Author Contributions

Conceptualization, T.S., V.M., T.A. and T.R.; methodology, A.R., I.M.A., I.A.B., A.A. (Ali Algahtani); software, T.S., V.M., T.A. and T.R.; validation, A.R., I.M.A., I.A.B., A.A. (Ali Algahtani); formal analysis, T.S., V.M., T.A. and T.R.; investigation, T.S., V.M., T.A. and T.R.; resources, A.A. (Asif Afzal); data curation, A.A. (Asif Afzal); writing—original draft preparation, T.S., V.M., T.A. and T.R.; writing—review and editing, A.R., I.M.A., I.A.B., A.A. (Ali Algahtani); visualization, A.R., I.M.A., I.A.B., A.A. (Ali Algahtani); supervision, A.A. (Asif Afzal); project administration, A.A. (Asif Afzal); funding acquisition, A.R., I.M.A., I.A.B., A.A. (Ali Algahtani). All authors have read and agreed to the published version of the manuscript.

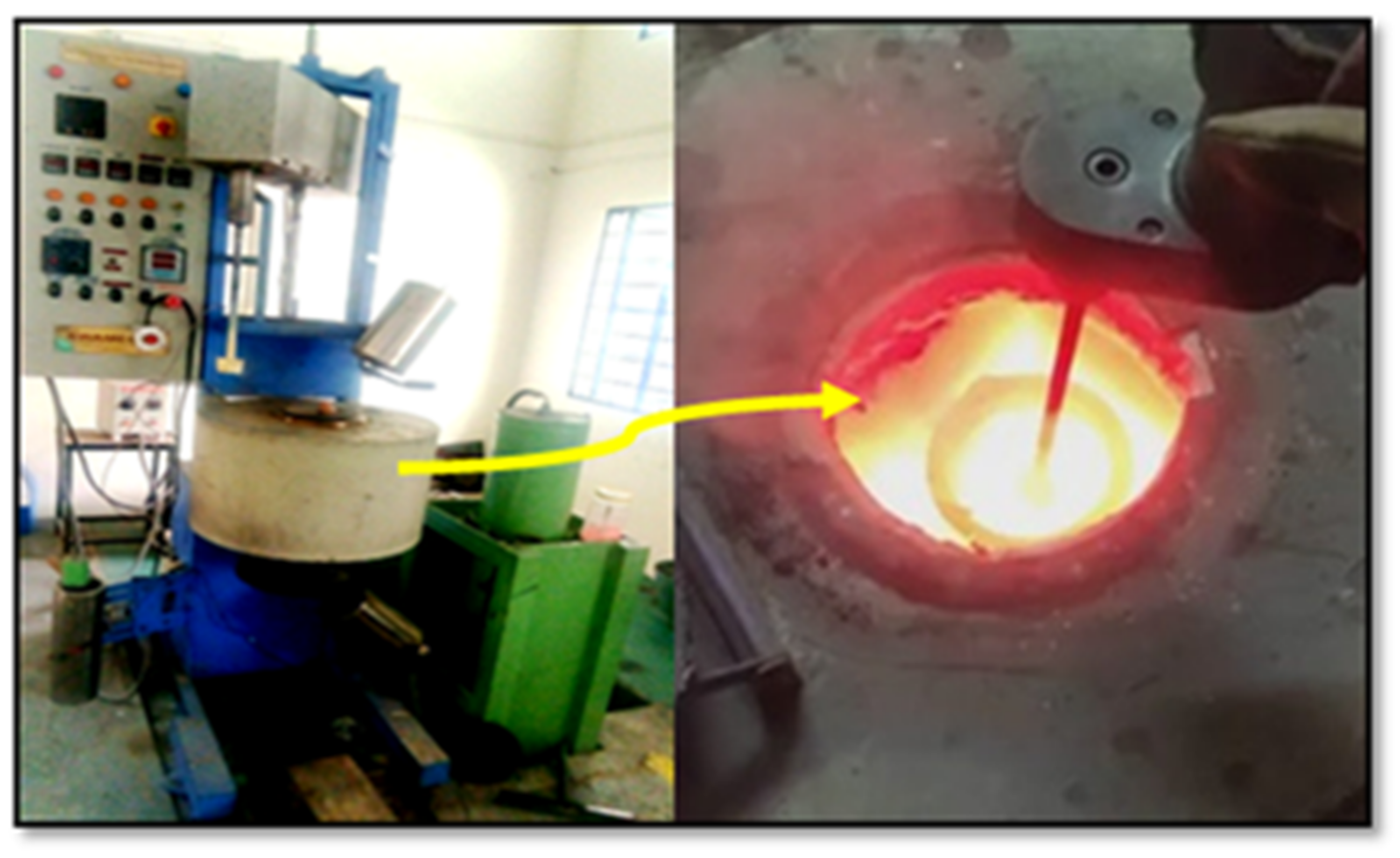

Figure 1.

Stir casting process setup.

Figure 1.

Stir casting process setup.

Figure 2.

Stir casted AA8079 + TiN + ZrO2 samples.

Figure 2.

Stir casted AA8079 + TiN + ZrO2 samples.

Figure 3.

Schematic view of 100 kN capacity of UTM with tensile test specimen.

Figure 3.

Schematic view of 100 kN capacity of UTM with tensile test specimen.

Figure 4.

Schematic view of dry sliding wear test apparatus.

Figure 4.

Schematic view of dry sliding wear test apparatus.

Figure 5.

Photographic view of corrosion specimens.

Figure 5.

Photographic view of corrosion specimens.

Figure 6.

Photographic view of microhardness specimens.

Figure 6.

Photographic view of microhardness specimens.

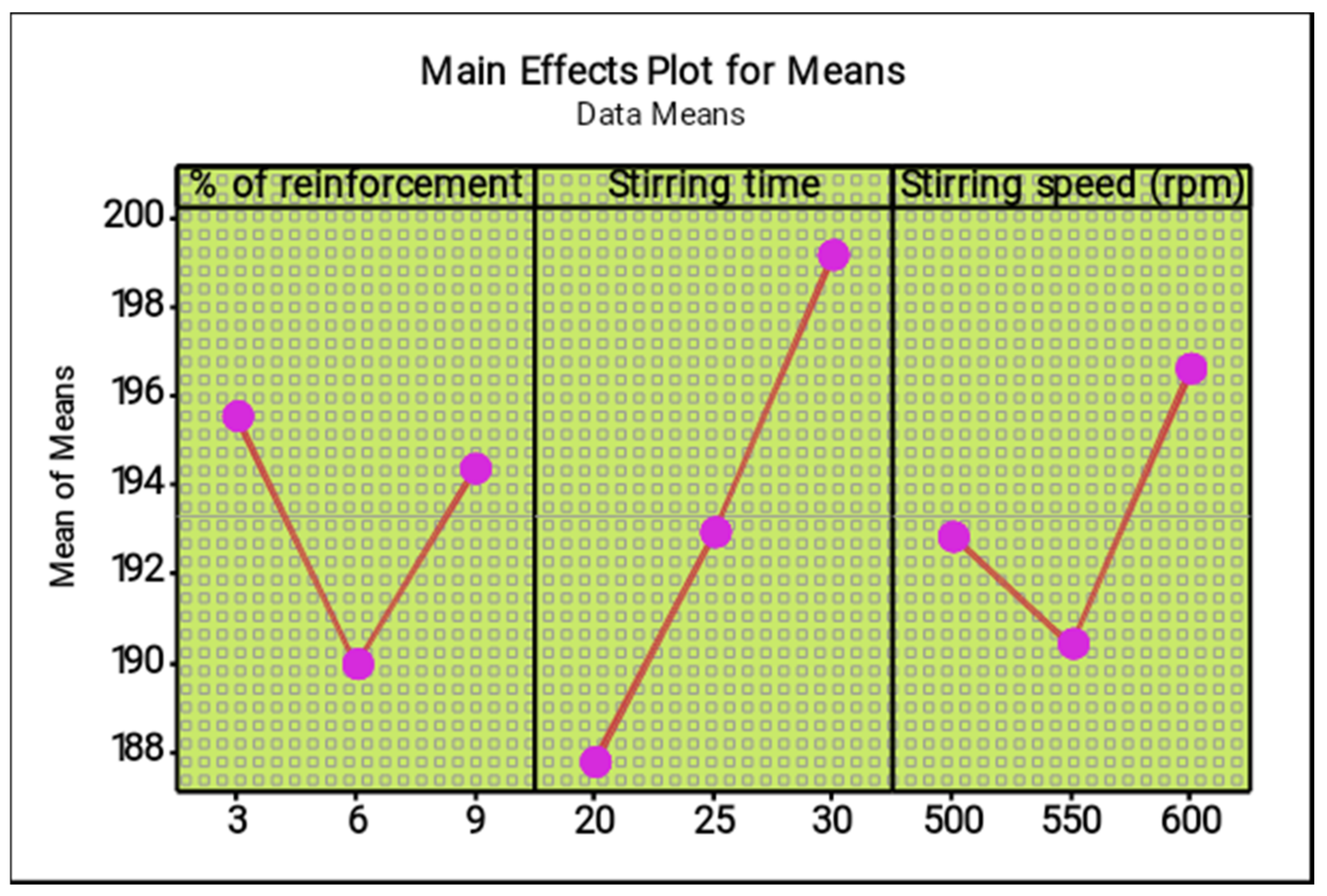

Figure 7.

Main effect plot for means (ultimate tensile strength).

Figure 7.

Main effect plot for means (ultimate tensile strength).

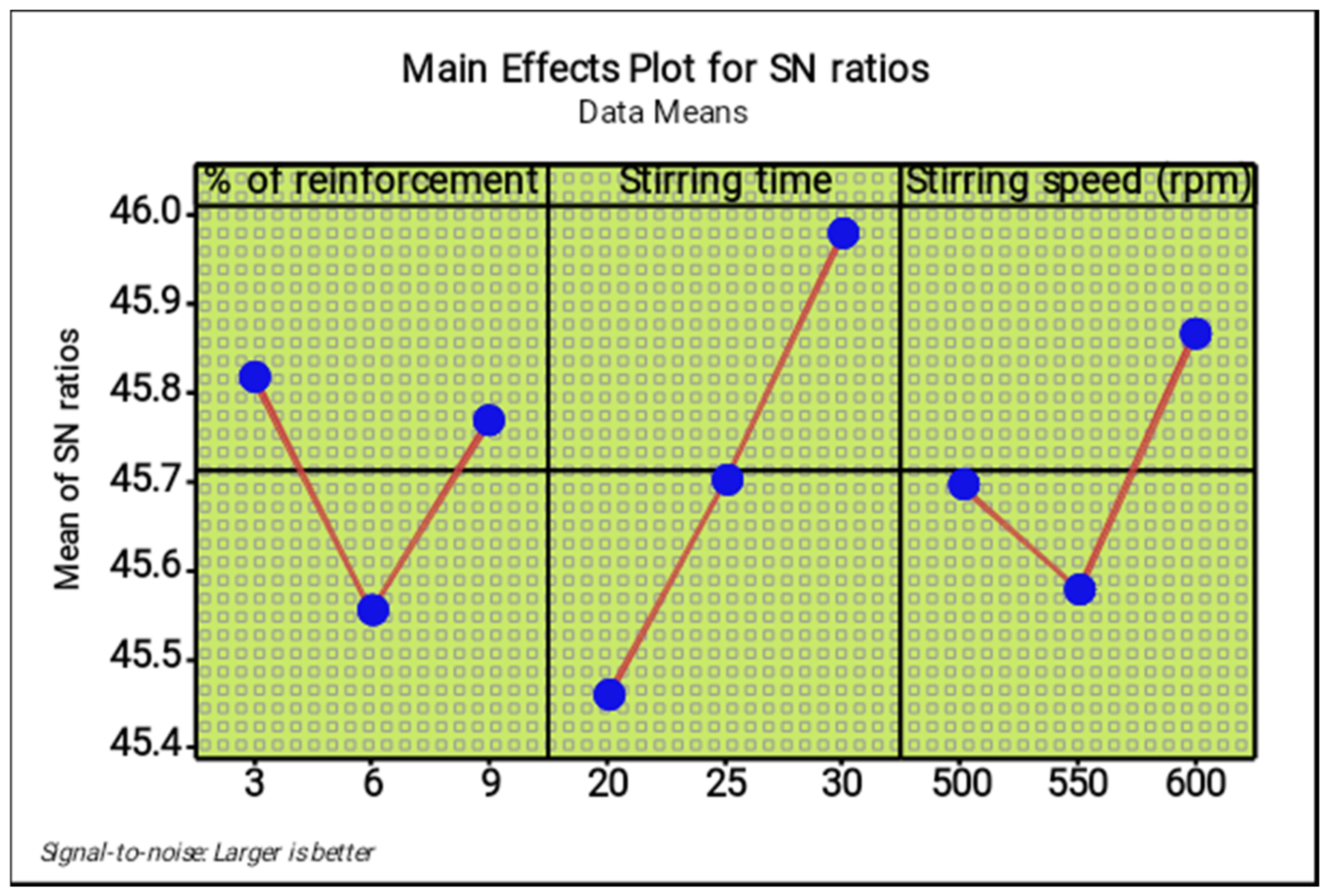

Figure 8.

Main effect plot for S/N ratios (ultimate tensile strength).

Figure 8.

Main effect plot for S/N ratios (ultimate tensile strength).

