Effects of TiB2 Particles on the Microstructure Evolution and Mechanical Properties of B4C/TiB2 Ceramic Composite

Abstract

:1. Introduction

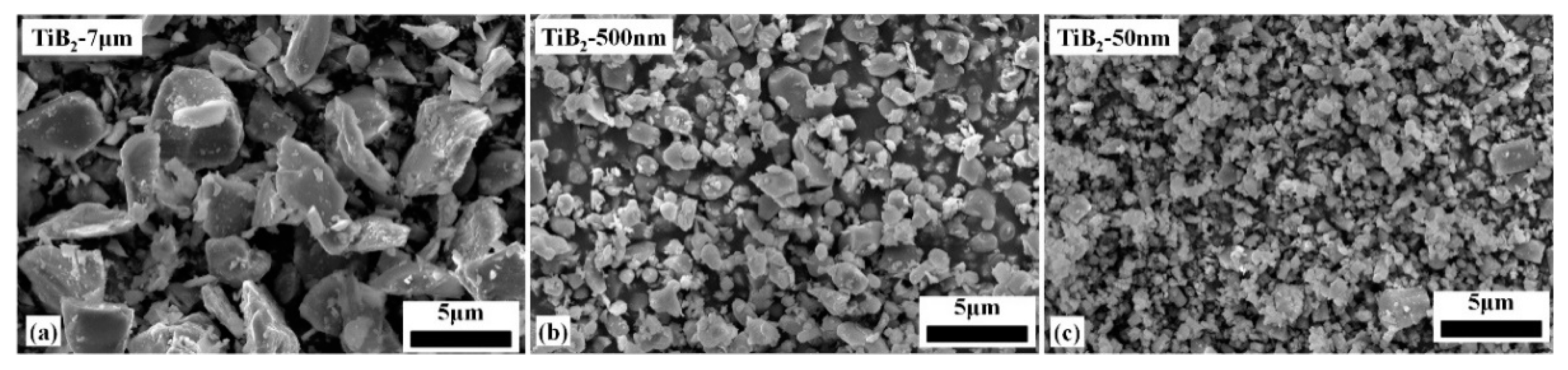

2. Materials and Methods

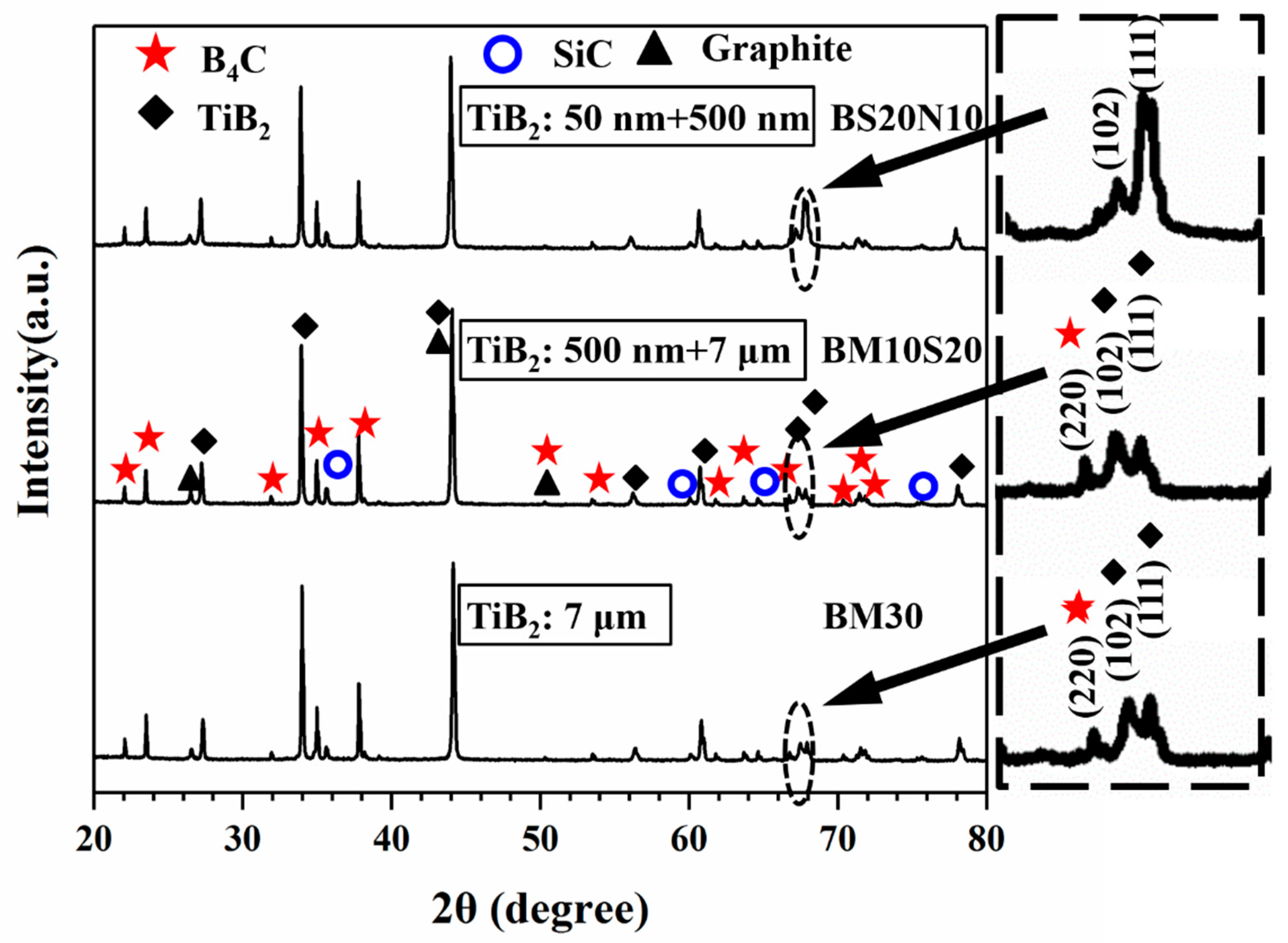

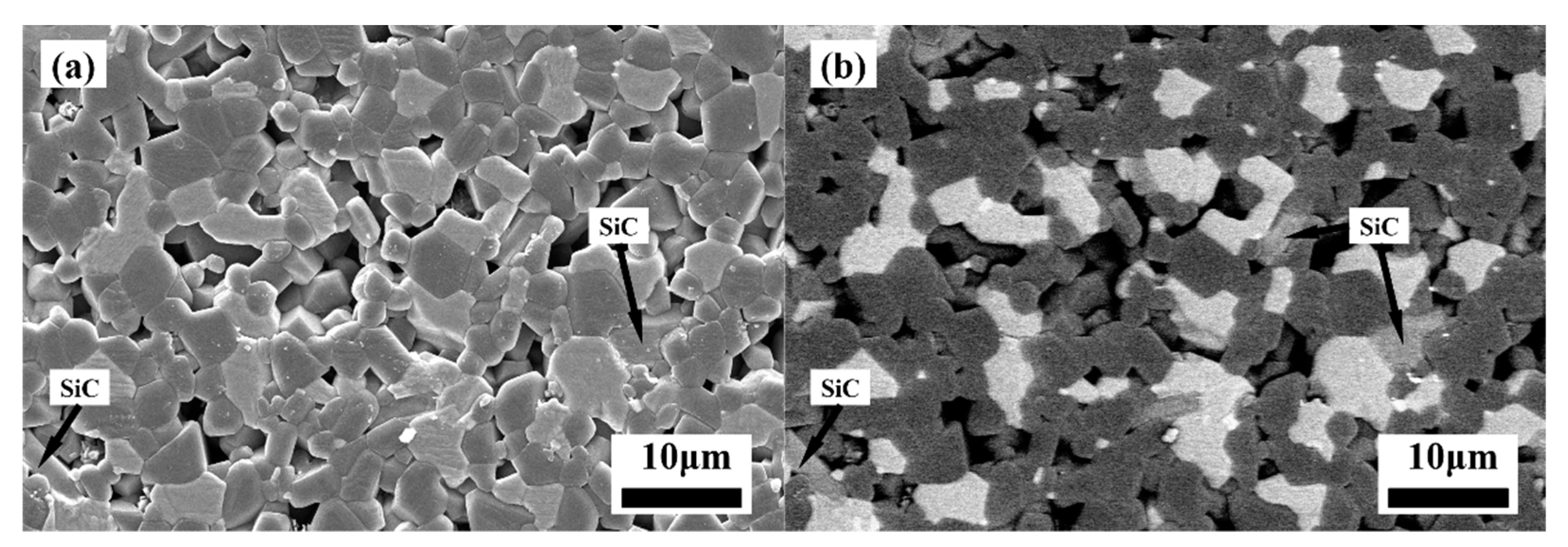

