Analysis of Magnetic Nondestructive Measurement Methods for Determination of the Degradation of Reactor Pressure Vessel Steel

Abstract

:1. Introduction

2. Materials and Methods

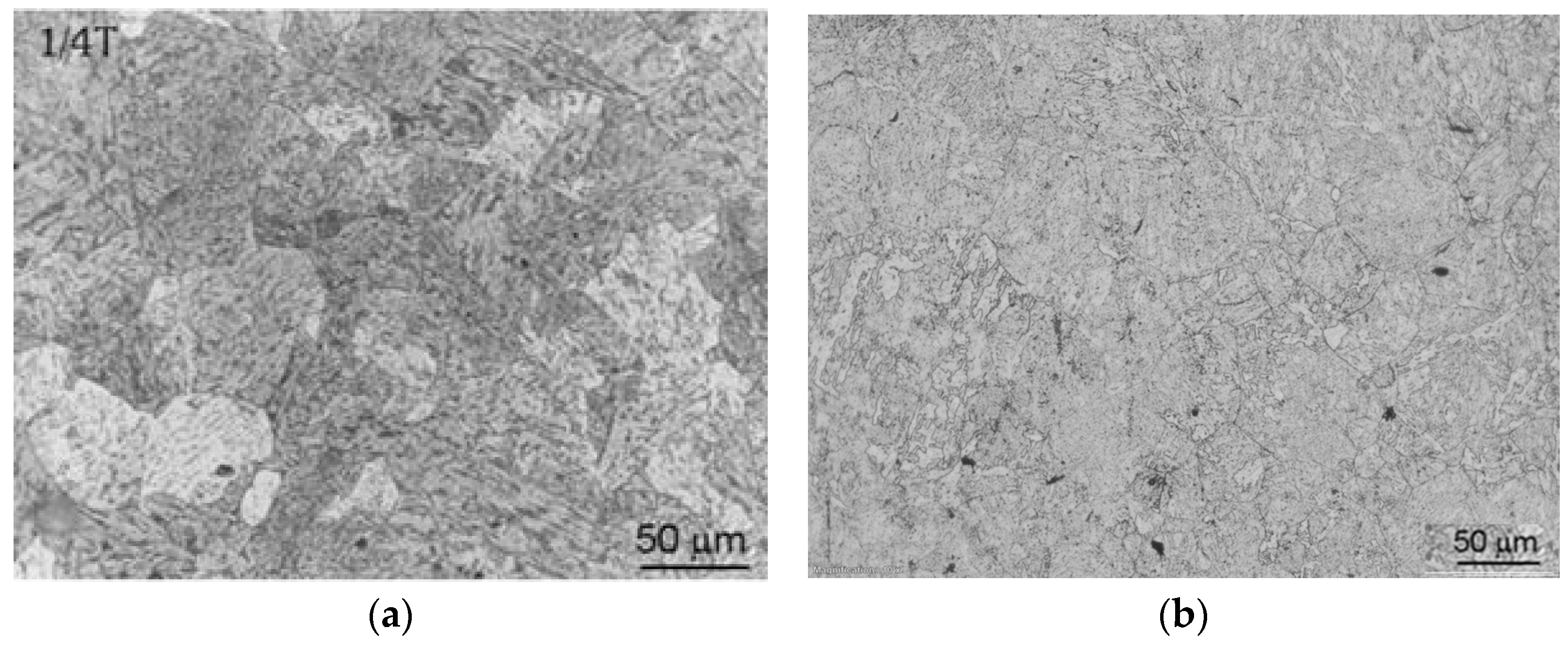

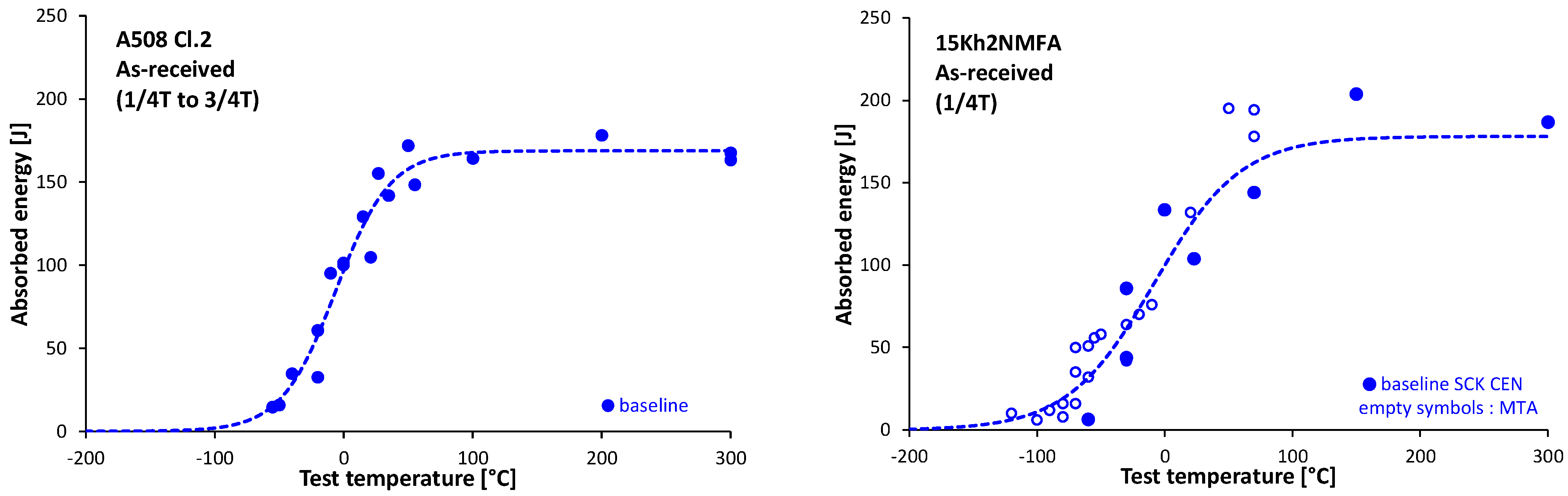

2.1. Materials and Mechanical Tests

2.2. Magnetic Adaptive Testing

2.3. Micromagnetic Multiparameter Microstructure and Stress Analysis

- Eddy currents (EC) are generated in the material under the influence of AC magnetic field. They depend on the σ electrical conductivity and on the µ magnetic permeability of the material, and they result a magnetic field with opposite direction to the originally applied magnetic field. It means, that σ and µ of the material has an influence on the excitation coil’s impedance. This impedance is measured.

- Analysis of incremental permeability (IP) is a method of separating the magnetic permeability information from the electrical conductivity information. For application of this method, the material should be magnetized with a low-frequency AC magnetic field and a continuous EC impedance analysis should be performed at a higher frequency. Considering the change of the coil impedance as a function of the magnetic field strength leads to an incremental permeability plot. In such a way, a qualitative correlation of the impedance change throughout the magnetic hysteresis and the magnetic field strength at maximum permeability (usually correlated with coercivity measured by means of magnetic hysteresis analysis) is obtained.

- Harmonics analysis (in time domain signal) of magnetizing current is used to describe the magnetic hysteresis behavior of the materials by applying one-sided access sensor. For this purpose, a magnetization electromagnet should be applied, which is driven by a sinusoidal voltage. A receiver coil measures the magnetizing current.