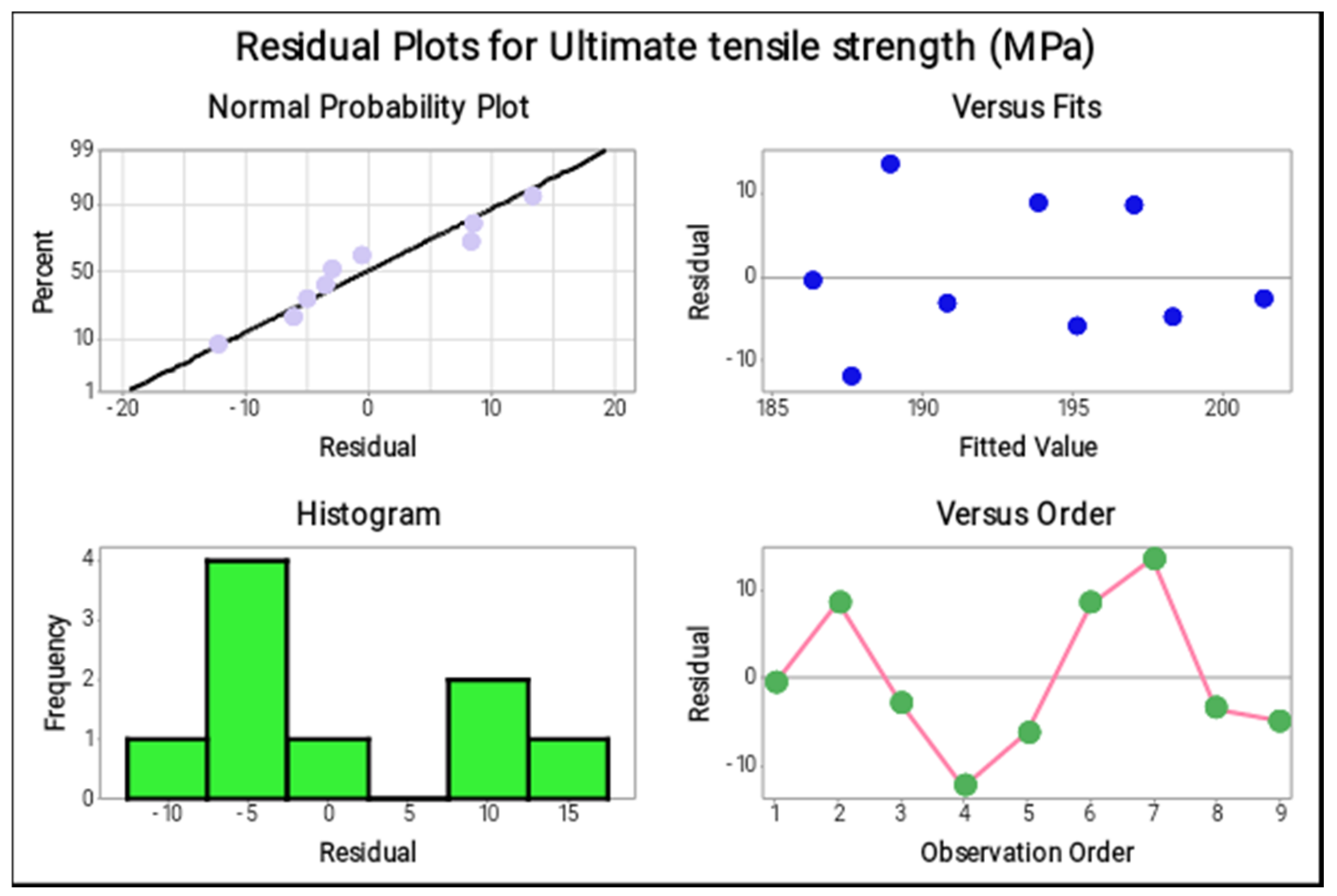

Figure 9.

Residual plots (Ultimate tensile strength).

Figure 9.

Residual plots (Ultimate tensile strength).

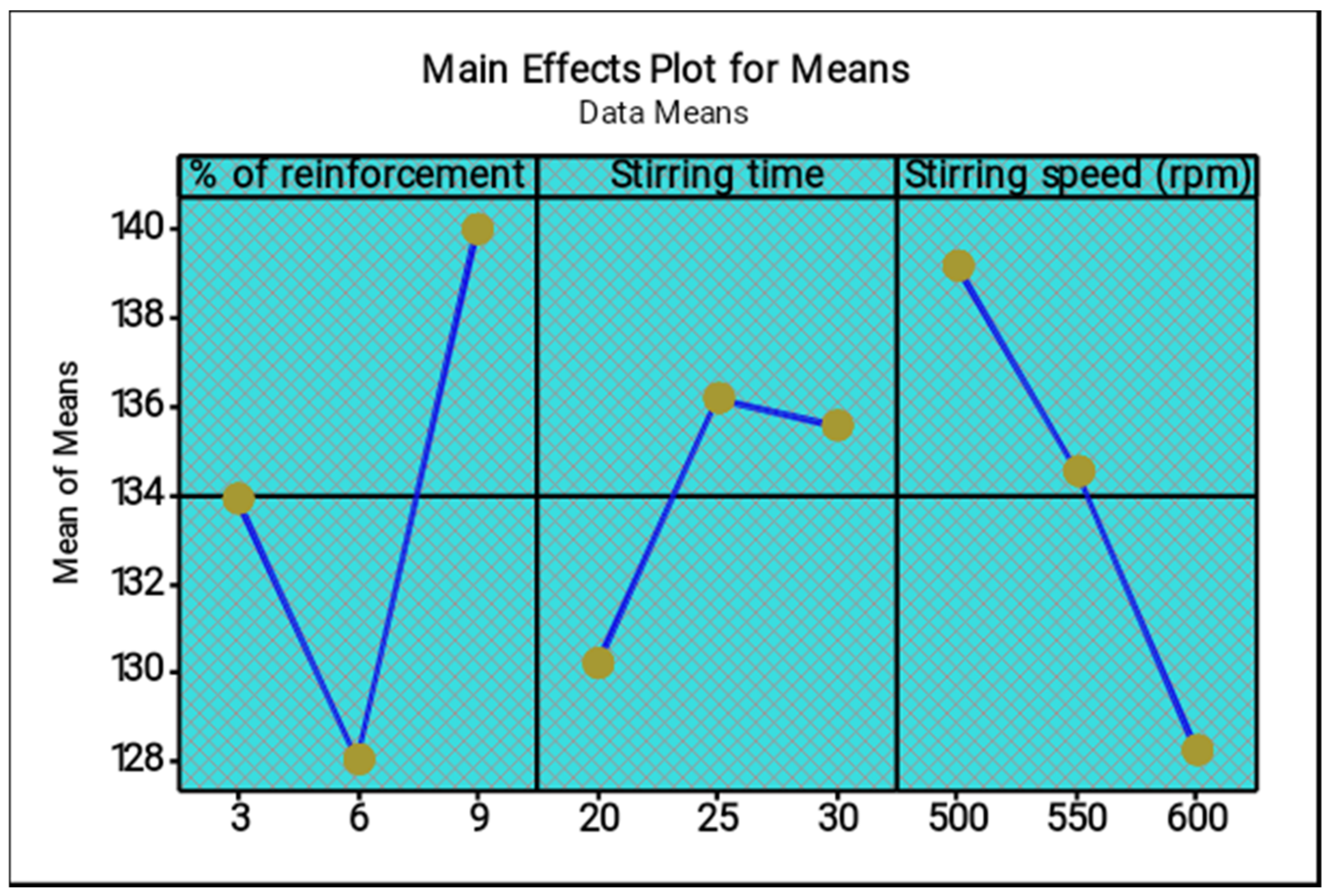

Figure 10.

Main effect plot for means (wear).

Figure 10.

Main effect plot for means (wear).

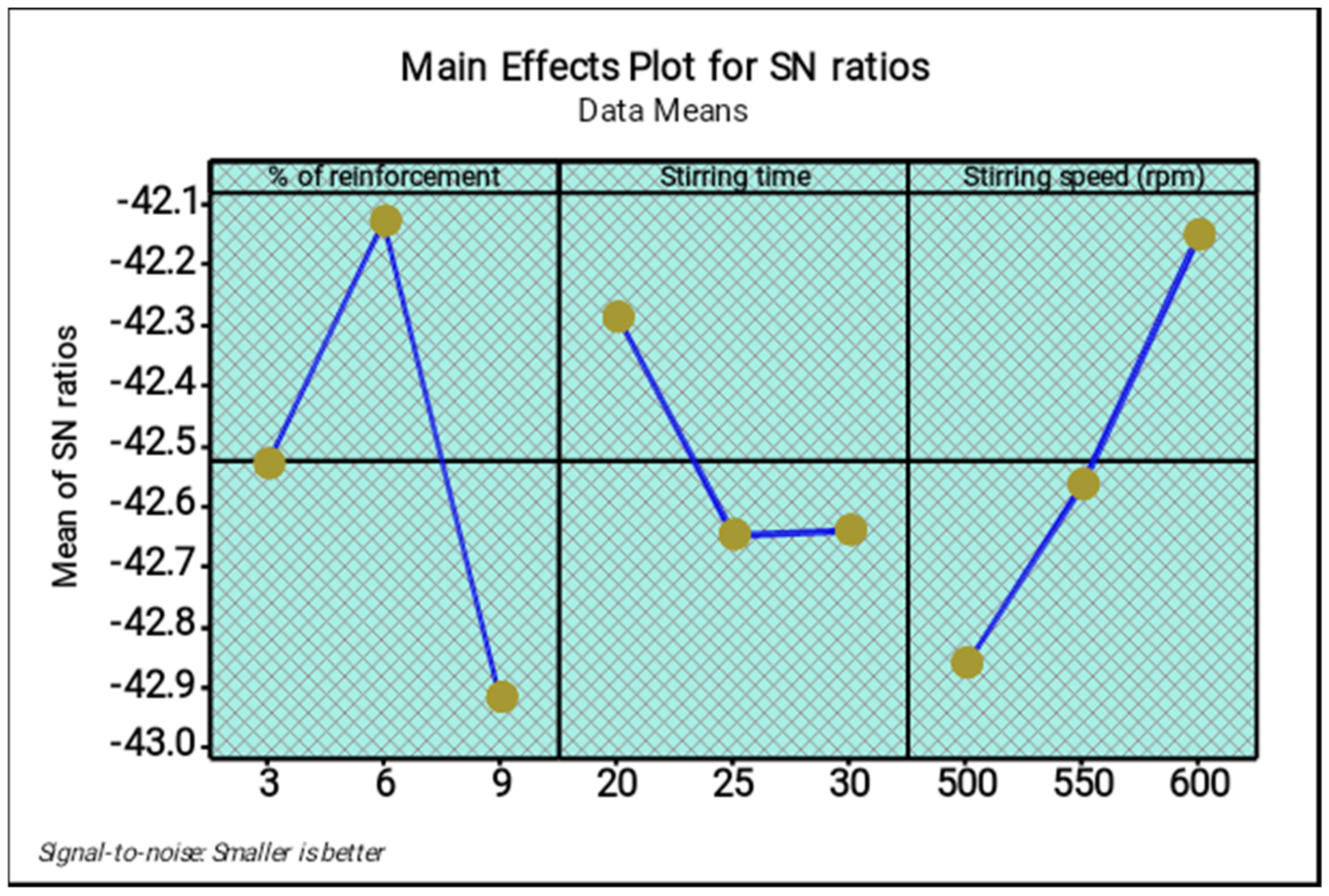

Figure 11.

Main effect plot for S/N ratios (wear).

Figure 11.

Main effect plot for S/N ratios (wear).

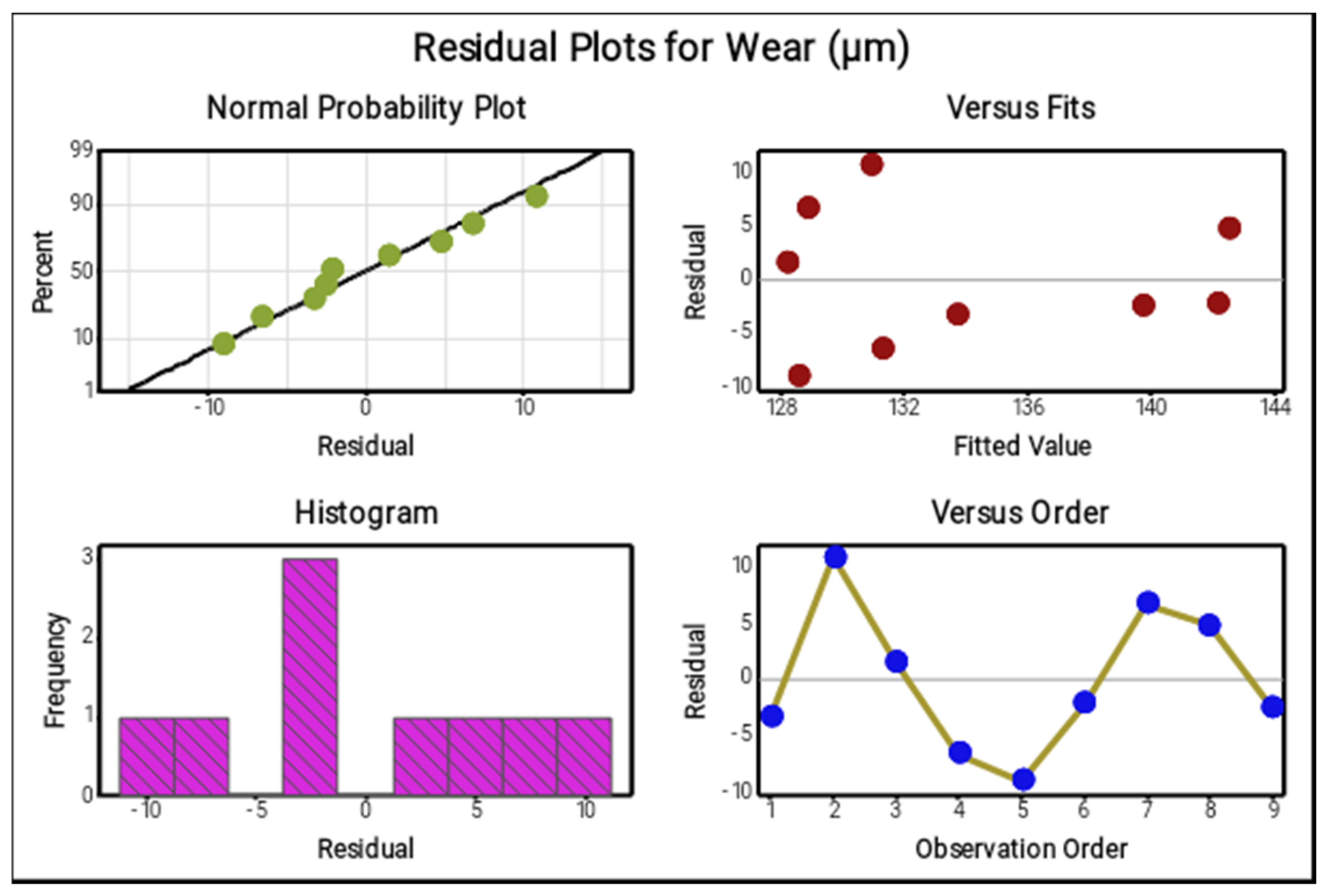

Figure 12.