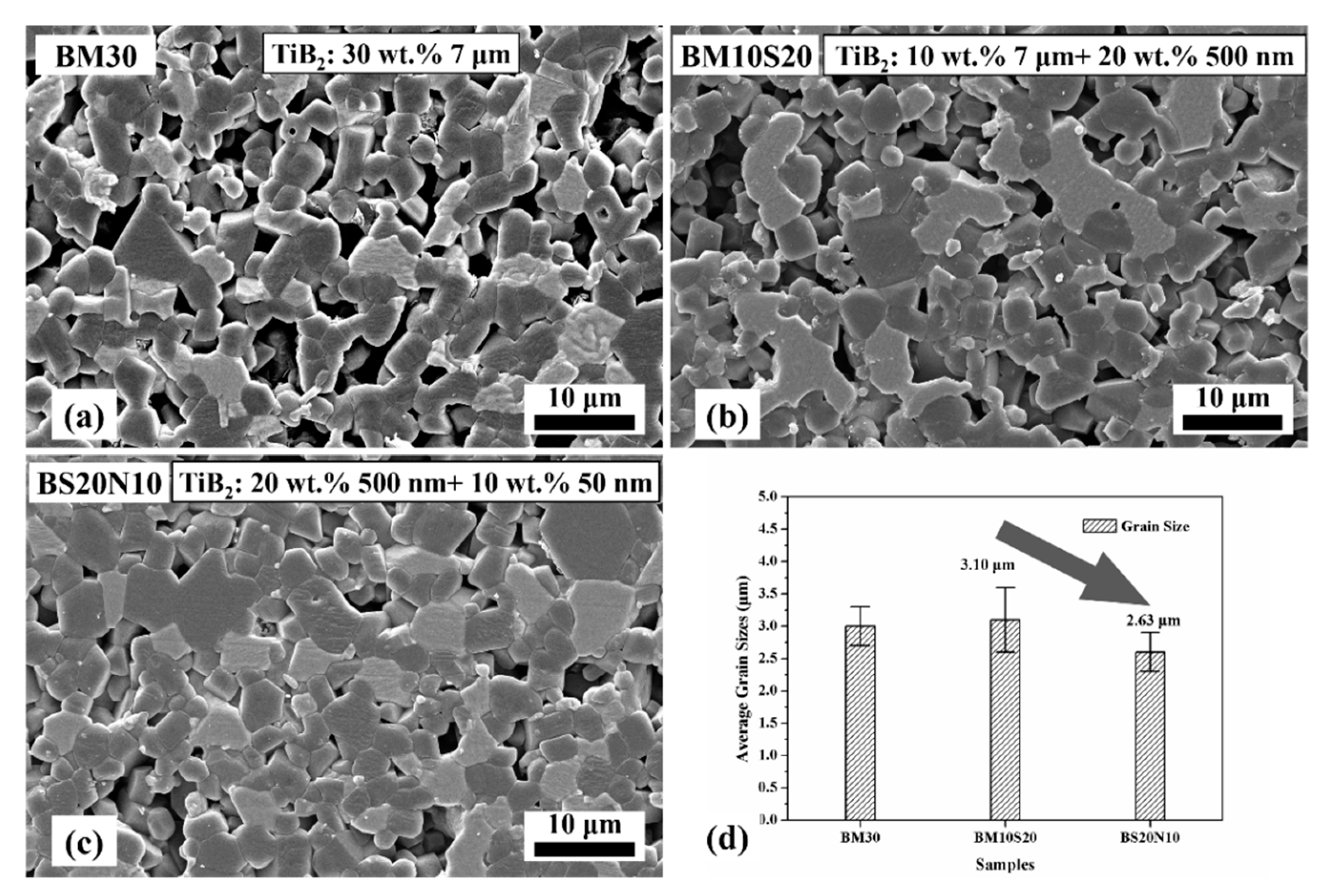

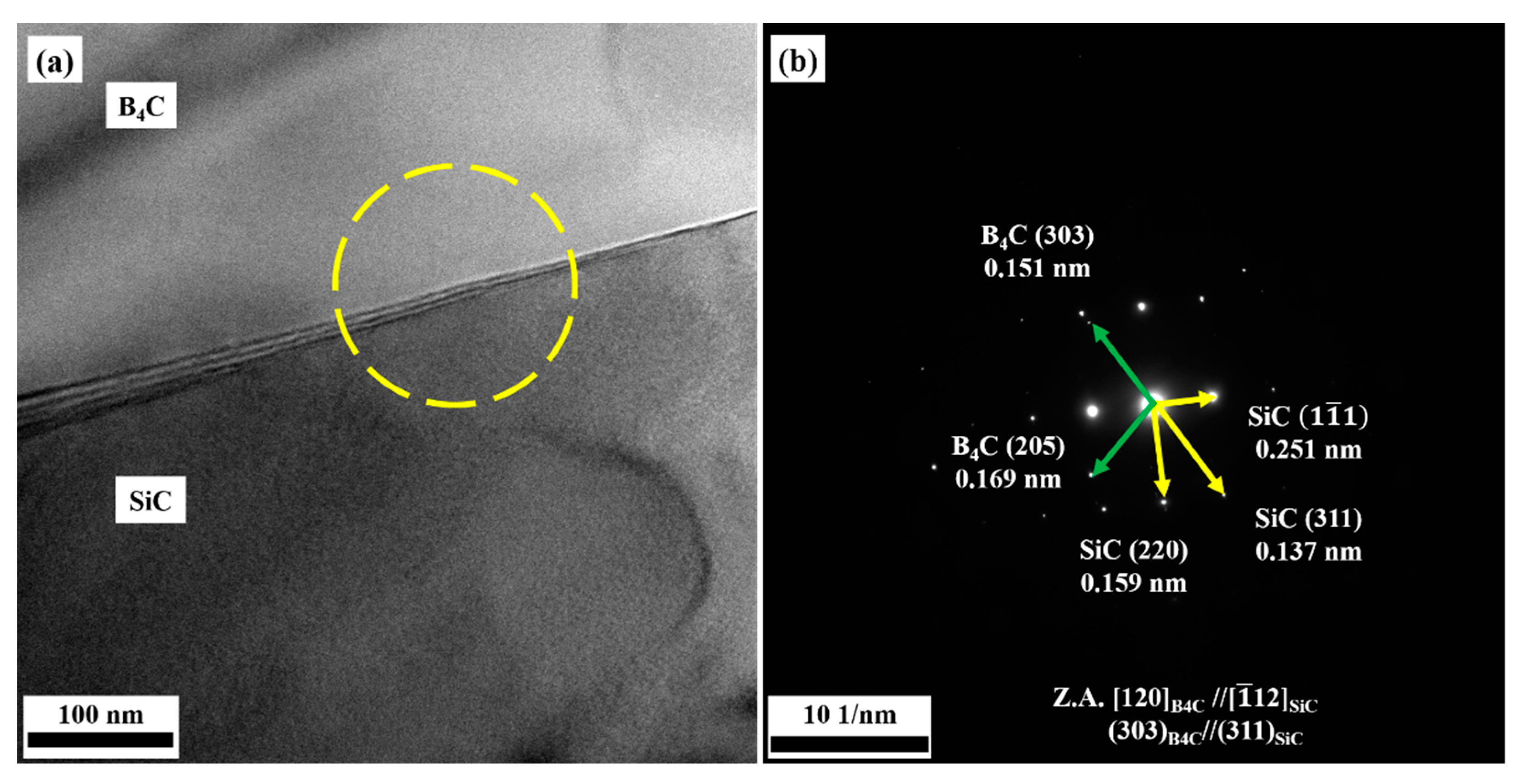

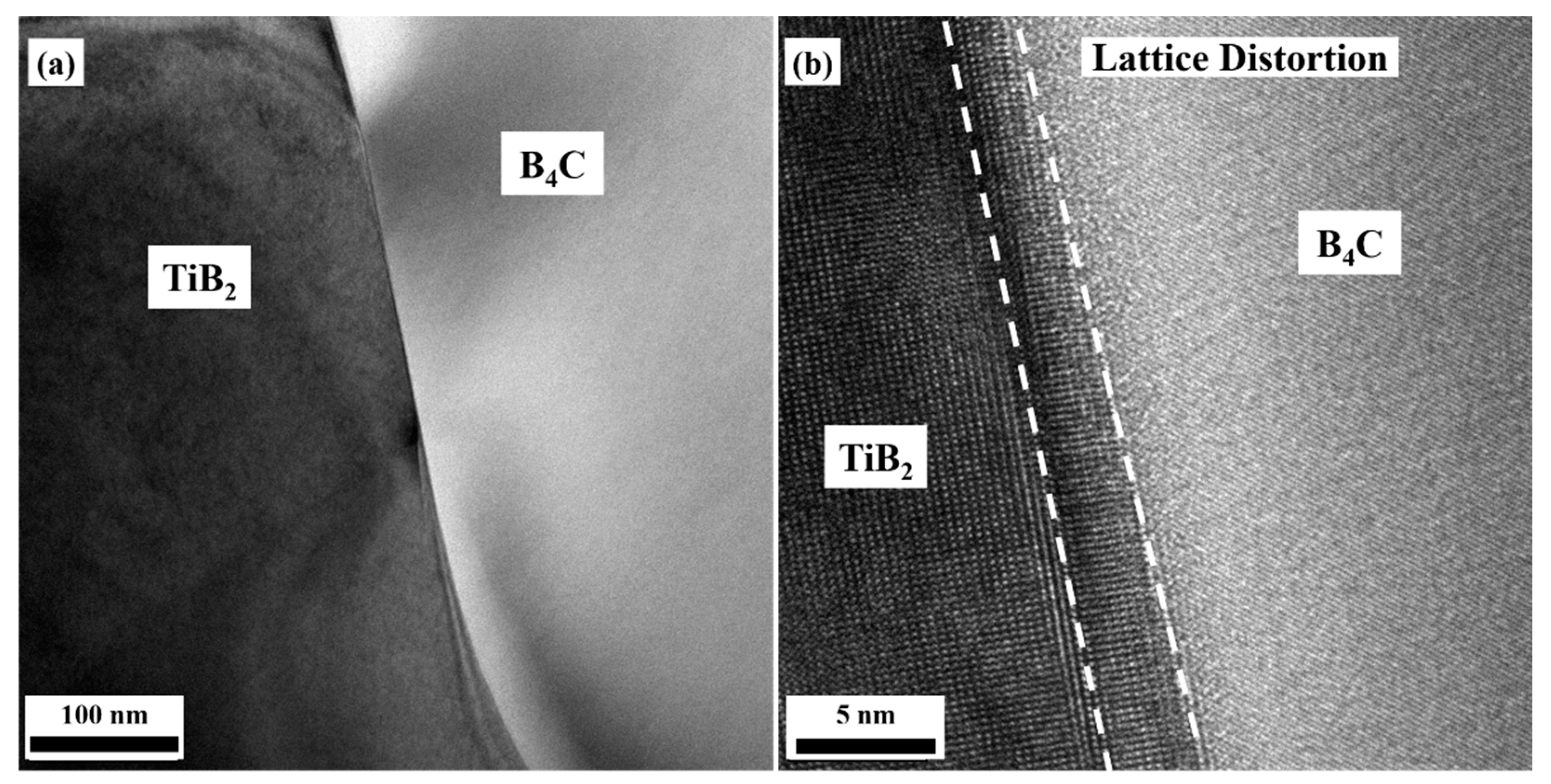

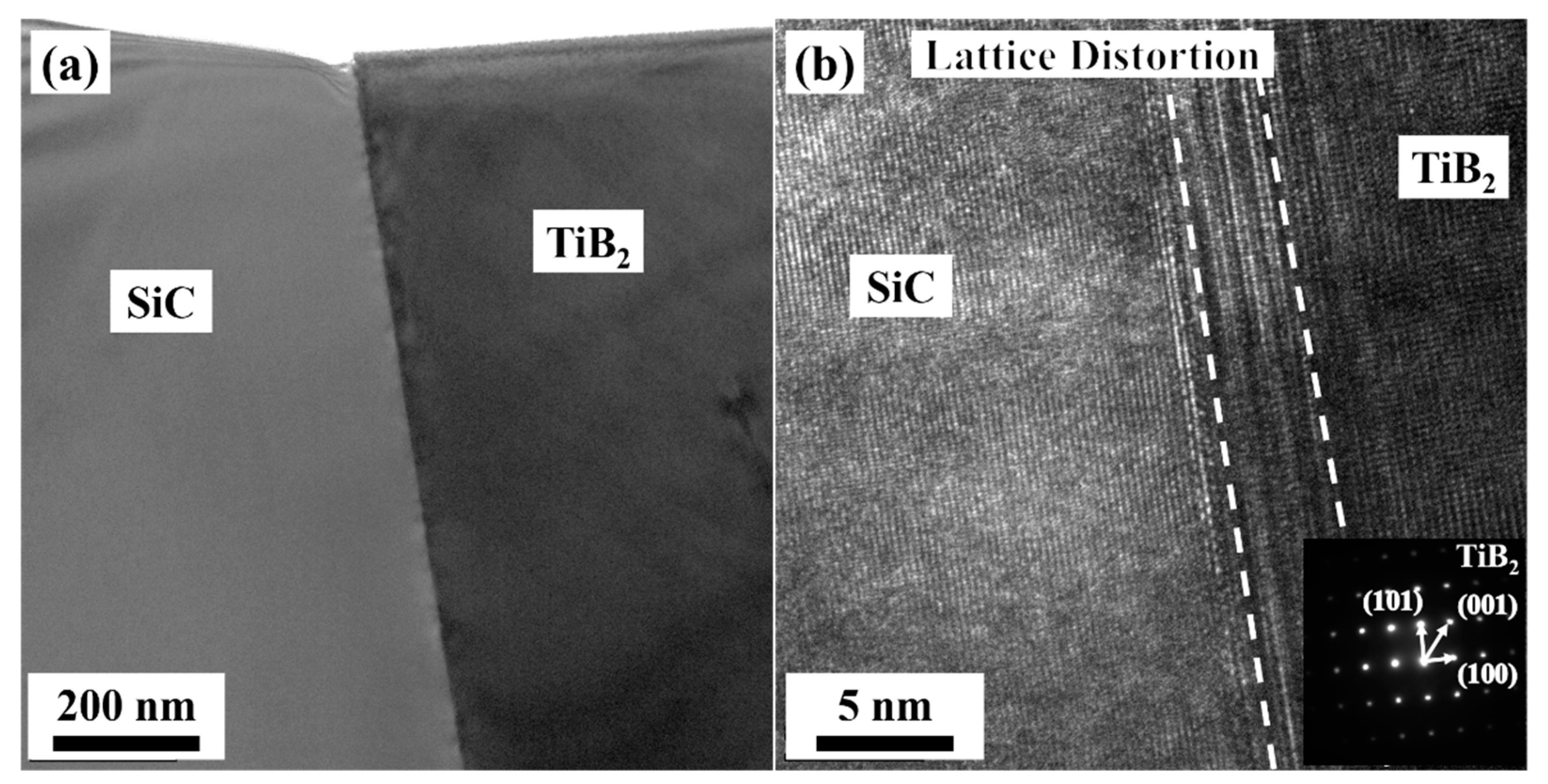

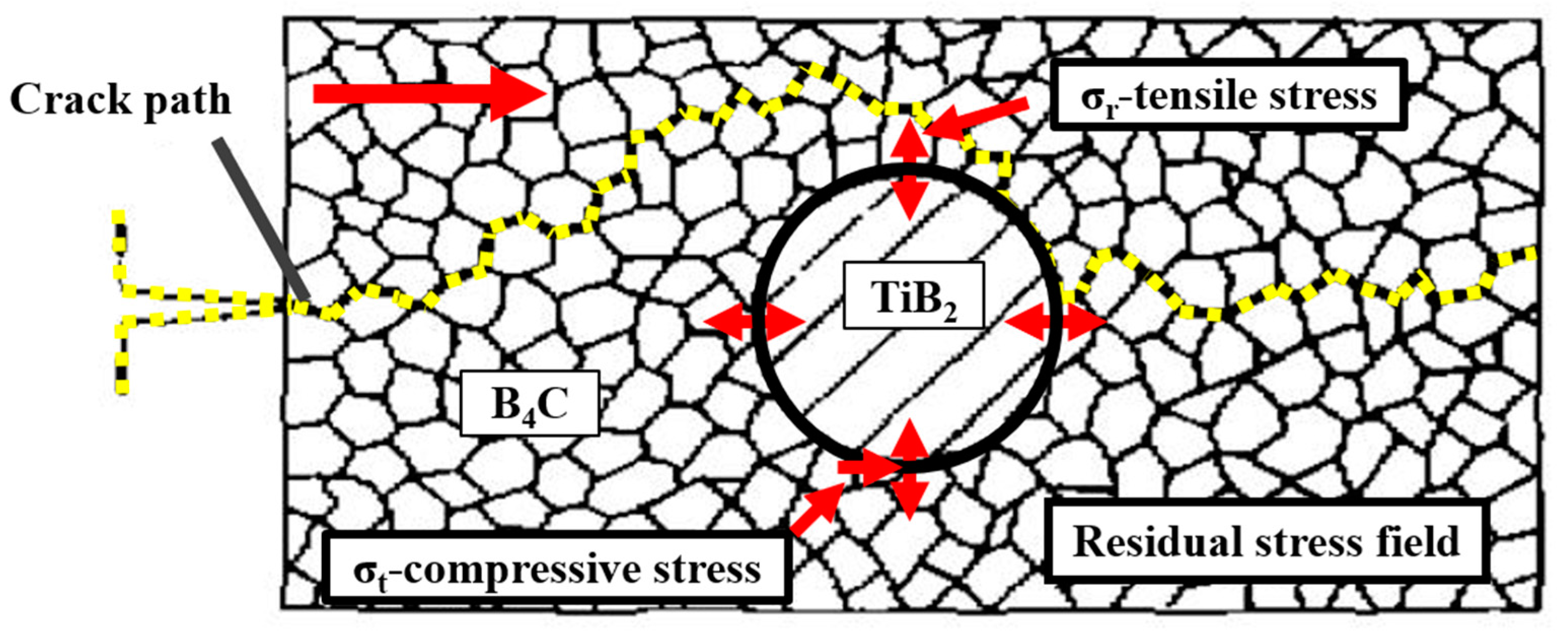

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thevent, F. Boron Carbide—A Comprehensive