Adaptive Finite Element Model for Simulating Crack Growth in the Presence of Holes

Abstract

:1. Introduction

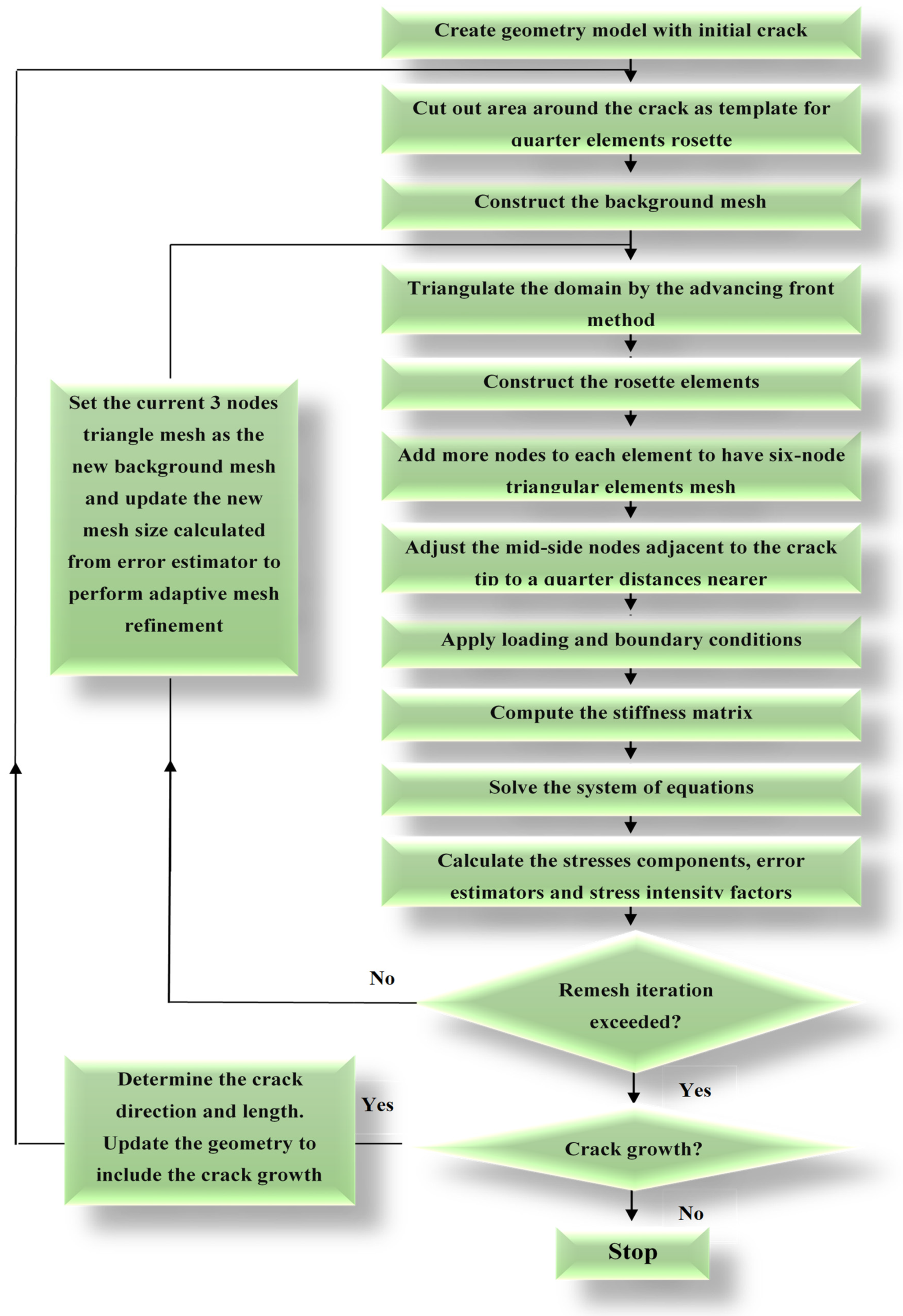

2. Developed Program Procedure

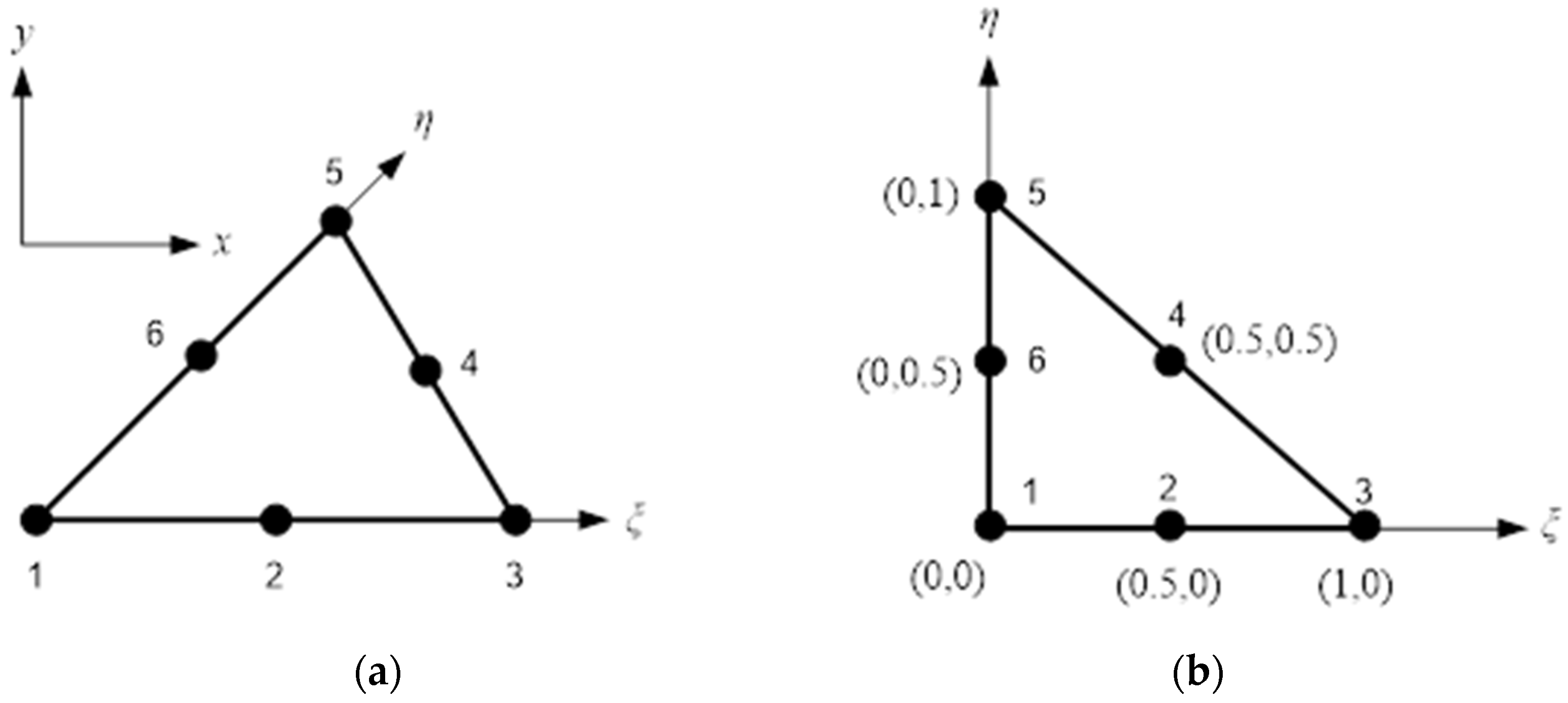

2.1. Adaptive Mesh Refinement

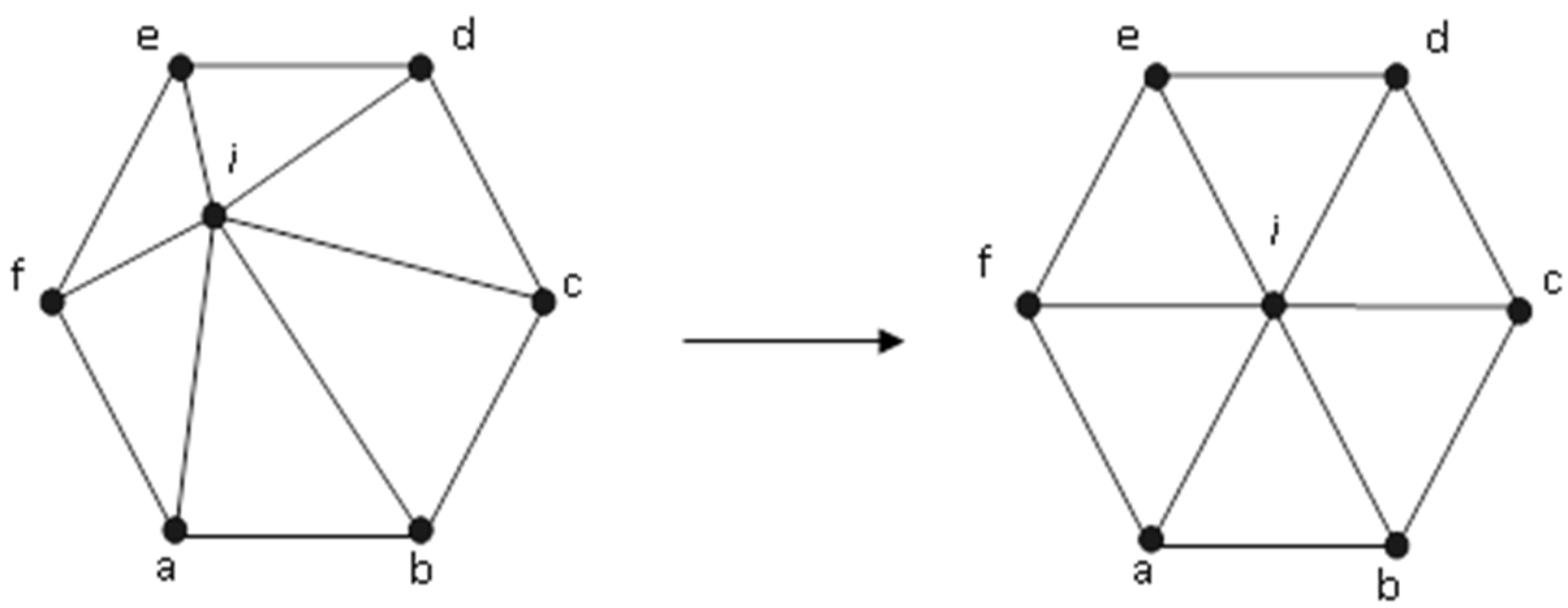

2.2. Mesh Smoothing

2.3. Crack Growth Increment

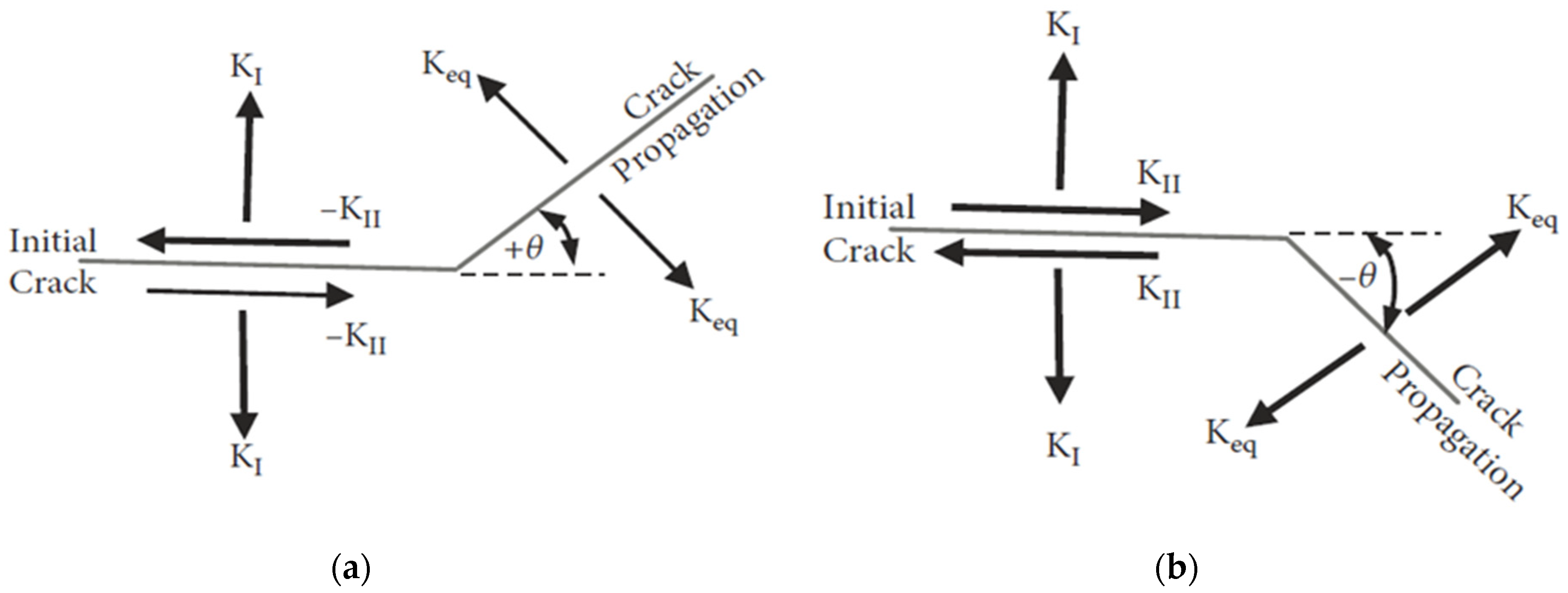

2.4. Crack Kinking Criteria

