A High-Similarity Modeling Method for Low-Porosity Porous Material and Its Application in Bearing Cage Self-Lubrication Simulation

Abstract

:1. Introduction

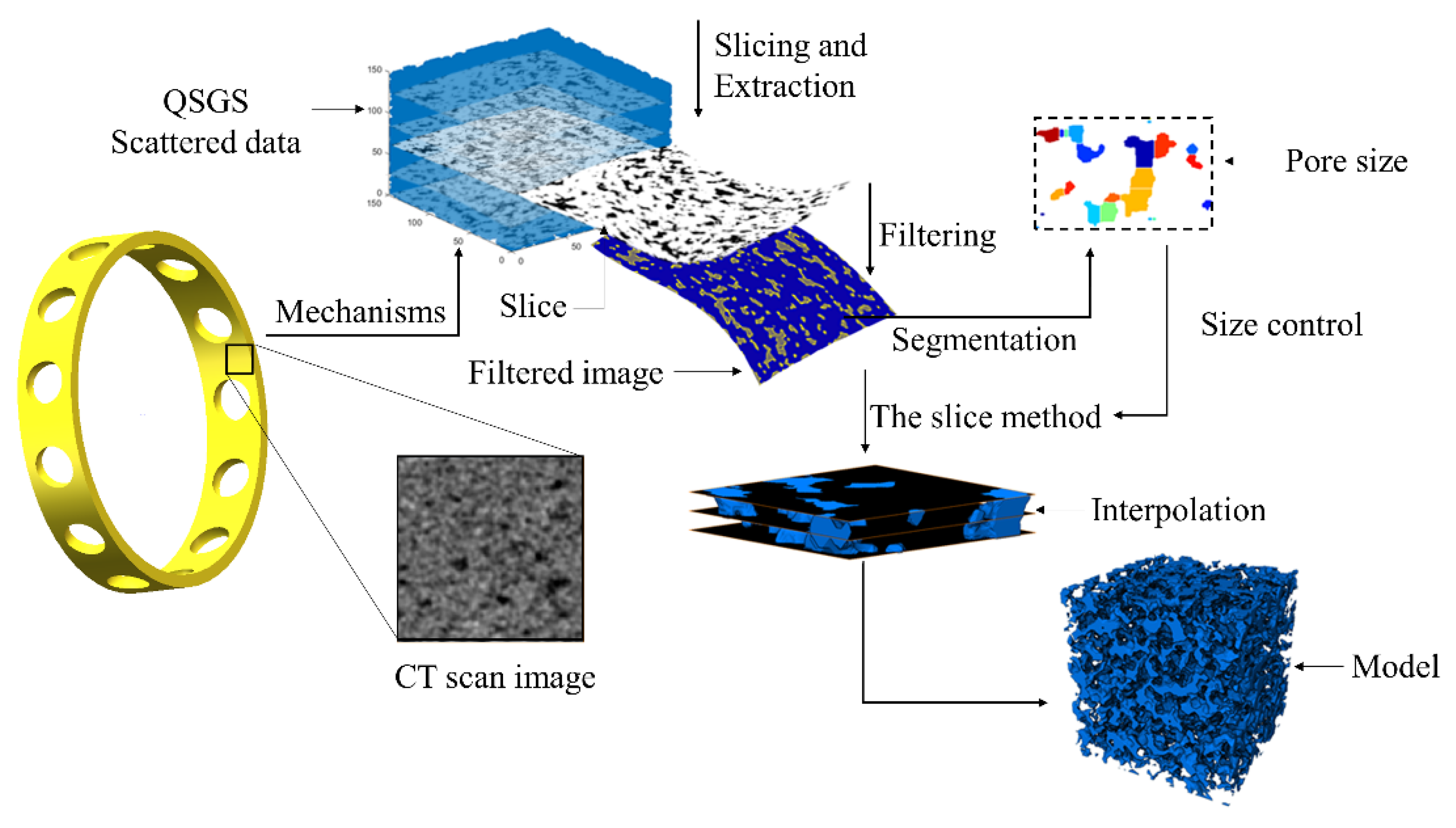

2. Modeling Principle

3. Modeling Process

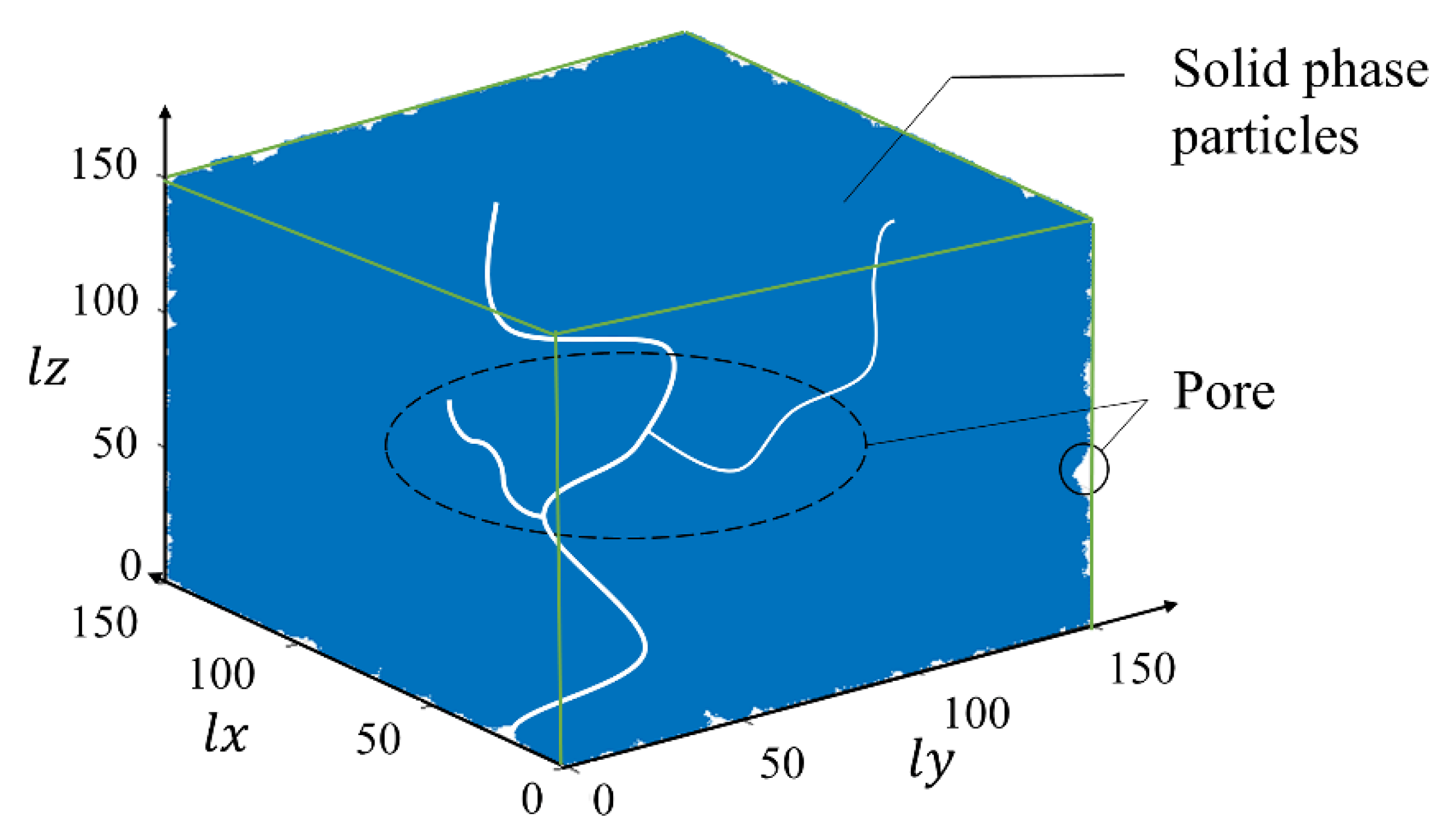

3.1. The QSGS Method

- (1)

- Set the dimensions (lx, ly, lz) and porosity n of the microscopic model, spread all the meshes within the set 3D porous model dimensions, and generate the growth phase nodes randomly, with each node representing a solid phase particle.

- (2)

- Set the growth probability and growth direction of the growing phase nodes so that the solid particles grow randomly in the three-dimensional space. The growth directions include 6 principal directions (Pd1–Pd6) and 12 angular directions (Pd7–Pd18). Due to the isotropic nature of the porous material, set Pd1–Pd6 to be equal and Pd7–Pd18 to be equal.

- (3)

- Iterate over the node coordinates of all growth phases, and assign a random number between 0 and 1 in each growth direction of each node. If this random number is less than the corresponding probability Pdi, add a growth phase node along the corresponding direction.