2.4. Barkhausen Noise Measurement

3. Results

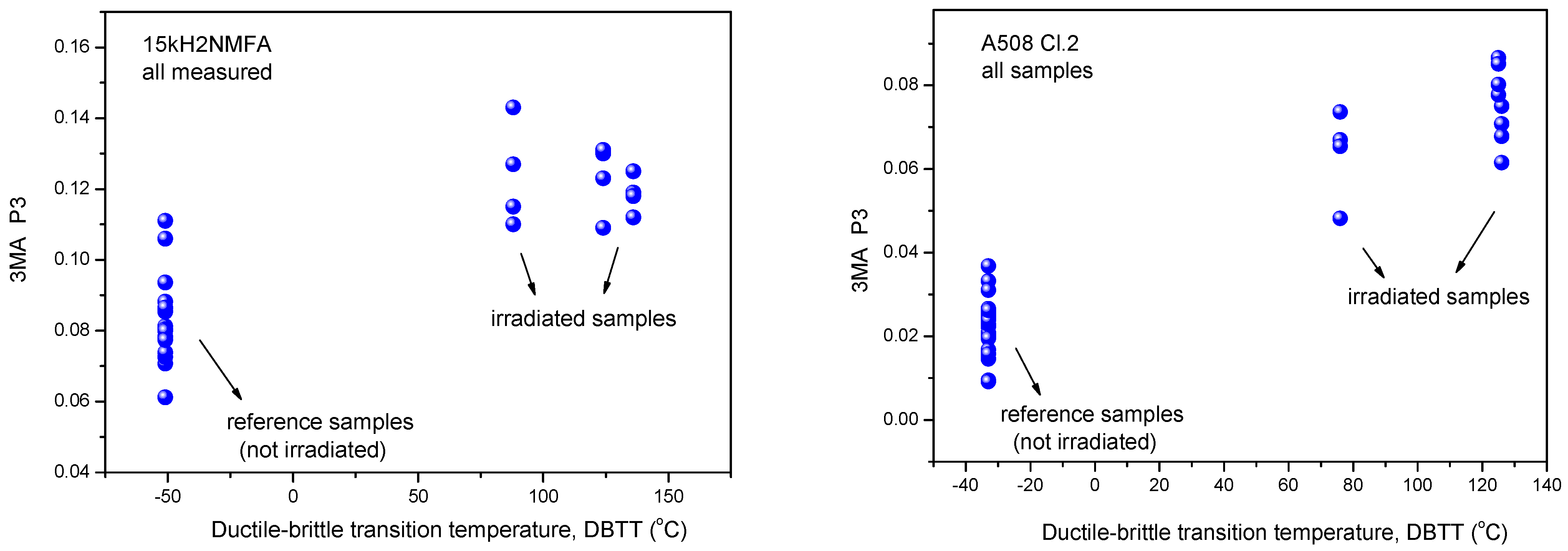

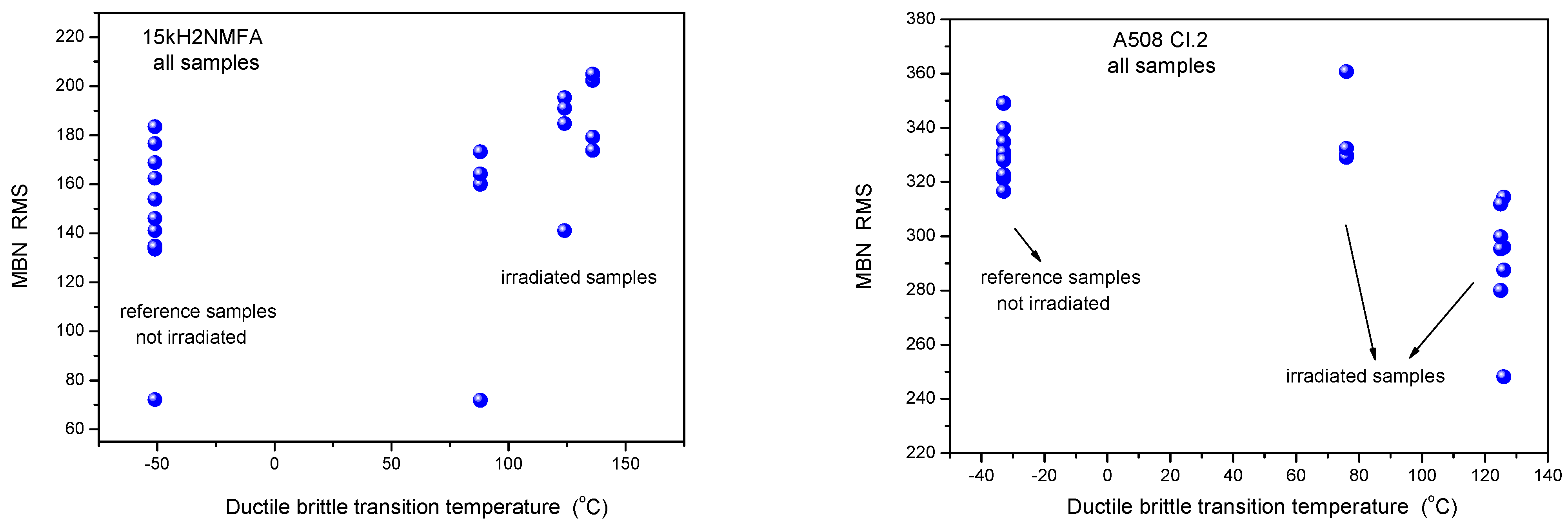

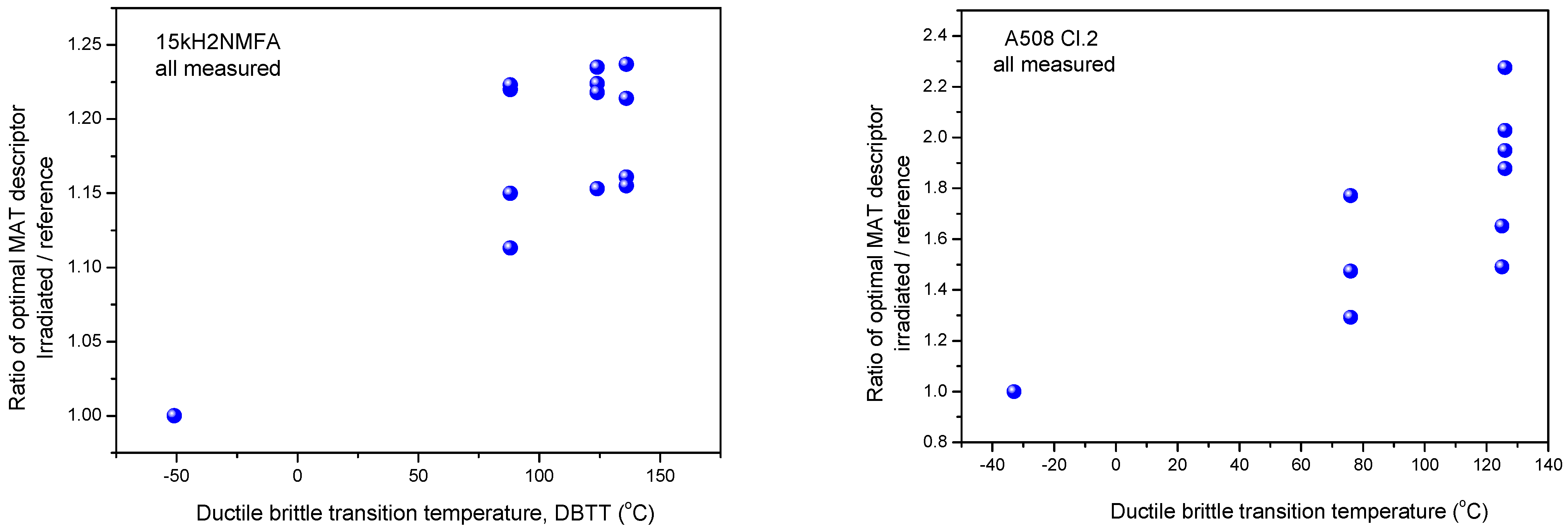

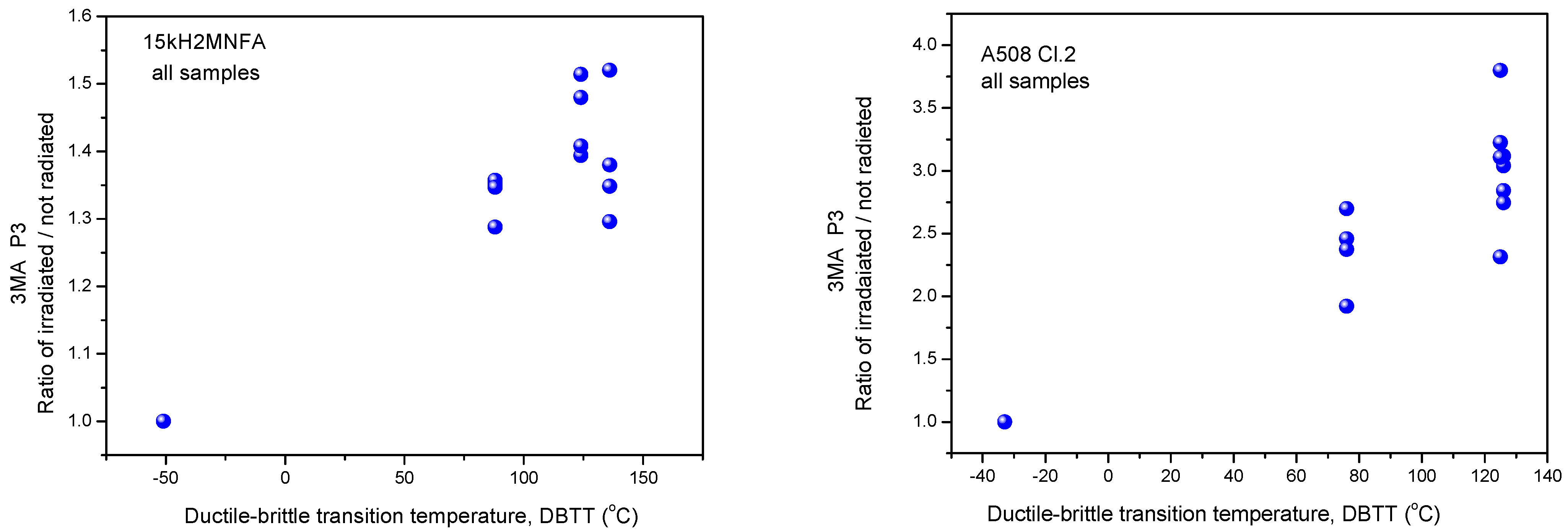

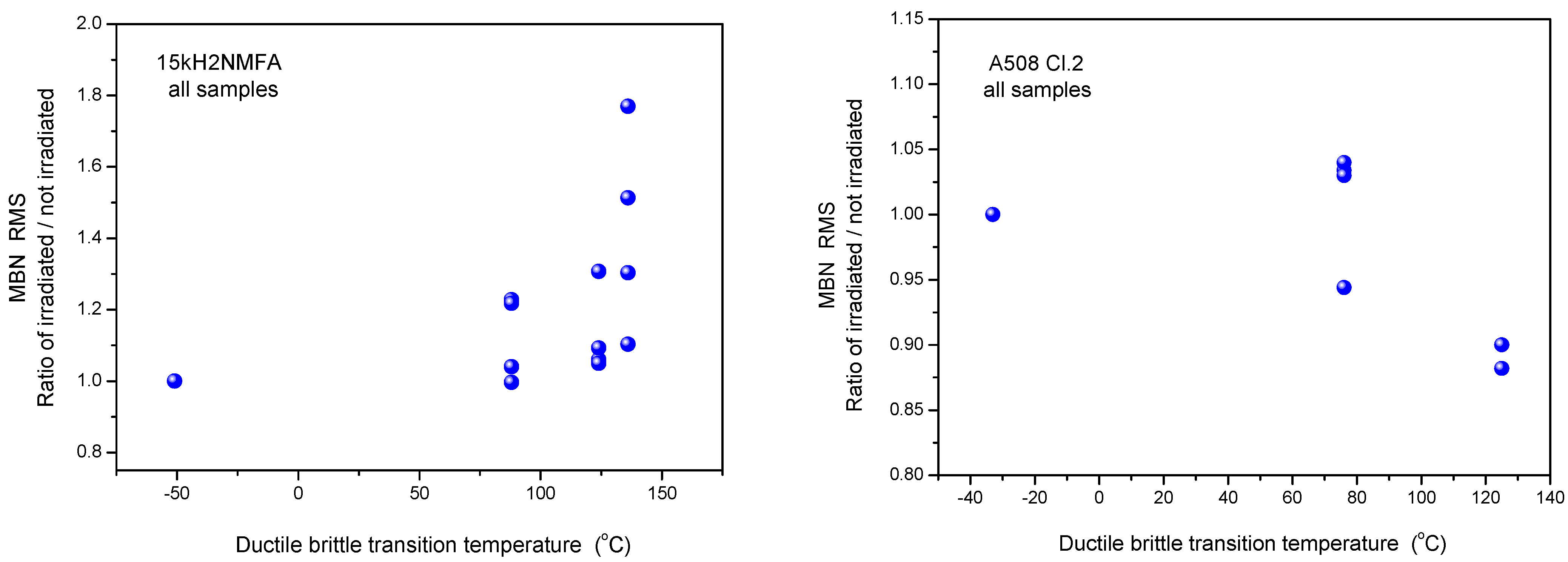

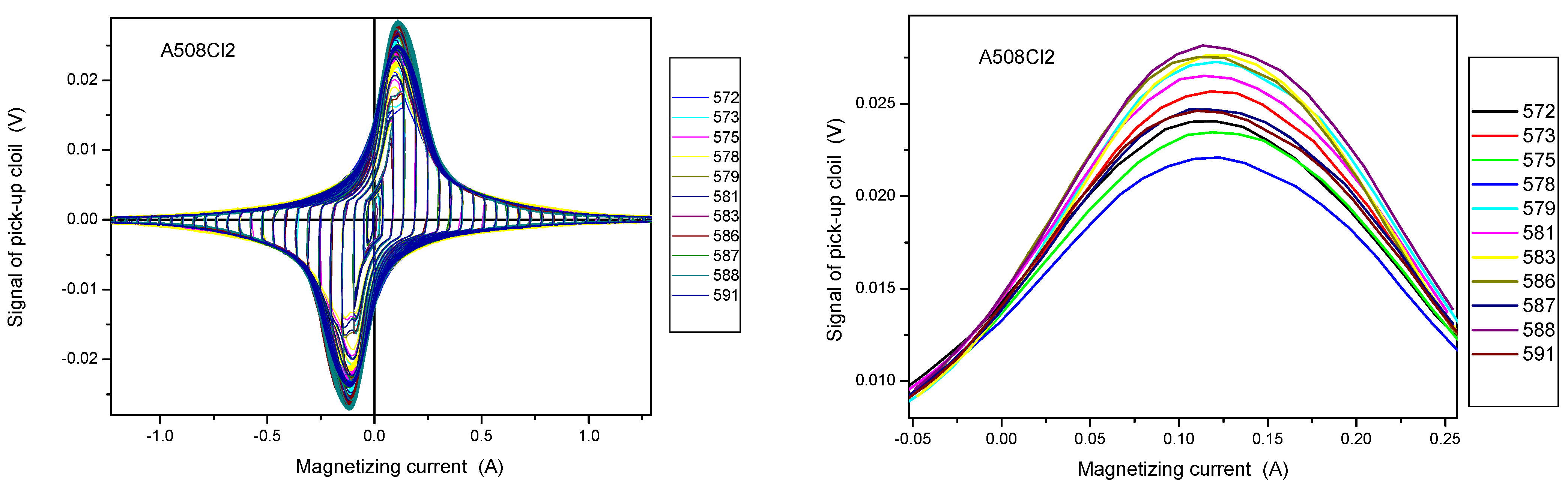

3.1. Results of MAT, 3MA and MBN Measurements Made on All Samples

3.1.1. Evaluation of Data without Normalization

3.1.2. Evaluation of Normalized Data

3.2. Selection of Samples

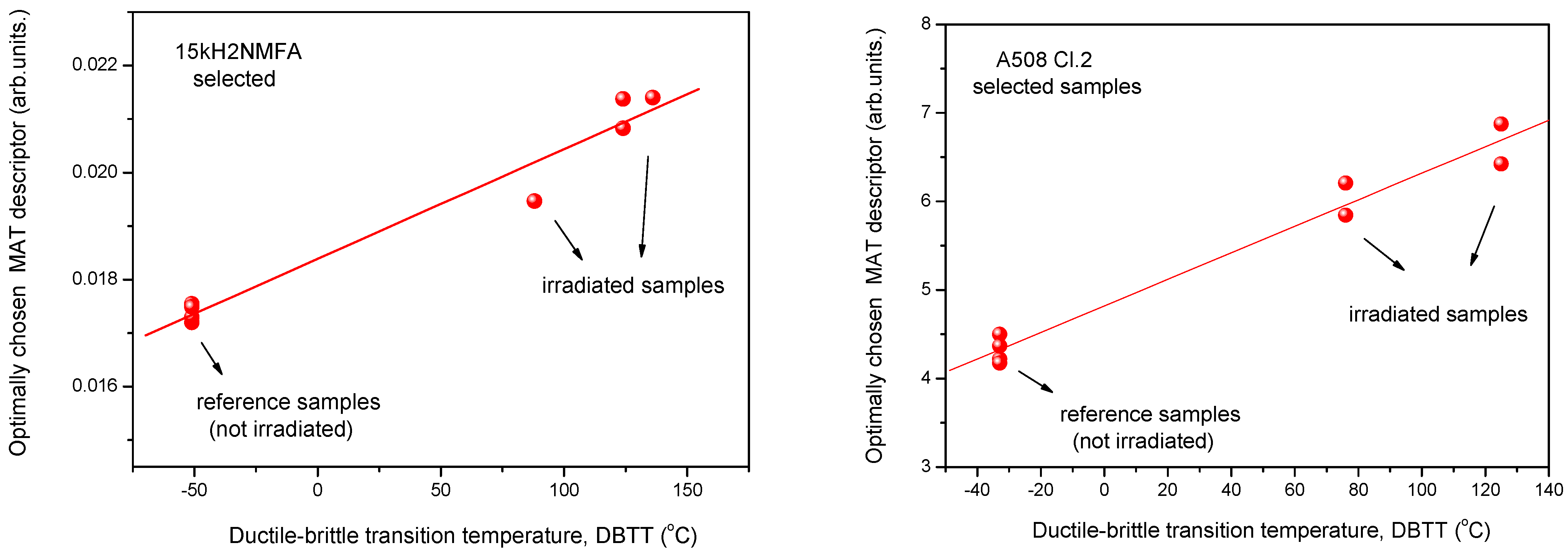

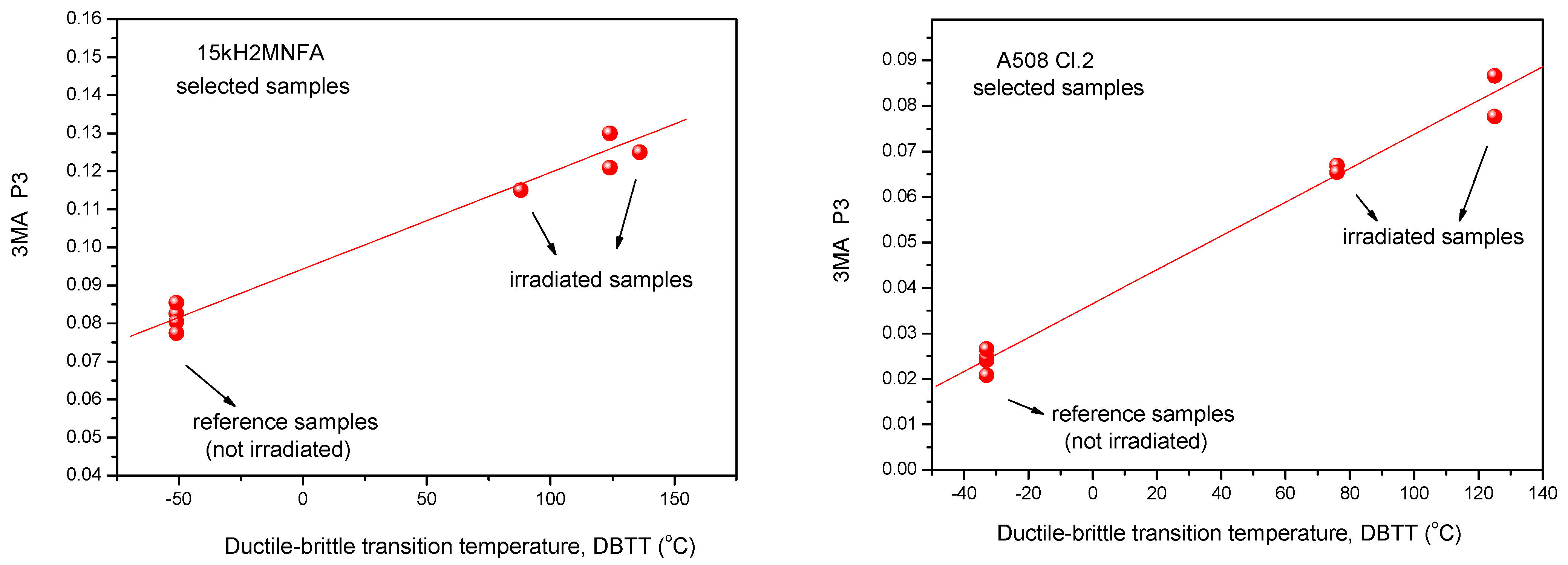

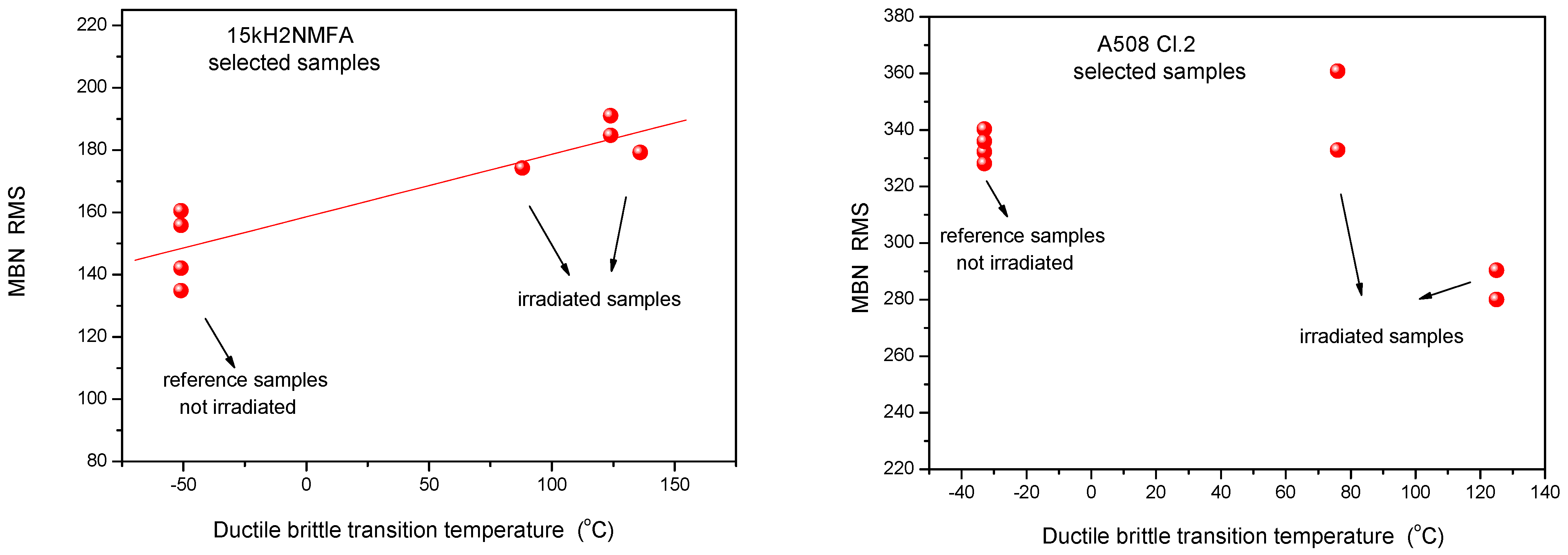

3.3. Results of 3MA, MAT and MBN Measurements Considering Selected Samples Only

4. Discussion

5. Conclusions

- Verification of MAT measurements;