Review. J. Eur. Ceram. Soc. 1990, 6, 205–225. [Google Scholar] [CrossRef]

- Jiang, Z.G.; Zeng, S.Y.; Shen, Z.Q. Research progress on lightweight ceramic composite armor structure. Acta Armamentarii 2010, 31, 603–610. [Google Scholar] [CrossRef]

- Karandikar, P.G.; Evans, G.; Wong, S.; Aghajanian, M.K.; Sennett, M. A review of ceramics for armor applications. Adv. Ceram. Armor IV 2009, 29, 163–175. [Google Scholar] [CrossRef]

- Savio, S.G.; Ramanjaneyulu, K.; Madhu, V.; Bhat, T.B. An experimental study on ballistic performance of boron carbide tiles. Int. J. Impact Eng. 2011, 38, 535–541. [Google Scholar] [CrossRef]

- Da Rocha, R.M.; de Melo, F.C.L. Pressureless Sintering of B4C-SiC Composites for Armor Applications. Ceram. Eng. Sci. Proc. 2009, 30, 113. [Google Scholar] [CrossRef]

- Wu, C.; Li, Y.K.; Wan, C.L. Reactive-sintering B4C matrix composite for Armor Applications. Rare Met. 2020, 39, 529–544. [Google Scholar] [CrossRef]

- Huang, S.G.; Vanmeensel, K.; van der Biest, O.; Vleugels, J. In situ synthesis and densification of submicormeter-grained B4C-TiB2 composites by pulsed electric current sintering. J. Eur. Ceram. Soc. 2011, 31, 637–644. [Google Scholar] [CrossRef]