Residual plots for wear.

Figure 12.

Residual plots for wear.

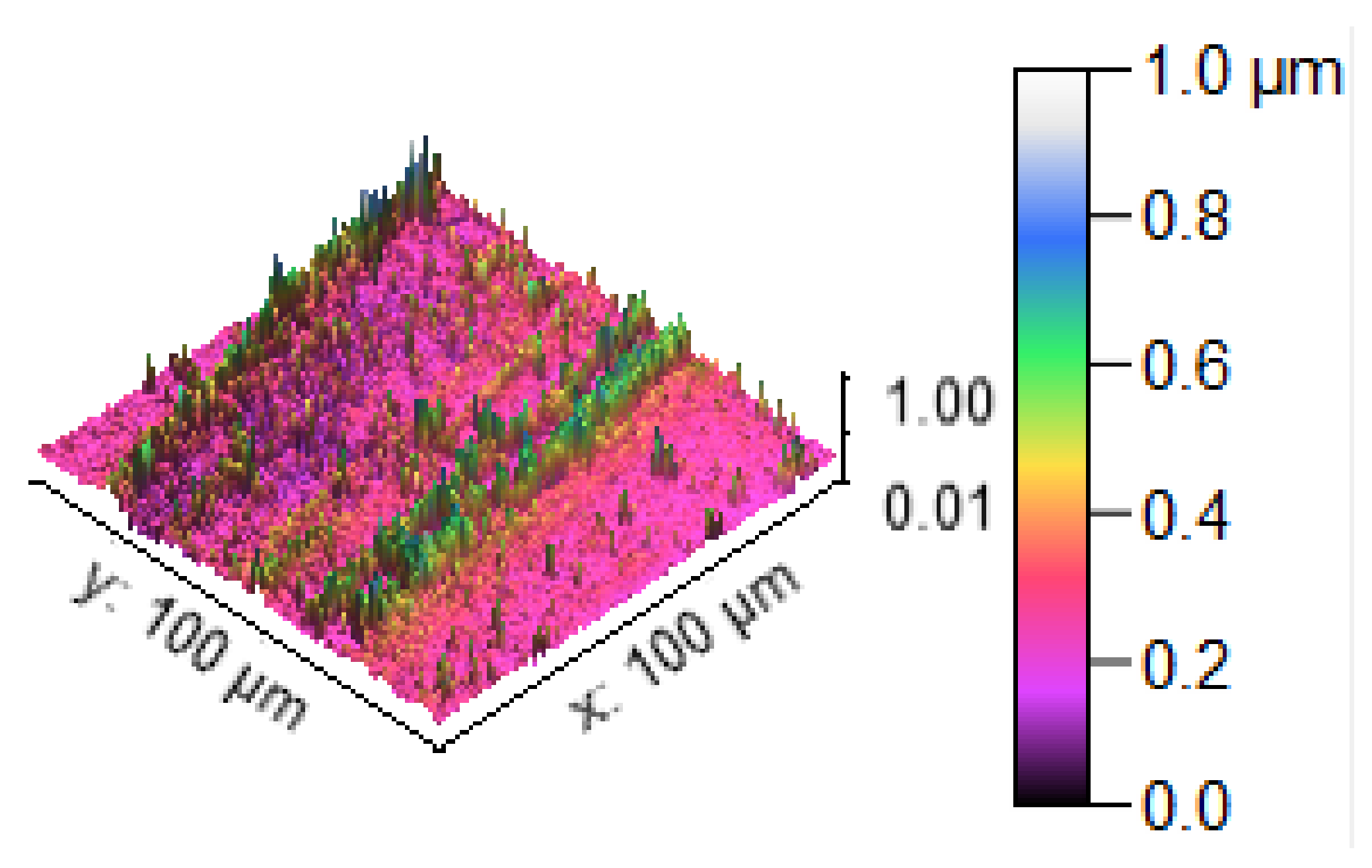

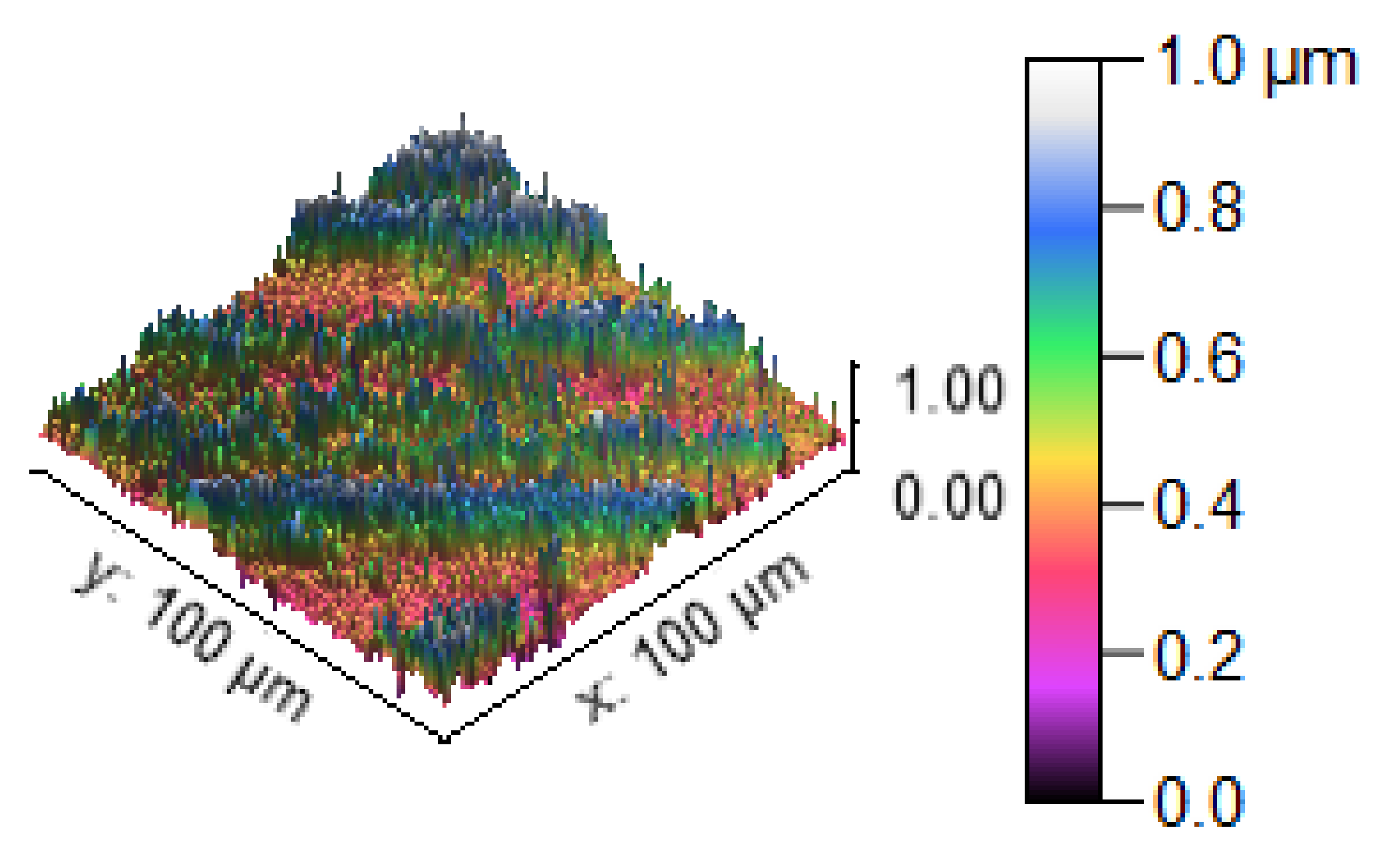

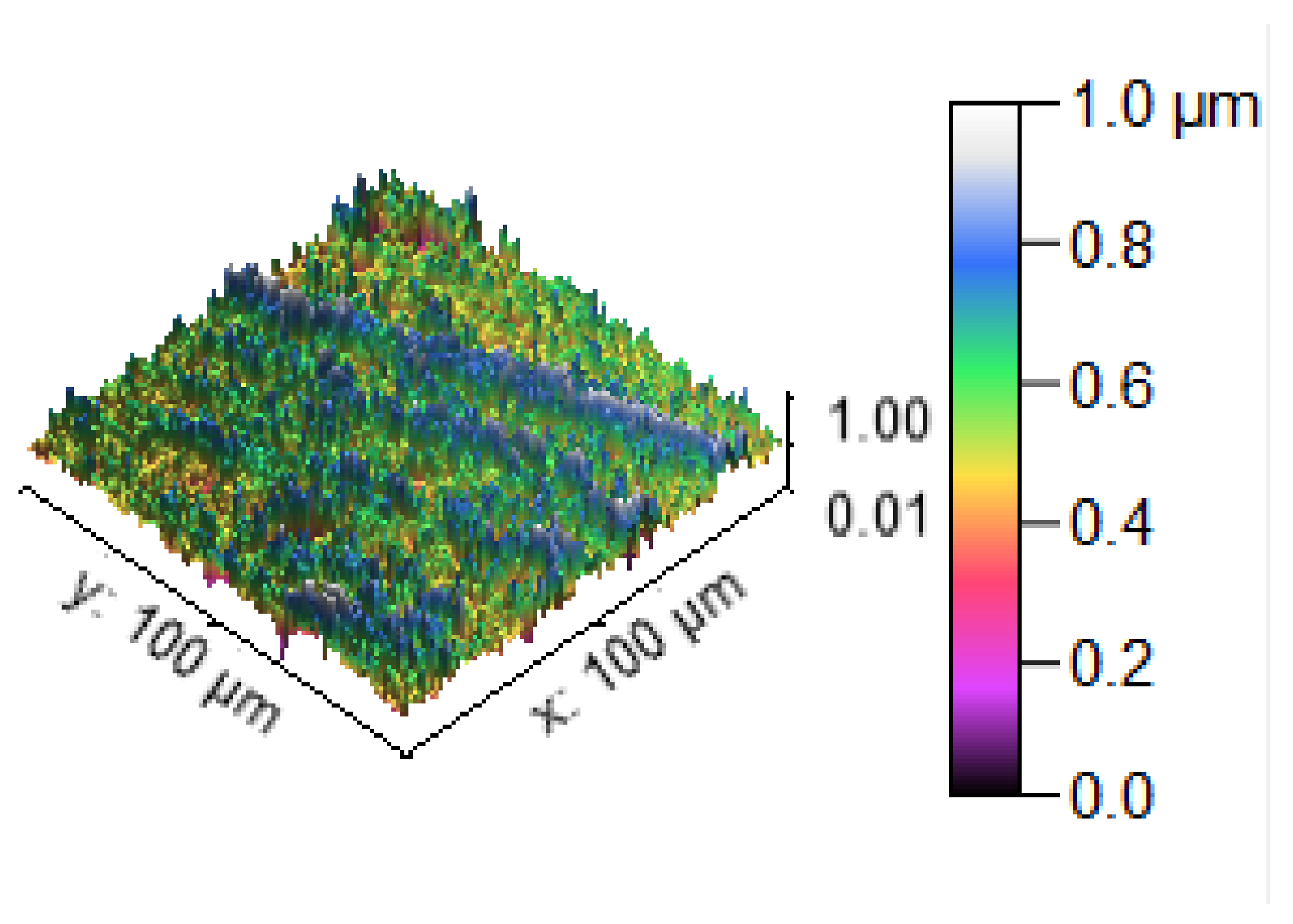

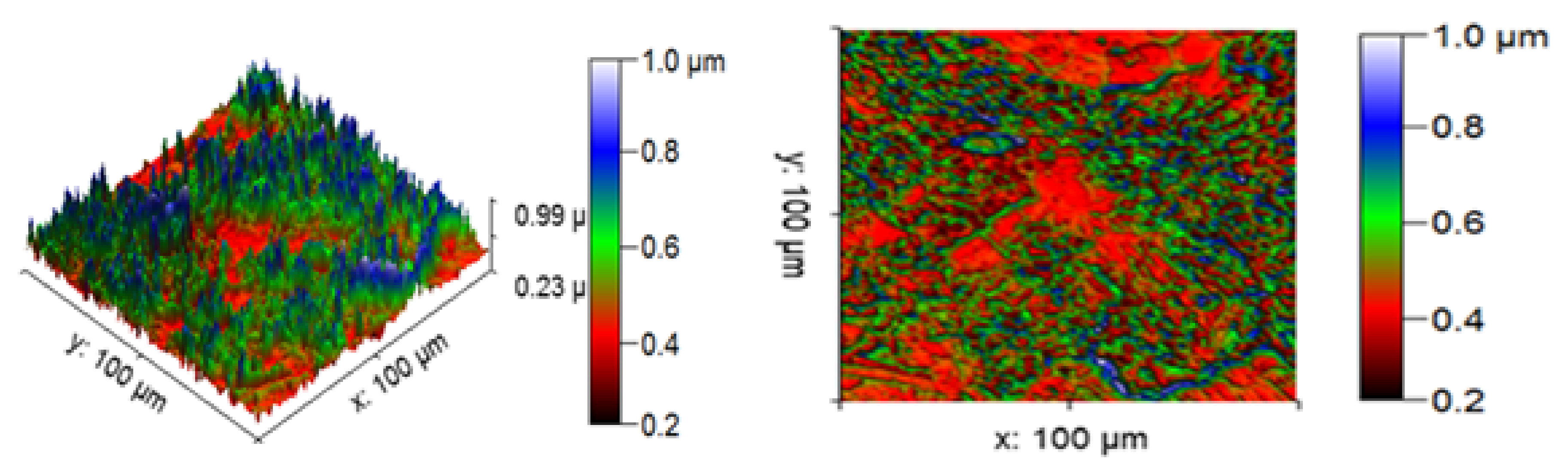

Figure 13.

