Microstructure Evolution Mechanism of Wf/Cu82Al10Fe4Ni4 Composites under Dynamic Compression at Different Temperatures and Strain Rates

Abstract

:1. Introduction

2. Materials and Experimental Procedure

3. Results and Discussion

3.1. Microstructure of Matrix with a Strain Rate of 800 s−1

3.2. Microstructure of Matrix with a Strain Rate of 1600 s−1

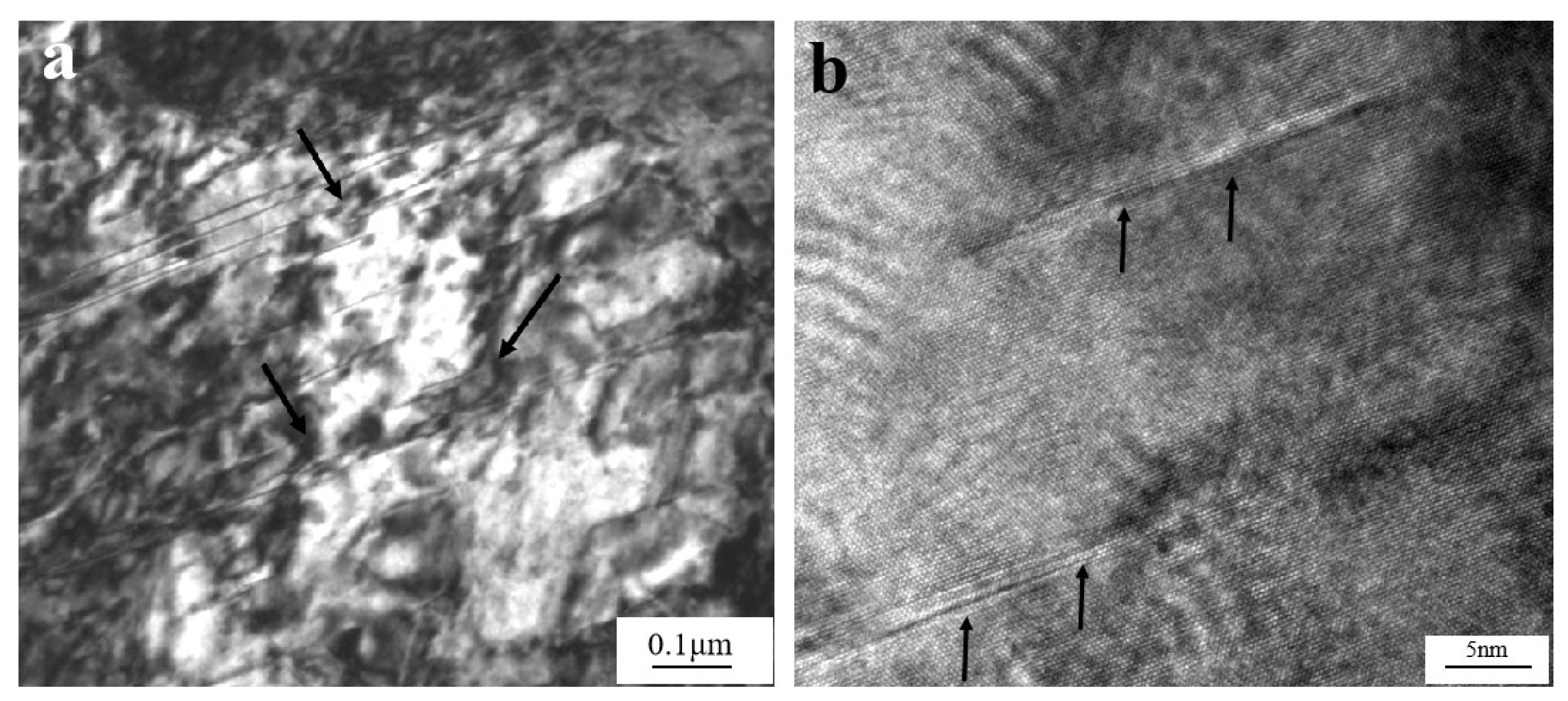

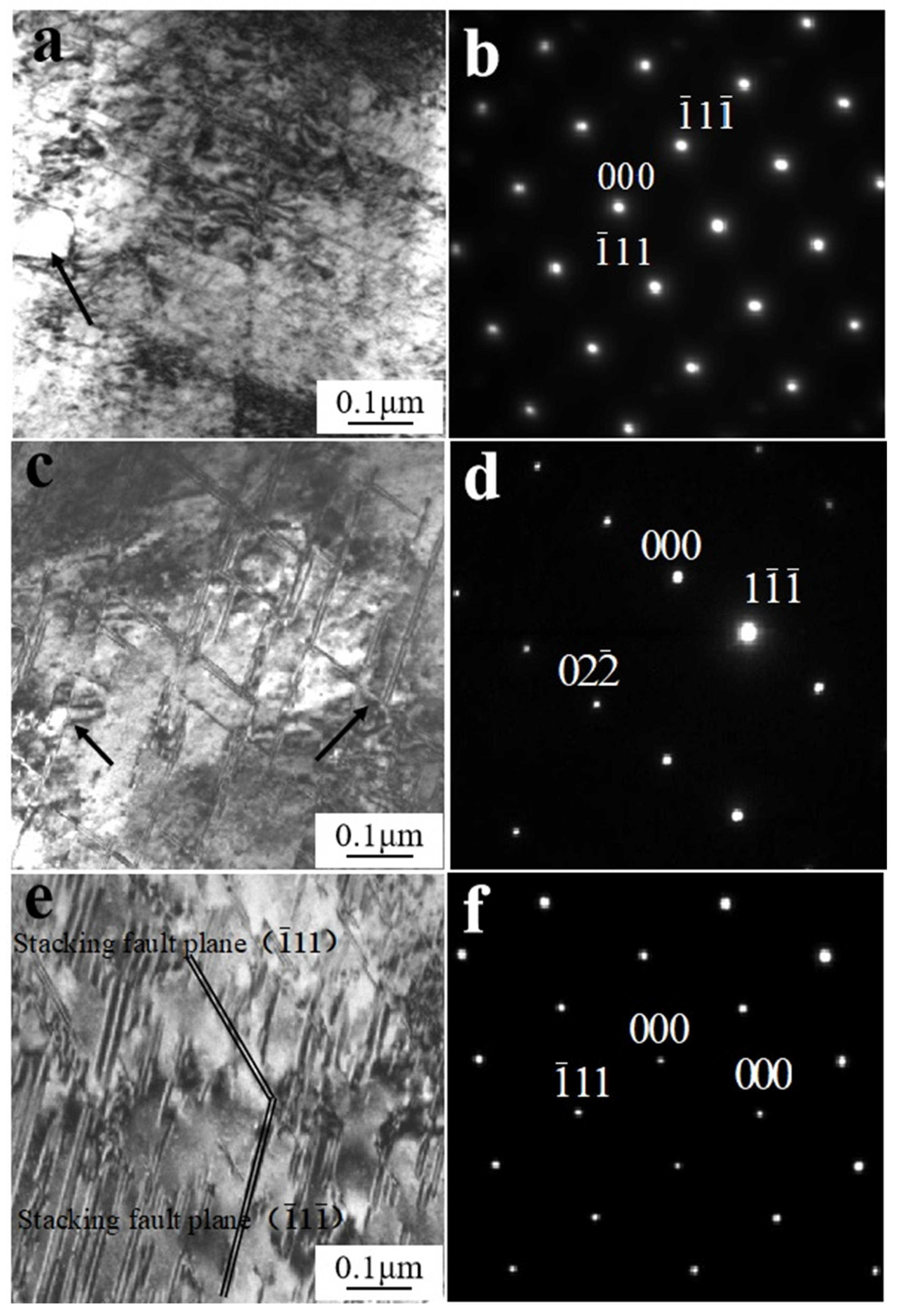

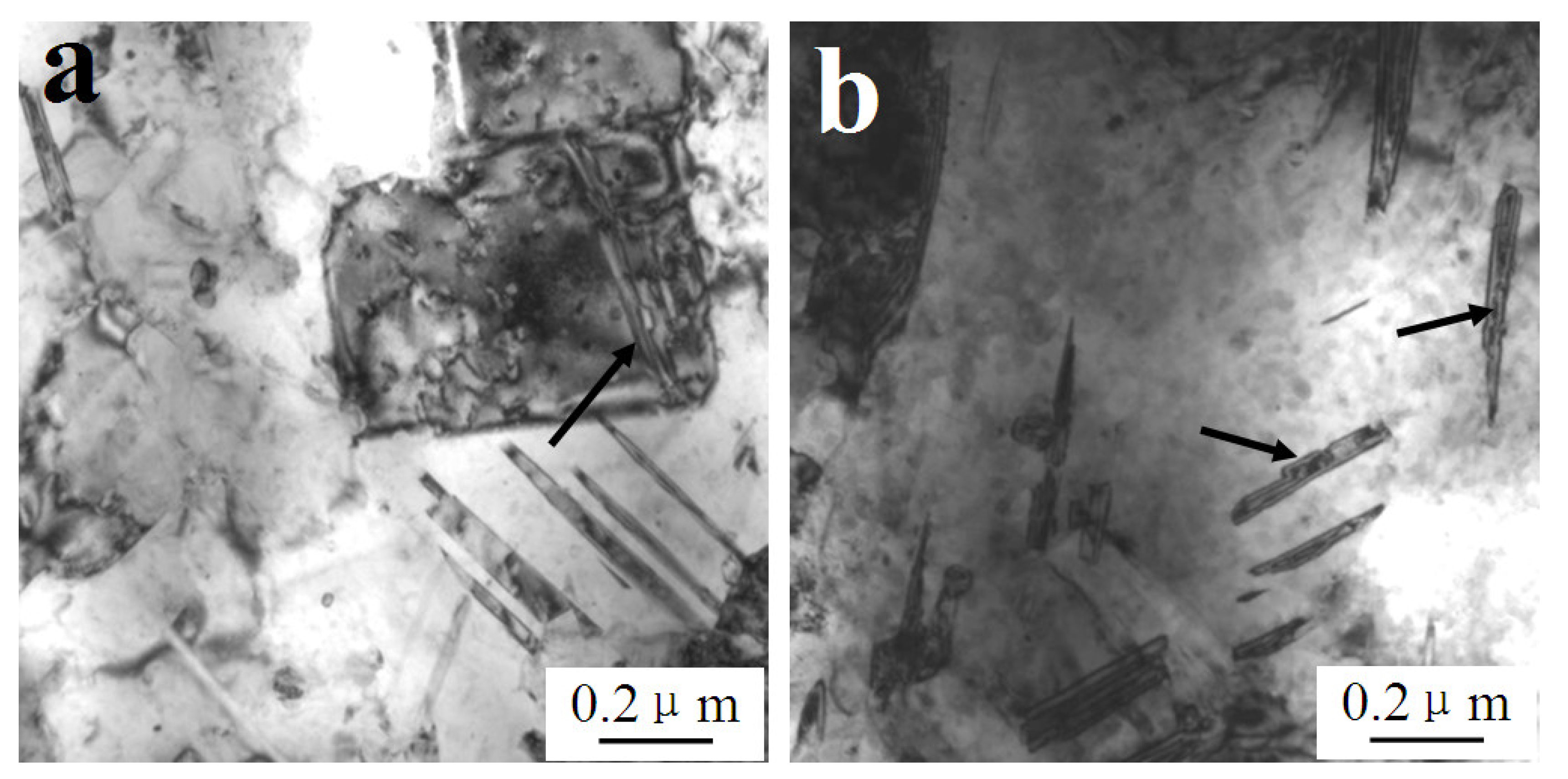

