Basalt/Glass Fiber Polypropylene Hybrid Composites: Mechanical Properties at Different Temperatures and under Cyclic Loading and Micromechanical Modelling

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- Polypropylene Moplen HP 500N (Basell Orlen Polyolefins, Płock, Poland).

- Basalt fibers (BCS17-6.4-KV16): nominal cutting length—6.4 mm, nominal diameter—17 μm (Basaltex, Wevelgem, Belgium).

- Glass fibers (Krosglass ER 5001): nominal cutting length—6 mm, nominal diameter —10 µm (Krosglass, Krosno, Poland).

- Coupling agent: anhydride maleic PP SCONA TPPP 9112 GA (MAPP) (Byk, Altana AG, Wesel, Germany).

2.2. Methods of Testing

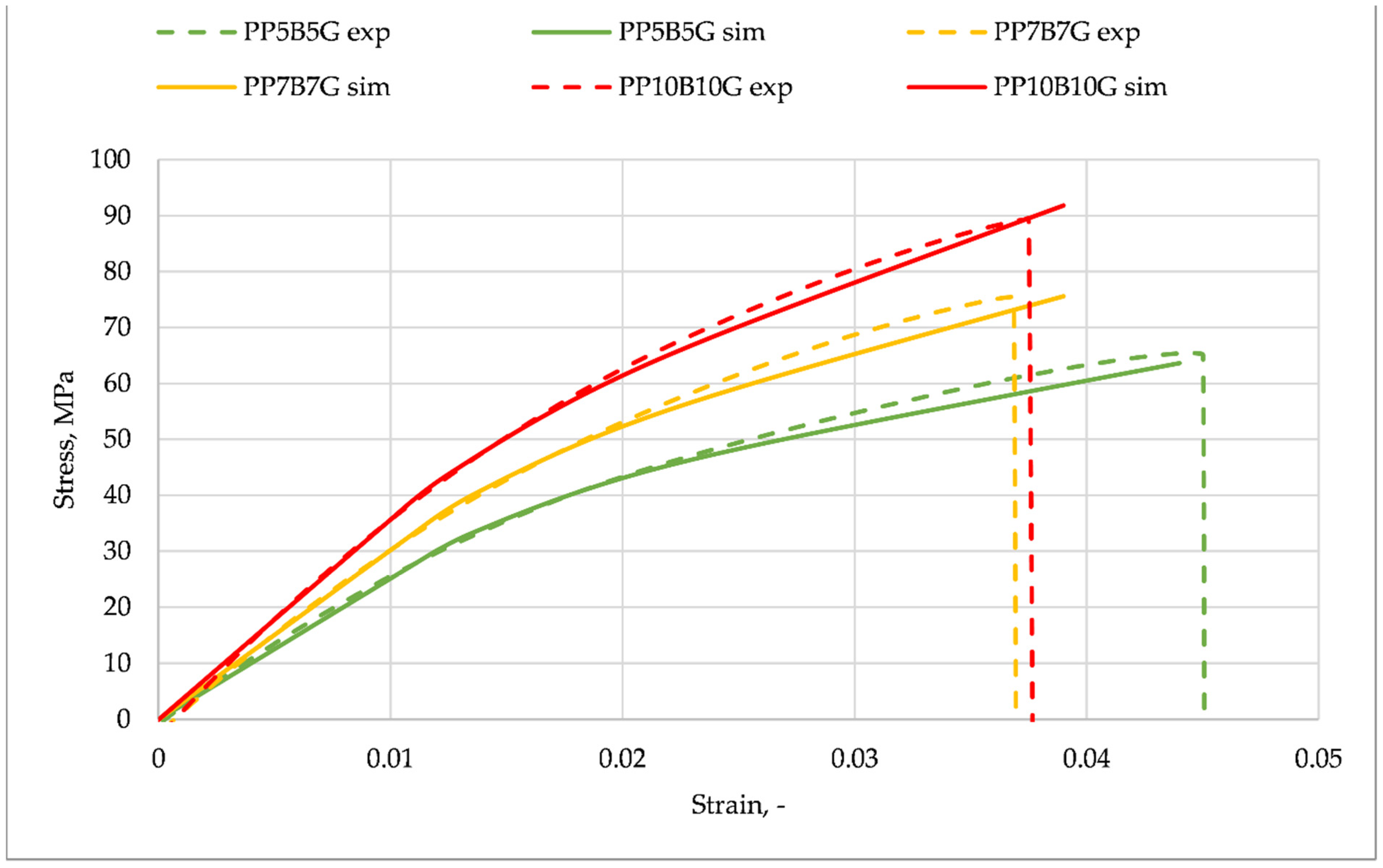

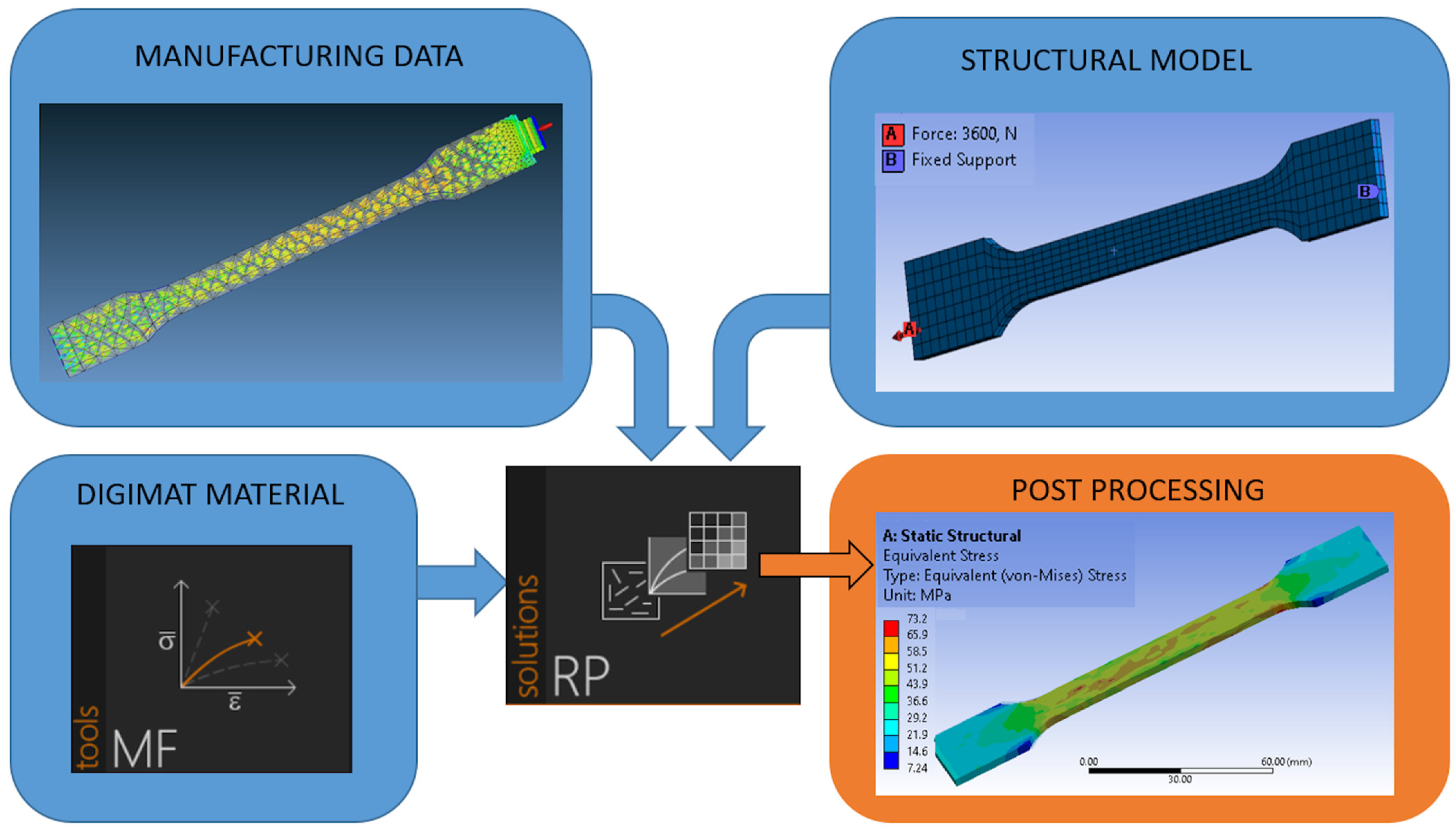

- Moldex3D—simulation of the injection molding process to generate the fiber orientation within the specimen (manufacturing data);

- Digimat-MF—reverse engineering of the material properties to set up material definition (Digimat material);

- Ansys—setup of a FAE model with defined mesh, boundary and load conditions (structural model) and post-processing of the results;

- Digimat-RP—numerical load analysis of the composite specimen by considering the fiber orientation and material data.

