Comparison of the Vibration Damping of the Wood Species Used for the Body of an Electric Guitar on the Vibration Response of Open-Strings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Construction and Assembling of Electric Guitar

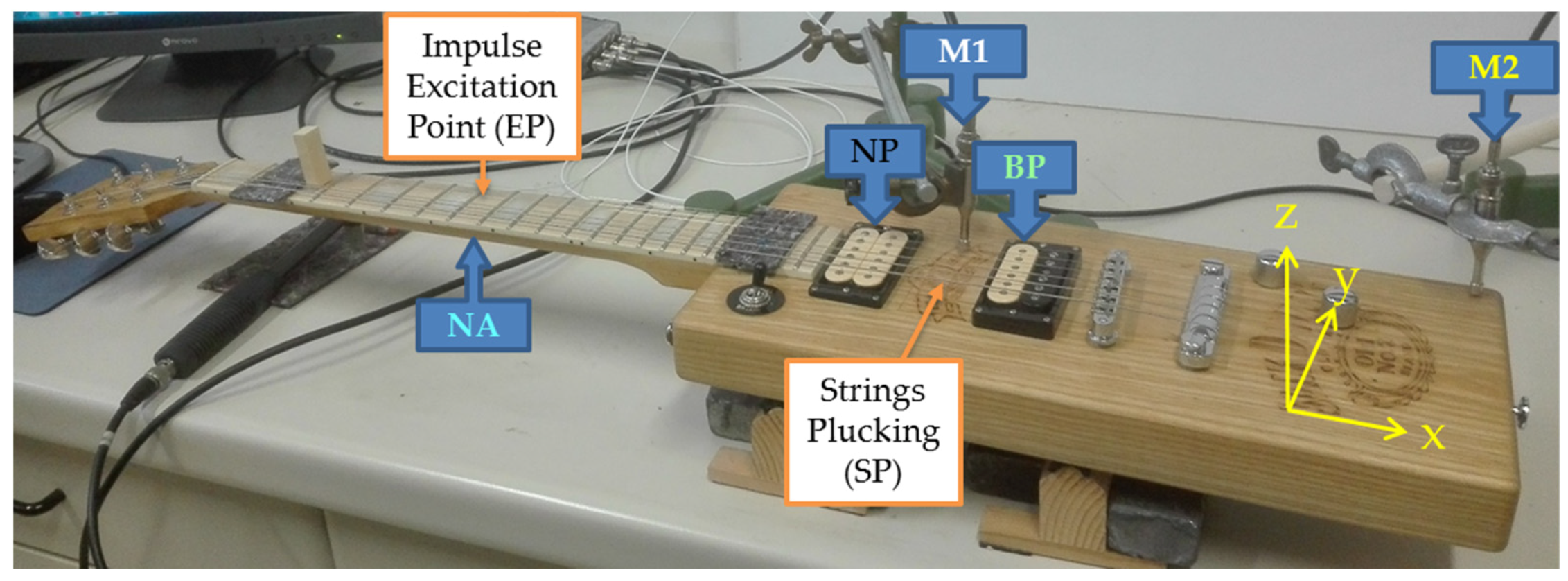

2.2. Analysis of Acoustic Behavior of Electric Guitar

2.2.1. Analysis of the Acoustic Response of Guitar at Impulse Excitation

