High Strain Rate Yielding of Additive Manufacturing Inconel 625 by Selective Laser Melting

Abstract

1. Introduction

2. Materials and Methods

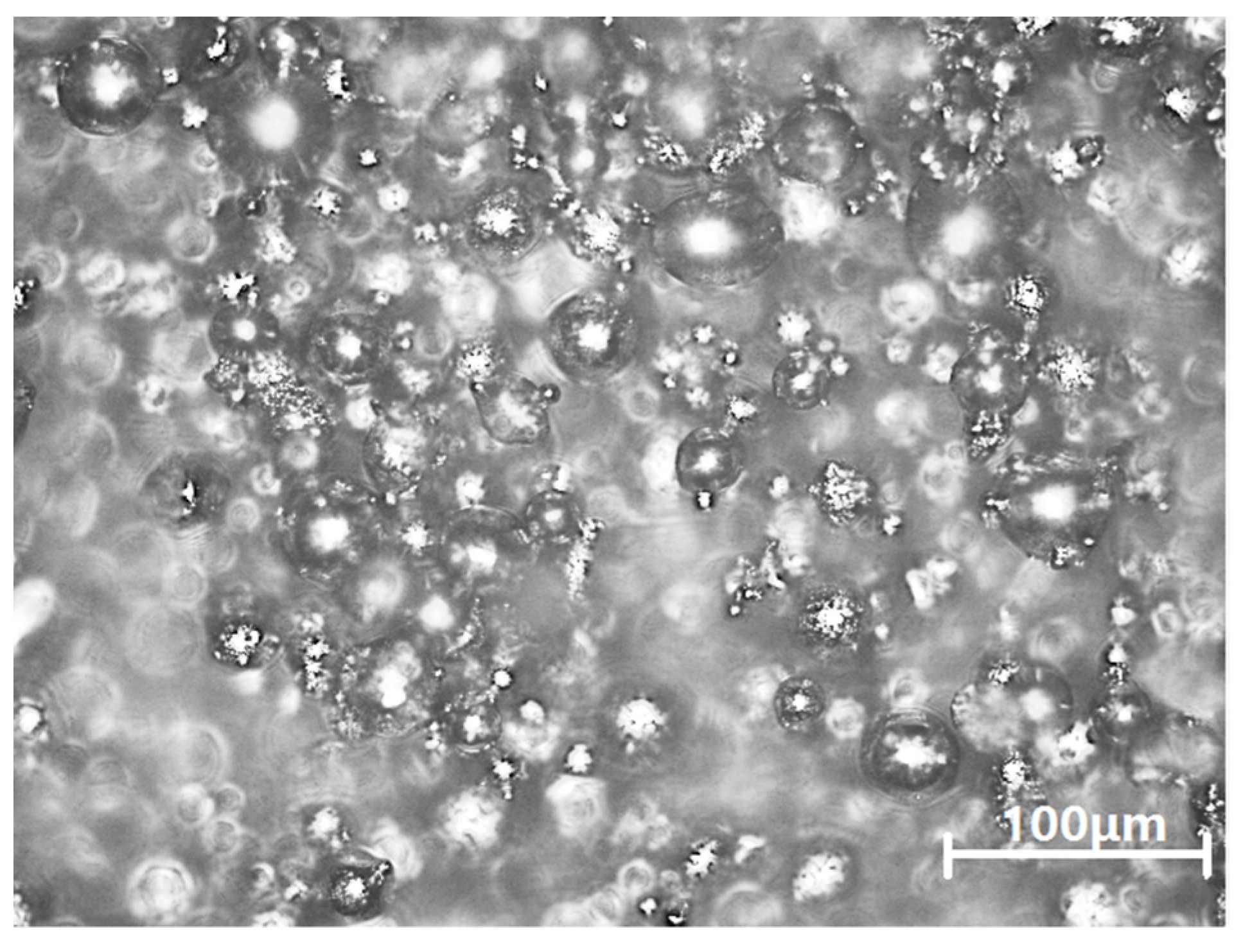

2.1. Materials Characterization

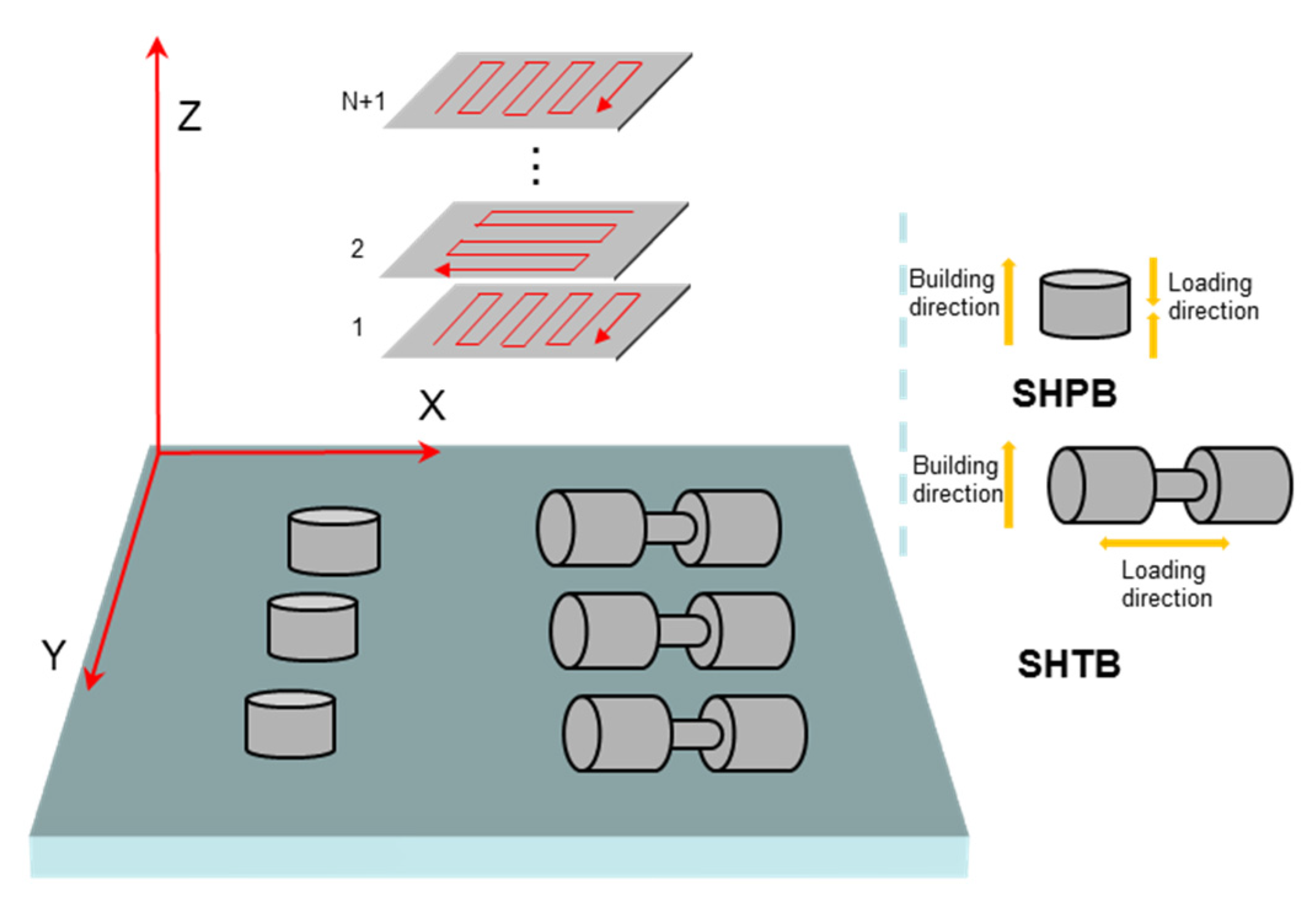

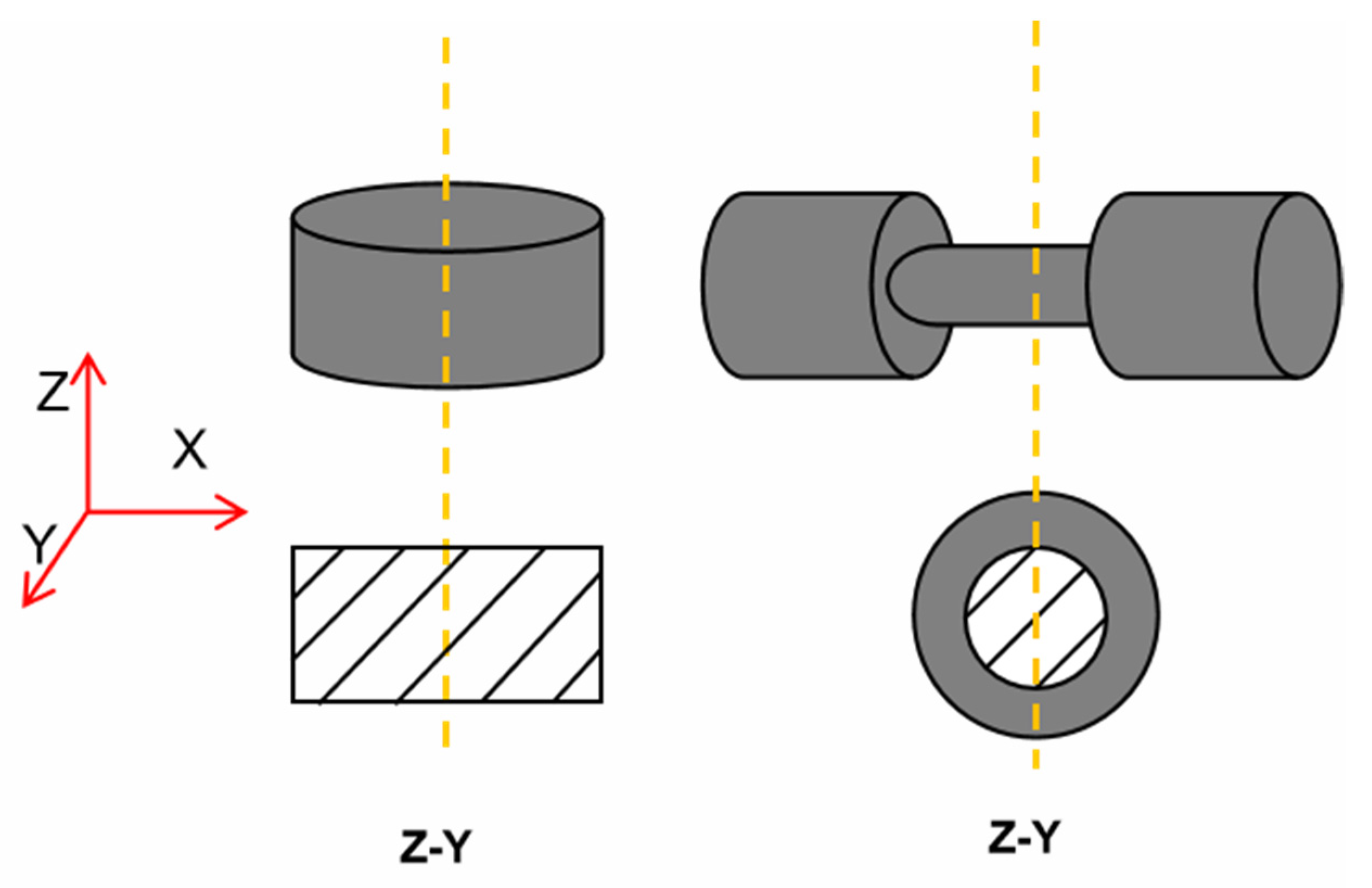

