2.3. Test Methods

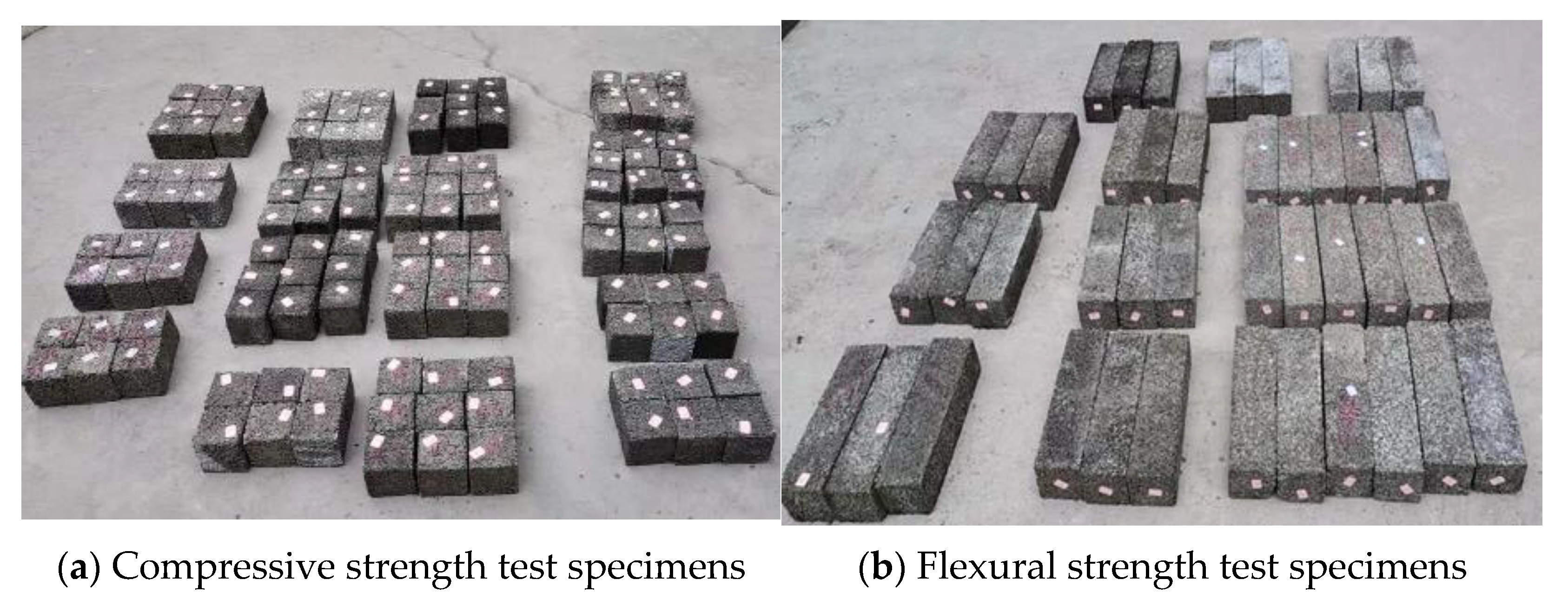

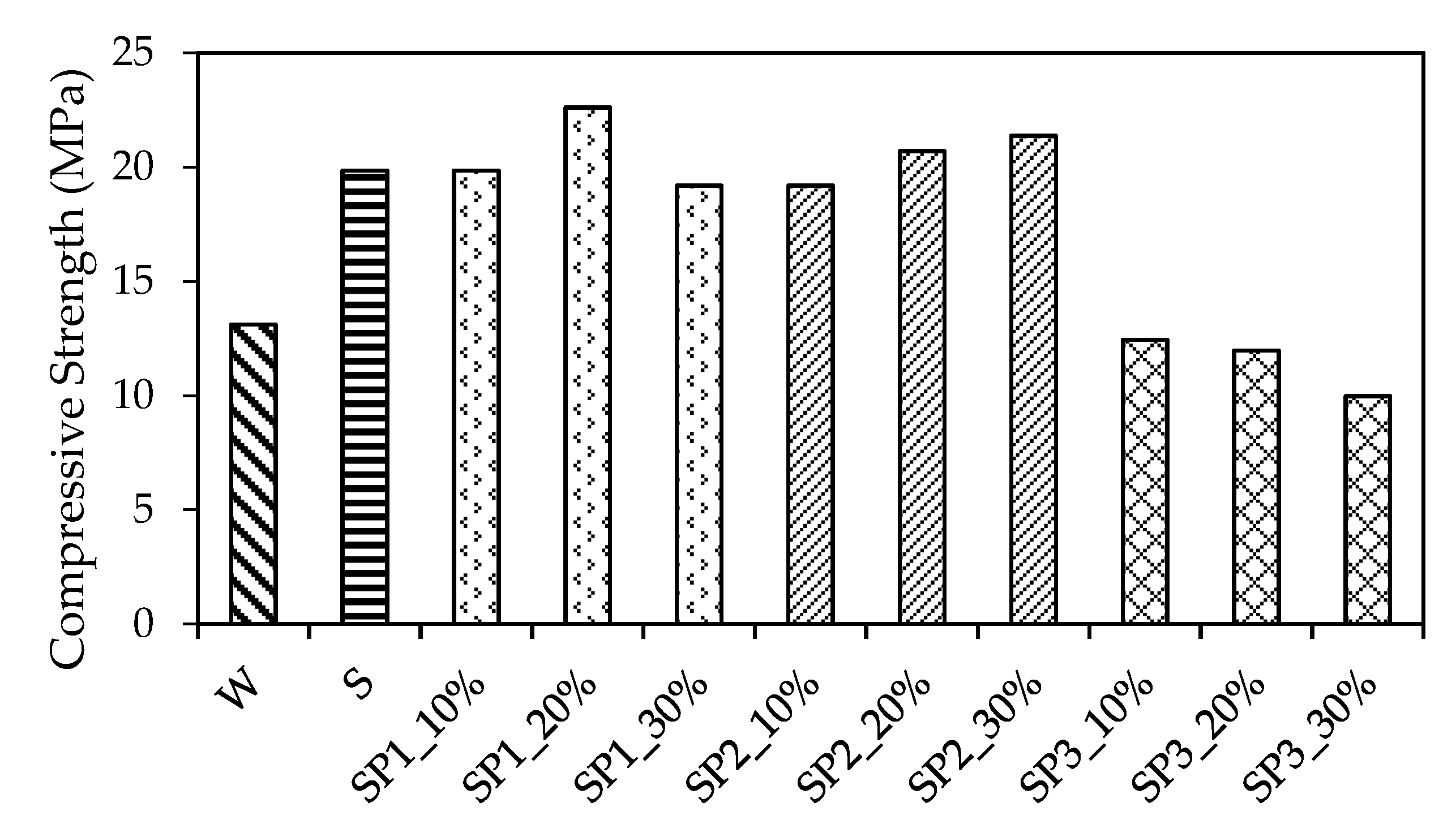

In this research, CMPC’s toughness is presented with compressive strength, flexural strength, flexural stiffness, impact resistance, and fracture toughness, so that the cube specimens, beam specimens, and cylindrical specimens were prepared for the corresponding test. Each test was carried out in 11 scenarios of the additive level for copolymer latex. The number of specimens for each scenario