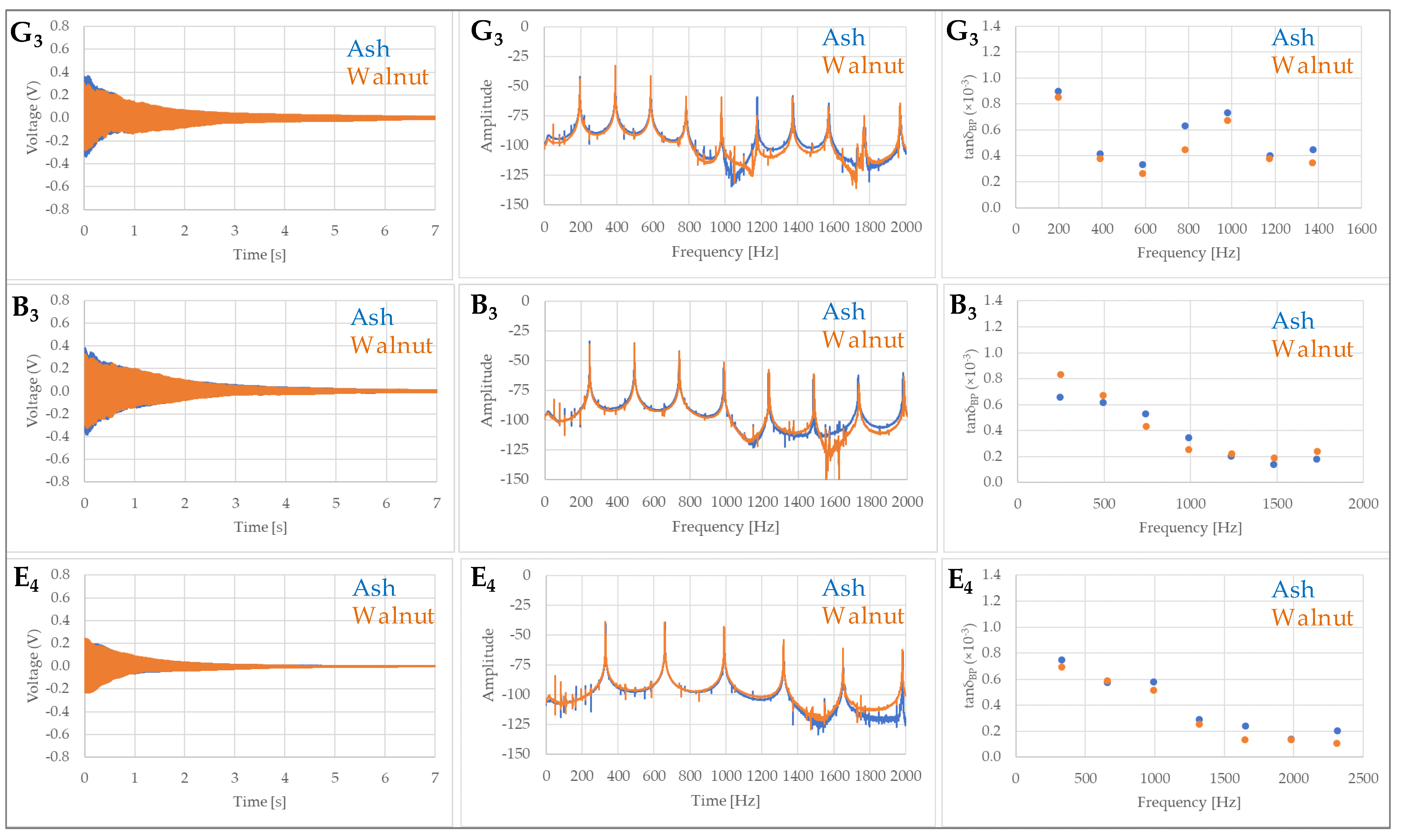

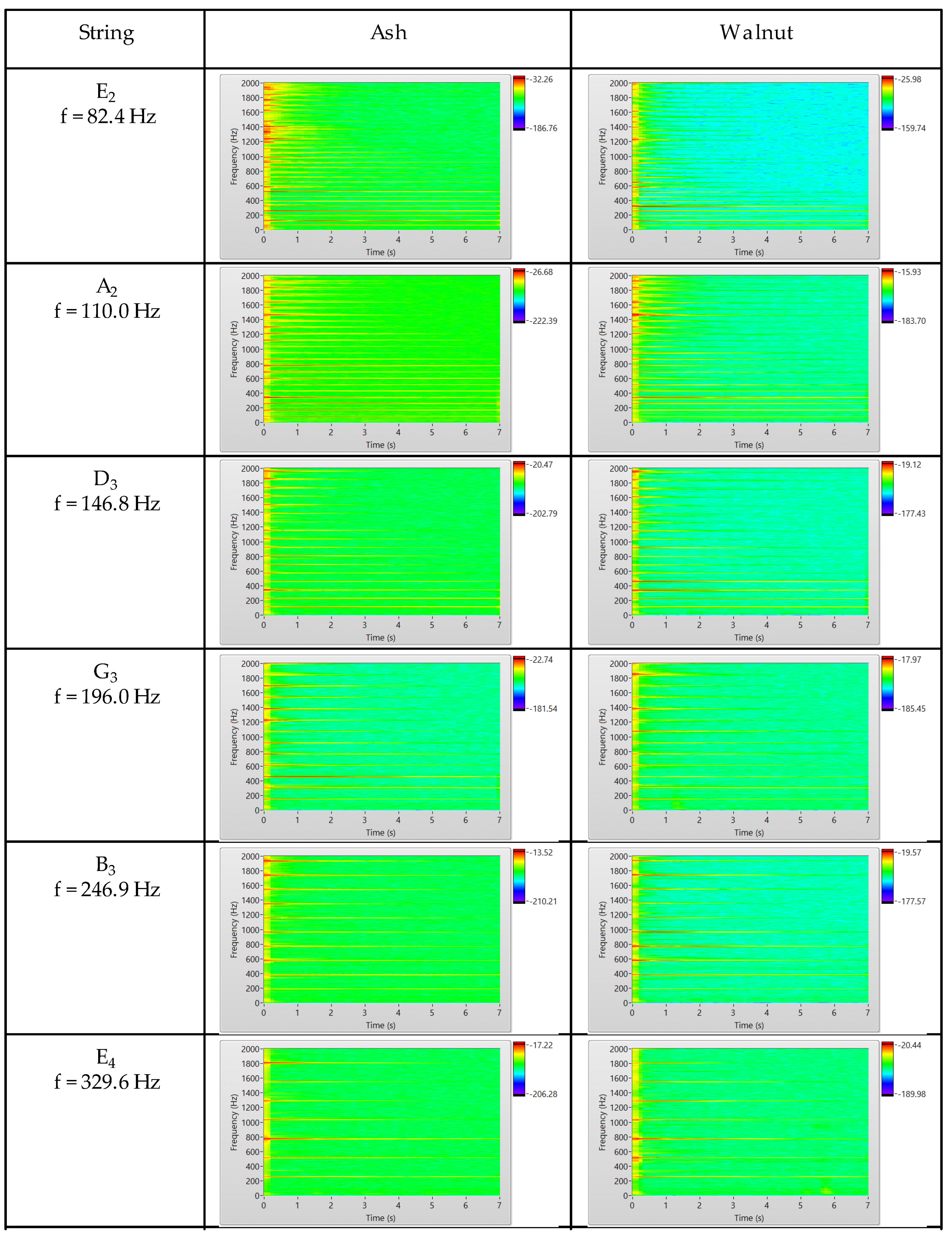

2.2.2. Analysis of Vibration of Open Strings in Time and Frequency Domain

3. Results

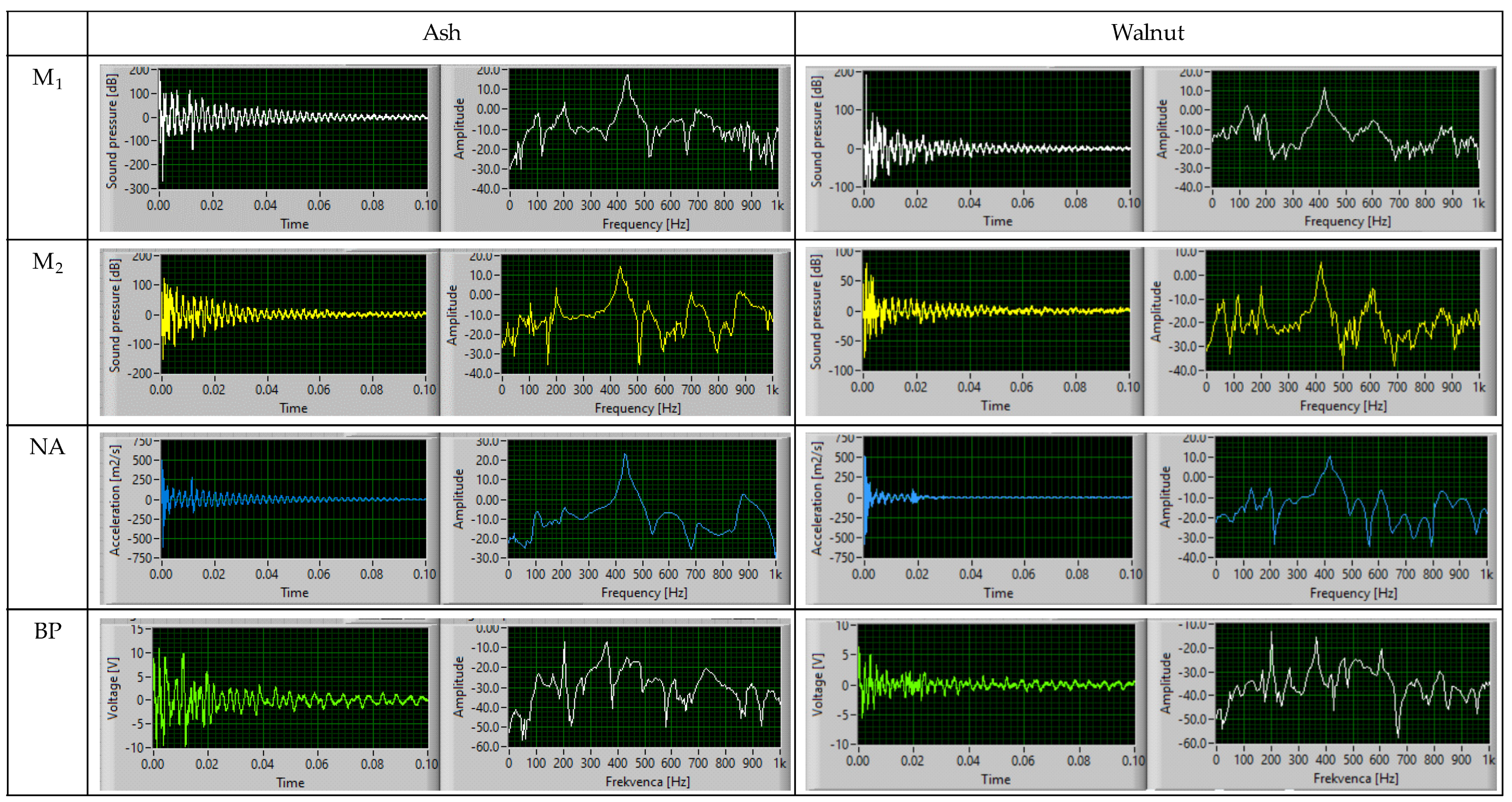

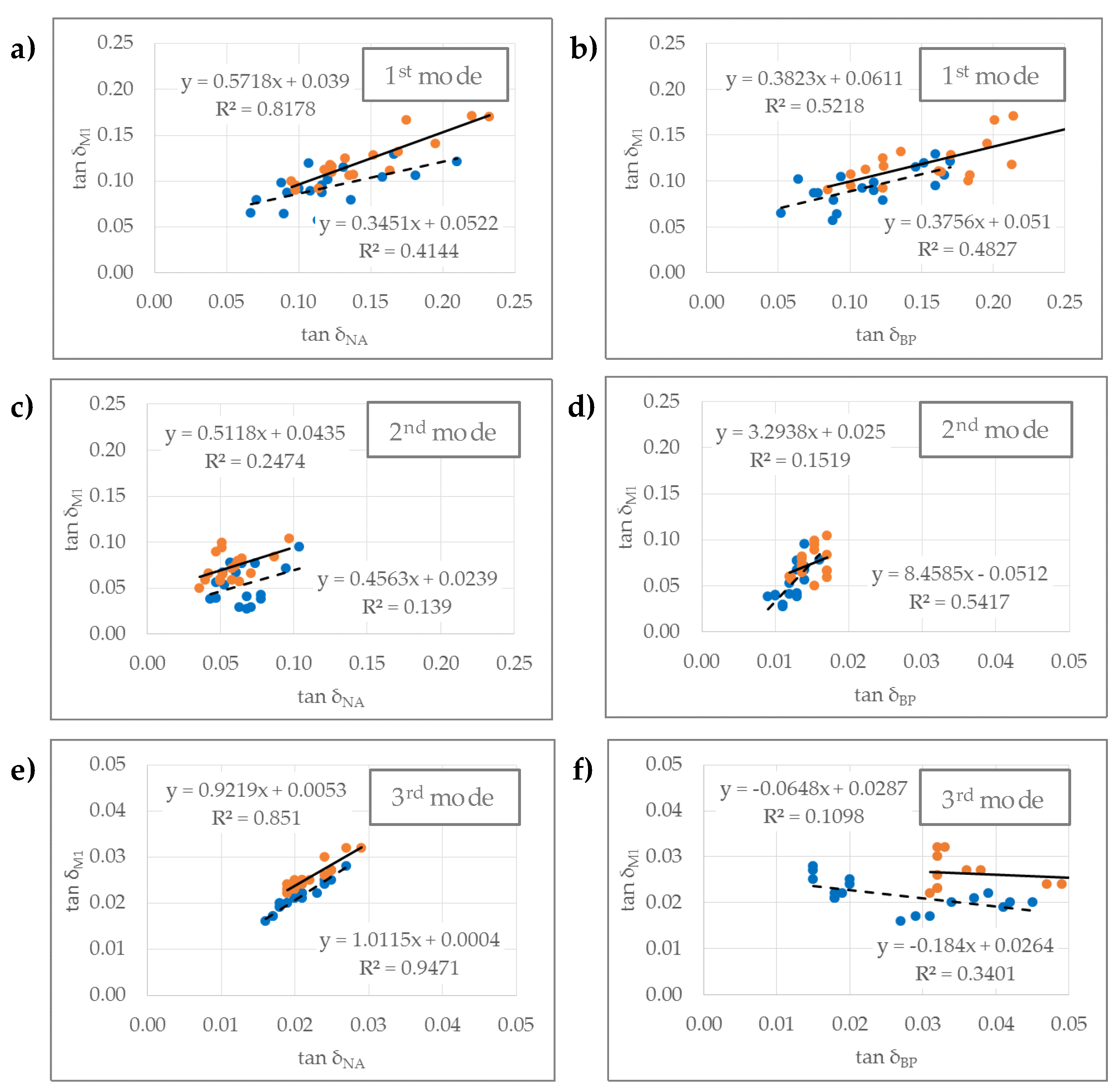

3.1. Acoustic Response of Electrical Guitar at Mechanical Excitation

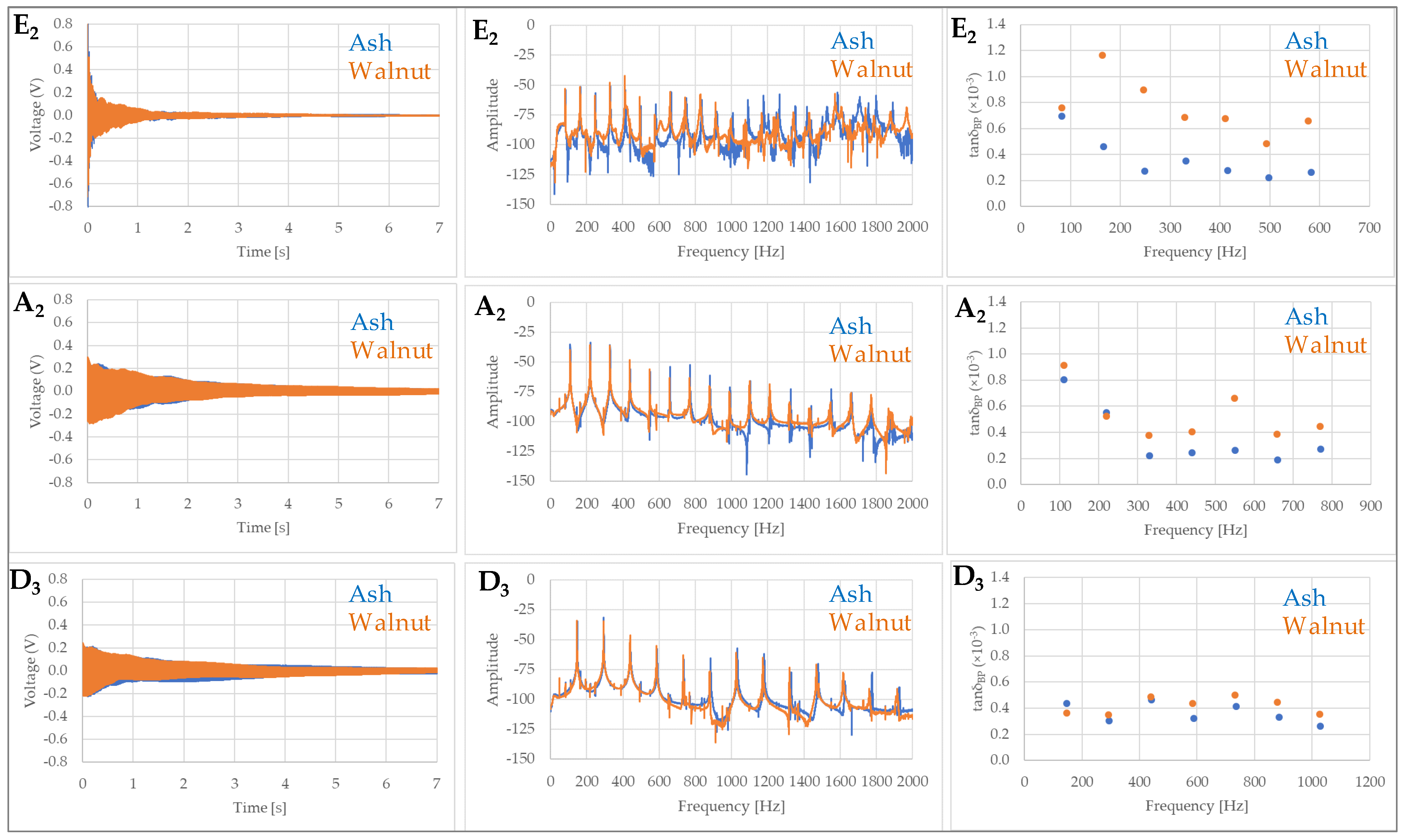

3.2. Acoustic Response of Electric Guitar at Vibration of Open Strings

