultrafine cement grouted sand. Constr. Build. Mater. 2021, 284, 122812. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, Y.; Ji, Y.; Liu, G.; Liu, C.; She, W.; Sun, W. Reducing environmental impacts and carbon emissions: Study of effects of superfine cement particles on blended cement containing high volume mineral admixtures. J. Clean. Prod. 2018, 196, 358–369. [Google Scholar] [CrossRef]

- Wu, P.; Lv, X.; Liang, Z.; Zhu, C.; Chen, Y. The Mechanism and Application of Concrete Hardening Accelerator. Metal Mine 2014, 12, 20–25. [Google Scholar]

- Zhang, F.; Bai, Y.; Cai, Y.; Du, J.; Ning, F. Research status of low temperature early strength agents for concrete. Mater. Rep. 2017, 11, 106–113. [Google Scholar]

- Zhang, M.S. Preparation and mechanism analysis of high-efficiency early strength agent. Adv. Master Res. 2012, 535–537, 2483. [Google Scholar] [CrossRef]

- Xu, F.; Chen, R.; Gu, K. The application of formic acid calcium early strength agent in dry powder mortar. Wall Mater Innov. Energy Sav. Build. 2008, 2, 56. (In Chinese) [Google Scholar]

- Ma, K.; Long, G.; Xie, Y. A real case of steam-cured concrete trac slab premature deterioration due to ASR and DEF. Case Stud. Constr. Mater. 2017, 6, 63–71. [Google Scholar]

- GB/T 17671-1999. Method of Testing Cement-Determination of Strength; China Quality and Standards Publishing & Media Co., Ltd.: Beijing, China, 1999. [Google Scholar]

- DL/T 5148-2012. Technical Specification for Cement Grouting Construction of Hydraulic Structures; China Electric Power Press: Beijing, China, 2012. [Google Scholar]

- Naber, C.; Stegmeyer, S.; Jansen, D.; Goetz-Neunhoeffer, F.; Neubauer, J. The PONKCS method applied for time resolved XRD quantification of supplementary cementitious material reactivity in hydrating mixtures with ordinary Portland cement. Constr. Build. Mater. 2019, 214, 449–457. [Google Scholar] [CrossRef]

- Soin, A.V.; Catalan, L.J.; Kinrade, S.D. A combined QXRD/TG method to quantify the phase composition of hydrated Portland cements. Cem. Concr. Res. 2013, 48, 17–24. [Google Scholar] [CrossRef]

- Vedalakshmi, R.; Raj, A.S.; Srinivasan, S.; Babu, K.G. Quantification of hydrated cement products of blended cements in low and medium strength concrete using TG and DTA technique. Thermochim. Acta 2003, 407, 49–60. [Google Scholar] [CrossRef]

- Slanika, T.; Madej, T.; Jakubekov, D. DTA contribution to study of hydration fly ash–Portland cement pastes. Thermochim. Acta 1985, 93, 601. [Google Scholar] [CrossRef]

- Monzo, J.; Paya, J.; Borrachero, M.V.; Peris-Mora, E.; Velazquez, S. Fluid catalytic cracking residue (FC3R) as a new pozzolanic material: Thermal analysis monitoring of FC3R/Portland cement reactions. In Proceedings of the Seventh CANMET/ACI International Conference on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, Madras, India, 11 May 2001; Supplementary Volume, p. 241. [Google Scholar]

- Sha, W.; Pereira, G.B. Differential scanning calorimetry study of normal Portland cement paste with 30% fly ash replacement and of the separate fly ash and ground granulated blast furnace slag powders. In Proceedings of the Seventh CANMET/ACI International Conference on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, ACI, Detroit, MI, USA, Madras, India, 11 May 2001; Supplementary Volume, p. 295. [Google Scholar]

- Justnes, H.; Ostnor, T. Pozzolanic, amorphous silica produced from the mineral olivine. In Proceedings of the Seventh CANMET/ACI International ACI Conference on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete-SP-199-44, Detroit, MI, USA, Madras, India, 11 May 2001; Volume 2, p. 769. [Google Scholar]

- Bhatty, J.I.; Dollimire, D.; Gamlen, G.A.; Mangabhai, R.J.; Olmez, H. Estimation of calcium hydrioxide in OPC. Thermochim. Acta 1986, 106, 115. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Palkovic, S.; Bumajdad, A.; Soriano, C.; Büyüköztürk, O. Use of silica fume and natural volcanic ash as a replacement to Portland cement: Micro and pore structural investigation using NMR, XRD, FTIR and X-ray microtomography. Constr. Build. Mater. 2018, 158, 574–590. [Google Scholar] [CrossRef]

| Sample | CX6000 | W/B | S/B | Na2SiO3 | KAl(SO4)2 | Ca(HCOO)2 |

|---|---|---|---|---|---|---|

| 0. Control | 100 | 0.3 | 1.64 | -- | -- | -- |

| 1.Na-1% | 100 | 0.3 | 1.64 | 1.0 | -- | -- |

| 2.K-1% | 100 | 0.3 | 1.64 | -- | 1.0 | -- |

| 3.Ca-1% | 100 | 0.3 | 1.64 | -- | -- | 1.0 |

| Ca2+ | Mg2+ | Na+ | K+ | Al3+ | Fe3+/Fe2+ | Cl− | SO42− | |

|---|---|---|---|---|---|---|---|---|

| Concentration mg/L | 2.1 | 0.9 | 4.0 | 0.5 | <0.005 | <0.05 | 0.4 | 26.7 |

| Cement | Na3SiO3 | KAl(SO4)2 | Ca(HCOO)2 | W/B | |

|---|---|---|---|---|---|

| 0.CX8000 | 100 | —— | —— | —— | 0.3 |

| 1.CX8000 Na | 100 | 1.0 | —— | —— | 0.3 |

| 2.CX8000 K | 100 | —— | 1.0 | —— | 0.3 |

| 3.CX8000 Ca | 100 | —— | —— | 1.0 | 0.3 |

| 4.C Ca | 100 | —— | —— | 1.0 | 0.3 |

| 5.CX6000 Ca | 100 | —— | —— | 1.0 | 0.3 |

| 6.CX7000 Ca | 100 | —— | —— | 1.0 | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Wang, T.; Li, H.; Wu, S. Exploring the Influence Factors of Early Hydration of Ultrafine Cement. Materials 2021, 14, 5677. https://doi.org/10.3390/ma14195677

Shi Y, Wang T, Li H, Wu S. Exploring the Influence Factors of Early Hydration of Ultrafine Cement. Materials. 2021; 14(19):5677. https://doi.org/10.3390/ma14195677

Chicago/Turabian StyleShi, Yi, Tao Wang, Haiyan Li, and Shaoliang Wu. 2021. "Exploring the Influence Factors of Early Hydration of Ultrafine Cement" Materials 14, no. 19: 5677. https://doi.org/10.3390/ma14195677

APA StyleShi, Y., Wang, T., Li, H., & Wu, S. (2021). Exploring the Influence Factors of Early Hydration of Ultrafine Cement. Materials, 14(19), 5677. https://doi.org/10.3390/ma14195677