Nanoparticle Additivation Effects on Laser Powder Bed Fusion of Metals and Polymers—A Theoretical Concept for an Inter-Laboratory Study Design All Along the Process Chain, Including Research Data Management

Abstract

:1. Introduction

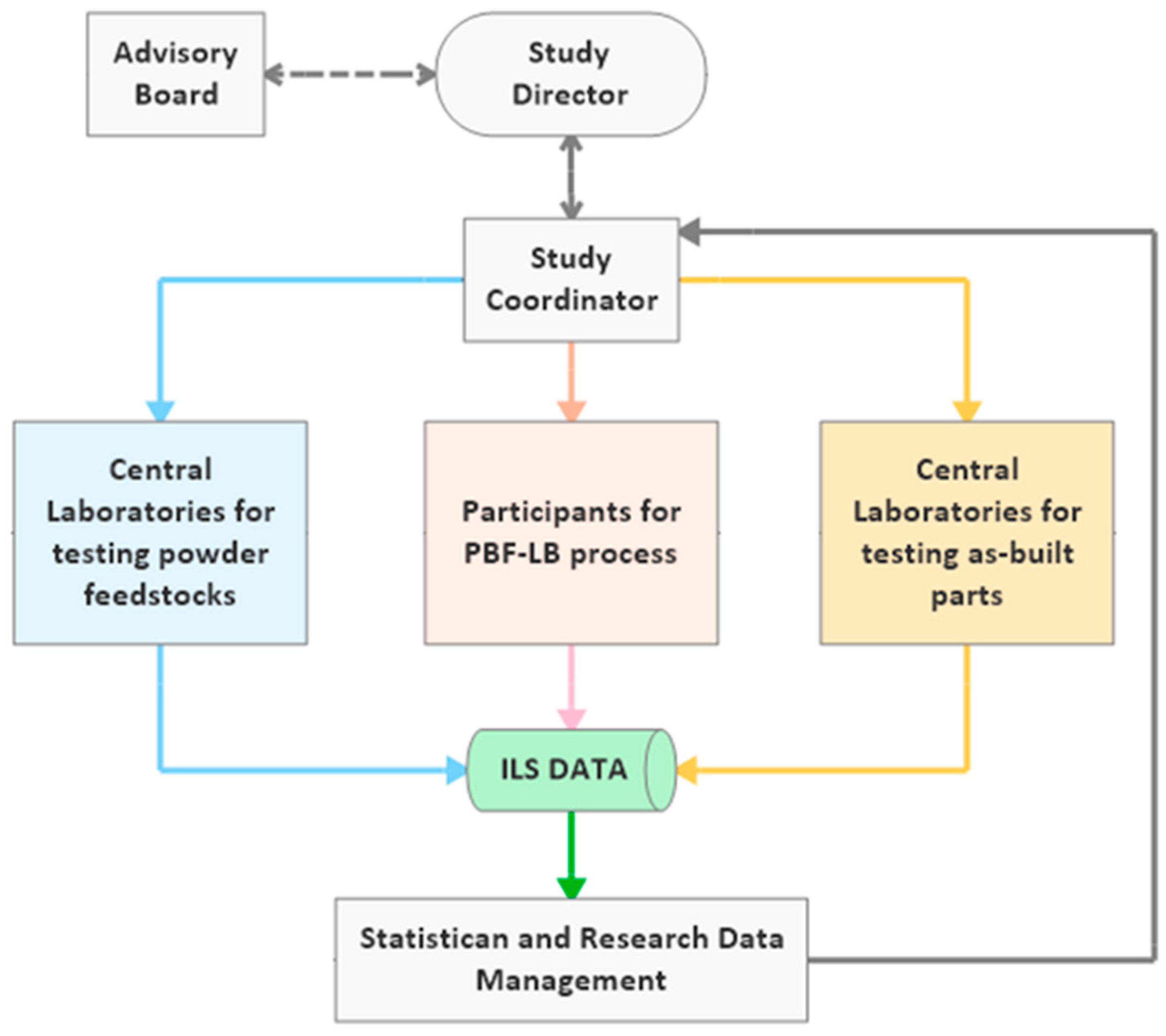

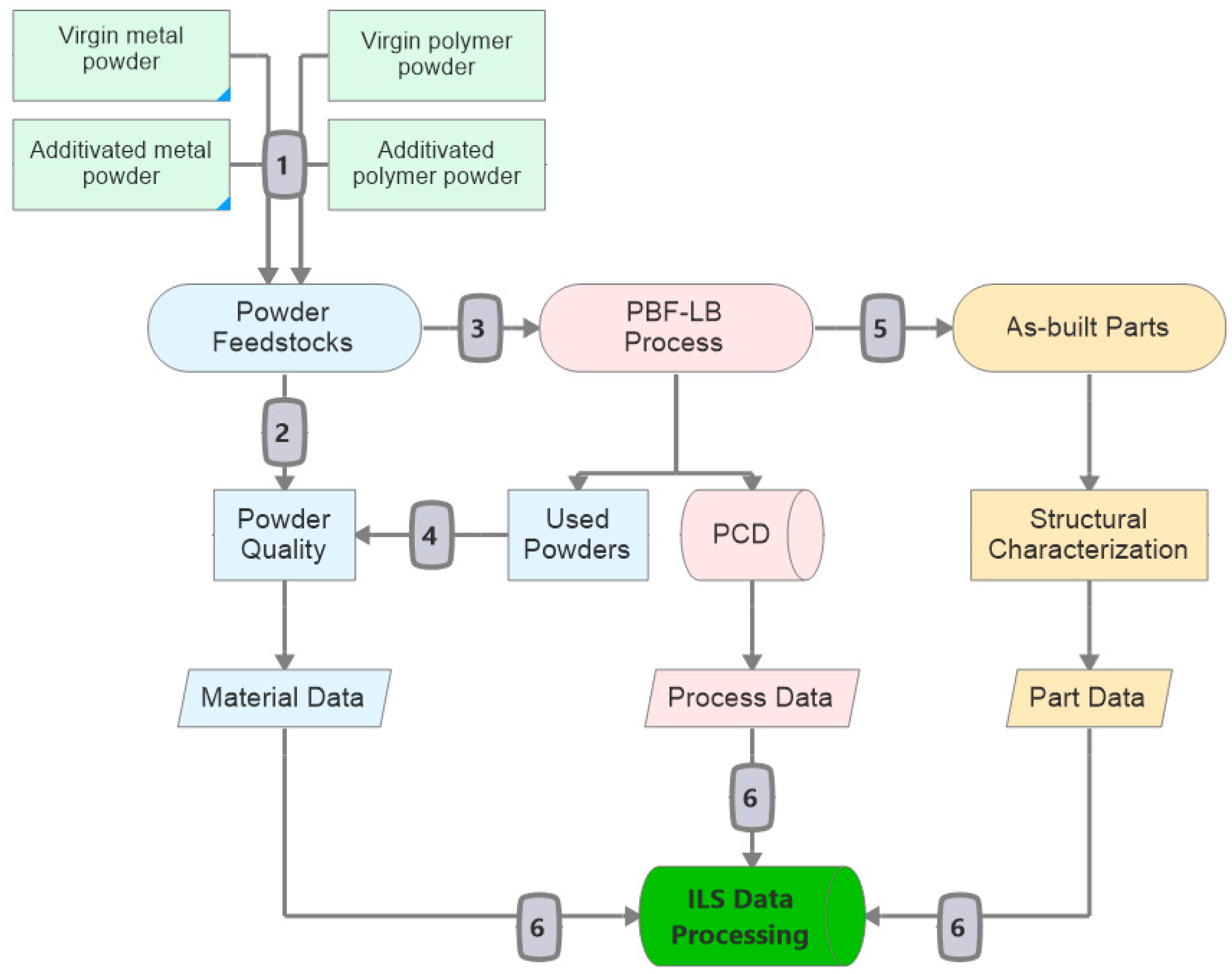

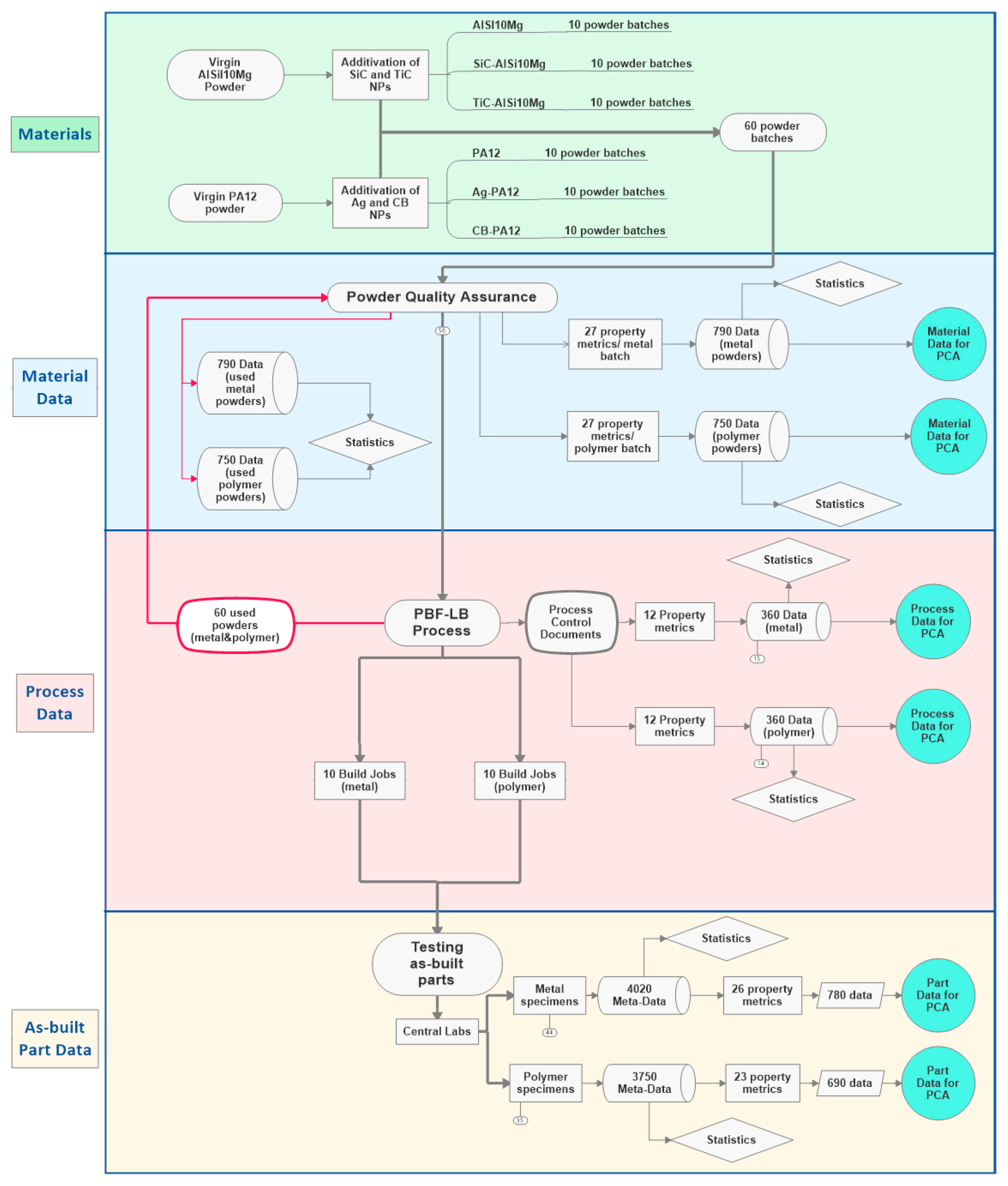

2. Design of Interlaboratory Study