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pate, A.; Le Carrou, J.L.; Fabre, B. Predicting the decay time of solid body guitar tones. J. Acoust. Soc. Am. 2014, 135, 3045–3055. [Google Scholar] [CrossRef] [Green Version]

- Lähdevaara, J. The Science of Electric Guitars and Guitars Electronics; Lähdevaara: Helsinki, Finland, 2014. [Google Scholar]

- Fleischer, H.; Zwicker, T. Mechanical vibrations of electrical guitars. Acta Acust. United Acust. 1998, 84, 758–765. [Google Scholar]

- Fleischer, H.M. Vibration of an electric bass guitar. Acta Acust. United Acust. 2005, 91, 247–260. [Google Scholar]

- Navarret, B.; Le Carrou, J.L.; Sedes, A.; Ollivier, S.; Fujiso, Y. Etude perceptive et dynamique de la guitare electrique. In Proceedings of the Conference on Interdisciplinary Musicology, Paris, France, 26–29 October 2009; pp. 126–128. [Google Scholar]

- Zwicker, T.; Buus, S. Distortion as an artistic tool for guitar players. J. Acoust. Soc. Am. 1998, 103, 2797. [Google Scholar] [CrossRef]

- Mustonen, M.; Kartofelev, D.; Stulov, A.; Välimäki, V. Experimental verification of pickup nonlinearity. In Proceedings of the International Symposium on Musical Acoustics, Le Mans, France, 7–12 July 2014; pp. 651–656. [Google Scholar]

- Horton, N.G.; Moore, T.R. Modeling the magnetic pickup of an electric guitar. Am. J. Phys. 2009, 77, 144–150. [Google Scholar] [CrossRef]

- Rossing, T.D. The Science of String Instruments; Springer: New York, NY, USA, 2010. [Google Scholar] [CrossRef] [Green Version]

- Woodhouse, J. Plucked guitar transients: Comparison of measurements and synthesis. Acta Acust. United Acust. 2004, 90, 945–965. [Google Scholar]

