Development and Laboratory Evaluation of a Cold Mix High-Early-Strength Epoxy Asphalt Concrete for Steel Bridge Deck Pavements

Abstract

:1. Introduction

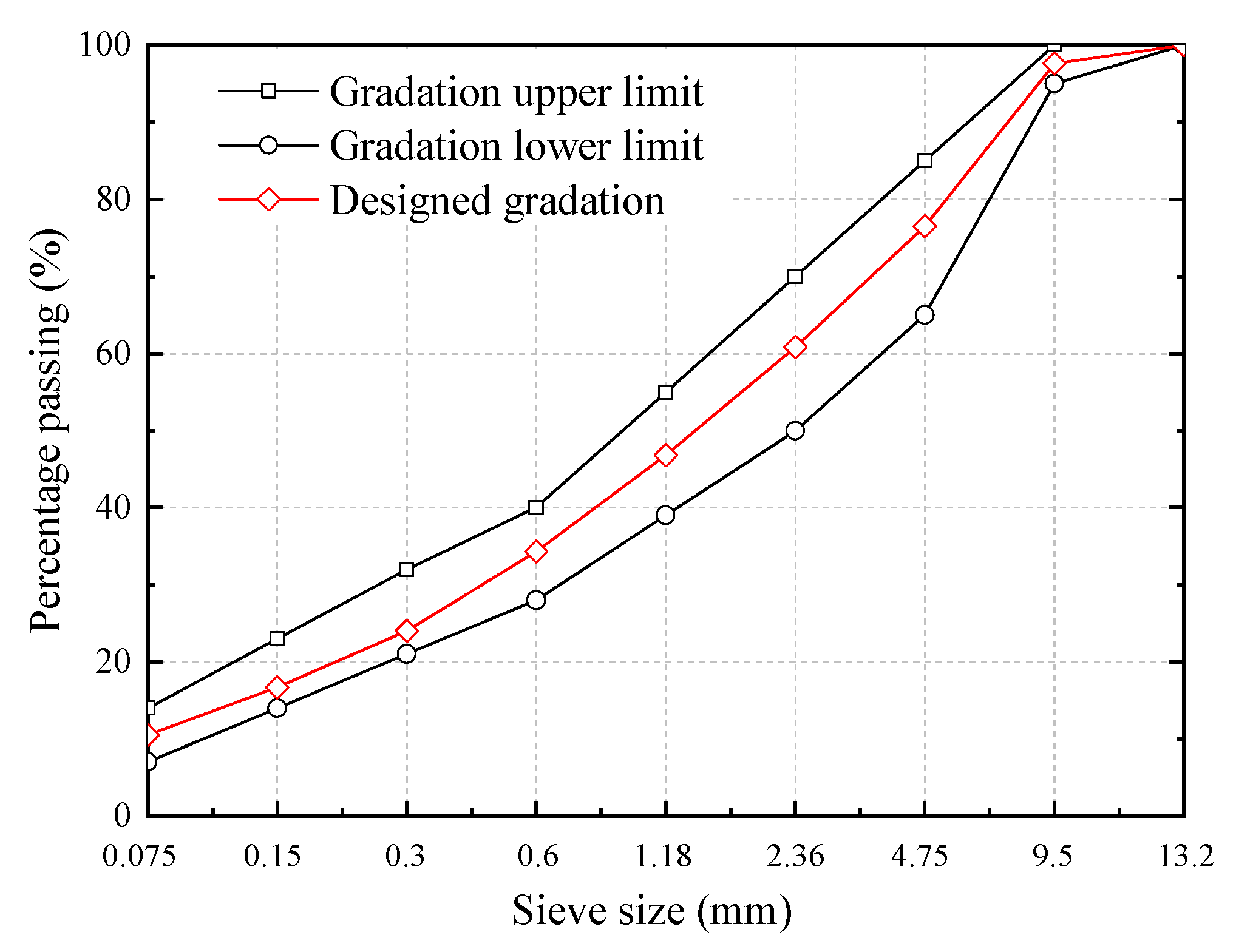

2. Materials and Methods

2.1. Material Selection

2.2. Preparation of CHES Epoxy Asphalt

2.3. Experimental Methods

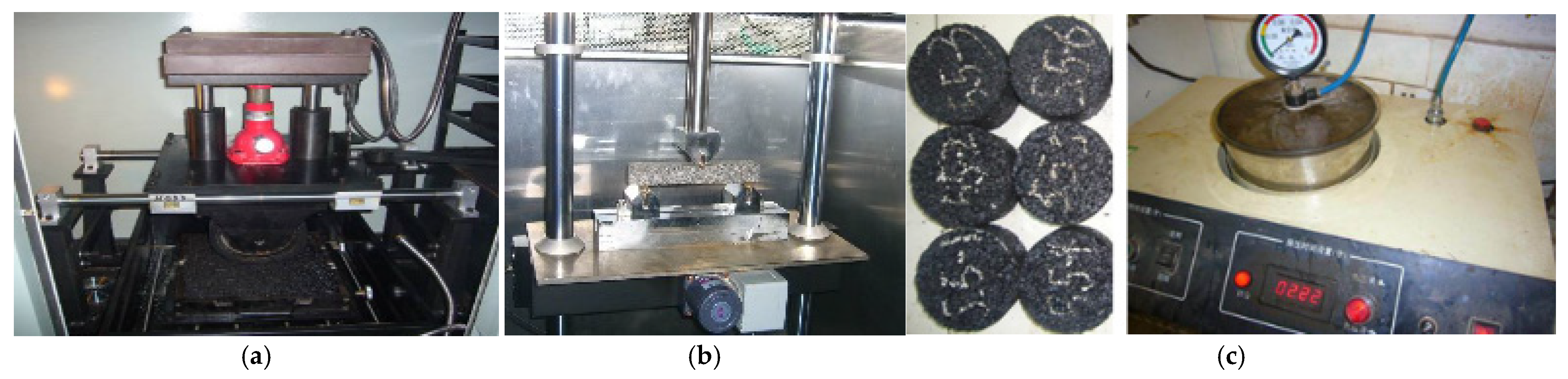

2.3.1. Segregation Test

2.3.2. Tensile Test

2.3.3. Rotational Viscosity Test

2.3.4. Marshall Stability Test

- (1)

- The CHES epoxy asphalt was mixed with aggregates at ambient temperature to form a mixture.

- (2)

- The mixture was compacted in a Marshall compactor with 75 blows on each side, and the Marshall specimens were extracted from the mold and kept at the room temperature (25 °C) for different curing periods. In addition, the volume parameters of the molded mixture were measured.

- (3)

- The specimens were immersed in the 60 °C constant-temperature water for 0.5 h, and the Marshall stability and flow values were measured subsequently.