3.2.1. Stacking Fault

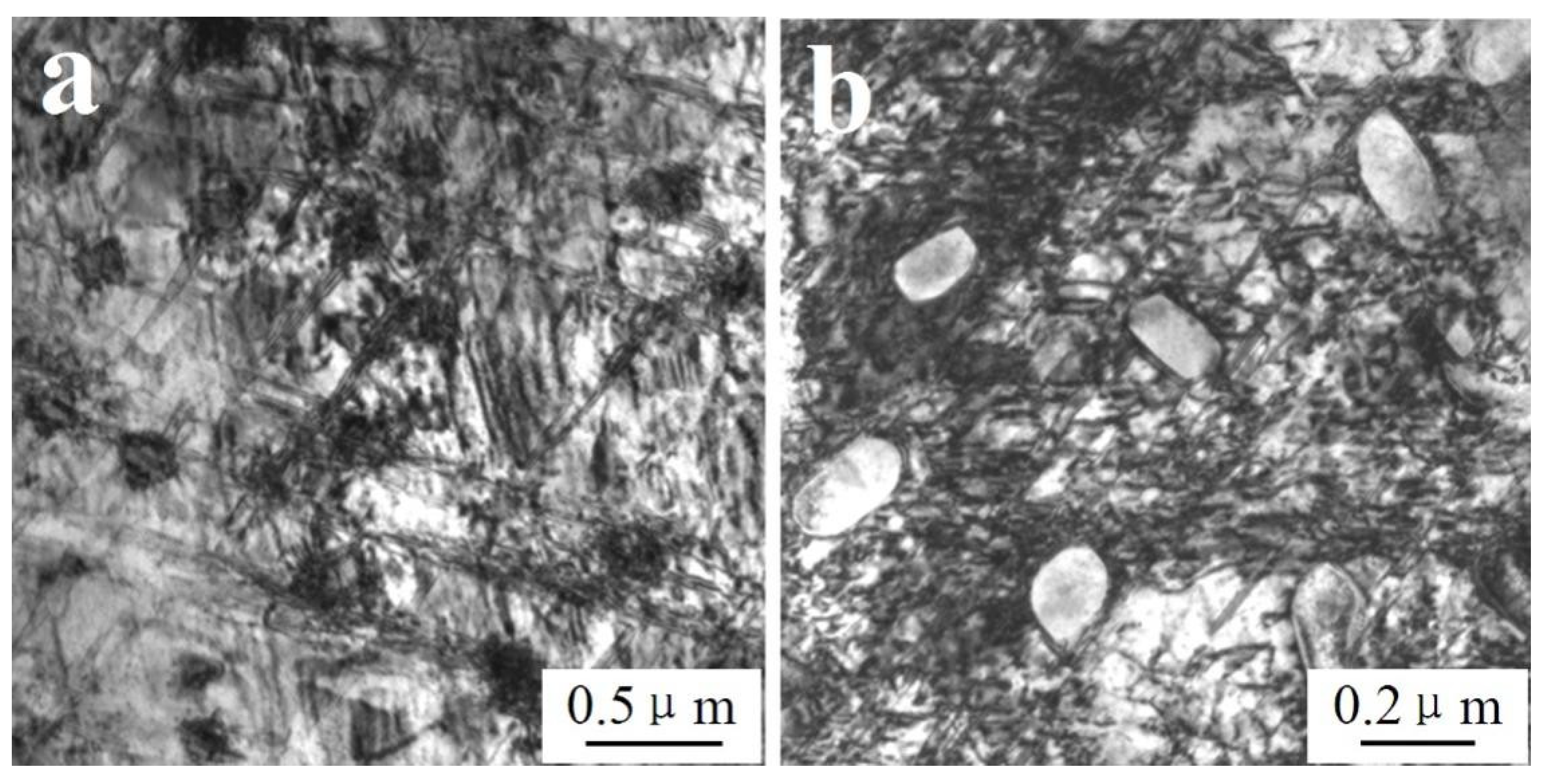

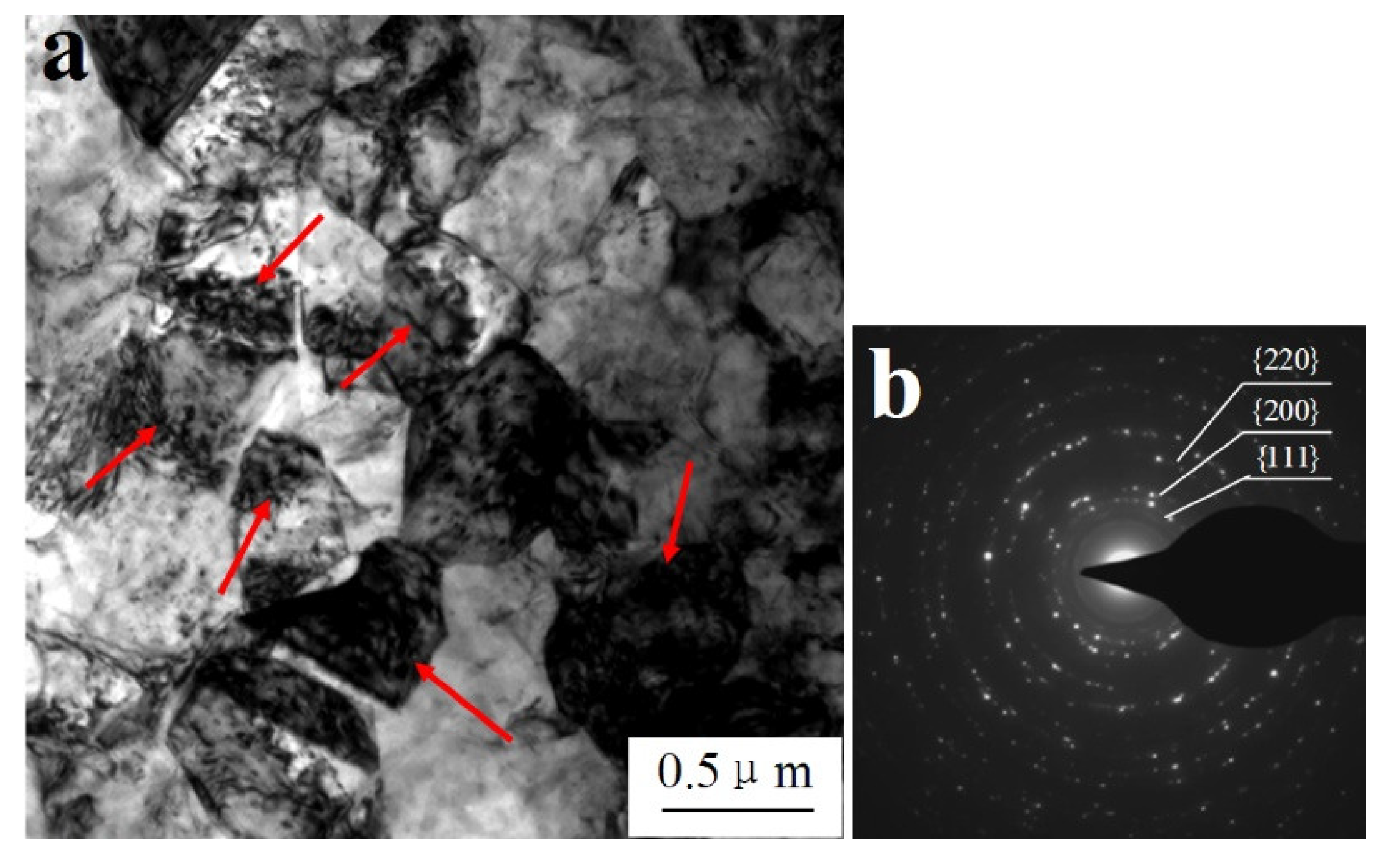

3.2.2. Twins

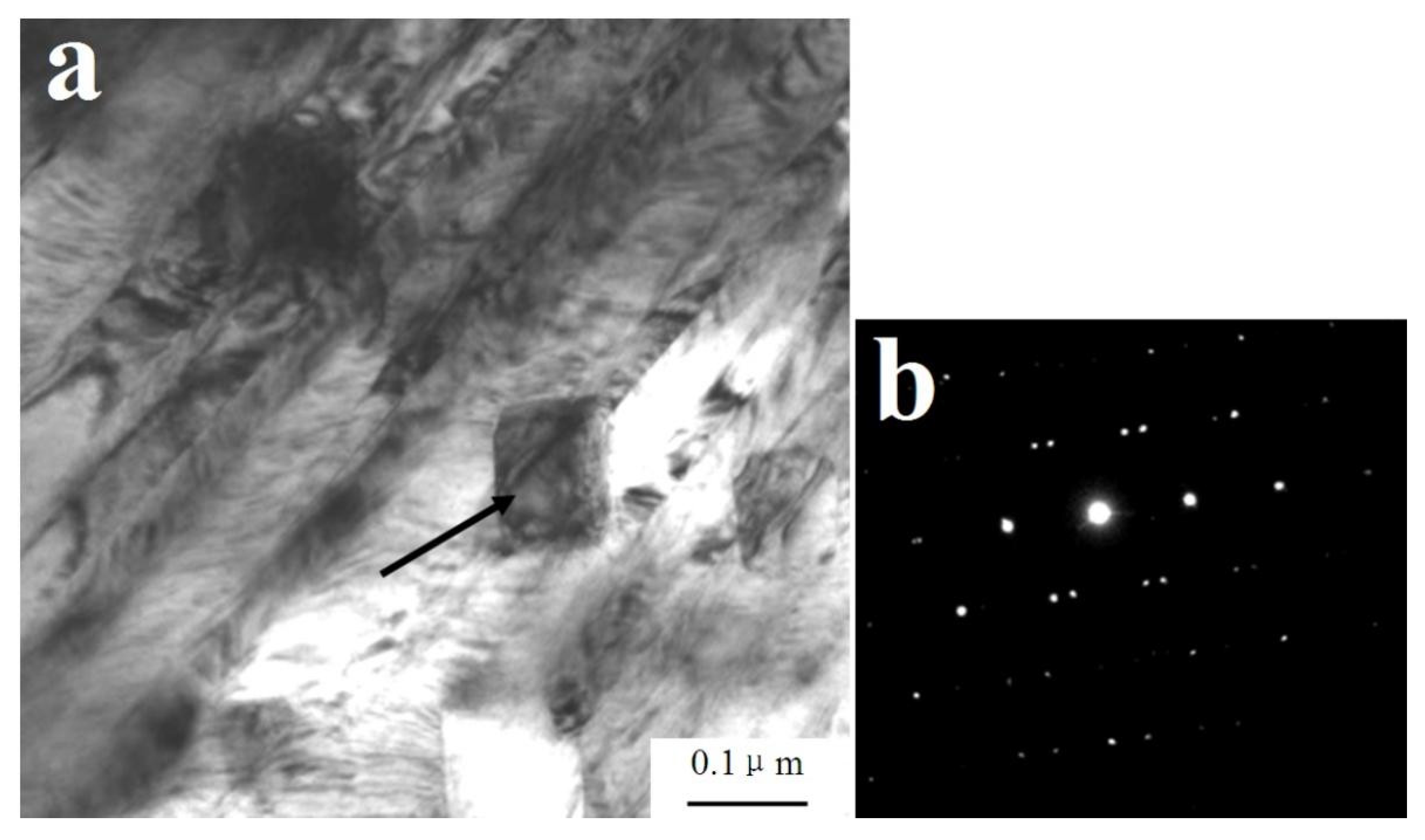

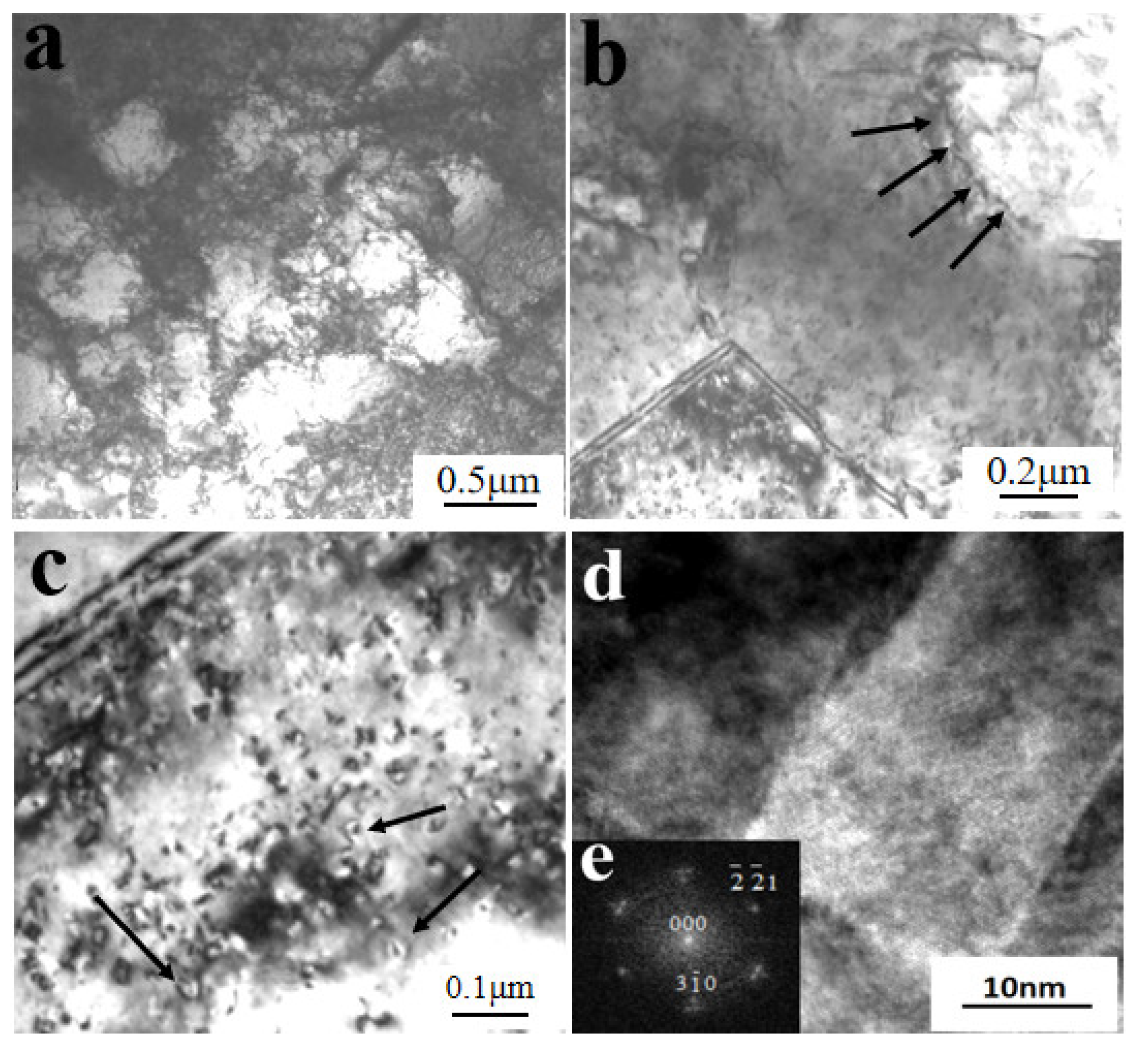

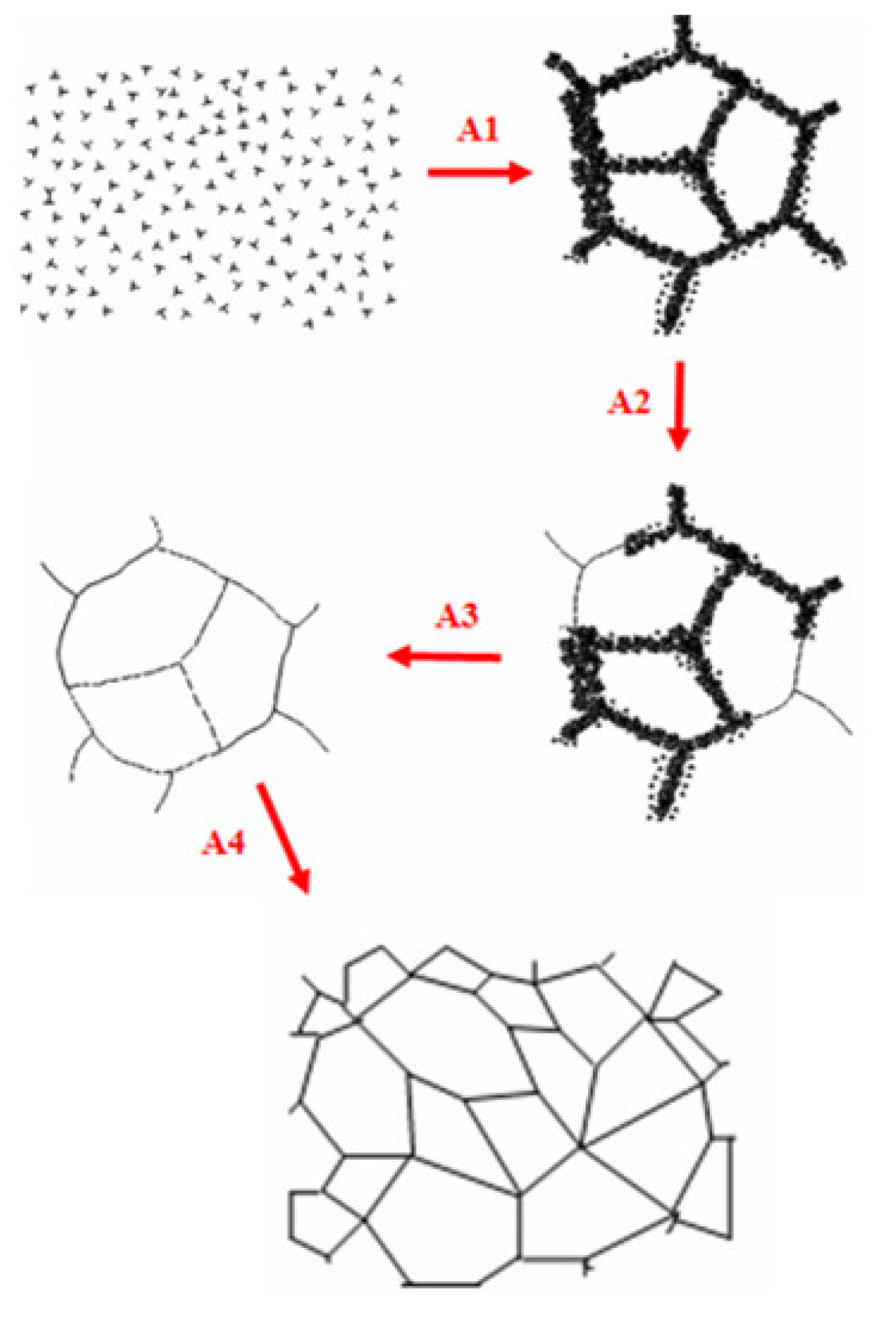

3.2.3. Dynamic Recrystallization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jung, J.K.; Cho, Y.J. Microstructural and mechanical responses of various aluminum alloys to ballistic impacts by armor piercing projectile. Mater. Charact. 2020, 19, 110033. [Google Scholar] [CrossRef]

- Ye, X.; Zou, M.; Chen, J. Characterization of Crater Area in a Target Penetrated by a Wf/Zr- Based Amorphous Matrix Composite Projectile. Materials 2020, 13, 397. [Google Scholar] [CrossRef] [PubMed]

- Zou, D.; Zhen, L.; Zhu, Y.; Xu, C.; Shao, W.; Pang, B. Deformed microstructure evolution in AM60B Mg alloy under hypervelocity impact at a velocity of 5 km s−1. Mater. Des. 2010, 31, 3708–3715. [Google Scholar] [CrossRef]

