Toolpath Planning and Generation for Multi-Stage Incremental Forming Based on Stretching Angle

Abstract

:1. Introduction

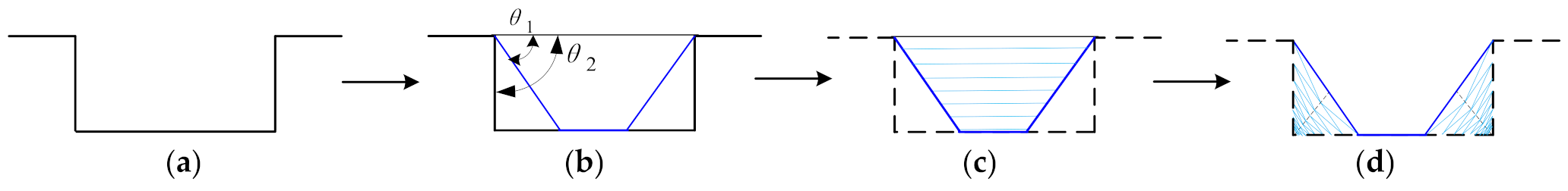

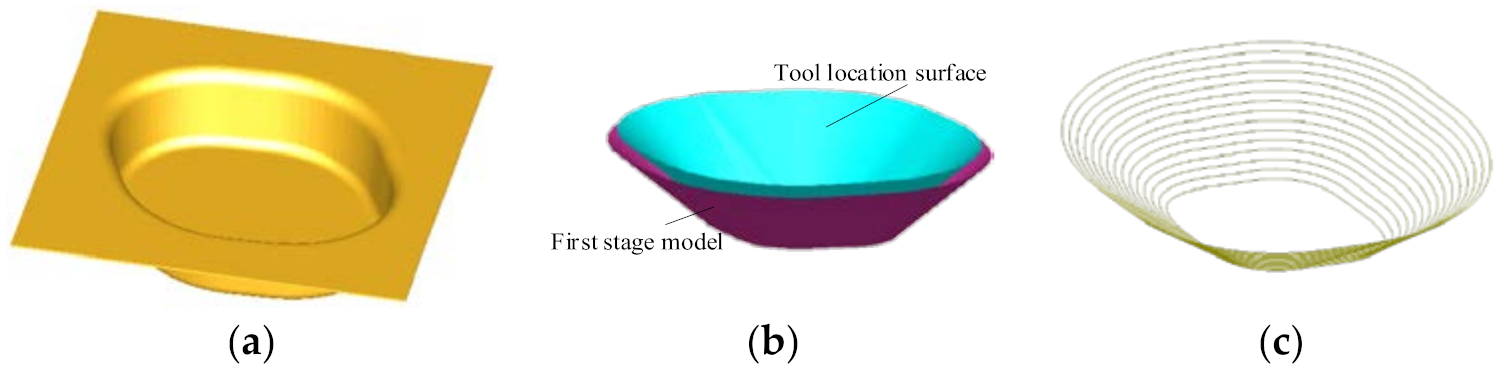

2. Proposed Toolpath Planning Strategy for the Multi-Stage Forming

3. Forming Toolpath Generation Algorithm for Each Stage Forming

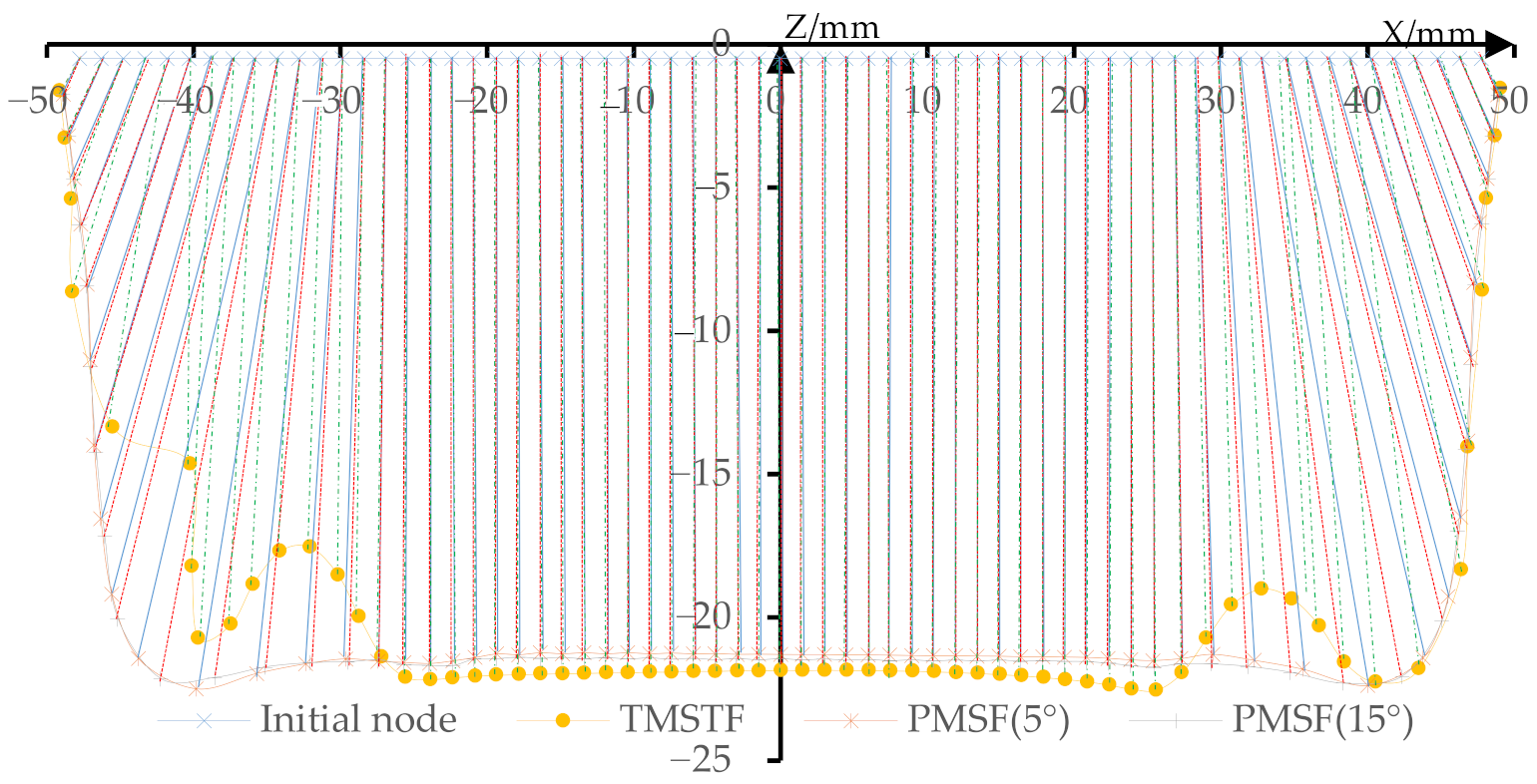

3.1. First Stage Forming Toolpath Generation Algorithm

3.2. Second Stage Forming Toolpath Generation Algorithm

- (1)

- Generate the tool location surface of the second forming stage. Offset the inner surface of the straight wall part equidistantly from the radius of the forming tool head along the direction of its normal vector to generate the tool location surface used to generate the second stage forming toolpath.

