Large Low-Field Reversible Magnetocaloric Effect in Itinerant-Electron Hf1−xTaxFe2 Alloys

Abstract

:1. Introduction

2. Materials and Methods

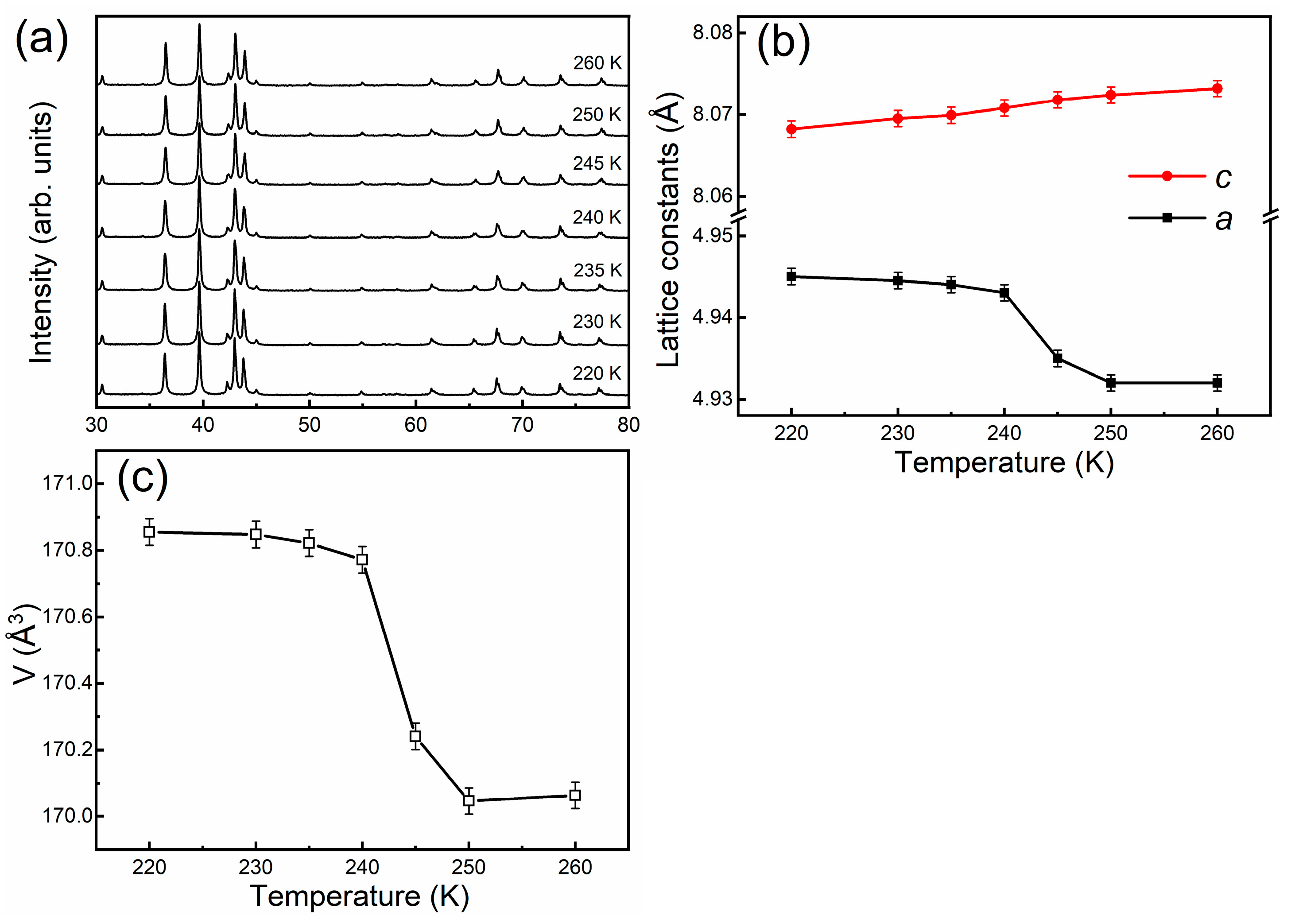

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Franco, V.; Blázquez, J.S.; Ipus, J.J.; Law, J.Y.; Moreno-Ramírez, L.M.; Conde, A. Magnetocaloric effect: From materials research to refrigeration devices. Prog. Mater. Sci. 2018, 93, 112–232. [Google Scholar] [CrossRef]