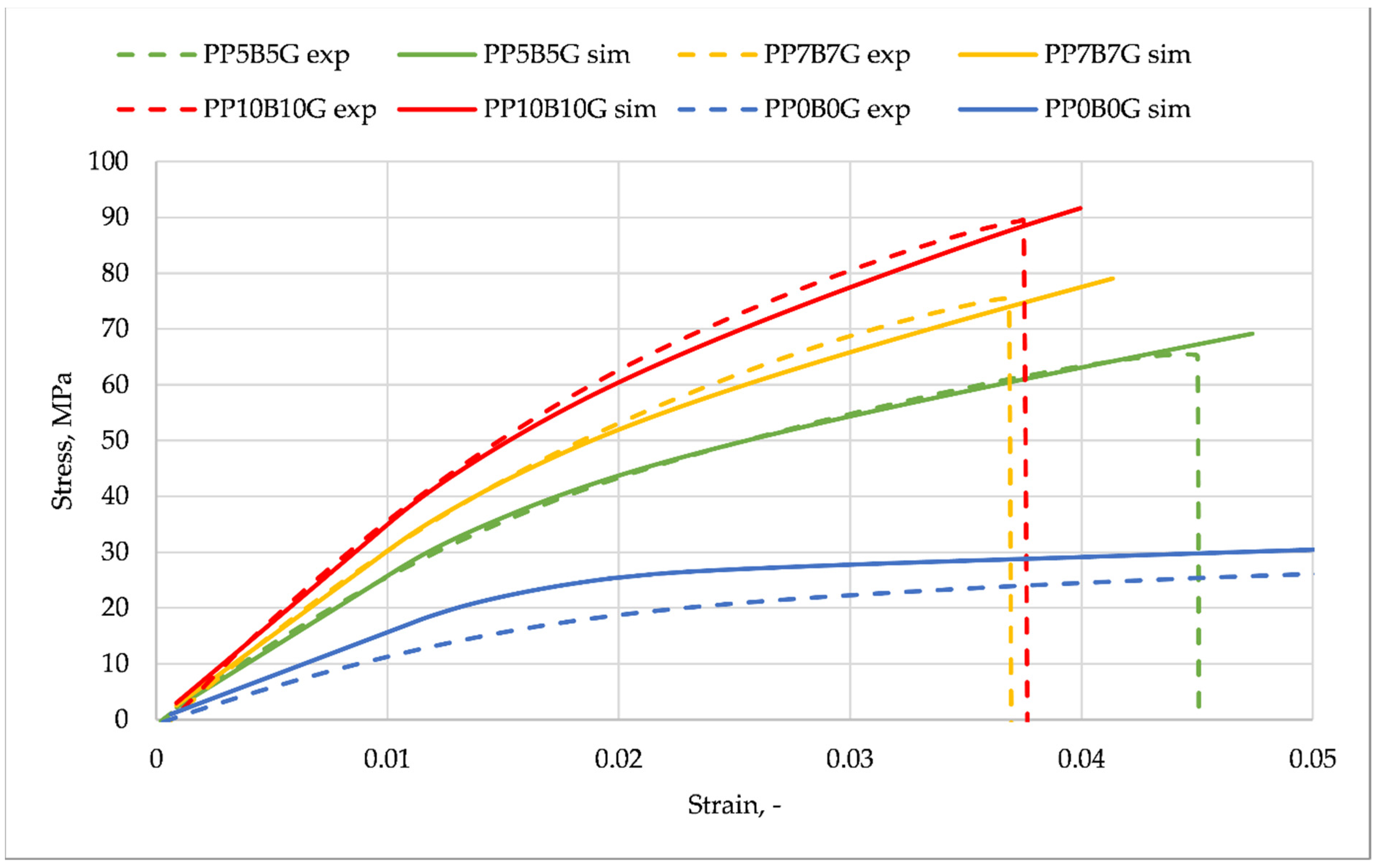

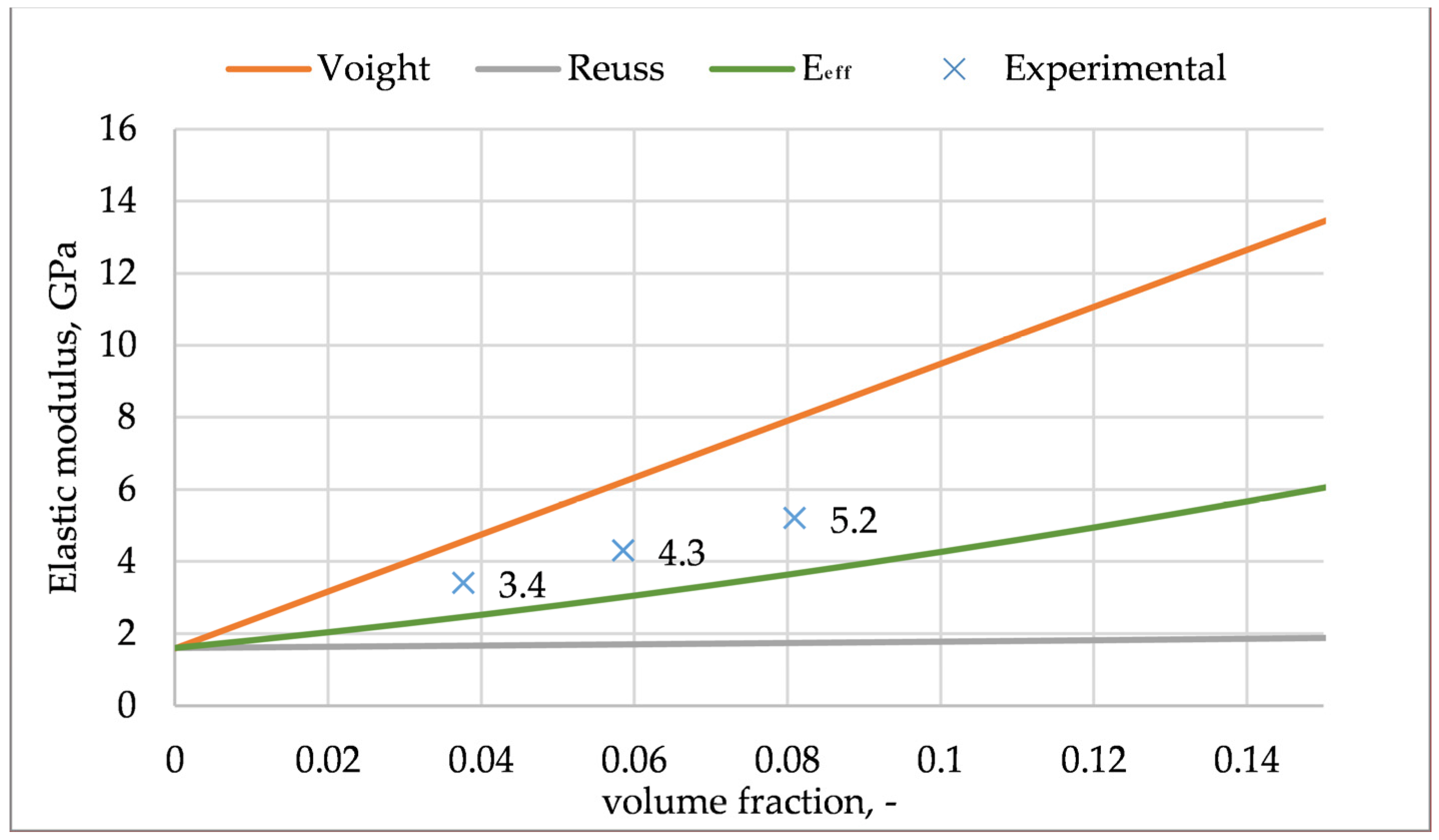

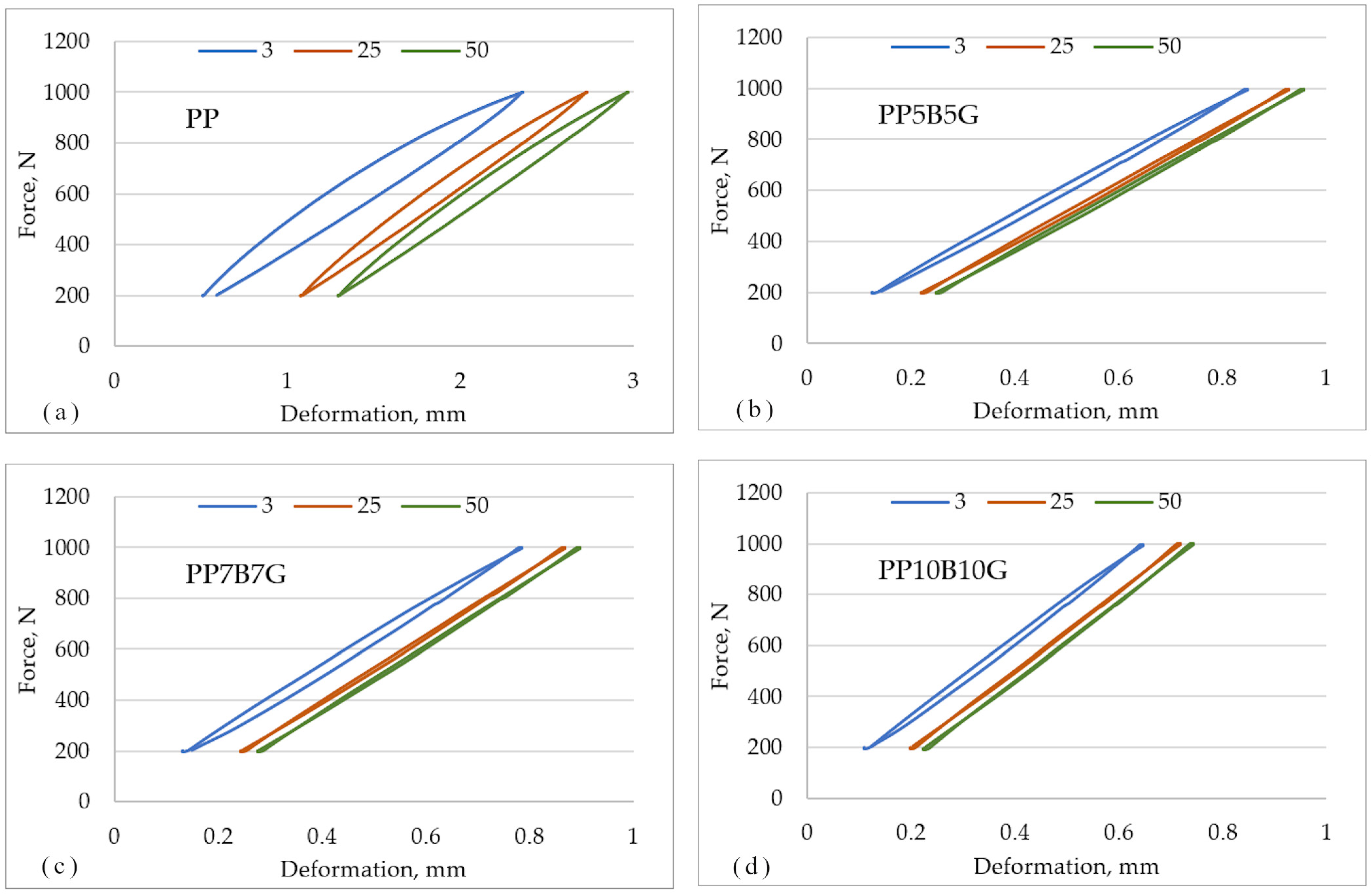

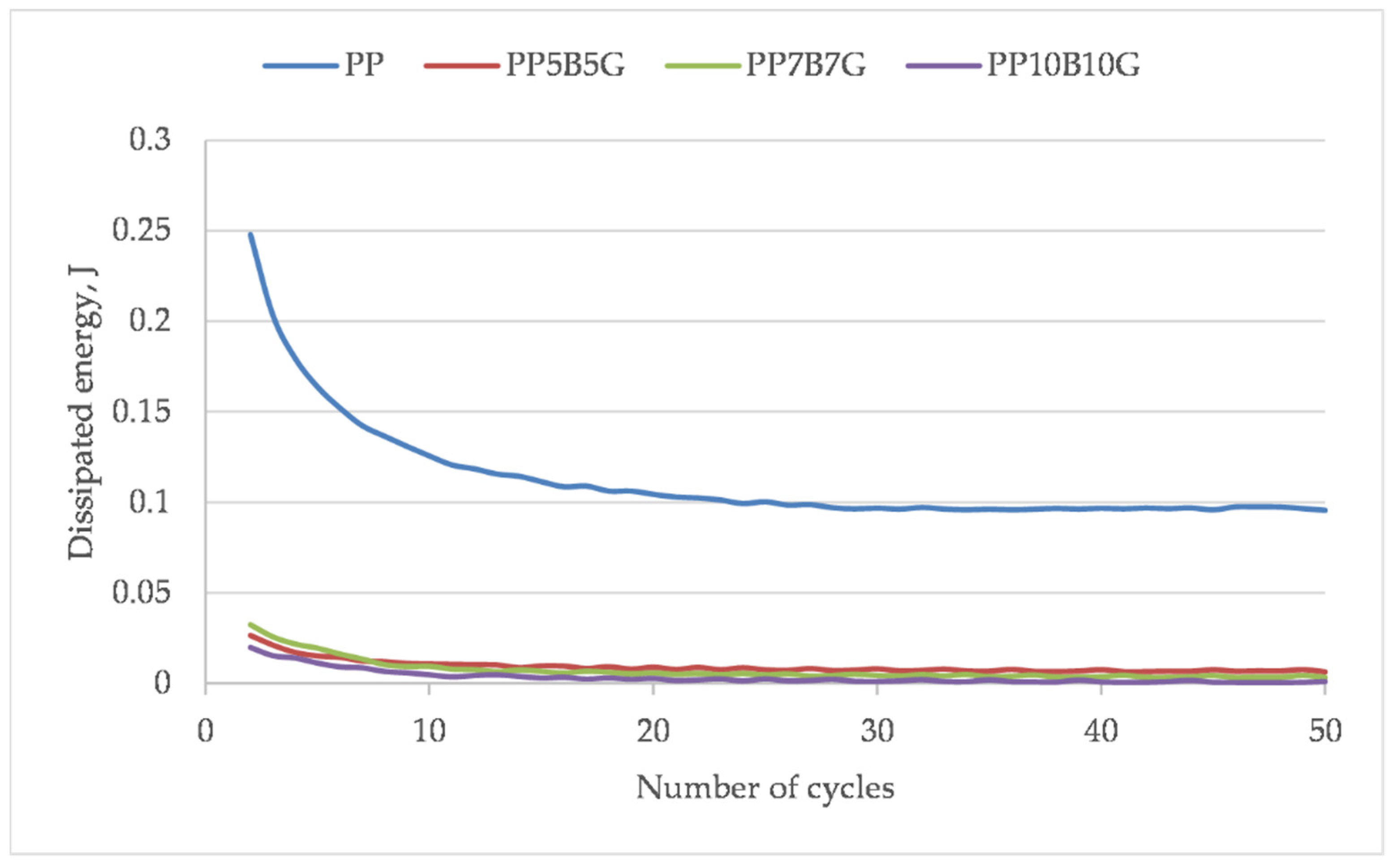

3. Results and Discussion

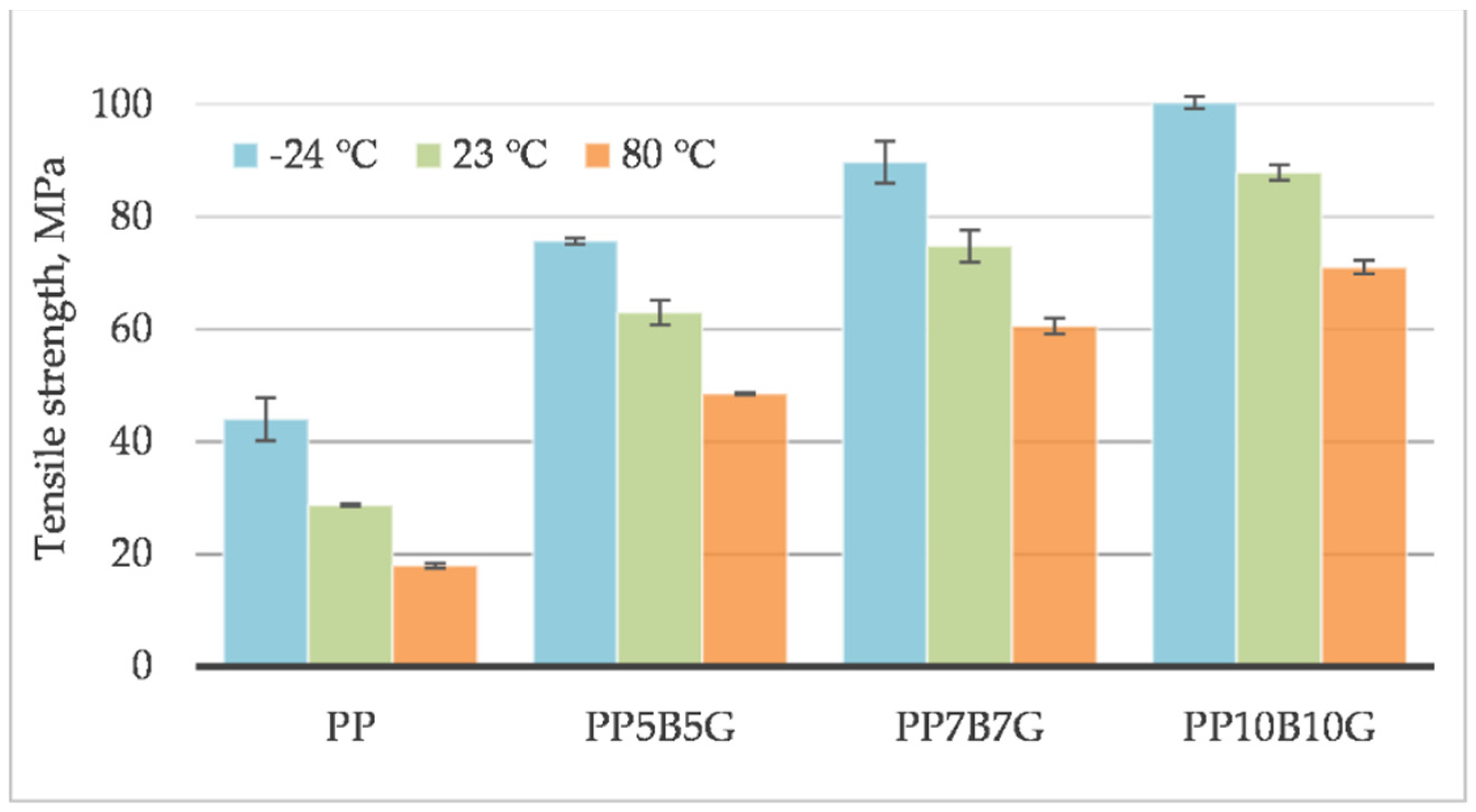

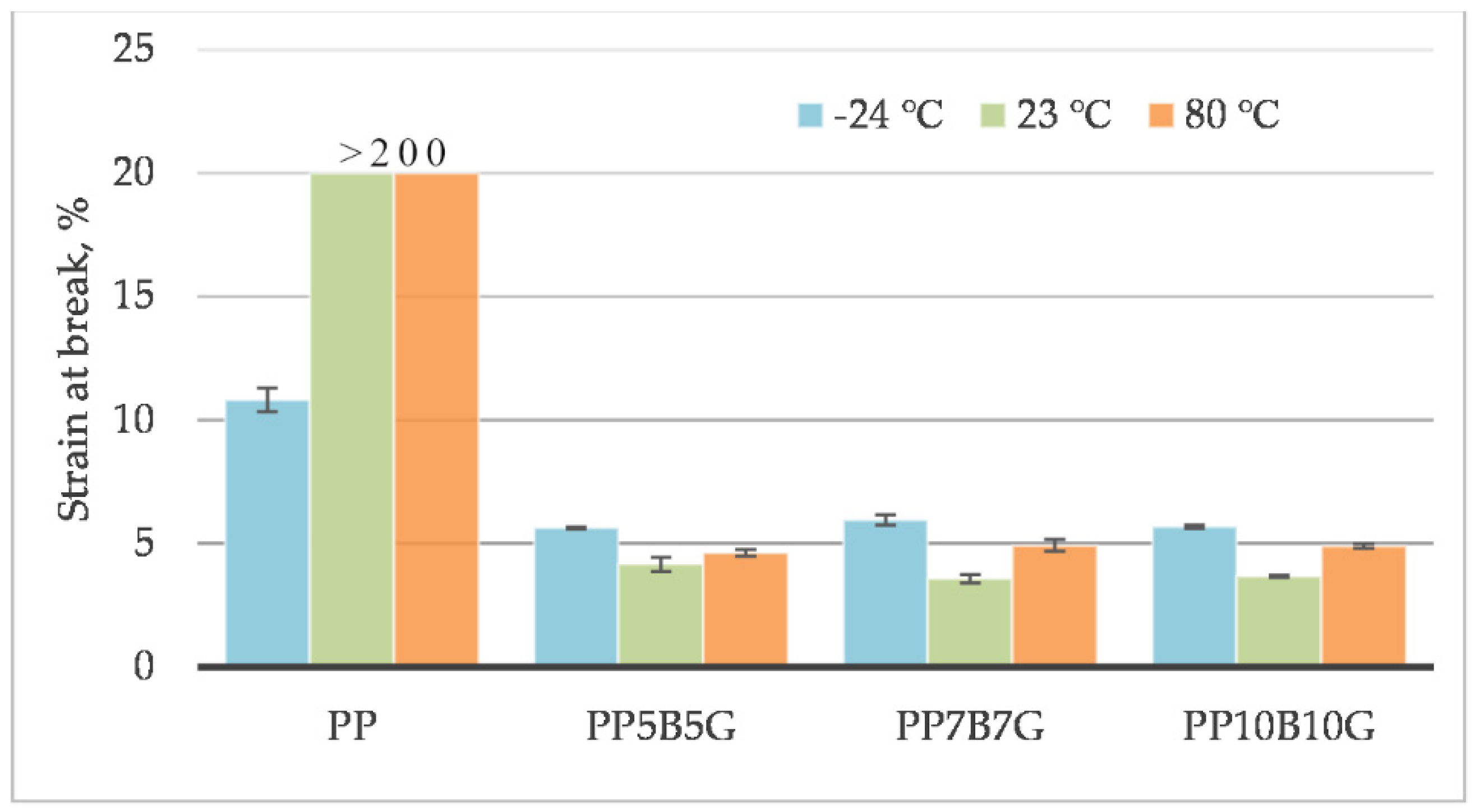

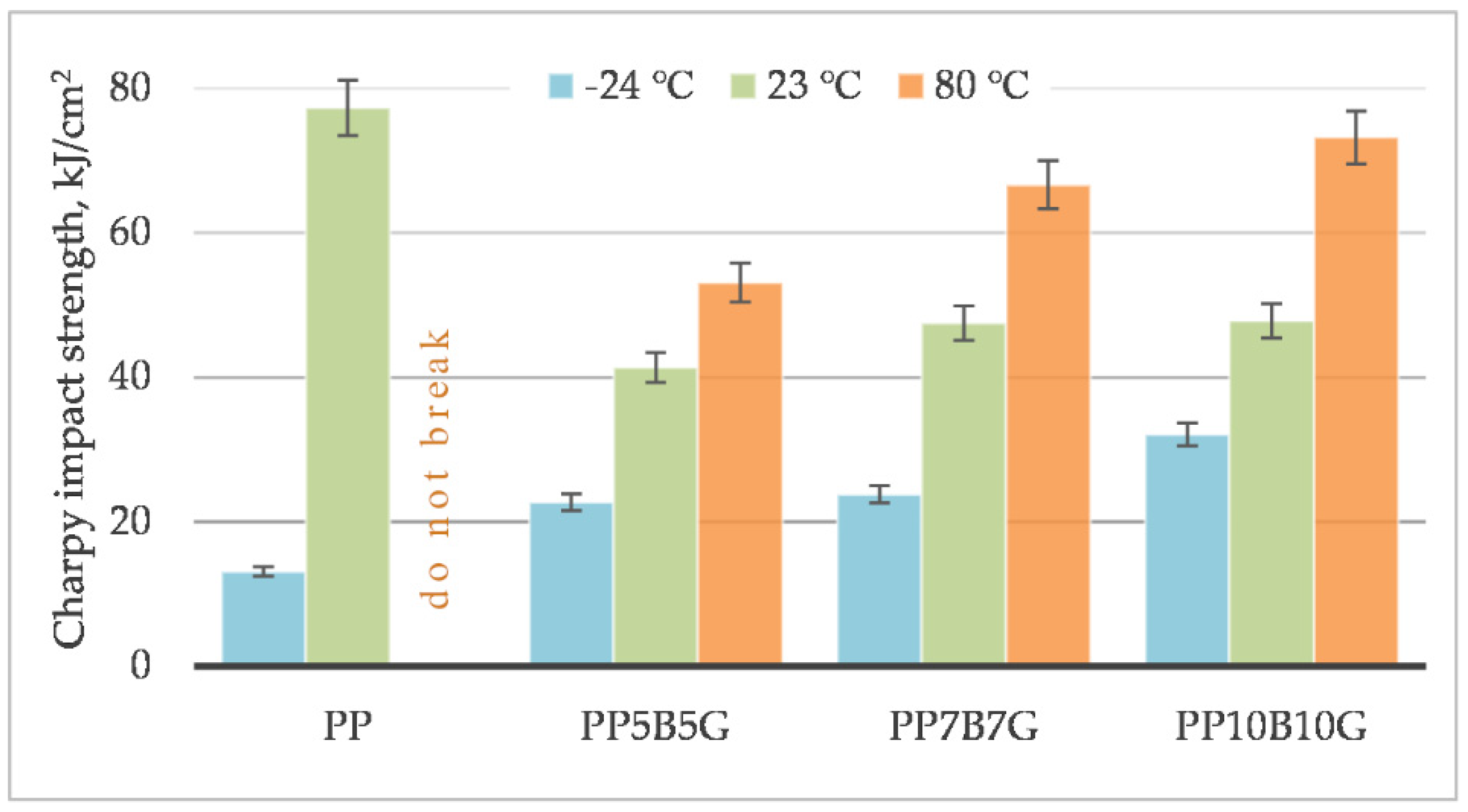

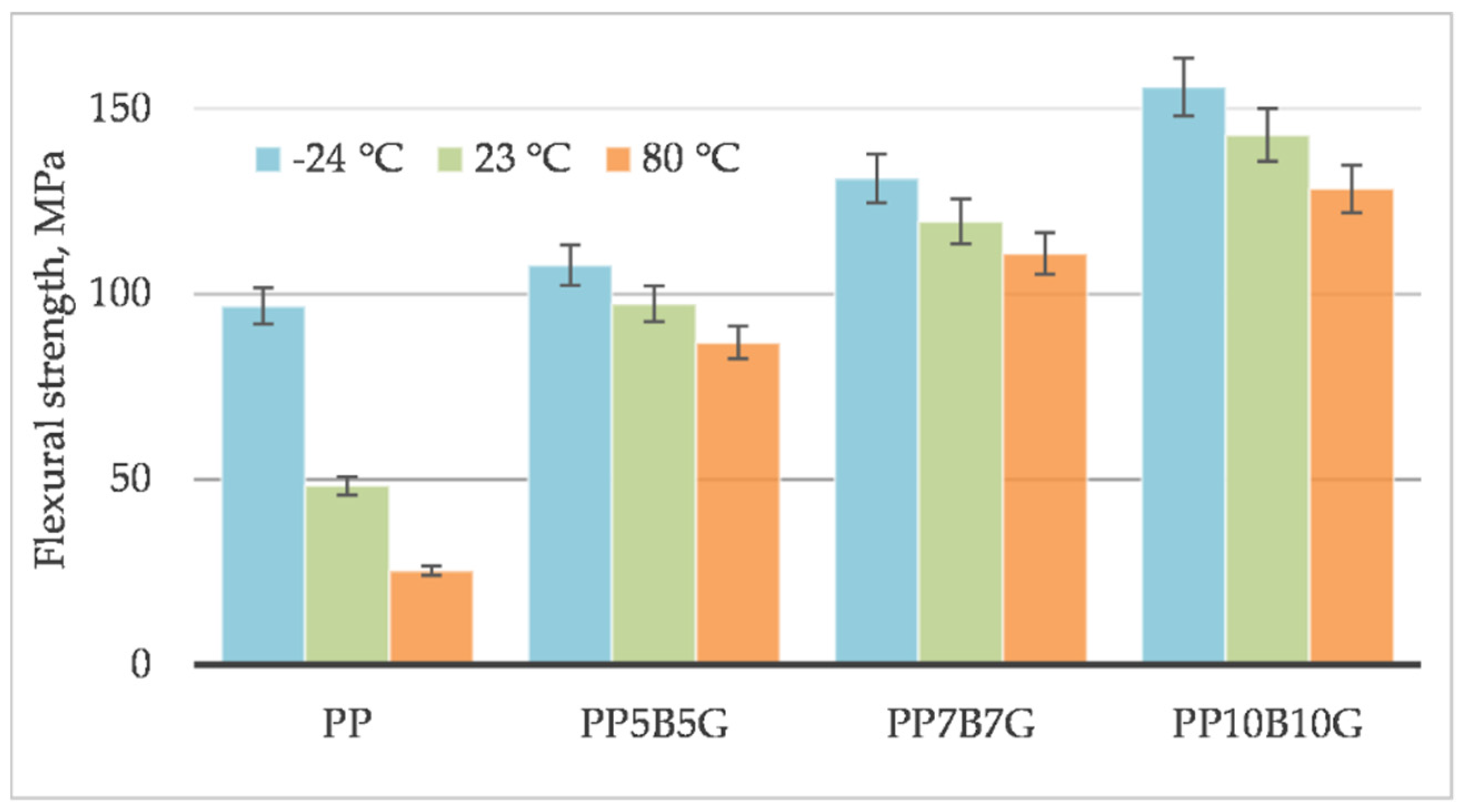

3.1. Physic-Mechanical Characterization

3.2. Micrograph Observation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites–a review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Tang, Y.; Fang, S.; Chen, J.; Ma, L.; Li, L.; Wu, X. Axial compression behavior of recycled-aggregate-concrete-filled GFRP–steel composite tube columns. Eng. Struct. 