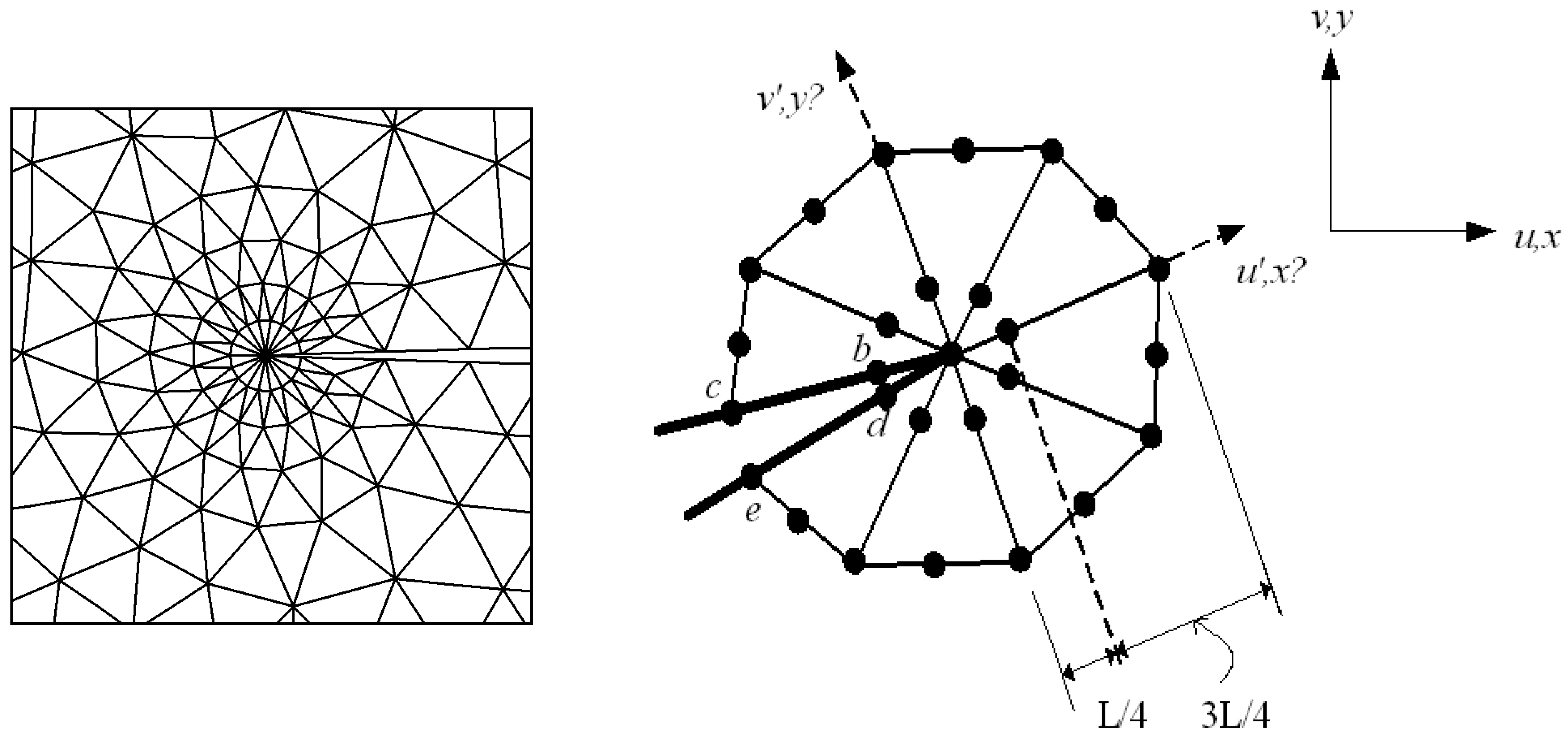

2.5. Displacement Extrapolation Technique (DET)

2.6. Static and Fatigue Crack Growth Analysis

3. Results and Discussions

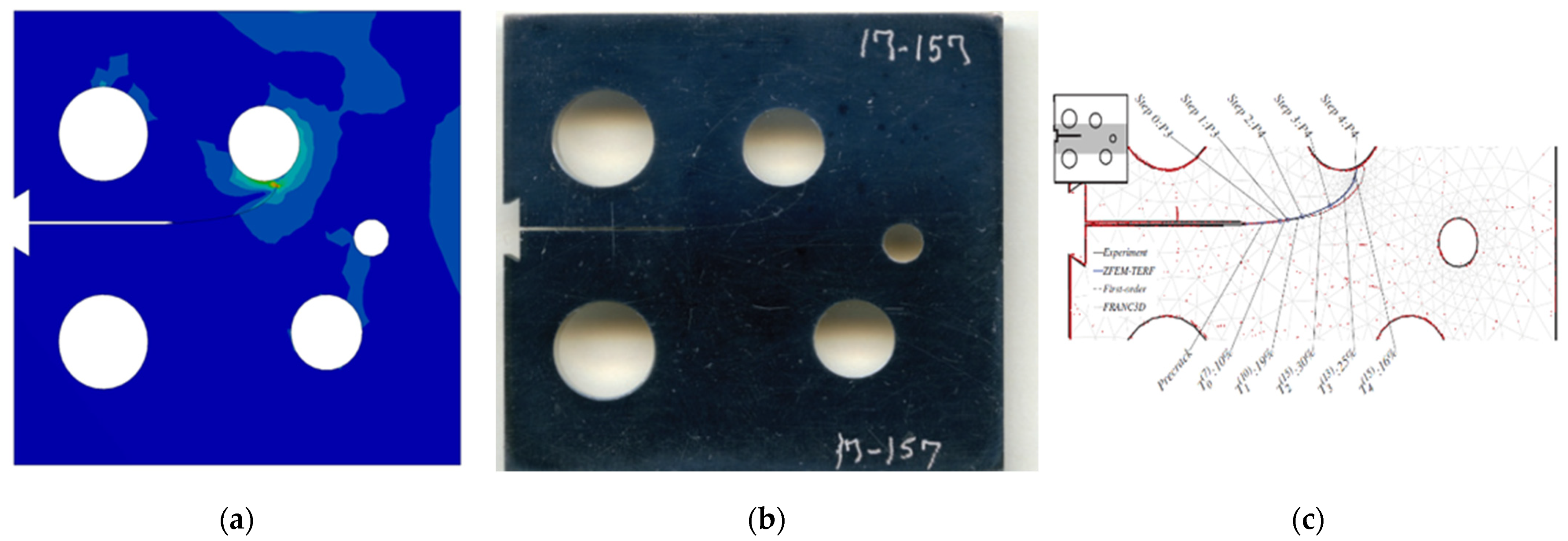

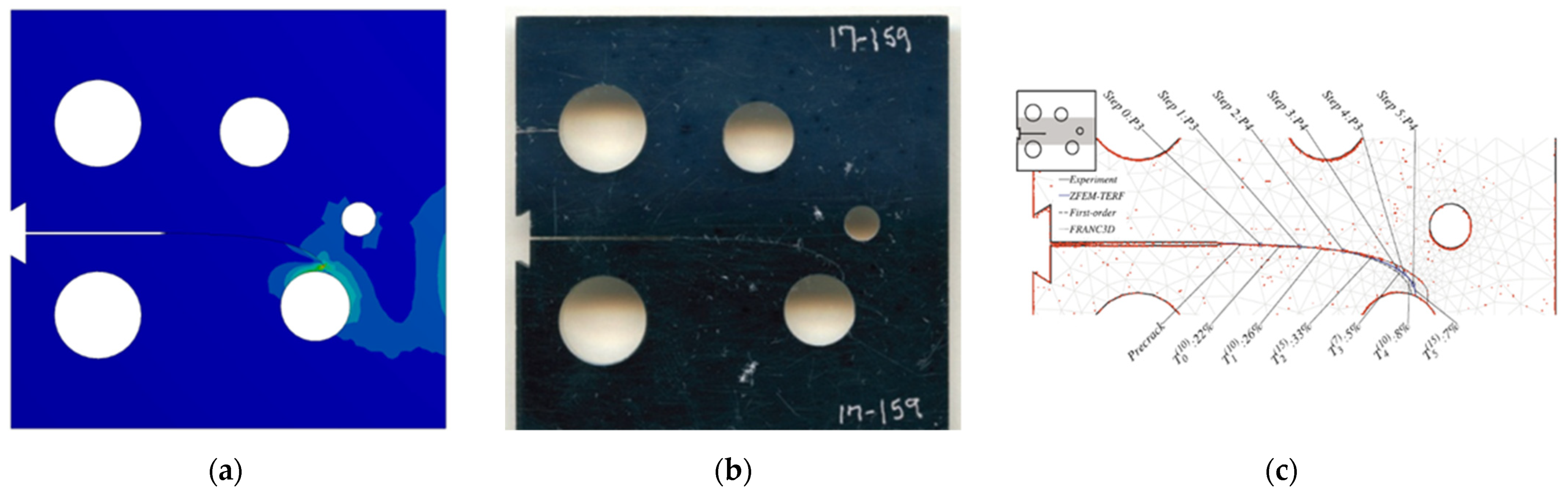

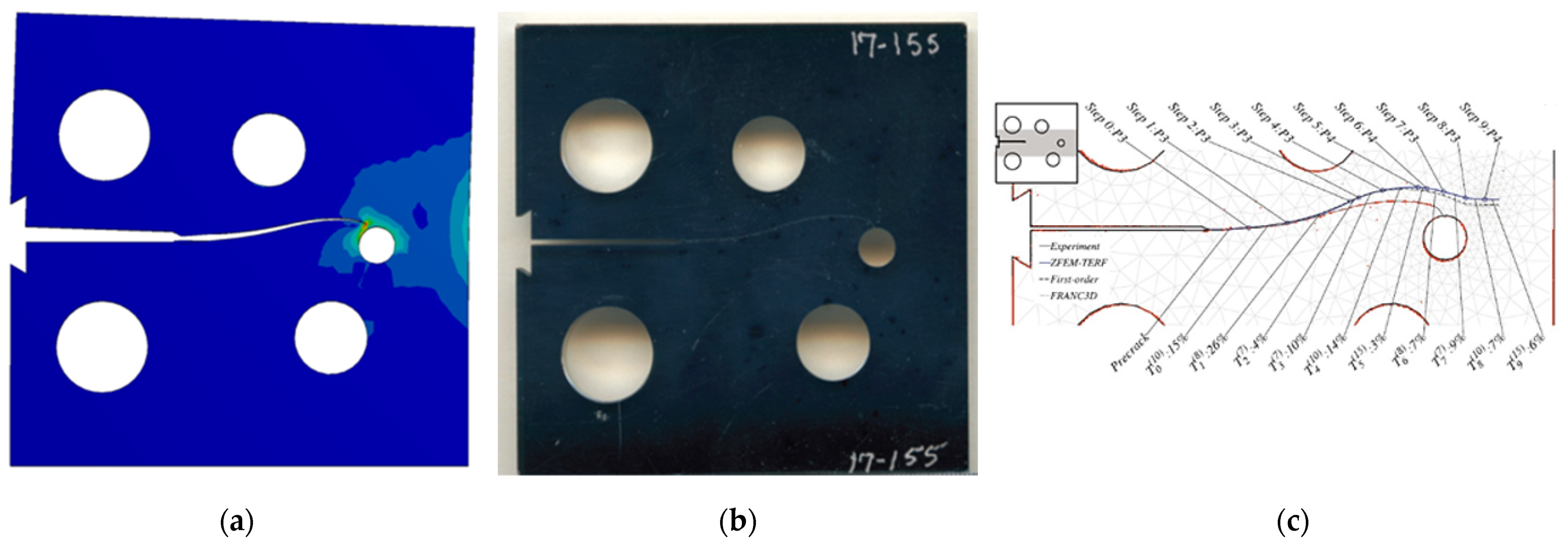

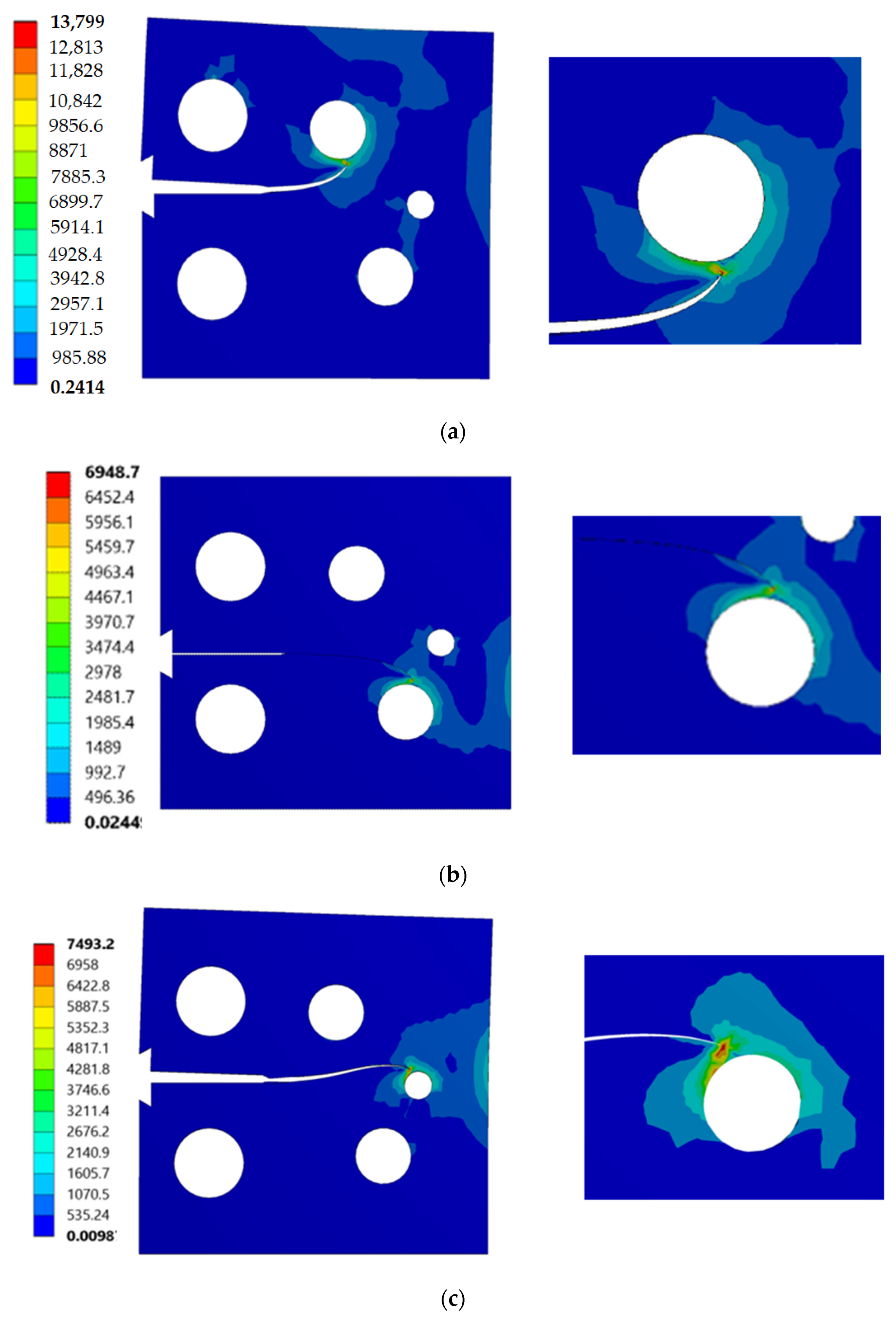

3.1. Modified Compact Tension Specimen with Different Initial Crack-Tip Position