- Hu, F.X.; Shen, B.G.; Sun, J.R.; Cheng, Z.H.; Zhang, X.X. Influence of negative lattice expansion and metamagnetic transition on magnetic entropy change in the compound LaFe11.4Si1.6. Appl. Phys. Lett. 2001, 78, 3675–3677. [Google Scholar] [CrossRef]

- Fujita, A.; Fujieda, S.; Hasegawa, Y.; Fukamichi, K. Itinerant-electron metamagnetic transition and large magnetocaloric effects in La(FexSi1−x)13 compounds and their hydrides. Phys. Rev. B 2003, 67, 104416. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Krautz, M.; Skokov, K.; Woodcock, T.G.; Gutfleisch, O. Systematic study of the microstructure, entropy change and adiabatic temperature change in optimized La-Fe-Si alloys. Acta Mater. 2011, 59, 3602–3611. [Google Scholar] [CrossRef]

- Tegus, O.; Brück, E.; Buschow, K.H.J.; de Boer, F.R. Transition-metal based magnetic refrigerants for room-temperature applications. Nature 2002, 415, 150–152. [Google Scholar] [CrossRef] [PubMed]

- Guillou, F.; Porcari, G.; Yibole, H.; van Dijk, N.; Brück, E. Taming the first order transition in giant magnetocaloric materials. Adv. Mater. 2014, 26, 2671–2675. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Trung, N.T.; Ou, Z.Q.; Gortenmulder, T.J.; Tegus, O.; Buschow, K.H.J.; Bruck, E. Tunable thermal hysteresis in MnFe(P, Ge) compounds. Appl. Phys. Lett. 2009, 94, 102513. [Google Scholar] [CrossRef] [Green Version]

- Pecharsky, V.K.; Gschneidner, K.A., Jr. Giant magnetocaloric effect in Gd5(Si2Ge2). Phys. Rev. Lett. 1997, 78, 4494–4497. [Google Scholar] [CrossRef]

- Giguere, A.; Foldeaki, M.; Gopal, B.R.; Chahine, R.; Bose, T.K.; Frydman, A. Direct measurement of the ‘‘giant” adiabatic temperature change in Gd5Si2Ge2. Phys. Rev. Let. 1999, 83, 2262–2265. [Google Scholar] [CrossRef]

- Liu, J.; Gottschall, T.; Skokov, K.P.; Moore, J.D.; Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nat. Mater. 2012, 11, 620–626. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, Y.D.; Sanchez-Valdes, C.F.; Sanchez Llamazares, J.L.; Esling, C.; Zhao, X.; Zuo, L. Giant magnetocaloric effect in melt-spun Ni-Mn-Ga ribbons with magneto-multistructural transformation. Appl. Phys. Lett. 2014, 104, 044101. [Google Scholar] [CrossRef]

- Li, Z.B.; Dong, S.Y.; Li, Z.Z.; Yang, B.; Liu, F.; Sánchez-Valdés, C.F.; Sánchez Llamazares, J.L.; Zhang, Y.D.; Esling, C.; Zhao, X.; et al. Giant low-field magnetocaloric effect in Si alloyed Ni-Co-Mn-In alloys. Scr. Mater. 2019, 159, 113–118. [Google Scholar] [CrossRef]

- Li, Z.B.; Jiang, Y.W.; Li, Z.Z.; Sánchez-Valdés, C.F.; Sánchez Llamazares, J.L.; Yang, B.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Phase transition and magnetocaloric properties of Mn50Ni42−xCoxSn8 (0 ≤ x ≤ 10) melt-spun ribbons. IUCrJ 2018, 5, 54–66. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koshkid’ko, Y.; Pandey, S.; Cwik, J.; Dubenko, I.; Aryal, A.; Granovsky, A.; Szymanski, D.; Stadler, S.; Lähderanta, E.; Ali, N. Relaxation phenomena in adiabatic temperature changes near magnetostructural transitions in Heusler alloys. J. Alloys Compd. 2020, 821, 153402. [Google Scholar] [CrossRef]

- Koshkid’ko, Y.; Pandey, S.; Quetz, A.; Aryal, A.; Dubenko, I.; Cwik, J.; Dilmieva, E.; Granovsky, A.; Lähderanta, E.; Stadler, S.; et al. Kinetic effects in magnetic and magnetocaloric properties of metamagnetic Ni50Mn35In14.25B0.75 alloy. J. Magn. Magn. Mater. 2018, 459, 98–101. [Google Scholar] [CrossRef]

