Effect of Service Environmental Parameters on Electrochemical Corrosion Behavior of L80 Casing Steel

Abstract

:1. Introduction

2. Experimental

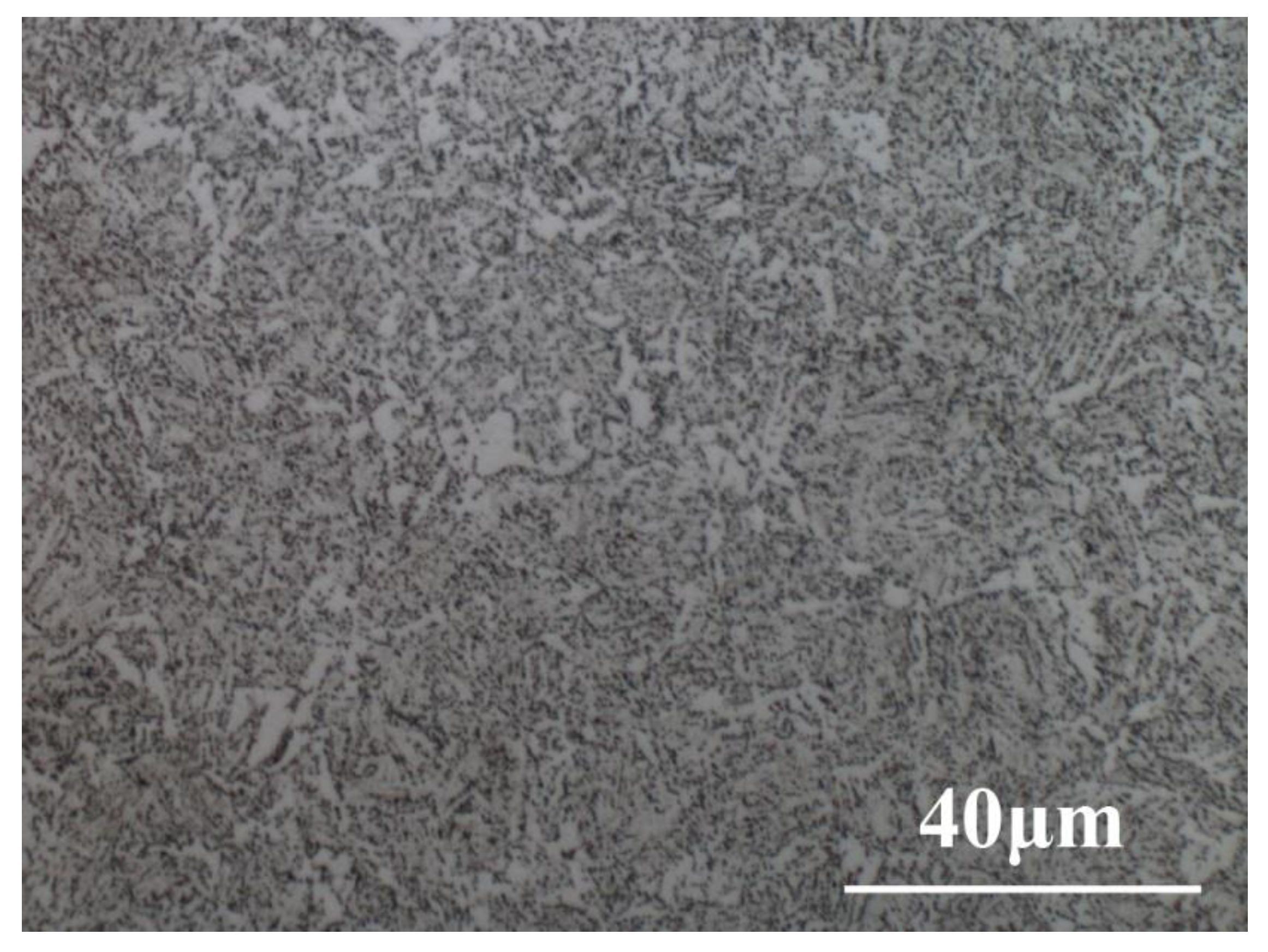

2.1. Material and Medium

2.2. Potentiodynamic Polarization Measurement

2.3. Immersion Test

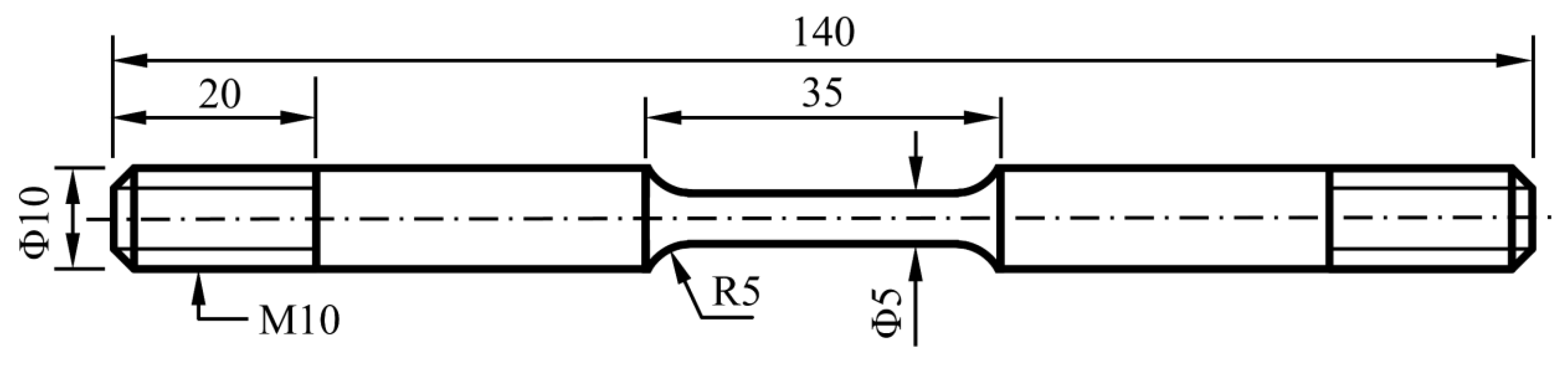

2.4. Slow Strain Rate Test (SSRT) after Immersion

3. Results

3.1. Corrosion Behavior of L80 Steel without Preloading Stress

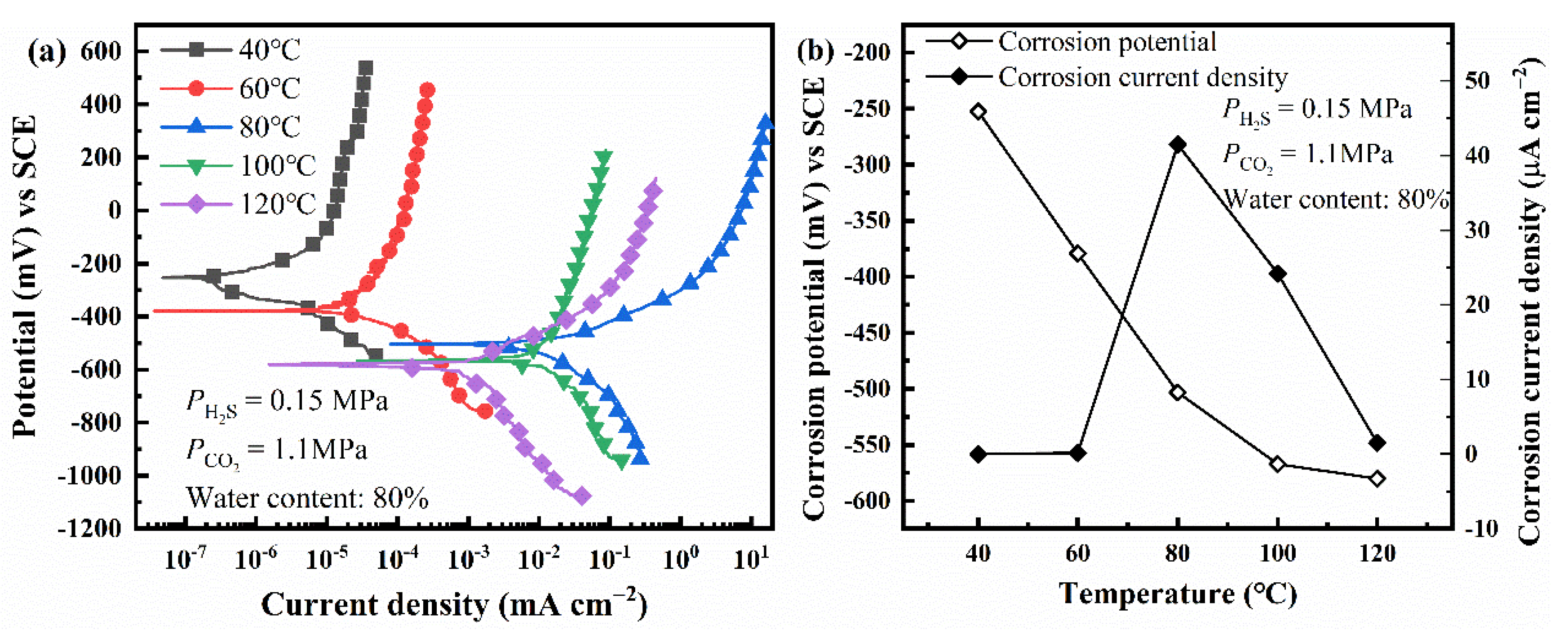

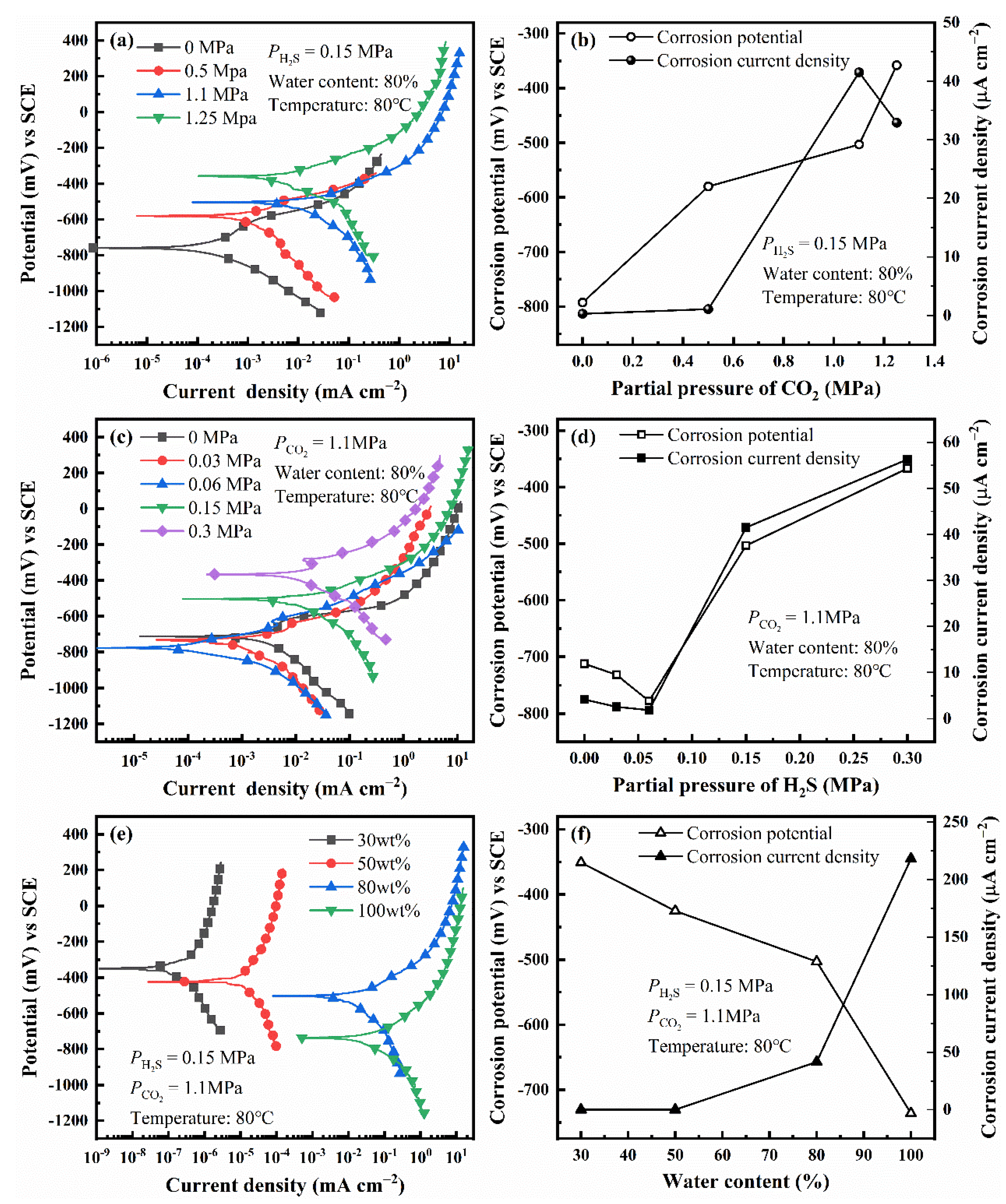

3.1.1. Effect of Environmental Factors on the Electrochemical Behavior of L80 Steel without Preloading Stress

3.1.2. SCC Susceptibility of L80 Steel without Preloading Stress after Immersion

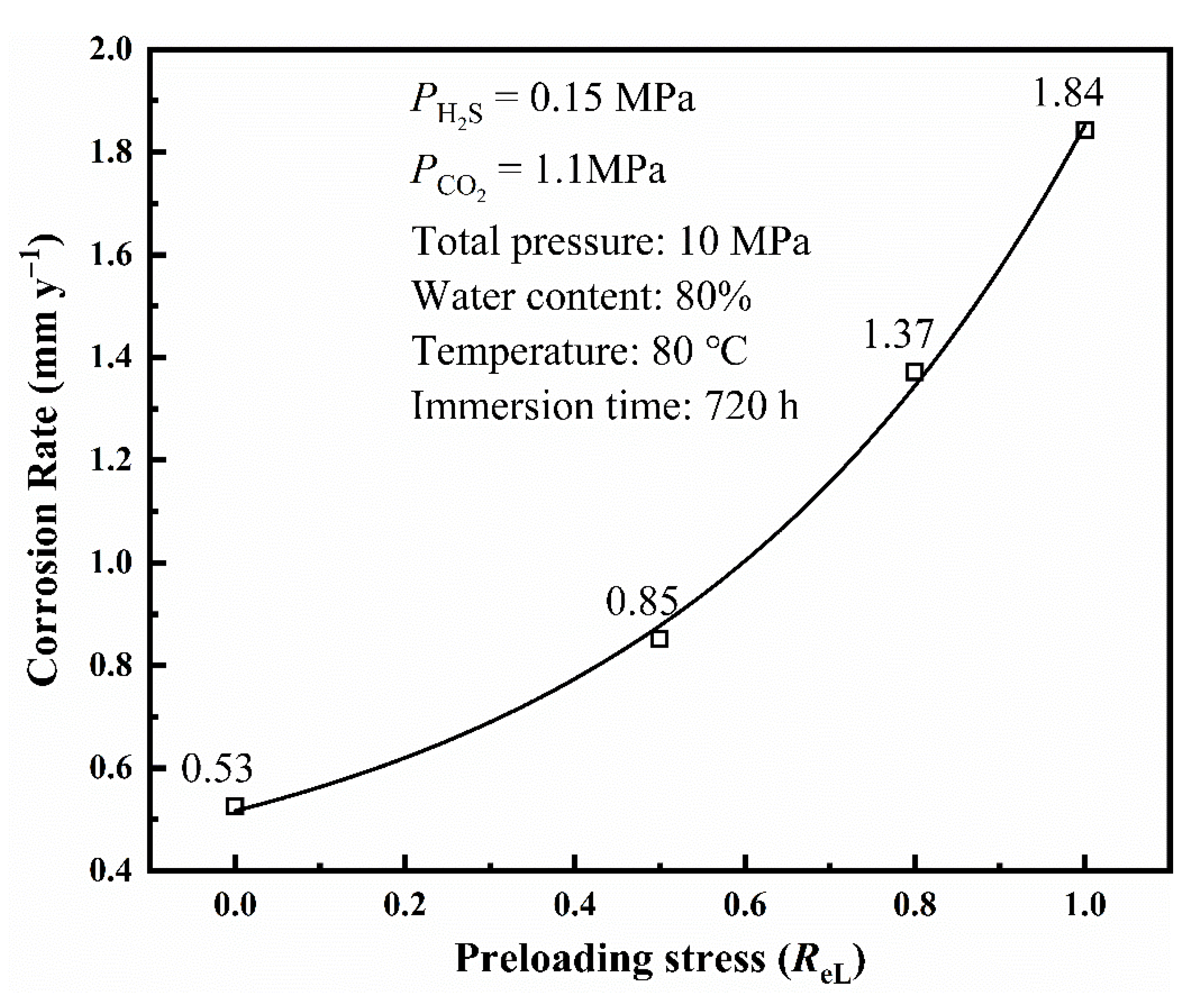

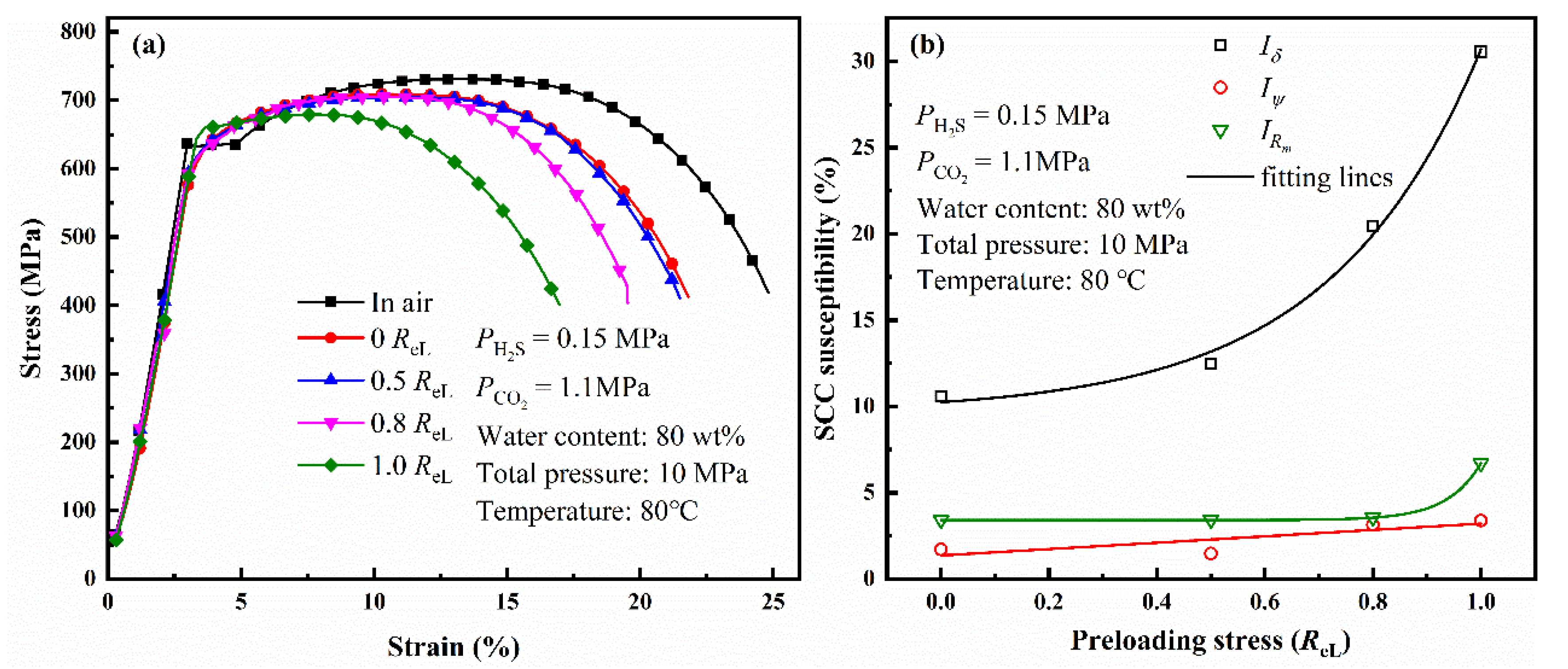