- Proving that the former MAT result is not methodology dependent;

- Proving that the former MAT result is not material dependent.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koutsky, J.; Kocık, J. Radiation Damage of Structural Materials; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Ferreño, D.; Gorrochategui, I.; Gutiérrez-Solana, F. Degradation due to neutron embrittlement of nuclear vessel steels: A critical review about the current experimental and analytical techniques to characterise the material, with particular emphasis on alternative methodologies. In Nuclear Power—Control, Reliability and Human Factors; Tsvetkov, P., Ed.; IntechOpen Limited: London, UK, 2011; ISBN 9789533075990. Available online: http://www.intechopen.com/articles/show/title/non-destructive-testing-for-ageing-management-of-nuclear-power-components (accessed on 14 May 2020).

- Jiles, D.C. Magnetic methods in nondestructive testing. In Encyclopedia of Materials Science and Technology; Buschow, K.H.J., Ed.; Elsevier: Oxford, UK, 2001; p. 6021. [Google Scholar]

- Tomáš, I. Non-destructive Magnetic Adaptive Testing of ferromagnetic materials. J. Magn. Magn. Mater. 2004, 268, 178–185. [Google Scholar] [CrossRef]

- Tomáš, I.; Vértesy, G. Magnetic Adaptive Testing. In Nondestructive Testing Methods and New Applications; Omar, M., Ed.; IntechOpen: London, UK, 2021; ISBN 978-953-51-0108-6. Available online: http://www.intechopen.com/articles/show/title/magnetic-adaptive-testing (accessed on 8 November 2020).