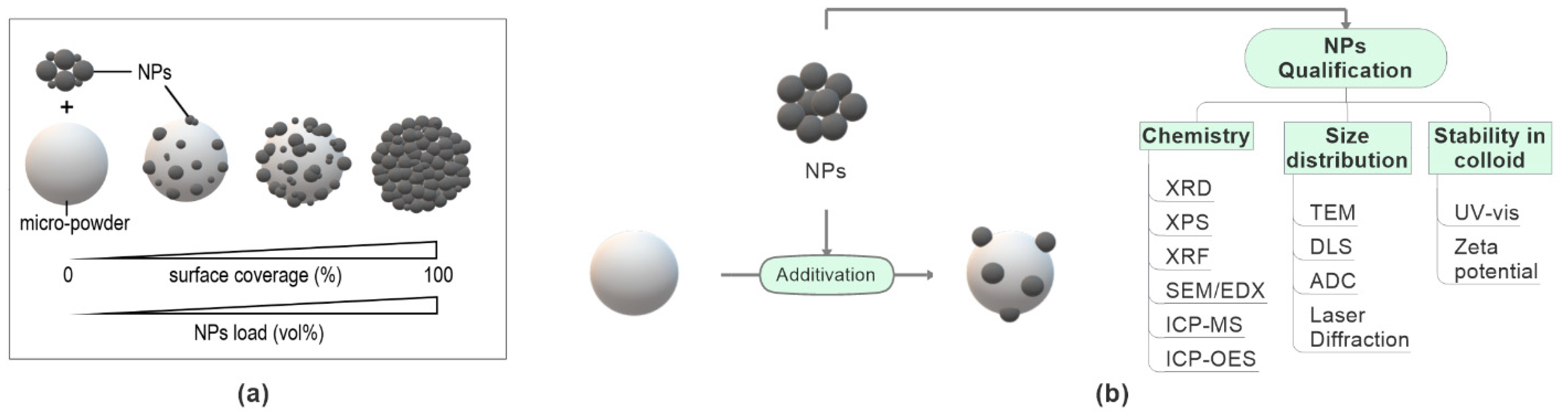

2.1. Additivation of NPs on As-Produced Metal and Polymer Powder Feedstocks

Additivation Process

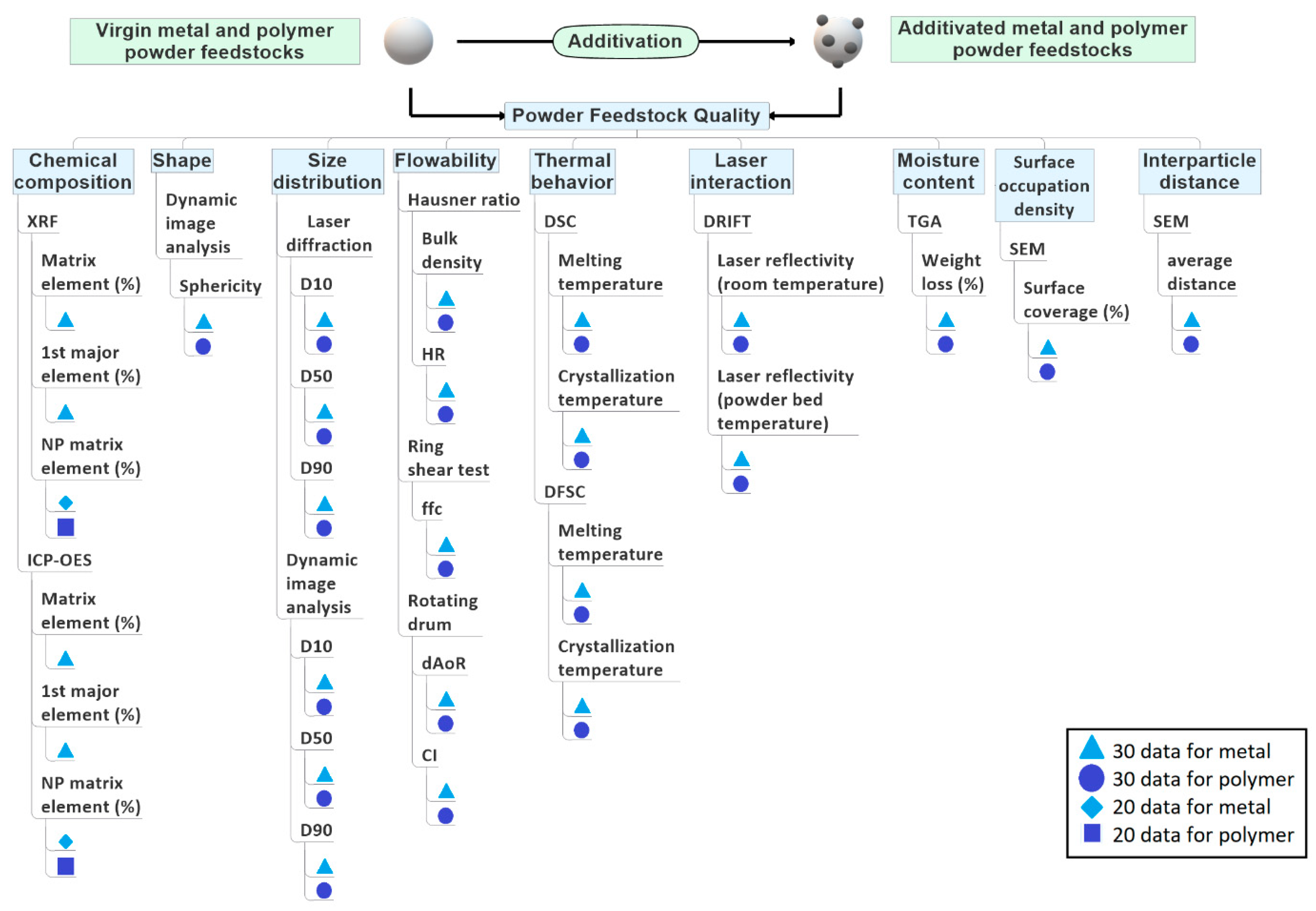

2.2. Powder Quality of Unmodified and NP-Additivated Powder Feedstocks

2.2.1. Chemical Composition

2.2.2. Powder Shape and Powder Size Distribution

2.2.3. Flowability

2.2.4. Thermal Behavior

2.2.5. Laser Reflectivity

2.2.6. Moisture Content