- (4)

- Count the number of the nodes of the growth phase, and calculate the porosity reached during growth to see if the porosity defined is reached; if not, repeat step (3).

- (5)

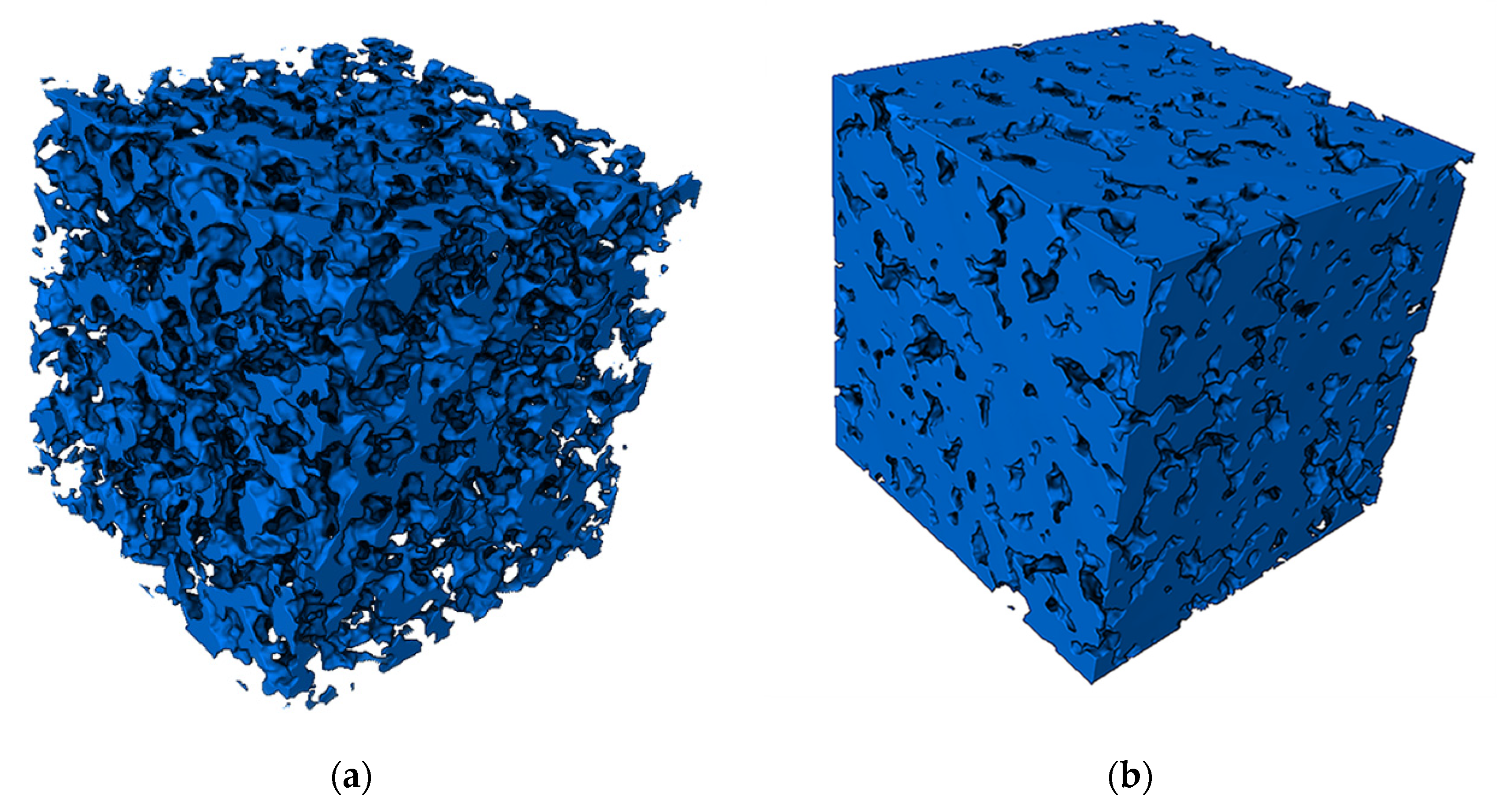

- The growth mechanism of the QSGS method leads to a lower growth probability of the grid edge than that of the internal growth phase. Therefore, remove the model boundary for a specific length range from the original pore model.

