Thermal Processing Map and Microstructure Evolution of Inconel 625 Alloy Sheet Based on Plane Strain Compression Deformation

Abstract

:1. Introduction

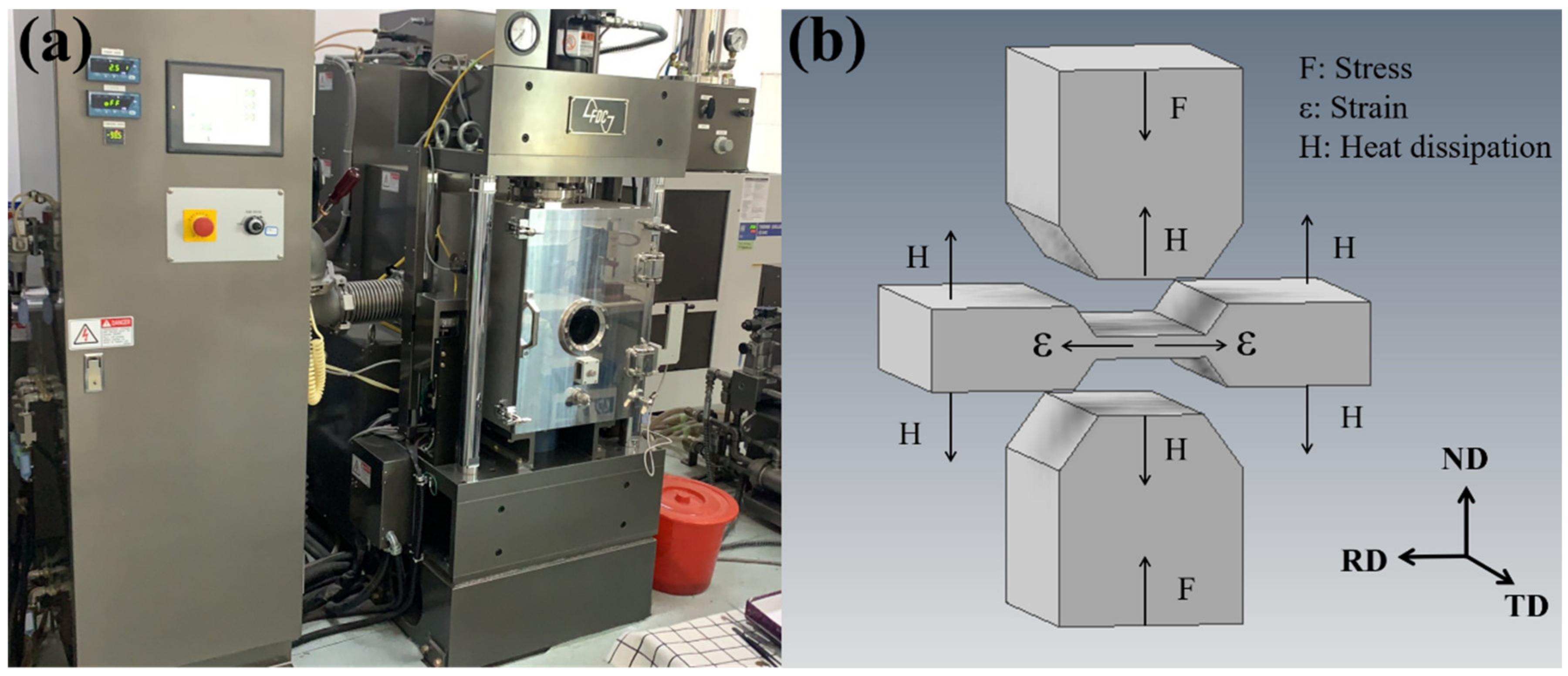

2. Experimental

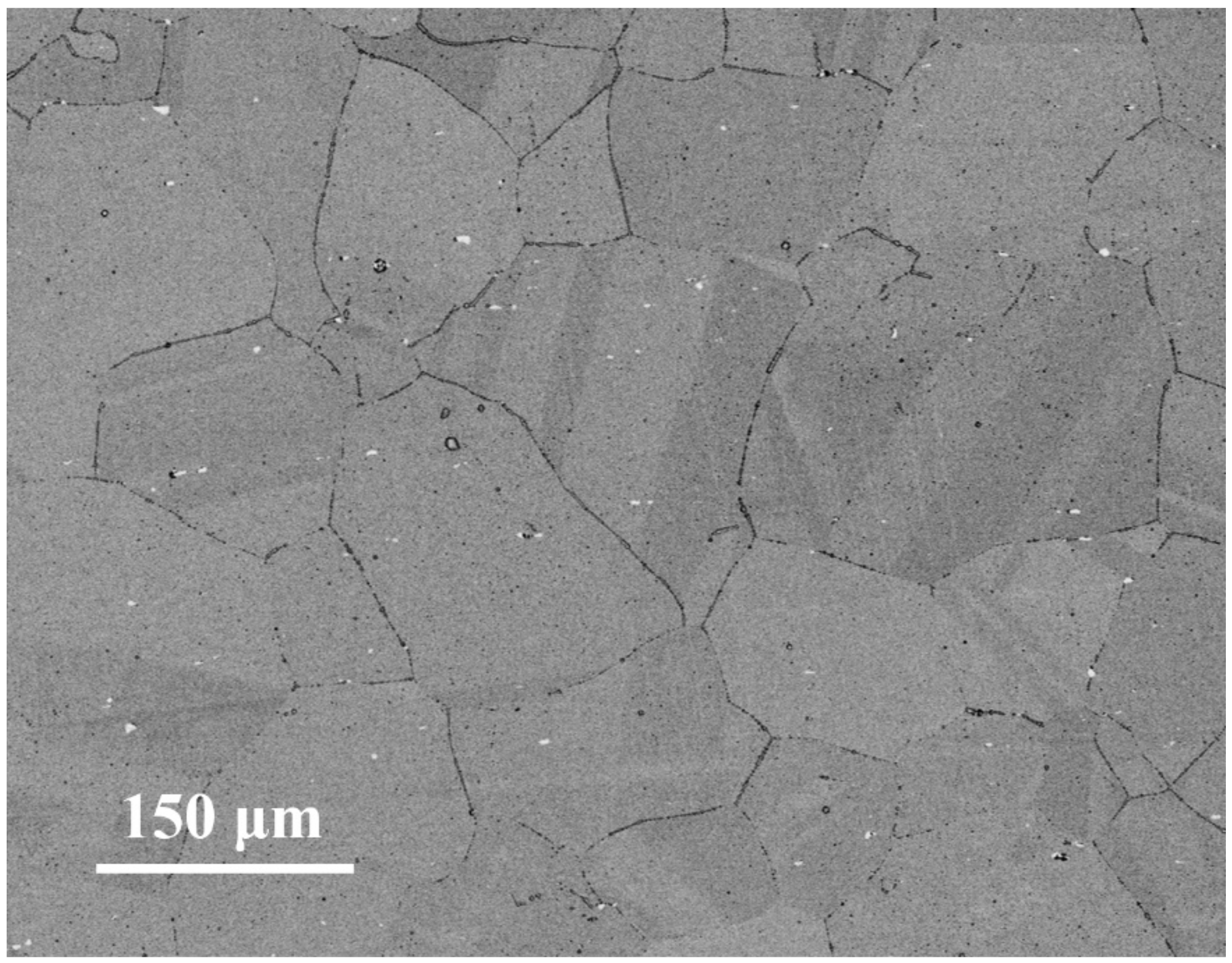

2.1. Plane Strain Isothermal Compression Test

2.2. Microstructure Analysis