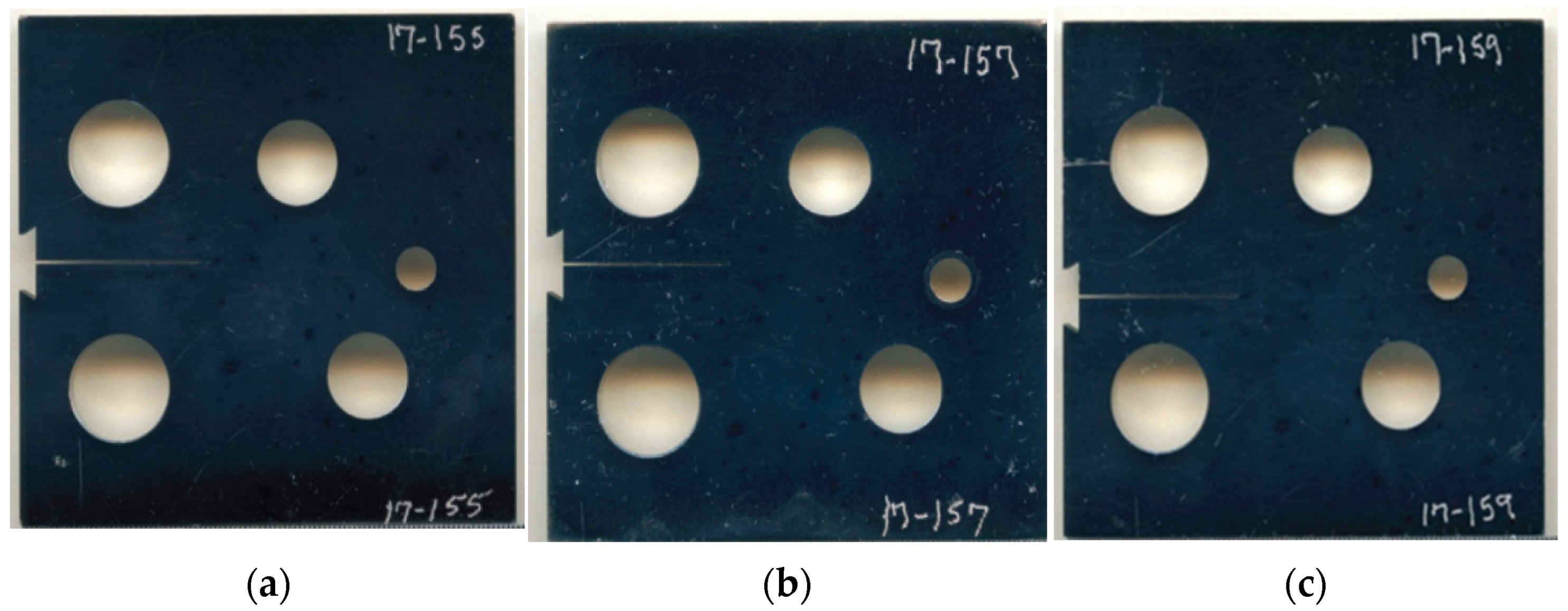

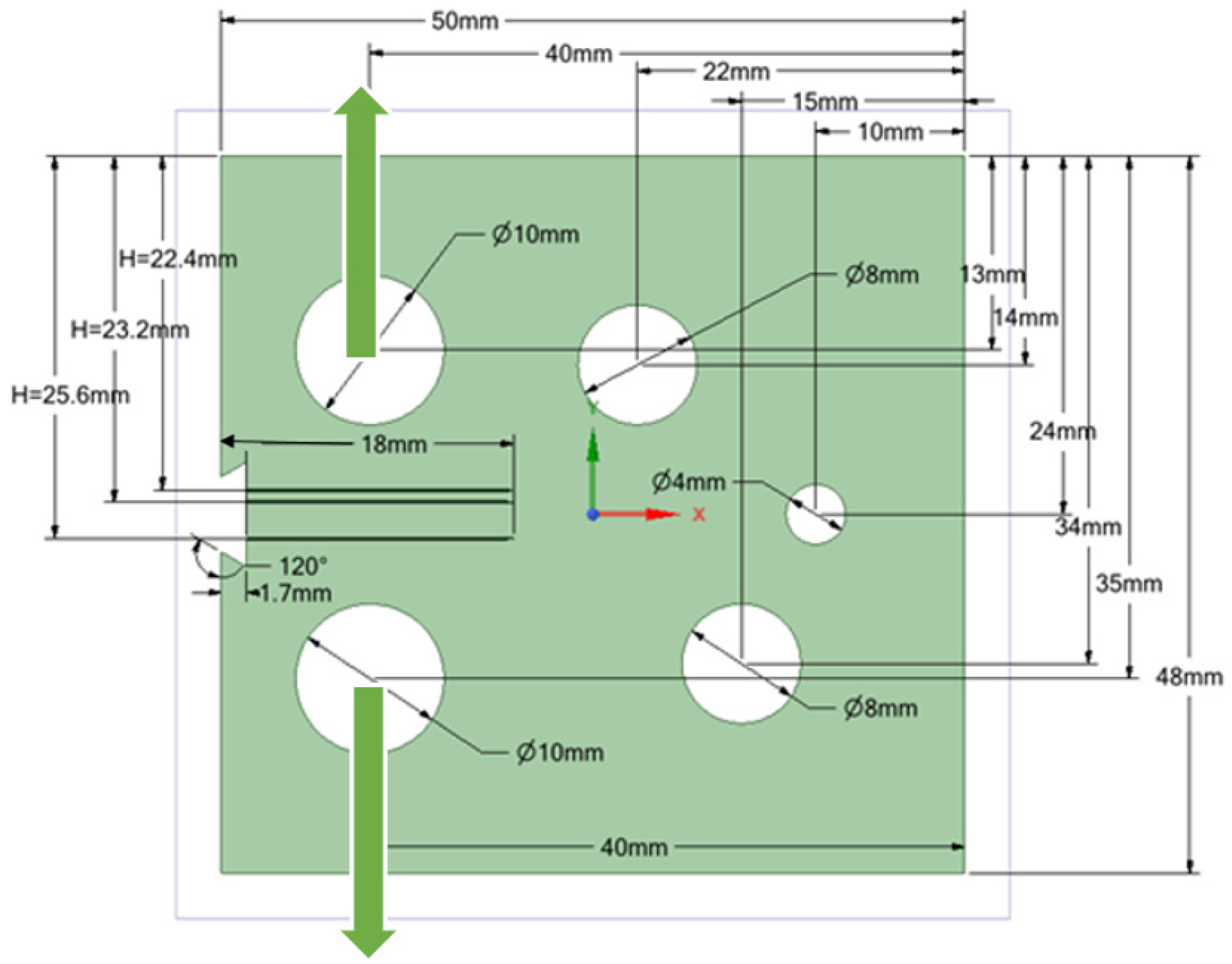

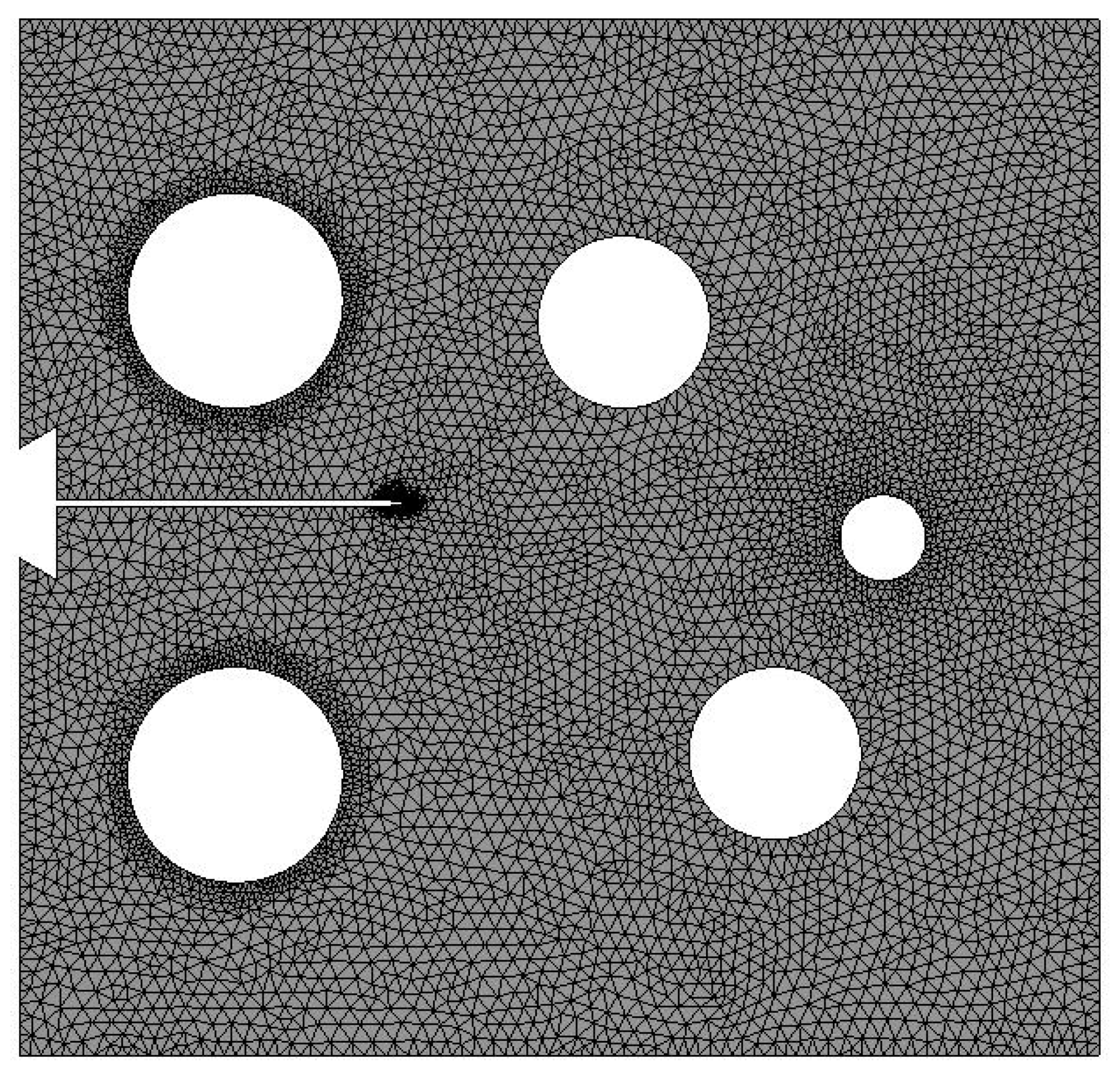

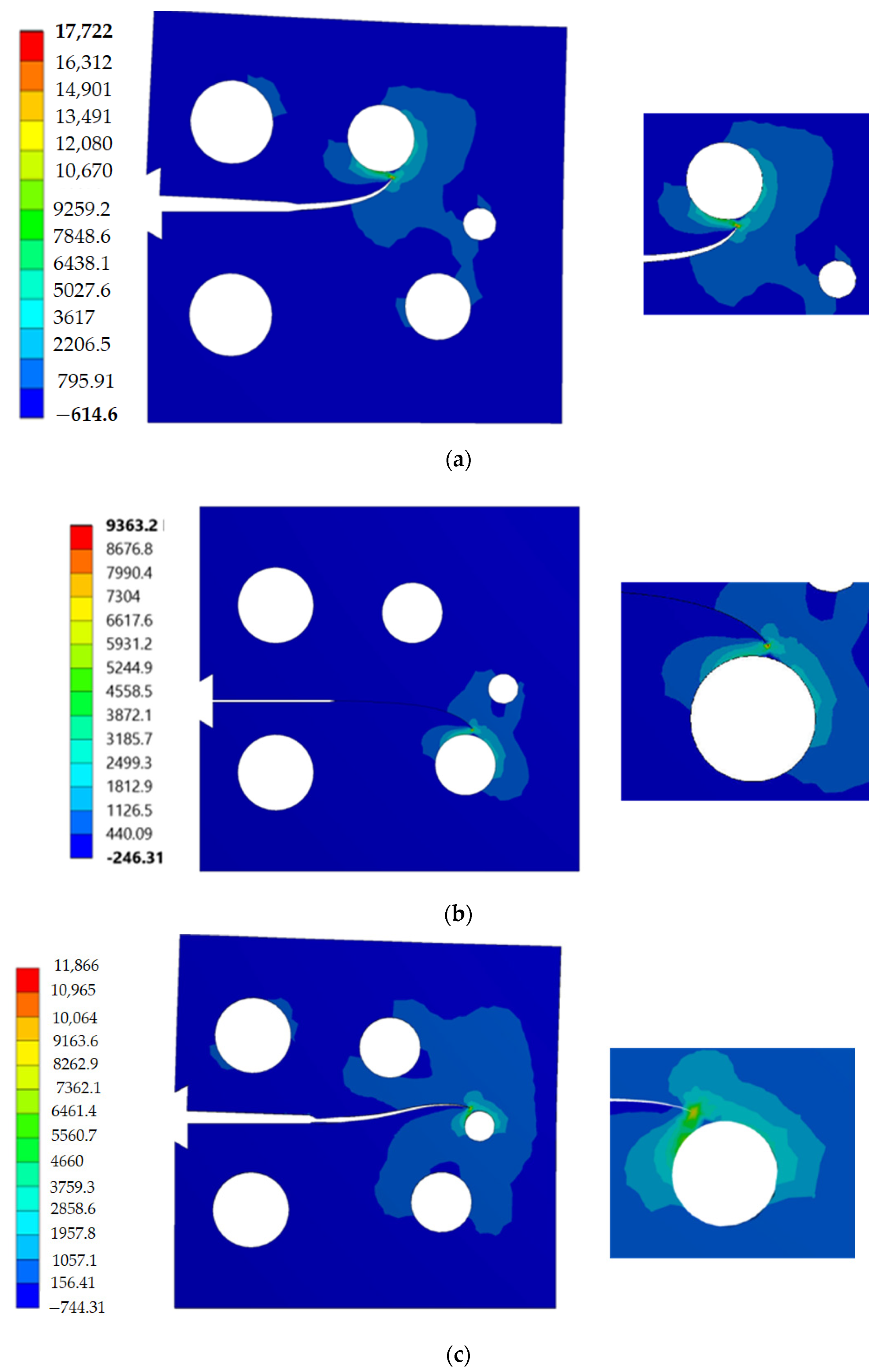

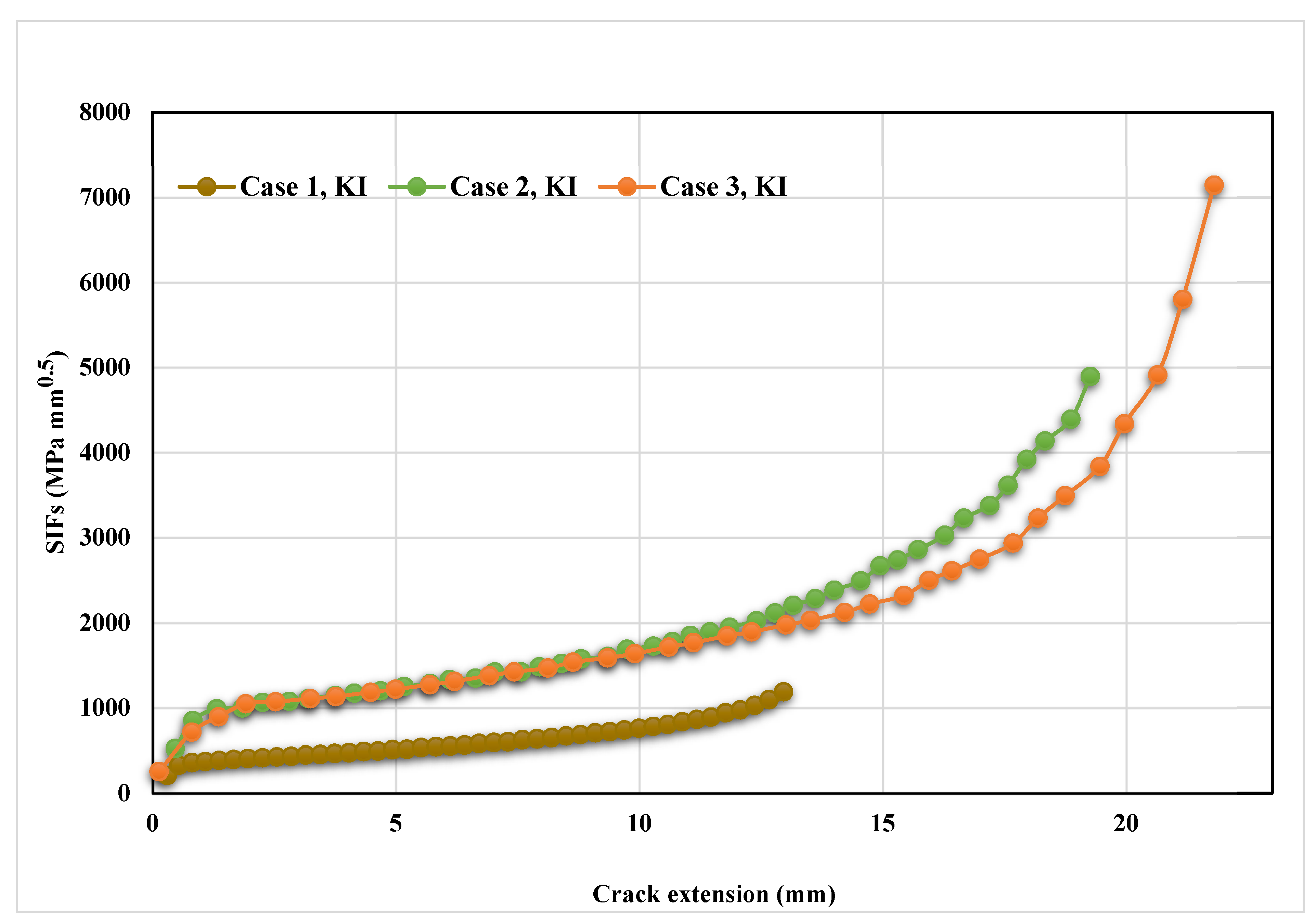

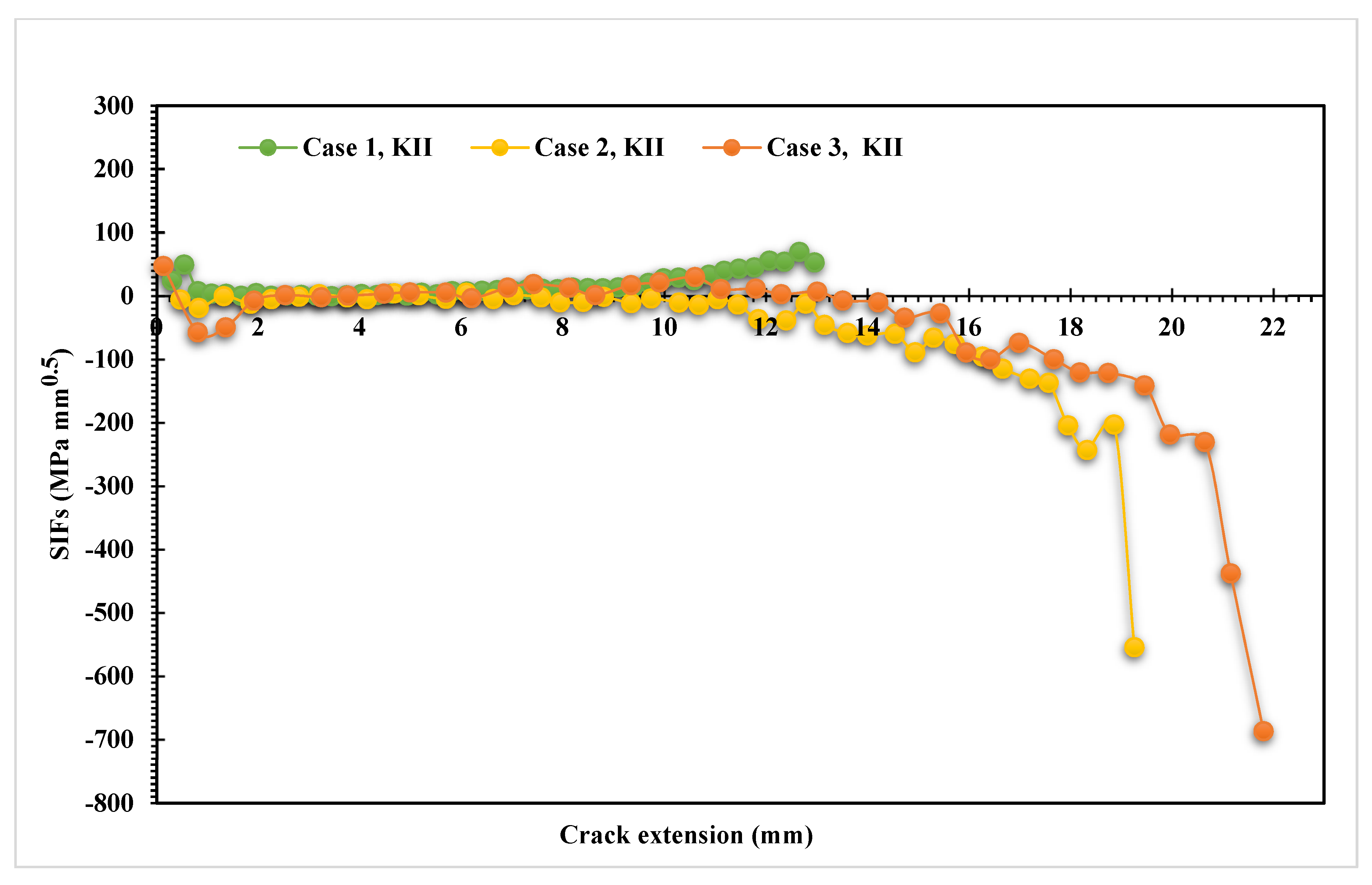

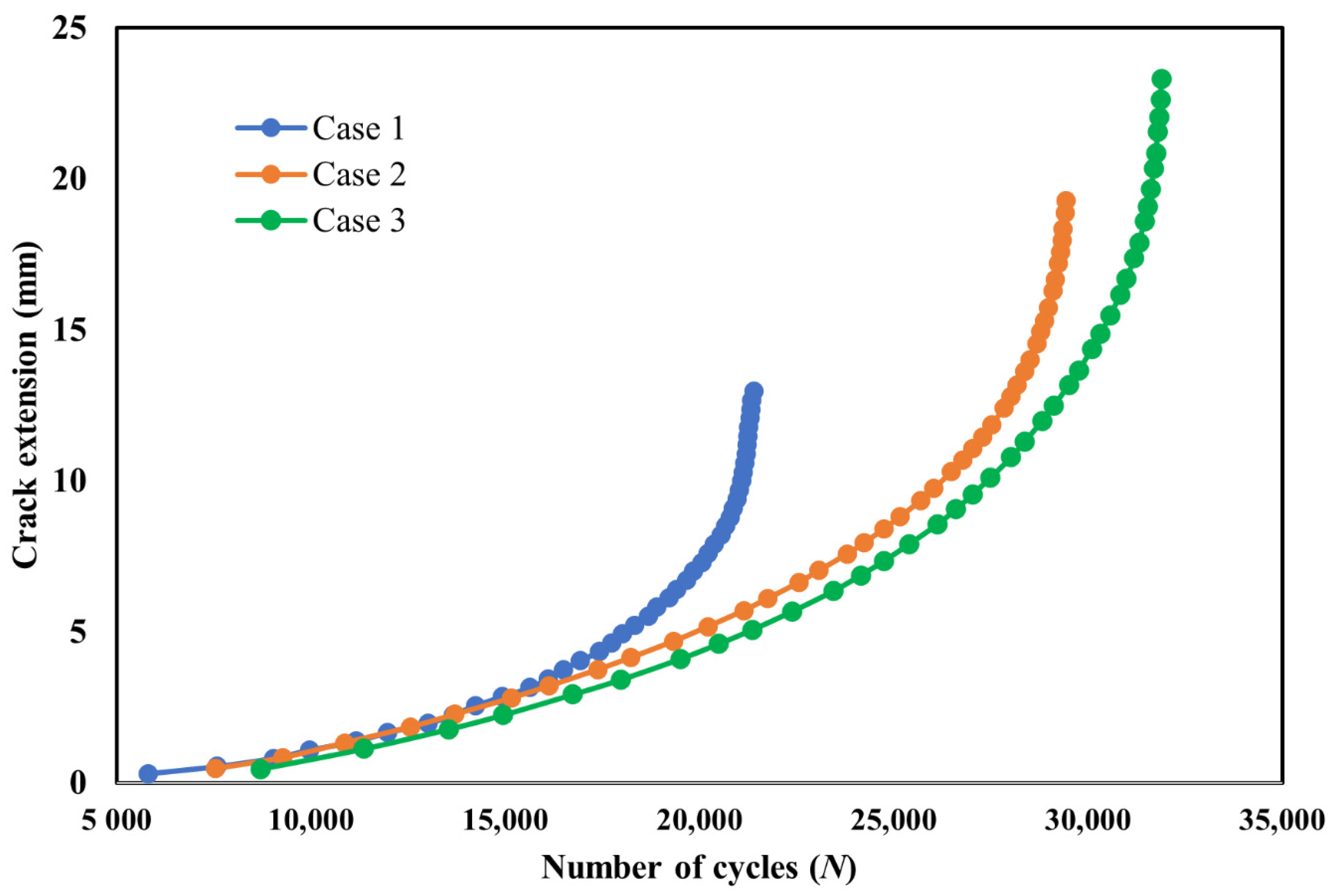

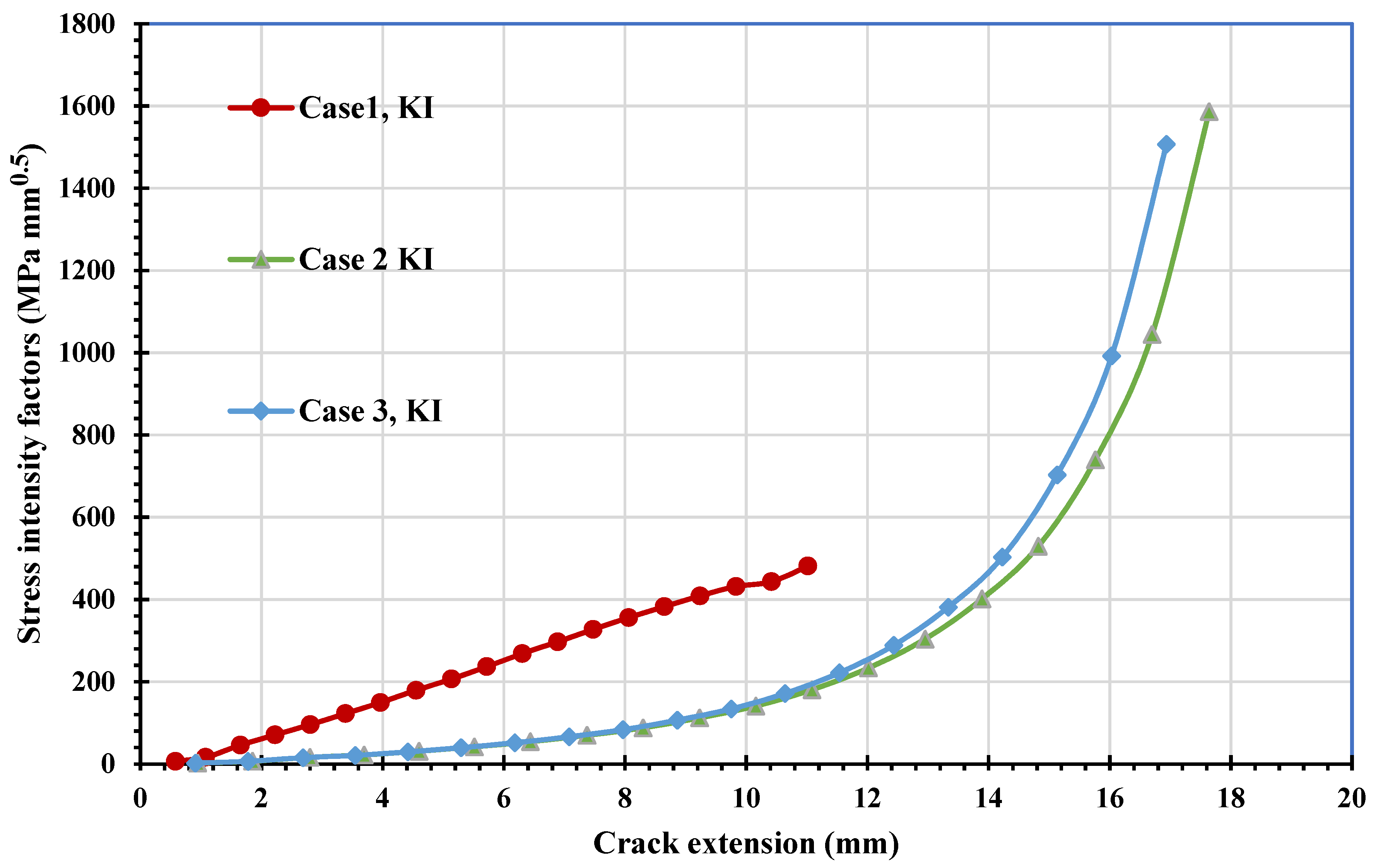

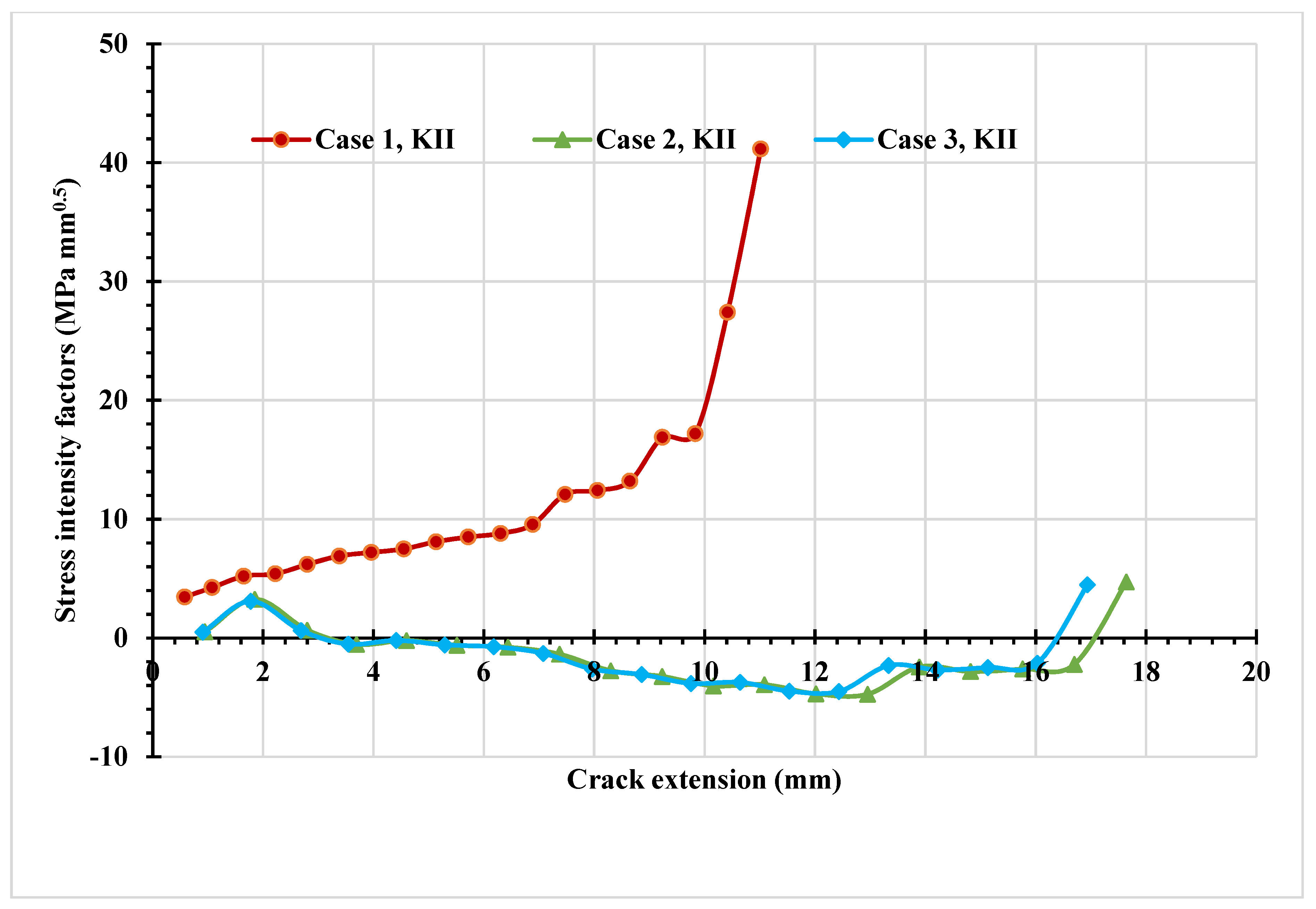

- Three different configurations of the modified compact tension specimen have been investigated in the present study. Wagner [49] conducted the experimental investigation on these specimens, as displayed in Figure 6. The modified specimens differed from standard specimens with three additional holes (Figure 7). These break the symmetry of the standard specimens, yielding curvilinear fatigue crack paths. As illustrated in Figure 7, the vertical notch location (H) is measured with reference to each specimen’s top edge. The notch tip positions in the specimens are represented in Table 2. The initial coordinate for these positions is in the middle of the specimens, beginning from the left-side edge. Depending on the location of the nominal notch, there are three distinct scenarios. Super alloy nickel-based rolled sheets with Young’s modulus E = 211 GPa, the Poisson’s ratio ν = 0.3, yield stress σy = 422 MPa, and ultimate stress σu = 838 MPa were used for these geometries. A 3.6 kN point load with a load ratio of R = 0.1 was applied. Both the crack-tip path and destination varied with the vertical position of the initial notch (H) (above or below its usual centerline location), as shown in Table 2. The initial adaptive 2D mesh for this geometry is shown in Figure 8 with 190,077 nodes and 120,838 elements.