2.2. Specimen Design

2.3. Specimen Manufacture

2.4. Experimental Methods

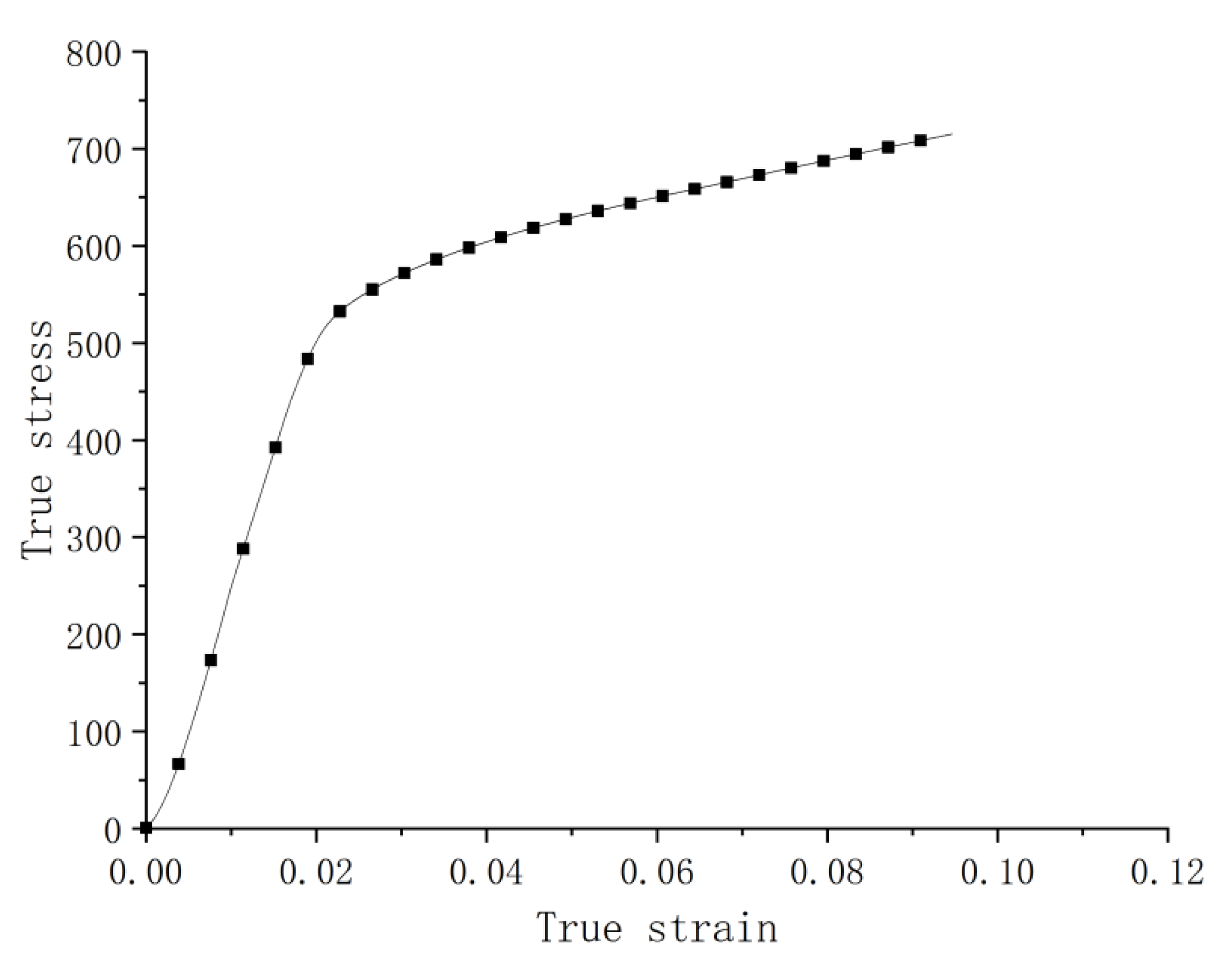

2.4.1. Quasi-Static Tensile Testing

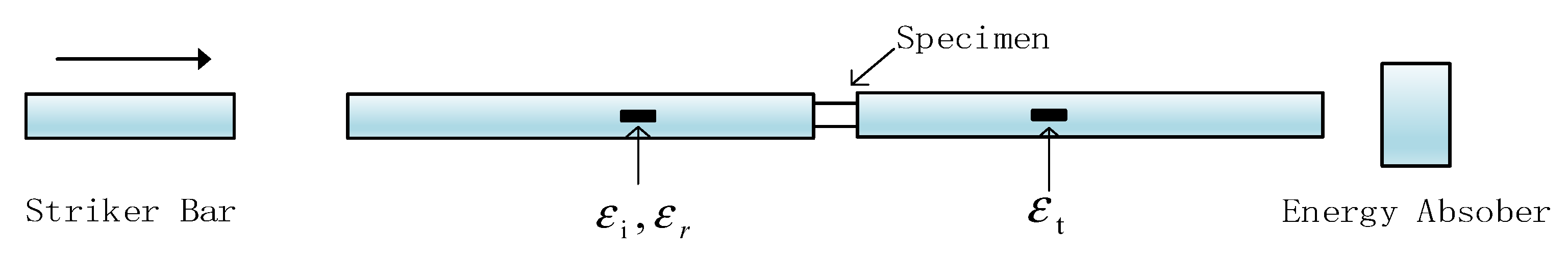

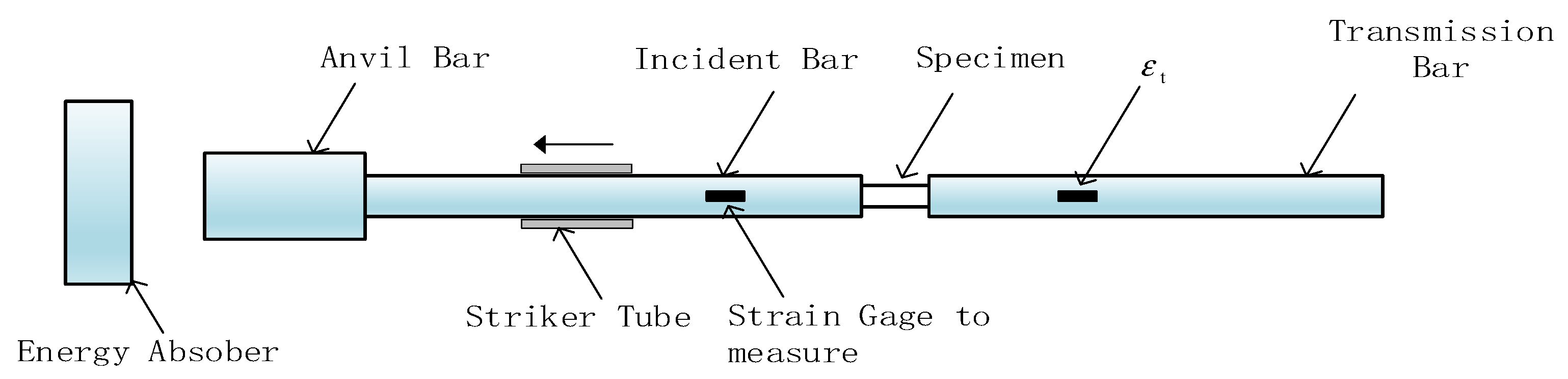

2.4.2. Split Hopkinson Compression Bar

2.4.3. Split Hopkinson Tension Bar