was six for the compressive strength test, three for the flexural strength test, three for the flexural stiffness test, five for the impact resistance test, and three for the fracture toughness test. The total number of specimens was 220. The specimens’ sizes and numbers are detailed in

Table 4.

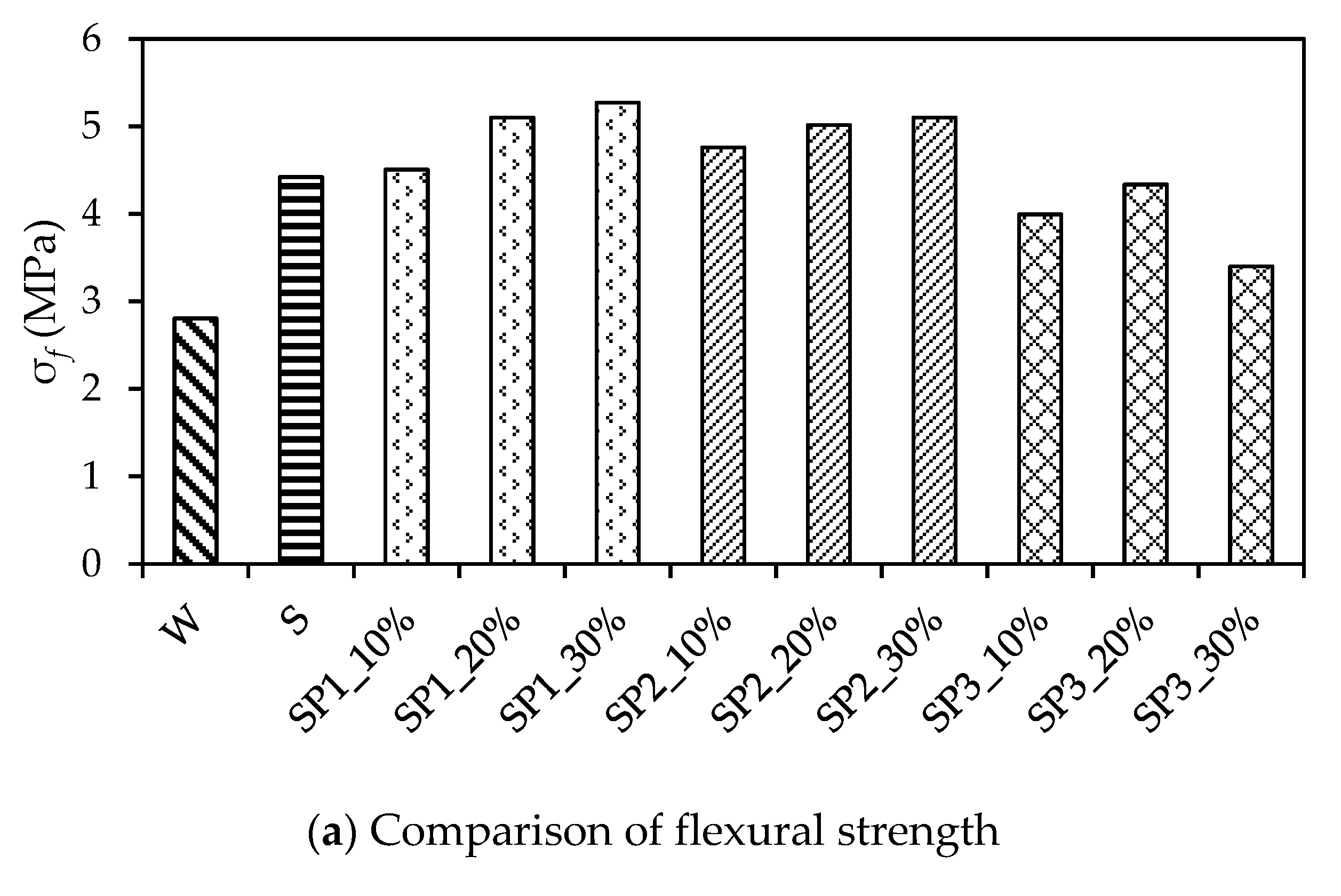

Compressive strength test and flexural strength test: The compressive strength and flexural strength were tested by following the Chinese Standard GB/T 50081 [