3. Results and Discussion

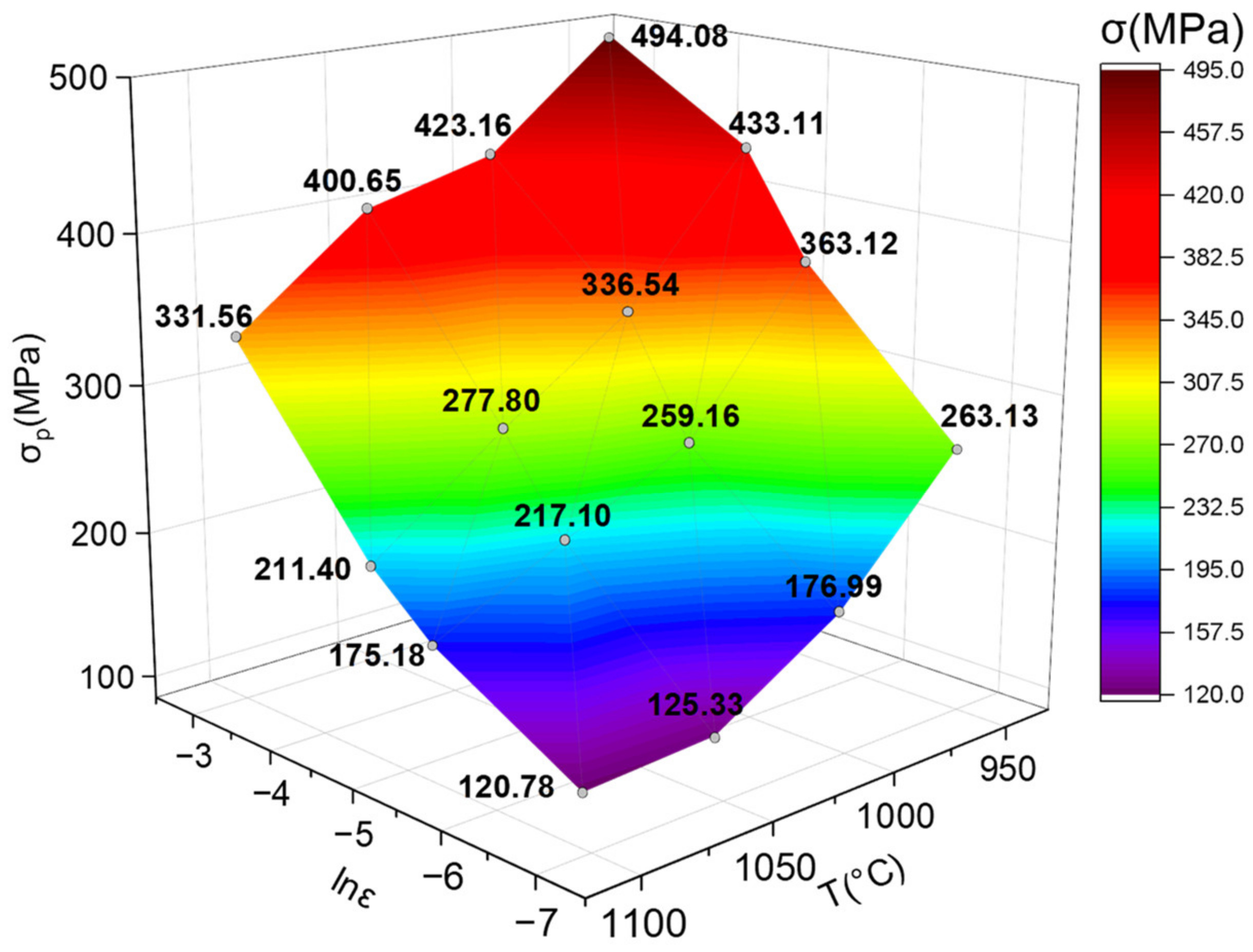

3.1. The Effective Stress–Strain Curves and Flow Behavior

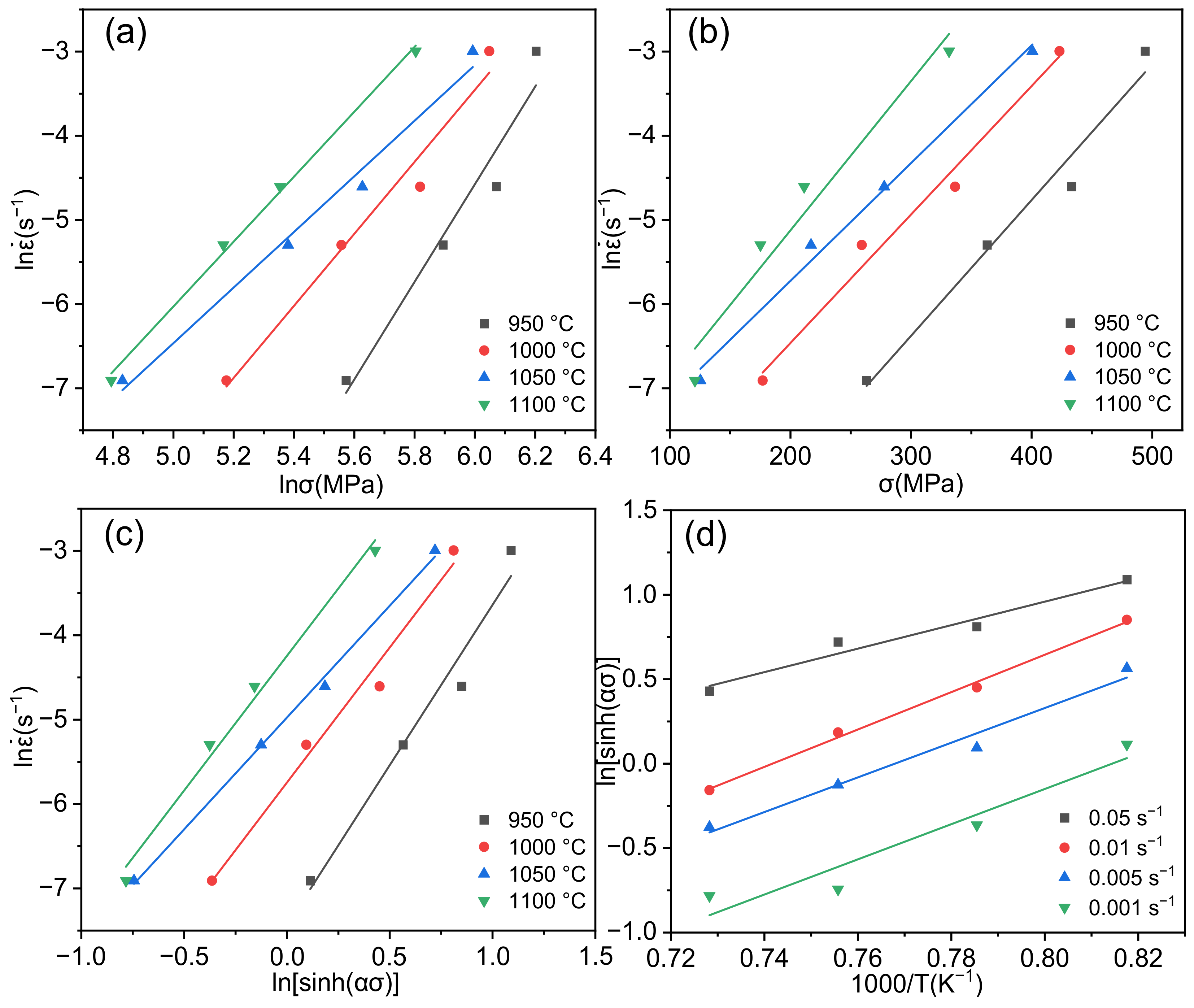

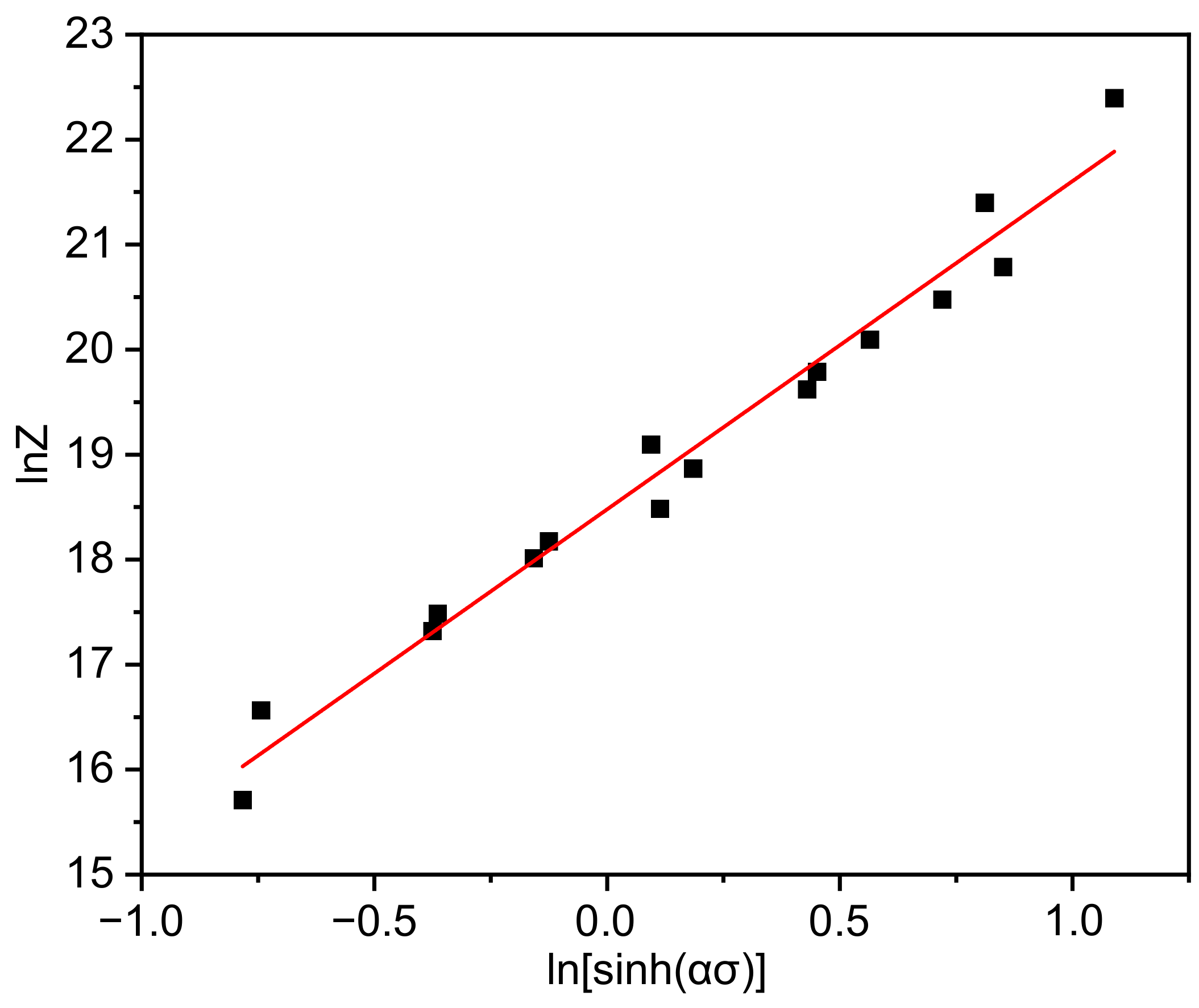

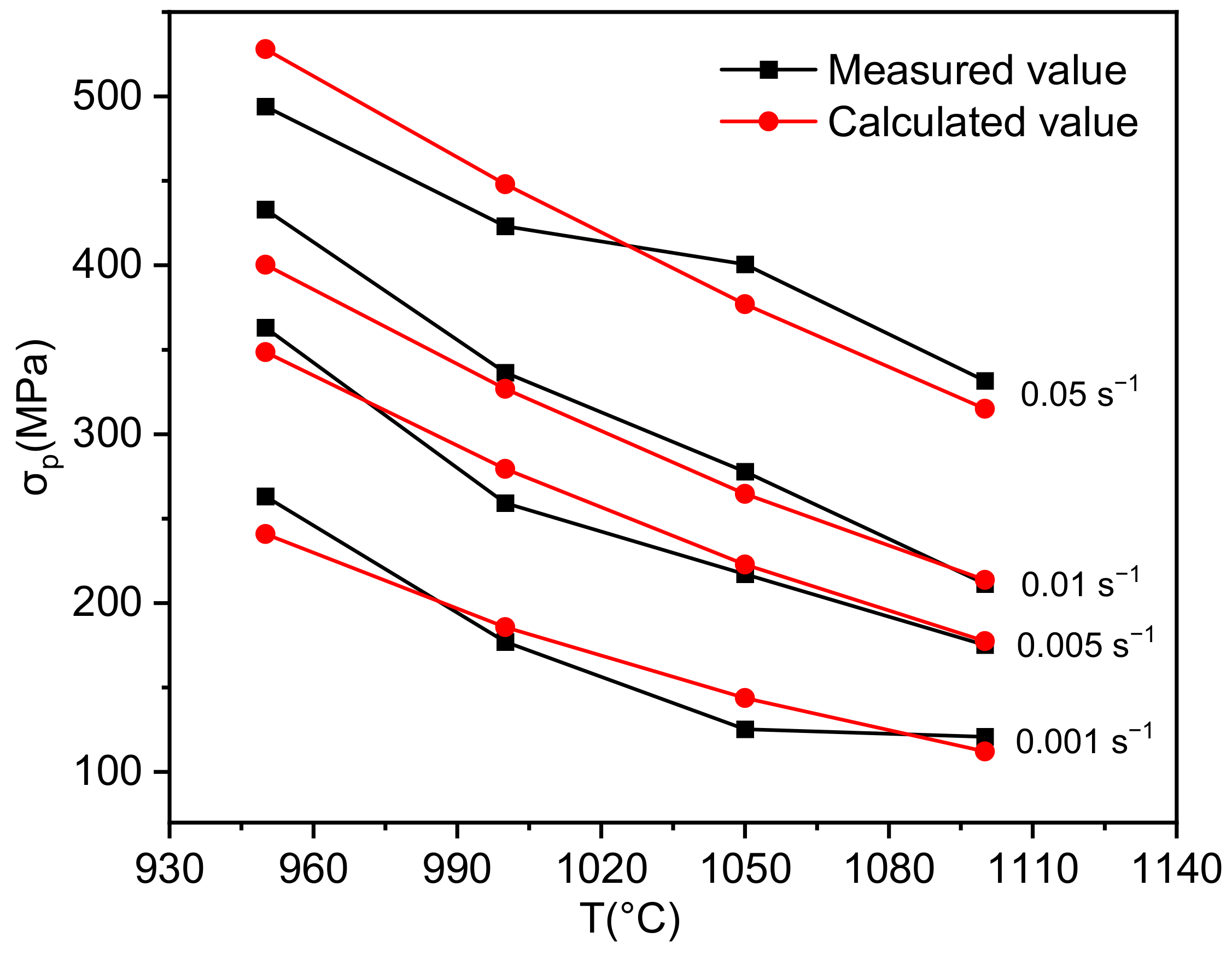

3.2. The Establishment and Solution of Constitutive Model

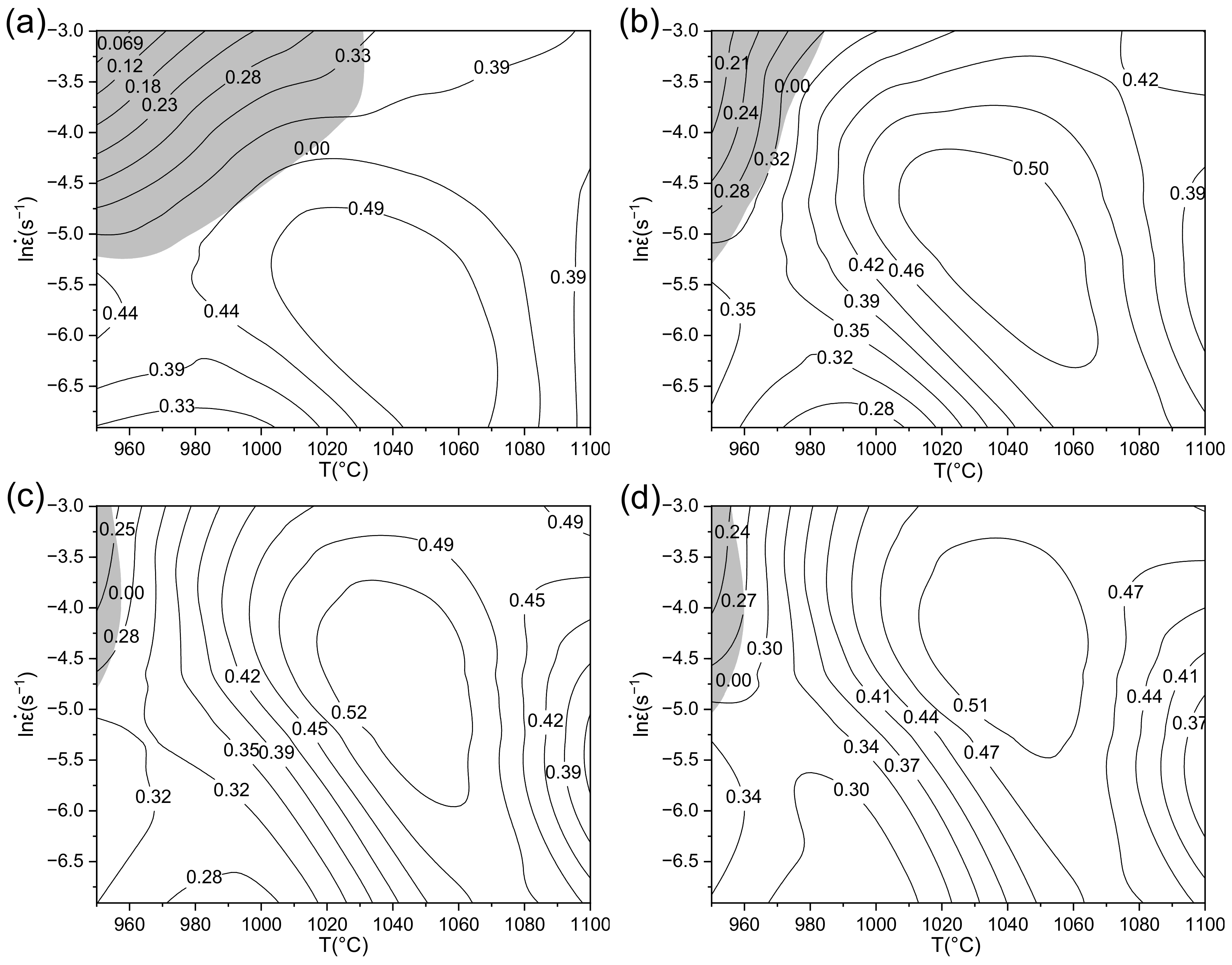