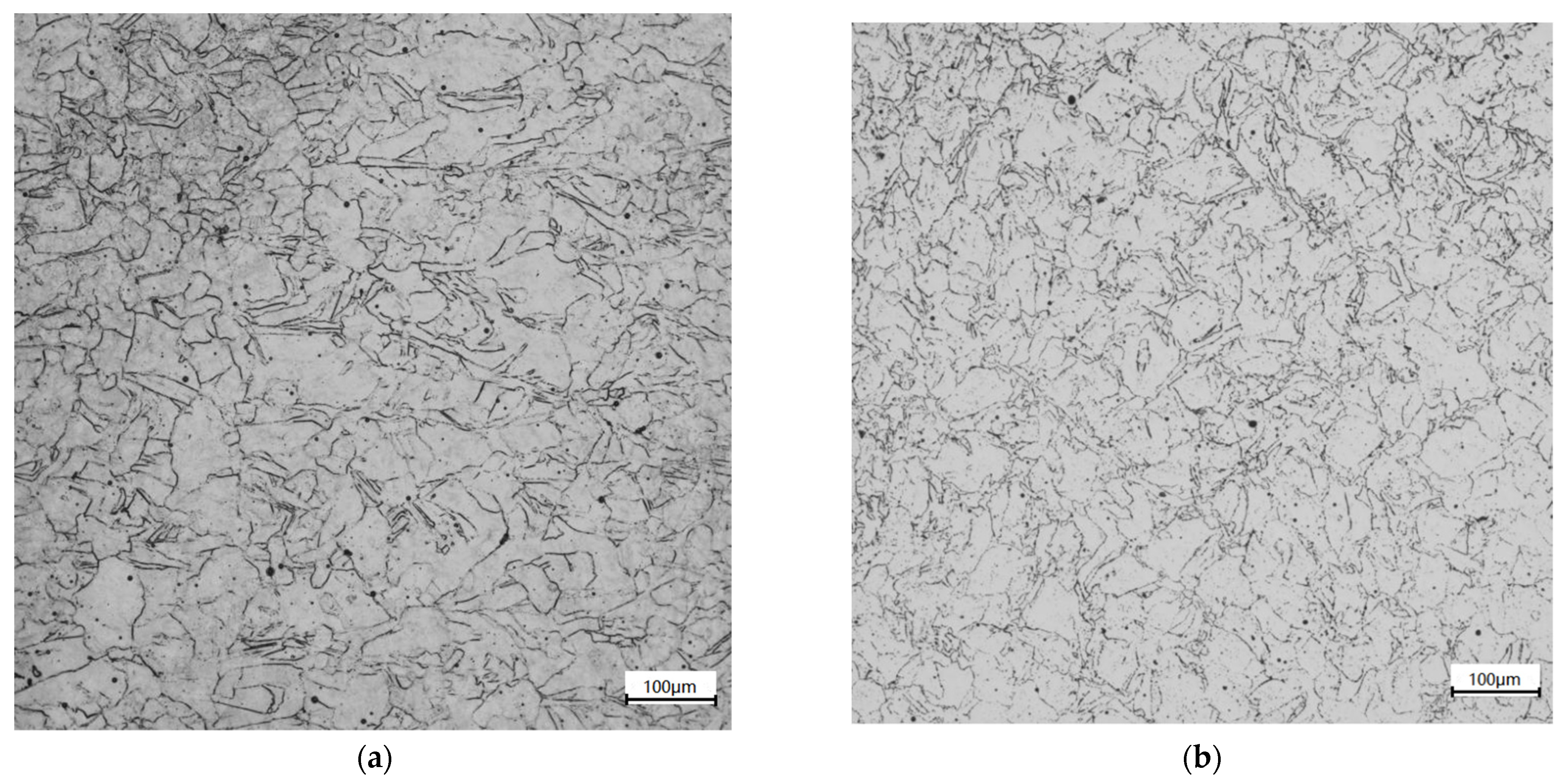

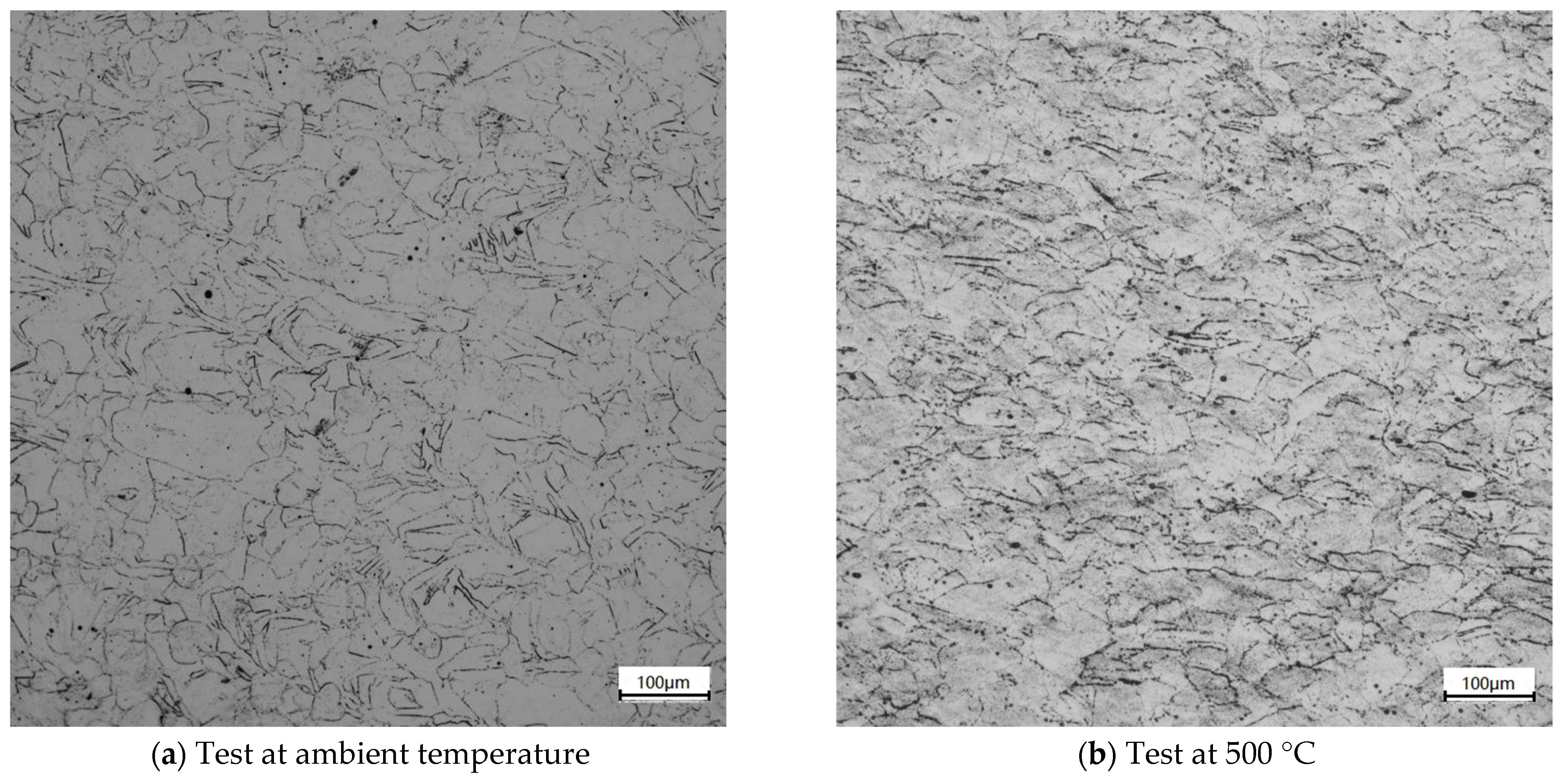

2.5. Microscopy of Original Specimens

3. Experimental Results

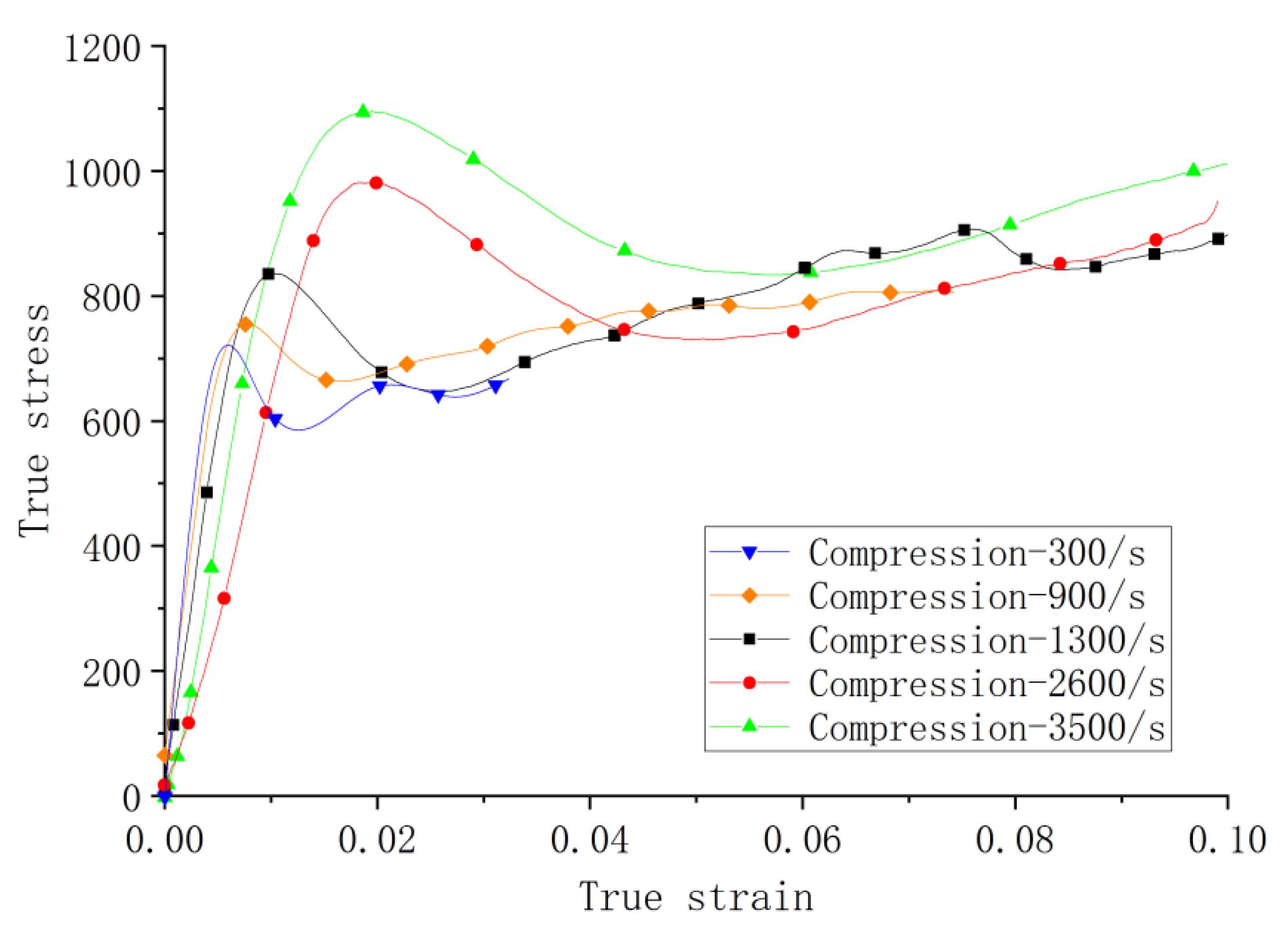

3.1. Dynamic Tests

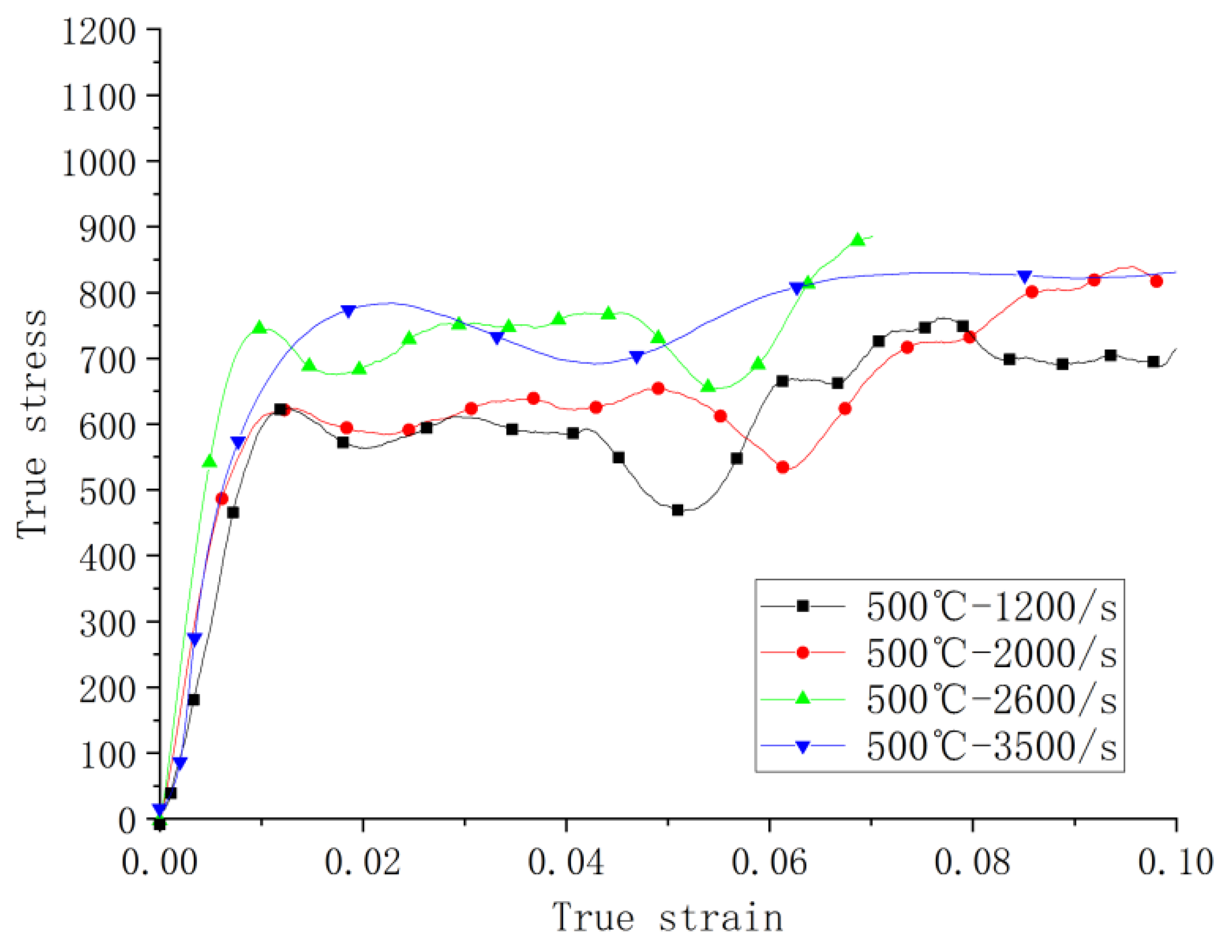

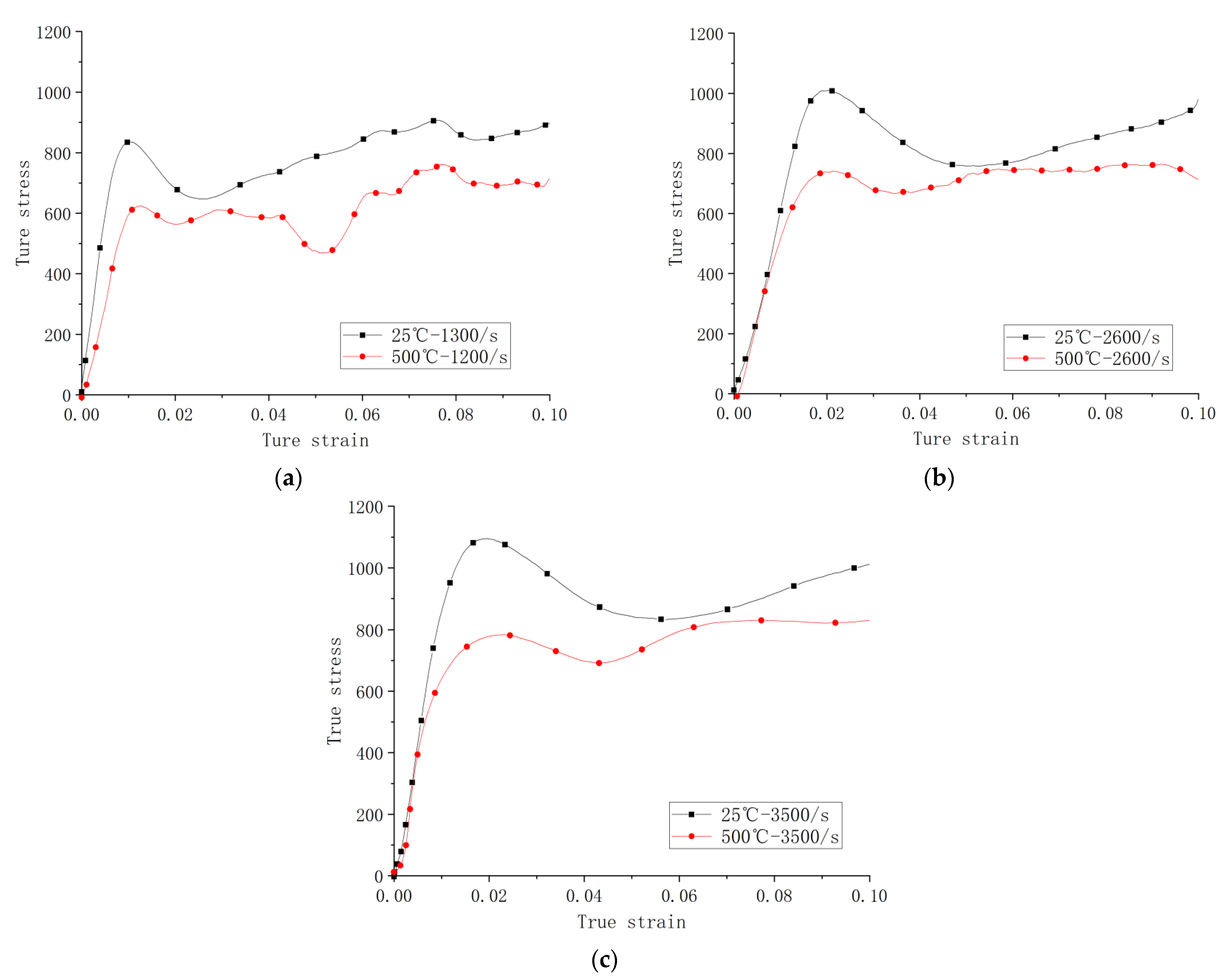