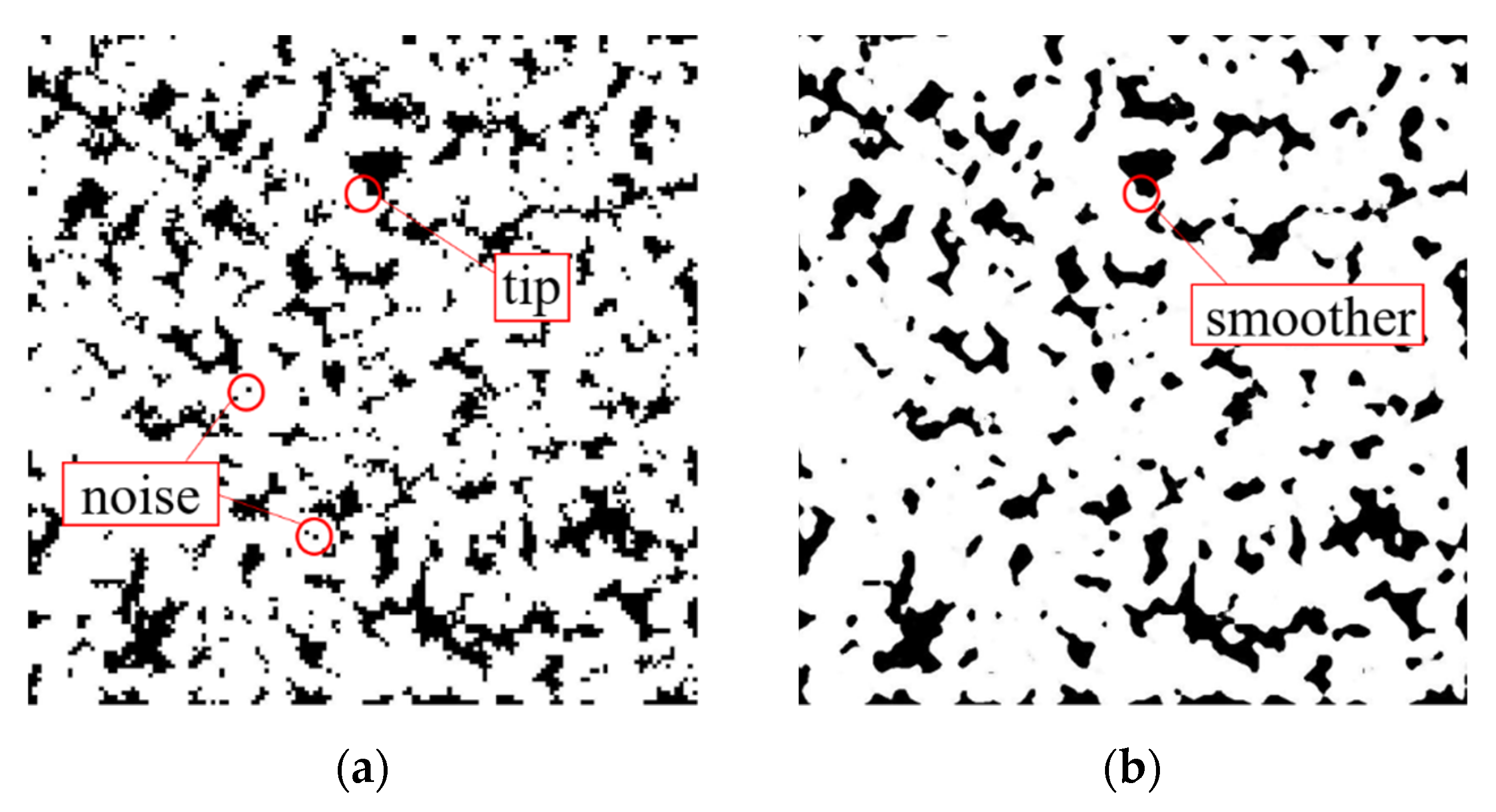

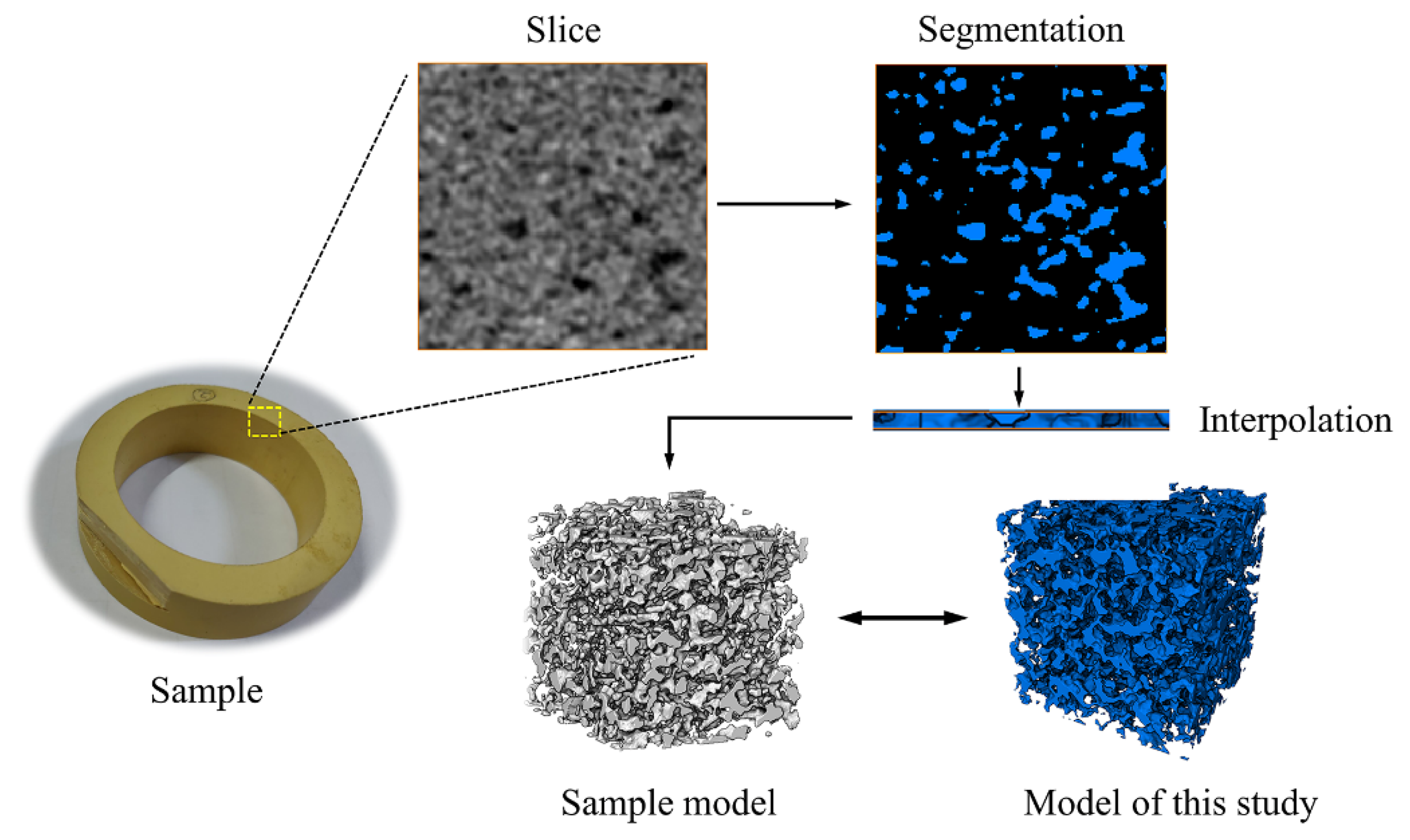

3.2. Slice Extraction and Median Filtering

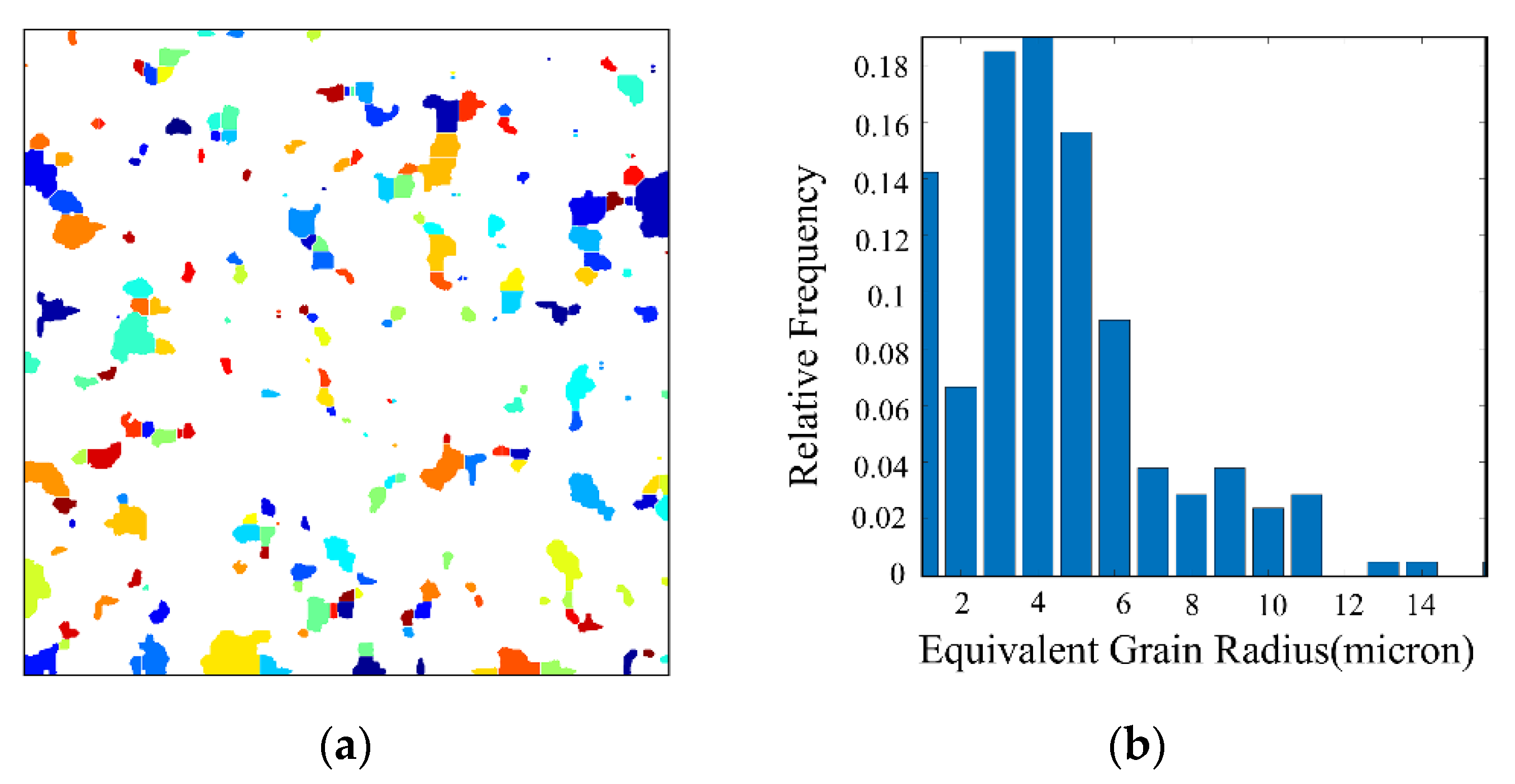

3.3. Watershed Segmentation and Pore Size Control

3.4. Model Reconstruction and Meshing

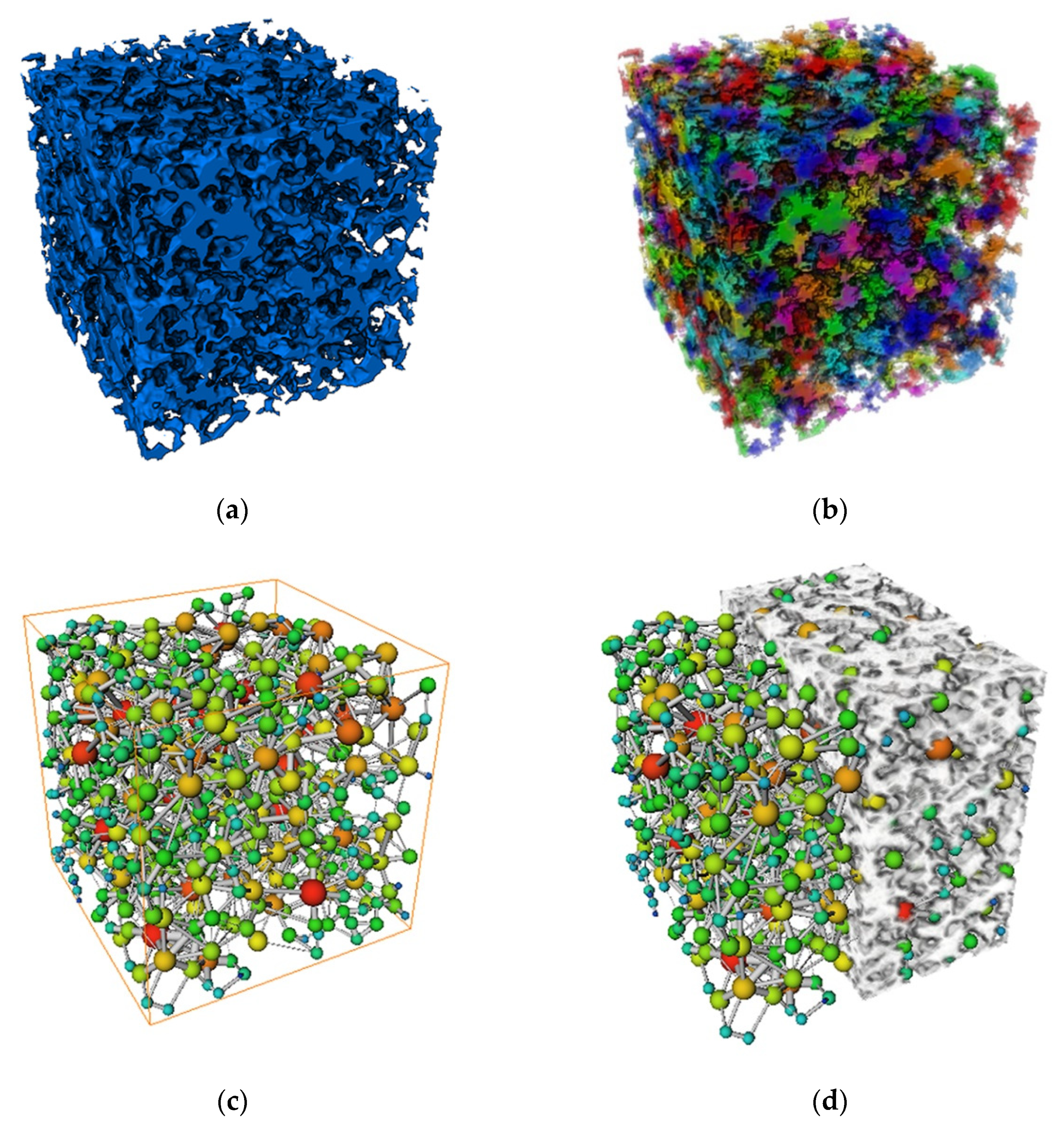

4. Structural Analysis of Porous Material Model

4.1. Experimental Verification

4.2. Analysis of Structural Parameters of Porous Materials

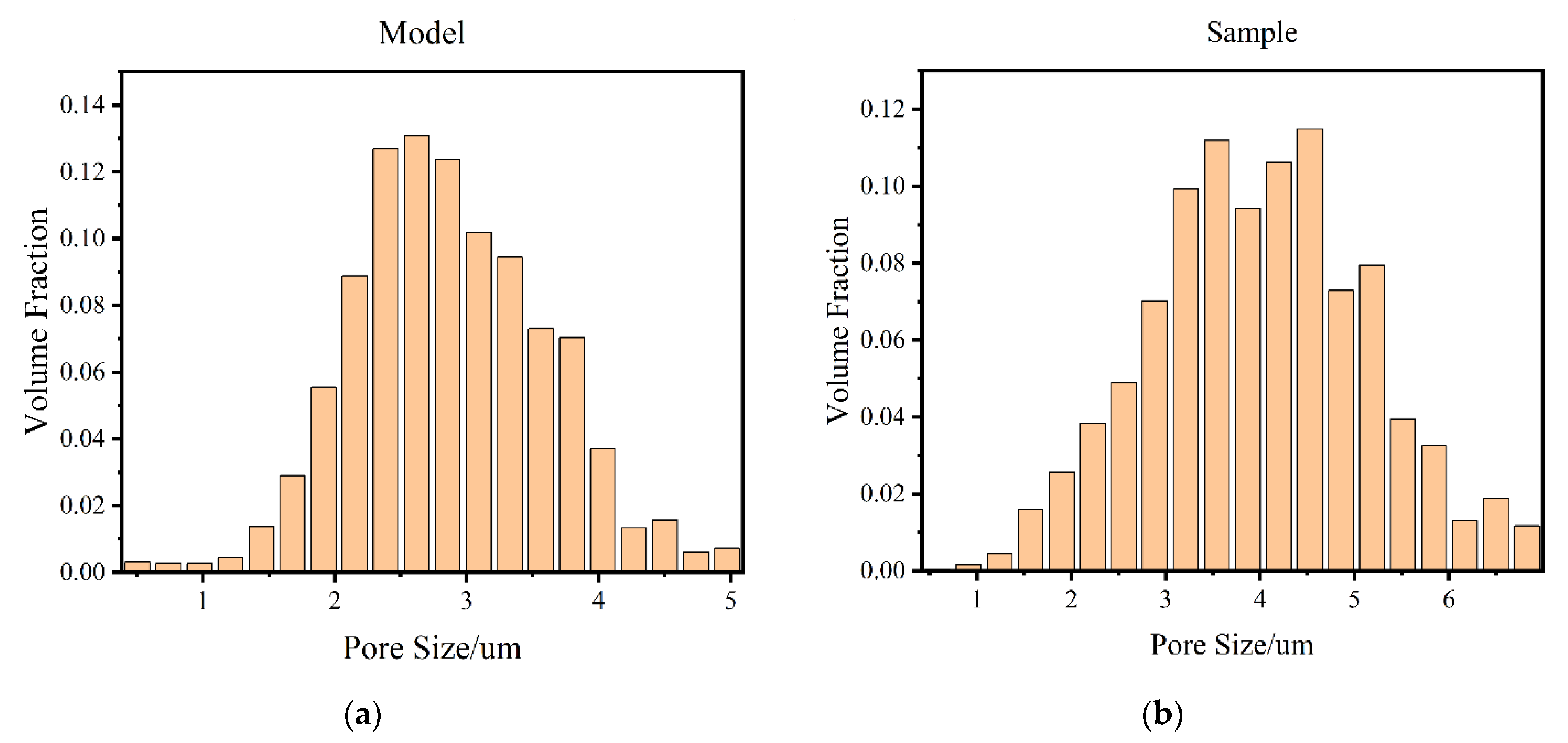

4.2.1. Pore Size Distribution

4.2.2. Coordination Number

4.2.3. Sphericity

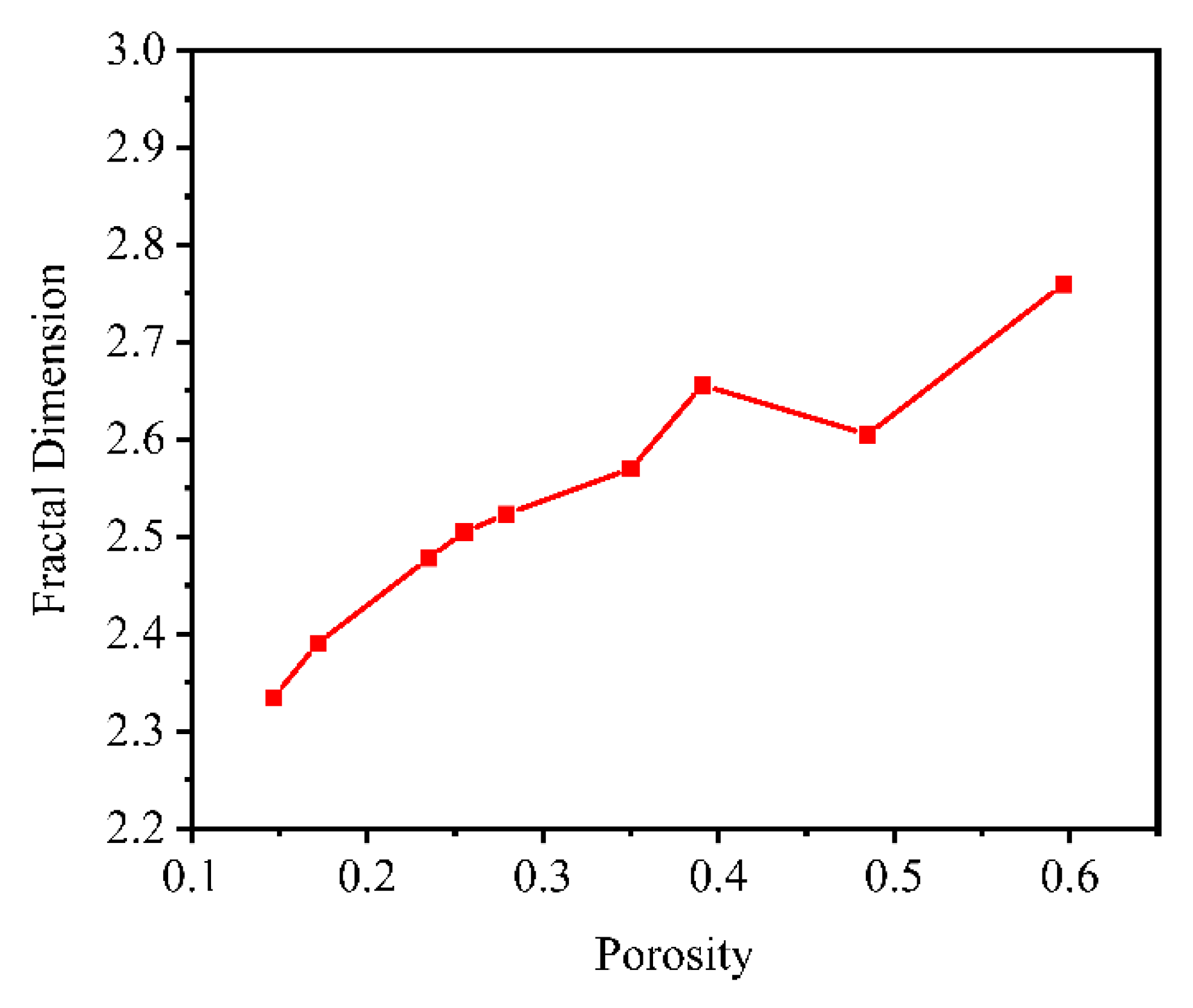

4.2.4. Fractal Dimension

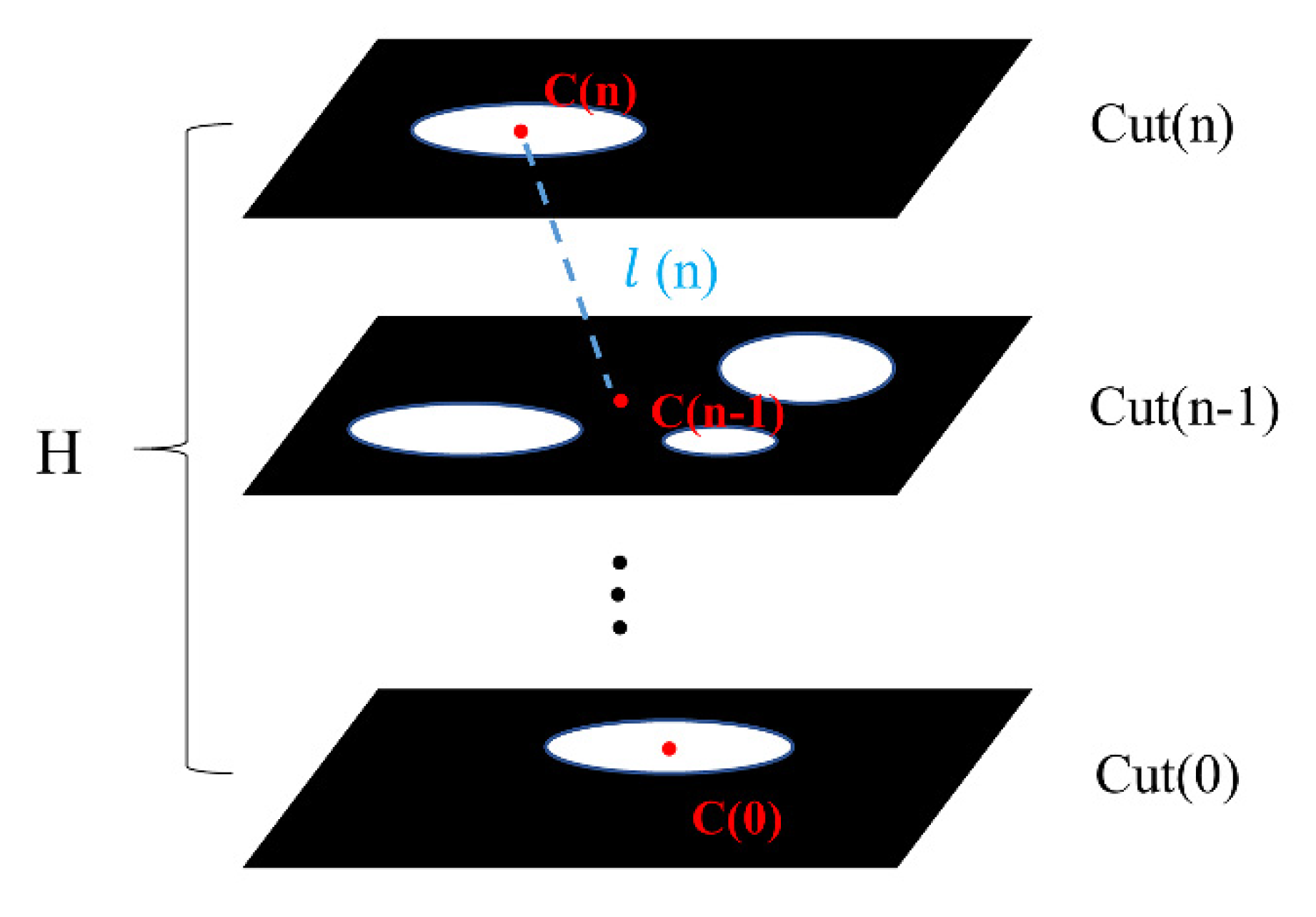

4.2.5. Tortuosity

4.3. Control of Porosity and Pore Size

5. Simulation

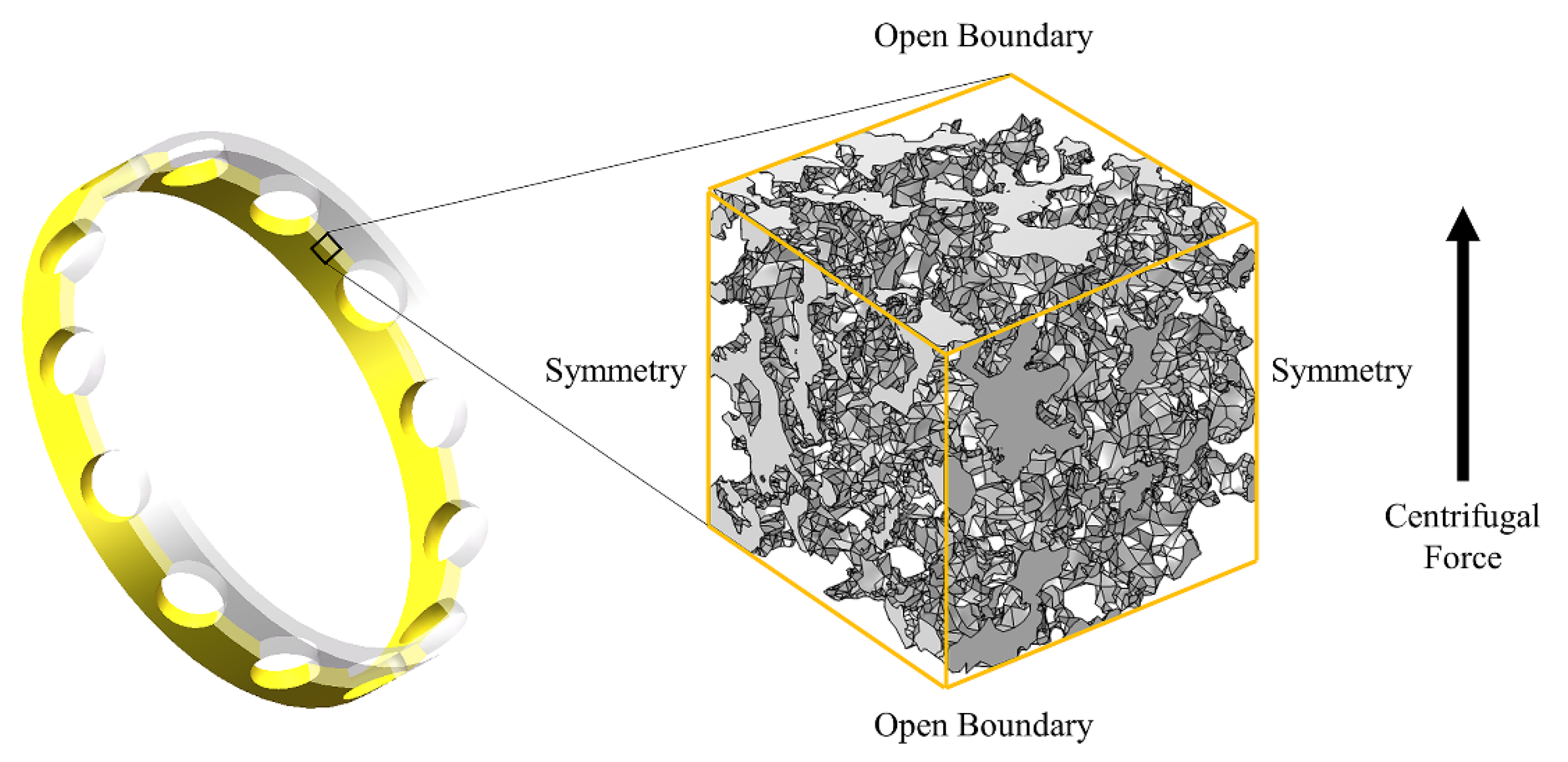

5.1. Centrifugal Force Simulation

5.1.1. Creeping Flow Equation and Boundary Conditions