- Barroso, S.P.; Horváth, M.; Horváth, Á. Magnetic measurements for evaluation of radiation damage on nuclear reactor materials. Nucl. Eng. Des. 2010, 240, 722–725. [Google Scholar] [CrossRef]

- Dobmann, G.; Altpeter, I.; Kopp, M.; Rabung, M.; Hubschen, G. ND-materials characterization of neutron induced embrittlement in German nuclear reactor pressure vessel material by micromagnetic NDT techniques. In Electromagnetic Nondestructive Evaluation (XI); IOS Press: Amsterdam, The Netherlands, 2008; p. 54. ISBN 978-1-58603-896-0. [Google Scholar]

- Vértesy, G.; Gasparics, A.; Uytdenhouwen, I.; Szenthe, I.; Gillemot, F.; Chaouadi, R. Nondestructive investigation of neutron irradiation generated structural changes of reactor steel material by magnetic hysteresis method. Metals 2020, 10, 642. [Google Scholar] [CrossRef]

- Tomáš, I.; Vértesy, G.; Gillemot, F.; Székely, R. Nondestructive Magnetic Adaptive Testing of Nuclear Reactor Pressure Vessel Steel Degradation. J. Nucl. Mater. 2013, 432, 371–377. [Google Scholar] [CrossRef]

- Rabung, M.; Kopp, M.; Gasparics, A.; Vértesy, G.; Szenthe, I.; Uytdenhouwen, I. Micromagnetic characterization of operation induced damage in Charpy specimens of RPV steels. Appl. Sci. 2021, 11, 2917. [Google Scholar] [CrossRef]

- Vértesy, G.; Gasparics, A.; Szenthe, I.; Uytdenhouwen, I. Interpretation of Nondestructive Magnetic Measurements on Irradiated Reactor Steel Material. Appl. Sci. 2021, 11, 3650. [Google Scholar] [CrossRef]

- Uytdenhouwen, I.; Chaouadi, R.; Other NOMAD Consortium Members. NOMAD: Non-destructive Evaluation (NDE) system for the inspection of operation-induced material degradation in nuclear power plants—Overview of the neutron irradiation campaigns. In ASME 2020 Pressure Vessels and Piping Conference; Non-Destructive Examination, V007T07A003, PVP2020-21512; ASME: New York, NY, USA, 2020; Volume 7. [Google Scholar] [CrossRef]

- Uytdenhouwen, I.; Chaouadi, R. Effect of neutron irradiation on the mechanical properties of an A508 Cl.2 forging irradiated in a BAMI capsule. In Pressure Vessels and Piping Conference; Codes and Standards, V001T01A060, PVP2020-21513; ASME: New York, NY, USA, 2020; Volume 1. [Google Scholar] [CrossRef]

- Available online: https://www.spectro.com/ (accessed on 26 August 2021).