3.1.1. Split Hopkinson Compression Bar Result

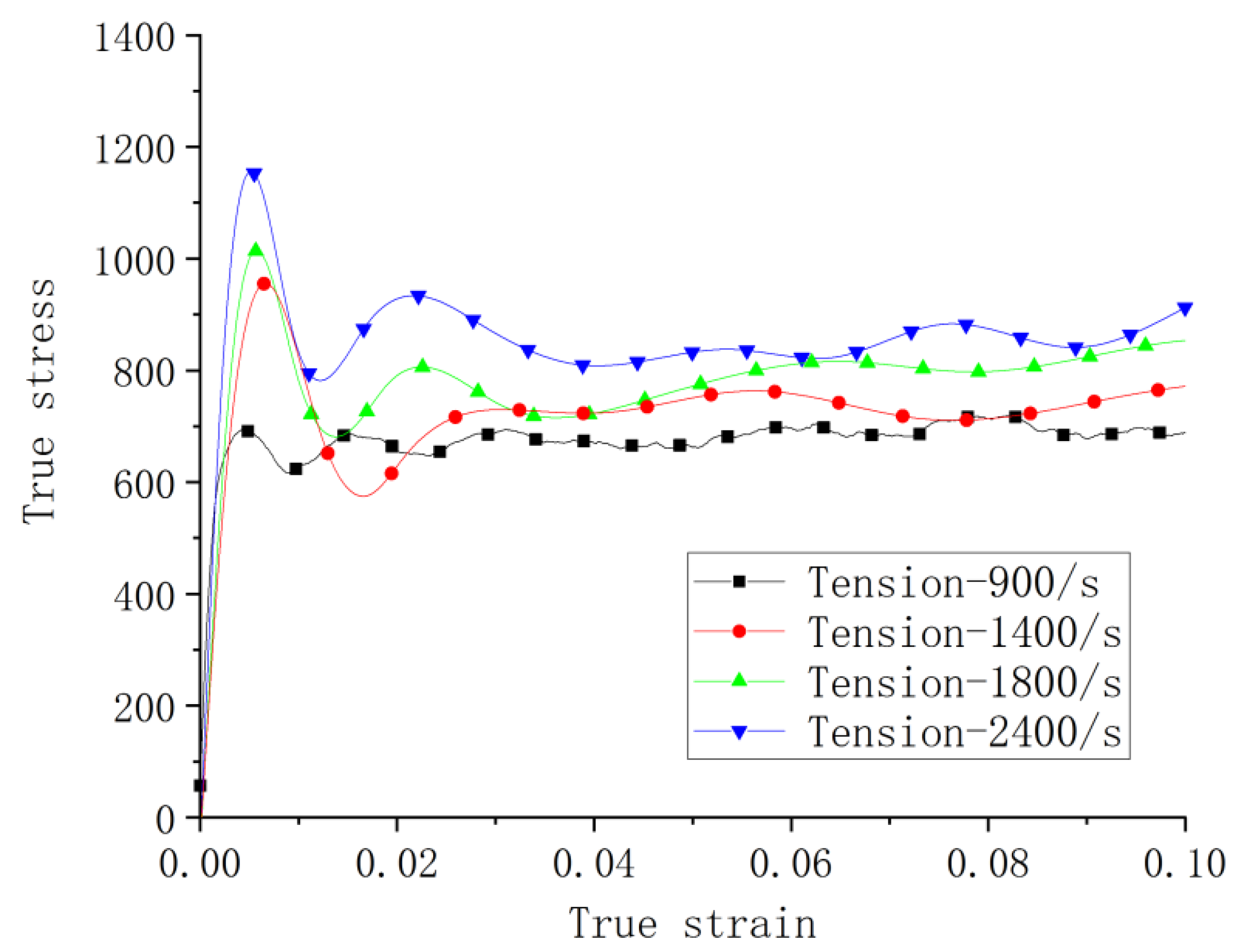

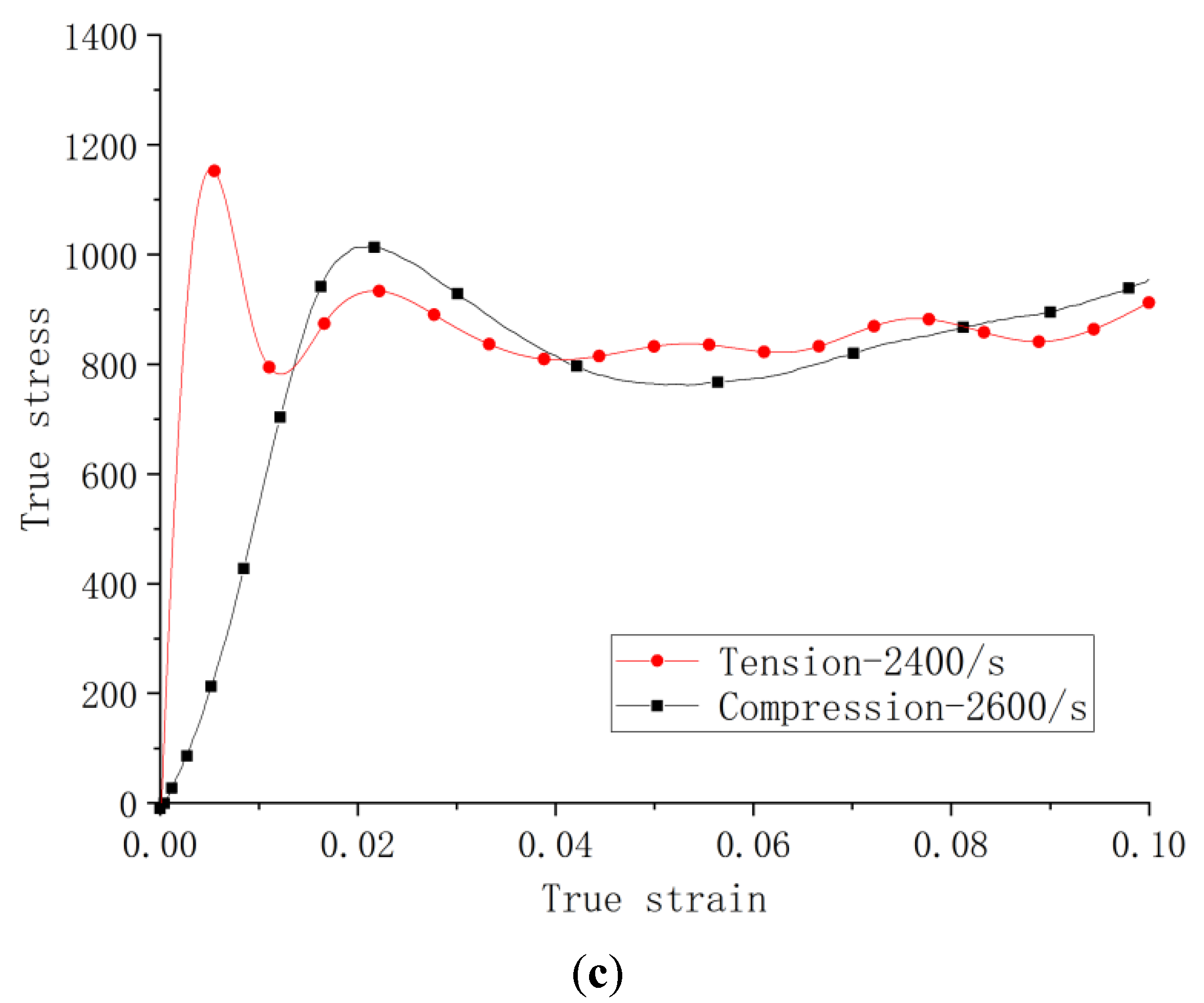

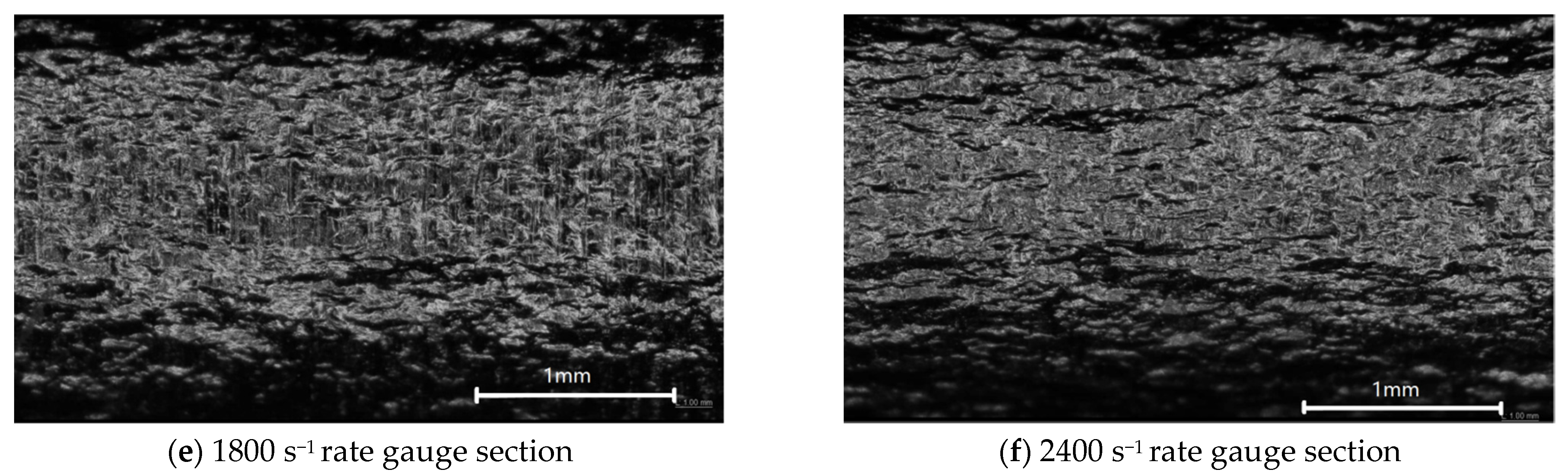

3.1.2. Split Hopkinson Tension Bar Results

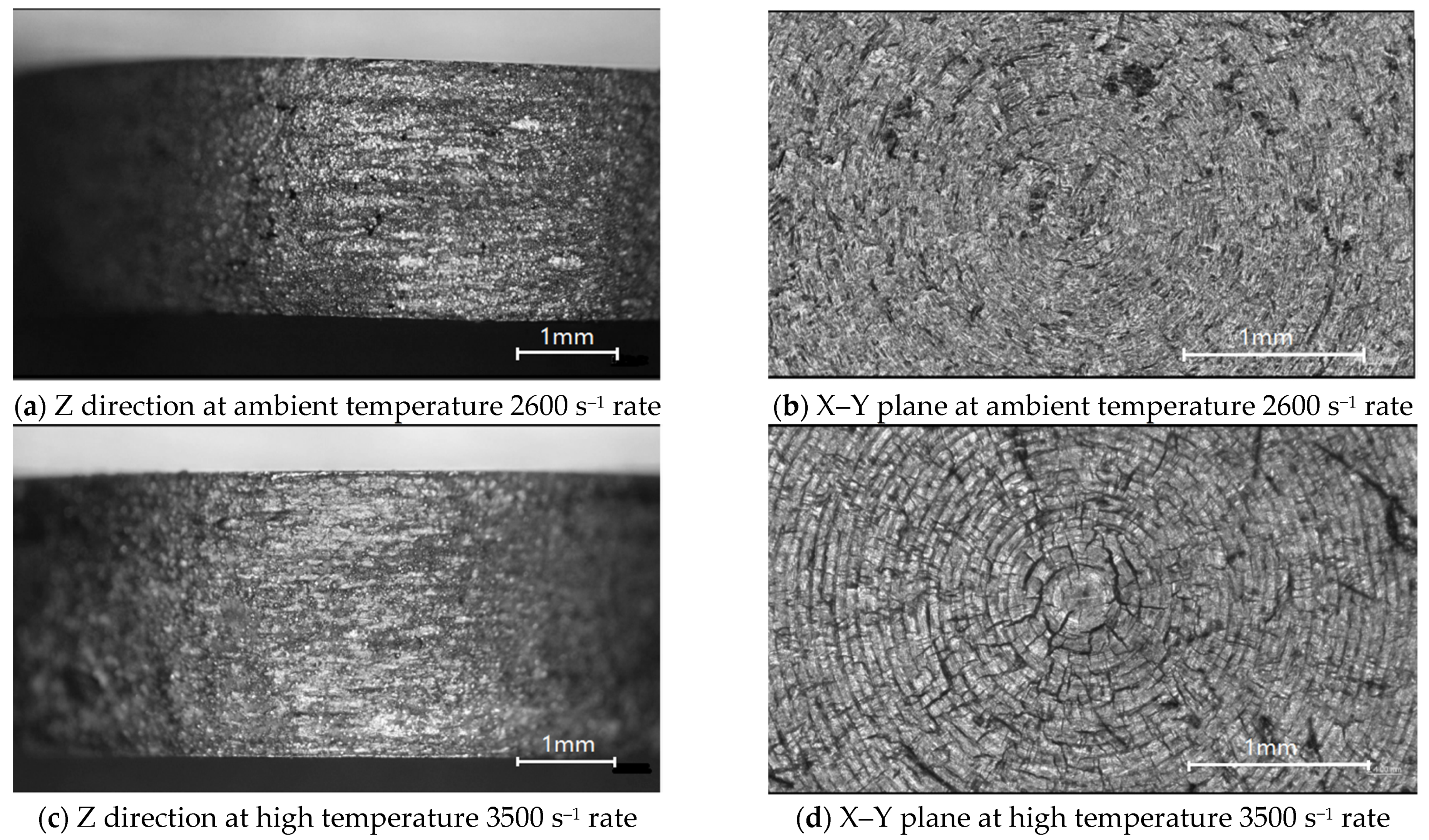

3.2. Microscopy Observation of Specimens under Dynamic Compression