- Guillou, F.; Pathak, A.K.; Paudyal, D.; Mudryk, Y.; Wilhelm, F.; Rogalev, A.; Pecharsky, V.K. Non-hysteretic first-order phase transition with large latent heat and giant low-field magnetocaloric effect. Nat. Commun. 2018, 9, 2925. [Google Scholar] [CrossRef]

- Law, J.Y.; Franco, V.; Moreno-Ramirez, L.M.; Conde, A.; Karpenkov, D.Y.; Radulov, I.; Skokov, K.P.; Gutfleisch, O. A quantitative criterion for determining the order of magnetic phase transitions using the magnetocaloric effect. Nat. Commun. 2018, 9, 2680. [Google Scholar] [CrossRef]

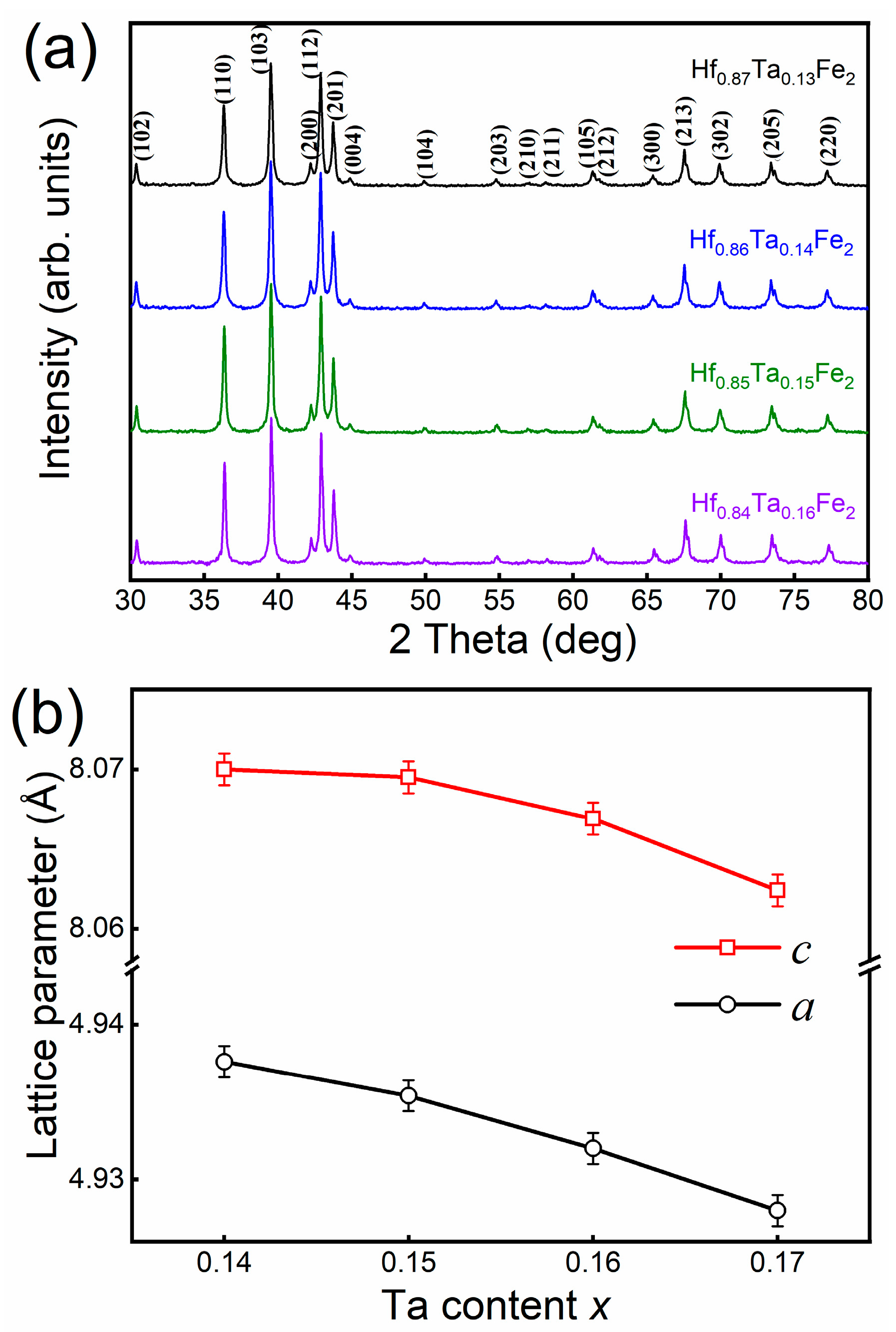

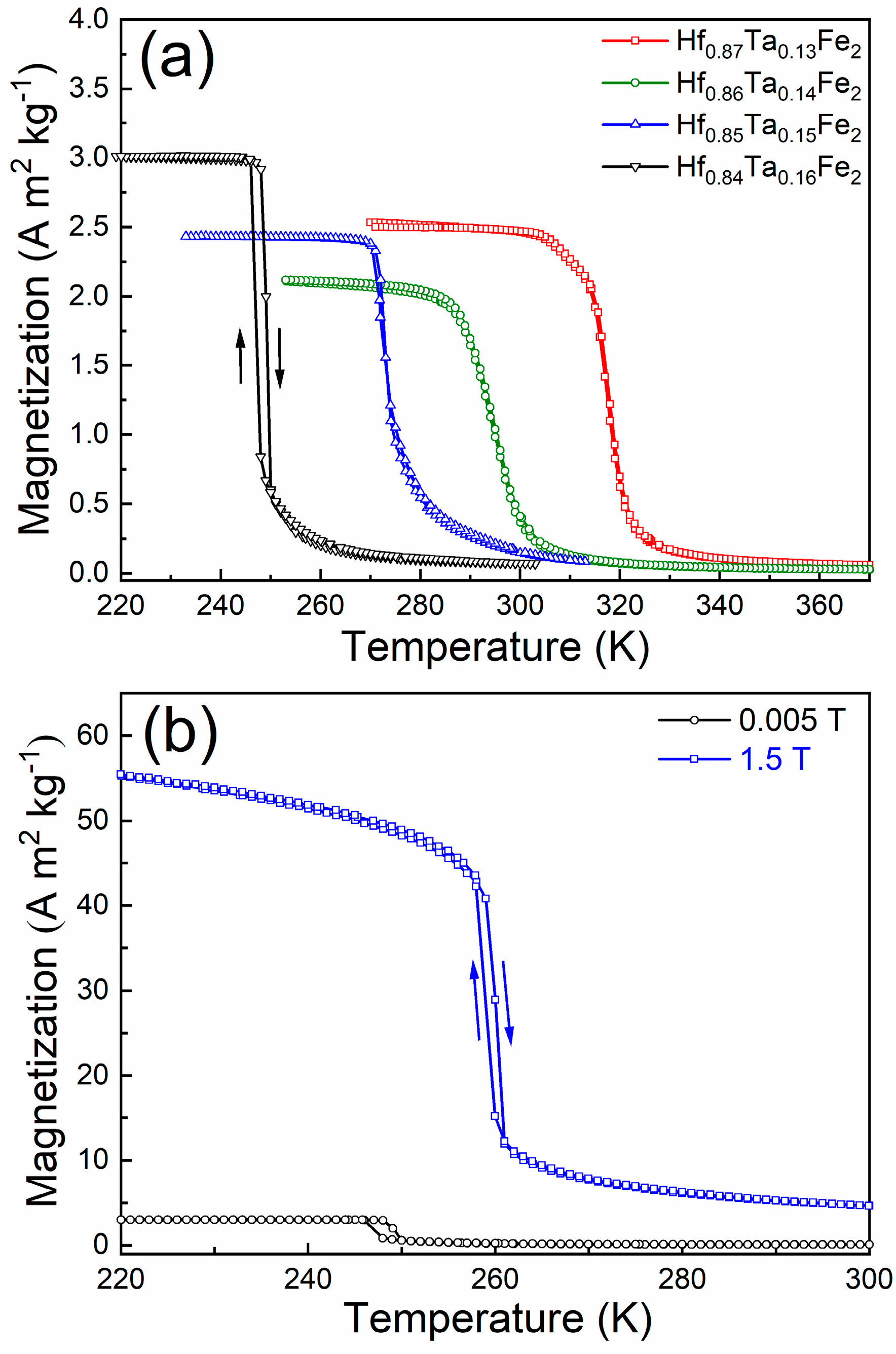

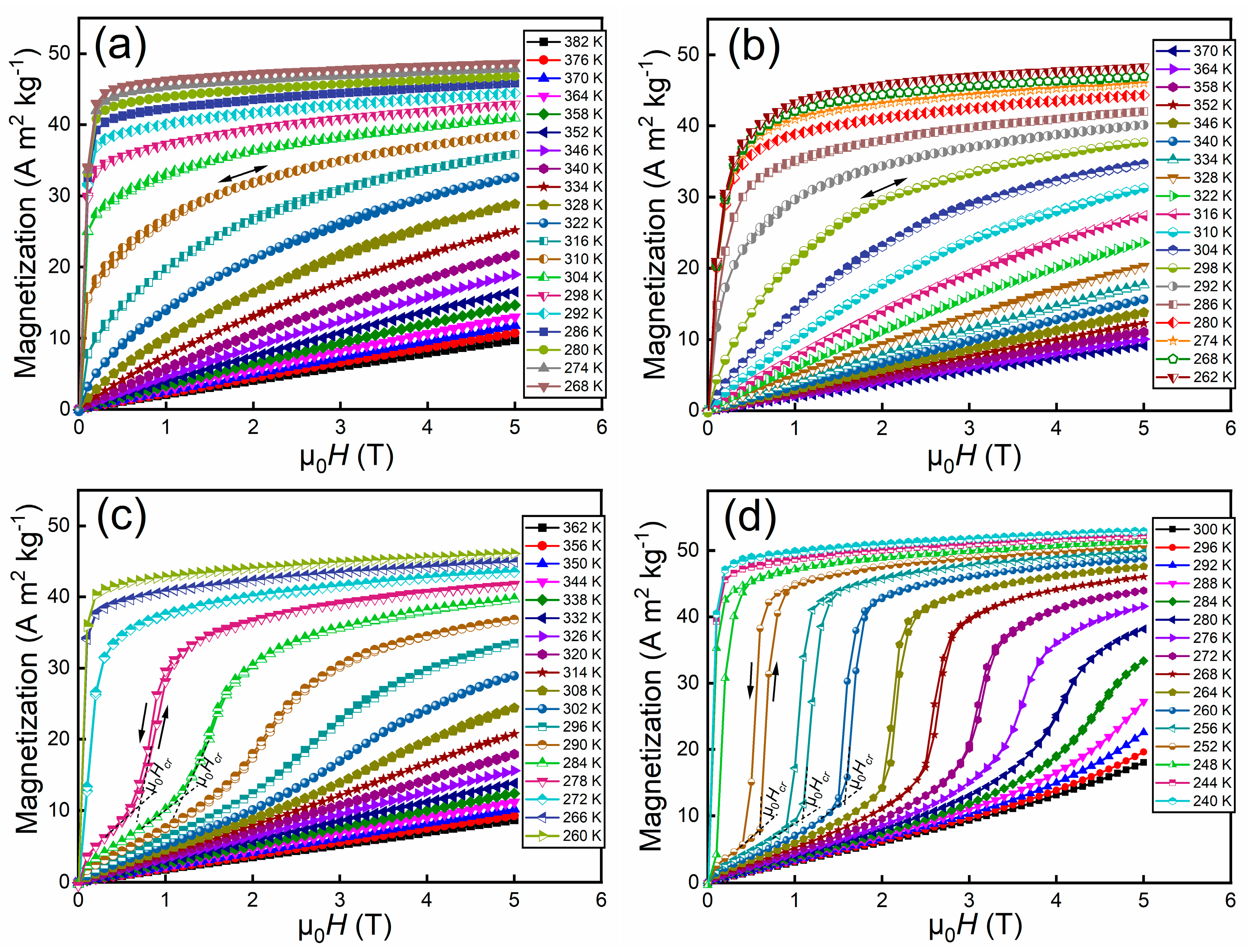

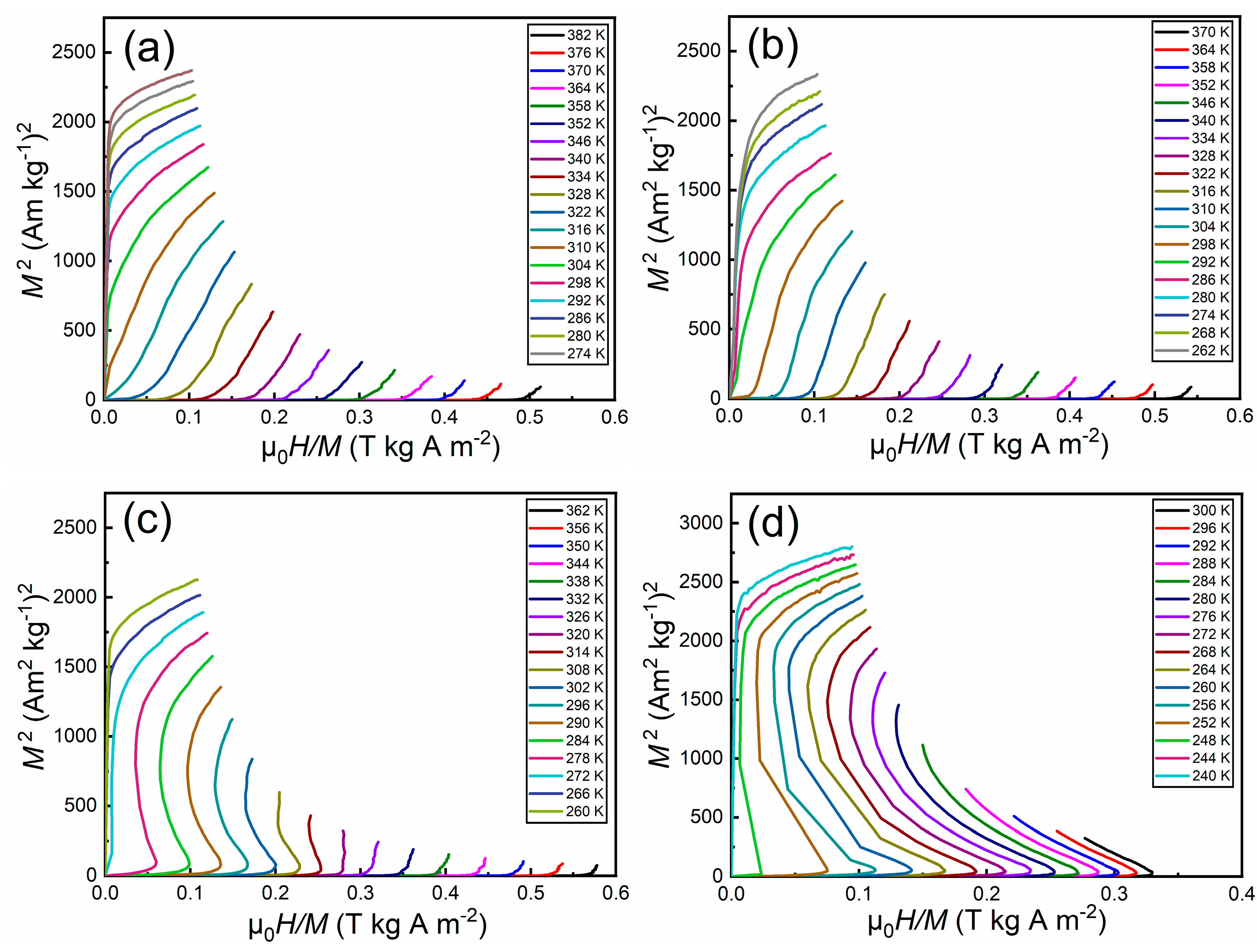

- Li, L.F.; Tong, P.; Zou, Y.M.; Tong, W.; Jiang, W.B.; Jiang, Y.; Zhang, X.K.; Lin, J.C.; Wang, M.; Yang, C.; et al. Good comprehensive performance of Laves phase Hf1-xTaxFe2 as negative thermal expansion materials. Acta Mater. 2018, 161, 258–265. [Google Scholar] [CrossRef]

- Li, B.; Luo, X.H.; Wang, H.; Ren, W.J.; Yano, S.; Wang, C.W.; Gardner, J.S.; Liss, K.D.; Miao, P.; Lee, S.H.; et al. Colossal negative thermal expansion induced by magnetic phase competition on frustrated lattices in Laves phase compound (Hf,Ta)Fe2. Phys. Rev. B. 2016, 93, 224405. [Google Scholar] [CrossRef] [Green Version]

- Diop, L.V.B.; Kastil, J.; Isnard, O.; Arnol, Z.; Kamarad, J. Magnetic and magnetocaloric properties of itinerant-electron system Hf1−xTaxFe2 (x = 0.125 and 0.175). J. Alloys Compd. 2015, 627, 446–450. [Google Scholar] [CrossRef]

- Diop, L.V.B.; Isnard, O.; Amara, M.; Gay, F.; Itié, J.P. Giant negative thermal expansion across the first-order magnetoelastic transition in Hf0.86Ta0.14Fe2. J. Alloys Compd. 2020, 845, 156310. [Google Scholar] [CrossRef]