Three dimensional (3D) profilometric image (S-1).

Figure 13.

Three dimensional (3D) profilometric image (S-1).

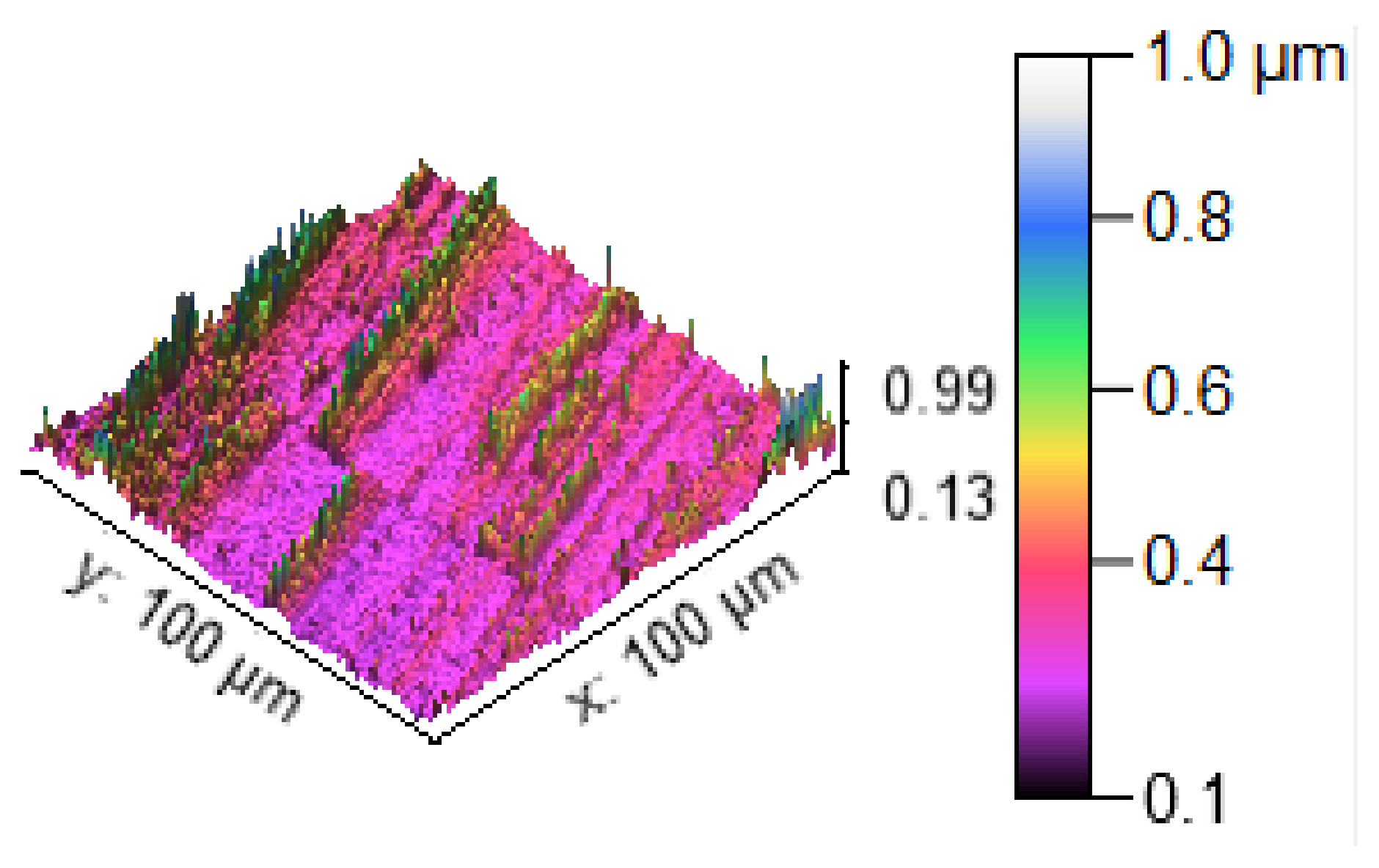

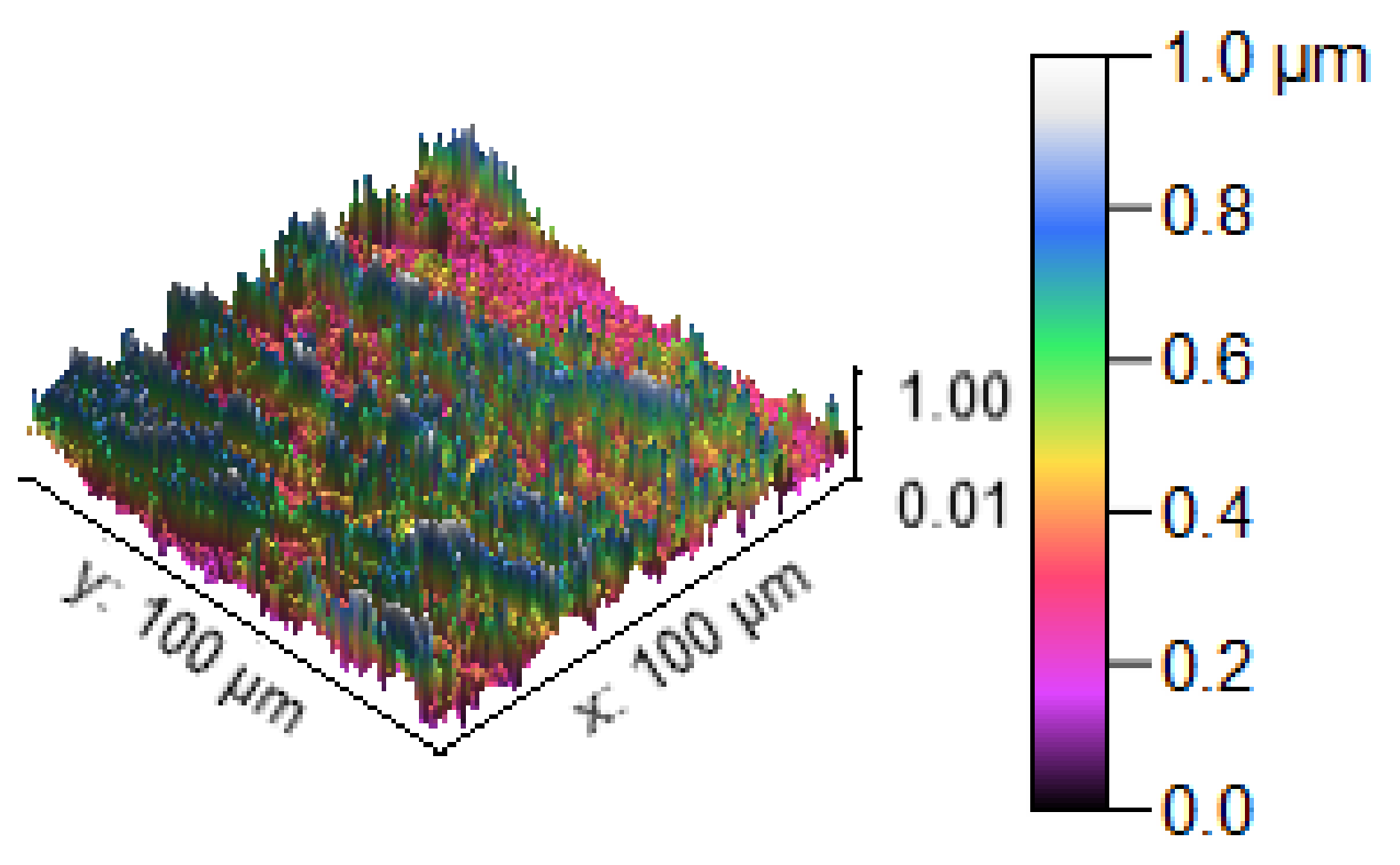

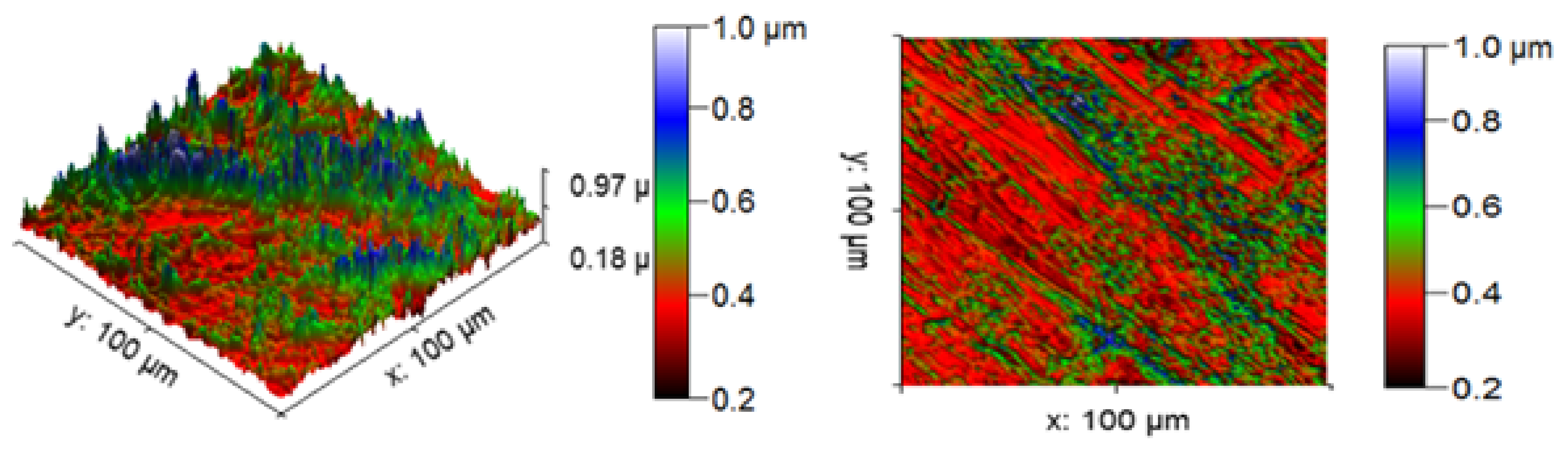

Figure 14.

Three dimensional (3D) profilometric image (S-2).

Figure 14.

Three dimensional (3D) profilometric image (S-2).

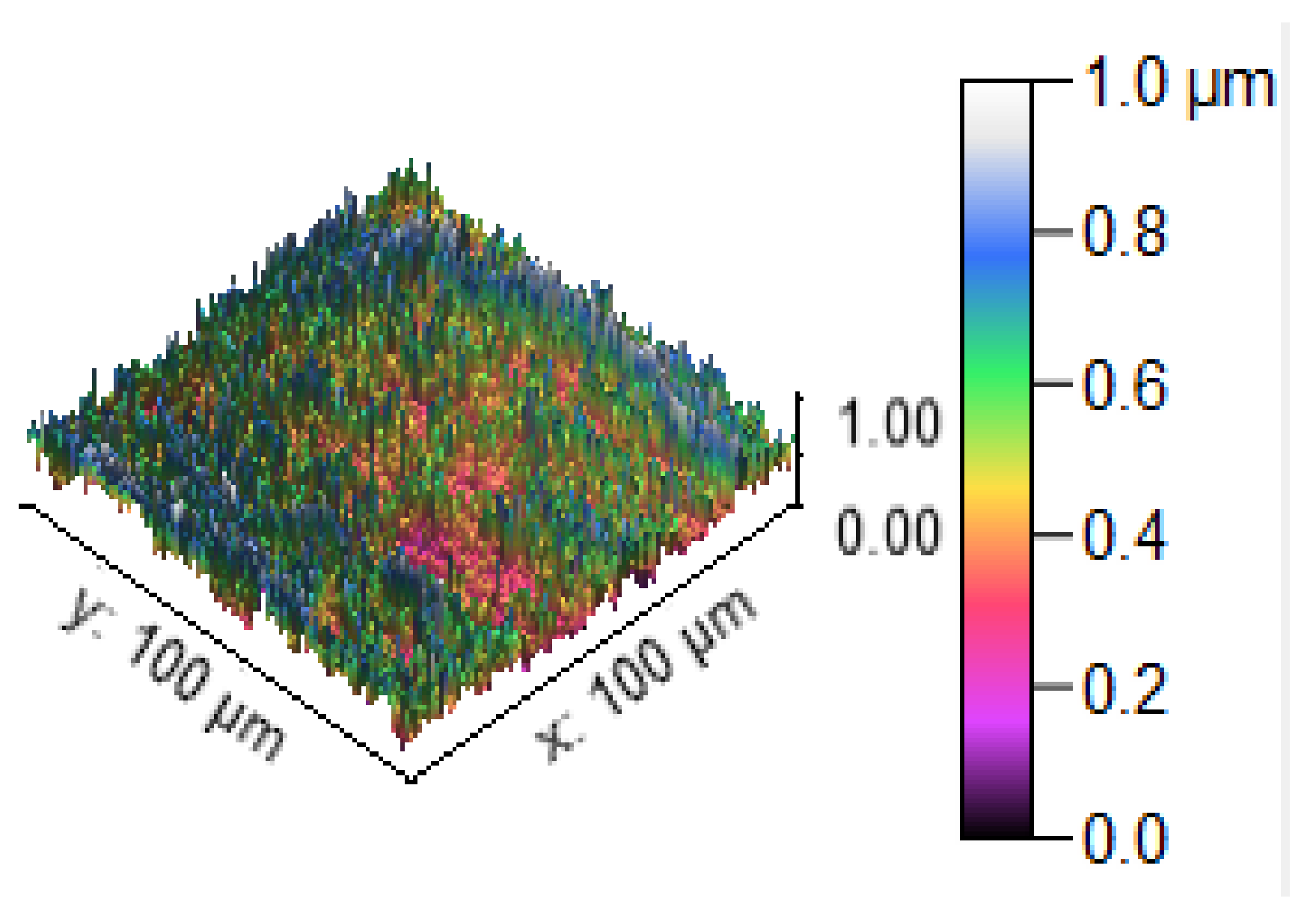

Figure 15.