4. Discussion on the Dynamic Yield Stress

5. Conclusions

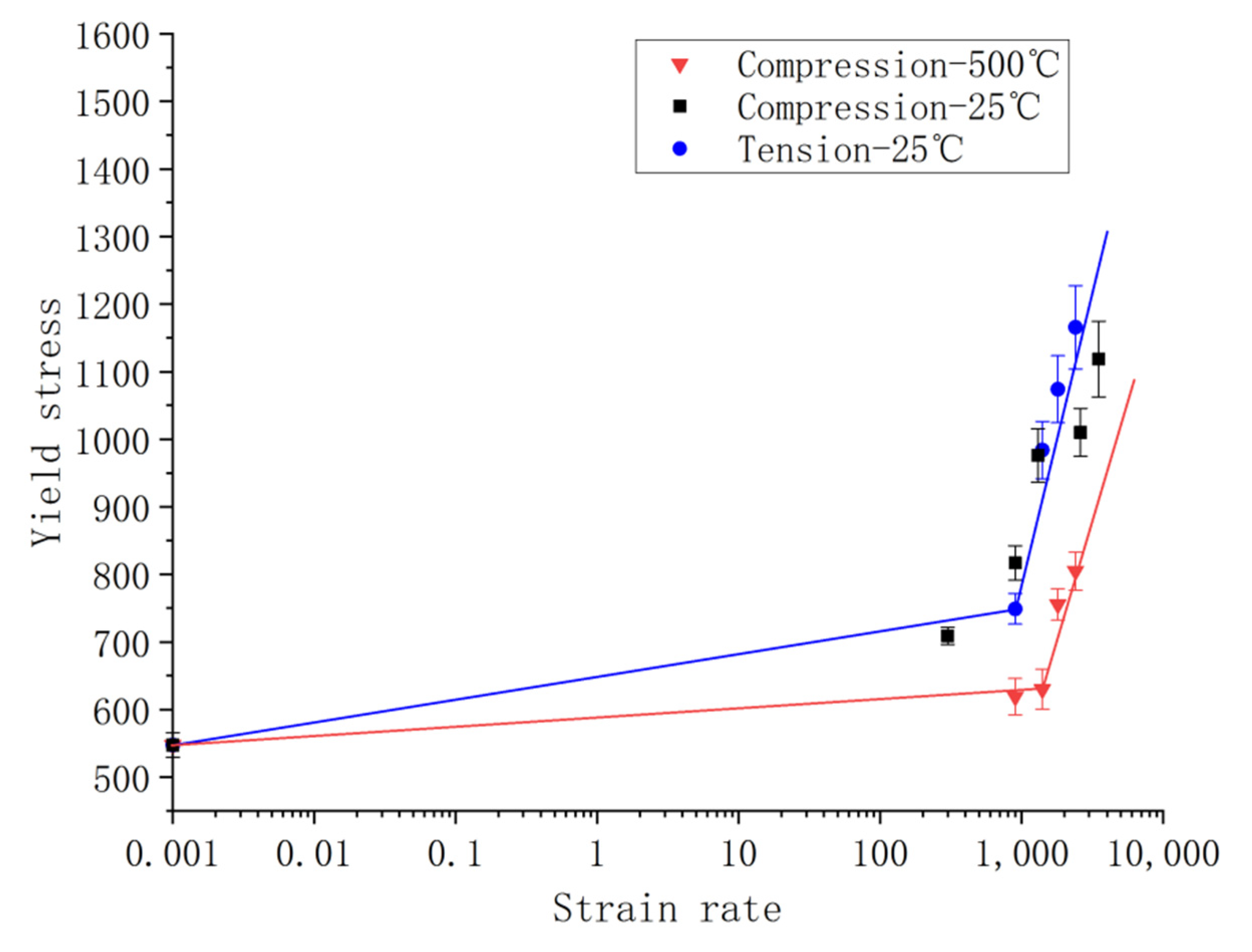

- The dynamic yield stress of Inconel 625 is influenced markedly by the strain rate loading with its value becoming significantly higher at high strain rates than that under quasi-static loading.