| Specimen Number | Notch Tip Location (mm) | ||

|---|---|---|---|

| (H) | (x) | (y) | |

| Case 1 | 22.4 | −32 | 25.6 |

| Case 2 | 25.6 | −32 | 22.4 |

| Case 3 | 23.2 | −32 | 24.8 |

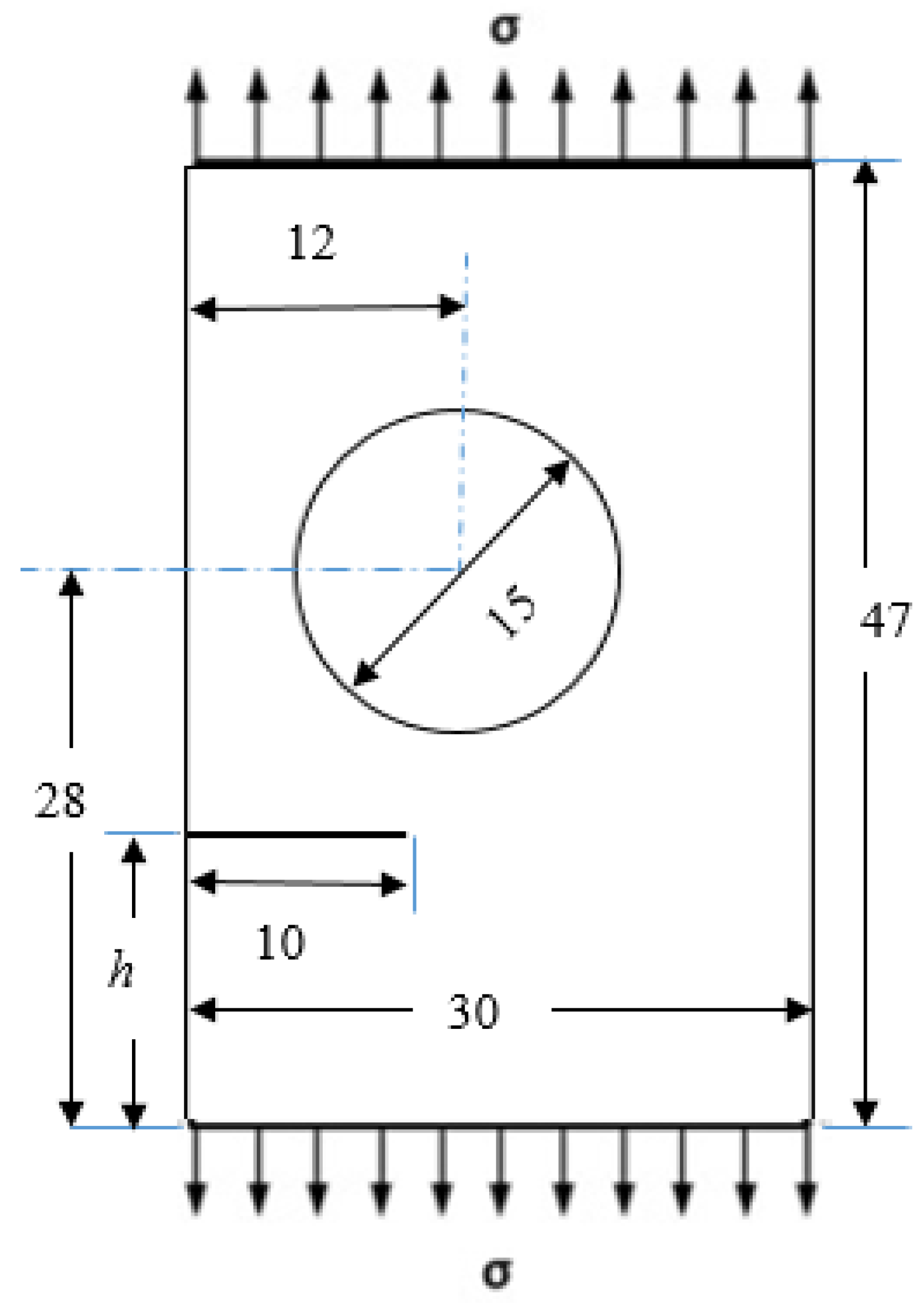

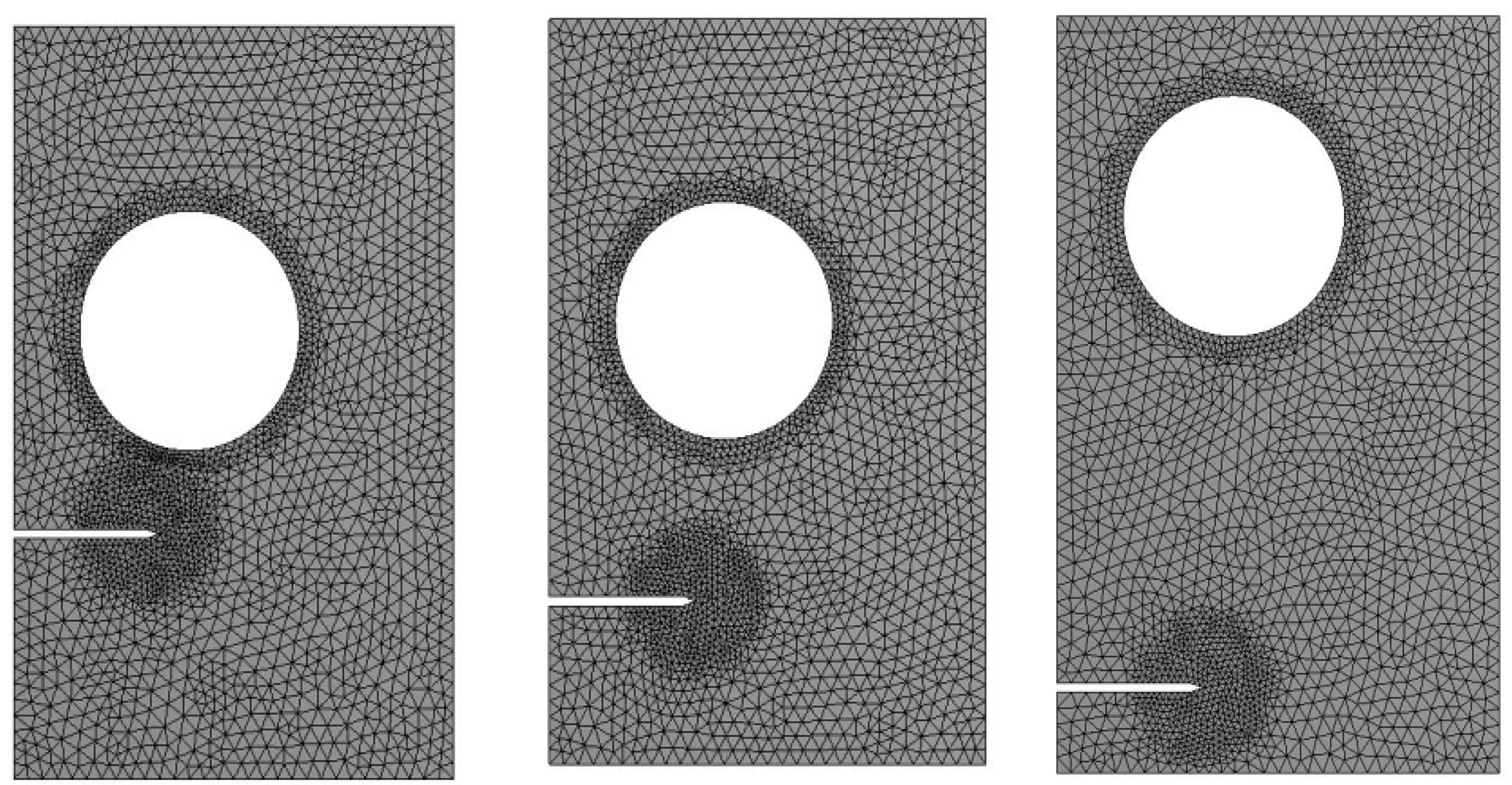

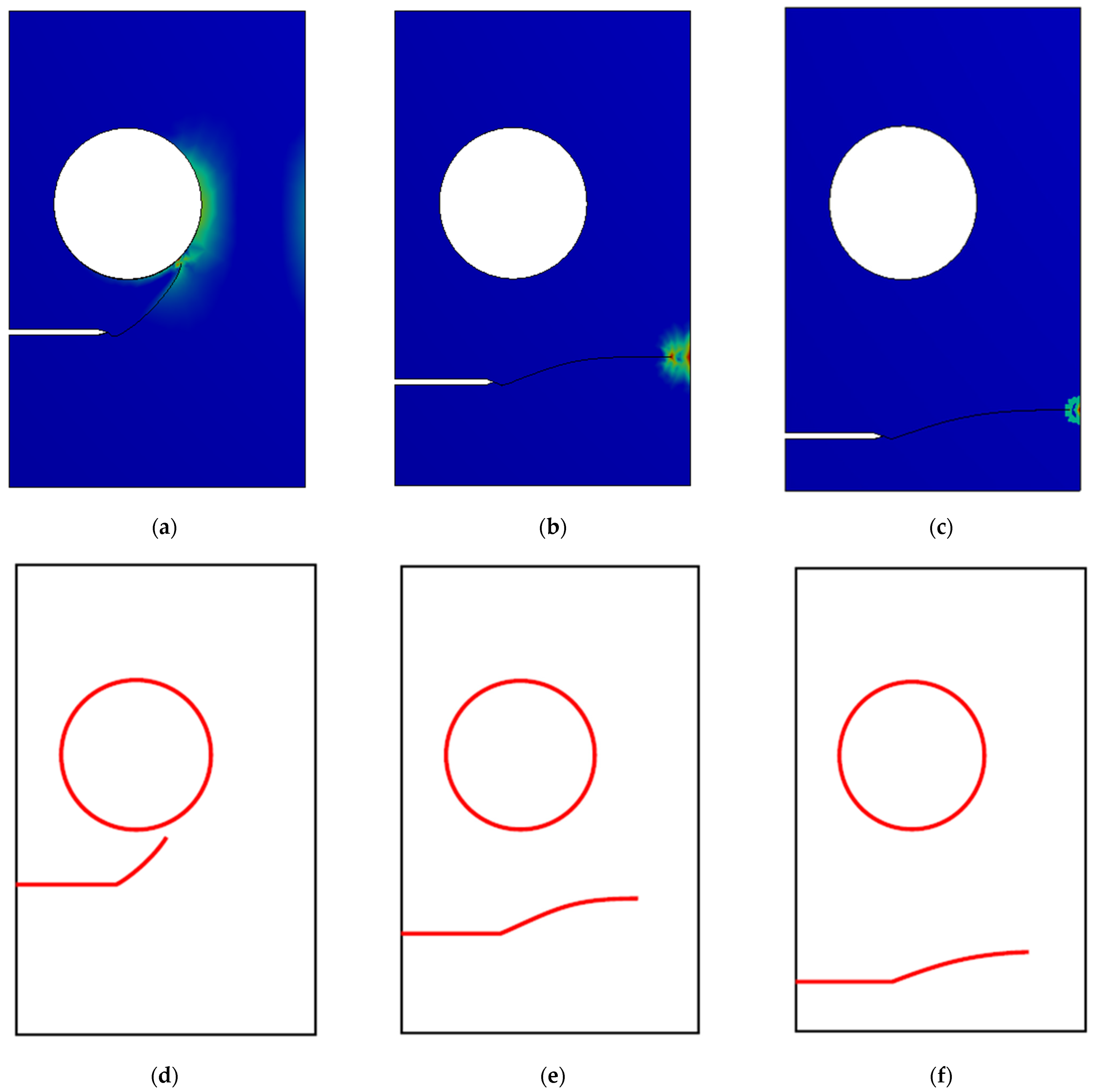

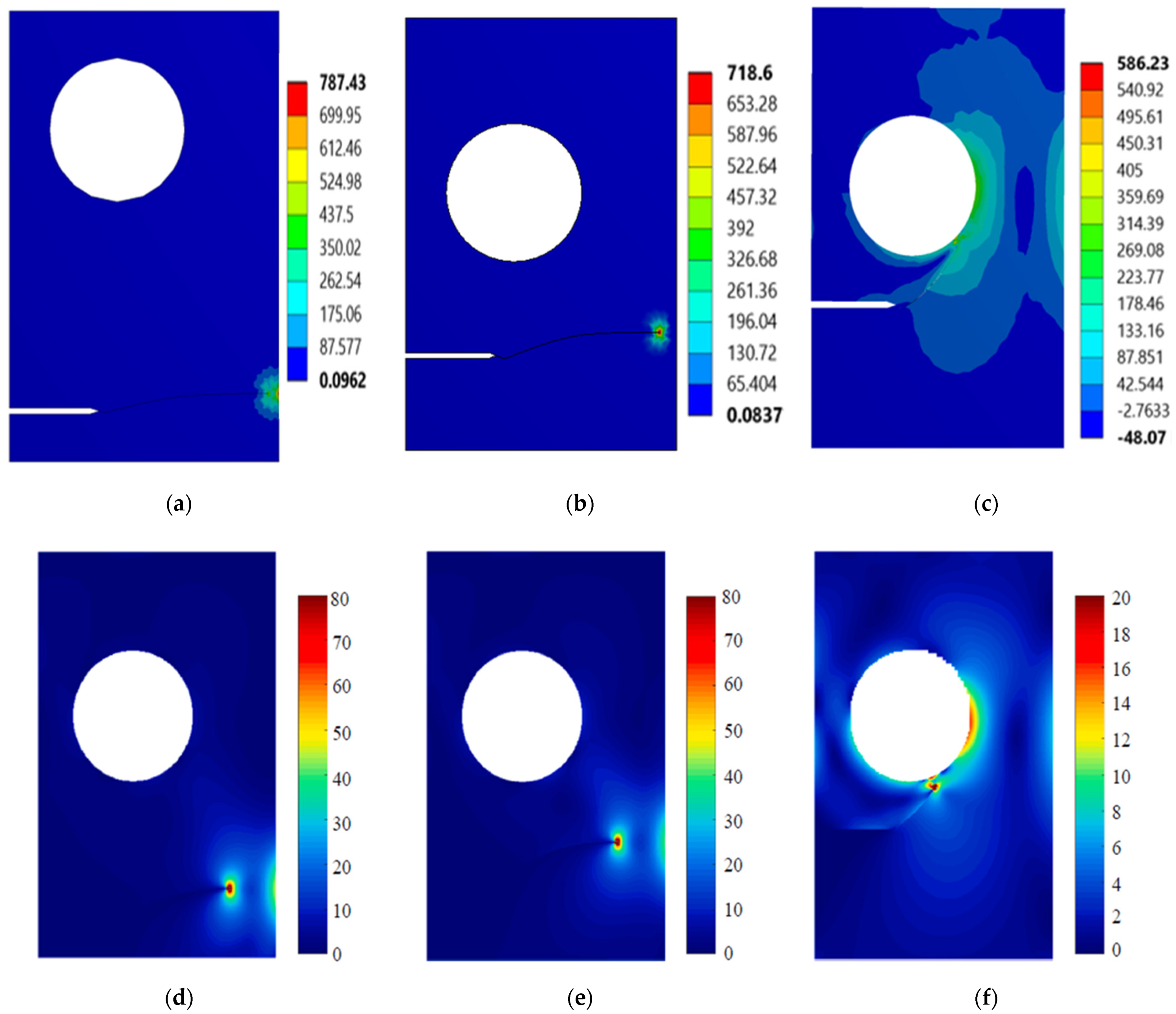

3.2. Plate Having Circular Hole and Edge Crack with Different Initial Crack-Tip Position

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ingraffea, A.R.; de Borst, R. Computational Fracture Mechanics. In Encyclopedia of Computational Mechanics, 2nd ed.; John Wiley & Sons, Ltd.: West Sussex, UK, 2017; pp. 1–26. [Google Scholar]

- Tavares, S.M.; De Castro, P.M. Damage Tolerance of Metallic Aircraft Structures: Materials and Numerical Modelling; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Petinov, S.V. Life-cycle fatigue reliability of ship structures: A proposed system. J. Ship Res. 2000, 44, 33–39. [Google Scholar] [CrossRef]

- Paris, P.C.; Tada, H.; Donald, J.K. Service load fatigue damage—A historical perspective. Int. J. Fatigue 1999, 21, S35–S46. [Google Scholar] [CrossRef]