- Xu, C.M.; Cai, Y.B.; Flodstrom, K.; Li, Z.; Esmaeilzadeh, S.; Zhang, G.J. Spark plasma sintering of B4C ceramics: The effects of milling medium and TiB2 addition. Int. Refract. Met. Hard Mater. 2012, 30, 139–144. [Google Scholar] [CrossRef]

- Goldstein, A.; Geffen, Y.; Goldenberg, A. Boron Carbide–Zirconium Boride In-Situ Composites by the Reactive Pressureless Sintering of Boron Carbide–Zirconia Mixtures. J. Am. Ceram. Soc. 2001, 84, 642–644. [Google Scholar] [CrossRef]

- Subramanian, C.; Roy, T.; Murthy, T.S.; Sengupta, P.; Kale, G.B.; Krishnaiah, M.V.; Suri, A.K. Effect of zirconia addition on pressureless sintering of boron carbide. Ceram. Int. 2008, 34, 1543–1549. [Google Scholar] [CrossRef]

- Sairam, K.; Sonber, J.K.; Murthy, T.S.; Subramanian, C.; Hubli, R.C.; Suri, A.K. Development of B4C–HfB2 composites by reaction hot pressing. Int. Refract. Met. Hard Mater. 2012, 35, 32–40. [Google Scholar] [CrossRef]

- Tang, J.; Tan, S.H.; Chen, Z.M.; Jiang, D.L. Strengthening and Toughening of B4C-TiB2 Multiphase Ceramics. J. Inorg. Mater. 1997, 12, 169–174. [Google Scholar] [CrossRef]

- Nils, C.; Bernhard, M.; Michael, V.S. Grain-Size dependence of fracture energy in ceramics. J. Am. Ceram. Soc. 1981, 64, 345–350. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, D.; Li, J.; Huang, Q.; Ran, S. Densification of high-strength B4C–TiB2 composites fabricated by pulsed electric current sintering of TiC–B mixture. Scr. Mater. 2017, 135, 15–18. [Google Scholar] [CrossRef]

- Wang, D.; Ran, S.; Shen, L.; Sun, H.; Huang, Q. Fast synthesis of B4C–TiB2 composite powders by pulsed electric current heating TiC–B mixture. J. Eur. Ceram. Soc. 2015, 35, 1107–1112. [Google Scholar] [CrossRef]

- Huang, S.G.; Vanmeensel, K.; Malek, O.J.A.; Van der Biest, O.; Vleugels, J. Microstructure and mechanical properties of pulsed electric current sintered B4C–TiB2 composites. Mater. Sci. Eng. A 2011, 528, 1302–1309. [Google Scholar] [CrossRef]

- Wu, C.; Li, Y.K. AlN-induced reinforcement of nano-amorphous B-C-N compound for TiB2–B4C ceramic composite. J. Alloys Compd. 2020, 831, 154074. [Google Scholar] [CrossRef]

- Mashhadi, M.; Taheri-Nassaj, E.; Mashhadi, M.; Sglavo, V.M. Pressureless sintering of B4C–TiB2 composites with al additions. Ceram. Int. 2011, 37, 3229–3235. [Google Scholar] [CrossRef]

- Malek, O.; Vleugels, J.; Vanmeensel, K.; Huang, S.; Liu, J.; Van den Berghe, S.; Datye, A.; Wu, K.H.; Lauwers, B. Electrical discharge machining of B4C–TiB2 composites. J. Eur. Ceram. Soc. 2011, 31, 2023–2030. [Google Scholar] [CrossRef]

- Goldstein, A.; Yeshurun, Y.; Goldenberg, A. B4C/metal boride composites derived from B4C/metal oxide mixtures. J. Eur. Ceram. Soc. 2007, 27, 695–700. [Google Scholar] [CrossRef]

- Yamada, S.; Hirao, K.; Yamauchi, Y.; Kanzaki, S. High strength B4C–TiB2 composites fabricated by reaction hot-pressing. J. Eur. Ceram. Soc. 2003, 23, 1123–1130. [Google Scholar] [CrossRef]

- Liu, Z.T.; Deng, X.G.; Li, J.M.; Sun, Y.; Ran, S. Effects of B4C particle size on the microstructures and mechanical properties of hot-pressed B4C-TiB2 composites. Ceram. Int. 2018, 44, 21415–21420. [Google Scholar] [CrossRef]

- Li, P.; Yang, J.F. Microstructure and Mechanical Properites of B4C-C Ceramic. Rare Met. Mater. Eng. 1999, 28, 151–154. [Google Scholar]

- Suri, A.K.; Subramanian, C.; Sonber, J.K.; Murthy, T.C. Synthesis and consolidation of boron carbide: A review. Int. Mater. Rev. 2010, 55, 4–40. [Google Scholar] [CrossRef]

- Hayun, S.; Frage, N.; Dariel, M.P. The morphology of ceramic phases in BxC-SiC-Si infiltrated composites. J. Solid State Chem. 2006, 179, 2875–2879. [Google Scholar] [CrossRef]