2020, 216, 110676. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; Ding, A.; Ni, A.; Chen, H. Flame retardancy and mechanical properties of glass fibre reinforced polyeth-ylene composites filled with novel intumescent flame retardant. Compos. Part B Eng. 2019, 179, 107555. [Google Scholar] [CrossRef]

- Russo, P.; Simeoli, G.; Vitiello, L.; Filippone, G. Bio-Polyamide 11 Hybrid Composites Reinforced with Basalt/Flax Interwoven Fibers: A Tough Green Composite for Semi-Structural Applications. Fibers 2019, 7, 41. [Google Scholar] [CrossRef]

- Etcheverry, M.; Barbosa, S.E. Glass Fiber Reinforced Polypropylene Mechanical Properties Enhancement by Adhesion Im-provement. Materials 2012, 5, 1084–1113. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, L.; Cui, X.; Guo, W. Crystallization Behavior and Properties of Glass Fiber Reinforced Polypropylene Com-posites. Polymers 2019, 11, 1198. [Google Scholar] [CrossRef]

- Asadi, A.; Baaij, F.; Mainka, H.; Rademacher, M.; Thompson, J.; Kalaitzidou, K. Basalt fibers as a sustainable and cost-effective alternative to glass fibers in sheet molding compound (SMC). Compos. Part B Eng. 2017, 123, 210–218. [Google Scholar] [CrossRef]