2.2.7. Surface Coverage of Micro-Powders by NPs and Interparticle Distance between NPs

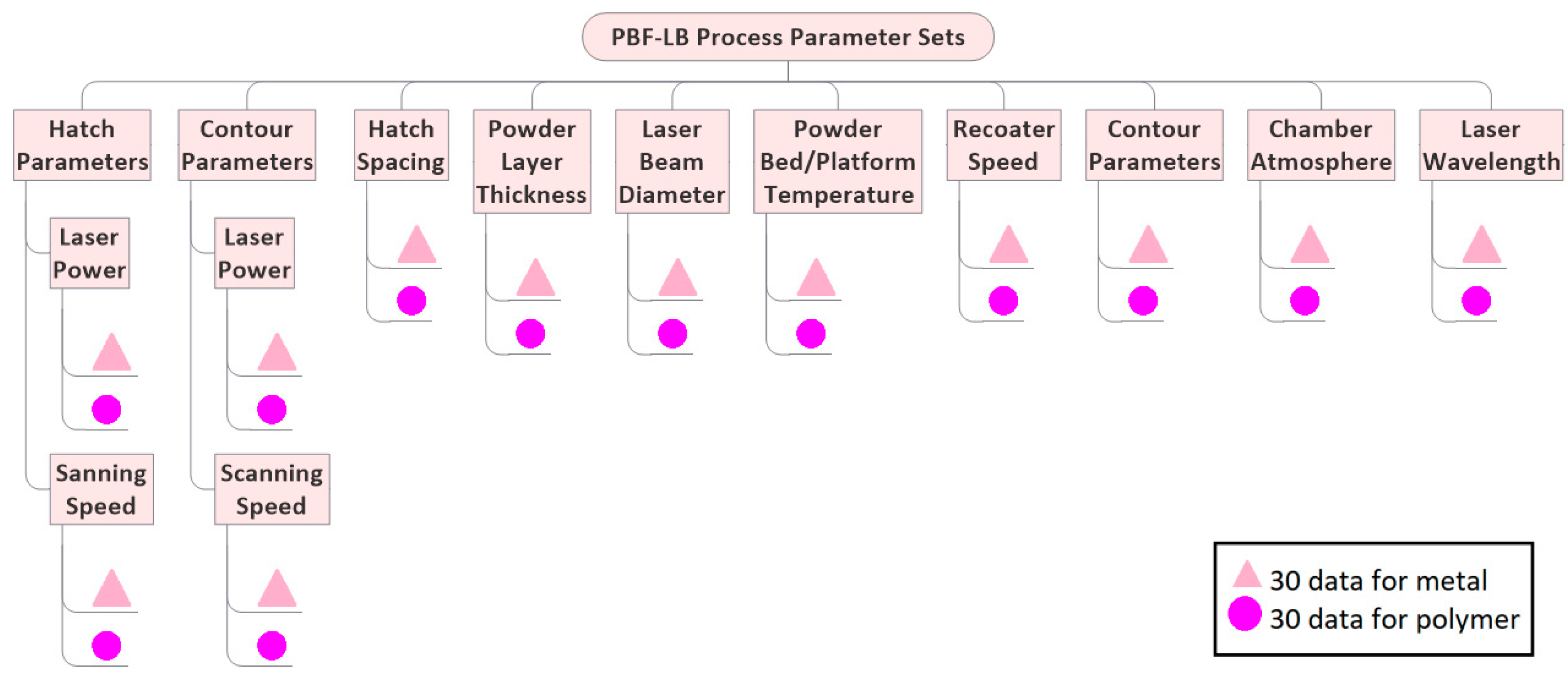

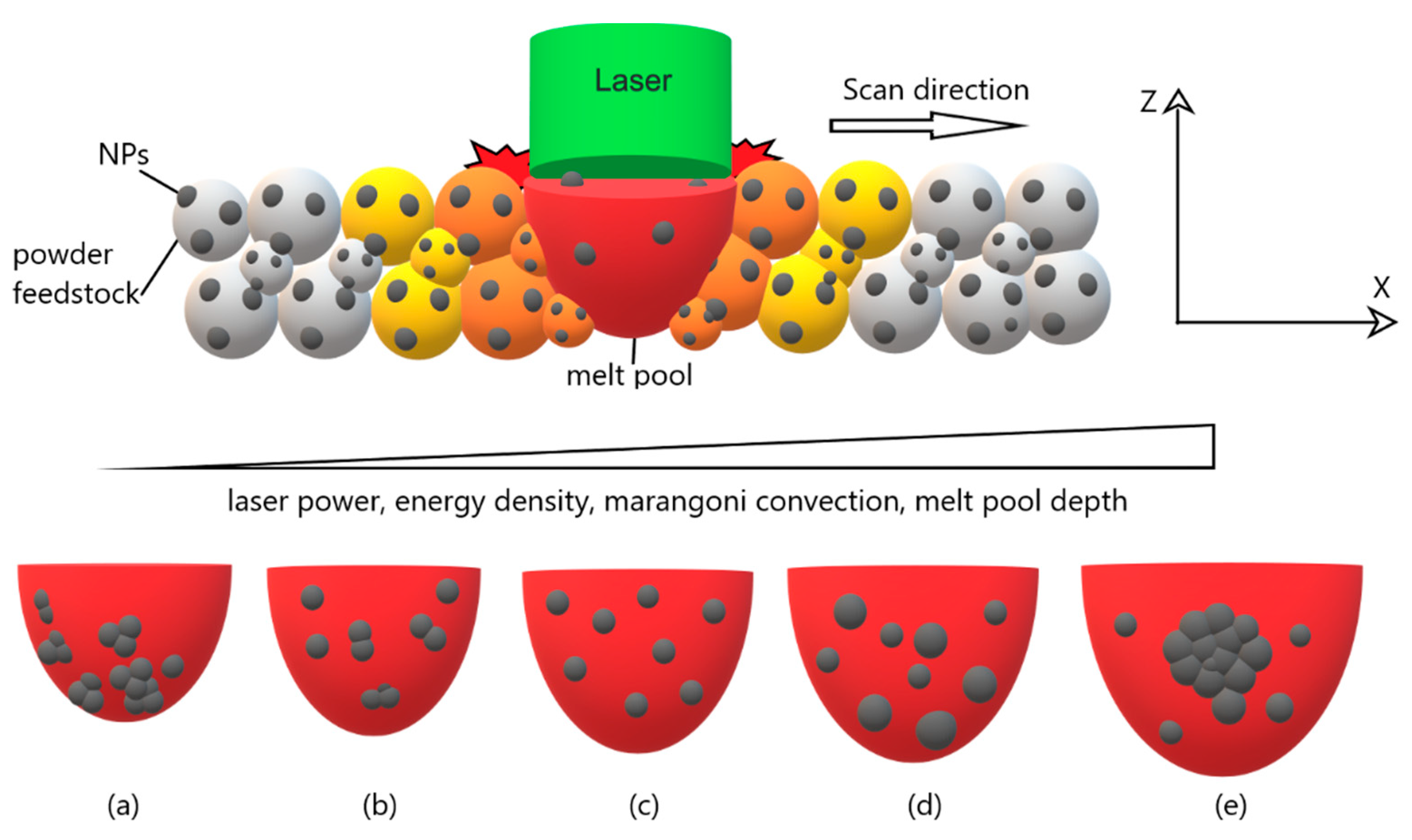

2.3. PBF-LB Process

2.4. Powder Quality of Used Powder Feedstocks

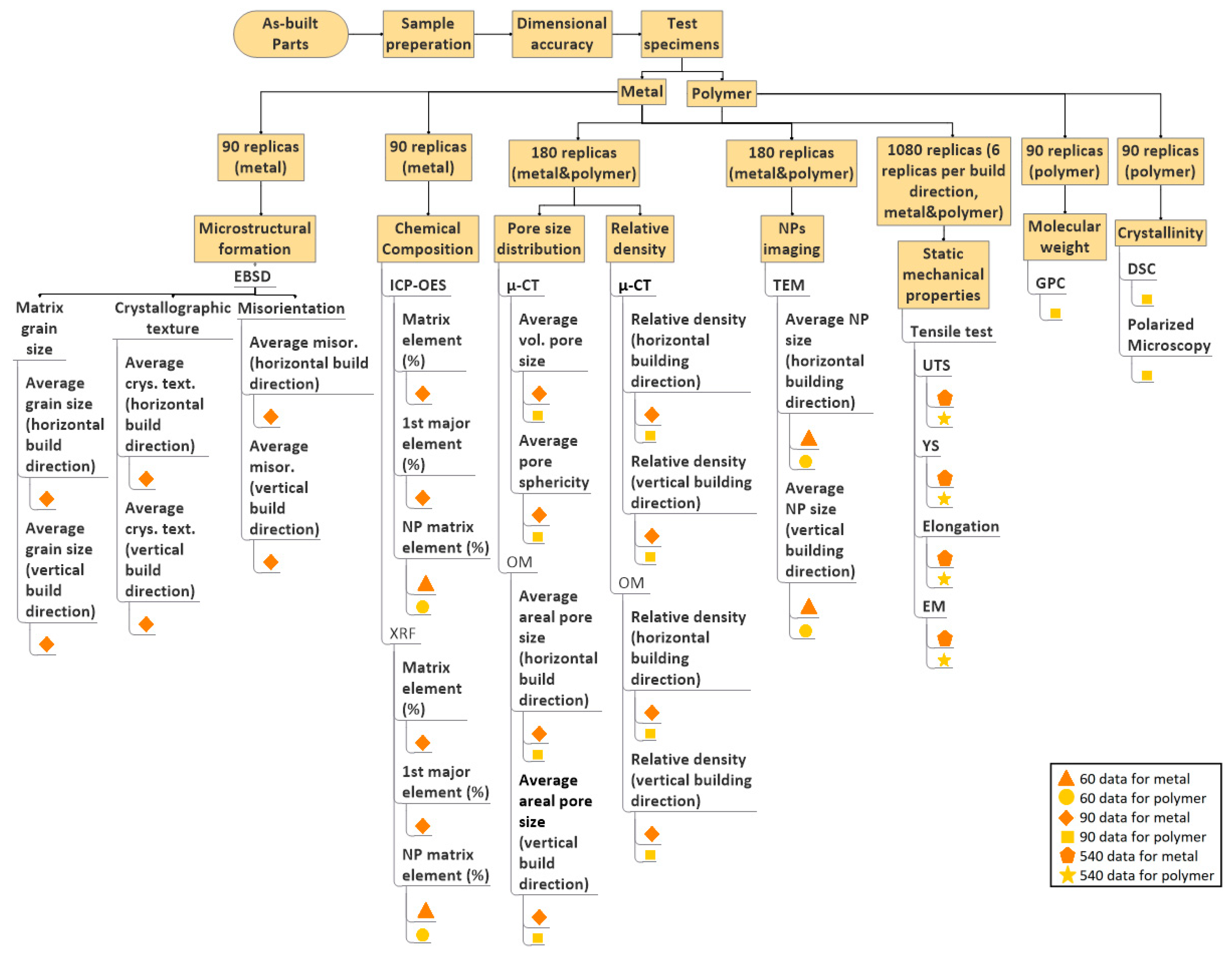

2.5. As-Built Parts

2.5.1. Microstructural Formations

2.5.2. Chemical Composition

2.5.3. Relative Density and Pore Size Distribution