- (2)

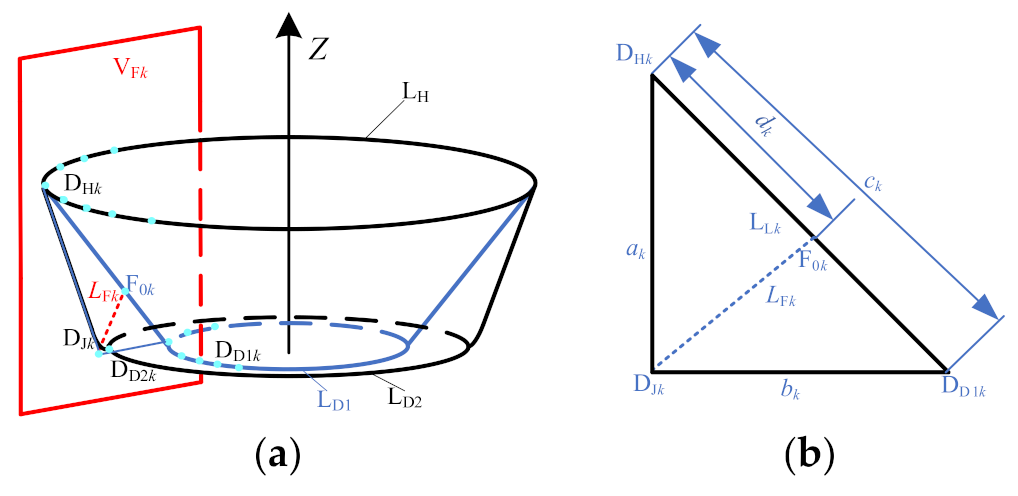

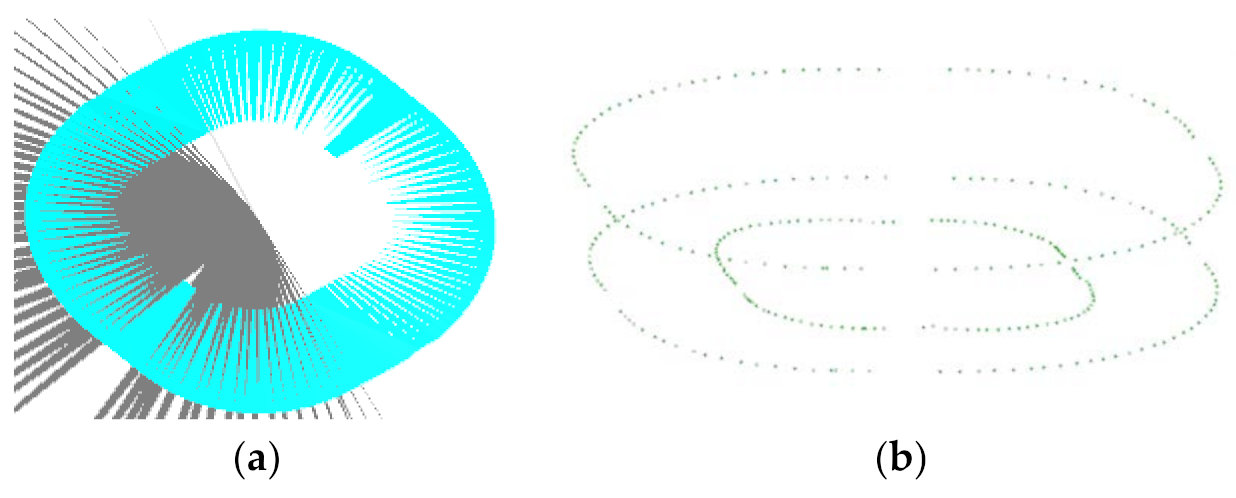

- Determine the position of auxiliary line LFk (k represents each position on the cross-sectional contour line). Use a vertical plane VFk passing the Z axis to intersect with the upper ring LH, lower ring LD1, and lower ring LD2 to obtain three intersection points DHk, DD1k, and DD2k, and intersect with the second stage forming model to obtain a straight wall part generatrix. Make the tangent line DHkDJk of the generatrix to intersect the connecting lines DD1k and DD2k at a point DJk and an auxiliary line LFk in the plane VFk, as shown in Figure 4a. The distance between F0k and point DHk, and the position of the starting point F0k of the auxiliary line (Figure 4b) are determined by using the length ratio of the sides, namelyHere, ak is the distance between the point DHk and the point DJk, bk is the distance between the point DD1k and the intersecting point DJk in the plane VFk, and ck is the distance between the connection LLk of the point DHk and the point DD1k. The auxiliary line LFk is the connection line between the starting point F0k and the intersection point DJk.

- (3)

- Set the size of the stretching angle ψ. The size of the stretching angle ψ can be set by the user.

- (4)