- Feng, Y.; Hou, Z.; Zhang, H.; Liu, L. Densification and Mechanical Properties of Spark Plasma Sintered B4C with Si as a Sintering Aid. J. Am. Ceram. Soc. 2010, 93, 2956–2959. [Google Scholar] [CrossRef]

- Zhang, Z.; Du, X.; Li, Z.; Wang, W.; Zhang, J.; Fu, Z. Microstructures and mechanical properties of B4C-SiC intergranular/intragranular nanocomposite ceramics fabricated from B4C, Si, and graphite powders. J. Eur. Ceram. Soc. 2014, 34, 2153–2161. [Google Scholar] [CrossRef]

- Skorokhod, V.V., Jr.; Vlajic, M.D.; Kristic, V.D. Pressureless Sintering of B4C-TiB2 Ceramic Composites. Mater. Sci. Forum 1998, 282–283, 219–224. [Google Scholar] [CrossRef]

- Baharvandi, H.R.; Hadian, A.M. Pressureless Sintering of TiB2-B4C Ceramic Matrix Composite. J. Mater. Eng. Perform. 2008, 17, 838–841. [Google Scholar] [CrossRef]

- Pan, J.S.; Tong, J.M.; Tian, M.B. Fundamentals of Materials Science; Tsinghua University Press: Beijing, China, 2011. [Google Scholar]

- Mu, B.C. Strengthening and Toughening of Ceramic Materials; Metallurgical Industry Press Co., Ltd.: Beijing, China, 2002. [Google Scholar]

- Choi, S.R.; Sanders, W.A.; Salem, J.A.; Tikare, V. Young’s modulus, strength and fracture toughness as a function of density of in situ toughened silicon nitride with 4 wt.% Scandia. J. Mater. Sci. Lett. 1995, 14, 276–278. [Google Scholar] [CrossRef]

- Li, Z.N. Applied Fracture Mechanics; Bei Hang University Press: Beijing, China, 2012. [Google Scholar]

- Wu, Q.R.; Wen, B.X. Study on temperature dependence of thermal conductivity and linear expansion for SiC material. J. South China Univ. Techno. Nat. Sci. Ed. 1996, 24, 11–15. [Google Scholar]

- Einarsrud, M.A.; Hagen, E.; Pettersen, G.; Grande, T. Pressureless sintering of titanium diboride with nickel, nickel boride, and iron additives. J. Am. Ceram. Soc. 2005, 80, 3013–3020. [Google Scholar] [CrossRef]

| Grade | B4C (wt.%) | C (wt.%) | Si (wt.%) | Micron TiB2 (wt.%) | Submicron TiB2 (wt.%) | Nano TiB2 (wt.%) |

|---|---|---|---|---|---|---|

| BM30 | 60 | 7 | 3 | 30 | / | / |

| BM10S20 | 60 | 7 | 3 | 10 | 20 | / |

| BS20N10 | 60 | 7 | 3 | / | 20 | 10 |

| Sample | Relative Density (%) | Flexural Strength (MPa) | Fracture Toughness (MPa·m1/2) | Vickers Hardness (GPa) |

|---|---|---|---|---|

| BM30 | 90.1 ± 0.2 | 217 ± 13 | 3.70 ± 0.19 | 8.3 ± 0.6 |

| BM10S20 | 92.6 ± 0.1 | 288 ± 12 | 4.46 ± 0.12 | 12.5 ± 1.1 |

| BS20N10 | 98.6 ± 0.1 | 364 ± 9 | 5.47 ± 0.12 | 30.2 ± 2.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, H.; Zhu, Y.; You, N.; Wang, Y.; Cheng, H.; Luo, D.; Tang, M.; Zhang, J. Effects of TiB2 Particles on the Microstructure Evolution and Mechanical Properties of B4C/TiB2 Ceramic Composite. Materials 2021, 14, 5227. https://doi.org/10.3390/ma14185227

Niu H, Zhu Y, You N, Wang Y, Cheng H, Luo D, Tang M, Zhang J. Effects of TiB2 Particles on the Microstructure Evolution and Mechanical Properties of B4C/TiB2 Ceramic Composite. Materials. 2021; 14(18):5227. https://doi.org/10.3390/ma14185227

Chicago/Turabian StyleNiu, Haiyan, Yu Zhu, Ning You, Yangwei Wang, Huanwu Cheng, Dujun Luo, Mengying Tang, and Jiamin Zhang. 2021. "Effects of TiB2 Particles on the Microstructure Evolution and Mechanical Properties of B4C/TiB2 Ceramic Composite" Materials 14, no. 18: 5227. https://doi.org/10.3390/ma14185227

APA StyleNiu, H., Zhu, Y., You, N., Wang, Y., Cheng, H., Luo, D., Tang, M., & Zhang, J. (2021). Effects of TiB2 Particles on the Microstructure Evolution and Mechanical Properties of B4C/TiB2 Ceramic Composite. Materials, 14(18), 5227. https://doi.org/10.3390/ma14185227