2.5.4. NP Imaging

2.5.5. Static Mechanical Properties

2.6. Research Data Management (RDM) of ILS

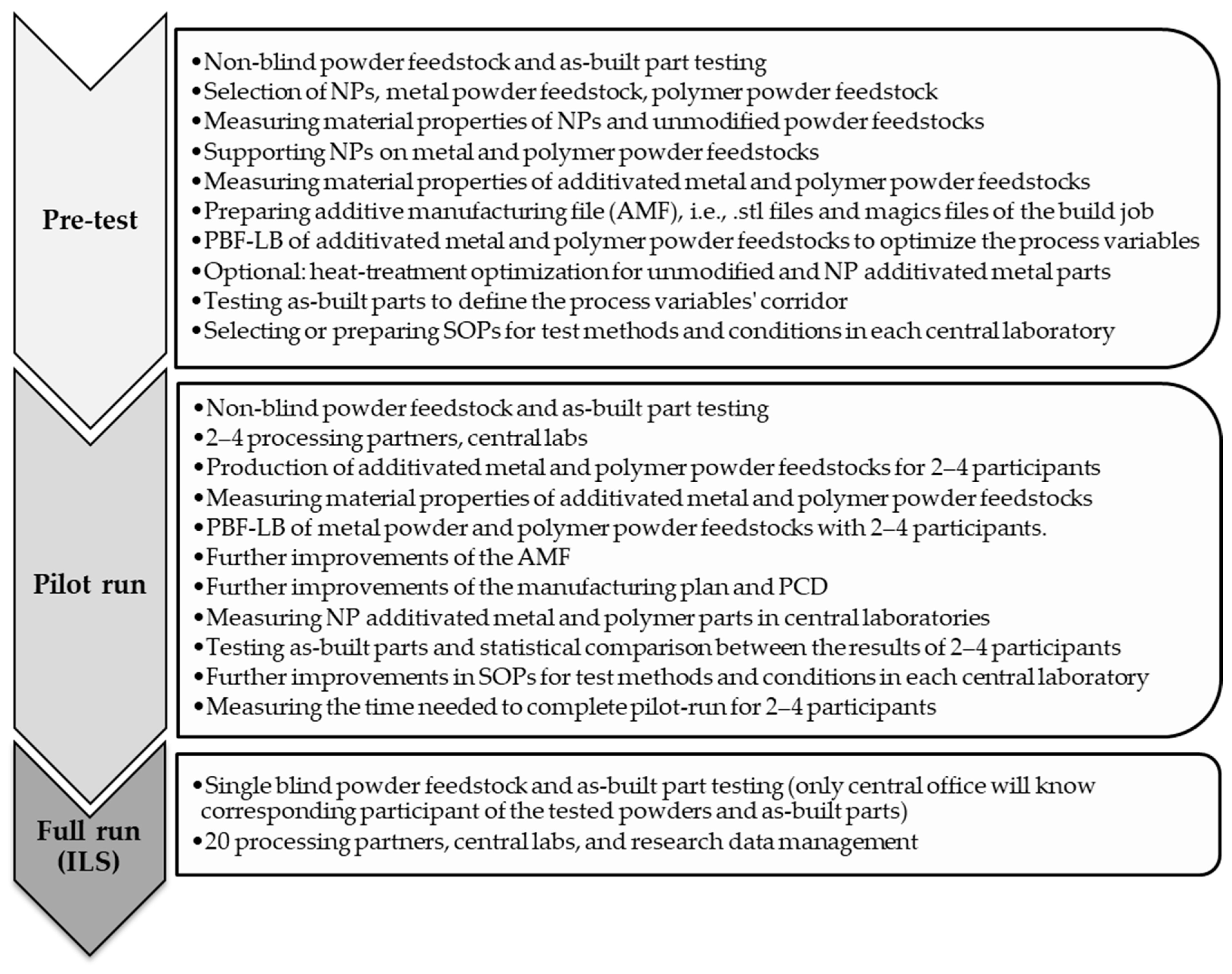

3. Recommended Implementation Procedure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ISO/ASTM 52910, Additive Manufacturing–Design–Requirements, Guidelines and Recommendations. Available online: https://www.iso.org/standard/67289.html (accessed on 14 February 2020).