2.3.5. Pavement Performance Test

3. Results and Discussions

3.1. Formula Design of CHES Epoxy Asphalt

3.1.1. Optimum Proportion Determination of Compatilizer

3.1.2. Curing Agent Design

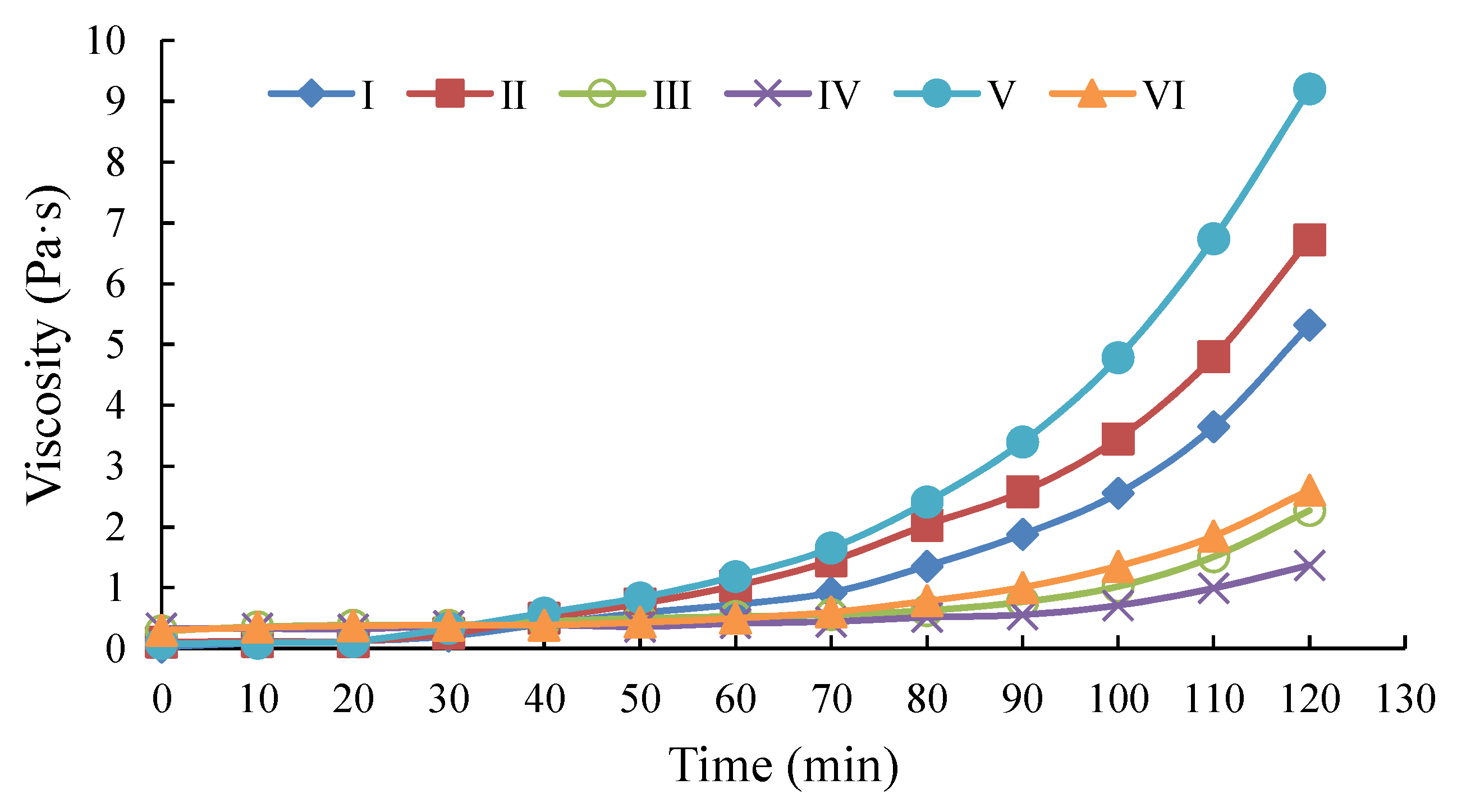

3.1.3. Optimum Formula Determination of CHES Epoxy Asphalt

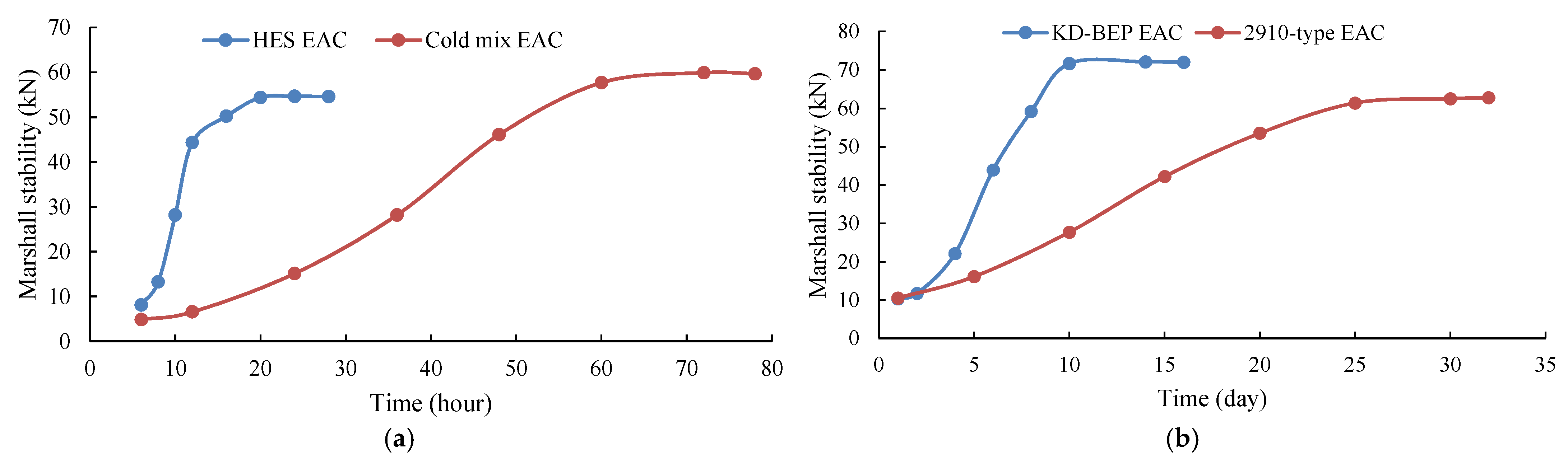

3.2. Strength Comparison of CHES EAC with Other EACs

3.3. Pavement Performances of CHES EAC

3.4. Construction Workability of CHES EAC

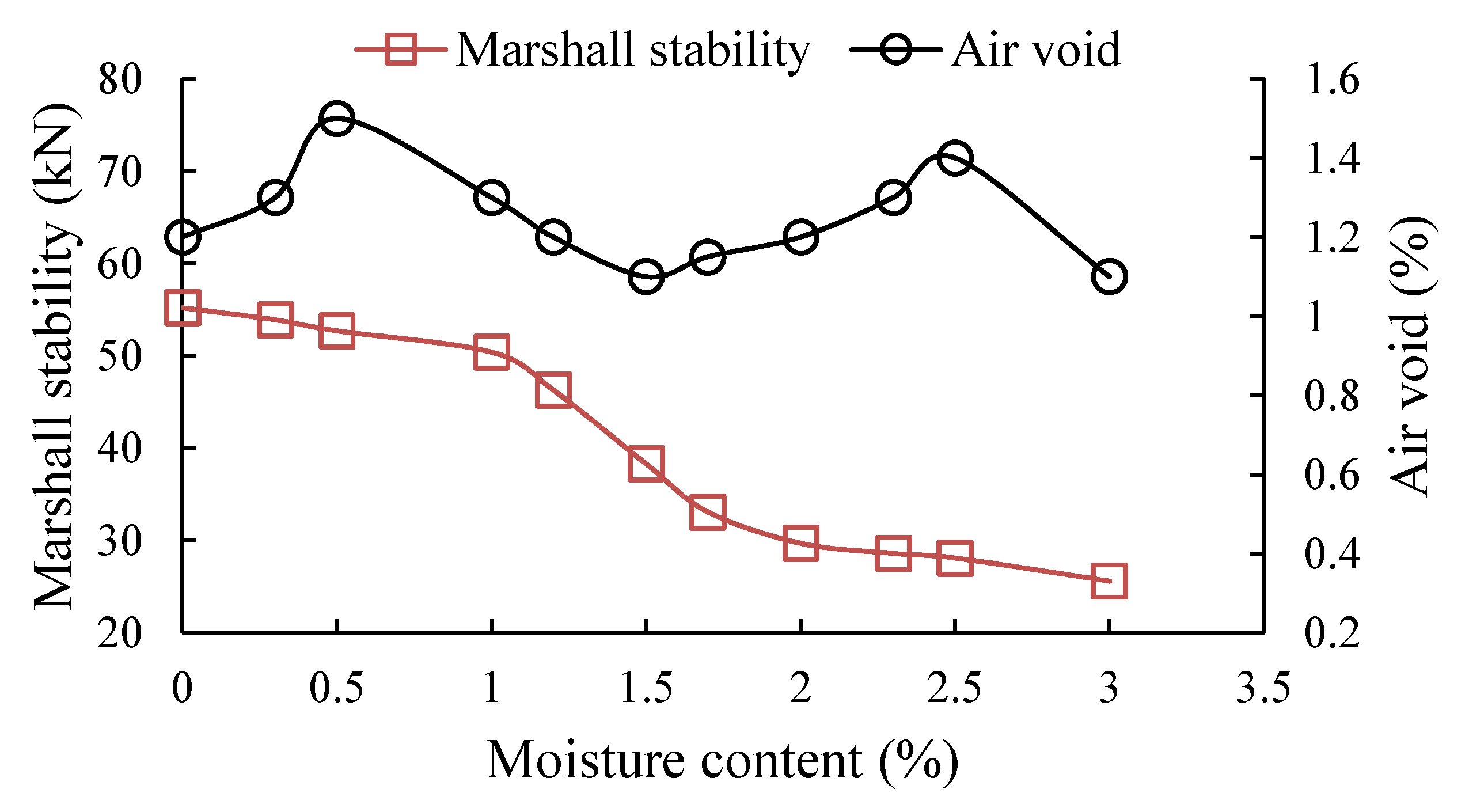

3.4.1. Effect of Moisture in the Aggregate

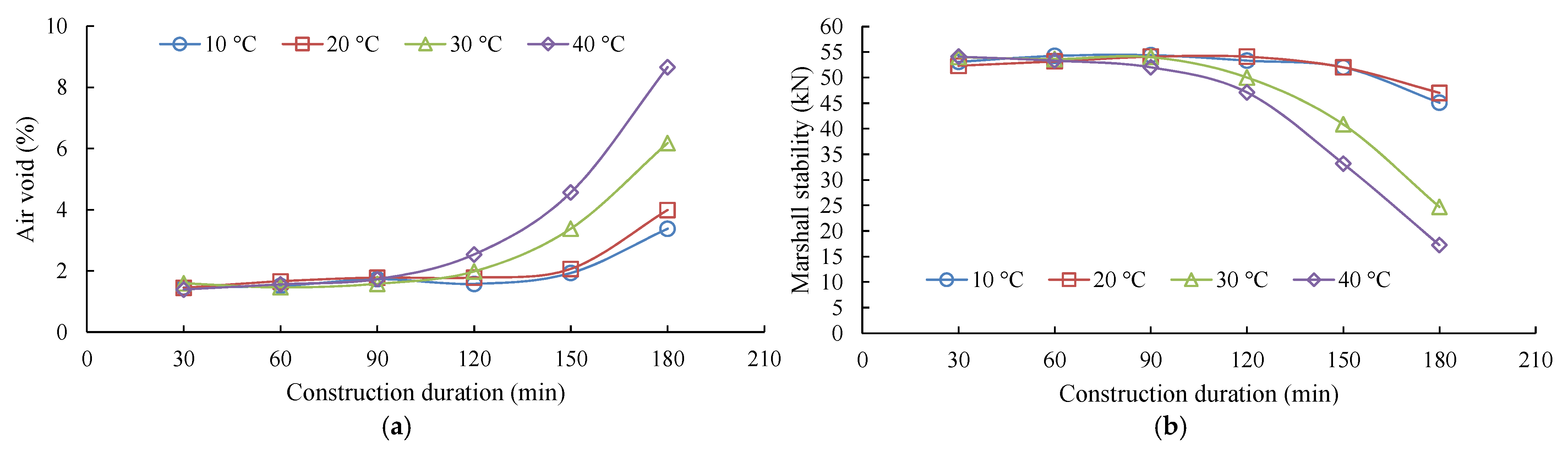

3.4.2. Allowable Construction Duration Determination

4. Conclusions

- (1)