- Randrianarivony, F.M.; Lair, S.; Quinones, S.A.; Murr, L.E. Experimental observations and computer simulations of spherical aluminum-alloy projectiles impacting plane limestone targets. J. Mater. Sci. 2002, 37, 5197–5207. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Fan, A.; Sun, H. Effect of fibrous orientation on dynamic mechanical properties and susceptibility to adiabatic shear band of tungsten heavy alloy fabricated through hot-hydrostatic extrusion. Mater. Sci. Eng. A. 2008, 487, 235–242. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, Y.; Du, S.; Yang, Z.; Cheng, H.; Wang, F. Effects of the adhesive layer on the multi-hit ballistic performance of ceramic/metal composite armors. J. Mater. Res. Technol. 2021, 13, 1496–1508. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Wang, A.; Fu, H.; Ding, B.; Hu, Z. Synthesis and characteristics of 80 vol.% tungsten (W) fibre/Zr based metallic glass composite. Intermetallics 2009, 17, 1070–1077. [Google Scholar] [CrossRef]

- Kim, H.G.; Kim, K.T. Densification behavior of tungsten-fiber-reinforced copper powder compacts under hot isostatic pressing. Int. J. Mech. Sci. 2000, 42, 1339–1356. [Google Scholar] [CrossRef]

- Huang, Y.; Zhou, X.; Hua, N.; Que, W.; Chen, W. High temperature friction and wear behavior of tungsten-copper alloys. Int. J. Refract. Met. Hard Mater. 2018, 77, 105–112. [Google Scholar] [CrossRef]

- Deng, N.; Tang, J.; Xiong, T.; Li, J.; Zhou, Z. Fabrication and characterization of WCu composite coatings with different W contents by cold spraying. Surf. Coat. Technol. 2019, 368, 8–14. [Google Scholar] [CrossRef]

- Su, S.; Lu, Y. Densified WCu composite fabricated via laser additive manufacturing. Int. J. Refract. Met. Hard Mater. 2020, 87, 105112. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, B.; Chen, Z.; Zhu, Z.; Hu, X.; Ding, Y.; Liang, S. Microstructure and properties of WCu composites reinforced by in-situ generated WC. Int. J. Refract. Met. Hard Mater. 2021, 9, 105585. [Google Scholar] [CrossRef]

- Manel, R.; Jan, O. Microstructure and texture evolution during the drawing of tungsten wires. Eng. Fract. Mech. 2009, 76, 1485–1499. [Google Scholar]

- Schade, P. 100 years of doped tungsten wire. Int. J. Refract. Met. Hard Mater. 2000, 28, 648–660. [Google Scholar] [CrossRef]

- Schade, P. Wire drawing failures and tungsten fracture phenomena. Int. J. Refract. Met. Hard Mater. 2006, 24, 332–337. [Google Scholar] [CrossRef]

- Umberto, M.C.; Lea, H.; Hanns, G.; Johann, R.; Wolfgang, P. Microstructural evolution in single tungsten fiber-reinforced tungsten composites during annealing: Recrystallization and abnormal grain growth. J. Nucl. Mater. 2021, 543, 152579. [Google Scholar]

- Kärcher, A.; Riesch, J.; Almanstötter, P.; Manhard, A.; Balden, M.; Coenen, J.M.; Hunger, K. Deuterium retention in tungsten fiber-reinforced tungsten composites. Nucl. Mater. Energy 2021, 27, 100972. [Google Scholar] [CrossRef]

- Dong, L.; Huo, W.; Ahangarkani, M.; Zhang, B.; Zhao, Y.; Zhang, Y. Microstructural evaluation and mechanical properties of in-situ WC/W-Cu composites fabricated by rGO/W-Cu spark plasma sintering reaction. Mater. Des. 2018, 160, 1196–1207. [Google Scholar] [CrossRef]

- Ma, W.; Kou, H.; Chen, C.; Li, J.; Chang, H.; Zhou, L.; Fu, H. Compressive deformation behaviors of tungsten fiber reinforced Zr-based metallic glass composites. Mater. Sci. Eng. A 2008, 486, 308–312. [Google Scholar] [CrossRef]

- Qiu, K.; Wang, A.; Zhang, H.; Ding, B.; Hua, Z. Mechanical properties of tungsten fiber reinforced ZrAlNiCuSi metallic glass matrix composite. Intermetallics 2002, 10, 1283–1288. [Google Scholar] [CrossRef]

- Chen, W.; Dong, L.; Zhang, H.; Song, J.; Deng, N.; Wang, J. Microstructure characterization of W-Cu alloy sheets produced by high temperature and high pressure deformation technique. Mater. Lett. 2017, 205, 198–201. [Google Scholar] [CrossRef]

- Yang, X.; Liang, S.; Wang, X.; Xiao, P.; Fan, Z. Effect of WC and CeO2 on microstructure and properties of W-Cu electrical contact material. Int. J. Refract. Met. Hard Mater. 2010, 28, 305–311. [Google Scholar] [CrossRef]

- Cheng, J.; Wan, L.; Cai, Y.; Zhu, J.; Song, P.; Dong, J. Fabrication of W-20 wt.% Cu alloys by powder injection molding. J. Mater. Process. Technol. 2010, 1, 137–142. [Google Scholar] [CrossRef]

- Hong, S.; Kim, B.; Munir, Z. Synthesis and consolidation of nanostructured W-10-40 wt.% Cu powders. Mater. Sci. Eng. A 2005, 405, 325–332. [Google Scholar] [CrossRef]