- Perov, P.; Johnson, W.; Perova-Mello, N. The physics of guitar strings vibrations. Am. J. Phys. 2016, 84, 38–43. [Google Scholar] [CrossRef]

- Pate, A.; Le Carrou, J.L.; Navarret, B.; Dubois, D.; Fabre, B. A vibro-acustical and perceptive study of the neck-to-body junction of solid-body electric guitar. In Acoustics, Proceedings of the 11th Congrès Français D’Acoustique, Nantes, France, 23–27 April 2012; Acoustics: Nantes, France, 2012; pp. 1–6. [Google Scholar]

- Fleischer, H.; Zwicker, T. Investigating of dead spots of electric guitars. Acta Acust. United Acust. 1999, 85, 128–135. [Google Scholar]

- Le Carrou, J.L.; Chornette, B.; Pate, A. Influence of the intrumentalist on the electric guitar vibratory behaviour. In Proceedings of the Intenational Symposium on Music Acoustics, Le Mans, France, 7–12 July 2014; pp. 413–417. [Google Scholar]

- Roberts, W.H. Physics and Psychoacoustics of Plucked-String Instruments. Ph.D. Thesis, Cardiff University, Cardiff, UK, 2015. [Google Scholar]

- Gough, C.E. Acoustical studies of stringed instruments using string resonances. In Proceedings of the Stockholm Music Acoustics Conference, Stockholm, Sweden, 28 July–1 August 1983; pp. 19–45. [Google Scholar]

- Russel, D.A.; Haveman, W.S.; Broden, W.; Weibull, N.P. Effect of body shape on vibration of electric guitars. J. Acoust. Soc. Am. 2003, 113, 2316. [Google Scholar] [CrossRef]

- Pate, A.; Le Carrou, J.L.; Teissier, F.; Fabre, B. Evolution of the modal behaviour of nominally identical electric guitars during the making process. Acta Acust. United Acust. 2015, 101, 567–580. [Google Scholar] [CrossRef]

- Mania, P.; Fabisiak, E.; Skrodzka, E. Differences in the modal and structural parameters of resonance and non-resonance wood of spruce. Acta Phys. Pol. 2015, 127, 110–113. [Google Scholar] [CrossRef]

- Sprossmann, R.; Zauer, M.; Pfriem, A. Regarding the influence of wood species in necks of bass guitars on the vibrational and acoustic behaviour. Holztechnologie 2013, 54, 19–25. [Google Scholar]

- Zauer, M.; Kowalewski, A.; Sprossmann, R.; Stonjek, H.; Wagenfuhr, A. Thermal modification of European beech at relatively mild temperatures for the use in electric bass guitars. Eur. J. Wood Wood Prod. 2015, 74, 43–49. [Google Scholar] [CrossRef]

- Parker, K.; Fishman, R. Molded Laminate for Musical Instrument and Method Manufacturing Molded Laminate Musical Instrument. U.S. Patent Application 10/756,973, 2004. [Google Scholar]

- Fujiso, Y. Vibroacoustical Study of a Solid-Body Electric Guitar; Chalmers University of Technology: Göteborg, Sweden, 2009. [Google Scholar]

- Zorič, A.; Kaljun, J.; Žveplan, E.; Straže, A. Selection of wood based on acoustic properties for the solid body of electric guitar. Arch. Acoust. 2019, 44, 51–58. [Google Scholar] [CrossRef]

- Pate, A.; Le Carrou, J.L.; Fabre, B. Modal parameter variability in industrial electric guitar making: Manufacturing process, wood variability, and lutherie decisions. Appl. Acoust. 2015, 96, 118–131. [Google Scholar] [CrossRef] [Green Version]

- Brancheriau, L.; Bailléres, H.; Detienne, P.; Gril, J.; Kronland, R. Key signal and wood anatomy parameters related to the acoustic quality of wood for xylophone-type percussion instruments. J. Wood Sci. 2006, 52, 270–273. [Google Scholar] [CrossRef]

- Pate, A.; Le Carrou, J.L.; Fabre, B. Ebony vs. rosewood: Experimental investigation about the influence of the fingerboard on the sound of a solid body electric guitar. In Proceedings of the Stockholm Musical Acoustics Conference, Stockholm, Sweden, 30 July–3 August 2013; pp. 182–187. [Google Scholar]