3.3. Thermal Processing Map

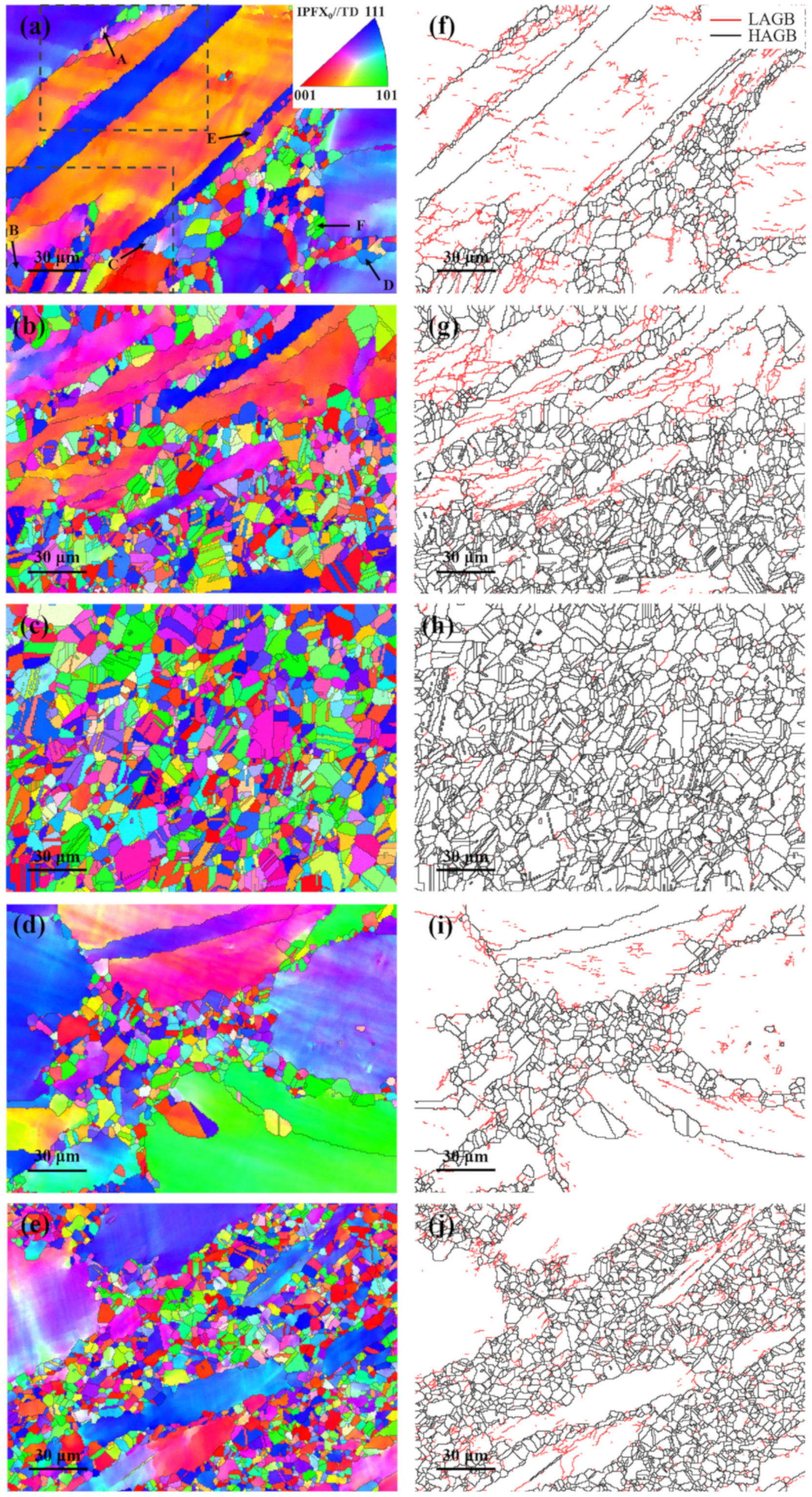

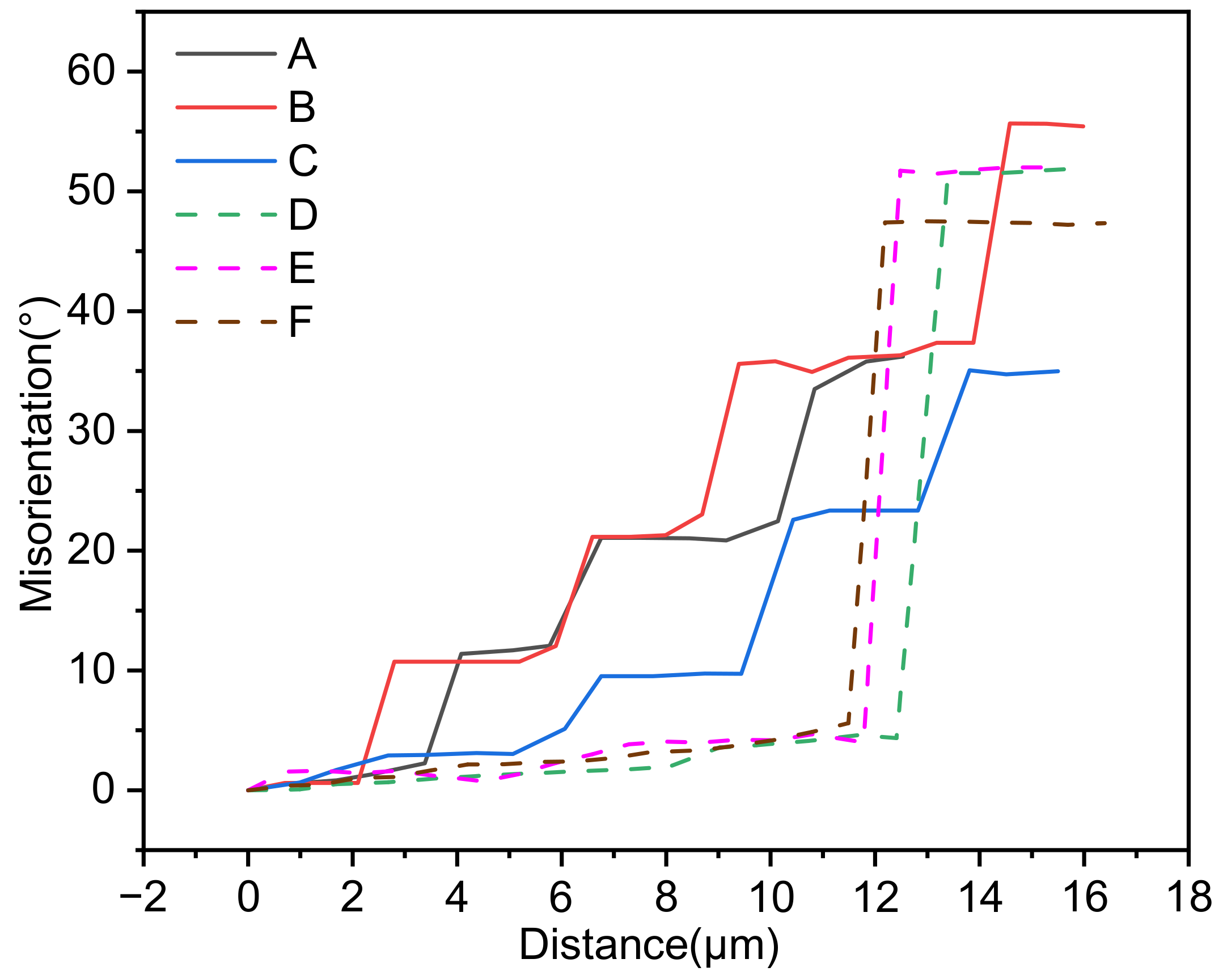

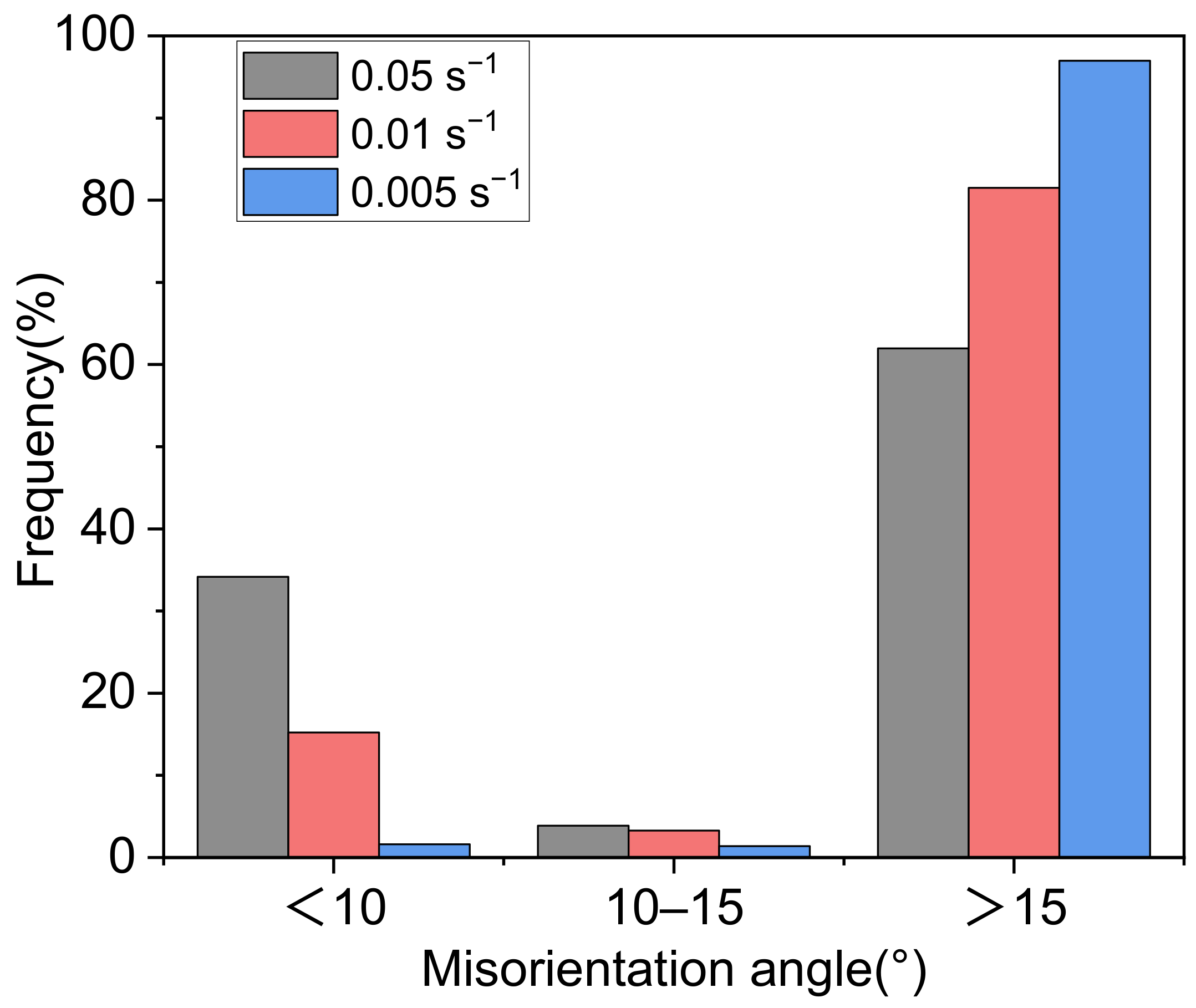

3.4. Microstructure Evolution of Inconel 625 during Thermal Deformation

4. Summary and Conclusions

- (1)

- Recrystallization occurs during hot pressing, and with the increasing of deformation temperature and the decreasing of strain rate, the recrystallization softening is more significant, so the stress level decreases. When the strain rate is higher, the curve is smooth. While the strain rate is low, the stress–strain curve shows high-frequency periodic oscillation.

- (2)

- Calculating the related parameters, we get the constitutive equation of plane compression strain of an Inconel 625 sheet as , and the average error is 5.68%.

- (3)

- The processing map of the Inconel 625 sheet under different strains was drawn. It was found that the Inconel 625 is a strain-insensitive material. The unstable region is: deformation temperatures at 950–960 °C, and strain rates at 0.007–0.05 s−1. The best deformation region is: deformation temperatures at 1020–1060 °C, and strain rates at 0.005–0.03 s−1. Under the condition of instability, obvious local plastic-rheological zones can be observed, in which the fine DRX grains are densely distributed.

