Effect of BaTiO3 on the Properties of PVC-Based Composite Thick Films

Abstract

1. Introduction

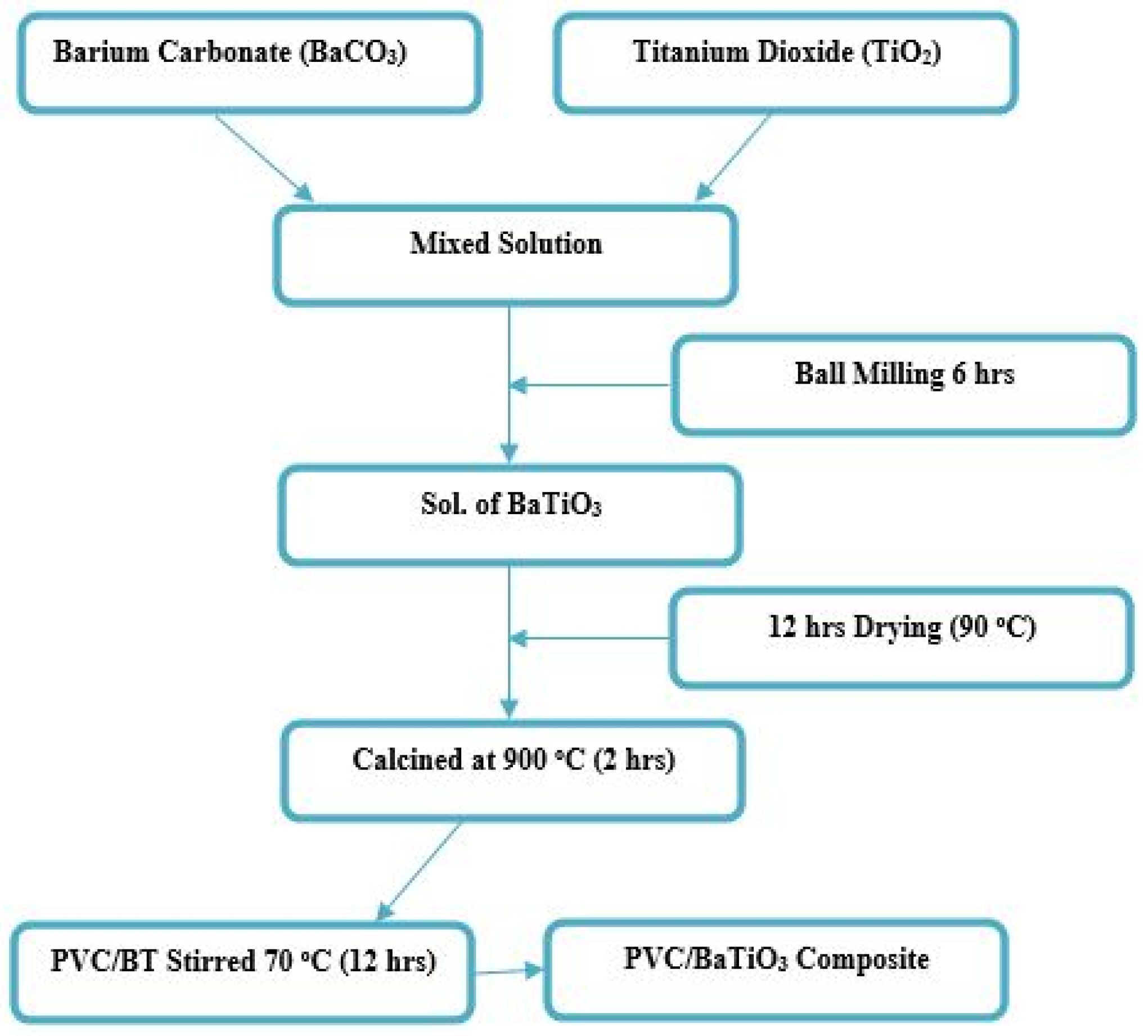

2. Materials and Synthesis

3. Characterization

4. Results and Discussion

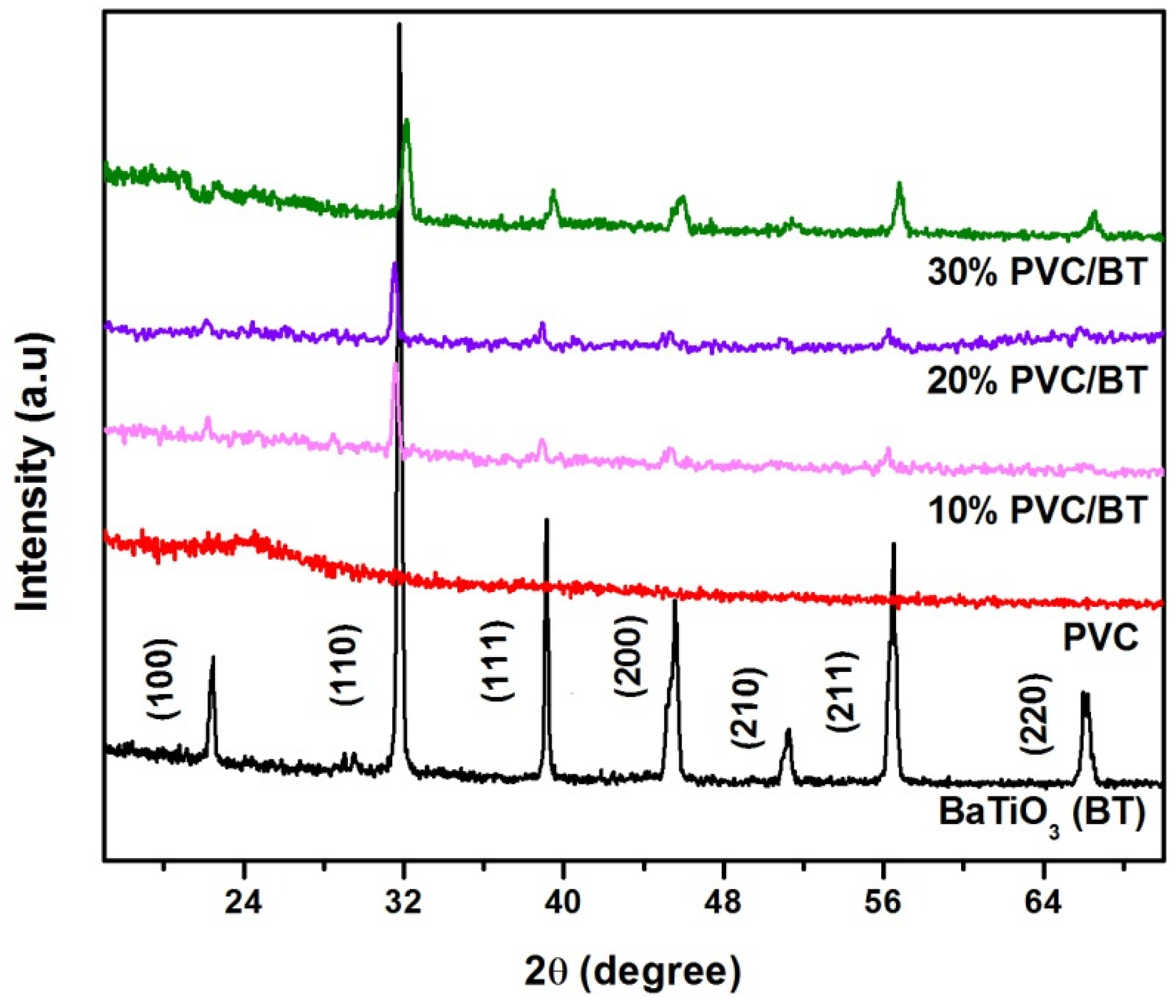

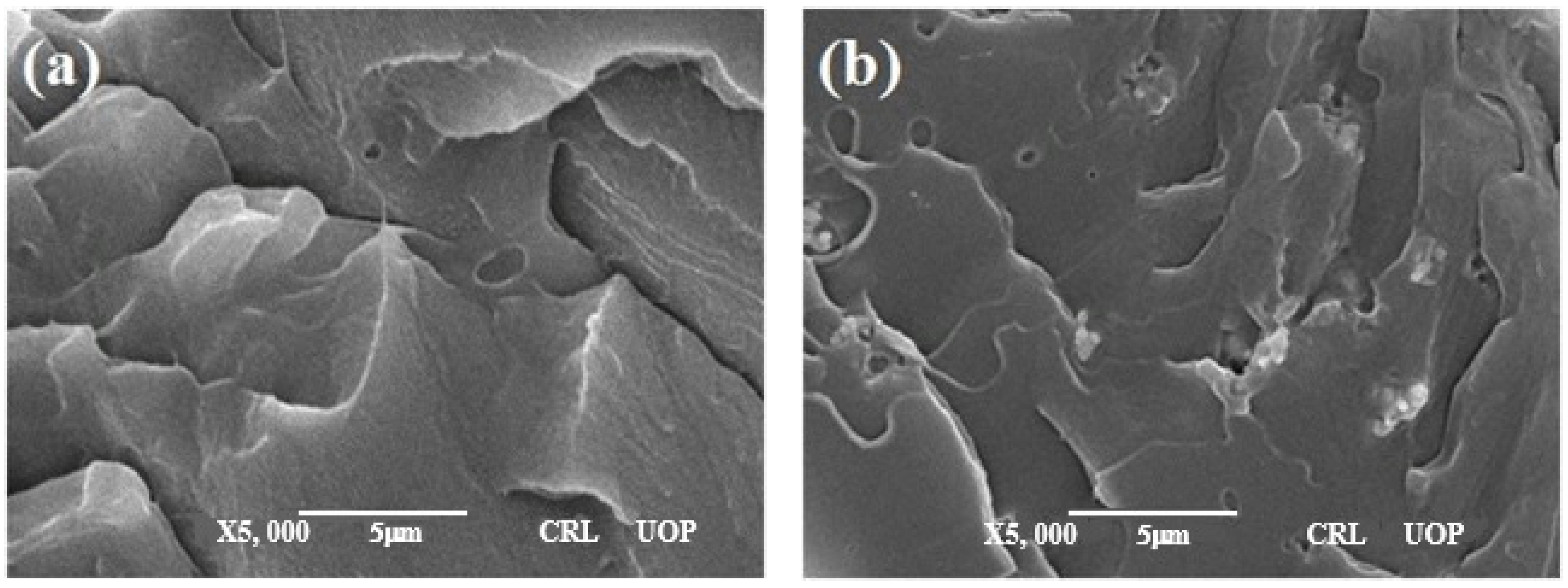

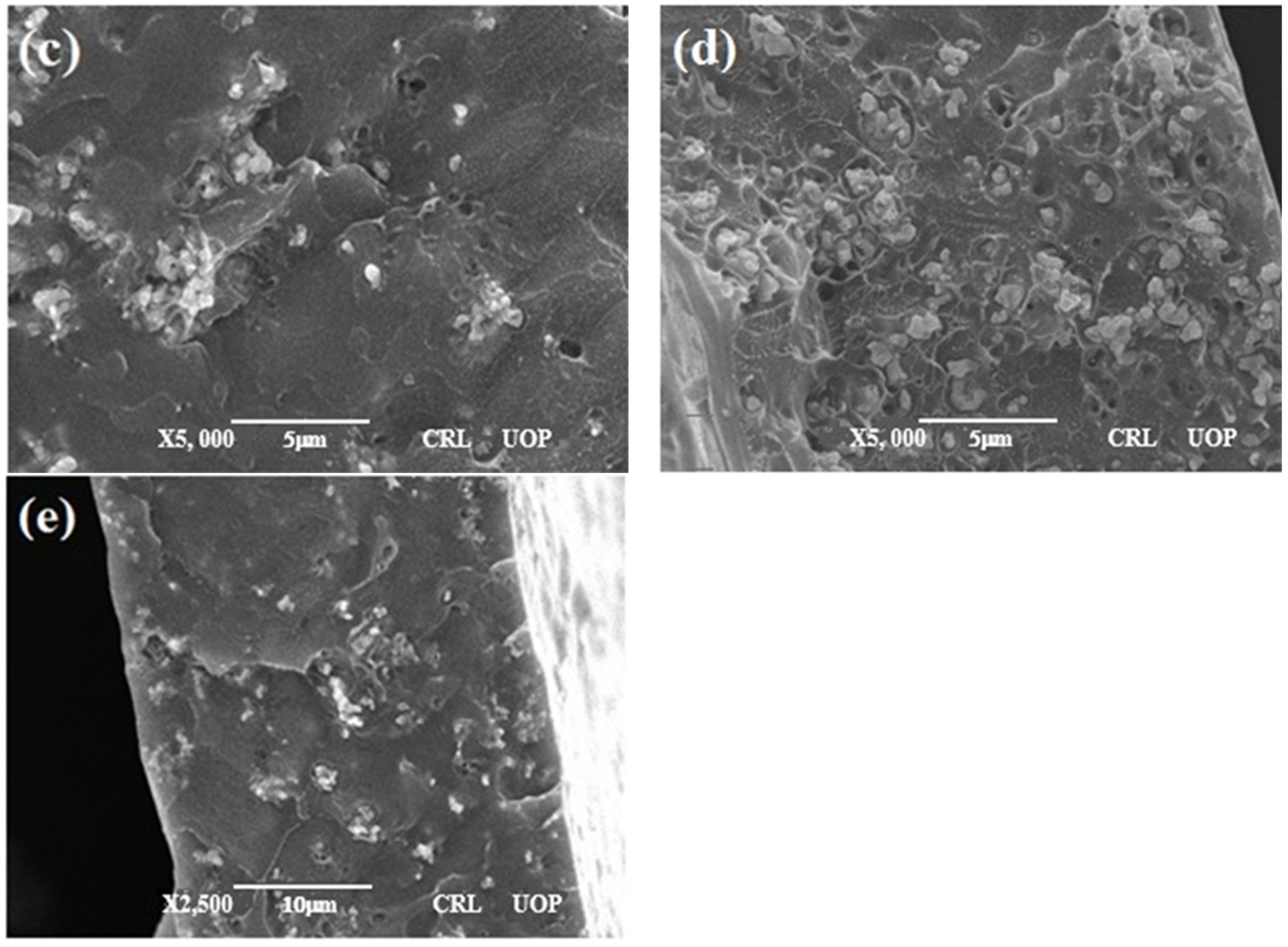

4.1. Phase and Microstructural Analyses

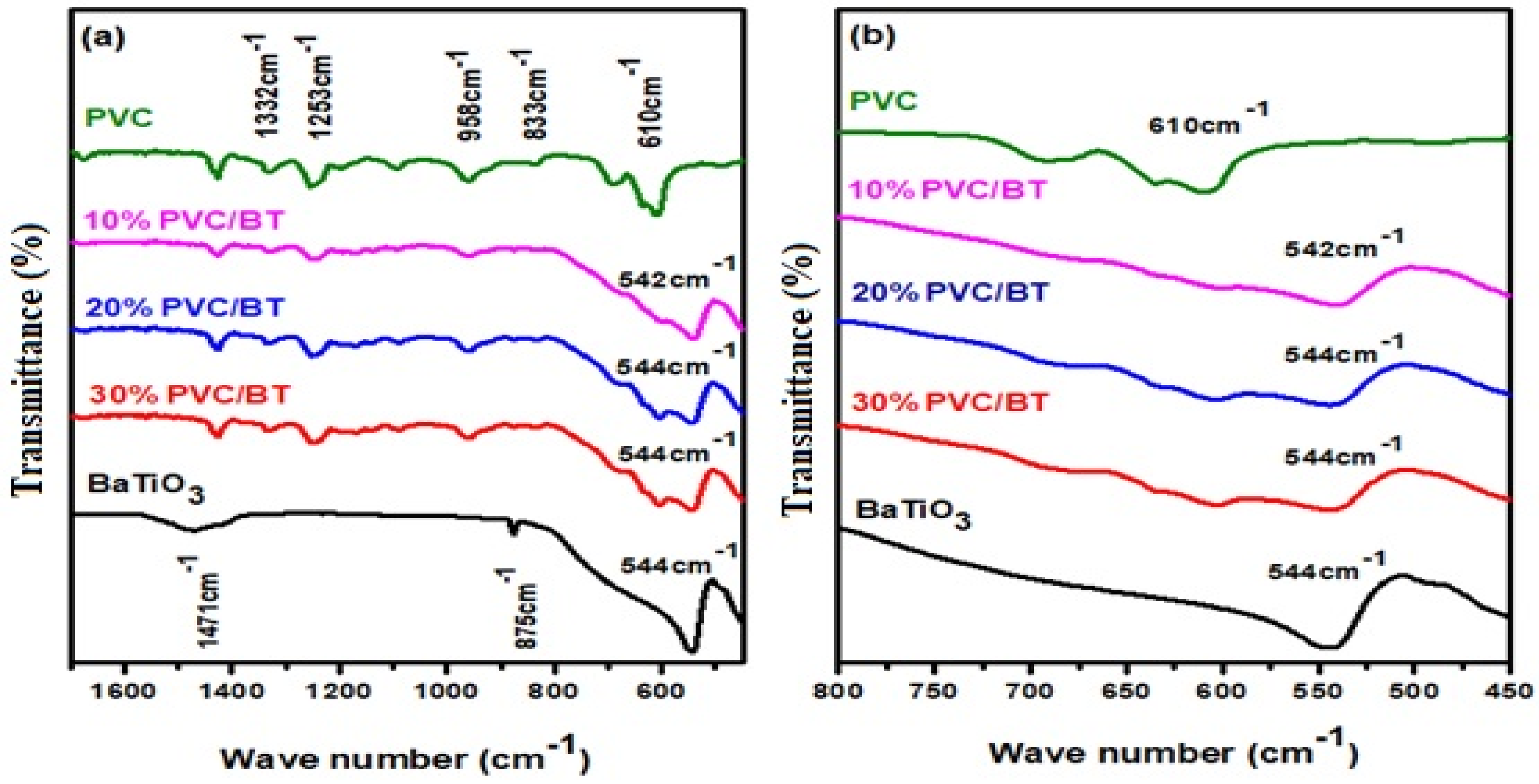

4.2. FTIR Analysis