- Kusoglu, I.M.; Gökce, B.; Barcikowski, S. Research trends in Laser Powder Bed Fusion of Al alloys within the last decade. Addit. Manuf. 2020, 36, 101489. [Google Scholar] [CrossRef]

- Kusoglu, I.M.; Doñate-Buendía, C.; Barcikowski, S.; Gökce, B. Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials 2021, 14, 1169. [Google Scholar] [CrossRef]

- EOS, 3D Printing for Metals. Available online: https://www.eos.info/en/additive-manufacturing/3d-printing-metal (accessed on 3 April 2021).

- SLM Solutions, Industrial Metal Additive Manufacturing Machines. Available online: https://www.slm-solutions.com/products-and-solutions/machines/ (accessed on 3 April 2021).

- 3D systems, Selective Laser Sintering. Available online: https://www.3dsystems.com/resources/information-guides/selective-laser-sintering/sls (accessed on 3 April 2021).

- EOS, 3D Printing with Plastics. Available online: https://www.eos.info/en/additive-manufacturing/3d-printing-plastic (accessed on 3 April 2021).

- Paul, C.P.; Jinoop, A.N.; Nayak, S.K.; Paul, A.C. Laser Additive Manufacturing in Industry 4.0: Overview, Applications, and Scenario in Developing Economies. In Additive Manufacturing Applications for Metals and Composites; Balasubramanian, K., Senthilkumar, V., Eds.; IGI Global: Hershey, PA, USA, 2020; pp. 271–295. [Google Scholar]

- DebRoy, T.; Mukherjee, T.; Wei, H.L.; Elmer, J.W.; Milewski, J.O. Metallurgy, mechanistic models and machine learning in metal printing. Nat. Rev. Mater. 2021, 6, 48–68. [Google Scholar] [CrossRef]

- Wei, H.L.; Mukherjee, T.; Zhang, W.; Zuback, J.S.; Knapp, G.L.; De, A.; DebRoy, T. Mechanistic models for additive manufacturing of metallic components. Prog. Mater. Sci. 2021, 116, 100703. [Google Scholar] [CrossRef]

- International Standard Organization, Committee ISO/TC261 on Additive Manufacturing. Available online: https://www.iso.org/committee/629086.html (accessed on 3 April 2021).

- ASTM International, Committee F42 on Additive Manufacturing Technologies. Available online: https://www.astm.org/COMMIT/SUBCOMMIT/F42.htm (accessed on 3 April 2021).

- Pannitz, O.; Sehrt, J.T. Transferability of Process Parameters in Laser Powder Bed Fusion Processes for an Energy and Cost Efficient Manufacturing. Sustainability 2020, 12, 1565. [Google Scholar] [CrossRef] [Green Version]

- Dechet, M.A.; Demina, A.; Römling, L.; Gómez Bonilla, J.S.; Lanyi, F.J.; Schubert, D.W.; Bück, A.; Peukert, W.; Schmidt, J. Development of poly(L-lactide) (PLLA) microspheres precipitated from triacetin for application in powder bed fusion of polymers. Addit. Manuf. 2020, 32, 100966. [Google Scholar] [CrossRef]

- Dechet, M.A.; Baumeister, I.; Schmidt, J. Development of Polyoxymethylene Particles via the Solution-Dissolution Process and Application to the Powder Bed Fusion of Polymers. Spec. Polym. Addit. Manuf. 2020, 13, 1535. [Google Scholar] [CrossRef] [Green Version]

- Dechet, M.A.; Schmidt, J. On the Development of Polymer Particles for Laser Powder Bed Fusion via Precipitation. Procedia CIRP 2020, 94, 95–99. [Google Scholar] [CrossRef]

- Bierwisch, C.; Mohseni-Mofidi, S.; Dietemann, B.; Kraft, T.; Rudloff, J.; Baumann, S.; Popp, K.; Lang, M. Particle-based Simulation and Dimensional Analysis of Laser Powder Bed Fusion for Polymers and Metals. Procedia CIRP 2020, 94, 74–79. [Google Scholar] [CrossRef]

- Sommereyns, A.; Hupfeld, T.; Gökce, B.; Barcikowski, S.; Schmidt, M. Evaluation of essential powder properties through complementary particle size analysis methods for laser powder bed fusion of polymers. Procedia CIRP 2020, 94, 116–121. [Google Scholar] [CrossRef]

- Hupfeld, T.; Doñate-Buendía, C.; Krause, M.; Sommereyns, A.; Wegner, A.; Sinnemann, T.; Schmidt, M.; Gökce, B.; Barcikowski, S. Scaling up colloidal surface additivation of polymer powders for laser powder bed fusion. Procedia CIRP 2020, 94, 110–115. [Google Scholar] [CrossRef]

- Bierwisch, C.; Mohseni-Mofidi, S.; Dietemann, B.; Kraft, T.; Rudloff, J.; Lang, M. Particle-based simulation, dimensional analysis and experimental validation of laser absorption and thermo-viscous flow during sintering of polymers. Procedia CIRP 2020, 94, 74–79. [Google Scholar] [CrossRef]

- Taruttis, A.; Hardes, C.; Röttger, A.; Uhlenwinkel, V.; Chehreh, A.B.; Theisen, W.; Walther, F.; Zoch, H.W. Laser additive manufacturing of hot work tool steel by means of a starting powder containing partly spherical pure elements and ferroalloys. Procedia CIRP 2020, 94, 46–51. [Google Scholar] [CrossRef]

- Abel, A.; Wessarges, Y.; Julmi, S.; Hoff, C.; Hermsdorf, J.; Klose, C.; Maier, H.J.; Kaierle, S.; Overmeyer, L. Laser powder bed fusion of WE43 in hydrogen-argon-gas atmosphere. Procedia CIRP 2020, 94, 21–24. [Google Scholar] [CrossRef]

- Döring, M.; Boussinot, G.; Hagen, J.F.; Apel, M.; Kohl, S.; Schmidt, M. Scaling melt pool geometry over a wide range of laser scanning speeds during laser-based Powder Bed Fusion. Procedia CIRP 2020, 94, 58–63. [Google Scholar] [CrossRef]

- Rudloff, J.; Lang, M.; Mohseni-Mofidi, S.; Bierwisch, C. Experimental investigations for improved modelling of the laser sintering process of polymers. Procedia CIRP 2020, 94, 80–84. [Google Scholar] [CrossRef]

- Kusoglu, I.M.; Gökce, B.; Barcikowski, S. Use of (Nano-)Additives in Laser Powder Bed Fusion of Al powder feedstocks: Research directions within the last decade. Procedia CIRP 2020, 94, 11–16. [Google Scholar] [CrossRef]

- Pannitz, O.; Lüddecke, A.; Sehrt, J.T.; Kwade, A. Improvement of the laser powder bed fusion process by surface tailored metal powders. In Proceedings of the Fraunhofer Direct Digital Manufacturing Conference (DDMC) 2020, Berlin, Germany, 18–19 March 2019. [Google Scholar]

- Vieth, P.; Voigt, M.; Ebberta, C.; Milkereit, B.; Zhuravlev, E.; Yang, B.; Keßler, O.; Grundmeier, G. Surface inoculation of aluminium powders for additive manufacturing of Al-7075 alloys. Procedia CIRP 2020, 94, 17–20. [Google Scholar] [CrossRef]

- Hupfeld, T.; Blasczyk, A.; Schuffenhauer, T.; Zhuravlev, E.; Krebs, M.; Gann, S.; Keßler, O.; Schmidt, M.; Gökce, B.; Barcikowski, S. How colloidal surface additivation of polyamide 12 powders with well-dispersed silver nanoparticles influences the crystallization already at low 0.01 vol%. Addit. Manuf. 2020, 36, 101419. [Google Scholar] [CrossRef]

- Hupfeld, T.; Sommereyns, A.; Riahi, F.; Doñate-Buendía, C.; Gann, S.; Schmidt, M.; Gökce, B.; Barcikowski, S. Analysis of the nanoparticle dispersion and its effect on the crystalline microstructure in carbon-additivated PA12 feedstock material for laser powder bed fusion. Materials 2020, 13, 3312. [Google Scholar] [CrossRef] [PubMed]

- Doñate-Buendia, C.; Streubel, R.; Kürnsteiner, P.; Wilms, M.B.; Stern, F.; Tenkamp, J.; Bruder, E.; Barcikowski, S.; Gault, B.; Durst, K.; et al. Effect of nanoparticle additivation on the microstructure and microhardness of oxide dispersion strengthened steels produced by laser powder bed fusion and directed energy deposition. Procedia CIRP 2020, 94, 41–45. [Google Scholar] [CrossRef]