- Singha, K. A Short Review on Basalt Fiber. Int. J. Text. Sci. 2012, 1, 19–28. [Google Scholar]

- Ogrodowska, K.; Łuszcz, K.; Garbacz, A. Nanomodification, Hybridization and Temperature Impact on Shear Strength of Basalt Fiber-Reinforced Polymer Bars. Polymers 2021, 13, 2585. [Google Scholar] [CrossRef]

- Guo, Y.; Zhou, M.; Yin, G.-Z.; Kalali, E.; Wang, N.; Wang, D.-Y. Basalt Fiber-Based Flame Retardant Epoxy Composites: Preparation, Thermal Properties, and Flame Retardancy. Materials 2021, 14, 902. [Google Scholar] [CrossRef]

- Plappert, D.; Ganzenmüller, G.C.; May, M.; Beisel, S. Mechanical Properties of a Unidirectional Basalt-Fiber/Epoxy Compo-site. J. Compos. Sci. 2020, 4, 101. [Google Scholar] [CrossRef]

- Haneefa, A.; Bindu, P.; Aravind, I.; Thomas, S. Studies on Tensile and Flexural Properties of Short Banana/Glass Hybrid Fiber Reinforced Polystyrene Composites. J. Compos. Mater. 2008, 42, 1471–1489. [Google Scholar] [CrossRef]

- Mansor, M.R.; Sapuan, S.M.; Zainudin, E.S.; Nuraini, A.A.; Hambali, A. Stiffness Prediction of Hybrid Kenaf/Glass Fiber Reinforced Polypropylene Composites using Rule of Mixtures (ROM) and Rule of Hybrid Mixtures (RoHM). J. Polym. Mater. 2013, 30, 321–334. [Google Scholar]