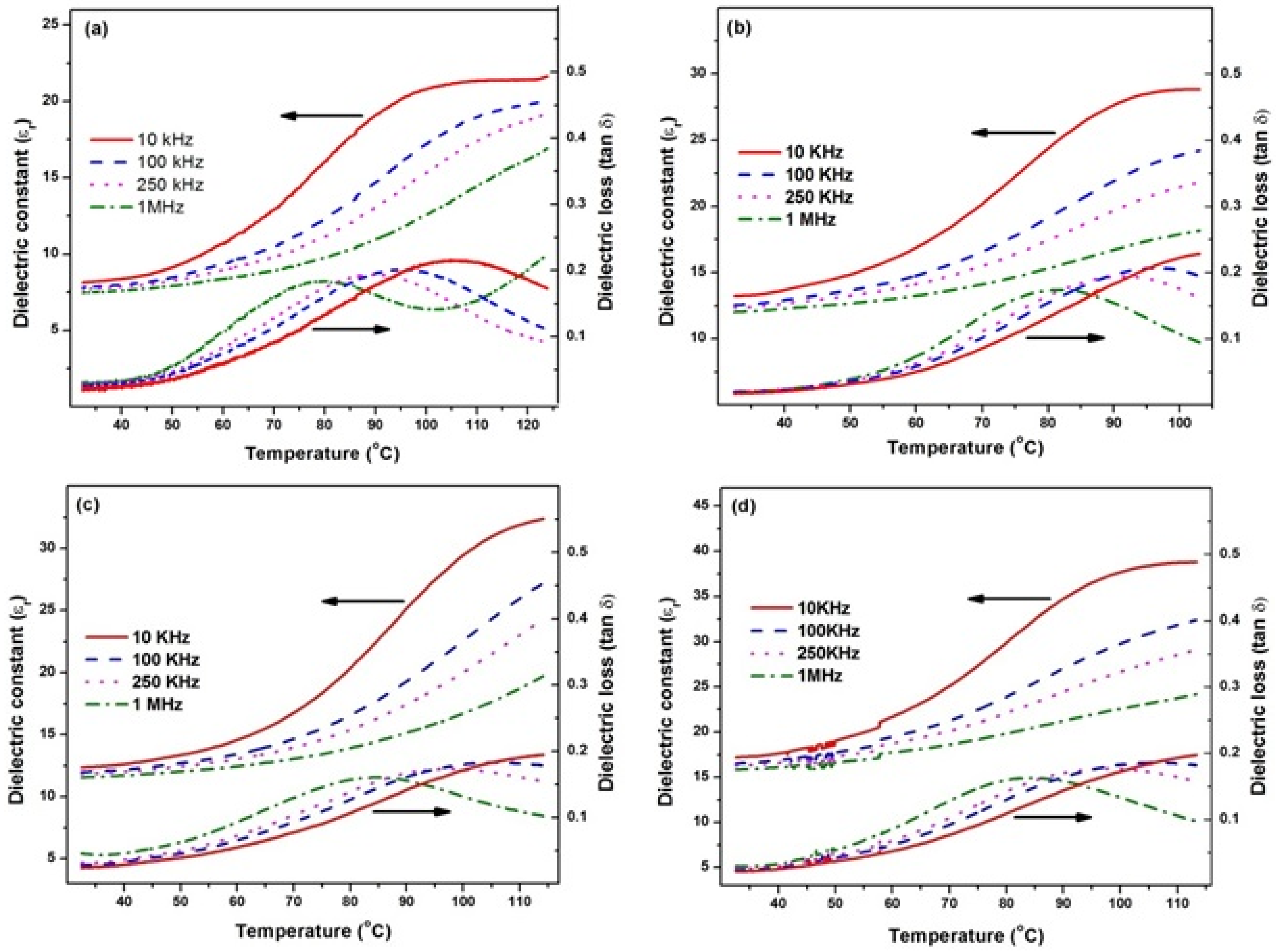

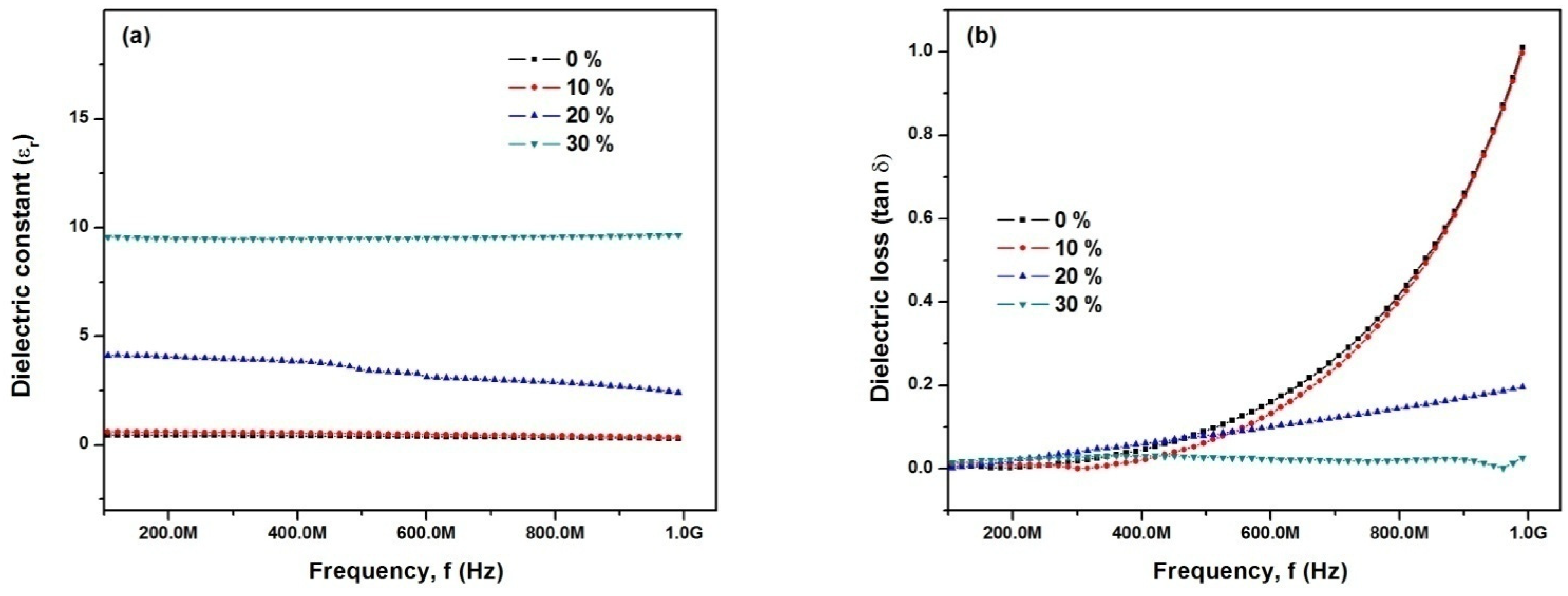

4.3. Dielectric Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jo, W.; Daniels, J.E.; Jones, J.L.; Tan, X.; Thomas, P.A.; Damjanovic, D.; Rödel, J. Evolving morphotropic phase boundary in lead-free (Bi1/2Na1/2)TiO3–BaTiO3 piezoceramics. J. Appl. Phys. 2011, 109, 014110. [Google Scholar] [CrossRef]