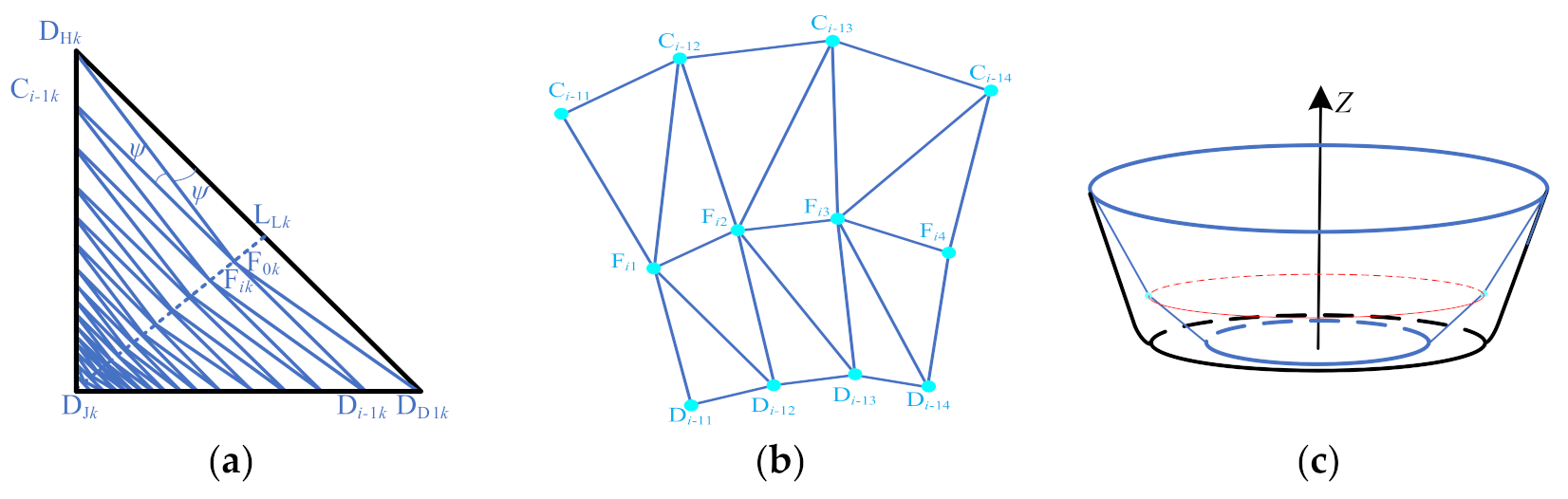

- Generate the sheet metal surface for the second stage forming. First, find the intersection point Fik (i represents the number of rotations of ψ) with each auxiliary line when the sheet material surface rotates ψ. For example, in the plane VFk, the line LLk is rotated ψ in the F0kDJk direction by using the point DHk as the center of rotation, and it intersects with the auxiliary line LFk at the point Fik. Then, take the point Fik as the center of rotation and then rotate ψ to intersect with the side wall at a point Ci-1k along the same direction, and extend the line segment Ci-1kFik to intersect the line segment DD1kDJk at point Di-1k (Figure 5a). Finally, the triangulation meshing is carried out on the sheet surface of each sheet posture adjusted. The method is to alternately connect the points Ci-1k, Fik, and Di-1k (Figure 5b) to construct a triangular surface to obtain the sheet surface (Figure 5c). Among them, the sheet surface of the first rotation ψ is obtained by constructing a triangular facet from alternately connected points DHk, F1k, and DD1k.

- (5)

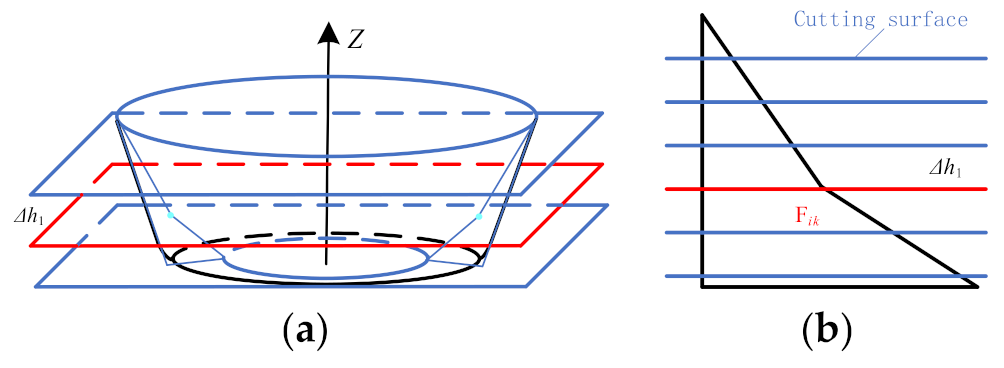

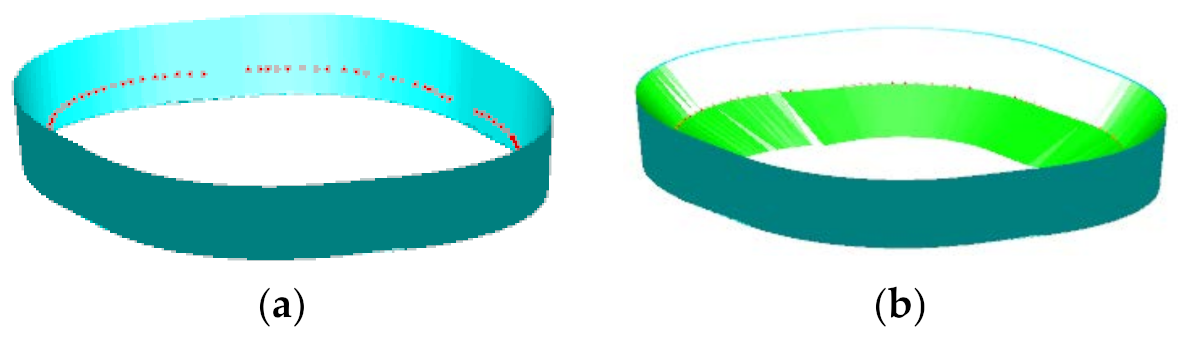

- Generate the second stage forming toolpath. A contour toolpath (Figure 6) is obtained by cutting the second stage forming sheet surface using a horizontal plane with a layer spacing of Δh1 equally from the horizontal plane where the point Fik is located. In addition, finally obtain the second forming toolpath by determining the moving direction of the forming tool according to the moving sequence of the forming tool.