- (4)

- Through EBSD characterization, it was found that increasing temperature and decreasing strain rate will promote the recrystallization behavior, and both the proportion and the size of recrystallized grains increase. Under the condition of high temperature and low strain rate, DDRX is the main deformation mechanism, while CDRX plays an auxiliary role.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, Y.B.; Ding, Y.T.; Meng, B.; Ma, Y.J.; Chen, J.J.; Xu, J.Y. Research progress in evolution of precipitated phases in Inconel 625 superalloy. Mater. Eng. 2020, 48, 13–22. [Google Scholar]

- Zhang, Q.; Wang, J.W.; Shi, Y.S.; Wei, Q.S. Effects of solution treatment on microstructure and tensile properties of hot isostatic pressed Inconel 625 alloy. Heat Treat. Met. 2013, 38, 65–69. [Google Scholar]

- Nguejio, J.; Szmytka, F.; Hallais, S.; Tanguy, A.; Nardone, S.; Martinez, M.G. Comparison of microstructure features and mechanical properties for additive manufactured and wrought nickel alloys 625. Mater. Sci. Eng. 2019, 764, 138214. [Google Scholar] [CrossRef]

- Yu, L.J.; Marquis, E.A. Precipitation behavior of Alloy 625 and Alloy 625 plus. J. Alloys Compd. 2019, 811, 151916. [Google Scholar] [CrossRef]

- Fei, J.X.; Liu, G.L.; Patel, K. Effects of Machining Parameters on Finishing Additively Manufactured Nickel-Based Alloy Inconel 625. Manuf. Mater. Process. 2020, 4, 32–54. [Google Scholar]

- Satish, G.J.; Gaitonde, V.N.; Kulkarni, V.N. Traditional and non-traditional machining of nickel-based superalloys: A brief review. Mater. Today Proc. 2021, 44, 1448–1454. [Google Scholar] [CrossRef]

- Chen, S.; Ma, J.X. Trend analysis of nickel-based superalloy based on journal literature. Mater. Rev. 2014, 28, 116–124. [Google Scholar]

- Wang, J.Z.; Li, K.Y.; Liu, A.J.; Ding, K.L. Microstructure and hardness of hot rolled Inconel 625 after heat treatment. Met. Heat Treat. 2018, 43, 96–100. [Google Scholar]

- Liu, X.D.; Fan, J.K.; Zhang, P.Z.; Xie, J.; Chen, F.L.; Liu, D.G.; Yuan, R.G.; Tang, B.; Kou, H.C.; Li, J.S. Temperature dependence of deformation behavior, microstructure evolution and fracture mechanism of Inconel 625 superalloy. J. Alloys Compd. 2021, 869, 159342. [Google Scholar] [CrossRef]

- Chen, F.L.; Li, K.D.; Tang, B.; Liu, D.G.; Zhong, H.; Li, J.S. Deformation behavior and microstructural evolution of Inconel 625 superalloy during the hot compression process. Metals 2021, 11, 824. [Google Scholar] [CrossRef]

- Parida, A.K.; Maity, K. FEM analysis and experimental investigation of force and chip formation on hot turning of Inconel 625. Def. Technol. 2019, 15, 853–860. [Google Scholar] [CrossRef]

- Liu, X.D.; Fan, J.K.; Li, K.D.; Song, Y.L.; Liu, D.G.; Yuan, R.H.; Wang, J.; Tang, B.; Kou, H.C.; Li, J.S. Serrated flow behavior and microstructure evolution of Inconel 625 superalloy during plane-strain compression with different strain rates. J. Alloys Compd. 2021, 881, 160648. [Google Scholar] [CrossRef]

- Chen, M.S.; Zou, Z.H.; Lin, Y.C.; Li, K.K. Hot deformation behaviors of a solution-treated Ni-based superalloy under constant and changed strain rates. Vacuum 2018, 155, 531–538. [Google Scholar] [CrossRef]

- Jia, Z.; Gao, Z.X.; Ji, J.J.; Liu, D.X.; Guo, T.B.; Ding, Y.T. Study of the Dynamic Recrystallization Process of the Inconel625 Alloy at a High Strain Rate. Materials 2019, 12, 510. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tao, L.; Cheng, M.; Zhang, W.H.; Song, G.S.; Zhang, S.H. High-temperature and high-speed hot deformation behavior of Inconel 625. J. Mater. Heat Treat. 2012, 33, 55–59. [Google Scholar]

- Lin, Y.C.; Min, H.E.; Chen, M.S.; Wen, D.X.; Chen, J. Effects of Initial Phase (Ni3Nb) on Hot Tensile Deformation Behaviors and Material Constants of a Ni-Based Superalloy. Trans. Nonferrous Met. Soc. China 2016, 26, 107–117. [Google Scholar] [CrossRef]

- Shi, X.N.; Liu, Y.Y.; Ning, Y.Q.; Zhang, J.Y.; Wang, M.T. Physically-Based Constitutive Model of Nickel-Based Superalloy ATI 718Plus. Chin. J. Rare Met. 2019, 43, 613–620. [Google Scholar]

- Zhang, M.; Liu, G.; Wang, H.; Hu, B. Modeling of thermal deformation behavior near γ’ solvus in a Ni-based powder metallurgy superalloy. Comput. Mater. Sci. 2019, 156, 241–245. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, J.; Chen, M.S.; Liu, Y.X.; Liang, Y.J. A deep belief network to predict the hot deformation behavior of a Ni-based superalloy. Neural Comput. Appl. 2018, 29, 1015–1023. [Google Scholar] [CrossRef]

- Lin, Y.C.; Nong, F.Q.; Chen, X.M.; Chen, D.D.; Chen, M.S. Microstructural evolution and constitutive models to predict hot deformation behaviors of a nickel-based superalloy. Vacuum 2017, 137, 104–114. [Google Scholar] [CrossRef]

- Liu, Y.H.; Liu, Z.Z.; Wang, M. Gradient microstructure evolution under thermo-mechanical coupling effects for a nickel-based powder metallurgy superalloy-Dynamic recrystallization coexist with static recrystallization. J. Mater. Process. Technol. 2021, 294, 117142. [Google Scholar] [CrossRef]

- Li, H.Z.; Yang, L.; Wang, Y.; Tan, G.; Qiao, S.C.; Huang, Z.Q.; Liu, M.X. Thermal deformation and dynamic recrystallization of a novel HEXed P/M nickel-based superalloy. Mater. Charact. 2020, 163, 110285. [Google Scholar] [CrossRef]

- Jia, D.; Sun, W.R.; Xu, D.S.; Yu, L.X.; Xin, X.; Zhang, W.H.; Qi, F. Abnormal dynamic recrystallization behavior of a nickel-based superalloy during hot deformation. J. Alloys Compd. 2019, 787, 196–205. [Google Scholar] [CrossRef]

- Sun, F. Integrated TEM/transmission-EBSD for recrystallization analysis in nickel-based disc superalloy. Prog. Nat. Sci. Mater. Int. 2020, 31, 63–67. [Google Scholar] [CrossRef]

- Kumar, S.; Raghu, T.; Bhattacharjee, P.P.; Rao, G.A.; Borah, U. Evolution of microstructure and microtexture during hot deformation in an advanced P/M nickel base superalloy. Mater. Charact. 2018, 146, 217–236. [Google Scholar] [CrossRef]

- Jia, Z.; Sun, X.; Ji, J.J.; Wang, Y.J.; Wei, B.L.; Yu, L.D. Hot Deformation Behavior and Dynamic Recrystallization Nucleation Mechanisms of Inconel 625 during Hot Compressive Deformation. Adv. Eng. Mater. 2021, 23, 2001048. [Google Scholar] [CrossRef]