3.2. Corrosion Behavior of L80 Steel with Preloading Stress

4. Discussion

5. Conclusions

- (1)

- The affects the corrosion behavior of steel in two aspects: Keeping the pH of the medium at a relatively low value and promoting form insoluble carbonate precipitation. The influence of on the corrosion rate and SCC susceptibility has an inflection point of approximately 1.1 MPa. The corrosion rate and SCC susceptibility reached the maximum when the is about 1.1 MPa;

- (2)

- The also affects the corrosion behavior of steel from two aspects: Inhibiting the hydrolysis of CO2 and promoting formation of FeS precipitation. The corrosion rate and SCC susceptibility have a positive correlation to ;

- (3)

- Corrosion rate has a linear relation to water content, and SCC susceptibility has a positive correlation to water content. Low water content can decrease the electrical conductivity of the corrosion medium and then restrict the corrosion of L80 steel;

- (4)

- The corrosion rate and SCC susceptibility of L80 steel have a positive correlation to preloading stress. SCC susceptibility of L80 steel can be explained by the local additional potential model. It means that preloading stress can promote the occurrence of defects in the surface of L80 steel. These defects can facilitate local corrosion, accelerate the diffusion of hydrogen into steel, and then increase SCC susceptibility.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, X.; Zhang, D.; Lu, Y.; Fan, Z.; Du, L.; Yuan, G.; Qiu, C.; Kang, J. CO2 Corrosion Behavior of High-Strength and Toughness V140 Steel for Oil Country Tubular Goods. J. Mater. Eng. Perform. 2020, 29, 8451–8460. [Google Scholar] [CrossRef]