- Hupfeld, T.; Salamon, S.; Landers, J.; Sommereyns, A.; Doñate-Buendía, C.; Schmidt, J.; Wende, H.; Schmidt, M.; Barcikowski, S.; Gökce, B. 3D Printing of magnetic parts by Laser Powder Bed Fusion of iron oxide nanoparticle functionalized polyamide powders. J. Mater. Chem. C 2020, 8, 12204–12217. [Google Scholar] [CrossRef]

- Hupfeld, T.; Wegner, A.; Blanke, M.; Doñate-Buendía, C.; Sharov, V.; Nieskens, S.; Piechotta, M.; Giese, M.; Barcikowski, S.; Gökce, B. Plasmonic seasoning: Giving color to desktop laser 3D-printed polymers by highly dispersed nanoparticles. Adv. Opt. Mater. 2020, 8, 2000473. [Google Scholar] [CrossRef]

- Doñate-Buendia, C.; Kürnsteiner, P.; Stern, F.; Wilms, M.B.; Streubel, R.; Kusoglu, I.M.; Tenkamp, J.; Bruder, E.; Pirch, N.; Barcikowski, S.; et al. Microstructure formation and mechanical properties of ODS steels built by Laser Additive Manufacturing of nanoparticle coated iron-chromium powders. Acta Mater. 2021, 26, 116566. [Google Scholar] [CrossRef]

- Sonawane, A.; Roux, G.; Blandin, J.-J.; Despres, A.; Martin, G. Cracking mechanism and its sensitivity to processing conditions during laser powder bed fusion of a structural aluminum alloy. Materiala 2021, 15, 100976. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.; Mayer, J.; Mone, R.; Stonkevitch, E.; Miller, J.; O’Masta, M.R.; Schaedler, T.; Hundley, J.; Callahan, P.; et al. Grain refinement mechanisms in additively manufactured nano-functionalized aluminum. Acta Mater. 2020, 200, 1022–1037. [Google Scholar] [CrossRef]

- Kleijnen, R.G.; Schmid, M.; Wegener, K. Impact of Flow Aid on the Flowability and Coalescence of Polymer Laser Sintering Powder, Solid Freeform Fabrication 2019. In Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference 2019, Austin, TX, USA, 12–14 August 2019; pp. 806–817. [Google Scholar]

- Sommereyns, A.; Hupfeld, T.; Gann, S.; Wang, T.; Wu, C.; Zhuravlev, E.; Lüddecke, A.; Baumann, S.; Rudloff, J.; Lang, M.; et al. Influence of sub-monolayer quantities of carbon nanoparticles on the melting and crystallization behavior of polyamide 12 powders for additive manufacturing. Mater. Des. 2021, 201, 109487. [Google Scholar] [CrossRef]

- Pannitz, O.; Lüddecke, A.; Kwade, A.; Sehrt, J.T. Investigation of the in situ thermal conductivity and absorption behavior of nanocomposite powder materials in laser powder bed fusion processes. Mater. Des. 2021, 201. [Google Scholar] [CrossRef]

- Lüddecke, A.; Pannitz, O.; Zetzener, H.; Sehrt, J.T.; Kwade, A. Powder properties and flowability measurements of tailored nanocomposites for powder bed fusion applications. Mater. Des. 2021, 202, 109536. [Google Scholar] [CrossRef]

- Gärtner, E.; Jung, H.Y.; Peter, N.J.; Dehm, G.; Jägle, E.A.; Uhlenwinkel, V.; Mädler, L. Reducing cohesion of metal powders for additive manufacturing by nanoparticle dry-coating. Powder Technol. 2021, 379, 585–595. [Google Scholar] [CrossRef]

- Doñate-Buendía, C.; Frömel, F.; Wilms, M.B.; Streubel, R.; Tenkamp, J.; Hupfeld, T.; Nachev, M.; Gökce, E.; Weisheit, A.; Barcikowski, S.; et al. Oxide dispersion-strengthened alloys generated by laser metal deposition of laser-generated nanoparticle-metal powder composites. Mater. Des. 2018, 154, 360–369. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Ho, I.-T.; Chen, Y.-T.; Yeh, A.-C.; Chen, C.-P.; Jen, K.-K. Microstructure evolution induced by inoculants during the selective laser melting of IN718. Addit. Manuf. 2018, 21, 465–471. [Google Scholar] [CrossRef]

- Gao, C.; Wang, Z.; Xiao, Z.; You, D.; Wong, K.; Akbarzadeh, A.H. Selective laser melting of TiN nanoparticle-reinforced AlSi10Mg composite: Microstructural, interfacial, and mechanical properties. J. Mater. Process. Technol. 2020, 281, 116618. [Google Scholar] [CrossRef]

- Mangour, B.A.; Kim, Y.-K.; Grzesiak, D.; Lee, K.-A. Novel TiB2-reinforced 316L stainless steel nanocomposites with excellent room- and high-temperature yield strength developed by additive manufacturing. Compos. Part B Eng. 2019, 156, 51–63. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Yakout, M.; Cadamuro, A.; Elbestawi, M.A.; Veldhuiset, S.C. The selection of process parameters in additive manufacturing for aerospace alloys. Int. J. Adv. Manuf. Technol. 2017, 92, 2081–2098. [Google Scholar] [CrossRef]

- Dowling, L.; Kennedy, J.; O’Shaughnessy, S.; Trimble, D. A review of critical repeatability and reproducibility issues in powder bed fusion. Mater. Des. 2020, 186, 108346. [Google Scholar] [CrossRef]

- Lefebvre, L.P.; Whiting, J.; Nijikovsky, B.; Brika, S.E.; Fayazfar, H.; Lyckfeldt, O. Assessing the robustness of powder rheology and permeability measurements. Addit. Manuf. 2020, 35, 101203. [Google Scholar] [CrossRef]

- Slotwinski, J.A.; Garboczi, E.J.; Stutzman, P.E.; Ferraris, C.F.; Watson, S.S.; Peltz, M.A. Characterization of metal powders used for additive manufacturing. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 460–493. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, F.; Levy, G.; Wegener, K. Flowability of powders for selective laser sintering (SLS) investigated by round robin test. In High Value Manufacturing, Proceedings of the 6th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 1–5 October 2013; Taylor & Francis: Abingdon, UK, 2013; pp. 95–99. [Google Scholar] [CrossRef]

- Affolter, S.; Ritter, A.; Schmid, M. Interlaboratory tests on polymers by Differential Scanning Calorimetry (DSC): Determination of glass transition temperature (Tg). Macromol. Mater. Eng. 2001, 286, 605–610. [Google Scholar] [CrossRef]

- Brown, C.U.; Jacob, G.; Stoudt, M.; Moylan, S.; Slotwinski, J.; Donmez, A. Interlaboratory Study for Nickel Alloy 625 Made by Laser Powder Bed Fusion to Quantify Mechanical Property Variability. J. Mater. Eng. Perform. 2016, 25, 3390–3397. [Google Scholar] [CrossRef]

- Ahuja, B.; Schaub, A.; Junker, D.; Karg, M.; Tenner, F.; Plettke, R.; Merklein, M.; Schmidt, M. A round robin study for laser beam melting in a metal powder. S. Afr. J. Ind. Eng. 2016, 27, 30–42. [Google Scholar] [CrossRef] [Green Version]

- Slotwinski, J.; Luecke, W.; Lass, E.; Possolo, A. Interlaboratory mechanical-property study for Cobalt-Chromium alloy made by laser powder-bed-fusion additive manufacturing. J. Res. NIST 2018. [Google Scholar] [CrossRef]

- Stichel, T.; Frick, T.; Laumer, T.; Tenner, F.; Hausotte, T.; Merklein, M.; Schmidt, M. A round robin study for selective laser sintering of polyamide 12: Microstructural origin of the mechanical properties. Opt. Laser Technol. 2017, 89, 31–40. [Google Scholar] [CrossRef]

- Stichel, T.; Frick, T.; Laumer, T.; Tenner, F.; Hausotte, T.; Merklein, M.; Schmidt, M. A round robin study for selective laser sintering of polyamide 12: Back tracing of the pore morphology to the process parameters. J. Mater. Process. Tech. 2018, 252, 537–545. [Google Scholar] [CrossRef]

- du Plessis, A.; le Roux, S.G. Standardized X-ray tomography testing of additively manufactured parts: A round robin test. Addit. Manuf. 2018, 24, 125–136. [Google Scholar] [CrossRef]