- Jiang, H.; Dong, J.X.; Zhang, M.C.; Yao, Z.H. Phenomenological model for the effect of strain rate on recrystallization and grain growth kinetics in the 617B alloy. J. Alloys Compd. 2018, 735, 1520–1535. [Google Scholar] [CrossRef]

- Liu, Y.X.; Lin, Y.C.; Zhou, Y. 2D cellular automaton simulation of hot deformation behavior in a Ni-based superalloy under varying thermal-mechanical conditions. Mater. Sci. Eng. A 2017, 691, 88–99. [Google Scholar] [CrossRef]

- Hsu, Y.C.; Yang, T.S.; Sung, S.Y.; Chang, S.Y. Constructing the predictive models of friction coefficient using cylindrical compression testing. Mater. Sci. Forum 2006, 540, 745–750. [Google Scholar] [CrossRef]

- Pan, H.B.; Tang, D.; Hu, P.P.; Wang, X.X. Study on plane strain physical compression technology. Forg. Technol. 2008, 33, 75–79. [Google Scholar]

- Jiang, Z.W.; Zhu, L.L.; Yu, L.X.; Sun, B.A.; Cao, Y.; Zhao, Y.H.; Zhang, Y. The mechanism for the serrated flow induced by Suzuki segregation in a Ni alloy. Mater. Sci. Eng. A 2021, 820, 141575. [Google Scholar] [CrossRef]

- Sadovskii, V.M.; Sadovskaya, O.V.; Petrakov, I.E. On the theory of constitutive equation for composites with different resistance in compression and tension. Compos. Struct. 2021, 268, 113921. [Google Scholar] [CrossRef]

- Dai, Q.S.; Deng, Y.L.; Tang, J.G.; Wang, Y. Deformation characteristics and strain-compensated constitutive equation for AA5083 aluminum alloy under hot compression. Trans. Nonferrous Met. Soc. China 2019, 29, 2252–2261. [Google Scholar] [CrossRef]

- Tan, G.; Li, H.Z.; Wang, Y.; Yang, L.; Qiao, X.C.; Huang, Z.Q.; Liu, M.X. Hot working characteristics of HEXed PM nickel-based superalloy during hot compression. Trans. Nonferrous Met. Soc. China 2020, 30, 2079–2723. [Google Scholar] [CrossRef]

- McQueen, H.J.; Ryan, N.D. Constitutive analysis in hot working. Mater. Sci. Eng. A 2002, 322, 43–63. [Google Scholar] [CrossRef]

- Guo, S.; Li, D.; Guo, Q.; Wu, Z.; Peng, H.; Hu, J. Investigation on hot workability characteristics of Inconel 625 superalloy using processing maps. J. Mater. Sci. 2012, 47, 5867–5878. [Google Scholar] [CrossRef]

- Jia, Z.; Gao, Z.X.; Ji, J.J.; Liu, D.X.; Ding, Y.T. High-temperature deformation behavior and processing map of the as-cast Inconel 625 alloy. Rare Met. 2021, 40, 2083–2091. [Google Scholar] [CrossRef]

- Huang, X.D.; Zhang, H.; Han, Y.; Wu, W.X.; Chen, J.H. Hot deformation behavior of 2026 aluminum alloy during compression at elevated temperature. Mater. Sci. Eng. A 2010, 527, 485–490. [Google Scholar] [CrossRef]

- Langkruis, J.; Kool, W.H.; Zwaag, S. Assessment of constitutive equations in modelling the hot deformability of some overaged Al–Mg–Si alloys with varying solute contents. Mater. Sci. Eng. A 1999, 266, 135–145. [Google Scholar] [CrossRef]

- Yin, X.Y.; Liu, X.K.; Ding, H.X.; Zhu, J. High temperature constitutive model modification and evolution law of deformation activation energy for HNi55-7-4-2 alloy. Forg. Stamp. Technol. 2021, 46, 221–228. [Google Scholar]

- Shen, B.; Deng, L.; Wang, X. A new dynamic recrystallisation model of an extruded Al-Cu-Li alloy during high-temperature deformation. Mater. Sci. Eng. 2015, 625, 288–295. [Google Scholar] [CrossRef]

- Zhang, B.X.; Zhao, X.; Zhang, B.H. Optimization of hot stamping process for deep blind hole cylinders based on thermal processing map. Ordnance Mater. Sci. Eng. 2021, 44, 17–24. [Google Scholar]

- Ahamed, H.; Senthilkumar, V. Hot deformation behavior of mechanically alloyed Al6063/0.75Al2O3/0.75Y2O3 nano-composite-A study using constitutive modeling and processing map. Mater. Sci. Eng. A 2012, 539, 349–359. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Modeling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243–258. [Google Scholar] [CrossRef]

- Coryell, S.P.; Findley, K.O.; Mataya, M.C.; Brown, E. Evolution of microstructure and texture during hot compression of a Ni-Fe-Cr superalloy. Metall. Mater. Trans. A 2012, 43, 633–649. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Sarma, V.S. A study on microstructural evolution and dynamic recrystallization during isothermal deformation of a Ti-modified austenitic stainless steel. Metall. Mater. Trans. A 2011, 42, 1062–1072. [Google Scholar] [CrossRef]

| Ni | Cr | Mo | Nb | Fe | Si | Al | Ti | Mn | C | S |

|---|---|---|---|---|---|---|---|---|---|---|

| 61.00 | 21.50 | 9.00 | 3.60 | 2.00 | 0.20 | 0.20 | 0.20 | 0.20 | 0.05 | 0.001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Fan, J.; Liu, X.; Zhang, P.; Li, J. Thermal Processing Map and Microstructure Evolution of Inconel 625 Alloy Sheet Based on Plane Strain Compression Deformation. Materials 2021, 14, 5059. https://doi.org/10.3390/ma14175059

Song Y, Fan J, Liu X, Zhang P, Li J. Thermal Processing Map and Microstructure Evolution of Inconel 625 Alloy Sheet Based on Plane Strain Compression Deformation. Materials. 2021; 14(17):5059. https://doi.org/10.3390/ma14175059

Chicago/Turabian StyleSong, Yuelin, Jiangkun Fan, Xudong Liu, Peizhe Zhang, and Jinshan Li. 2021. "Thermal Processing Map and Microstructure Evolution of Inconel 625 Alloy Sheet Based on Plane Strain Compression Deformation" Materials 14, no. 17: 5059. https://doi.org/10.3390/ma14175059

APA StyleSong, Y., Fan, J., Liu, X., Zhang, P., & Li, J. (2021). Thermal Processing Map and Microstructure Evolution of Inconel 625 Alloy Sheet Based on Plane Strain Compression Deformation. Materials, 14(17), 5059. https://doi.org/10.3390/ma14175059