35]. The cube specimens and beam specimens cured for 28 days were prepared as in

Figure 2a,b. The compressive strength tests were conducted on a WHY-3000 microcomputer-controlled automatic compression testing machine, as shown in

Figure 2c. The flexural strength of the specimen was measured by the four-point bending test method, as shown in

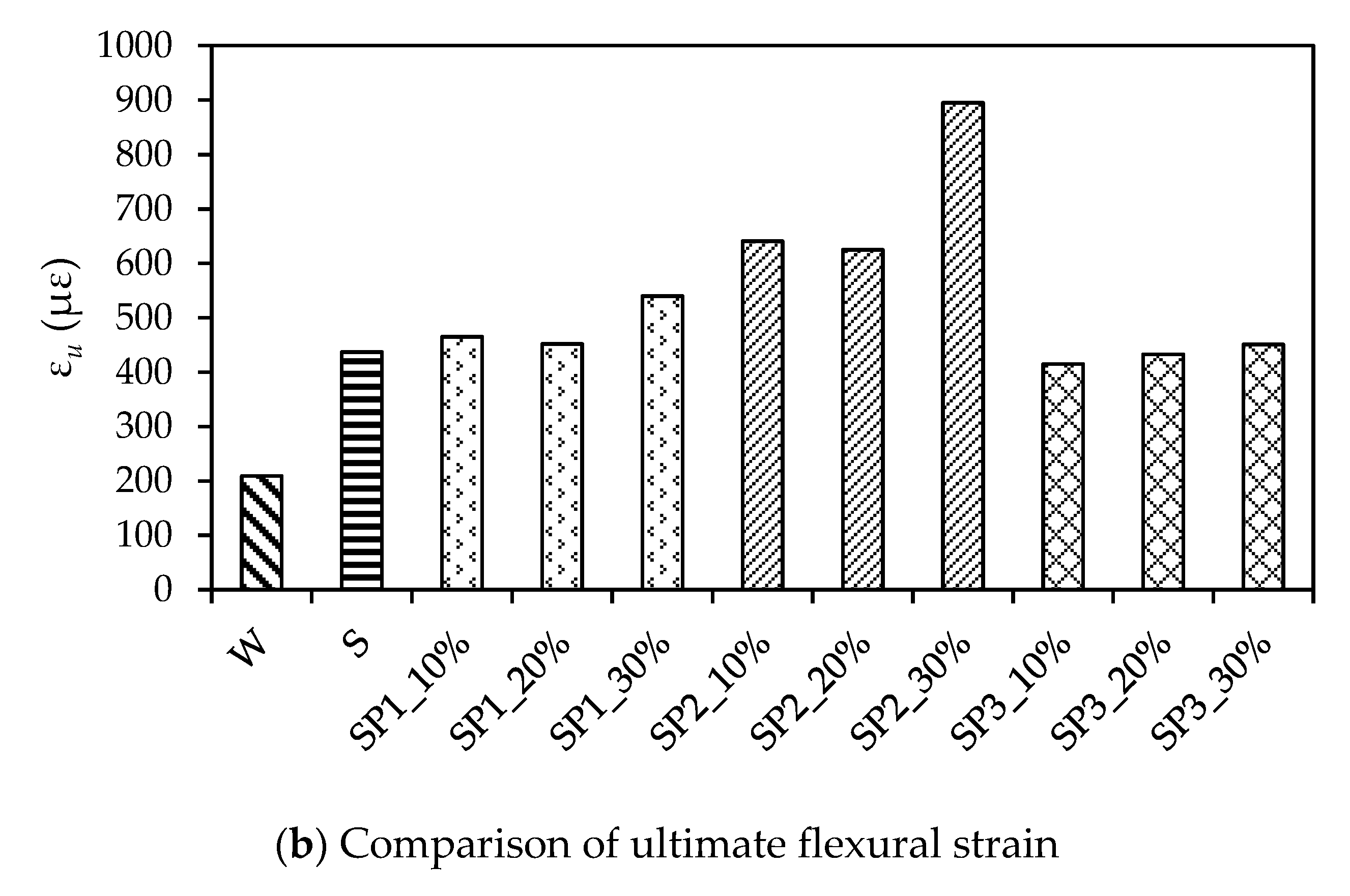

Figure 2d. Two strain gauges aiming to detect the ultimate flexural strain were attached to the middle section of the specimen’s bottom, as shown in

Figure 2e. Its sensing signal was transmitted by cables to the High-Speed Static Strain Data Acquisition and Analysis System, as shown in

Figure 2f. The flexural strength was tested on a CMT5504 microcomputer-controlled electronic universal testing machine and was calculated as follows:

where

is the flexural strength (MPa),

is the rupture load,

is the distance between the supports (300 mm),

b is the width of the specimen (100 mm), and

h is the height of the specimen (100 mm).