3.3. Case Studies

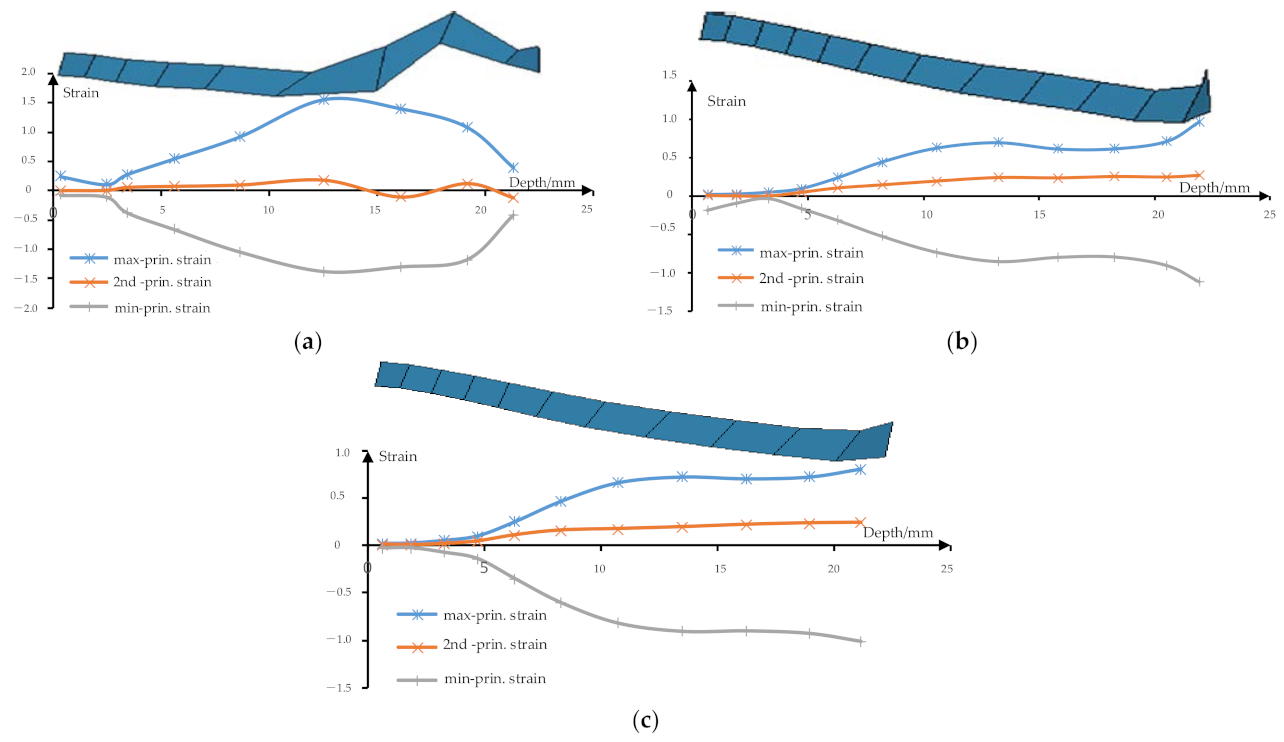

4. Finite Element Analysis

4.1. Establishment of the Finite Element Analysis Model

4.2. Finite Element Analysis Results

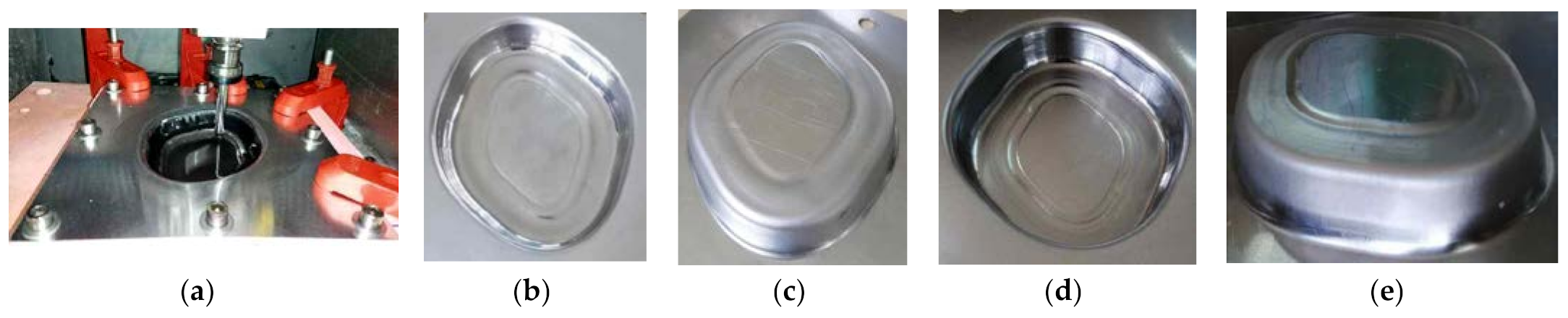

5. Forming Experiment

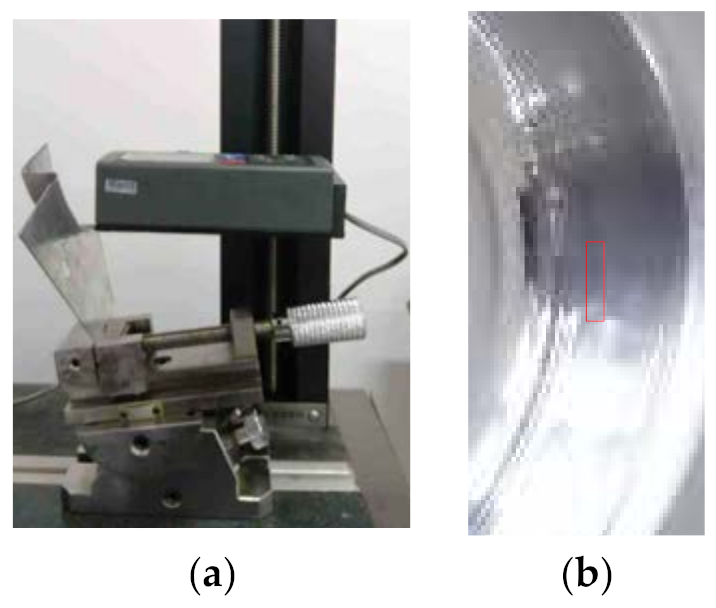

5.1. Experimental Process

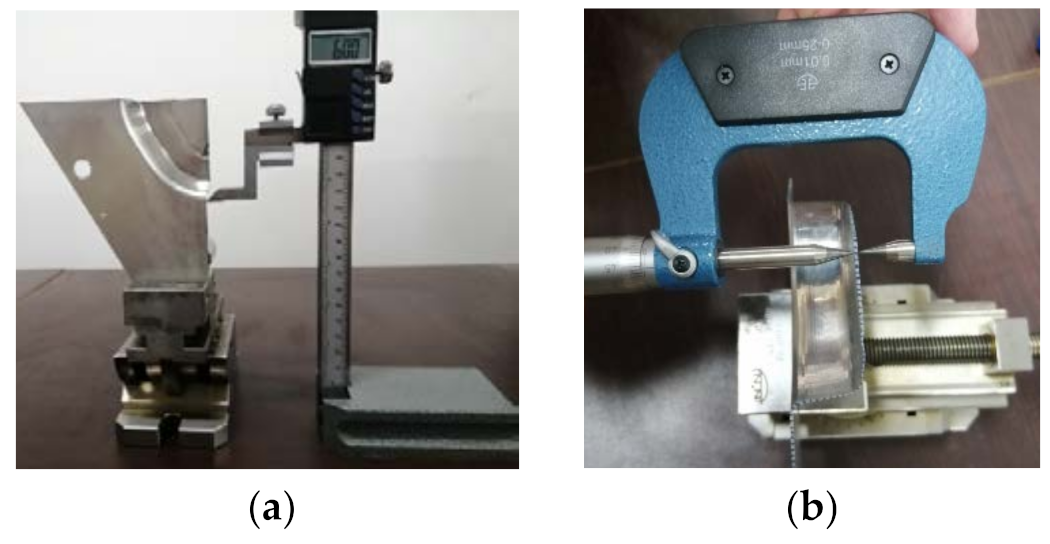

5.2. Forming Experimental Results

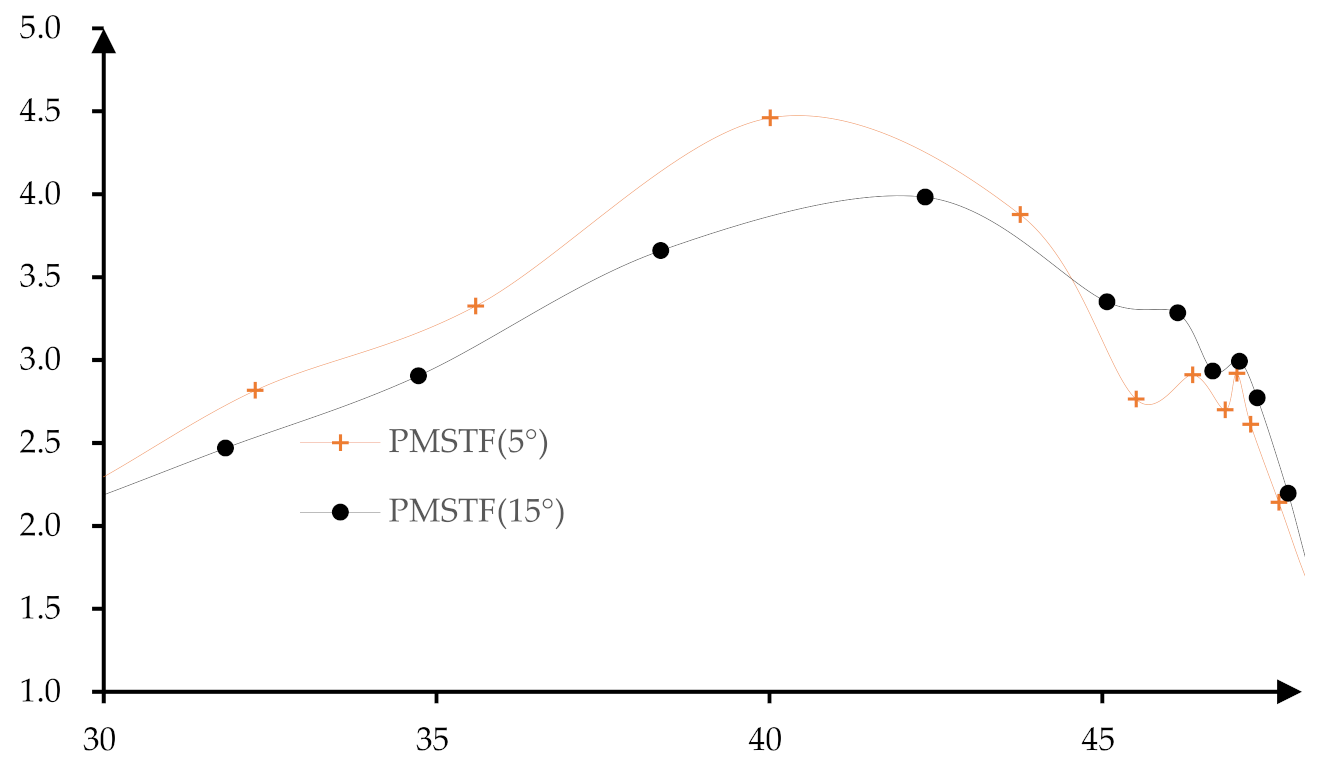

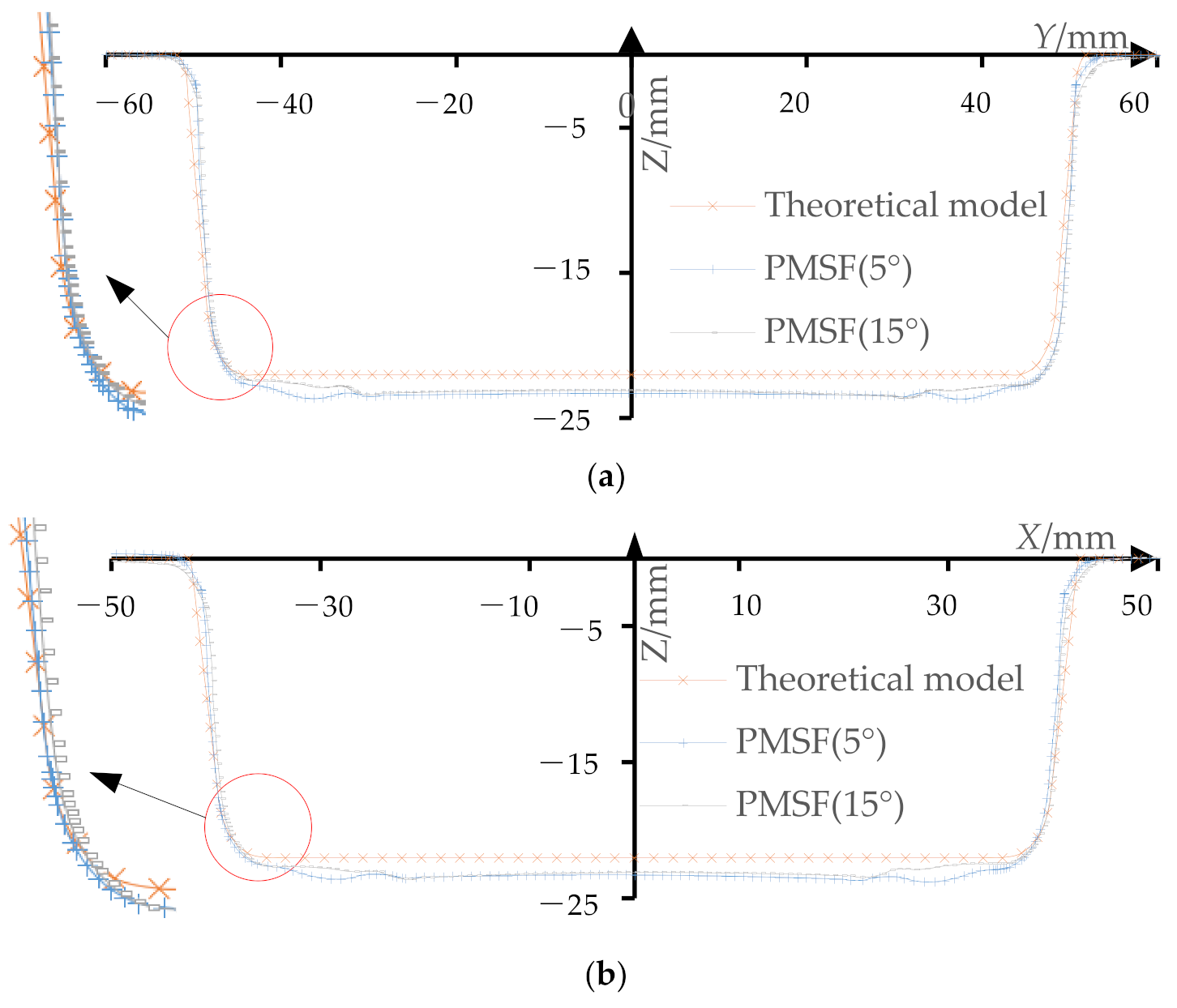

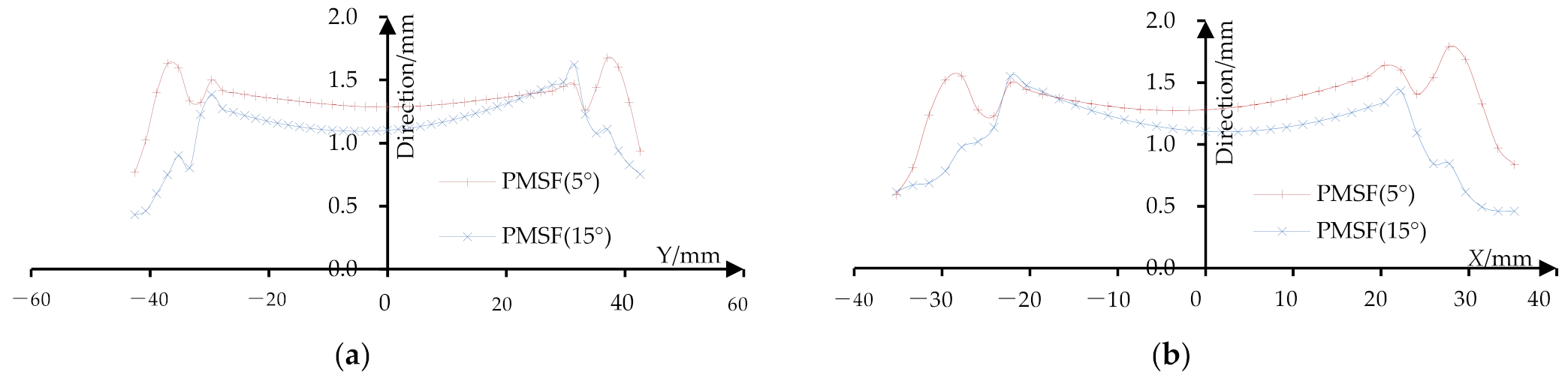

5.2.1. Dimensional Accuracy of Profile

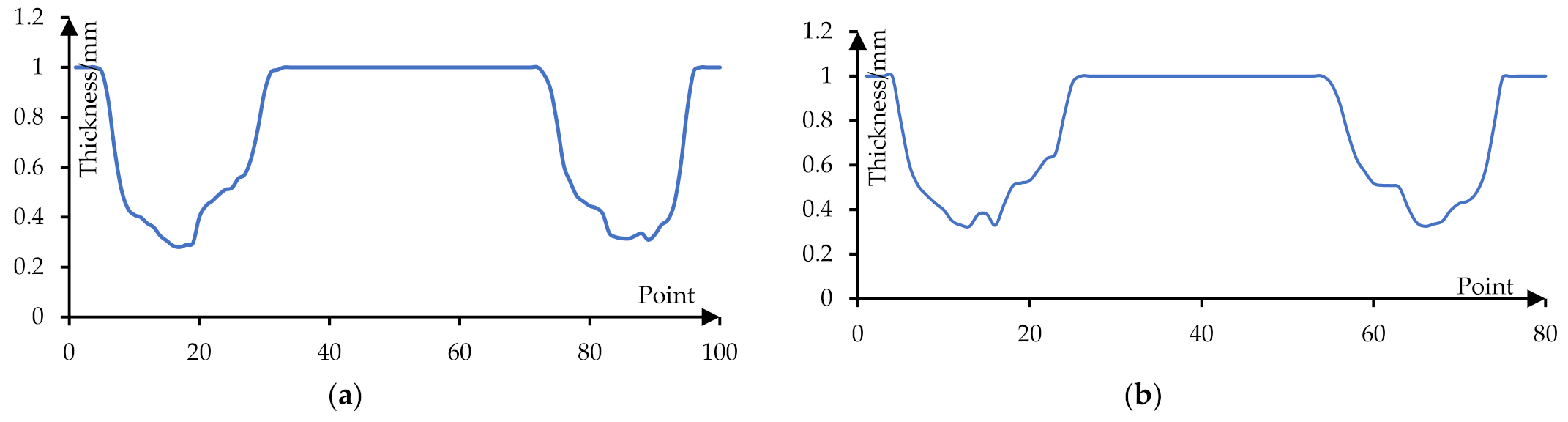

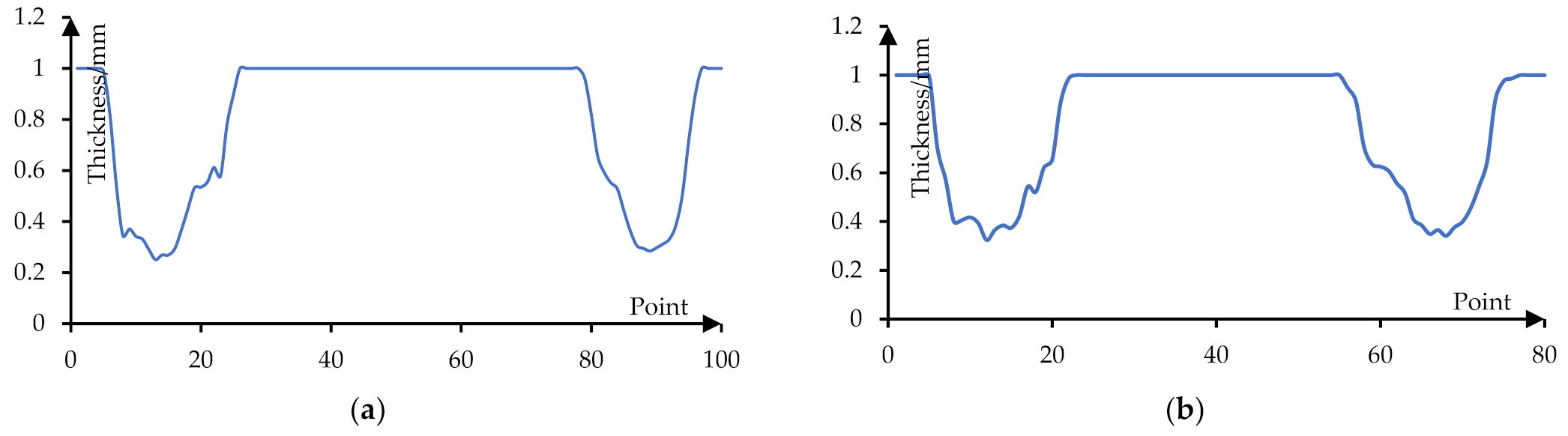

5.2.2. Thickness Distribution

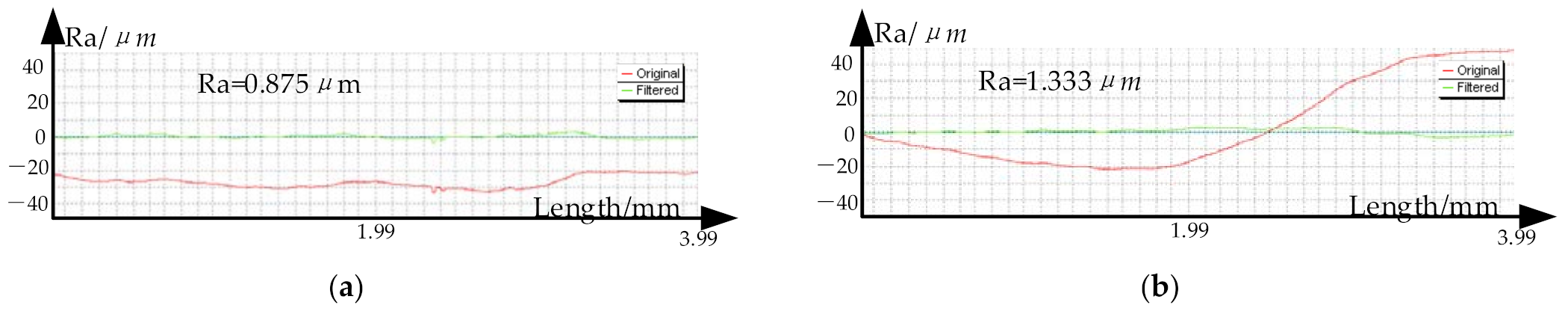

5.2.3. Roughness

5.3. Discussion and Analysis

6. Conclusions

- (1)

- The straight wall parts with the forming angle of 80° cannot be formed by the single stage forming, in which the sheet metal has been cracked when the forming depth reaches 14 mm.

- (2)

- The traditional two stage incremental forming cannot form the straight wall parts with the forming angle of 80°. There are two cracks on the side wall at the depth of 16 mm and 17 mm, and serious bulging occurs at the bottom.

- (3)

- The straight wall parts with the forming angle of 80° can be formed by using the proposed multi-stage incremental forming strategy. Although there is a slight subsidence at the bottom, the profile of the side wall becomes closer to that of the target model with the increase in depth. By analyzing the thickness distribution of the section in the direction of the long axis and the short axis of the straight wall parts, it can be concluded that the thickness decreases gradually with the increase in depth. The thickness of the long axis is smaller than that of the short axis, and the minimum thickness is 0.28 mm.