Three dimensional (3D) profilometric image (S-3).

Figure 15.

Three dimensional (3D) profilometric image (S-3).

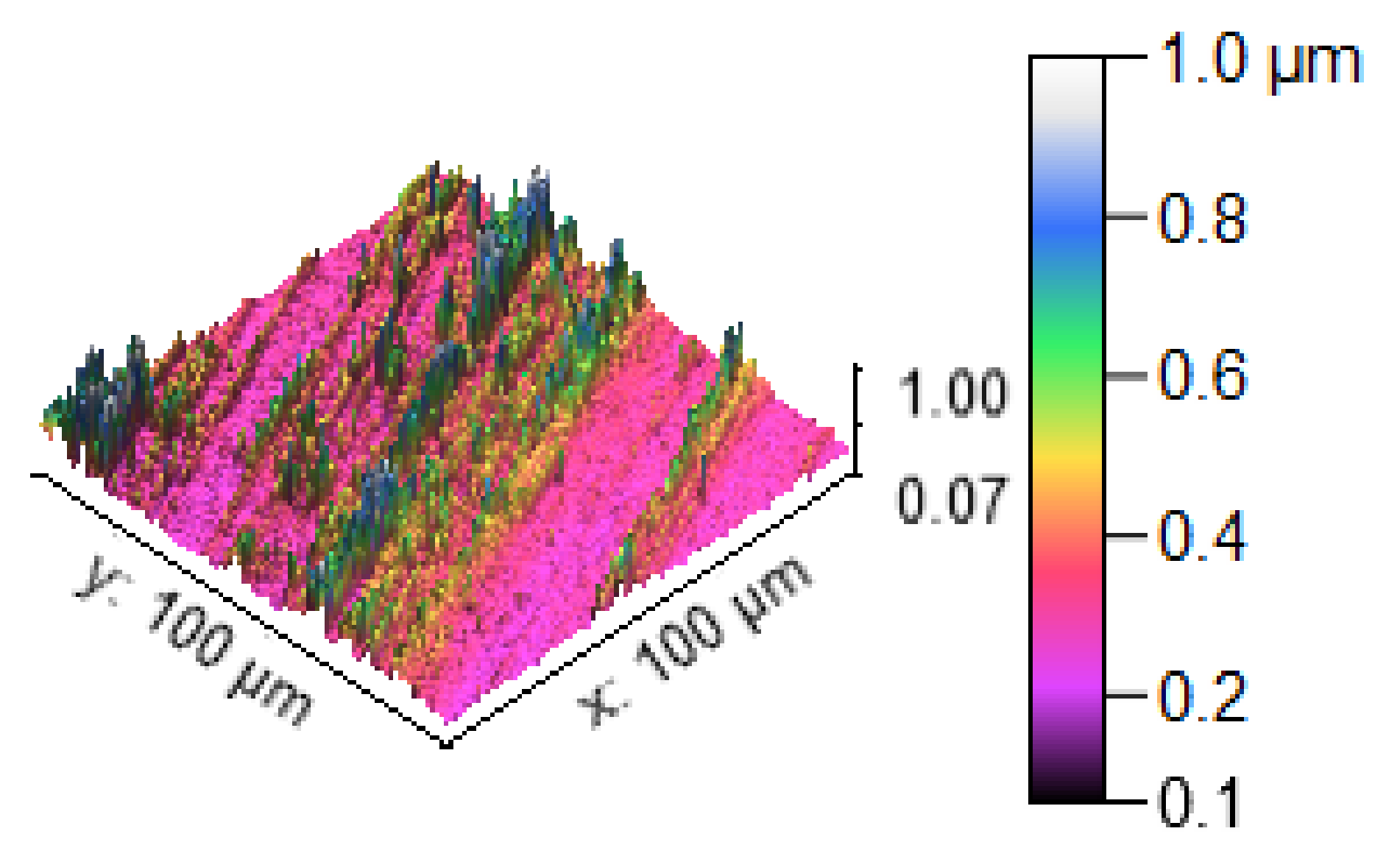

Figure 16.

Three dimensional (3D) profilometric image (S-4).

Figure 16.

Three dimensional (3D) profilometric image (S-4).

Figure 17.

Three dimensional (3D) profilometric image (S-5).

Figure 17.

Three dimensional (3D) profilometric image (S-5).

Figure 18.

Three dimensional (3D) profilometric image (S-6).

Figure 18.

Three dimensional (3D) profilometric image (S-6).

Figure 19.

Three dimensional (3D) profilometric image (S-7).

Figure 19.

Three dimensional (3D) profilometric image (S-7).

Figure 20.

Three dimensional (3D) profilometric image (S-8).

Figure 20.

Three dimensional (3D) profilometric image (S-8).

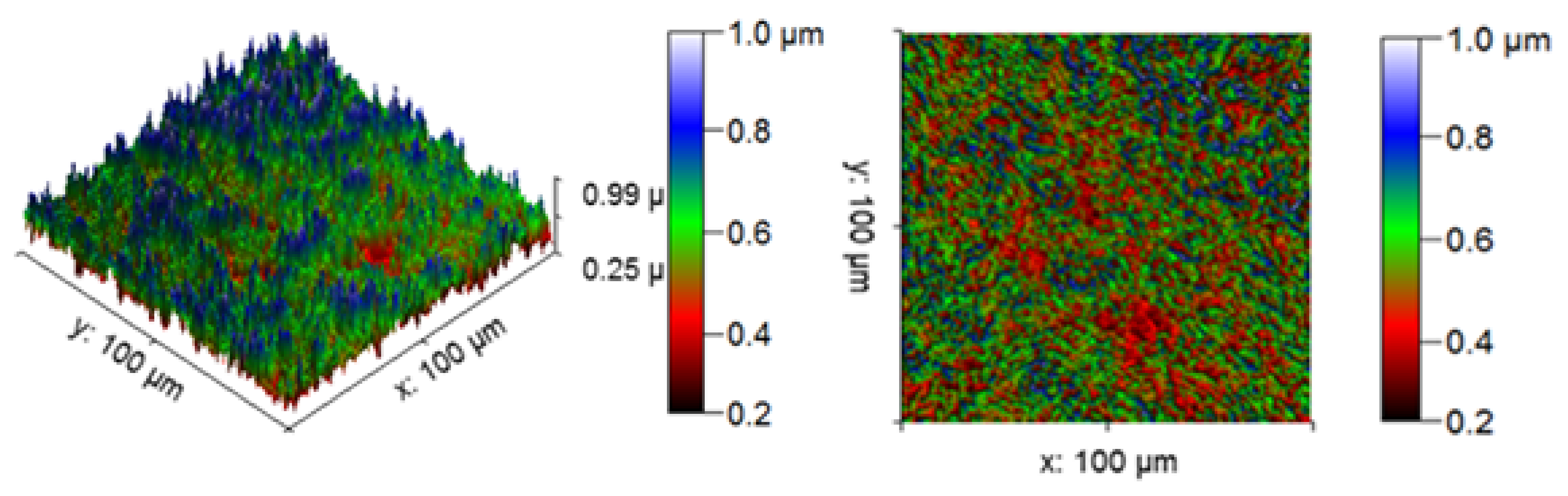

Figure 21.

Three dimensional (3D) profilometric image (S-9).

Figure 21.

Three dimensional (3D) profilometric image (S-9).

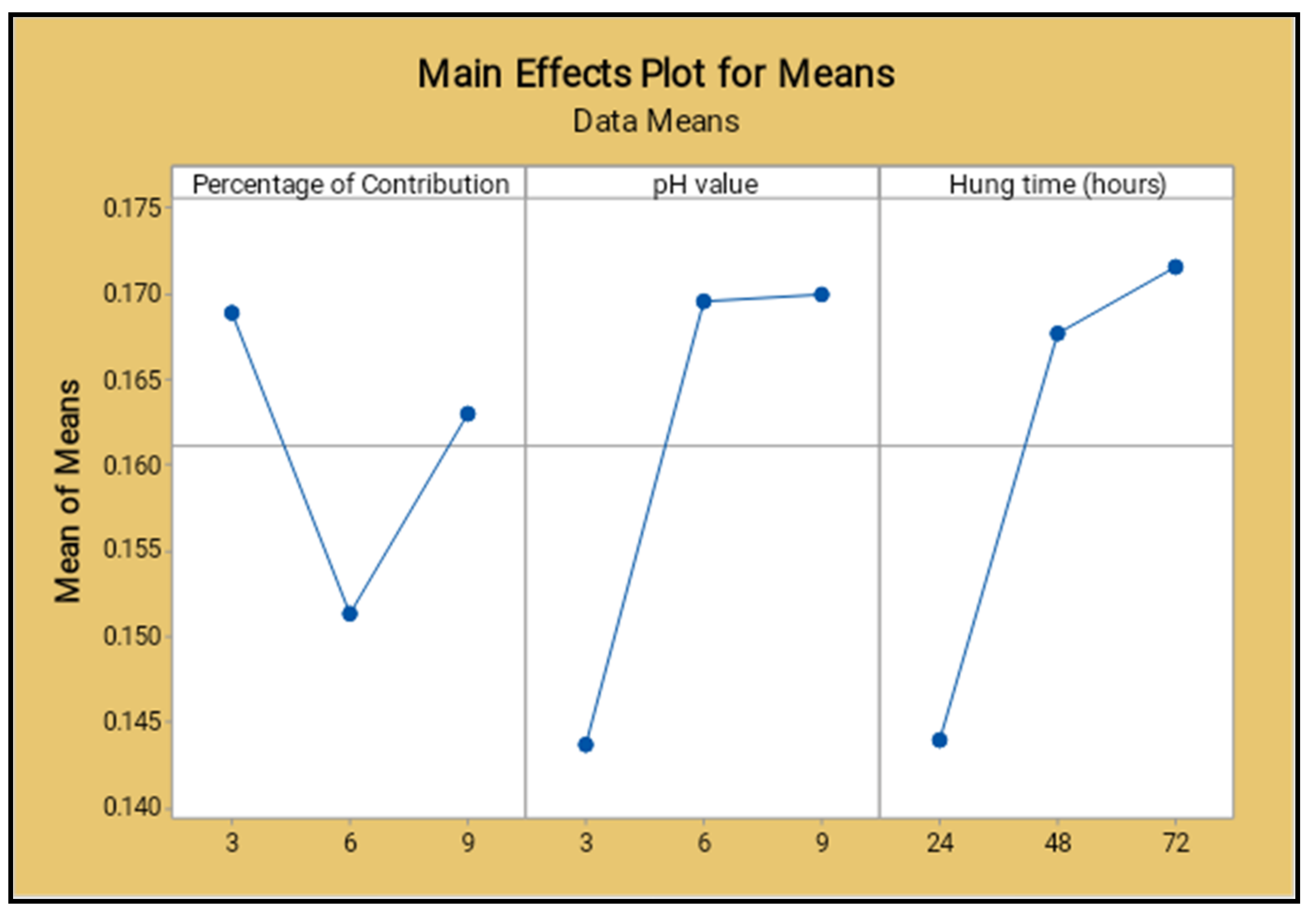

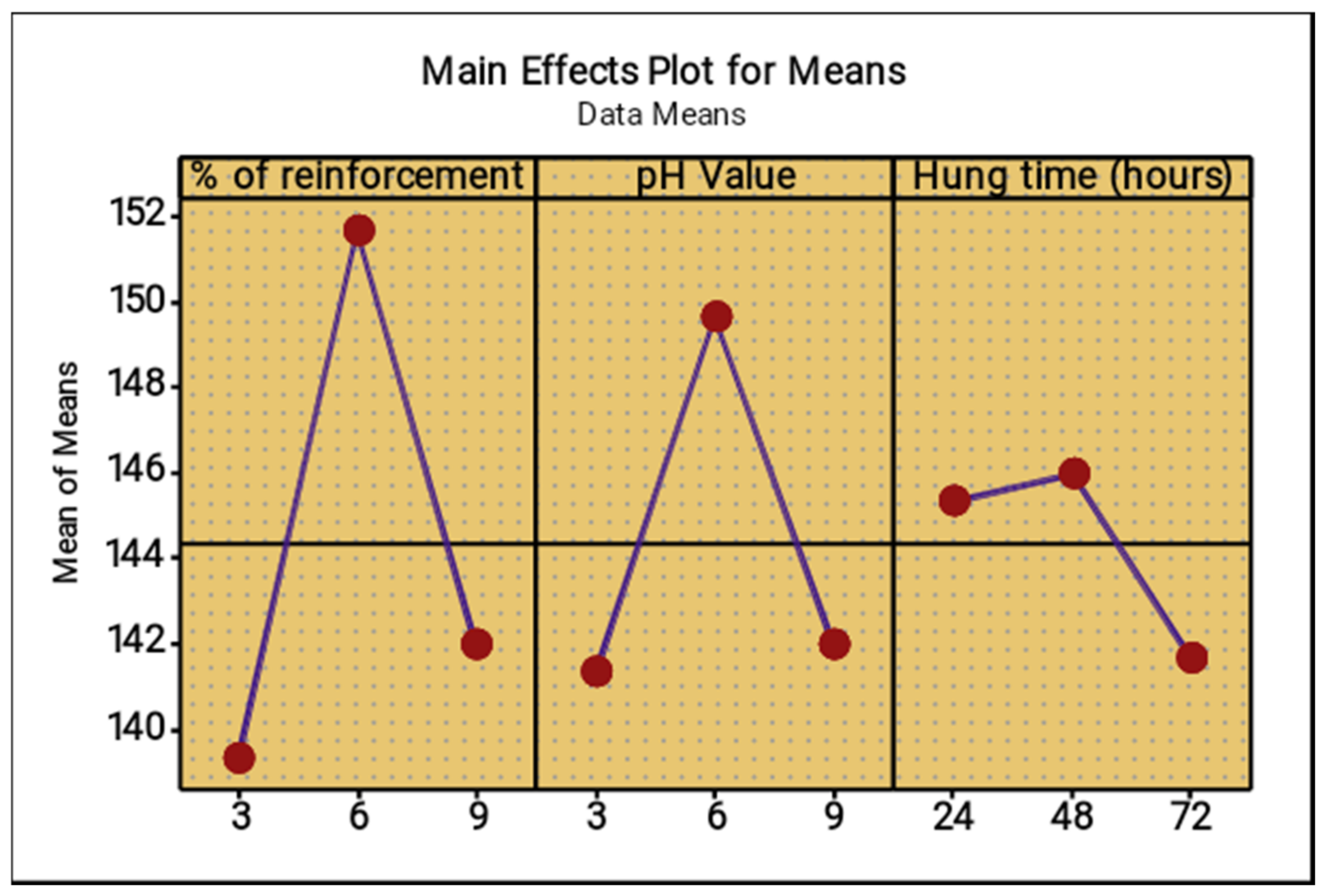

Figure 22.