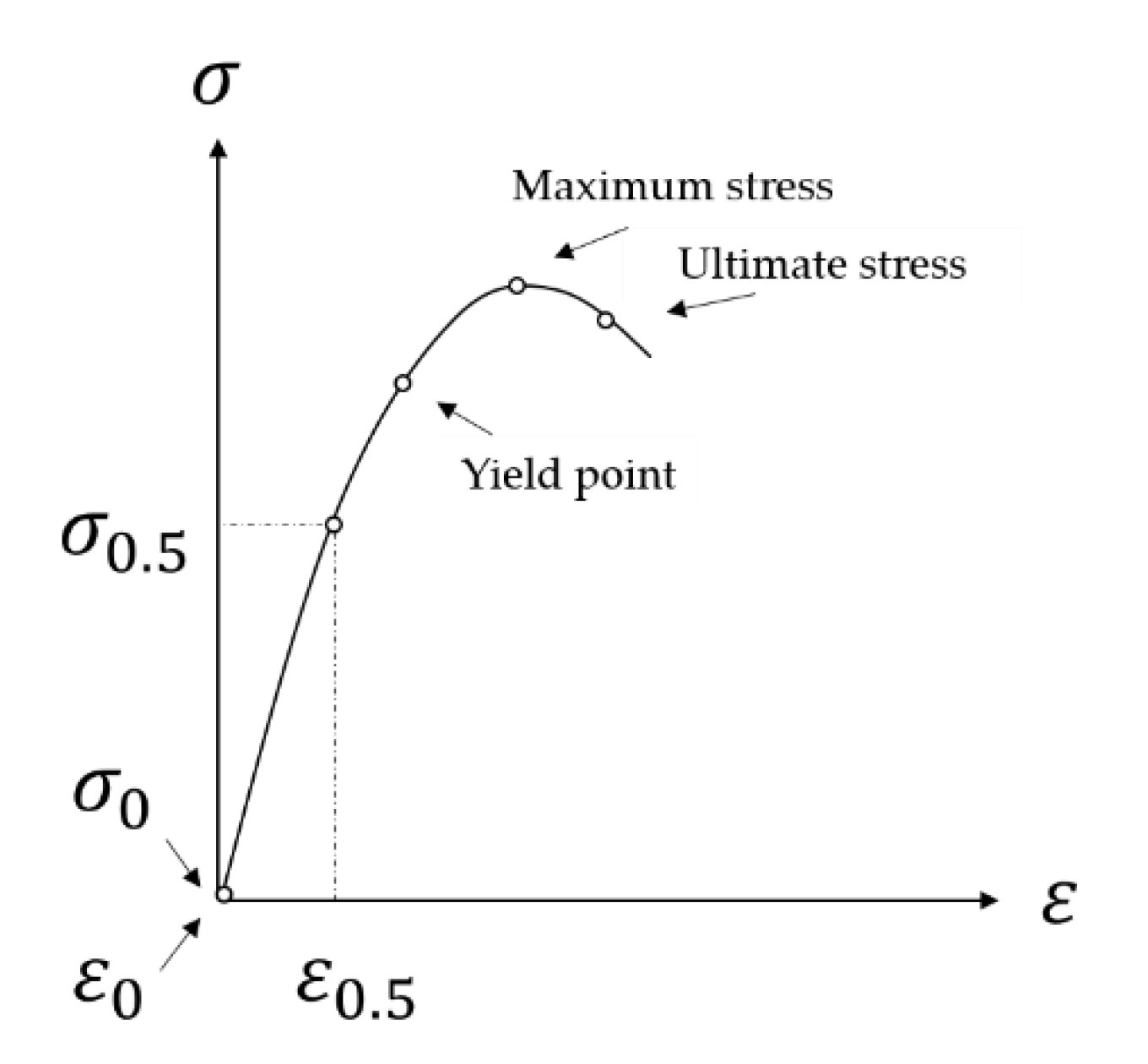

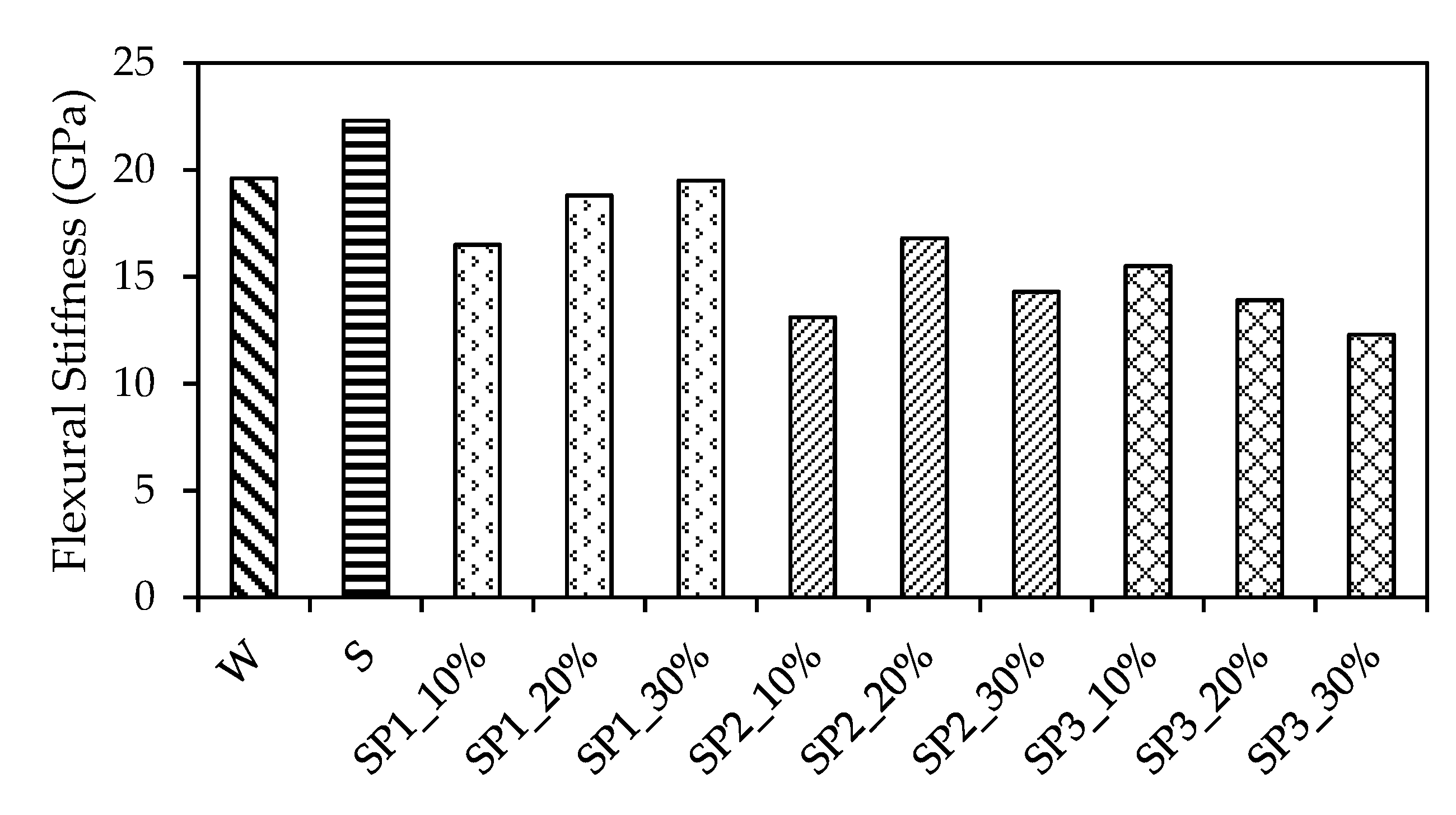

Flexural stiffness test: The flexural stiffness revealed the stiffness measured in bend for characterizing the property of concrete pavement on orthotropic steel decks or subgrade [

42]. The flexural stiffness was defined as the slope line that connected the origin and yield point by means of a bending stress–strain schematic method according to the literature [

43,

44], as shown in