- Sun, C.; Zeng, H.; Luo, J.-L. Unraveling the Effects of CO2 and H2S on the Corrosion Behavior of Electroless Ni-P Coating in CO2/H2S/Cl– Environments at High Temperature and High Pressure. Corros. Sci. 2019, 148, 317–330. [Google Scholar] [CrossRef]

- Abayarathna, D.; Naraghi, A.R.; Wang, S. The Effect of Surface Films on Corrosion of Carbon Steel in a CO2-H2S-H2O System; NACE International: Houston, TX, USA, 2005. [Google Scholar]

- Cui, H.; Mei, P.; Liu, Z.; Lu, L. Effect of CO2 Partial Pressure on the Stress Corrosion Cracking Behavior of N80 Tubing Steel in the Annulus Environment of CO2 Injection Well. Chin. J. Eng. 2020, 42, 1182–1189. [Google Scholar]

- Zhang, C. Study of the Corrosion Inhibition Mechanism and the Synergistic Corrosion Inhibition Effect of Inhibitors CO2/H2S System. Master’s Thesis, Beijing University of Chemical Technology, Beijing, China, 2018. [Google Scholar]

- Liu, Z.Y.; Wang, X.Z.; Liu, R.K.; Du, C.W.; Li, X.G. Electrochemical and Sulfide Stress Corrosion Cracking Behaviors of Tubing Steels in a H2S/CO2 Annular Environment. J. Mater. Eng. Perform. 2014, 23, 1279–1287. [Google Scholar] [CrossRef] [Green Version]

- Parkins, R.N.; Zhou, S. The Stress Corrosion Cracking of C-Mn Steel in CO2-HCO3−-CO32− Solutions. I: Stress Corrosion Data. Corros. Sci. 1997, 39, 159–173. [Google Scholar] [CrossRef]

- Zhou, C.; Zheng, S.; Chen, C.; Lu, G. The Effect of the Partial Pressure of H2S on the Permeation of Hydrogen in Low Carbon Pipeline Steel. Corros. Sci. 2013, 67, 184–192. [Google Scholar] [CrossRef]