- Valente, M.; Sarasini, F.; Marra, F.; Tirillò, J.; Pulci, G. Hybrid recycled glass fiber/wood flour thermoplastic composites: Man-ufacturing and mechanical characterization. Compos. Part A Appl. Sci. Manuf. 2011, 42, 649–657. [Google Scholar] [CrossRef]

- Izwan, S.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Mohamed, A.R. Thermal Stability and Dynamic Mechanical Analysis of Ben-zoylation Treated Sugar Palm/Kenaf Fiber Reinforced Polypropylene Hybrid Composites. Polymers 2021, 13, 2961. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Gapiński, B.; Islam, A.; Szostak, M. The Influence of the Hybridization Process on the Mechanical and Thermal Properties of Polyoxymethylene (POM) Composites with the Use of a Novel Sustainable Reinforcing System Based on Biocarbon and Basalt Fiber (BC/BF). Materials 2020, 13, 3496. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Hong, B. Effects of rod size and fiber hybrid mode on the interface shear strength of carbon/glass fiber composite rods exposed to freezing-thawing and outdoor environments. J. Mater. Res. Technol. 2021, 14, 2812–2831. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Aulia, H.S.; Ilyas, R.A.; Atiqah, A.; Dele-Afolabi, T.T.; Nurazzi, M.N.; Supian, A.B.M.; Atikah, M.S.N. Mechanical properties of longitudinal basalt/woven-glass-fiber-reinforced unsaturated polyester-resin hybrid composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef]

- Cousin, P.; Hassan, M.; Vijay, P.; Robert, M.; Benmokrane, B. Chemical resistance of carbon, basalt, and glass fibers used in FRP reinforcing bars. J. Compos. Mater. 2019, 53, 3651–3670. [Google Scholar] [CrossRef]

- Lingesh, B.V.; Kumar, B.N.R.; Rudresh, B.M.; Reddappa, H.N. Hybridization effect of fibers on mechanical properties of PA66/PP blend-based thermoplastic composites. Adv. Compos. Hybrid Mater. 2018, 1, 766–776. [Google Scholar] [CrossRef]

- Czigany, T. Basalt Fiber Reinforced Hybrid Polymer Composites. Mater. Sci. Forum 2005, 473, 59–66. [Google Scholar] [CrossRef]

- Saleem, A.; Medina, L.; Skrifvars, M. Influence of Fiber Coating and Polymer Modification on Mechanical and Thermal Properties of Bast/Basalt Reinforced Polypropylene Hybrid Composites. J. Compos. Sci. 2020, 4, 119. [Google Scholar] [CrossRef]

- Sergi, C.; Sbardella, F.; Lilli, M.; Tirillò, J.; Calzolari, A.; Sarasini, F. Hybrid Cellulose–Basalt Polypropylene Composites with Enhanced Compatibility: The Role of Coupling Agent. Molecules 2020, 25, 4384. [Google Scholar] [CrossRef] [PubMed]

- Saleem, A.; Medina, L.; Skrifvars, M.; Berglin, L. Hybrid Polymer Composites of Bio-Based Bast Fibers with Glass, Carbon and Basalt Fibers for Automotive Applications—A Review. Molecules 2020, 25, 4933. [Google Scholar] [CrossRef] [PubMed]

- Lutsey, N. Review of technical literature and trends related to automobile mass-reduction technology. UC Davis Inst. Transp. Studies 2010, 1–43. Available online: https://escholarship.org/uc/item/9t04t94w (accessed on 31 August 2021).

- Volpe, V.; Lanzillo, S.; Affinita, G.; Villacci, B.; Macchiarolo, I.; Pantani, R. Lightweight High-Performance Polymer Composite for Automotive Applications. Polymers 2019, 11, 326. [Google Scholar] [CrossRef] [PubMed]

- User’s Manual; MSC Software: Newport Beach, CA, USA, 2021.

- Flodr, J.; Krejsa, M.; Mikolášek, D.; Sucharda, O.; Židek, L. Mathematical modelling of thin-walled cold-rolled cross-section. Appl. Mech. Mater. 2014, 617, 171–174. [Google Scholar] [CrossRef]

- Isaincu, A.; Dan, M.; Ungureanu, V.; Marșavina, L. Numerical investigation on the influence of fiber orientation mapping procedure to the mechanical response of short-fiber reinforced composites using Moldflow, Digimat and Ansys software. Mater. Today Proc. 2021, 45, 4304–4309. [Google Scholar] [CrossRef]

- Tseng, H.C.; Hsu, C.H.; Chang, R.Y. Long fiber orientation and structural analysis using MOLDEX3D, digimat and ABAQUS simulations. In Proceedings of the Technical Conference & Exhibition, Anaheim, CA, USA, 8–10 May 2017; pp. 939–944. [Google Scholar]

- Tseng, H. Latest Molding Simulation and Mechanical Performance Prediction for Long Fiber Composites Using Moldex3D and Digimat. In Proceedings of the SPE ACCE Conference 2018, Novi, ME, USA, 5–7 September 2018. [Google Scholar]

- Kurkin, E.I.; O Spirina, M. Accuracy of the short fibers reinforced composite material plasticity models. J. Phys. Conf. Ser. 2021, 1925, 012040. [Google Scholar] [CrossRef]

- Micota, D.; Isaincu, A.; Marsavina, L. Micromechanical modeling of glass fiber reinforced plastic material. Mater. Today Proc. 2021, 45, 4330–4336. [Google Scholar] [CrossRef]

- Abhilash, R.M.; Venkatesh, G.S.; Chauhan, S.S. Micromechanical modeling of bamboo short fiber reinforced polypropylene composites. Multiscale Multidiscip. Model. Exp. Des. 2021, 4, 25–40. [Google Scholar] [CrossRef]

- Liber-Kneć, A.; Kuźniar, P.; Kuciel, S. Accelerated Fatigue Testing of Biodegradable Composites with Flax Fibers. J. Polym. Environ. 2015, 23, 400–406. [Google Scholar] [CrossRef]

- Li, C.; Xian, G.; Li, H. Tension-tension fatigue performance of a large-diameter pultruded carbon/glass hybrid rod. Int. J. Fatigue 2019, 120, 141–149. [Google Scholar] [CrossRef]

- Chen, D.; Sun, G.; Meng, M.; Jin, X.; Li, Q. Flexural performance and cost efficiency of carbon/basalt/glass hybrid FRP com-posite laminates. Thin-Walled Struct. 2019, 142, 516–531. [Google Scholar] [CrossRef]

- El-Baky, M.A.; Attia, M.; Abdelhaleem, M.; Hassan, M. Mechanical characterization of hybrid composites based on flax, basalt and glass fibers. J. Compos. Mater. 2020, 54, 4185–4205. [Google Scholar] [CrossRef]

- Patel, N.; Patel, K.; Chaudhary, V.; Gohil, P. Investigations on drilling of hybrid basalt/glass polyester composites. Aust. J. Mech. Eng. 2020, 1–10. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Environmental effects on bamboo-glass/polypropylene hybrid composites. J. Mater. Sci. 2003, 38, 363–376. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Studies on the water absorption properties of short hemp-glass fiber hybrid polypropylene com-posites. J. Compos. Mater. 2007, 41, 1871–1883. [Google Scholar] [CrossRef]