- Bang, D.; Ince, A.; Noban, M. Modeling approach for a unified crack growth model in short and long fatigue crack regimes. Int. J. Fatigue 2019, 128, 105182. [Google Scholar] [CrossRef]

- Tada, H.; Paris, P.C.; Irwin, G.R. The Stress Analysis of Cracks Handbook; Professional Engineering Publishing: London, UK, 2001; Volume 2, p. 25. [Google Scholar]

- Al Laham, S.; Branch, S.I. Stress Intensity Factor and Limit Load Handbook; British Energy Generation Limited: Gloucester, UK, 1998; Volume 3. [Google Scholar]

- Rooke, D.P.; Cartwright, D.J. Compendium of Stress Intensity Factors. In Procurement Executive, Ministry of Defence; H.M.S.O.: London, UK, 1976; 330p. [Google Scholar]

- Sih, G.C. Handbook of Stress-Intensity Factors: Stress-Intensity Factor Solutions and Formulas for Reference; Lehigh University: Bethlehem, PA, USA, 1973; 815p. [Google Scholar]

- Li, X.; Li, H.; Liu, L.; Liu, Y.; Ju, M.; Zhao, J. Investigating the crack initiation and propagation mechanism in brittle rocks using grain-based finite-discrete element method. Int. J. Rock Mech. Min. Sci. 2020, 127, 104219. [Google Scholar] [CrossRef]

- Leclerc, W.; Haddad, H.; Guessasma, M. On the suitability of a Discrete Element Method to simulate cracks initiation and propagation in heterogeneous media. Int. J. Solids Struct. 2017, 108, 98–114. [Google Scholar] [CrossRef]

- Shao, Y.; Duan, Q.; Qiu, S. Adaptive consistent element-free Galerkin method for phase-field model of brittle fracture. Comput. Mech. 2019, 64, 741–767. [Google Scholar] [CrossRef]

- Kanth, S.A.; Harmain, G.; Jameel, A. Modeling of Nonlinear Crack Growth in Steel and Aluminum Alloys by the Element Free Galerkin Method. Mater. Today Proc. 2018, 5, 18805–18814. [Google Scholar] [CrossRef]

- Surendran, M.; Natarajan, S.; Palani, G.; Bordas, S.P. Linear smoothed extended finite element method for fatigue crack growth simulations. Eng. Fract. Mech. 2019, 206, 551–564. [Google Scholar] [CrossRef]

- Fageehi, Y.A.; Alshoaibi, A.M. Numerical Simulation of Mixed-Mode Fatigue Crack Growth for Compact Tension Shear Specimen. Adv. Mater. Sci. Eng. 2020, 2020, 5426831. [Google Scholar] [CrossRef] [Green Version]

- Dekker, R.; van der Meer, F.; Maljaars, J.; Sluys, L. A cohesive XFEM model for simulating fatigue crack growth under mixed-mode loading and overloading. Int. J. Numer. Methods Eng. 2019, 118, 561–577. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Tabiei, A. An Efficient Implementation of Phase Field Method with Explicit Time Integration. J. Appl. Comput. Mech. 2020, 6, 373–382. [Google Scholar]

- Fageehi, Y.A.; Alshoaibi, A.M. Nonplanar Crack Growth Simulation of Multiple Cracks Using Finite Element Method. Adv. Mater. Sci. Eng. 2020, 2020, 8379695. [Google Scholar] [CrossRef] [Green Version]

- Ma, W.; Liu, G.; Wang, W. A coupled extended meshfree–smoothed meshfree method for crack growth simulation. Theor. Appl. Fract. Mech. 2020, 107, 102572. [Google Scholar] [CrossRef]

- Chan, S.; Tuba, I.; Wilson, W. On the finite element method in linear fracture mechanics. Eng. Fract. Mech. 1970, 2, 1–17. [Google Scholar] [CrossRef]

- Irwin, G.R. Analysis of stresses and strains near the end of a crack transversing a plate. Trans. ASME Ser. E J. Appl. Mech. 1957, 24, 361–364. [Google Scholar] [CrossRef]

- Rybicki, E.F.; Kanninen, M.F. A finite element calculation of stress intensity factors by a modified crack closure integral. Eng. Fract. Mech. 1977, 9, 931–938. [Google Scholar] [CrossRef]

- Rice, J.R. A path independent integral and the approximate analysis of strain concentration by notches and cracks. J. Appl. Mech. 1968, 35, 379–386. [Google Scholar] [CrossRef] [Green Version]

- Xuan, Z.; Khoo, B.; Li, Z. Computing bounds to mixed-mode stress intensity factors in elasticity. Arch. Appl. Mech. 2006, 75, 193–209. [Google Scholar] [CrossRef]

- Alshoaibi, A.M.; Fageehi, Y.A. 2D finite element simulation of mixed mode fatigue crack propagation for CTS specimen. J. Mater. Res. Technol. 2020, 9, 7850–7861. [Google Scholar] [CrossRef]

- Alshoaibi, A.M. Finite element procedures for the numerical simulation of fatigue crack propagation under mixed mode loading. Struct. Eng. Mech. 2010, 35, 283–299. [Google Scholar] [CrossRef]

- Alshoaibi, A.M.; Hadi, M.; Ariffin, A. Finite element simulation of fatigue life estimation and crack path prediction of two-dimensional structures components. HKIE Trans. 2008, 15, 1–6. [Google Scholar] [CrossRef]

- Bashiri, A.H.; Alshoaibi, A.M. Adaptive Finite Element Prediction of Fatigue Life and Crack Path in 2D Structural Components. Metals 2020, 10, 1316. [Google Scholar] [CrossRef]

- Alshoaibi, A.M.; Fageehi, Y.A. Simulation of Quasi-Static Crack Propagation by Adaptive Finite Element Method. Metals 2021, 11, 98. [Google Scholar] [CrossRef]

- Alshoaibi, A.M.; Hadi, M.; Ariffin, A. Two-dimensional numerical estimation of stress intensity factors and crack propagation in linear elastic Analysis. J. Struct. Durab. Health Monit. 2007, 3, 15–27. [Google Scholar]

- Alshoaibi, A.M.; Ariffin, A. Finite element modeling of fatigue crack propagation using a self adaptive mesh strategy. Int. Rev. Aerosp. Eng. (IREASE) 2015, 8, 209–215. [Google Scholar] [CrossRef]

- Liu, G.; Tu, Z. An adaptive procedure based on background cells for meshless methods. Comput. Methods Appl. Mech. Eng. 2002, 191, 1923–1943. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, Z.; Wang, M. An adaptive interpolation element free Galerkin method based on a posteriori error estimation of FEM for Poisson equation. Eng. Anal. Bound. Elem. 2021, 130, 186–195. [Google Scholar] [CrossRef]

- Cavendish, J.C. Automatic triangulation of arbitrary planar domains for the finite element method. Int. J. Numer. Methods Eng. 1974, 8, 679–696. [Google Scholar] [CrossRef]

- Bittencourt, T.; Wawrzynek, P.; Ingraffea, A.; Sousa, J. Quasi-automatic simulation of crack propagation for 2D LEFM problems. Eng. Fract. Mech. 1996, 55, 321–334. [Google Scholar] [CrossRef]

- Phongthanapanich, S.; Dechaumphai, P. Adaptive Delaunay triangulation with object-oriented programming for crack propagation analysis. Finite Elem. Anal. Des. 2004, 40, 1753–1771. [Google Scholar] [CrossRef]

- Erdogan, F.; Sih, G. On the crack extension in plates under plane loading and transverse shear. J. Basic Eng. 1963, 85, 519–525. [Google Scholar] [CrossRef]

- Chang, K.J. On the maximum strain criterion—a new approach to the angled crack problem. Eng. Fract. Mech. 1981, 14, 107–124. [Google Scholar] [CrossRef]

- Hussain, M.; Pu, S.; Underwood, J. Strain energy release rate for a crack under combined mode I and mode II. In Fracture Analysis, Proceedings of the 1973 National Symposium on Fracture Mechanics, Part II; ASTM: West Conshohocken, PA, USA, 1974. [Google Scholar]

- Nuismer, R. An energy release rate criterion for mixed mode fracture. Int. J. Fract. 1975, 11, 245–250. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Barsoum, R.S. Application of quadratic isoparametric finite elements in linear fracture mechanics. Int. J. Fract. 1974, 10, 603–605. [Google Scholar] [CrossRef]

- Henshell, R.; Shaw, K. Crack tip finite elements are unnecessary. Int. J. Numer. Methods Eng. 1975, 9, 495–507. [Google Scholar] [CrossRef]

- Wanhill, R.; Barter, S.; Molent, L. Fatigue Crack Growth Failure and Lifing Analyses for Metallic Aircraft Structures and Components; Springer: Heidelberg, Germany, 2019. [Google Scholar]

- Tanaka, K. Fatigue crack propagation from a crack inclined to the cyclic tensile axis. Eng. Fract. Mech. 1974, 6, 493–507. [Google Scholar] [CrossRef]

- Richard, H.A.; Buchholz, F.G.; Kullmer, G.; Schöllmann, M. 2D-and 3D-mixed mode fracture criteria. Key Eng. Mater. 2003, 251, 251–260. [Google Scholar] [CrossRef]

- Richard, H.; Schramm, B.; Schirmeisen, N.-H. Cracks on mixed mode loading—Theories, experiments, simulations. Int. J. Fatigue 2014, 62, 93–103. [Google Scholar] [CrossRef]

- Demir, O.; Ayhan, A.O.; İriç, S. A new specimen for mixed mode-I/II fracture tests: Modeling, experiments and criteria development. Eng. Fract. Mech. 2017, 178, 457–476. [Google Scholar] [CrossRef]

- Wagner, D. A Finite Element-Based Adaptive Energy Response Function Method for Curvilinear Progressive Fracture. Ph.D. Thesis, The University of Texas at San Antonio, San Antonio, TX, USA, 2018. [Google Scholar]

- Alshoaibi, A.M.; Abdulrahman, A.B.G.; Yahya, A.F. Three-Dimensional Simulation of Crack Propagation using Finite Element Method. Int. J. Eng. Adv. Technol. 2019, 9, 892–897. [Google Scholar]

- Wagner, D.; Garcia, M.J.; Montoya, A.; Millwater, H. A finite element-based adaptive energy response function method for 2D curvilinear progressive fracture. Int. J. Fatigue 2019, 127, 229–245. [Google Scholar] [CrossRef]

- Fang, W.; Chen, X.; Yu, T.; Bui, T.Q. Effects of arbitrary holes/voids on crack growth using local mesh refinement adaptive XIGA. Theor. Appl. Fract. Mech. 2020, 109, 102724. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshoaibi, A.M.; Fageehi, Y.A. Adaptive Finite Element Model for Simulating Crack Growth in the Presence of Holes. Materials 2021, 14, 5224. https://doi.org/10.3390/ma14185224

Alshoaibi AM, Fageehi YA. Adaptive Finite Element Model for Simulating Crack Growth in the Presence of Holes. Materials. 2021; 14(18):5224. https://doi.org/10.3390/ma14185224

Chicago/Turabian StyleAlshoaibi, Abdulnaser M., and Yahya Ali Fageehi. 2021. "Adaptive Finite Element Model for Simulating Crack Growth in the Presence of Holes" Materials 14, no. 18: 5224. https://doi.org/10.3390/ma14185224

APA StyleAlshoaibi, A. M., & Fageehi, Y. A. (2021). Adaptive Finite Element Model for Simulating Crack Growth in the Presence of Holes. Materials, 14(18), 5224. https://doi.org/10.3390/ma14185224