- Townsend, A.; Racasan, R.; Leach, R.; Senin, N.; Thompson, A.; Ramsey, A.; Bate, D.; Woolliams, P.; Brown, S.; Blunt, L. An interlaboratory comparison of X-ray computed tomography measurement for texture and dimensional characterization of additively manufactured parts. Addit. Manuf. 2018, 23, 422–432. [Google Scholar]

- Moylan, S.; Brown, C.U.; Slotwinski, J. Recommended protocol for Round-Robin studies in Additive Manufacturing. J. Test. Eval. 2016, 44, 1009–1018. [Google Scholar] [CrossRef] [Green Version]

- Maier, E.A. Techniques and Instrumentation in Analytical Chemistry, Chapter 12 Interlaboratory Studies; Elsevier: Amsterdam, The Netherlands, 1999; Volume 22, pp. 481–535. [Google Scholar]

- Yuan, P.; Gu, D.; Dai, D. Particulate migration behavior and its mechanism during selective laser melting of TiC reinforced Al matrix nanocomposites. Mater. Des. 2015, 82, 46–55. [Google Scholar] [CrossRef]

- Garmay, A.V.; Oskolok, K.V.; Monogarova, O.V. Improved Accuracy of Multicomponent Samples Analysis by X-ray Fluorescence Using Relative Intensities and Scattered Radiation: A Review. Anal. Lett. 2020, 53, 2685–2699. [Google Scholar] [CrossRef]

- Rumpf, H. Die Wissenschaft des Agglomerierens. Chem. Ing. Tech. 1974, 1, 1–46. [Google Scholar] [CrossRef]

- Meyer, K.; Zimmermann, I. Effect of glidants in binary powder mixtures. Powder Technol. 2004, 139, 40–54. [Google Scholar] [CrossRef]

- Mourdikoudis, S.; Pallares, R.M.; Thanh, N.T.K. Characterization techniques for nanoparticles: Comparison and complementarity upon studying nanoparticle properties. Nanoscale 2018, 10, 12871–12934. [Google Scholar] [CrossRef] [Green Version]

- Teulon, J.-M.; Godon, C.; Chantalat, L.; Moriscot, C.; Cambedouzou, J.; Odorico, M.; Ravaux, J.; Podor, R.; Gerdil, A.; Habert, A.; et al. On the Operational Aspects of Measuring Nano-particle Sizes. Nanomaterials 2019, 9, 18. [Google Scholar] [CrossRef] [Green Version]

- Letzel, A.; Gökce, B.; Menzel, A.; Plech, A.; Barcikowski, S. Primary particle diameter differentiation and bimodality identification by five analytical methods using gold nanoparticle size distributions synthesized by pulsed laser ablation in liquids. Appl. Surf. Sci. 2018, 435, 743–751. [Google Scholar] [CrossRef]

- Pereira, J.S.F.; Knorr, C.L.; Pereira, L.S.F.; Moraes, D.P.; Paniz, J.N.G.; Flores, E.M.M.; Knapp, G. Evaluation of sample preparation methods for polymer digestion and trace elements determination by ICPMS and ICPOES. J. Anal. At. Spectrom. 2011, 26, 1849–1857. [Google Scholar] [CrossRef]

- Bonesso, M.; Rebesan, P.; Gennari, C.; Dima, R.; Pepato, A.; Calliari, I. Effect of particle size distribution on laser powder bed fusion manufacturability of copper. Berg Huettenmaenn Mon. 2021, 166, 256–262. [Google Scholar] [CrossRef]

- Brika, S.E.; Letenneur, M.; Dion, C.A.; Brailovski, V. Influence of particle morphology and size distribution on the powder flowability and laser powder bed fusion manufacturability of Ti-6Al-4V alloy. Addit. Manuf. 2020, 31, 100929. [Google Scholar] [CrossRef]

- Kuznetsov, P.A.; Shakirov, I.V.; Zukov, A.S.; Bobyr’, V.V.; Starytsin, M.V. Effect of particle size distribution on the structure and mechanical properties in the process of laser powder bed fusion. J. Phys. Conf. Ser. 2021, 1758, 1–9. [Google Scholar] [CrossRef]

- Beitz, S.; Uerlich, R.; Bokelmann, T.; Diener, A.; Vietor, T.; Kwade, A. Influence of Powder Deposition on Powder Bed and Specimen Properties. Materials 2019, 12, 297. [Google Scholar] [CrossRef] [Green Version]

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An overview of powder granulometry on feedstock and part performance in the selective laser melting process. Addit. Manuf. 2017, 18, 228–255. [Google Scholar] [CrossRef] [Green Version]

- Fissan, H.; Ristig, S.; Kaminski, H.; Asbach, C.; Epple, M. Comparison of different characterization methods for nanoparticle dispersions before and after aerosolization. Anal. Methods 2014, 6, 7324–7334. [Google Scholar] [CrossRef] [Green Version]

- ASTM F3318-18: Standard for Additive Manufacturing, Finished Part Properties, Specification for AlSi10Mg with Powder Bed Fusion-Laser Beam. ASTM International: West Conshohocken, PA, USA, 2018. Available online: www.astm.org (accessed on 3 April 2021).

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef] [Green Version]

- ASTM E112-13: Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2018. Available online: www.astm.org (accessed on 3 April 2021).

- Wudy, K.; Drummer, D. Aging effects of polyamide 12 in selective laser sintering: Molecular weight distribution and thermal properties. Addit. Manuf. 2019, 25, 1–9. [Google Scholar] [CrossRef]

- Zhao, M.; Wudy, K.; Drummer, D. Crystallization Kinetics of Polyamide 12 during Selective Laser Sintering. Polymers 2018, 10, 168. [Google Scholar] [CrossRef] [Green Version]

- Sehrt, J.T.; Kleszczynski, S.; Notthoff, C. Nanoparticle improved metal materials for additive manufacturing. Prog. Addit. Manuf. 2017, 2, 179–191. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Shi, J.; Lu, S.; Xiao, W. Investigation of Porosity and Mechanical Properties of Graphene Nanoplatelets-Reinforced AlSi10Mg by Selective Laser Melting. J. Micro Nano-Manuf. March 2018, 6. [Google Scholar] [CrossRef] [Green Version]

- Sastri, V.R. 5-Polymer Additives Used to Enhance Material Properties for Medical Device Applications. In Plastics in Medical Devices, 2nd ed.; Sastri, V.R., Ed.; William Andrew Publishing: Norwich, NY, USA, 2014; pp. 55–72. [Google Scholar]

- Wagner, H.D.; Vaia, R.A. Nanocomposites: Issues at the interface. Mater. Today 2004, 7, 38–42. [Google Scholar] [CrossRef]

- Yang, Y.; Doñate-Buendía, C.; Oyedeji, T.D.; Gökce, B.; Xu, B.-X. Nanoparticle Tracing during Laser Powder Bed Fusion of Oxide Dispersion Strengthened Steels. Materials 2021, 14, 3463. [Google Scholar] [CrossRef]

- Gu, D. Nanoscale TiC particle-reinforced AlSi10Mg bulk-form nanocomposites by selective laser melting (SLM) additive manufacturing (AM): Tailored microstructures and enhanced properties. In Laser Additive Manufacturing of High-Performance Materials; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- DIN EN ISO 6892-1:2020-06: Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature, DIN Standards. Available online: https://www.beuth.de/de/norm/din-en-iso-6892-1/317931281 (accessed on 3 April 2021).

- ISO 527-2:2012, Plastics-Determination of tensile properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. Available online: https://www.iso.org/standard/56046.html (accessed on 3 April 2021).

- Wilkinson, M.D.; Dumontier, M.; Aalbersberg, I.J.; Appleton, G.; Axton, M.; Baak, A.; Blomberg, N.; Boiten, J.-W.; da Silva Santos, L.B.; Bourne, P.E.; et al. The FAIR Guiding Principles for scientific data management and stewardship. Sci. Data 2016, 3, 160018. [Google Scholar] [CrossRef] [Green Version]

- ASTM F2971-13: Standard Practice for Reporting Data for Test Specimens Prepared by Additive Manufacturing; ASTM International: West Conshohocken, PA, USA, 2013; Available online: www.astm.org (accessed on 3 April 2021).

- ASTM WK73978, New Specification for Additive Manufacturing—Data Registration. Available online: https://www.astm.org/DATABASE.CART/WORKITEMS/WK73978.htm (accessed on 3 April 2021).