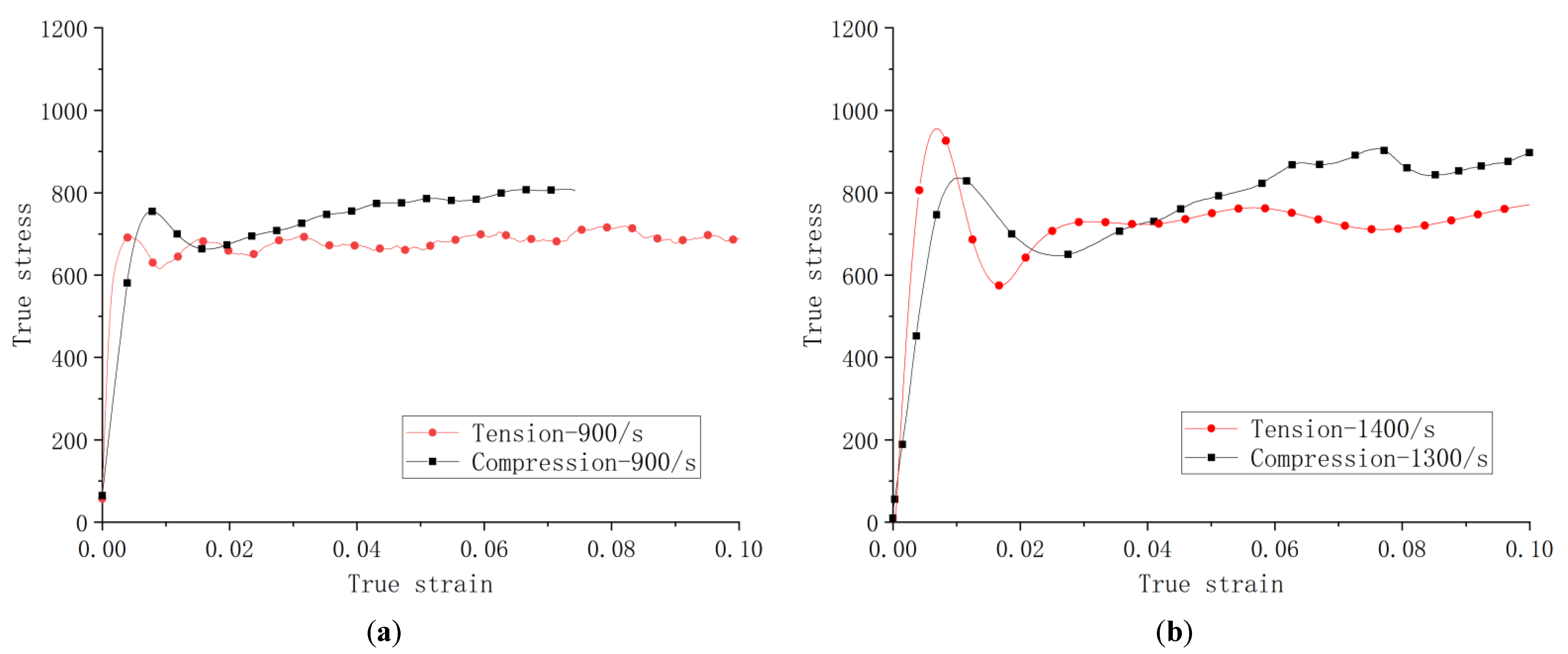

- At the ambient temperature, the dynamic yield strength of the material under tension appears to be slightly higher than that under compression test at the same or similar strain rate.

- At the same or similar strain rate, a high temperature yields in a lower dynamic yield stress compared to that at the ambient temperature.

- The relationship between the dynamic yield stress of Inconel 625 and the strain rate can be approximately described as bi-linear, for which a “curve fitting” exercise can be taken to quantify the relationship if needed.