Main effect plot for means (salt spray test).

Figure 22.

Main effect plot for means (salt spray test).

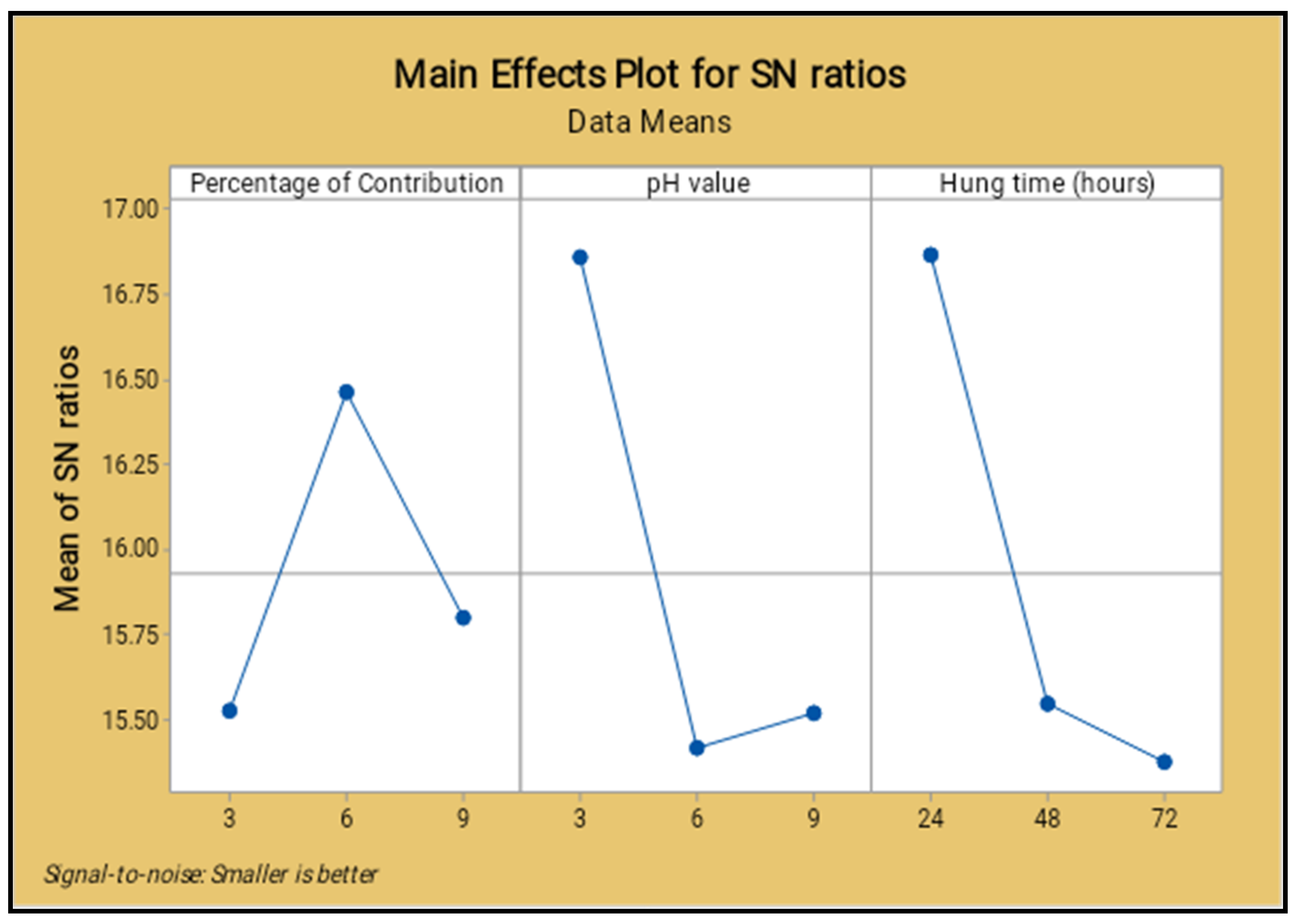

Figure 23.

Main effect plot for signal to noise ratio (salt spray test).

Figure 23.

Main effect plot for signal to noise ratio (salt spray test).

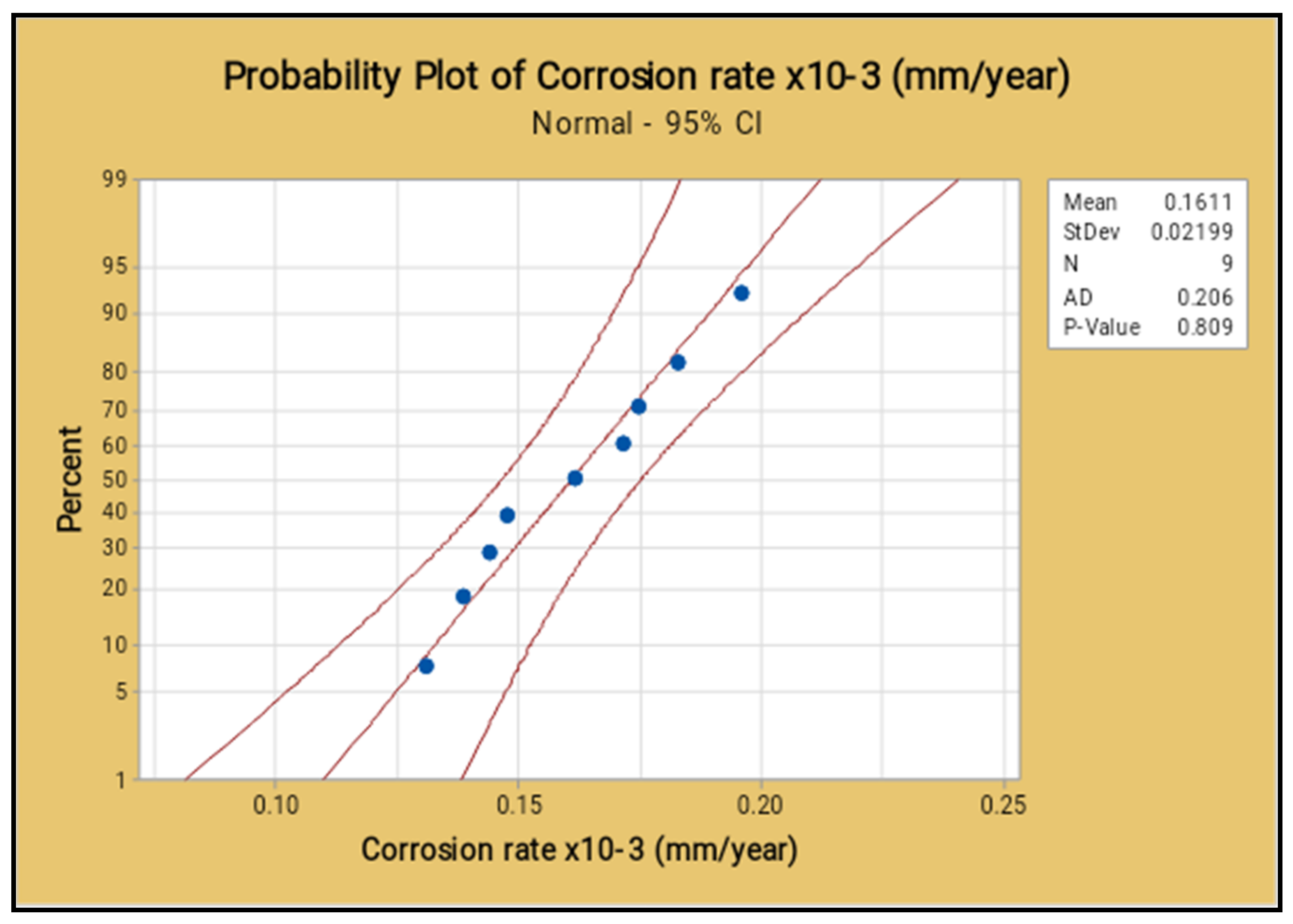

Figure 24.

Probability plot for corrosion rate.

Figure 24.

Probability plot for corrosion rate.

Figure 25.

Surface plot of corrosion rate vs. percentage of reinforcement and pH value.

Figure 25.

Surface plot of corrosion rate vs. percentage of reinforcement and pH value.

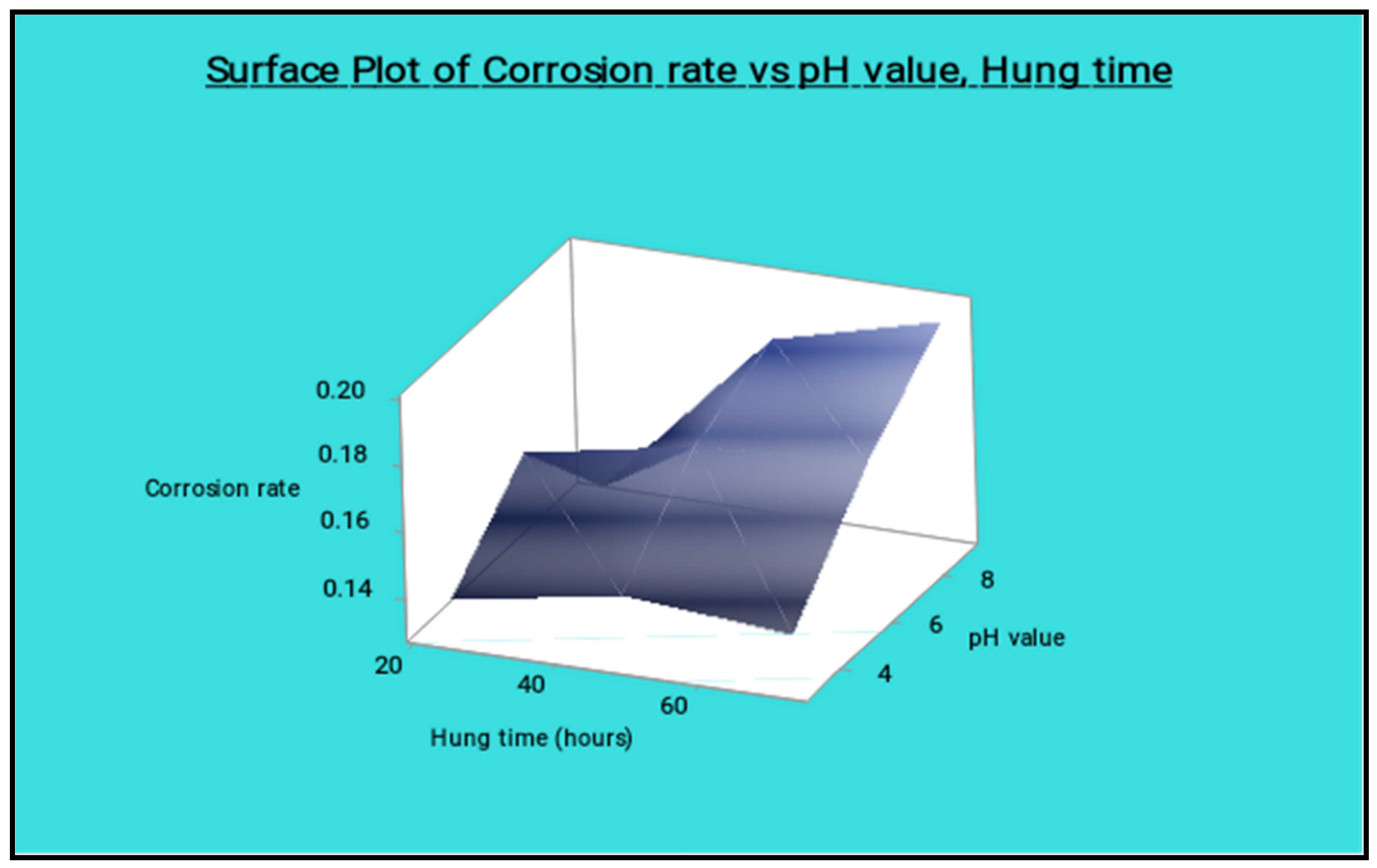

Figure 26.

Surface plot of corrosion rate vs. pH value and hang time.

Figure 26.

Surface plot of corrosion rate vs. pH value and hang time.