- Diop, L.V.B.; Kastil, J.; Isnard, O.; Arnold, Z.; Kamarad, J. Collapse of ferromagnetism in itinerant-electron system: A magnetic, transport properties, and high pressure study of (Hf,Ta)Fe2 compounds. J. Appl. Phys. 2014, 116, 163907. [Google Scholar] [CrossRef]

- Li, S.; Yang, J.C.; Zhao, N.; Wang, Q.; Fan, X.M.; Yin, X.W.; Cui, W.B. Phase-transition-induced magneto-elastic coupling and negative thermal expansion in (Hf,Ta)Fe1.98 Laves phase. J. Magn. Magn. Mater. 2021, 517, 167236. [Google Scholar] [CrossRef]

- Han, Z.D.; Wang, D.H.; Huang, S.L.; Su, Z.H.; Tang, S.L.; Du, Y.W. Low-field magnetic entropy changes in Hf1−XTaXFe2. J. Alloys Compd. 2004, 377, 75–77. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Fries, M.; Taubel, A.; Radulov, I.; Scheibel, F.; Benke, D.; Riegg, S.; Gutfleisch, O. Making a Cool Choice: The Materials Library of Magnetic Refrigeration. Adv. Energy Mater. 2019, 9, 1901322. [Google Scholar] [CrossRef] [Green Version]

- Bag, P.; Rawat, R.; Chaddah, P.; Babu, P.D.; Siruguri, V. Unconventional thermal effects across first-order magnetic transition in the Ta-doped HfFe2 intermetallic. Phys. Rev. B 2016, 93, 014416. [Google Scholar] [CrossRef] [Green Version]

- Arrott, A. Criterion for ferromagnetism from observations of magnetic isotherms. Phys. Rev. 1957, 108, 1394–1396. [Google Scholar] [CrossRef]

- Chirkova, A.; Skokov, K.P.; Schultz, L.; Baranov, N.V.; Gutfleisch, O.; Woodcock, T.G. Giant adiabatic temperature change in FeRh alloys evidenced by direct measurements under cyclic conditions. Acta Mater. 2016, 106, 15–21. [Google Scholar] [CrossRef]

- Tekgül, A.; Acet, M.; Scheibel, F.; Farle, M.; Ünal, N. The reversibility of the inverse magnetocaloric effect in Mn2−xCrxSb0.95Ga0.05. Acta Mater. 2017, 124, 93–99. [Google Scholar] [CrossRef]

- Çakιr, Ö.; Acet, M. Reversibility in the inverse magnetocaloric effect in Mn3GaC studied by direct adiabatic temperature-change measurements. Appl. Phys. Lett. 2012, 100, 202404. [Google Scholar] [CrossRef]

- Liu, J.; You, Y.; Batashev, I.; Gong, Y.; You, X.; Huang, B.; Zhang, F.; Miao, X.; Xu, F.; van Dijk, N.; et al. Design of Reversible Low-Field Magnetocaloric Effect at Room Temperature in Hexagonal MnMX Ferromagnets. Phys. Rev. Appl. 2020, 13, 054003. [Google Scholar] [CrossRef]

- Li, Z.B.; Li, Z.Z.; Yang, J.J.; Yang, B.; Zhao, X.; Zuo, L. Large room temperature adiabatic temperature variation in a Ni40Co8Mn42Sn10 polycrystalline alloy. Intermetallics 2018, 100, 57–62. [Google Scholar] [CrossRef]

- Li, Z.Z.; Li, Z.B.; Yang, B.; Zhao, X.; Zuo, L. Giant low-field magnetocaloric effect in a textured Ni45.3Co5.1Mn36.1In13.5 alloy. Scr. Mater. 2018, 151, 61–65. [Google Scholar] [CrossRef]

- Li, Z.B.; Yang, J.J.; Li, D.; Li, Z.Z.; Yang, B.; Yan, H.L.; Sánchez-Valdés, C.F.; Llamazares, J.L.S.; Zhang, Y.D.; Esling, C.; et al. Tuning the Reversible Magnetocaloric Effect in Ni–Mn–In-Based Alloys through Co and Cu Co-Doping. Adv. Electron. Mater. 2019, 5, 1800845. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Scheibel, F.; Acet, M.; Ghorbani Zavareh, M.; Skourski, Y.; Wosnitza, J.; Farle, M.; Gutfleisch, O. Dynamical Effects of the Martensitic Transition in Magnetocaloric Heusler Alloys from Direct ΔTad Measurements under Different Magnetic-Field-Sweep Rates. Phys. Rev. Appl. 2016, 2, 024013. [Google Scholar] [CrossRef]