- Ali, A.; Uddin, S.; Lal, M.; Zaman, A.; Iqbal, Z.; Althubeiti, K. Structural, Optical and Microwave Dielectric Properties of Ba (Ti1−xSnx)4O9, 0 ≤ x ≤ 0.7 Ceramics. Sci. Rep. 2021, 11, 17889. [Google Scholar] [CrossRef]

- Ahmad, A.; Uddin, S.; Zheng, G.P.; Nasir, M.F. Synthesis and temperature dependent energy storage characterization of (Bi1/2Na1/2)0.94Ba0.06TiO3)–Ba1/2Sr1/2TiO3 ceramics. Phys. Scr. 2021, 96, 095809. [Google Scholar] [CrossRef]

- Kao, K.C. Dielectric Phenomena in Solids; Elsevier Academic Press: Cambridge, MA, USA, 2004; pp. 250–251. [Google Scholar]

- Dang, Z.M.; Yuan, J.K.; Yao, S.H.; Liao, R.J. Flexible nanodielectric materials with high permittivity for power energy storage. Adv. Mater. 2013, 25, 6334–6365. [Google Scholar] [CrossRef] [PubMed]

- Moulson, J.; Herbert, J.M. Electroceramics; John Wiley & Sons Ltd.: Sussex, UK, 2003; pp. 339–432. [Google Scholar]

- Sebastian, M.T.; Jantunen, H. Polymer–ceramic composites of 0–3 connectivity for circuits in electronics: A review. Int. J. Appl. Ceram. Technol. 2010, 7, 415–434. [Google Scholar] [CrossRef]

- Dang, Z.M.; Yuan, J.K.; Zha, J.W.; Zhou, T.; Li, S.T.; Hu, G.H. Fundamentals, processes and applications of high-permittivity polymer–matrix composites. Prog. Mater. Sci. 2012, 57, 660–723. [Google Scholar] [CrossRef]

- Koulouridis, S.; Kiziltas, G.; Zhou, Y.; Hansford, D.J.; Volakis, J.L. Polymer–ceramic composites for microwave applications: Fabrication and performance assessment. IEEE Trans. Microw. Theory Tech. 2006, 54, 4202–4208. [Google Scholar] [CrossRef]

- Subodh, G.; Deepu, V.; Mohanan, P.; Sebastian, M.T. Dielectric response of high permittivity polymer ceramic composite with low loss tangent. Appl. Phys. Lett. 2009, 95, 062903. [Google Scholar] [CrossRef]