5.1.2. Simulation Results

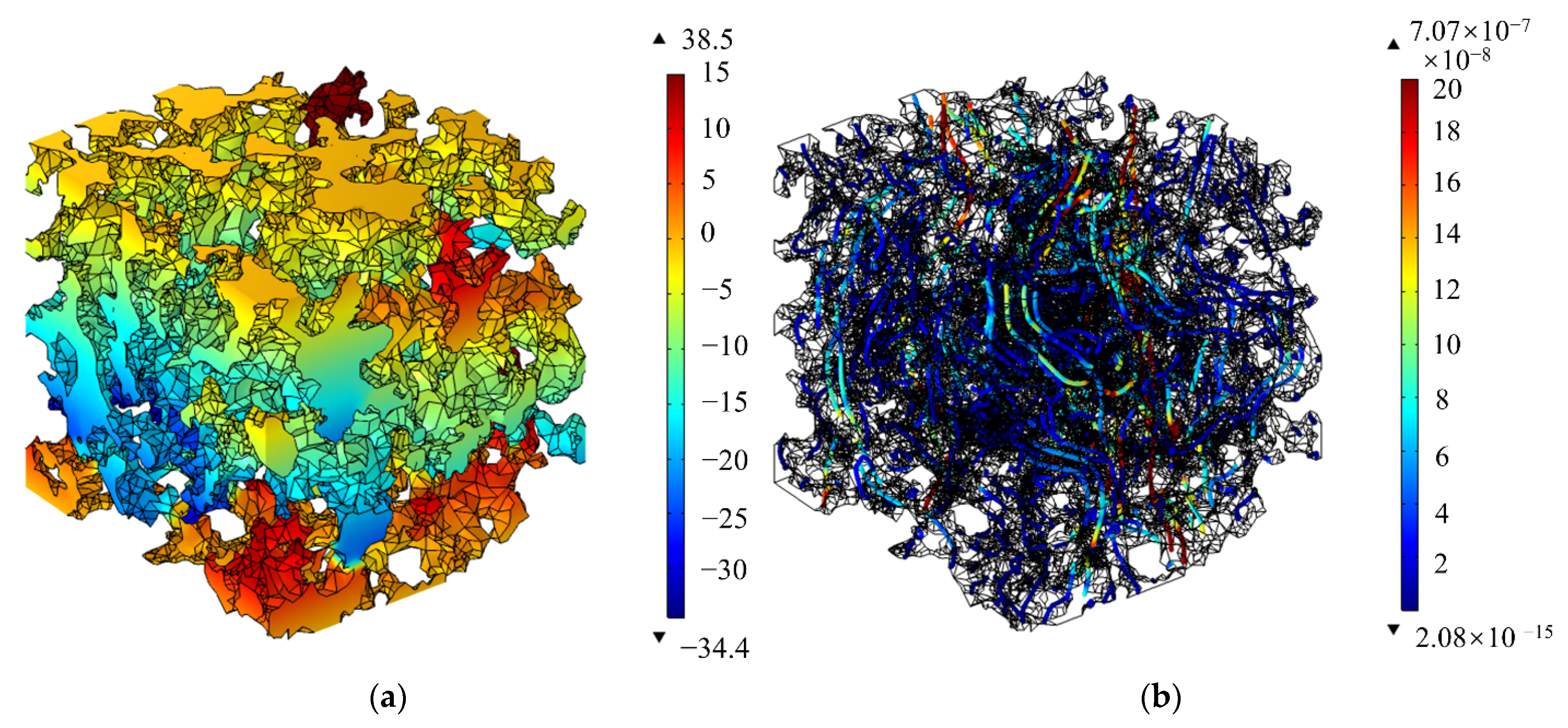

- Simulation ProcessThe transient solver was selected to study the oil flow out of the porous material under the action of centrifugal force. The input of the simulation is shown in Table 3.The oil pressure and velocity streamlines in porous materials were obtained, as shown in Figure 17.

- As can be seen in Figure 17, the distribution and structure of the pores in a porous material had a significant effect on the local pressure and flow rate of the fluid. Within the porous material, the pressure at the blind end of the pore growing in the direction of the centrifugal force was more drastic and the oil pressure is higher. The closed pores growing in the opposite direction of the centrifugal force had a lower oil pressure because it was difficult to replenish