- Taubel, A.; Gottschall, T.; Fries, M.; Riegg, S.; Soon, C.; Skokov, K.P.; Gutfleisch, O. A Comparative Study on the Magnetocaloric Properties of Ni-Mn-X(-Co) Heusler Alloys. Phy. Status Solidi B 2018, 255, 1700331. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Frincu, B.; Gutfleisch, O. Large reversible magnetocaloric effect in Ni-Mn-In-Co. Appl. Phys. Lett. 2015, 106, 021901. [Google Scholar] [CrossRef]

- Titov, I.; Acet, M.; Farle, M.; González-Alonso, D.; Mañosa, L.; Planes, A.; Krenke, T. Hysteresis effects in the inverse magnetocaloric effect in martensitic Ni-Mn-In and Ni-Mn-Sn. J. Appl. Phys. 2012, 112, 073914. [Google Scholar] [CrossRef]

| Alloys | Transition Type | Temperature (K) | ΔTcyclicmax (K) | μ0ΔH (T) | Reference |

|---|---|---|---|---|---|

| Hf0.85Ta0.15Fe2 | Magnetoelastic | 275 | 2.7 | 1.5 | This work |

| Hf0.84Ta0.16Fe2 | Magnetoelastic | 253 | 3.4 | 1.5 | This work |

| MnFe0.95P0.595B0.075Si0.33 | Magnetoelastic | 277 | 2.8 | 1.1 | [6] |

| Fe49Rh51 | Magnetoelastic | 321 | 6.2 | 1.9 | [28] |

| Eu2In | Magnetoelastic | 56 | 5.0 | 2.0 | [16] |

| Mn1.87Cr0.13Sb0.95Ga0.05 | Magnetoelastic | 280 | 1.9 | 5.0 | [29] |

| Mn3GaC | Magnetoelastic | 150 | 3.0 | 3.0 | [30] |

| MnCo0.93Cu0.07Ge | Magnetostructural | 304 | 1.1 | 1.1 | [31] |

| Ni40Co8Mn42Sn10 | Magnetostructural | 298 | 0.8 | 1.5 | [32] |

| Ni45.3Co5.1Mn36.1In13.5 | Magnetostructural | 294 | 1.1 | 1.5 | [33] |

| Ni46Co3Mn35Cu2In14 | Magnetostructural | 272 | 2.5 | 1.5 | [34] |

| Ni50Mn35In15 | Magnetostructural | 286 | 1.5 | 1.9 | [35] |

| Ni45.7Mn37.9Sn11.8Co4.9 | Magnetostructural | 330 | 1.2 | 1.93 | [36] |

| Ni45.7Mn36.6In13.5Co4.2 | Magnetostructural | 282 | 3.0 | 1.95 | [37] |

| Ni51.3Mn32.9In15.8 | Magnetostructural | 251 | 0.7 | 3.0 | [38] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Z.; Li, Z.; Yang, B.; Yan, H.; Esling, C.; Zhao, X.; Zuo, L. Large Low-Field Reversible Magnetocaloric Effect in Itinerant-Electron Hf1−xTaxFe2 Alloys. Materials 2021, 14, 5233. https://doi.org/10.3390/ma14185233

Song Z, Li Z, Yang B, Yan H, Esling C, Zhao X, Zuo L. Large Low-Field Reversible Magnetocaloric Effect in Itinerant-Electron Hf1−xTaxFe2 Alloys. Materials. 2021; 14(18):5233. https://doi.org/10.3390/ma14185233

Chicago/Turabian StyleSong, Zhao, Zongbin Li, Bo Yang, Haile Yan, Claude Esling, Xiang Zhao, and Liang Zuo. 2021. "Large Low-Field Reversible Magnetocaloric Effect in Itinerant-Electron Hf1−xTaxFe2 Alloys" Materials 14, no. 18: 5233. https://doi.org/10.3390/ma14185233

APA StyleSong, Z., Li, Z., Yang, B., Yan, H., Esling, C., Zhao, X., & Zuo, L. (2021). Large Low-Field Reversible Magnetocaloric Effect in Itinerant-Electron Hf1−xTaxFe2 Alloys. Materials, 14(18), 5233. https://doi.org/10.3390/ma14185233