Figure 3. Nevertheless, the yield point is hard to detect so that the stress and strain under half of the rupture load, namely,

in

Figure 3, are adopted in this study according to Chinese Standard JTG 3420 [

45].

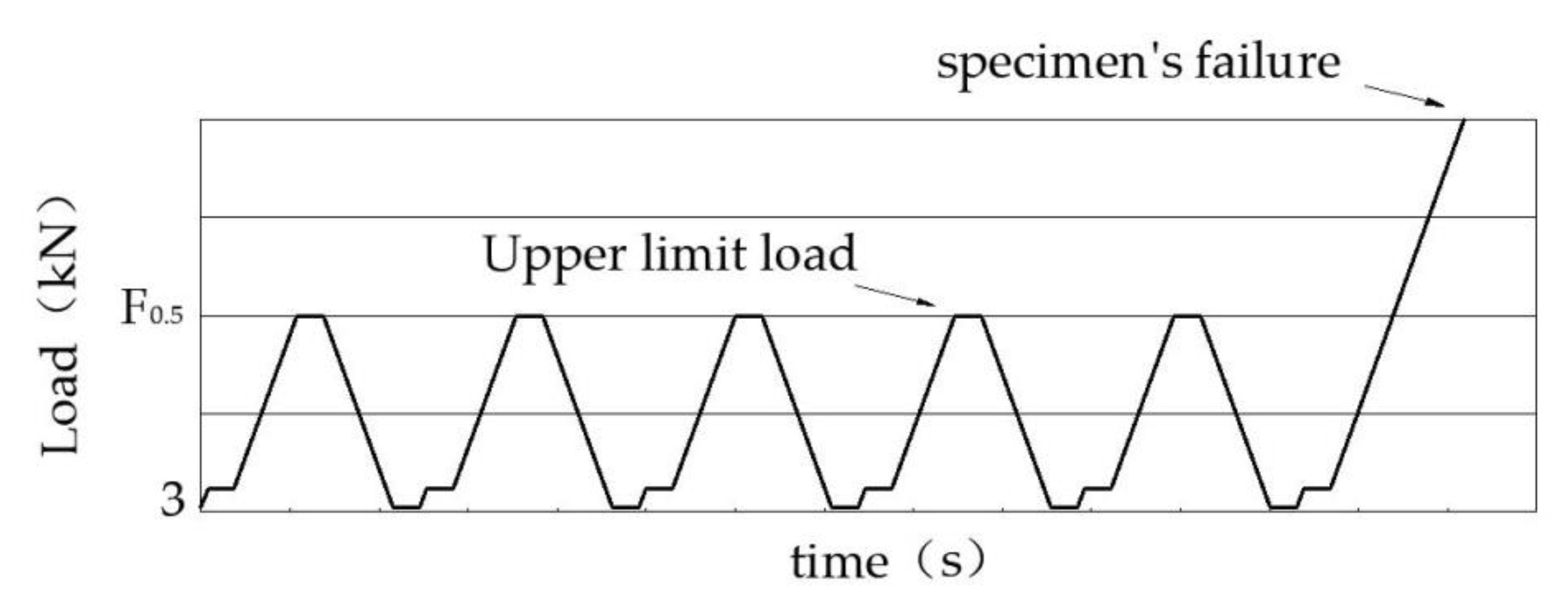

The flexural stiffness of the specimens was tested at 28 days. Its test procedure was roughly similar to the flexural strength test; the only difference was the loading manner. The loading process was undertaken for five cycles as shown in