- (4)

- Different stretching angles have different effects on the thickness and contour of the formed parts. In this paper, the stretching angle of 5° and 15° were respectively used to carry out the forming experiments. It is concluded that the profile size accuracy of the stretching angle 15° is higher and the bottom subsidence of the stretching angle 15° is smaller, while the thickness of 5° is reduced slowly, but the thickness of the stretching angle 15° is thicker. In the area near the bottom, the surface roughness at a stretching angle of 5° is better.

- (5)

- In future research, it will be necessary to further study the influence of the stretching angle, moving direction on the forming quality, and process parameter optimization methods. In addition, the influence of the different auxiliary line positions on the thickness distribution and the influence of force, material properties, and springback on the forming quality are needed to be studied.

- (6)

- The research in this paper provides a new forming toolpath for the multi-stage incremental forming, which can successfully form the straight wall parts and prompt the development of the incremental forming of straight wall parts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vijayakumar, M.; Chandramohan, D.; Gopalaramasubramaniyan, G. Experimental investigation on single point incremental forming of IS513Cr3 using response surface method. Mater. Today Proc. 2019, 21, 902–907. [Google Scholar] [CrossRef]

- Kurra, S.; Praveen, K.G.; Amrita, P.; Nitin, K. Analysis of formability in incremental forming processes. Mater. Today Proc. 2018, 5, 18905–18910. [Google Scholar]

- Mercedes, M.G.; Nathan, A.L.; Joseph, D.F.; Mitchell, R.W.; Douglas, A.B.; Robert, G.L. Analysis of geometric accuracy and thickness reduction in multistage incremental sheet forming using digital image correlation. Procedia Manuf. 2019, 34, 950–960. [Google Scholar]

- Kumar, A.; Gulati, V.; Kumar, P.; Singh, H. Forming force in incremental sheet forming: A comparative analysis of the state of the art. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 251. [Google Scholar] [CrossRef]

- Duflou, J.R.; Habraken, A.-M.; Cao, J.; Malhotra, R.; Bambach, M.; Adams, D.; Vanhove, H.; Mohammadi, A.; Jeswiet, J. Single point incremental forming: State-of-the-art and prospects. Int. J. Mater. Form. 2018, 11, 743–773. [Google Scholar] [CrossRef]

- Mohanty, S.; Regalla, S.P.; Rao, Y.D. Tool Path Planning for manufacturing of Asymmetric parts by incremental sheet metal forming by means of Robotic manipulator. Mater. Today Proc. 2017, 4, 811–819. [Google Scholar] [CrossRef]

- Li, Z.; Lu, S.; Zhang, T.; Feng, T.; An, Z.; Xue, C. Numerical prediction of ductile fracture in multi-stage single point incremental forming based on phenomenological modified Mohr–Coulomb. Measurement 2020, 154, 107505. [Google Scholar] [CrossRef]

- Nirala, H.K.; Jain, P.K.; Roy, J.J.; Samal, M.K.; Tandon, P. An approach to eliminate stepped features in multistage incre-mental sheet forming process: Experimental and FEA analysis. J. Mech. Sci. Technol. 2017, 31, 599–604. [Google Scholar] [CrossRef]