- ASTM E691-20: Standard Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method; ASTM International: West Conshohocken, PA, USA, 2019; Available online: www.astm.org (accessed on 3 April 2021).

- Luping, T.; Schouenborg, B. Methodology of Inter-Comparison Tests and Statistical Analysis of Test Results, SP Report; SP Swedish National Testing and Research Institute: Boras, Sweden, 2000; Volume 35, Available online: http://www.nordtest.info/wp/2001/10/28/methodology-of-inter-comparison-tests-and-statistical-analysis-of-test-results-nt-tr-482/ (accessed on 3 April 2021).

- ISO/ASTM 52907-19: Additive Manufacturing, Feedstock Materials, Methods to Characterize Metallic Powders. Available online: https://www.iso.org/standard/73565.html (accessed on 3 April 2021).

- ASTM F3049-14: Standard Guide for Characterizing Properties of Metal Powders Used for Additive Manufacturing Processes; ASTM International: West Conshohocken, PA, USA, 2014; Available online: www.astm.org (accessed on 3 April 2021).

- ASTM B527-20: Standard Test Method for Tap Density of Metal Powders and Compounds by Fluorescence Spectrometry; ASTM International: West Conshohocken, PA, USA, 2020; Available online: www.astm.org (accessed on 3 April 2021).

- ASTM B822-20: Standard Test Method for Particle Size Distribution of Metal Powders and Related Compounds by Light Scattering; ASTM International: West Conshohocken, PA, USA, 2020; Available online: www.astm.org (accessed on 3 April 2021).

- ISO 13320:2020 Particle Size Analysis, Laser Diffraction Methods. Available online: https://www.iso.org/standard/69111.html (accessed on 3 April 2021).

- WK66030: Quality Assessment of Metal Powder Feedstock Characterization Data for Additive Manufacturing. Available online: https://www.astm.org/DATABASE.CART/WORKITEMS/WK66030.htm (accessed on 3 April 2021).

- WK55610: The Characterization of Powder Flow Properties for Additive Manufacturing Applications. Available online: https://www.astm.org/DATABASE.CART/WORKITEMS/WK55610.htm (accessed on 3 April 2021).

- WK74905: Additive Manufacturing-Feedstock-Particle Shape Analysis to Identify Agglomerates/Satellites in Feedstock. Available online: https://www.astm.org/DATABASE.CART/WORKITEMS/WK74905.htm (accessed on 3 April 2021).

- ASTM F3122-14: Standard Guide for Evaluating Mechanical Properties of Metal Materials Made via Additive Manufacturing Processes; ASTM International: West Conshohocken, PA, USA, 2014; Available online: www.astm.org (accessed on 3 April 2021).

- ASTM E572-13: Standard Test Method for Analysis of Stainless and Alloy Steels by Wavelength Dispersive X-Ray Fluorescence Spectrometry; ASTM International: West Conshohocken, PA, USA, 2013; Available online: www.astm.org (accessed on 3 April 2021).

- ASTM E8/E8M-16ae1: Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016; Available online: www.astm.org (accessed on 3 April 2021).

- WK49229: Orientation and Location Dependence Mechanical Properties for Metal Additive Manufacturing. Available online: https://www.astm.org/DATABASE.CART/WORKITEMS/WK49229.htm (accessed on 3 April 2021).

- ASTM E3166-20: Standard Guide for Nondestructive Examination of Metal Additively Manufactured Aerospace Parts after Build; ASTM International: West Conshohocken, PA, USA, 2020; Available online: www.astm.org (accessed on 3 April 2021).

- ISO 527-1:2012, Plastics-Determination of Tensile Properties—Part 1: General Principles. Available online: https://www.iso.org/standard/56045.html (accessed on 3 April 2021).

- WK66029: Mechanical Testing of Polymer Additively Manufactured Materials. Available online: https://www.astm.org/DATABASE.CART/WORKITEMS/WK66029.htm (accessed on 3 April 2021).

- ASTM F1877-16: Standard Practice for Characterization of Particles; ASTM International: West Conshohocken, PA, USA, 2016; Available online: www.astm.org (accessed on 3 April 2021).

- ASTM E2834-12(2018) Standard Guide for Measurement of Particle Size Distribution of Nanomaterials in Suspension by Nanoparticle Tracking Analysis (NTA); ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 3 April 2021).

- ASTM E3247-20 Standard Test Method for Measuring the Size of Nano-particles in Aqueous Media Using Dynamic Light Scattering; ASTM International: West Conshohocken, PA, USA, 2020; Available online: www.astm.org (accessed on 3 April 2021).

- ISO 17200:2020(en), Nanotechnology, Nanoparticles in Powder Form, Characteristics and Measurements. Available online: https://www.iso.org/obp/ui/#iso:std:iso:17200:ed-1:v1:en (accessed on 3 April 2021).

- ISO/TR 14187:2020(en), Surface Chemical Analysis, Characterization of Nanostructured Materials. Available online: https://www.iso.org/obp/ui/#iso:std:iso:tr:14187:ed-2:v1:en (accessed on 3 April 2021).

| Material | International Standards | Content |

|---|---|---|

| Metal Powder | ISO/ASTM 52907-19 [95] | Technical specification of as-produced and used feedstocks |

| ASTM F3049-14 [96] | Test methods for powder size, morphology, chemistry, flowability, and density | |

| ASTM B527-20 [97] | Test method for tap density | |

| ASTM B822-20 [98] | Particle size distribution by light scattering | |

| ISO 13320:2020 [99] | Particle size distribution by laser diffraction | |

| WK66030 [100] | Quality assessment guidelines for powder reusability | |

| WK55610 [101] | Powder dynamic flow properties | |

| WK74905 [102] | Particle shape analysis to identify agglomerates/satellites | |

| Polymer Powder | ISO 13320:2020 [99] | Particle size distribution by laser diffraction |

| WK55610 [101] | Powder dynamic flow properties | |

| As-built Metal Part | ASTM F3122-14 [103] | Evaluating mechanical properties |

| ASTM E572-13 [104] | Measuring chemical composition by wide wavelength XRF | |

| ASTM E8/E8M-16ae1 [105] | Tensile test | |

| WK49229 [106] | Orientation and location-dependent mechanical properties | |

| ASTM E3166-20 [107] | Non-destructive examination of as-built parts | |

| As-built Polymer Part | ISO 527-1:2012 [108] | General principles of tensile test |

| WK66029 [109] | Tensile test |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kusoglu, I.M.; Huber, F.; Doñate-Buendía, C.; Rosa Ziefuss, A.; Gökce, B.; T. Sehrt, J.; Kwade, A.; Schmidt, M.; Barcikowski, S. Nanoparticle Additivation Effects on Laser Powder Bed Fusion of Metals and Polymers—A Theoretical Concept for an Inter-Laboratory Study Design All Along the Process Chain, Including Research Data Management. Materials 2021, 14, 4892. https://doi.org/10.3390/ma14174892

Kusoglu IM, Huber F, Doñate-Buendía C, Rosa Ziefuss A, Gökce B, T. Sehrt J, Kwade A, Schmidt M, Barcikowski S. Nanoparticle Additivation Effects on Laser Powder Bed Fusion of Metals and Polymers—A Theoretical Concept for an Inter-Laboratory Study Design All Along the Process Chain, Including Research Data Management. Materials. 2021; 14(17):4892. https://doi.org/10.3390/ma14174892

Chicago/Turabian StyleKusoglu, Ihsan Murat, Florian Huber, Carlos Doñate-Buendía, Anna Rosa Ziefuss, Bilal Gökce, Jan T. Sehrt, Arno Kwade, Michael Schmidt, and Stephan Barcikowski. 2021. "Nanoparticle Additivation Effects on Laser Powder Bed Fusion of Metals and Polymers—A Theoretical Concept for an Inter-Laboratory Study Design All Along the Process Chain, Including Research Data Management" Materials 14, no. 17: 4892. https://doi.org/10.3390/ma14174892

APA StyleKusoglu, I. M., Huber, F., Doñate-Buendía, C., Rosa Ziefuss, A., Gökce, B., T. Sehrt, J., Kwade, A., Schmidt, M., & Barcikowski, S. (2021). Nanoparticle Additivation Effects on Laser Powder Bed Fusion of Metals and Polymers—A Theoretical Concept for an Inter-Laboratory Study Design All Along the Process Chain, Including Research Data Management. Materials, 14(17), 4892. https://doi.org/10.3390/ma14174892