- The post yield dynamic behaviour of Inconel 625 poses to be strain hardening under dynamic compression, but attenuation to a plateau under dynamic tension.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shoemaker, L.E. Superalloys 718, 625, 706 and Derivatives; Loria, E.A., Ed.; TMS: Pittsburgh, PA, USA, 2005; pp. 409–418. [Google Scholar]

- Singh, G.; Kumar, H. Influence of chemically assisted magnetic abrasive finishing process parameters on external roundness of Inconel 625 tubes. Mater. Today Proc. 2020, 37, 3283–3288. [Google Scholar] [CrossRef]

- Huebner, J.; Kata, D.; Rutkowski, P.; Petrzak, P.; Kusiński, J. Grain-Boundary Interaction between Inconel 625 and WC during Laser Metal Deposition. Materials 2018, 11, 1797. [Google Scholar] [CrossRef] [PubMed]

- Rajkumar, V.; Nagesha, B.K.; Tigga, A.K.; Barad, S.; Suresh, T.N. Single crystal metal deposition using laser additive manufacturing technology for repair of aero-engine components. Mater. Today Proc. 2021, 45, 5395–5399. [Google Scholar] [CrossRef]

- Singh, N.; Hameed, P.; Ummethala, R.; Manivasagam, G.; Prashanth, K.; Eckert, J. Selective laser manufacturing of Ti-based alloys and composites: Impact of process parameters, application trends, and future prospects. Mater. Today Adv. 2020, 8, 100097. [Google Scholar] [CrossRef]

- Zhu, L.; Li, N.; Childs, P.R.N. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Deng, D.; Peng, R.L.; Moverare, J. High temperature mechanical integrity of selective laser melted alloy 718 evaluated by slow strain rate tests. Int. J. Plast. 2021, 140, 102974. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.; Zhang, W. A review of topology optimization for additive manufacturing: Status and challenges. Chin. J. Aeronaut. 2020, 34, 91–110. [Google Scholar] [CrossRef]

- Solberg, K.; Torgersen, J.; Berto, F. Fatigue Behaviour of Additively Manufactured Inconel 718 Produced by Selective Laser Melting. Procedia Struct. Integr. 2018, 13, 1762–1767. [Google Scholar] [CrossRef]

- Staehle, R.W. Historical views on stress corrosion cracking of nickel-based alloys: The Coriou effect. In Stress Corrosion Cracking of Nickel Based Alloys in Water-cooled Nuclear Reactors; Féron, D., Staehle, R.W., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 3–131. ISBN 9780081000496. [Google Scholar]

- Ruzzi, R.D.S.; da Silva, R.B.; da Silva, L.R.R.; Machado, Á.R.; Jackson, M.J.; Hassui, A. Influence of grinding parameters on Inconel 625 surface grinding. J. Manuf. Process. 2020, 55, 174–185. [Google Scholar] [CrossRef]

- Arslan, H. Analytical determination of partial and integral properties of the six components systems Ni–Cr–Co–Al–Mo–Ti and their subsystems. Phys. B Condens. Matter 2014, 438, 48–52. [Google Scholar] [CrossRef]

- Bakkar, A.; Ahmed, M.M.; Alsaleh, N.; Seleman, M.M.E.-S.; Ataya, S. Microstructure, wear, and corrosion characterization of high TiC content Inconel 625 matrix composites. J. Mater. Res. Technol. 2018, 8, 1102–1110. [Google Scholar] [CrossRef]

- Buchbinder, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Selective Laser Melting of aluminum die-cast alloy–correlations between process parameters, solidification conditions, and resulting mechanical properties. J. Laser Appl. 2015, 27, 1–6. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Humbeeck, J.V.; Kruth, J.P. Processing AlSi10Mg by selective laser melting: Parameter optimisation and material characterization. Mater. Sci. Technol. 2015, 31, 917–923. [Google Scholar] [CrossRef]

- Yang, F.; Hou, J.; Wang, C.; Zhou, L. Effects of solution treatment on microstructure and tensile properties of as-cast alloy. Trans. Nonferr. Met. Soc. China 2021, 31, 426–437. [Google Scholar] [CrossRef]

- Fesharaki, M.N.; Razavi, R.S.; Mansouri, H.A.; Jamali, H. Microstructure investigation of Inconel 625 coating obtained by laser cladding and TIG cladding methods. Surf. Coat. Technol. 2018, 353, 25–31. [Google Scholar] [CrossRef]

- Iqbal, N.; Xue, P.; Liao, H.; Wang, B.; Li, Y. Material characterization of porous bronze at high strain rates. Mater. Sci. Eng. A 2011, 528, 4408–4412. [Google Scholar] [CrossRef]

- Iqbal, N.; Xue, P.; Wang, B.; Li, Y. On the high strain rate behavior of 63–37 Sn–Pb eutectic solders with temperature effects. Int. J. Impact Eng. 2014, 74, 126–131. [Google Scholar] [CrossRef][Green Version]

- Jankowiak, T.; Rusinek, A.; Voyiadjis, G.Z. Modeling and Design of SHPB to Characterize Brittle Materials under Compression for High Strain Rates. Materials 2020, 13, 2191. [Google Scholar] [CrossRef]

- Tripathy, M.; Munther, M.; Davami, K.; Beheshti, A. Surface property study of additively manufactured Inconel 625 at room temperature and 510 °C. Manuf. Lett. 2020, 26, 69–73. [Google Scholar] [CrossRef]

- Kim, K.-S.; Kang, T.-H.; Kassner, M.E.; Son, K.-T.; Lee, K.-A. High-temperature tensile and high cycle fatigue properties of inconel 625 alloy manufactured by laser powder bed fusion. Addit. Manuf. 2020, 35, 101377. [Google Scholar] [CrossRef]

- Ganzenmüller, G.; Plappert, D.; Trippel, A.; Hiermaier, S. A Split-Hopkinson Tension Bar study on the dynamic strength of basalt-fibre composites. Compos. Part B Eng. 2019, 171, 310–319. [Google Scholar] [CrossRef]

- Pang, K.; Wang, D. Study on the performances of the drilling process of nickel-based superalloy Inconel 718 with differently micro-textured drilling tools. Int. J. Mech. Sci. 2020, 180, 105658. [Google Scholar] [CrossRef]

- Madhankumar, S.; Kumaar, K.A.; Arunachalam, S.; Suhirtharaj, J.B.; Anil, K.A.; Aadhavan, P.; Narayanan, K.H.; Akshey, P. Assessments and comparison of Inconel 625 and Inconel 718 alloys from overcut in micro ECM. Mater. Today Proc. 2020, 45, 6459–6464. [Google Scholar] [CrossRef]

- Ji, H.; Gupta, M.K.; Song, Q.; Cai, W.; Zheng, T.; Zhao, Y.; Liu, Z.; Pimenov, D.Y. Microstructure and machinability evaluation in micro milling of selective laser melted Inconel 718 alloy. J. Mater. Res. Technol. 2021, 14, 348–362. [Google Scholar] [CrossRef]

- Mohsin, M.A.A.; Iannucci, L.; Greenhalgh, E.S. On the Dynamic Tensile Behaviour of Thermoplastic Composite Carbon/Polyamide 6.6 Using Split Hopkinson Pressure Bar. Materials 2021, 14, 1653. [Google Scholar] [CrossRef] [PubMed]

- Xue, P.; Iqbal, N.; Liao, H.; Wang, B.; Li, Y. Experimental study, on strain rate sensitivity of ductile porous irons. Int. J. Impact Eng. 2012, 48, 82–86. [Google Scholar] [CrossRef]

| Ni | Cr | Mo | Fe | Nb (Cb) | Nb (Cb) + Ta | Co | W | Mn | Si | Cu | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ≥58 | 20–23 | 8–10 | ≤5.0 | 3.15–4.15 | 3.15–4.15 | ≤1.0 | 0.1–1.0 | ≤0.05 | ≤0.5 | ≤0.05 | ≤0.4 | ≤0.4 |

| Laser Power (w) | Scanning Velocity (mm/s) | Scanning Interval (μm) | Spot Diameter (μm) | Increment in Z (μm) |

|---|---|---|---|---|

| 380 | 500 | 70 | 60 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, K.; Yang, L.; Xu, C.; Wang, B.; Gao, Y. High Strain Rate Yielding of Additive Manufacturing Inconel 625 by Selective Laser Melting. Materials 2021, 14, 5408. https://doi.org/10.3390/ma14185408

Du K, Yang L, Xu C, Wang B, Gao Y. High Strain Rate Yielding of Additive Manufacturing Inconel 625 by Selective Laser Melting. Materials. 2021; 14(18):5408. https://doi.org/10.3390/ma14185408

Chicago/Turabian StyleDu, Kang, Laixia Yang, Chao Xu, Bin Wang, and Yang Gao. 2021. "High Strain Rate Yielding of Additive Manufacturing Inconel 625 by Selective Laser Melting" Materials 14, no. 18: 5408. https://doi.org/10.3390/ma14185408

APA StyleDu, K., Yang, L., Xu, C., Wang, B., & Gao, Y. (2021). High Strain Rate Yielding of Additive Manufacturing Inconel 625 by Selective Laser Melting. Materials, 14(18), 5408. https://doi.org/10.3390/ma14185408