Figure 4, in which the upper limit load was half of the rupture load, which was determined from the flexural strength test. The flexural strain was also detected by the strain gauges and High-Speed Static Strain Data Acquisition and Analysis System, as shown in

Figure 2f. The flexural stiffness could be calculated by the following equations:

where E is the flexural stiffness at 28 days (MPa),

and

represent the flexural stress and strain increment of the specimen when loading from the initial state to the upper limit load.

and

are the specimen’s flexural stress and strain subjected to half of the rupture load (

),

and

are the specimen’s initial flexural stress and strain (

),

is the upper limit load (kN),

is the initial load (3 kN),

is the distance between the supports (300 mm),

h is the height of the specimen (100 mm), and

b is the width of the specimen (100 mm).

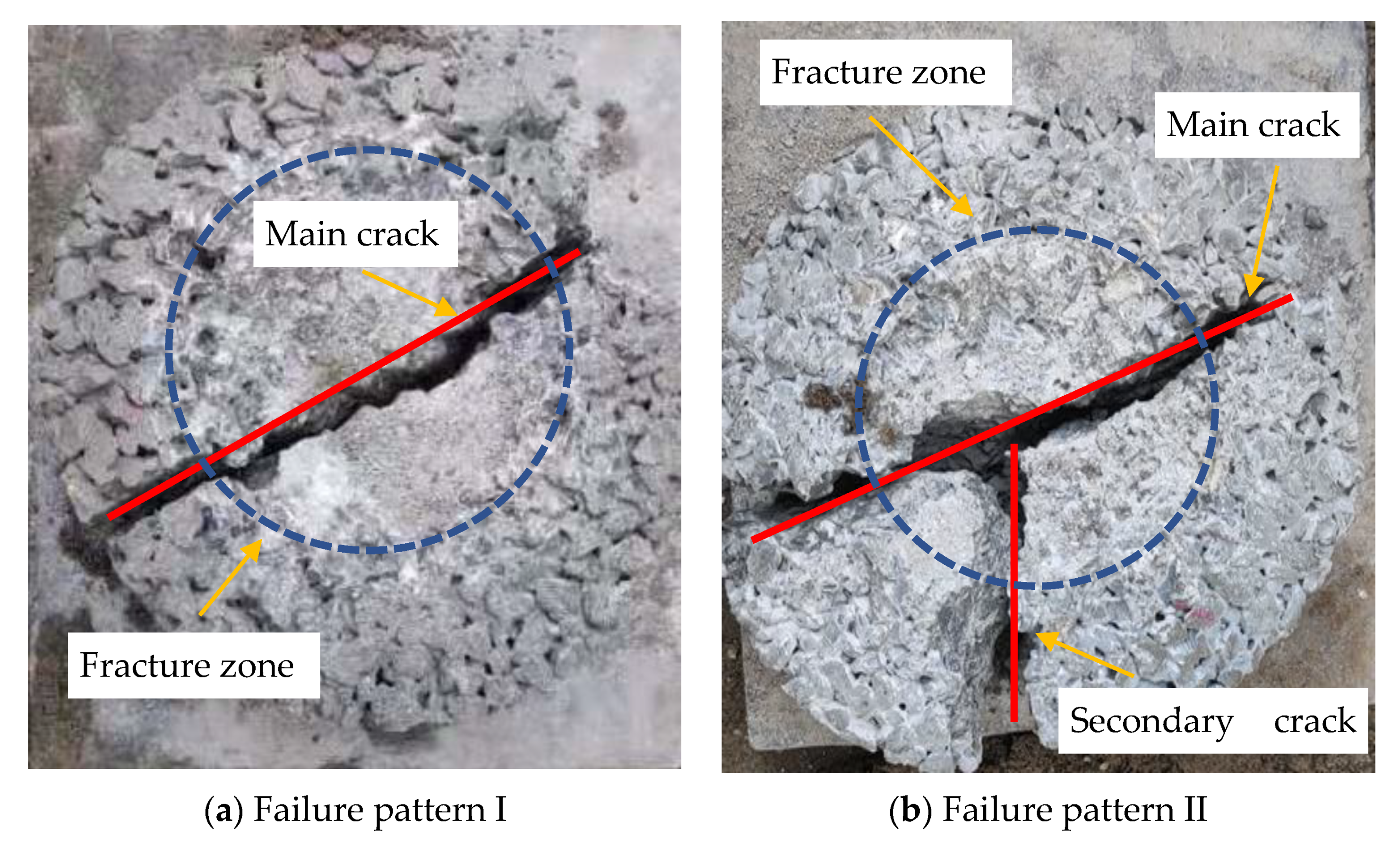

Impact resistance test: Impact resistance represents the CMPC’s energy absorption capability under repeated impact load. The impact resistance was tested at 28 days by using the Repeated Blows Drop Weight Impact (RBDWI) test according to American standard ACI 544-2R [