- Monnot, M.; Nogueira, R.P.; Roche, V.; Berthomé, G.; Chauveau, E.; Estevez, R.; Mantel, M. Sulfide Stress Corrosion Study of a Super Martensitic Stainless Steel in H2S Sour Environments: Metallic Sulfides Formation and Hydrogen Embrittlement. Appl. Surf. Sci. 2017, 394, 132–141. [Google Scholar] [CrossRef]

- Zhou, C.; Huang, Q.; Guo, Q.; Zheng, J.; Chen, X.; Zhu, J.; Zhang, L. Sulphide Stress Cracking Behaviour of the Dissimilar Metal Welded Joint of X60 Pipeline Steel and Inconel 625 Alloy. Corros. Sci. 2016, 110, 242–252. [Google Scholar] [CrossRef]

- Jia, Y. Study on Stress Corrosion Sensitivity of Cold Deformed 316L Austenitic Stainless Steel in H2S Environment; China University of Petroleum: Beijing, China, 2019. [Google Scholar]

- Wang, S. Multiphysical Simulation of CO2 Enhanced Oil Recovery in Unconventional Reservoirs: From Fundamental Physics to Simulator Development; Colorado School of Mines: Golden, CO, USA, 2019. [Google Scholar]

- Liu, Q.; Li, Z.; Liu, Z.Y.; Li, X.G.; Wang, S.Q. Effects of H2S/HS− on Stress Corrosion Cracking Behavior of X100 Pipeline Steel Under Simulated Sulfate-Reducing Bacteria Metabolite Conditions. J. Mater. Eng. Perform. 2017, 26, 2763–2775. [Google Scholar] [CrossRef]

- Vyboishchik, M.A.; Ioffe, A.V.; Zyryanov, A.O. Failure of Pump–Compressor Pipes in Highly Aggressive Oil-Field Media. Russ. Metall. 2019, 2019, 1067–1073. [Google Scholar] [CrossRef]

- Khalaf, A.M.; Seibi, A.C. Failure Analysis of Lube Oil Feed Tube of a Gas Turbine Operating in Oil Fields. Eng. Fail. Anal. 2011, 18, 1341–1350. [Google Scholar] [CrossRef]

- De Assis Severiano, J.; Silva, A.S.; Sussushi, E.M.; da Silva Sant’Anna, M.V.; da Cunha, M.A.; Bergmann, C.P.; Griza, S. Corrosion Damages of Flow Regulation Valves for Water Injection in Oil Fields. Eng. Fail. Anal. 2019, 96, 362–373. [Google Scholar] [CrossRef]

- Liu, R.; Li, J.; Liu, Z.; Du, C.; Dong, C.; Li, X. Effect of PH and H2S Concentration on Sulfide Stress Corrosion Cracking (SSCC) of API 2205 Duplex Stainless Steel. IJMR 2015, 106, 608–613. [Google Scholar] [CrossRef]

- Zhao, T.; Liu, Z.; Du, C.; Hu, J.; Li, X. A Modelling Study for Predicting Life of Downhole Tubes Considering Service Environmental Parameters and Stress. Materials 2016, 9, 741. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yucheng, L.; Yinlong, Z.; Jianmei, Y.; Mengjing, Y.; Junzhong, X. Research on Corrosion Perforation on Pipeline by Media of High Salinity Acidic Oil–Water Mixture. Eng. Fail. Anal. 2013, 34, 35–40. [Google Scholar] [CrossRef]

- Bouazaze, H.; Huet, F.; Nogueira, R.P. A New Approach for Monitoring Corrosion and Flow Characteristics in Oil/Brine Mixtures. Electrochim. Acta 2005, 50, 2081–2090. [Google Scholar] [CrossRef]

- Liu, R. Stress Corrosion Cracking Behaviour and Prevention of High Strength Tubing Steels in Typical H2S/CO2 Annulus Environments. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2015. [Google Scholar]

- Hong, C.; Estefen, S.F.; Wang, Y.; Lourenço, M.I. Mixed-Integer Nonlinear Programming Model for Layout Design of Subsea Satellite Well System in Deep Water Oil Field. Autom. Constr. 2021, 123, 103524. [Google Scholar] [CrossRef]

- NACE International Standard: TM0177-2005 Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking in H2S Environments; NACE International: Houston, TX, USA, 2005.

- Li, N.; Ding, N.; Liu, L.; Hu, S.; Sun, S.; Qu, S.; Wu, C.-M.L. Stress Corrosion Cracking of an Electrohydraulic Oil Pipe. J. Fail. Anal. Prev. 2019, 19, 29–35. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, W.; Shu, Z.; Zhao, Q.; Han, L. Failure Analysis of Casing Dropping in Shale Oil Well During Large Scale Volume Fracturing. Eng. Fail. Anal. 2020, 118, 104849. [Google Scholar] [CrossRef]

- Tian, J.; Wang, L.; Sun, W.; Yang, Y.; Liu, Z.; Wang, G.; Zhao, L.; Zhou, Y.; Liu, G. Failure Analysis of Steam Jet Pump at Top of Crude Oil Vacuum Distillation Tower. Eng. Fail. Anal. 2019, 103, 9–19. [Google Scholar] [CrossRef]