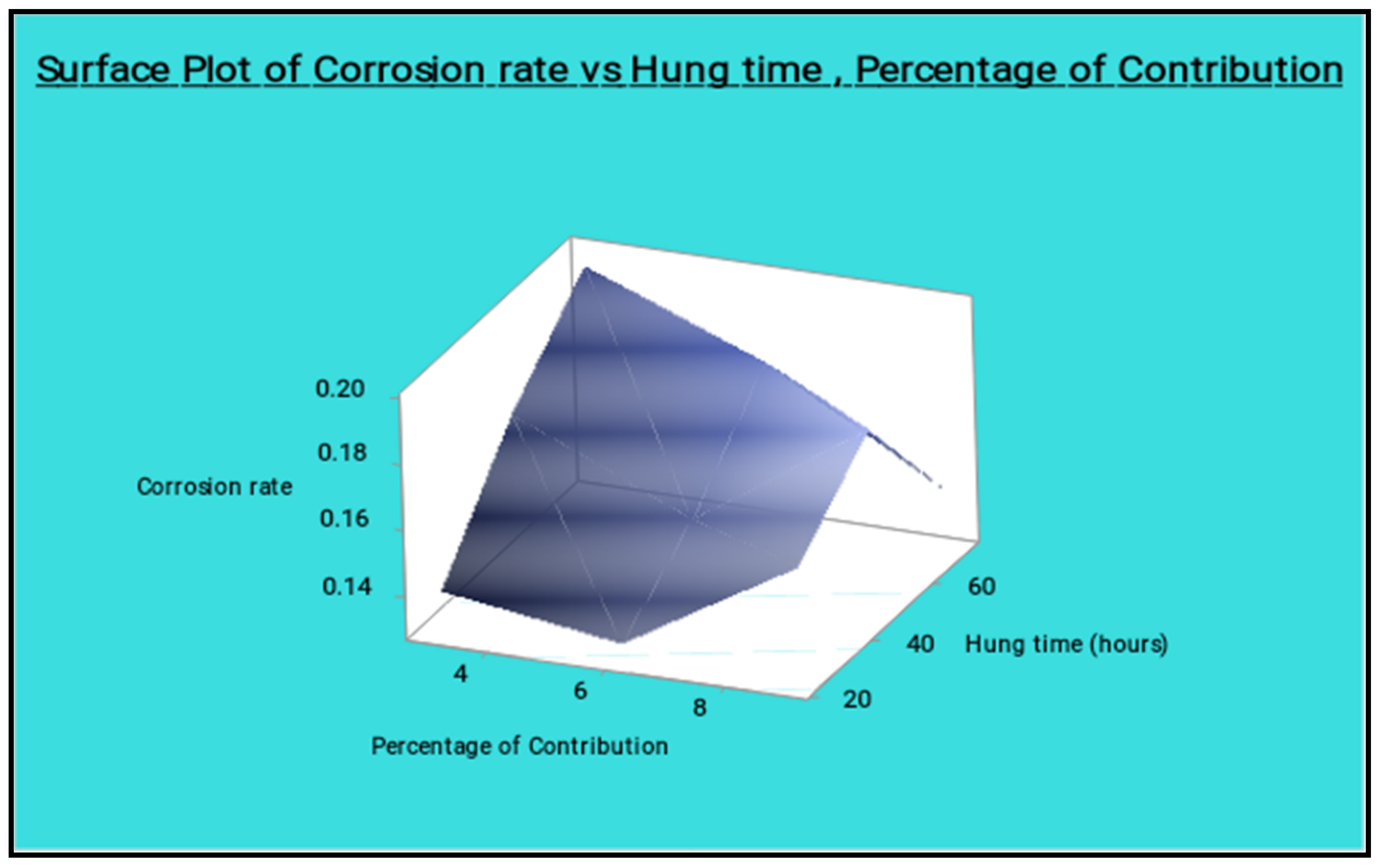

Figure 27.

Surface plot of corrosion rate vs. hang time, percentage of reinforcement.

Figure 27.

Surface plot of corrosion rate vs. hang time, percentage of reinforcement.

Figure 28.

Corrosion test specimen (minimum corrosion).

Figure 28.

Corrosion test specimen (minimum corrosion).

Figure 29.

Corrosion test specimen (moderate corrosion).

Figure 29.

Corrosion test specimen (moderate corrosion).

Figure 30.

Corrosion test specimen (aximum corrosion).

Figure 30.

Corrosion test specimen (aximum corrosion).

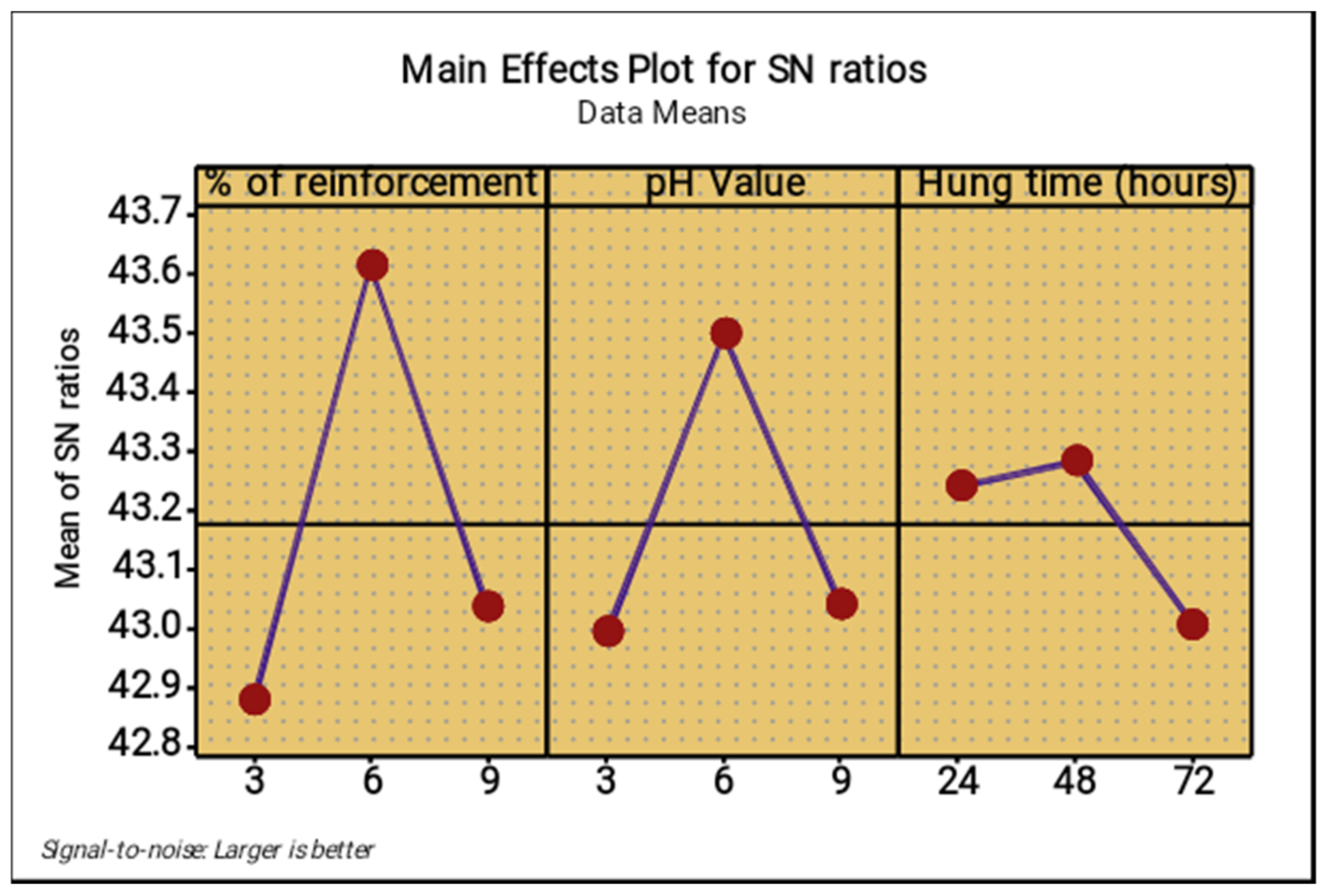

Figure 31.

Main effect plot for means (microhardness).

Figure 31.

Main effect plot for means (microhardness).

Figure 32.

Main effect plot for S/N ratios (microhardness).

Figure 32.

Main effect plot for S/N ratios (microhardness).

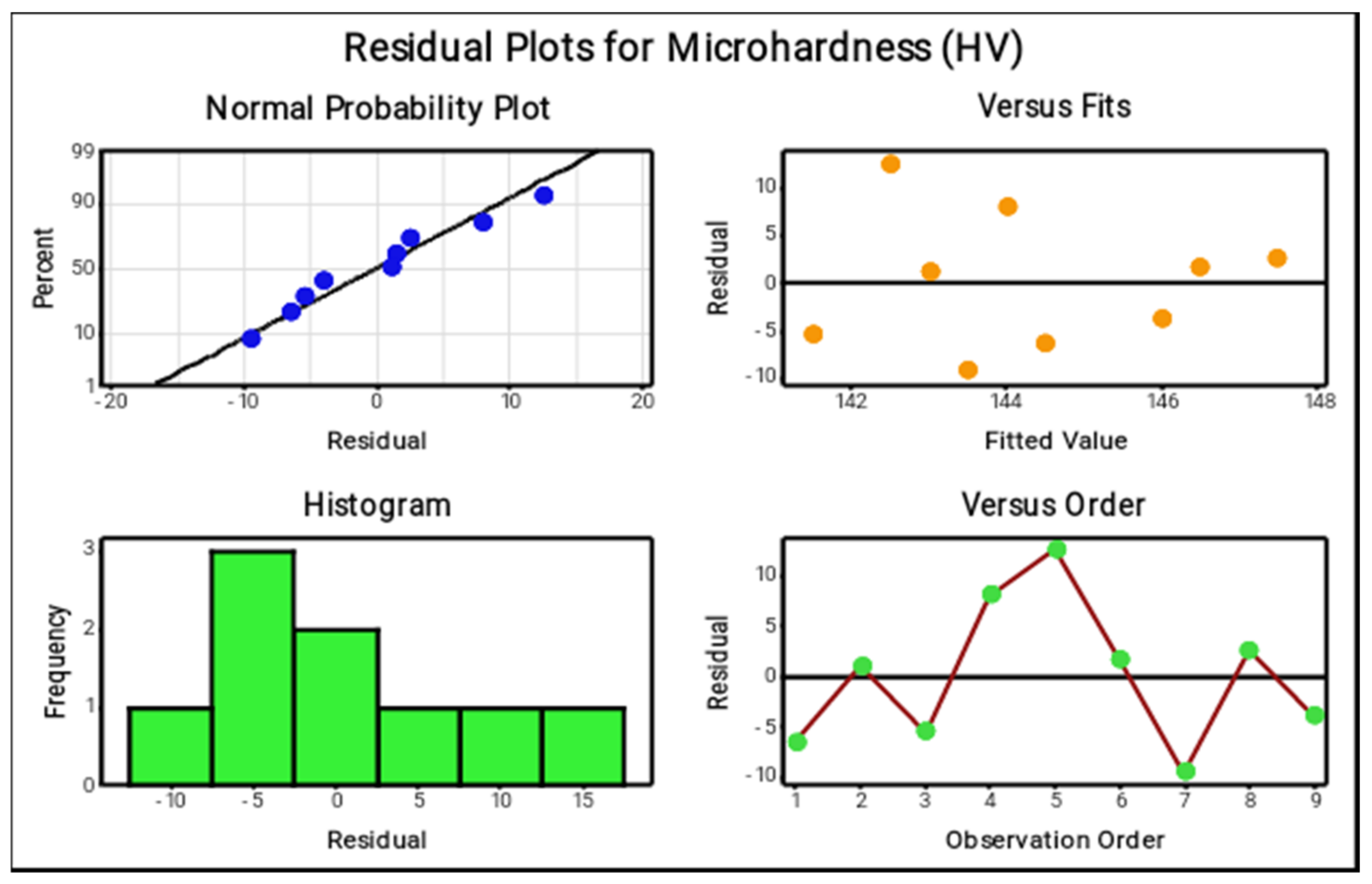

Figure 33.

Residual plots for microhardness.

Figure 33.

Residual plots for microhardness.

Figure 34.

SEM image of worn out wear specimen.

Figure 34.

SEM image of worn out wear specimen.

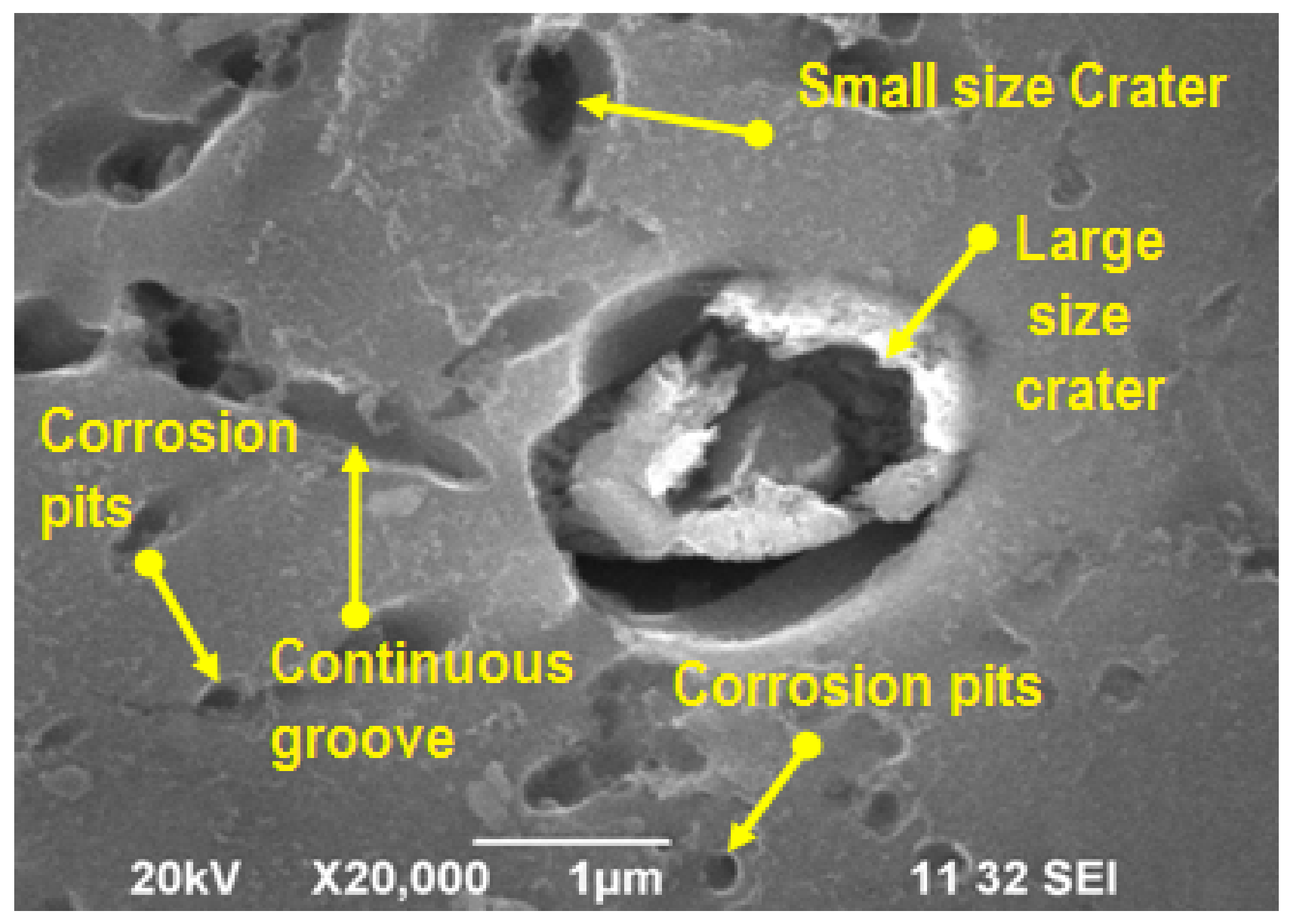

Figure 35.