- William Coaker, A. Fire and flame retardants for PVC. J. Vinyl Addit. Technol. 2003, 9, 108–115. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Zheng, X.C.; Zheng, G.P. The enhanced electrocaloric effect in P (VDF-TrFE) copolymer with barium strontium titanate nano-fillers synthesized via an effective hydrothermal method. RSC Adv. 2015, 5, 61946–61954. [Google Scholar] [CrossRef]

- Uddin, S.; Zheng, G.P.; Jiang, Z. The effects of anti-ferroelectric nanofillers on the negative electrocaloric effects in Poly (vinylidene fluoride-trifluoroethylene) matrix composites. Solid State Sci. 2019, 90, 9–13. [Google Scholar] [CrossRef]

- Salih, A.A.; Ibn Al-Haitham, D.C. Electrical Properties of MgCl2–Filled PEO Films. J. Pure Appl. Sci. 2009, 22, 1–11. [Google Scholar]

- Ali, A.; Uddin, S.; Zaman, A.; Ahmad, A.; Iqbal, Z. Effect of Zr4+ on the properties of layered structured Ba(Ti1−xZrx)4O9 perovskites. J. Adv. App. Ceram. 2020, 119, 482–486. [Google Scholar] [CrossRef]

- Davis, G.T. Polymers for Electronic and Photonic Applications; Academic Press Inc.: Boston, MA, USA, 1993; p. 435. [Google Scholar]

- Zaman, A.; Uddin, S.; Mehboob, N. Synthesis and Microwave Dielectric Characterization of Ca1−xSrxTiO3, Low-Loss Ceramics. Iran. J. Sci. Technol. Trans. Sci. 2021, 45, 367–371. [Google Scholar] [CrossRef]

- Uddin, S.; Zaman, A.; Rasool, I.; Akbar, S.; Kamran, M.; Mehboob, N.; Ali, A.; Ahmad, A.; Nasir, F.N.; Iqbal, Z. Structural investigation and improvement of microwave dielectric properties in Ca1−xBaxTiO3, low loss ceramics. J. Ceram. Process. Res. 2020, 21, 745–750. [Google Scholar]

- Ramesh, S.; Leen, K.H.; Kumutha, K.; Arof, A.K. FTIR studies of PVC/PMMA blend based polymer electrolytes. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2007, 66, 1237–1242. [Google Scholar] [CrossRef] [PubMed]

- Olszowy, M. Dielectric and pyroelectric properties of the composites of ferroelectric ceramic and poly (vinyl chloride). Condens. Matter Phys. 2003, 6, 307–313. [Google Scholar] [CrossRef][Green Version]

- Berrag, A.; Belkhiat, S.; Madani, L. Investigation of dielectric behavior of the PVC/BaTiO3 composite in low-frequencies. Int. J. Mod. Phys. B 2018, 32, 1850110. [Google Scholar] [CrossRef]

- Mansour, S.A.; Elsad, R.A.; Izzularab, M.A. Dielectric properties enhancement of PVC nanodielectrics based on synthesized ZnO nanoparticles. J. Polym. Res. 2016, 23, 85–91. [Google Scholar] [CrossRef]

- Ali, A.; Uddin, S.; Iqbal, Z.; Lal, M.; Jameel, M.H.; Zaman, A.; Khan, W. Synthesis and characterizations of (Ba1−xCax)Ti4O9, 0 ≤ x ≤ 0.9 ceramics. J. Mater. Res. Technol. 2021, 11, 1828–1833. [Google Scholar] [CrossRef]

- Sebastian, M.T.; Ubic, R.; Jantunen, H. Low-loss dielectric ceramic materials and their properties. Int. Mater. Rev. 2015, 60, 392–412. [Google Scholar] [CrossRef]

- Hu, Q.; Wei, X. Abnormal phase transition and polarization mismatch phenomena in BaTiO3-based relaxor ferroelectrics. J. Adv. Dielect. 2019, 9, 1930002. [Google Scholar] [CrossRef]

- Fu, D.; Itoh, M.; Koshihara, S.Y. Invariant lattice strain and polarization in BaTiO3–CaTiO3 ferroelectric alloys. J. Phys. Condens. Matter 2010, 22, 052204. [Google Scholar] [CrossRef]

- Ibrahim, S.S.; Ayesh, A.S.; Shoaibi, A.A. Optoelectrical properties of ferroelectric PC/ceramic composites. J. Thermoplast. Compos. Mater. 2009, 22, 335–348. [Google Scholar] [CrossRef]

- Khasim, S.; Raghavendra, S.C.; Revanasiddappa, M.; Ambika Prasad, M.V.N. Synthesis, characterization and electrical properties of polyaniline/BaTiO3 composites. Ferroelectrics 2005, 325, 111–119. [Google Scholar] [CrossRef]