- Rozman, H.D.; Tay, G.S.; Kumar, R.N.; Abubakar, A.; Ismail, H.; Ishak, Z.A.M. Polypropylene Hybrid Composites: A Preliminary Study on the use of Glass and Coconut Fiber as Reinforcements in Polypropylene Composites. Polym. Technol. Eng. 1999, 38, 997–1011. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, B.-H.; Choi, S.-W.; Kim, S.; Kim, H.-J. The effect of types of maleic anhydride-grafted polypropylene (MAPP) on the interfacial adhesion properties of bio-flour-filled polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1473–1482. [Google Scholar] [CrossRef]

- Techawinyutham, L.; Frick, A.; Siengchin, S. Polypropylene/Maleic Anhydride Grafted Polypropylene (MAgPP)/Coconut Fiber Composites. Adv. Mech. Eng. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- Tripathi, D. Practical Guide to Polypropylene; Smithers Rapra Technology: Shrewsbury, UK, 2002; pp. 24–63. [Google Scholar]

- Frącz, W.; Janowski, G. Advanced method of strength simulation of a WPC composite molding with orientation of fibers in polymer matrix considered. Mechanik 2016, 628–630. [Google Scholar] [CrossRef][Green Version]

- Landervik, M.; Jergeus, J. Digimat Material Model for Short Fiber Reinforced Plastics at Volvo Car Corporation. In Proceedings of the 10th European LS-DYNA Conference, Würzburg, Germany, 15–17 June 2015. [Google Scholar]

- Voigt, W. Ueber die Beziehung zwischen den beiden Elasticitätsconstanten isotroper Körper. Ann. der Phys. 1889, 274, 573–587. [Google Scholar] [CrossRef]

- Reuss, A. Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizitätsbedingung für Einkristalle ZAMM-Zeitschrift für Angew. Math. Mech. 1929, 9, 49–58. [Google Scholar]

- Espinach, F.X.; Julian, F.; Verdaguer, N.; Torres, L.; Pelach, M.A.; Vilaseca, F.; Mutje, P. Analysis of tensile and flexural mod-ulus in hemp strands/polypropylene composites. Compos. Part B Eng. 2013, 47, 339–343. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.; Tresserras, J.; DEL Rey, R.; Pellicer, N.; Mutje, P. Macro and micromechanics analysis of short fiber composites stiffness: The case of old newspaper fibers–polypropylene composites. Mater. Des. 2014, 55, 319–324. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Moshrefzadeh-Sani, H. On the constant parameters of Halpin-Tsai equation. Polymer 2016, 106, 14–20. [Google Scholar] [CrossRef]

- Wiśniewska, A.; Hernik, S.; Liber-Kneć, A.; Egner, H. Effective properties of composite material based on total strain energy equivalence. Compos. Part B Eng. 2019, 166, 213–220. [Google Scholar] [CrossRef]

- Wiśniewska, A.; Egner, H. Optimization of Functionally Graded Structural Members by Means of New Effective Properties Estimation Method. Materials 2019, 12, 3139. [Google Scholar] [CrossRef]

- Liber-Kneć, A. Wpływ Zmian w Strukturze na Właściwości Mechaniczne Poliamidu z Włóknem Szklanym w Warunkach Obciążeń długotrwałych. Ph.D. Thesis, Cracow University of Technology, Cracow, Poland, 2007. [Google Scholar]

- Romańska, P. Kształtowanie Właściwości Kompozytów na Osnowie poliamidów z Surowców Odnawialnych Poprzez Dobór Rodzaju i Ilości Napełniaczy. Ph.D. Thesis, Cracow University of Technology, Cracow, Poland, 2018. [Google Scholar]

- Mazurkiewicz, S.; Porębska, R. Energia dyssypacji w kompozytach polimerowych. Czas. Tech. Mech. 2009, 106, 245–248. [Google Scholar]

- Kuciel, S.; Kufel, A. Novel hybrid composites based on polypropylene with basalt/carbon fiber (Rapid communication). Polimery 2018, 63, 387–390. [Google Scholar] [CrossRef]

- Mayer, P.; Kaczmar, J.W. Właściwości i zastosowania włókien węglowych i szklanych. Tworzywa Sztuczne i Chem. 2008, 6, 52–56. [Google Scholar]

- Thomason, J. The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene: 5. Injection moulded long and short fibre PP. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1641–1652. [Google Scholar] [CrossRef]

| Properties | Polypropylene | Glass Fiber | Basalt Fiber |

|---|---|---|---|

| Constitutive law | Elastoplastic | Elastic | Elastic |

| Elasticity | Isotropic | Isotropic | Isotropic |

| Density (kg/mm3) | 9.2 × 10−7 | 2.5 × 10−6 | 2.6 × 10−6 |

| Young’s modulus (MPa) | 1600 | 75,000 | 89,000 |

| Poisson’s ratio (-) | 0.42 | 0.22 | 0.25 |

| Plasticity model | J2 | - | - |

| Isotropic hardening model | Hardening modulus (MPa): 9.5 Hardening exponent (-): 300 Linear hardening modulus (MPa): 4 | - | - |

| Kinematic hardening model | Linear hardening modulus (MPa): 120 Restoration parameter (-): 50 | - | - |

| Symbol | Composition | Density, g/cm3 |

|---|---|---|

| PP | neat polypropylene HP 500N | 0.886 ± 0.001 |

| PP5B5G | PP + 5 wt.% basalt fibers + 5 wt.% glass fibers + 3 wt.% MAPP | 0.974 ± 0.003 |

| PP7B7G | PP + 7.5 wt.% basalt fibers + 7.5 wt.% glass fibers + 3 wt.% MAPP | 0.995 ± 0.005 |

| PP10B10G | PP + 10 wt.% basalt fibers + 10 wt.% glass fibers + 3 wt.% MAPP | 1.017 ± 0.001 |

| Material | PP | PP5B5G | PP7B7G | PP10B10G |

|---|---|---|---|---|

| Maximum force (N) | 1200 | 2700 | 3100 | 3600 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kufel, A.; Para, S.; Kuciel, S. Basalt/Glass Fiber Polypropylene Hybrid Composites: Mechanical Properties at Different Temperatures and under Cyclic Loading and Micromechanical Modelling. Materials 2021, 14, 5574. https://doi.org/10.3390/ma14195574

Kufel A, Para S, Kuciel S. Basalt/Glass Fiber Polypropylene Hybrid Composites: Mechanical Properties at Different Temperatures and under Cyclic Loading and Micromechanical Modelling. Materials. 2021; 14(19):5574. https://doi.org/10.3390/ma14195574

Chicago/Turabian StyleKufel, Anna, Slawomir Para, and Stanisław Kuciel. 2021. "Basalt/Glass Fiber Polypropylene Hybrid Composites: Mechanical Properties at Different Temperatures and under Cyclic Loading and Micromechanical Modelling" Materials 14, no. 19: 5574. https://doi.org/10.3390/ma14195574

APA StyleKufel, A., Para, S., & Kuciel, S. (2021). Basalt/Glass Fiber Polypropylene Hybrid Composites: Mechanical Properties at Different Temperatures and under Cyclic Loading and Micromechanical Modelling. Materials, 14(19), 5574. https://doi.org/10.3390/ma14195574