- Liu, H.; Gu, T.; Zhang, G.; Wang, W.; Dong, S.; Cheng, Y.; Liu, H. Corrosion Inhibition of Carbon Steel in CO2-Containing Oilfield Produced Water in the Presence of Iron-Oxidizing Bacteria and Inhibitors. Corros. Sci. 2016, 105, 149–160. [Google Scholar] [CrossRef]

- Zhang, G.A.; Zeng, Y.; Guo, X.P.; Jiang, F.; Shi, D.Y.; Chen, Z.Y. Electrochemical Corrosion Behavior of Carbon Steel under Dynamic High Pressure H2S/CO2 Environment. Corros. Sci. 2012, 65, 37–47. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard Test Method for Tension Testing of Metallic Materials. In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Wu, W.; Hao, W.; Liu, Z.; Li, X.; Du, C. Comparative Study of The Stress Corrosion Behavior of a Multiuse Bainite Steel in the Simulated Tropical Marine Atmosphere and Seawater Environments. Constr. Build. Mater. 2020, 239, 117903. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Hao, W.K.; Wu, W.; Luo, H.; Li, X.G. Fundamental Investigation of Stress Corrosion Cracking of E690 Steel in Simulated Marine Thin Electrolyte Layer. Corros. Sci. 2019, 148, 388–396. [Google Scholar] [CrossRef]

- Wu, W.; Cheng, X.; Zhao, J.; Li, X. Benefit of The Corrosion Product Film Formed on a New Weathering Steel Containing 3% Nickel under Marine Atmosphere in Maldives. Corros. Sci. 2020, 165, 108416. [Google Scholar] [CrossRef]

- Zheng, Y.; Ning, J.; Brown, B.; Nešić, S. Electrochemical Model of Mild Steel Corrosion in a Mixed H2S/CO2 Aqueous Environment in the Absence of Protective Corrosion Product Layers. Corrosion 2014, 71, 316–325. [Google Scholar] [CrossRef]

- Barker, R.; Burkle, D.; Charpentier, T.; Thompson, H.; Neville, A. A Review of Iron Carbonate (FeCO3) Formation in the Oil and Gas Industry. Corros. Sci. 2018, 142, 312–341. [Google Scholar] [CrossRef]

- Cui, G.; Yang, Z.; Liu, J.; Li, Z. A Comprehensive Review of Metal Corrosion in a Supercritical CO2 Environment. Int. J. Greenh. Gas Control 2019, 90, 102814. [Google Scholar] [CrossRef]

- Li, Z.; Xu, X.; Li, Y.; Liu, Z. Effect of Imidazoline Inhibitor on Stress Corrosion Cracking of P110 Steel in Simulated Annulus Environments of CO2 Injection Well. J. Electroanal. Chem. 2021, 886, 115105. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z.; Ke, L.; Huang, L.; Du, C.; Li, X. Stress Corrosion Cracking Behavior of TP95S Tube Steel in an Acidic Gas Field Environment. Int. J. Electrochem. Sci. 2016, 5021–5034. [Google Scholar] [CrossRef]

- Cao, C. Principles of Electrochemistry of Corrosion, 3rd ed.; Chemical Industry Press: Beijing, China, 2008. [Google Scholar]

- Chen, Z.; Li, L.; Zhang, G.; Qiu, Y.; Guo, X. Inhibition Effect of Propargyl Alcohol on the Stress Corrosion Cracking of Super 13Cr Steel in a Completion Fluid. Corros. Sci. 2013, 69, 205–210. [Google Scholar] [CrossRef]

- Haynes, W.M. CRC Handbook of Chemistry and Physics, 94th ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Liu, R.; Yin, G.; Wei, C.; Wang, X.; Ma, F.; Liu, Z.; Du, C.; Li, X. Electrochemical Corrosion Behaviour of P110 Tubing Steel in Annular Environment. Corros. Sci. Prot. Technol. 2013, 25, 450–454. [Google Scholar]

- Zhao, X.; Huang, W.; Li, G.; Feng, Y.; Zhang, J. Effect of CO2/H2S and Applied Stress on Corrosion Behavior of 15Cr Tubing in Oil Field Environment. Metals 2020, 10, 409. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Wu, W.; Li, Q. Under-Deposit Corrosion of Tubing Served for Injection and Production Wells of CO2 Flooding. Eng. Fail. Anal. 2021, 127, 105540. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Li, X.G.; Du, C.W.; Cheng, Y.F. Local Additional Potential Model for Effect of Strain Rate on SCC of Pipeline Steel in an Acidic Soil Solution. Corros. Sci. 2009, 51, 2863–2871. [Google Scholar] [CrossRef]