the fluid. Besides, it can be seen that the flow velocity was faster in the orifice with less curvature of the material structure and smooth flow lines. Effect of porosity on oil output;

5.2. Capillary Force Simulation

5.2.1. Level Set Equations, Wetted Wall, and Boundary Conditions

5.2.2. Simulation Results

6. Conclusions

- (1)

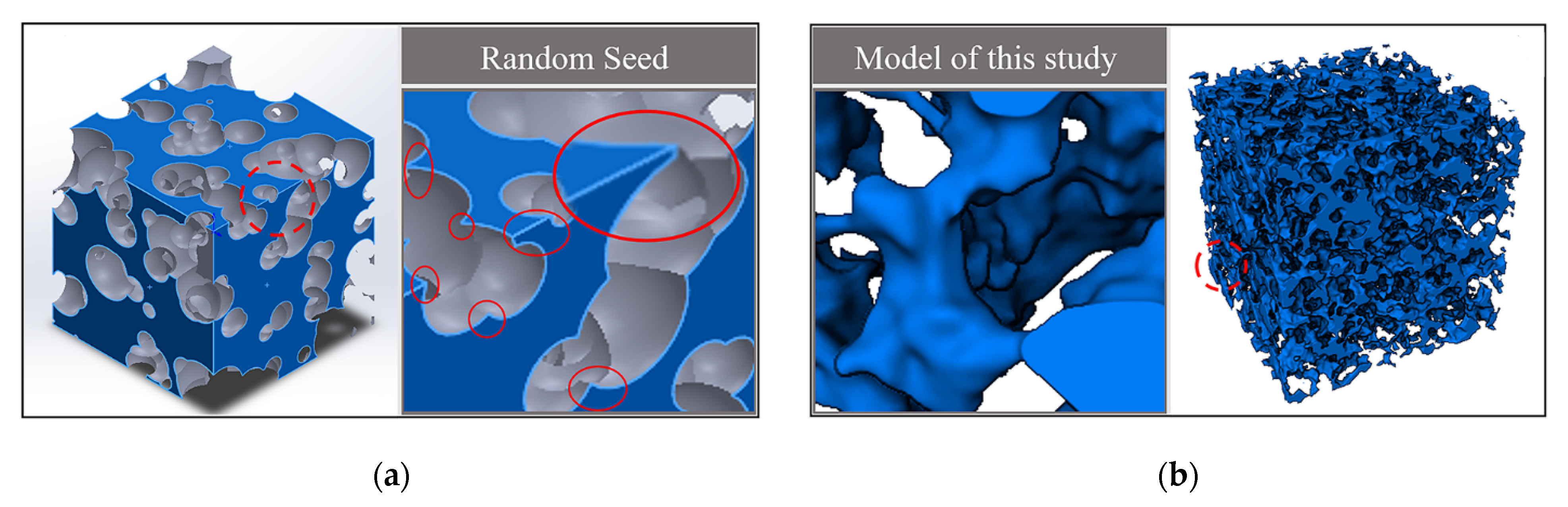

- Considering the process of pore generation in porous materials, this study proposed a modeling method of a highly similar micro-pore structure based on the idea of median filtering and the combination of the quartet structure generation set (QSGS) method and the slice method. The pore structure scatter data of porous materials were constructed by the QSGS method. In addition, the median filtering method, watershed segmentation method, and the slice method were used to optimize the pore structure, control the pore size, and build the solid model, respectively. The model had a curved structure and smooth transition of pore structure, which had high similarity with porous materials. In addition, the original numerical modeling method was difficult for simulation software analysis, while the model constructed by the modeling method in this paper used the median filtering algorithm and interpolation to optimize the edges of the pore structure, avoiding the influence of tip and distortion on the mesh division, resulting in the constructed model being beneficial to meshing and finite element software simulation. Compared with the traditional modeling methods, the 3D solid model constructed by the method in this paper is more natural; moreover, the porosity and average pore size of the model can be effectively controlled.