SEM image of corrosion specimen.

Figure 35.

SEM image of corrosion specimen.

Table 1.

Chemical constituent of AA 8079.

Table 1.

Chemical constituent of AA 8079.

| Material | Composition in % |

|---|

| Copper | 0.05 |

| Iron | 1.3 |

| Zinc | 0.10 |

| Silicon | 0.30 |

| Other | 0.15 |

| Aluminum (Al) | Remaining |

Table 2.

Mechanical strength of AA 8079.

Table 2.

Mechanical strength of AA 8079.

| Properties | Metric |

|---|

| Tensile strength | 150 MPa |

| Yield strength | 120 MPa |

| Fatigue strength | 56 MPa |

| Elongation | 2.2% |

Table 3.

Process parameters and their levels of stir casting process.

Table 3.

Process parameters and their levels of stir casting process.

| S. No | Parameters | Level 1 | Level 2 | Level 3 |

|---|

| 1. | % of reinforcement | 3 | 6 | 9 |

| 2. | Stirring time | 20 | 25 | 30 |

| 3. | Stirring speed | 500 | 550 | 600 |

Table 4.

Equipment used for testing and specifications.

Table 4.

Equipment used for testing and specifications.

| Equipment Used | Specification |

|---|

| Stir casting apparatus | Bottom pouring type

Maximum operating temperature 1000 °C

Stirring speed:100 to 1500 rpm |

| Universal Testing Machine (UTM) | ZY 2075—A series, 100 kN capacity |

| Dry sliding wear test machine | DUCOM Model TR-20-M-106,

Disc material: EN-8 medium carbon steel |

| Salt spray testing machine | Brand: Weiss, Material: Stainless Steel, Frequency level: 70 Hz, Voltage: 230 V

Power: Electric, Size: 500 × 300 × 500 |

| Vickers microhardness tester | Model: V-5 series, Range: 1 HV-2967 HV, Eyepiece: 10×,

Dimension: 500 × 250 × 650 mm |

Table 5.

Process variables and their levels (corrosion test).

Table 5.

Process variables and their levels (corrosion test).

| S. No | Parameters | Level 1 | Level 2 | Level 3 |

|---|

| 1. | Percentage of reinforcement | 3 | 6 | 9 |

| 2. | pH value | 3 | 6 | 9 |

| 3. | Hang time (hours) | 24 | 48 | 72 |

Table 6.

Experimental summary of ultimate tensile strength.

Table 6.

Experimental summary of ultimate tensile strength.

| S. No | % of Reinforcement | Stirring Time | Stirring Speed (rpm) | Ultimate Tensile Strength (MPa) | S/N Ratio |

|---|

| 1 | 3 | 20 | 500 | 185.67 | 45.3748 |

| 2 | 3 | 25 | 550 | 202.42 | 46.1251 |

| 3 | 3 | 30 | 600 | 198.47 | 45.9539 |

| 4 | 6 | 20 | 550 | 175.39 | 44.8801 |

| 5 | 6 | 25 | 600 | 188.96 | 45.5274 |

| 6 | 6 | 30 | 500 | 205.52 | 46.2571 |

| 7 | 9 | 20 | 600 | 202.31 | 46.1203 |

| 8 | 9 | 25 | 500 | 187.34 | 45.1203 |

| 9 | 9 | 30 | 550 | 193.41 | 45.4526 |

Table 7.

Response table for means (ultimate tensile strength).

Table 7.

Response table for means (ultimate tensile strength).

| Level | % of Reinforcement | Stirring Time | Stirring Speed (rpm) |

|---|

| 1 | 195.5 | 187.8 | 192.8 |

| 2 | 190.0 | 192.9 | 190.4 |

| 3 | 194.4 | 199.1 | 196.6 |

| Delta | 5.6 | 11.3 | 6.2 |

| Rank | 3 | 1 | 2 |

Table 8.

Response table for signal to noise ratios (ultimate tensile strength).

Table 8.

Response table for signal to noise ratios (ultimate tensile strength).

| Level | % of Reinforcement | Stirring Time | Stirring Speed (rpm) |

|---|

| 1 | 45.82 | 45.46 | 45.69 |

| 2 | 45.55 | 45.70 | 45.58 |

| 3 | 45.77 | 45.98 | 45.87 |

| Delta | 0.26 | 0.52 | 0.29 |

| Rank | 3 | 1 | 2 |

Table 9.

Analysis of variance for ultimate tensile strength.

Table 9.

Analysis of variance for ultimate tensile strength.

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|

| Regression | 3 | 215.993 | 27.91% | 215.993 | 71.998 | 0.65 | 0.619 |

| % of reinforcement | 1 | 2.042 | 0.26% | 2.042 | 2.042 | 0.02 | 0.898 |

| Stirring time | 1 | 193.007 | 24.94% | 193.007 | 193.007 | 1.73 | 0.245 |

| Stirring speed (rpm) | 1 | 20.944 | 2.71% | 20.944 | 20.944 | 0.19 | 0.683 |

| Total | 8 | 773.761 | 100.00% | | | | |

Table 10.

Experimental summary of the wear test.

Table 10.

Experimental summary of the wear test.

| S. No | % of Reinforcement | Stirring Time | Stirring Speed (rpm) | Wear (µm) | S/N Ratio |

|---|

| 1 | 3 | 20 | 500 | 130.34 | −42.3016 |

| 2 | 3 | 25 | 550 | 141.76 | −43.0311 |

| 3 | 3 | 30 | 600 | 129.67 | −42.2568 |

| 4 | 6 | 20 | 550 | 124.68 | −41.9159 |

| 5 | 6 | 25 | 600 | 119.53 | −41.5495 |

| 6 | 6 | 30 | 500 | 139.93 | −42.9182 |

| 7 | 9 | 20 | 600 | 135.61 | −42.6458 |

| 8 | 9 | 25 | 500 | 147.26 | −43.3617 |

| 9 | 9 | 30 | 550 | 137.19 | −42.7464 |

Table 11.

Response table for means (wear).

Table 11.

Response table for means (wear).

| Level | % of Reinforcement | Stirring Time | Stirring Speed (rpm) |

|---|

| 1 | 133.9 | 130.2 | 139.2 |

| 2 | 128.0 | 136.2 | 134.5 |

| 3 | 140.0 | 135.6 | 128.3 |

| Delta | 12.0 | 6.0 | 10.9 |

| Rank | 1 | 3 | 2 |

Table 12.

Response table for signal to noise ratios (wear). Smaller is better.

Table 12.

Response table for signal to noise ratios (wear). Smaller is better.

| Level | % of Reinforcement | Stirring Time | Stirring Speed (rpm) |

|---|

| 1 | −42.53 | −42.29 | −42.86 |

| 2 | −42.13 | −42.65 | −42.56 |

| 3 | −42.92 | −42.64 | −42.15 |

| Delta | 0.79 | 0.36 | 0.71 |

| Rank | 1 | 3 | 2 |

Table 13.

Analysis of variance for wear test.

Table 13.

Analysis of variance for wear test.

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|

| Regression | 3 | 277.71 | 45.35% | 277.71 | 92.57 | 1.38 | 0.350 |

| % of reinforcement | 1 | 55.75 | 9.10% | 55.75 | 55.75 | 0.83 | 0.403 |

| Stirring time | 1 | 43.52 | 7.11% | 43.52 | 43.52 | 0.65 | 0.457 |

| Stirring speed (rpm) | 1 | 178.43 | 29.14% | 178.43 | 178.43 | 2.67 | 0.163 |

| Total | 8 | 612.37 | 100.00% | | | | |

Table 14.

Summary of corrosion test.

Table 14.

Summary of corrosion test.

| S. No | Percentage of Reinforcement | pH Value | Hang Time (Hours) | Corrosion Rate × 10−3 (mm/Year) | S/N Ratio |

|---|

| 1 | 3 | 3 | 24 | 0.139 | 17.1397 |

| 2 | 3 | 6 | 48 | 0.172 | 15.2894 |

| 3 | 3 | 9 | 72 | 0.196 | 14.1549 |

| 4 | 6 | 3 | 48 | 0.148 | 16.5948 |

| 5 | 6 | 6 | 72 | 0.175 | 15.1392 |

| 6 | 6 | 9 | 24 | 0.131 | 17.6546 |

| 7 | 9 | 3 | 72 | 0.144 | 16.8328 |

| 8 | 9 | 6 | 24 | 0.162 | 15.8097 |

| 9 | 9 | 9 | 48 | 0.183 | 14.7510 |

Table 15.

Response table for means (corrosion test).

Table 15.

Response table for means (corrosion test).

| Level | Percentage of Reinforcement | pH Value | Hang Time (Hours) |

|---|

| 1 | 0.1690 | 0.1437 | 0.1440 |

| 2 | 0.1513 | 0.1697 | 0.1677 |

| 3 | 0.1630 | 0.1700 | 0.1717 |

| Delta | 0.0177 | 0.0263 | 0.0277 |

| Rank | 3 | 2 | 1 |

Table 16.

Response table for signal to noise ratios (smaller is better).

Table 16.

Response table for signal to noise ratios (smaller is better).

| Level | Percentage of Reinforcement | pH Value | Hang Time (Hours) |

|---|

| 1 | 15.53 | 16.86 | 16.87 |

| 2 | 16.46 | 15.41 | 15.55 |

| 3 | 15.80 | 15.52 | 15.38 |

| Delta | 0.93 | 1.44 | 1.49 |

| Rank | 3 | 2 | 1 |

Table 17.

Outline of ANOVA analysis (corrosion test).

Table 17.

Outline of ANOVA analysis (corrosion test).

| Source | DOF | Seq SS | Contribution % | Adj SS | Adj MS | F-Value | p-Value |

|---|

| Percentage of reinforcement | 1 | 0.000520 | 12.36 | 0.000520 | 0.000520 | 1.60 | 0.067 |

| pH value | 1 | 0.001148 | 29.68 | 0.001148 | 0.001148 | 2.30 | 0.119 |

| Hang time (hours) | 1 | 0.002242 | 57.96 | 0.002242 | 0.000747 | 3.53 | 0.195 |

| Total | 8 | 0.000007 | 100.00 | | | | |

Table 18.

Experimental summary of microhardness test.

Table 18.

Experimental summary of microhardness test.

| Exp. Runs | % of Reinforcement | pH Value | Hang Time (Hours) | Microhardness (HV) | S/N Ratio |

|---|

| 1 | 3 | 3 | 24 | 138 | 42.7976 |

| 2 | 3 | 6 | 48 | 144 | 43.1672 |

| 3 | 3 | 9 | 72 | 136 | 42.6708 |

| 4 | 6 | 3 | 48 | 152 | 43.6369 |

| 5 | 6 | 6 | 72 | 155 | 43.8066 |

| 6 | 6 | 9 | 24 | 148 | 43.4052 |

| 7 | 9 | 3 | 72 | 134 | 42.5421 |

| 8 | 9 | 6 | 24 | 150 | 43.5218 |

| 9 | 9 | 9 | 48 | 142 | 43.0458 |

Table 19.

Response table for means (microhardness test).

Table 19.

Response table for means (microhardness test).

| Level | % of Reinforcement | pH Value | Hang Time (Hours) |

|---|

| 1 | 139.3 | 141.3 | 145.3 |

| 2 | 151.7 | 149.7 | 146.0 |

| 3 | 142.0 | 142.0 | 141.7 |

| Delta | 12.3 | 8.3 | 4.3 |

| Rank | 1 | 2 | 3 |

Table 20.

Response table for signal to noise ratios (microhardness test). Larger is better.

Table 20.

Response table for signal to noise ratios (microhardness test). Larger is better.

| Level | % of Reinforcement | pH Value | Hang Time (Hours) |

|---|

| 1 | 42.88 | 42.99 | 43.24 |

| 2 | 43.62 | 43.50 | 43.28 |

| 3 | 43.04 | 43.04 | 43.01 |

| Delta | 0.74 | 0.51 | 0.28 |

| Rank | 1 | 2 | 3 |

Table 21.

Analysis of variance for microhardness.

Table 21.

Analysis of variance for microhardness.

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|

| Regression | 3 | 31.500 | 7.16% | 31.500 | 10.5000 | 0.13 | 0.939 |

| % of reinforcement | 1 | 10.667 | 2.42% | 10.667 | 10.6667 | 0.13 | 0.733 |

| pH Value | 1 | 0.667 | 0.15% | 0.667 | 0.6667 | 0.01 | 0.932 |

| Hang time (hours) | 1 | 20.167 | 4.58% | 20.167 | 20.1667 | 0.25 | 0.640 |

| Total | 8 | 440.000 | 100.00% | | | | |