- Brechtl, J.; Chen, B.; Xie, X.; Ren, Y.; Venable, J.D.; Liaw, P.K.; Zinkle, S.J. Entropy Modeling on Serrated Flows in Carburized Steels. Mater. Sci. Eng. A 2019, 753, 135–145. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhu, L.; Yu, L.; Sun, B.; Cao, Y.; Zhao, Y.; Zhang, Y. The Mechanism for the Serrated Flow Induced by Suzuki Segregation in a Ni Alloy. Mater. Sci. Eng. A 2021, 820, 141575. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.P.; Chen, S.Y.; Xie, X.; Liaw, P.K.; Dahmen, K.A.; Qiao, J.W.; Wang, Y.L. Serration and Noise Behaviors in Materials. Prog. Mater. Sci. 2017, 90, 358–460. [Google Scholar] [CrossRef]

- Song, L.; Liu, Z.; Li, X.; Du, C. Characteristics of Hydrogen Embrittlement in High-PH Stress Corrosion Cracking of X100 Pipeline Steel in Carbonate/Bicarbonate Solution. Constr. Build. Mater. 2020, 263, 120124. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | P | S | Cr | Cu | Fe |

|---|---|---|---|---|---|---|---|---|

| L80 | 0.29 | 0.24 | 1.52 | 0.010 | 0.0033 | <0.10 | 0.028 | Bal. |

| Steel | Yield Strength ReL (MPa) | Tensile Strength Rm (MPa) | Elongation δ0 (%) | Reduction of Area ψ (%) |

|---|---|---|---|---|

| L80 | 633 | 731 | 24.8 | 74.6 |

| Experiment | Water Content (%) | Temperature (°C) | ||

|---|---|---|---|---|

| 1-1 | 0 | 0.15 | 80 | 80 |

| 1-2 | 0.5 | |||

| 1-3 | 1.1 | |||

| 1-4 | 1.25 | |||

| 2-1 | 1.1 | 0 | 80 | 80 |

| 2-2 | 0.03 | |||

| 2-3 | 0.06 | |||

| 2-4 | 0.15 | |||

| 2-5 | 0.3 | |||

| 3-1 | 1.1 | 0.15 | 30 | 80 |

| 3-2 | 50 | |||

| 3-3 | 80 | |||

| 3-4 | 100 |

| Experiment | MPa | MPa | Water Content % | Temperature °C | Preloading Stress (ReL) |

|---|---|---|---|---|---|

| 4-1 | 0.5 | 0.15 | 80 | 80 | 0 |

| 4-2 | 1.1 | ||||

| 4-3 | 1.5 | ||||

| 5-1 | 1.1 | 0.03 | 80 | 80 | 0 |

| 5-2 | 0.15 | ||||

| 5-3 | 0.3 | ||||

| 6-1 | 1.1 | 0.15 | 30 | 80 | 0 |

| 6-2 | 50 | ||||

| 6-3 | 80 | ||||

| 6-4 | 100 | ||||

| 7-1 | 1.1 | 0.15 | 80 | 80 | 0.5 |

| 7-2 | 0.8 | ||||

| 7-3 | 1.0 |

| Parameters | Numerical Value | ||||

|---|---|---|---|---|---|

| (MPa) | 0.5 | 1.1 | 1.5 | ||

| Iδ (%) | 7.58 | 10.60 | 10.40 | ||

| (MPa) | 0.03 | 0.15 | 0.30 | ||

| Iδ (%) | 6.61 | 10.60 | 15.88 | ||

| Water content (%) | 5 | 30 | 50 | 80 | 100 |

| Iδ (%) | 0.36 | 3.42 | 5.93 | 10.60 | 17.73 |

| Parameters | Numerical Value | |||

|---|---|---|---|---|

| Preloading stress (ReL) | 0 | 0.5 | 0.8 | 1.0 |

| Iδ (%) | 10.60 | 12.45 | 20.48 | 30.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Cui, H.; Li, Z.; He, R.; Liu, Z.; Lu, L. Effect of Service Environmental Parameters on Electrochemical Corrosion Behavior of L80 Casing Steel. Materials 2021, 14, 5575. https://doi.org/10.3390/ma14195575

Sun X, Cui H, Li Z, He R, Liu Z, Lu L. Effect of Service Environmental Parameters on Electrochemical Corrosion Behavior of L80 Casing Steel. Materials. 2021; 14(19):5575. https://doi.org/10.3390/ma14195575

Chicago/Turabian StyleSun, Xiaoguang, Huaiyun Cui, Zhong Li, Renyang He, Zhiyong Liu, and Lin Lu. 2021. "Effect of Service Environmental Parameters on Electrochemical Corrosion Behavior of L80 Casing Steel" Materials 14, no. 19: 5575. https://doi.org/10.3390/ma14195575

APA StyleSun, X., Cui, H., Li, Z., He, R., Liu, Z., & Lu, L. (2021). Effect of Service Environmental Parameters on Electrochemical Corrosion Behavior of L80 Casing Steel. Materials, 14(19), 5575. https://doi.org/10.3390/ma14195575