- (2)

- Based on the constructed porous material model, the pore structure parameters of the model, such as pore diameter, coordination number, sphericity, fractal dimension, and tortuosity, were extracted and analyzed to facilitate the study of the structure and lubrication performance of porous oil-containing cages. The pore size distribution and sphericity distribution of the model were compared with the experimental results of CT scanning, and the reasonableness of the model was verified.

- (3)

- Based on the 3D model generated by the above modeling method, the simulation of oil splashing by centrifugal force and the simulation of capillary oil absorption for porous materials were performed. Combined with structural parameters such as porosity, the effect of pore structure on the self-lubricating performance of the porous oil-containing cage was analyzed. The feasibility of the modeling method proposed in this study was verified by comparing the simulation results with the experimental findings of others.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qiu, Y.; Wang, Q.; Wang, C.; Wang, T. Oil-containing and Tribological Properties of Porous Polyimide Containing Lubricant Oil. Tribology 2012, 32, 538–543. (In Chinese) [Google Scholar]

- Niu, R.; Zhang, J.; Ni, Y. 2018 8th International Conference on Manufacturing Science and Engineering (ICMSE 2018). In Performance Analysis of Graphene Modified Porous Oil Retainer Materials; Atlantis Press: Shenzhen, China, 2018; pp. 164–168. [Google Scholar]

- Wang, J.; Zhao, H.; Huang, W.; Wang, X. Investigation of porous polyimide lubricant retainers to improve the performance of rolling bearings under conditions of starved lubrication. Wear 2017, 380–381, 52–58. [Google Scholar] [CrossRef]

- Lee, Y.-J.; Lee, K.-H.; Lee, C.-H. Self-Lubricating and Friction Performance of a Three-Dimensional-Printed Journal Bearing. J. Tribol. 2018, 140, 054501. [Google Scholar] [CrossRef]

- Whitaker, A. A Self-Lubricating Bearing; Final Report; NASA Marshall Space Flight Center: Huntsville, AL, USA, 1974.

- Baychev, T.G.; Jivkov, A.P.; Rabbani, A.; Raeini, A.Q.; Xiong, Q.; Lowe, T.; Withers, P.J. Reliability of Algorithms Interpreting Topological and Geometric Properties of Porous Media for Pore Network Modelling. Transp. Porous Media 2019, 128, 271–301. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Wu, K.; Scott, G.G.; Akisanya, A.R.; Gan, Q.; Zhou, Y. A New Method for Pore Structure Quantification and Pore Network Extraction from SEM Images. Energy Fuels 2020, 34, 82–94. [Google Scholar] [CrossRef]

- Eslami, H.; Rahimi, M.; Müller-Plathe, F. Molecular Dynamics Simulation of a Silica Nanoparticle in Oligomeric Poly(methyl methacrylate): A Model System for Studying the Interphase Thickness in a Polymer–Nanocomposite via Different Properties. Macromolecules 2013, 46, 8680–8692. [Google Scholar] [CrossRef]

- Eslami, H.; Gharibi, A.; Müller-Plathe, F. Mechanisms of Nucleation and Solid-Solid-Phase Transitions in Triblock Janus Assemblies. J. Chem. Theory Comput. 2021, 17, 1742–1754. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Chen, B. Feature-based three-dimensional reconstruction of scanning electron microscope stereo pairs. J. Chin. Electron Microsc. Soc. 1997, 1, 51–58. (In Chinese) [Google Scholar]

- Hidajat, I.; Rastogi, A.; Singh, M.; Mohanty, K. Transport Properties of Porous Media Reconstructed From Thin-Sections. SPE J. 2002, 7, 40–48. [Google Scholar] [CrossRef]

- Huang, F. Three-Dimensional Reconstruction and Simulation of Porous Media (in Chinese). Ph.D. Dissertation, University of Science and Technology of China, Hefei, China, 2007. [Google Scholar]

- Hajizadeh, A.; Safekordi, A.; Farhadpour, F.A. A multiple-point statistics algorithm for 3D pore space reconstruction from 2D images. Adv. Water Resour. 2011, 34, 1256–1267. [Google Scholar] [CrossRef]

- Li, R.; Liu, S.; Fang, L.; Du, Y. Micro-structure of Clay Generated by Quartet Structure Generation Set. J. Zhejiang Univ. 2010, 44, 1897–1901. (In Chinese) [Google Scholar]

- Yin, T.; Sun, X.; Yan, K.; Hong, J.; Zhu, Y.; Li, Y. Research on Modeling Method of Porous Oil-containing Cage Based on Random Seeds. J. Mech. Eng. in press. (In Chinese).

- Zhu, H. Pore Structure Characterization of Low Permeability Sandstone Reservoirs and Application. Ph.D. Dissertation, Southwest Petroleum University, Chengdu, China, 2014. (In Chinese). [Google Scholar]

- Fakhari, A.; Li, Y.; Bolster, D.; Christensen, K.T. A phase-field lattice Boltzmann model for simulating multiphase flows in porous media: Application and comparison to experiments of CO2 sequestration at pore scale. Adv. Water Resour. 2018, 114, 119–134. [Google Scholar] [CrossRef]

- Fakhari, A.; Geier, M.; Bolster, D. A simple phase-field model for interface tracking in three dimensions. Comput. Math. Appl. 2016, 78, 1154–1165. [Google Scholar] [CrossRef]

- Wang, M.; Pan, N. Numerical analyses of effective dielectric constant of multiphase microporous media. J. Appl. Phys. 2007, 101, 114102. [Google Scholar] [CrossRef] [Green Version]

- Vincent, L.; Soille, P. Watersheds in digital spaces: An efficient algorithm based on immersion simulations. IEEE Comput. Arch. Lett. 1991, 13, 583–598. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Zhou, X.; Wei, L. Image Segmentation Based on Watershed Algorithm. Comput. Simul. 2009, 26, 255–258. [Google Scholar] [CrossRef]

- Xie, C.; Zhang, W.; Yao, D.; Wang, J.; Zhu, Y. Quantitative Characterization of Spatial Pore Network of Soils Based on Maximal-balls Algorithm (in Chinese). J. Eng. Geol. 2020, 28, 60–68. (In Chinese) [Google Scholar]

- Peng, R.; Yang, Y.; Ju, Y.; Mao, L.; Yang, Y. Calculation of Fractal Dimension of Rock Pores Based on Grayscale CT Images. Chin. Sci. Bull. 2011, 56, 2256–2266. (In Chinese) [Google Scholar] [CrossRef] [Green Version]

- Yan, K.; Yin, T.; Sun, J.; Hong, J.; Zhu, Y. Flow Mechanism Characterization of Porous Oil-Containing Material Base on Micro-Scale Pore Modeling. Materials 2021, 14, 3896. [Google Scholar] [CrossRef] [PubMed]

- Valikhani, A.; Jaberi Jahromi, A.; Mantawy, I.M.; Azizinamini, A. Numerical Modelling of Concrete-to-UHPC Bond Strength. Materials 2020, 13, 1379. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sucharda, O. Identification of Fracture Mechanic Properties of Concrete and Analysis of Shear Capacity of Reinforced Concrete Beams without Transverse Reinforcement. Materials 2020, 13, 2788. [Google Scholar] [CrossRef] [PubMed]