- Vignesh, G.; Pandivelan, C.; Narayanan, C.S. Review on multi-stage incremental forming process to form vertical walled cup. Mater. Today Proc. 2020, 27, 2297–2302. [Google Scholar] [CrossRef]

- Pranav, G.; Jacob, J. Manufacture of an aerospace component by single point incremental forming. Procedia Manuf. 2019, 29, 112–119. [Google Scholar]

- Pranav, G.; Alexander, S.; Jacob, J. Manufacture of an aerospace component with hybrid incremental forming methodology. Int. J. Mater. Form. 2021, 14, 293–308. [Google Scholar]

- Suresh, K.; Regalla, S.P.; Kotkundae, N. Finite element simulations of multistage stage incremental forming process. Mater. Today Proc. 2018, 5, 3802–3810. [Google Scholar] [CrossRef]

- Wu, S.; Ma, Y.; Gao, L.; Zhao, Y.; Rashed, S.; Ma, N. A novel multi-step strategy of single point incremental forming for high wall angle shape. J. Manuf. Process. 2020, 56, 697–706. [Google Scholar] [CrossRef]

- Dai, P.; Chang, Z.; Li, M.; Chen, J. Reduction of geometric deviation by multi-pass incremental forming combined with tool path compensation for non-axisymmetric aluminum alloy component with stepped feature. Int. J. Adv. Manuf. Technol. 2019, 102, 809–817. [Google Scholar] [CrossRef]

- Liu, Z.B.; Meehan, P.A. Investigation on wrinkling deformation in multi-pass incremental sheet forming process. Key Eng. Mater. 2016, 725, 578–585. [Google Scholar] [CrossRef]

- Chang, Z.; Chen, J. Investigations on the deformation mechanism of a novel three-sheet incremental forming. J. Mater. Process. Technol. 2020, 281, 116619. [Google Scholar] [CrossRef]