- Ibrahim, A.; Abdallah, M.; Mostafa, S.F.; Hegazy, A.A. An experimental investigation on the W-Cu composites. Mater. Des. 2009, 30, 1398–1403. [Google Scholar] [CrossRef]

- Luo, C.; Wang, Y.; Xu, J.; Xu, G.; Yan, Z.; Li, J.; Li, H.; Lu, H.; Suo, J. The activated sintering of WCu composites through spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2019, 81, 27–35. [Google Scholar] [CrossRef]

- Doré, F.; Lay, S.; Eustathopoulos, N.; Allibert, C.H. Segregation of Fe during the sintering of doped W-Cu Alloys. Scripta Mater. 2003, 49, 237–242. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, M.; Wang, R.; Li, Z.; Zhu, J.; Peng, K.; Li, D.; Li, S. Enhanced adhesion of Cu-W thin films by ion beam assisting bombardment implanting. Trans. Nonferrous Met. Soc. China 2008, 18, 372–377. [Google Scholar] [CrossRef]

- Wu, Z.; Kang, P.C.; Wu, G.H.; Guo, Q.; Chen, G.Q.; Jiang, L.T. The effect of interface modification on fracture behavior of tungsten fiber reinforced copper matrix composites. Mater. Sci. Eng. A 2012, 536, 45–48. [Google Scholar] [CrossRef]

- Yang, C.M.; Zhang, Y.; Wu, Z.; Ma, Y.; Liu, Q.J. Mechanical properties and fracture characteristics of Wf/Cu82Al10Fe4Ni4 composites. Optoelectron. Adv. Mater. 2015, 9, 1479–1482. [Google Scholar]

- Cook, A.J.; Werner, P.S. Pressure infiltration casting of metal matrix composites. Mater. Sci. Eng. A 1991, 144, 189–206. [Google Scholar] [CrossRef]

- Soy, U.; Demir, A.; Findik, F. Friction and wear behaviors of Al-SiC-B 4 C composites produced by pressure infiltration method. Ind. Lubr. Tribol. 2011, 65, 387–393. [Google Scholar] [CrossRef]

- Etter, T.; Papakyriacou, M.; Schulz, P.; Uggowitzer, P.J. Physical properties of graphite/aluminium composites produced by gas pressure infiltration method. Carbon 2003, 41, 1017–1024. [Google Scholar] [CrossRef]

- Lee, O.S.; Choi, H.; Kim, H. High-temperature dynamic deformation of aluminum alloys using SHPB. J. Mech. Sci. Technol. 2011, 25, 143–148. [Google Scholar] [CrossRef]

- Meyers, M.A.; Andrade, R.U.; Chokshi, H.A. The effect of grain size on the highstrain, high-strain-rate behavior of copper. Metall. Mater. Trans. A 1995, 26, 2881–2893. [Google Scholar] [CrossRef]

- Zhang, X.; Grabowski, B.; Körmann, F.; Ruban, A.V.; Gong, Y.L.; Reed, R.C.; Hickel, T.; Neugebauer, J. Temperature dependence of the stacking-fault Gibbs energy for Al, Cu, and Ni. Phys. Rev. B 2018, 98, 224106. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Liu, J.; Du, Y. Experimental and Numerical Study on the Flight and Penetration Properties of Explosively-formed Projectile. Int. J. Impact Eng. 2007, 34, 1147–1162. [Google Scholar] [CrossRef]

- Schneider, M.S.; Kad, B.; Kalantar, D.H.; Remington, B.A.; Kenik, E.; Jarmakani, H.; Meyers, M.A. Laser Shock Compression of Copper and Copper-aluminum Alloys. Int. J. Impact Eng. 2005, 32, 473–507. [Google Scholar] [CrossRef]

- Rittel, D.; Wang, Z. Thermo-mechanical aspects of adiabatic shear failure of AM50 and Ti6Al4V alloys. Mech. Mater. 2008, 40, 629–635. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Zhang, Y.; Jiang, H.; Zhao, S.; Wang, Q. Microstructure Evolution Mechanism of Wf/Cu82Al10Fe4Ni4 Composites under Dynamic Compression at Different Temperatures and Strain Rates. Materials 2021, 14, 5563. https://doi.org/10.3390/ma14195563

Wu Z, Zhang Y, Jiang H, Zhao S, Wang Q. Microstructure Evolution Mechanism of Wf/Cu82Al10Fe4Ni4 Composites under Dynamic Compression at Different Temperatures and Strain Rates. Materials. 2021; 14(19):5563. https://doi.org/10.3390/ma14195563

Chicago/Turabian StyleWu, Zhe, Yang Zhang, Haifeng Jiang, Shuai Zhao, and Qingnan Wang. 2021. "Microstructure Evolution Mechanism of Wf/Cu82Al10Fe4Ni4 Composites under Dynamic Compression at Different Temperatures and Strain Rates" Materials 14, no. 19: 5563. https://doi.org/10.3390/ma14195563

APA StyleWu, Z., Zhang, Y., Jiang, H., Zhao, S., & Wang, Q. (2021). Microstructure Evolution Mechanism of Wf/Cu82Al10Fe4Ni4 Composites under Dynamic Compression at Different Temperatures and Strain Rates. Materials, 14(19), 5563. https://doi.org/10.3390/ma14195563