| Porosity | Fractal Dimension |

|---|---|

| 0.235056 | 2.47984 |

| 0.236298 | 2.47773 |

| 0.235618 | 2.48099 |

| 0.23559 | 2.47853 |

| 0.234892 | 2.47744 |

| Model | Porosity |

|---|---|

| MATLAB | 0.26 |

| Avizo | 0.2374 |

| Avizo-connectivity | 0.2356 |

| Model Settings | Value |

|---|---|

| Model Size [um] | 50 × 50 × 50 |

| Porosity | 27.298% |

| Cage speed [rpm] | 2000 |

| Output time [s] | Range (0, 0.025, 5) |

| Pore size (Matlab) [um] | 1 |

| Material | Polyimide |

| Physical Field | Creep flow |

| Temperature (K) | 303 |

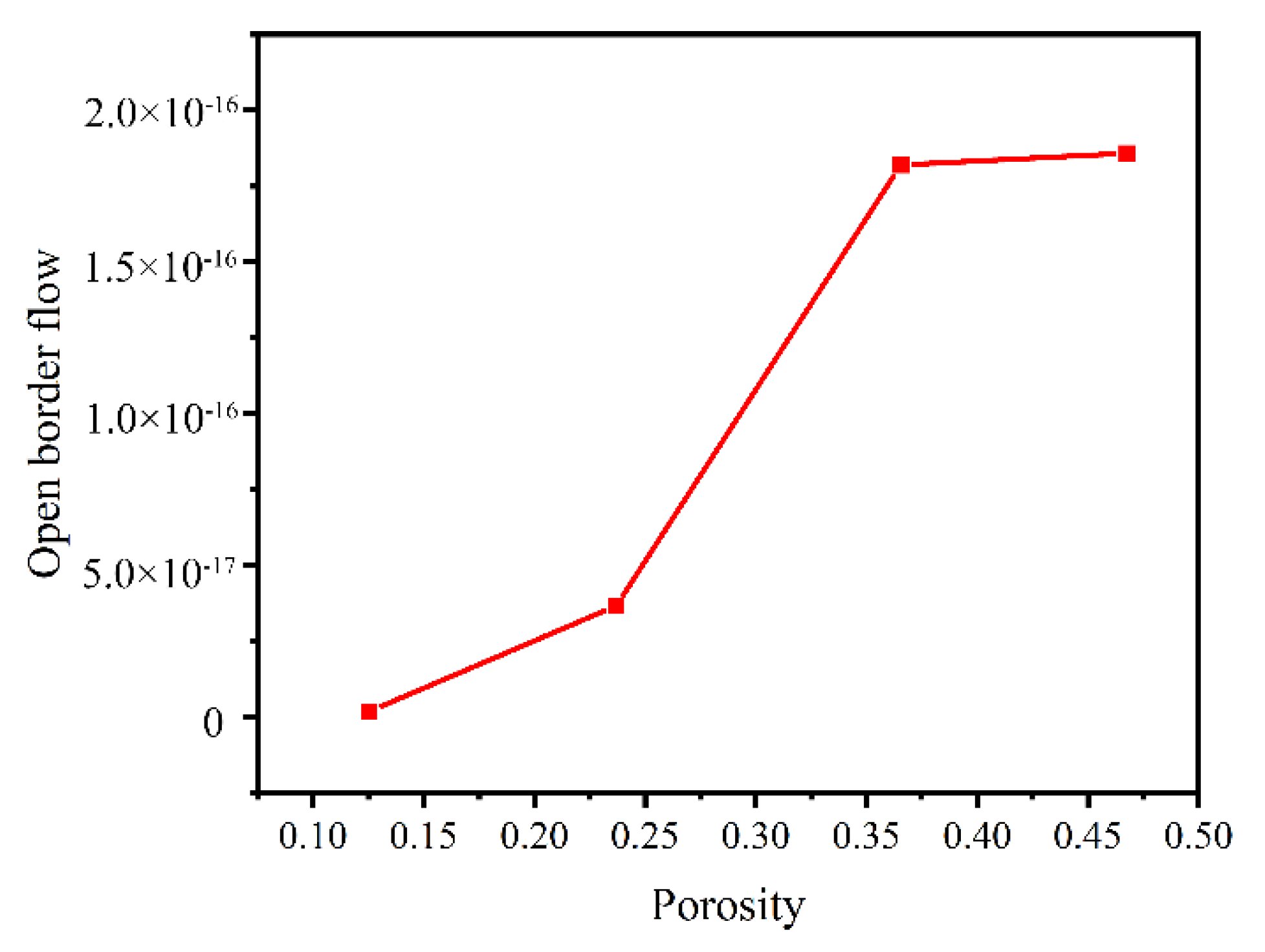

| Model | Porosity |

|---|---|

| 1 | 12.545% |

| 2 | 23.691% |

| 3 | 36.541% |

| 4 | 46.759% |

| Model | Oil Output [m3/s] |

|---|---|

| 1 | 1.92 × 10−18 |

| 2 | 3.66 × 10−17 |

| 3 | 1.82 × 10−16 |

| 4 | 1.86 × 10−16 |

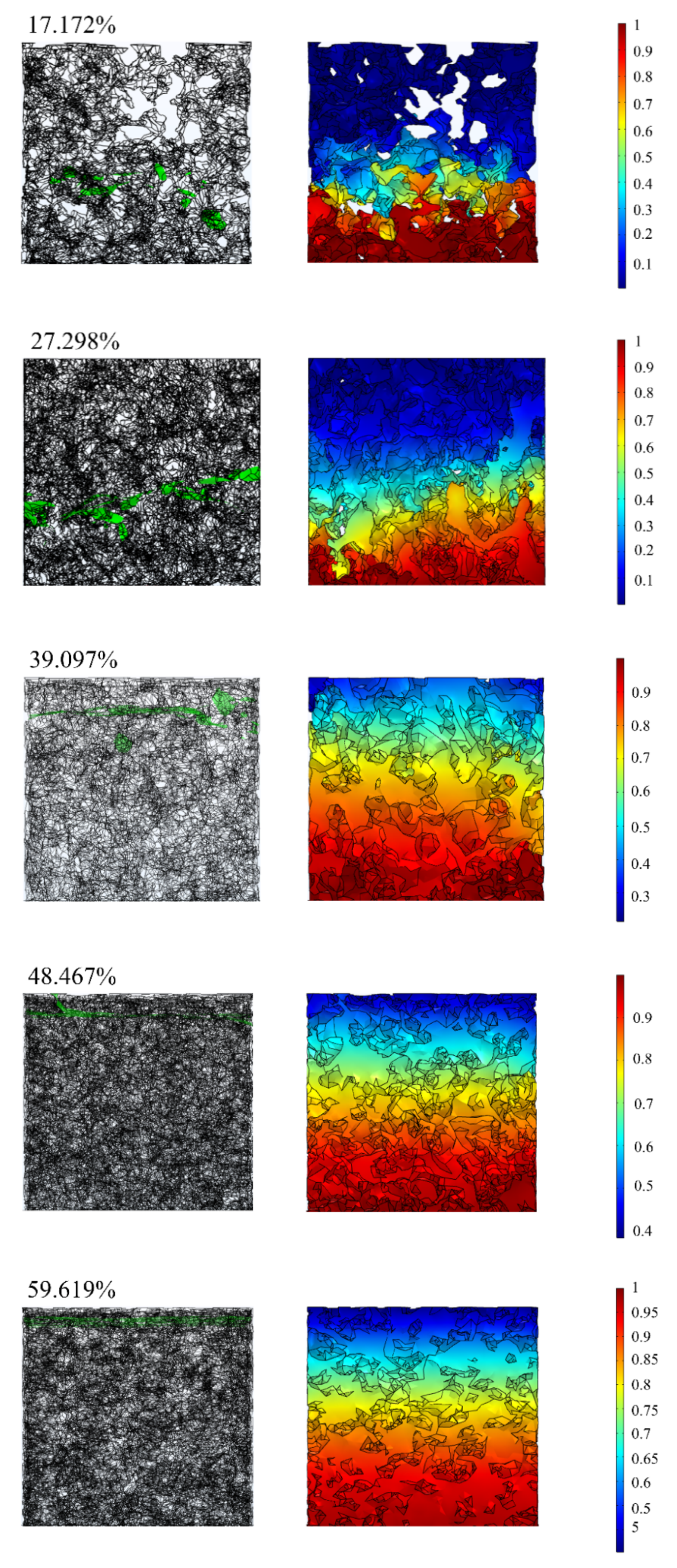

| Model Settings | Value |

|---|---|

| Model Size [um] | 50 × 50 × 50 |

| Porosity | 17.172%, 27.298%, 39.097%, 48.467%, 59.619% |

| Output time [s] | range (0, 0.02 × 10−3, 0.002) |

| Average Pore size (Matlab) [um] | 1 |

| Material | Polyimide |

| Physical Field | Creep flow, level set |

| Temperature [K] | 293 |

| Contact angle [°] | 15 |

| surface tension coefficient [N/m] | 0.04 |

| Dynamic viscosity [Pa·s] | 0.799407 (oil), 1.81323 × 10−5 (air) |

| Density [kg/m3] | 887.6808 (oil), 1.205 (air) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Yan, K.; Zhu, Y.; Hong, J. A High-Similarity Modeling Method for Low-Porosity Porous Material and Its Application in Bearing Cage Self-Lubrication Simulation. Materials 2021, 14, 5449. https://doi.org/10.3390/ma14185449

Sun J, Yan K, Zhu Y, Hong J. A High-Similarity Modeling Method for Low-Porosity Porous Material and Its Application in Bearing Cage Self-Lubrication Simulation. Materials. 2021; 14(18):5449. https://doi.org/10.3390/ma14185449

Chicago/Turabian StyleSun, Jiannan, Ke Yan, Yongsheng Zhu, and Jun Hong. 2021. "A High-Similarity Modeling Method for Low-Porosity Porous Material and Its Application in Bearing Cage Self-Lubrication Simulation" Materials 14, no. 18: 5449. https://doi.org/10.3390/ma14185449

APA StyleSun, J., Yan, K., Zhu, Y., & Hong, J. (2021). A High-Similarity Modeling Method for Low-Porosity Porous Material and Its Application in Bearing Cage Self-Lubrication Simulation. Materials, 14(18), 5449. https://doi.org/10.3390/ma14185449