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials, 2nd ed.; Wiley & Sons: New York, NY, USA, 2009; ISBN 978-0-471-47741-9. [Google Scholar]

- Bozorth, R.M. Ferromagnetism; IEEE Press: New York, NY, USA, 1993. [Google Scholar]

- Altpeter, I.; Becker, R.; Dobmann, G.; Kern, R.; Theiner, W.A.; Yashan, A. Robust Solutions of Inverse Problems in Eletromagnetic Non-Destructive Evaluation. Inverse Probl. 2002, 18, 1907–1921. [Google Scholar] [CrossRef]

- Szielasko, K.; Tschuncky, R.; Rabung, M.; Seiler, G.; Altpeter, I.; Dobmann, G.; Herrmann, H.G.; Boller, C. Early Detection of Critical Material Degradation by Means of Electromagnetic Multi-Parametric NDE. AIP Conf. Proc. 2014, 711, 1581. [Google Scholar]

- Lo, C.C.H.; Jakubovics, J.P.; Scrub, C.B. Non-destructive evaluation of spheroidized steel using magnetoacoustic and Barkhausen emission. IEEE Trans. Magn. 1997, 33, 4035–4037. [Google Scholar] [CrossRef]

- Kikuchi, H.; Ara, K.; Kamada, Y.; Kobayashi, S. Effect of microstructure changes on Barkhausen noise properties and hysteresis loop in cold rolled low carbon steel. IEEE Trans. Magn. 2009, 45, 2744–2747. [Google Scholar] [CrossRef]

- Hartmannn, K.; Moses, A.J.; Meydan, T. A system for measurement of AC Barkhausen noise in electrical steels. J. Magn. Magn. Mater. 2003, 254–255, 318–320. [Google Scholar] [CrossRef]

- Jiles, D.C. Introduction to Magnetism and Magnetic Materials; Chapman and Hall: New York, NY, USA, 1991. [Google Scholar]

- Stresstech Group. Rollscan 350. Available online: https://www.stresstech.com/products/barkhausen-noise-equipment/barkhausen-noise-signal-analyzers/rollscan-350/ (accessed on 26 August 2021).

| C | Si | Mn | Cr | S | P | Ni | Mo | Cu | V |

|---|---|---|---|---|---|---|---|---|---|

| 0.16 | 0.29 | 0.42 | 1.97 | 0.008 | 0.012 | 1.29 | 0.52 | 0.12 | 0.12 |

| C | Si | Mn | Cr | S | P | Ni | Mo | Cu |

|---|---|---|---|---|---|---|---|---|

| 0.201 | 0.27 | 0.578 | 0.372 | 0.0085 | 0.0091 | 0.668 | 0.599 | 0.0472 |

| Fast Fluence (E > 1 MeV) (×1019 n/cm2) | DBTT T41J (°C) |

|---|---|

| 0 | −33 ± 9 |

| 1.55 | 76 ± 15 |

| 4.38 | 125 ± 15 |

| 7.04 | 126 ± 15 |

| Fast Fluence (E > 1 MeV) (×1019 n/cm2) | DBTT T41J (°C) |

|---|---|

| 0 | −51 ± 12 |

| 2.78 | 88 ± 15 |

| 6.83 | 136 ± 15 |

| 7.9 | 124 ± 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vértesy, G.; Gasparics, A.; Szenthe, I.; Rabung, M.; Kopp, M.; Griffin, J.M. Analysis of Magnetic Nondestructive Measurement Methods for Determination of the Degradation of Reactor Pressure Vessel Steel. Materials 2021, 14, 5256. https://doi.org/10.3390/ma14185256

Vértesy G, Gasparics A, Szenthe I, Rabung M, Kopp M, Griffin JM. Analysis of Magnetic Nondestructive Measurement Methods for Determination of the Degradation of Reactor Pressure Vessel Steel. Materials. 2021; 14(18):5256. https://doi.org/10.3390/ma14185256

Chicago/Turabian StyleVértesy, Gábor, Antal Gasparics, Ildikó Szenthe, Madalina Rabung, Melanie Kopp, and James M. Griffin. 2021. "Analysis of Magnetic Nondestructive Measurement Methods for Determination of the Degradation of Reactor Pressure Vessel Steel" Materials 14, no. 18: 5256. https://doi.org/10.3390/ma14185256

APA StyleVértesy, G., Gasparics, A., Szenthe, I., Rabung, M., Kopp, M., & Griffin, J. M. (2021). Analysis of Magnetic Nondestructive Measurement Methods for Determination of the Degradation of Reactor Pressure Vessel Steel. Materials, 14(18), 5256. https://doi.org/10.3390/ma14185256