32]. The blow numbers of the specimen’s first cracking and failure were considered as impact resistance; thus, the specimen’s absorbed impact energy could be calculated. In this research, modifications were suggested to simplify the test procedures. One steel ball with a 160 mm diameter and a 3 kg mass was used as a load distributor, while another steel ball with the same diameter and mass was used as a drop-weight and was dropped from the distance of approximately 690 mm to agree with the standard ACI 544-2R in terms of impact energy. The specimens were prepared as shown in

Figure 5a. It was necessary to horizontally lay the specimen on the ground and locate the load-distributing ball on the central point of the specimen’s upper surface during the test, as shown in

Figure 5b. A cylinder was used to fix the location of the load-distributing ball and dropping ball instead of the steel holding frame and steel holding ring so that the drop weight could drop freely on the top of the cylinder and directly impact the load-distributing ball, as shown in

Figure 5c. The blow numbers were recorded, where

N1 denotes the first cracking number of blows, and

N2 is the failure number of blows. The impact energy is calculated as follows:

where

W is the absorbed impact energy by specimen,

N is the number of blows,

m is the drop weight (3 kg), g is the gravity acceleration (9.8 m/s

2), and

h is the drop distance (0.69 m).

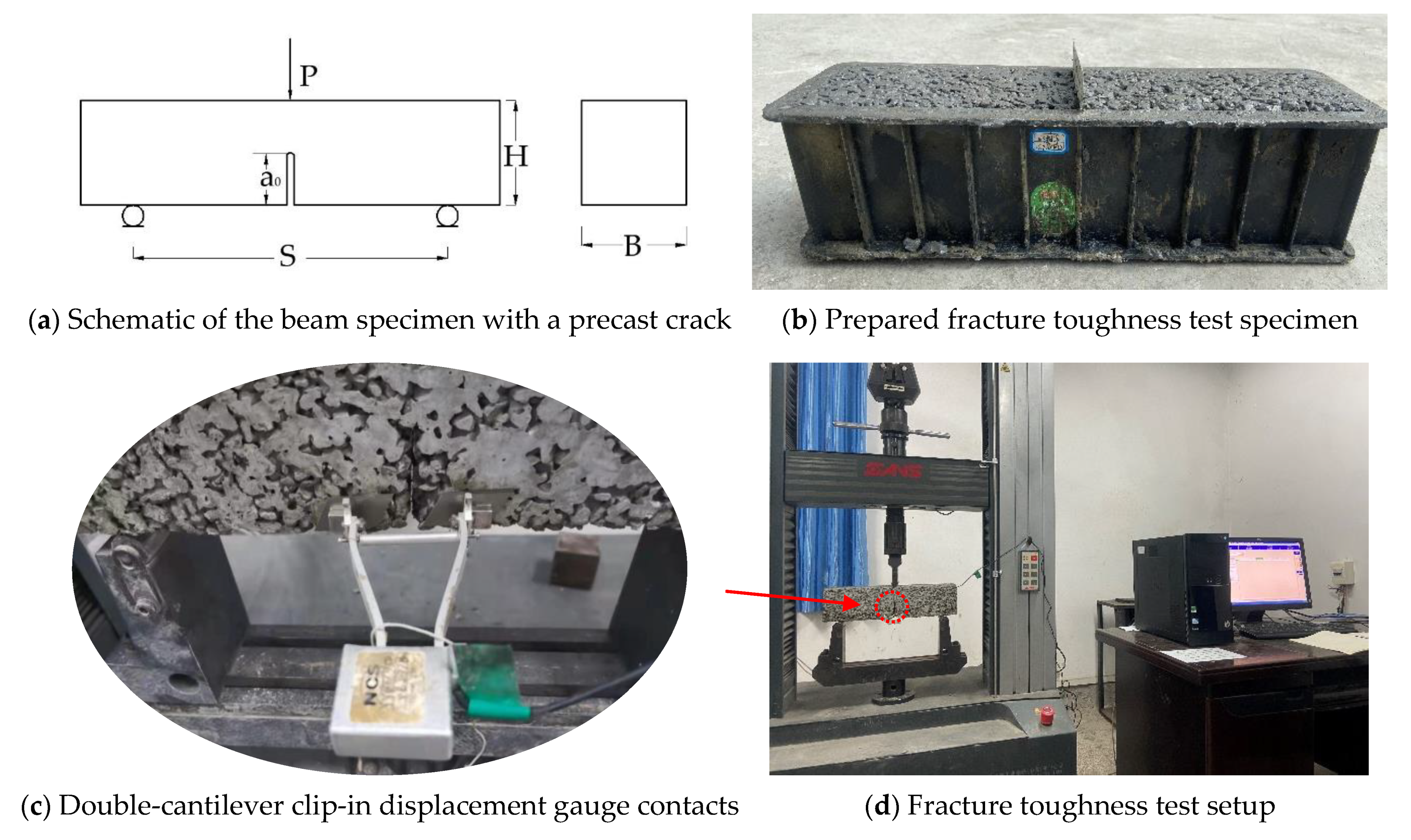

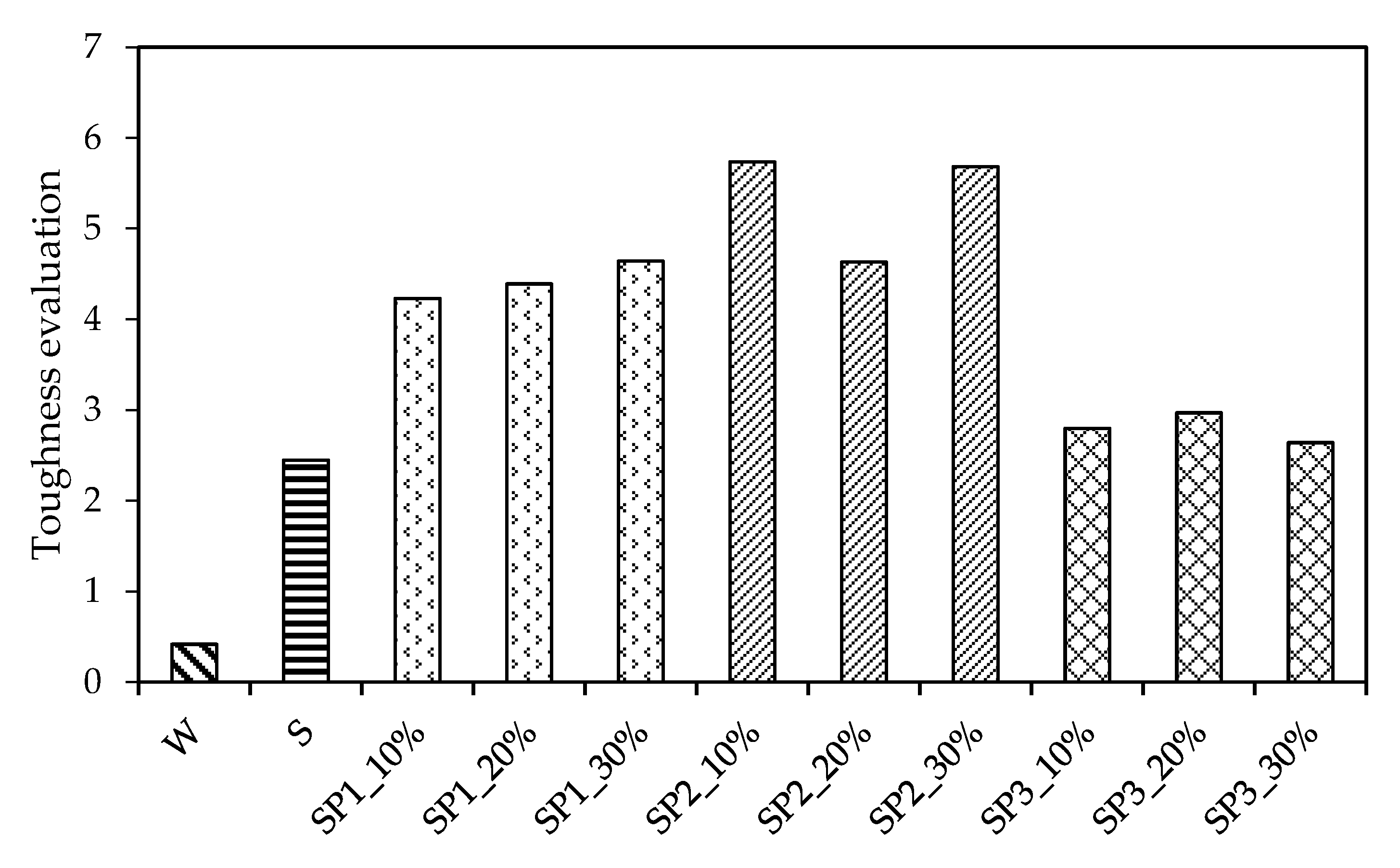

Fracture toughness test: Pervious concrete’s fracture toughness is a measure of its ability to resist the unstable macroscopic crack growth. The most problematic concrete property is its response to the tensile load as the tensile strength; thus, the fracture mode I among all the fracture mechanics parameters was studied in this research [