- Ndip-Agbor, E.; Cheng, P.; Moser, N.; Ehmann, K.; Cao, J. Prediction of rigid body motion in multi-pass single point in-cremental forming. J. Mater. Process. Technol. 2019, 269, 117–127. [Google Scholar] [CrossRef]

- Gianluca, B.; Marco, G.; Livan, F.; Fabrizio, M. Multi-directional vs. mono-directional multi-step strategies for single point incremental forming of non-axisymmetric components. J. Manuf. Process. 2020, 55, 22–30. [Google Scholar]

- Li, Z.F.; Lu, S.H.; Zhang, T.; Zhang, C.; Mao, Z.X. 1060 Al electric hot incremental sheet forming process: Analysis of di-mensional accuracy and temperature. Trans. Indian Inst. Met. 2018, 71, 961–970. [Google Scholar] [CrossRef]

- Yang, M.; Bai, L.; Li, Y.; Yuan, Q. Influences of vibration parameters on formability of 1060 aluminum sheet processed by ultrasonic vibration-assisted single point incremental forming. Adv. Mater. Sci. Eng. 2019, 2019, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.F.; Lu, S.H.; Zhang, T.; Zhang, C.; Mao, Z.X. Analysis of geometrical accuracy based on multistage single point in-cremental forming of a straight wall box part. Int. J. Adv. Manuf. Technol. 2017, 93, 2783–2789. [Google Scholar] [CrossRef]

- Ramkumar, K.; Baskar, N.; Elangovan, K.; Sathiya, N.C.; Selvarajan, A.; Varatharajulu, M. Comparison of incremental sheet metal forming process using newly designed multipoint tool with the existing single point tool by optimization and char-acterization methods on austenite stainless steel 202. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1298–1308. [Google Scholar]

- Zhu, H.; Liu, L. Research the CNC incremental forming of straight-wall parts based on a virtual auxiliary body. J. Mater. Process. Technol. 2021, 288, 116841. [Google Scholar] [CrossRef]

- Tanaka, S. Incremental sheet metal formed square-cup obtained through multi-stepped process. Procedia Manuf. 2018, 15, 1170–1176. [Google Scholar] [CrossRef]

- Wernicke, S.; Dang, T.; Gies, S.; Tekkaya, A.E. Effect of multiple forming tools on geometrical and mechanical properties in incremental sheet forming. In Proceedings of the 21st International Esaform Conference on Material Forming (ESAFORM 2018), Palermo, Italy, 23–25 April 2018; Volume 1960, p. 160031. [Google Scholar] [CrossRef]

- Tera, M.; Breaz, R.-E.; Racz, S.-G.; Girjob, C.-E. Processing strategies for single point incremental forming—A CAM approach. Int. J. Adv. Manuf. Technol. 2019, 102, 1761–1777. [Google Scholar] [CrossRef]

- Nirala, H.K.; Agrawal, A. Fractal geometry rooted incremental toolpath for incremental sheet forming. J. Manuf. Sci. Eng. 2017, 140, 021005. [Google Scholar] [CrossRef]

- Tyler, J.G.; Laine, M. Investigation of a radial toolpath in single point incremental forming. Procedia Manuf. 2020, 48, 215–222. [Google Scholar]

- Carette, Y.; Vanhove, H.; Duflou, J. Multi-step incremental forming using local feature based toolpaths. Procedia Manuf. 2019, 29, 28–35. [Google Scholar] [CrossRef]

- Li, X.; Han, K.; Li, D. Multi-stage two point incremental sheet forming. J. Phys. Conf. Ser. 2018, 1063, 012064. [Google Scholar] [CrossRef]

- Li, X.Q.; Han, K.; Xu, P.; Wang, H.B.; Li, D.S.; Li, Y.L.; Li, Q. Experimental and theoretical analysis of the thickness distri-bution in multistage two point incremental sheet forming. Int. J. Adv. Manuf. Technol. 2020, 107, 191–203. [Google Scholar] [CrossRef]

- Skjoedt, M.; Bay, N.; Endelt, B.; Ingarao, G. Multi stage strategies for single point incremental forming of a cup. Int. J. Mater. Form. 2008, 1, 1199–1202. [Google Scholar] [CrossRef]

- Malhotra, R.; Bhattacharya, A.; Kumar, A.; Reddy, N.; Cao, J. A new methodology for multi-pass single point incremental forming with mixed toolpaths. CIRP Ann. 2011, 60, 323–326. [Google Scholar] [CrossRef]

- Bouzid, M.F.; ben Ahmed, M.; Zid, K.; Tarchoun, R. Effect of multi-stage incremental formatting strategy (DDDD) on sheet thickness and profile. Recent Adv. Comput. Mech. Simul. 2020, 335–344. [Google Scholar] [CrossRef]

| Material | Density [kg·m−3] | Elastic Modulus [GPa] | Poisson’s Ratio | Yield Stress [MPa] | Tangent Modulus [GPa] | Hardening Coefficient |

|---|---|---|---|---|---|---|

| Al1060 | 2700 | 55.94 | 0.324 | 153.6 | 2.9 | 0.198 |

| GCr15 | 8160 | 218 | 0.30 | - | - | - |

| W6Mo5Cr4V2 | 7810 | 212 | 0.29 | - | - | - |

| Stretch Angle | Maximum Deviation at Long Axis [mm] | Mean Deviation at Long Axis [mm] | Maximum Deviation at Short Axis [mm] | Mean Deviation at Short Axis [mm] |

|---|---|---|---|---|

| 5° | 1.6759 | 1.3160 | 1.7947 | 1.3455 |

| 15° | 1.6212 | 1.1219 | 1.5517 | 1.0706 |

| Stretch Angle | Minimum Thickness at Long Axis [mm] | Minimum Thickness at Short Axis [mm] |

|---|---|---|

| 5° | 0.280 | 0.325 |

| 15° | 0.290 | 0.324 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Cheng, G.; Jung, D. Toolpath Planning and Generation for Multi-Stage Incremental Forming Based on Stretching Angle. Materials 2021, 14, 4818. https://doi.org/10.3390/ma14174818

Zhu H, Cheng G, Jung D. Toolpath Planning and Generation for Multi-Stage Incremental Forming Based on Stretching Angle. Materials. 2021; 14(17):4818. https://doi.org/10.3390/ma14174818

Chicago/Turabian StyleZhu, Hu, Guixi Cheng, and Dongwon Jung. 2021. "Toolpath Planning and Generation for Multi-Stage Incremental Forming Based on Stretching Angle" Materials 14, no. 17: 4818. https://doi.org/10.3390/ma14174818

APA StyleZhu, H., Cheng, G., & Jung, D. (2021). Toolpath Planning and Generation for Multi-Stage Incremental Forming Based on Stretching Angle. Materials, 14(17), 4818. https://doi.org/10.3390/ma14174818