- Mara, R.T.; Sutherland, G.B.B.M.; Tyrell, H.V. Infrared spectrum of barium titanate. Phys. Rev. 1954, 96, 801. [Google Scholar] [CrossRef]

- Uddin, S.; Zheng, G.P.; Iqbal, Y.; Ubic, R.; Chan, N.Y.; Chan, H.L.W. Elastic softening near the phase transitions in (1−x)Bi1/2Na1/2TiO3−xBaTiO3 solid solutions. Mater. Res. Express 2014, 1, 046102. [Google Scholar] [CrossRef]

- Zheng, G.P.; Uddin, S.; Zheng, X.; Yang, J. Structural and electrocaloric properties of multiferroic-BiFeO3 doped 0.94Bi0.5Na0.5TiO3–0.06BaTiO3 solid solutions. J. Alloy. Compd. 2016, 663, 249–255. [Google Scholar] [CrossRef]

- Cao, W.; Gerhardt, R. Calculation of various relaxation times and conductivity for a single dielectric relaxation process. Solid State Ion. 1990, 42, 213–221. [Google Scholar] [CrossRef]

- Zaman, A.; Uddin, S.; Mehboob, N.; Ali, A. Structural investigation and improvement of microwave dielectric properties in Ca(HfxTi1−x)O3 ceramics. Phys. Scr. 2020, 96, 025701. [Google Scholar] [CrossRef]

- Singh, R.; Tandon, R.P.; Panwar, V.S.; Chandra, S. Low-frequency ac conduction in lightly doped polypyrrole films. J. Appl. Phys. 1991, 69, 2504–2511. [Google Scholar] [CrossRef]

- El-Mallah, H.M. AC electrical conductivity and dielectric properties of perovskite (Pb, Ca)TiO3 ceramic. Acta Phys. Pol. -Series A Gen. Phys. 2012, 122, 174. [Google Scholar] [CrossRef]

- Jo, W.; Schaab, S.; Sapper, E.; Schmitt, L.A.; Kleebe, H.J.; Bell, A.J.; Rödel, J. On the phase identity and its thermal evolution of lead free (Bi1/2Na1/2)TiO3-6 mol% BaTiO3. J. Appl. Phys. 2011, 110, 074106. [Google Scholar] [CrossRef]

- Zhang, S.T.; Kounga, A.B.; Aulbach, E.; Deng, Y. Temperature-dependent electrical properties of 0.94Bi0.5Na0.5TiO3–0.06BaTiO3 ceramics. J. Am. Ceram. Soc. 2008, 91, 3950–3954. [Google Scholar] [CrossRef]

- Smolenskii, G.A.; Agranovskaya, A.I. Dielectric polarization of a number of complex compounds. Sov. Phys. Solid State 1960, 1, 1429–1437. [Google Scholar]

- Randall, C.A. A Transmission Electron Microscopy Study of Normal and Relaxor Perovskite Ferroelectric Materials. Ph.D. Thesis, University of Essex, Colchester, UK, 1989. [Google Scholar]

- Randall, C.A.; Bhalla, A.S.; Shrout, T.R.; Cross, L.E. Classification and consequences of complex lead perovskite ferroelectrics with regard to B-site cation order. J. Mater. Res. 1990, 5, 829–834. [Google Scholar] [CrossRef]

- Sebastian, M.T. Dielectric Materials for Wireless Communication, 1st ed.; Elsevier: Amsterdam, The Netherlands; London, UK, 2008; pp. 10–50. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uddin, S.; Akhtar, N.; Bibi, S.; Zaman, A.; Ali, A.; Althubeiti, K.; Alrobei, H.; Mushtaq, M. Effect of BaTiO3 on the Properties of PVC-Based Composite Thick Films. Materials 2021, 14, 5430. https://doi.org/10.3390/ma14185430

Uddin S, Akhtar N, Bibi S, Zaman A, Ali A, Althubeiti K, Alrobei H, Mushtaq M. Effect of BaTiO3 on the Properties of PVC-Based Composite Thick Films. Materials. 2021; 14(18):5430. https://doi.org/10.3390/ma14185430

Chicago/Turabian StyleUddin, Sarir, Naheed Akhtar, Sumbal Bibi, Abid Zaman, Asad Ali, Khaled Althubeiti, Hussein Alrobei, and Muhammad Mushtaq. 2021. "Effect of BaTiO3 on the Properties of PVC-Based Composite Thick Films" Materials 14, no. 18: 5430. https://doi.org/10.3390/ma14185430

APA StyleUddin, S., Akhtar, N., Bibi, S., Zaman, A., Ali, A., Althubeiti, K., Alrobei, H., & Mushtaq, M. (2021). Effect of BaTiO3 on the Properties of PVC-Based Composite Thick Films. Materials, 14(18), 5430. https://doi.org/10.3390/ma14185430