46]. The fracture toughness test was conducted according to Chinese Standard DLT5332-2005 [

34] and the literature [

47,

48]: L = 400 mm, B = 100 mm, H = 100 mm, S = 300 mm,

mm, as shown in

Figure 6a. A beam specimen with one precast crack in the centerline of its bottom (as shown in

Figure 6b) was used for three-point bending tests on a microcomputer-controlled electronic universal testing machine. The razor blades were positively attached adjacent to the precast crack, and the double-cantilever clip-in displacement gauge was recommended to detect the crack mouth opening displacement (CMOD), as shown in

Figure 6c. The maximum loading capacity of the test machine was 50 kN, and the loading speed was 0.1 mm/min. The beam deflection is represented by the line displacement. The load–line displacement curve (P−L curve) and load–crack mouth opening displacement curve (P−CMOD curve) were recorded by the connected computer.

The fracture energy,

(N·m), was calculated as follows [

49]:

where

is the energy calculated from the area under the P-L curve,

is the specimen mass between the supports (6.6 Kg), g is the acceleration due to gravity,

is the maximum deflection of the specimen, and

A is the area of the fracture ligament,

.

The fracture toughness

(kN/m

3/2) was calculated as follows [

47,

48]:

where

is the rupture load (kN),

is the support span of the beam (300 mm), B is the thickness of the beam (100 mm),

H is the height of the beam, and

is the precast crack original depth (50 mm).