- Brémaud, I.; Kaim, E.Y.; Guibal, D.; Minato, K.; Thibaut, B.; Gril, J. Characterization and categorization of the diversity of viscoelastic vibrational properties between 98 wood types. Ann. For. Sci. 2012, 69, 373–386. [Google Scholar] [CrossRef]

- Obataya, E.; Ono, T.; Norimoto, M. Vibrational properties of wood along the grain. J. Mater. Sci. 2000, 35, 2993–3001. [Google Scholar] [CrossRef]

- Wegst, U.G.K. Wood for sound. Am. J. Bot. 2006, 93, 1439–1448. [Google Scholar] [CrossRef] [PubMed]

| Acoustic Parameter | Ash (CV%) | Walnut (CV%) |

|---|---|---|

| f1 [s−1] | 923 (0.1) | 748 (0.1) |

| tanδ | 0.008 (7.9) | 0.011 (11.4) |

| E/ρ [GPa] | 14.93 (4.5) | 9.79 (6.7) |

| K [m4 s−1 kg−1] | 4.81 (9.8) | 5.04 (12.2) |

| ACE [m4 s−1 kg−1] | 261 (8.5) | 246 (10.6) |

| RACE [km s−1] | 209 (7.7) | 153 (9.4) |

| Material | EL (GPa) | ER (GPa) | ET (GPa) | GLR (GPa) | GLT (GPa) | GRT (GPa) |

|---|---|---|---|---|---|---|

| Ash (A) | 17.22 | 2.13 | 1.91 | 1.62 | 1.13 | 0.63 |

| CV% | 16.6 | 9.2 | 8.4 | 11.3 | 15.6 | 14.7 |

| Walnut (W) | 8.63 | 1.34 | 1.89 | 1.79 | 1.10 | 0.44 |

| CV% | 15.4 | 7.9 | 5.6 | 8.9 | 11.5 | 12.4 |

| Ash (A) | Walnut (W) | |||||||

|---|---|---|---|---|---|---|---|---|

| NA | BP | M1 | M2 | NA | BP | M1 | M2 | |

| 1st mode | 119.8 | 119.0 | 119.1 | 114.1 | 104.2 | 108.2 | 109.2 | 111.2 |

| CV% | 10.2 | 7.9 | 8.3 | 8.0 | 12.6 | 12.6 | 11.7 | 6.3 |

| 2nd mode | 201.8 | 204.7 | 205.6 | 200.5 | 200.1 | 200.5 | 201.7 | 200.3 |

| CV% | 0.8 | 0.4 | 0.3 | 0.4 | 1.8 | 0.3 | 5.2 | 0.4 |

| 3rd mode | 437.0 | 440.4 | 437.6 | 437.0 | 418.9 | 420.6 | 418.9 | 418.5 |

| CV% | 0.1 | 1.0 | 0.1 | 0.1 | 0.1 | 6.1 | 0.1 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ray, T.; Kaljun, J.; Straže, A. Comparison of the Vibration Damping of the Wood Species Used for the Body of an Electric Guitar on the Vibration Response of Open-Strings. Materials 2021, 14, 5281. https://doi.org/10.3390/ma14185281

Ray T, Kaljun J, Straže A. Comparison of the Vibration Damping of the Wood Species Used for the Body of an Electric Guitar on the Vibration Response of Open-Strings. Materials. 2021; 14(18):5281. https://doi.org/10.3390/ma14185281

Chicago/Turabian StyleRay, Tony, Jasmin Kaljun, and Aleš Straže. 2021. "Comparison of the Vibration Damping of the Wood Species Used for the Body of an Electric Guitar on the Vibration Response of Open-Strings" Materials 14, no. 18: 5281. https://doi.org/10.3390/ma14185281

APA StyleRay, T., Kaljun, J., & Straže, A. (2021). Comparison of the Vibration Damping of the Wood Species Used for the Body of an Electric Guitar on the Vibration Response of Open-Strings. Materials, 14(18), 5281. https://doi.org/10.3390/ma14185281