- A new CHES epoxy asphalt was developed through blending a compatilizer and optimizing the curing agent system, and the optimum proportion of epoxy resin, curing agent, compatilizer, and 70# asphalt in the CHES epoxy asphalt is 1:0.8:0.2:3.

- (2)

- The developed CHES epoxy asphalt can significantly reduce the curing period for EAC, and the curing time for CHES EAC to reach its ultimate strength at 25 °C is about 20 h.

- (3)

- The CHES EAC has good high-temperature rutting resistance, low-temperature cracking resistance, and moisture susceptibility, and its pavement performance is, overall, excellent for application in SBDP.

- (4)

- The moisture in the aggregate has an adverse effect on the Marshall stability of CHES EAC. It is suggested that the moisture content of aggregate for CHES EAC should be less than 1%. If the moisture content of aggregate is high, a drying treatment should be applied to the aggregate before producing the CHES EAC.

- (5)

- The allowable construction duration of CHES EAC at the ambient temperatures of 10 °C and 20 °C exceeds 150 min, and the allowable construction duration at the ambient temperature of 30 °C and 40 °C is about 120 min.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, Q.; Bors, J. Alternate uses of epoxy asphalt on bridge decks and roadways. Constr. Build. Mater. 2015, 78, 18–25. [Google Scholar] [CrossRef]

- Huang, W. Integrated design procedure for epoxy asphalt concrete-based wearing surface on long-span orthotropic steel deck bridges. J. Mater. Civ. Eng. 2016, 28, 04015189. [Google Scholar] [CrossRef]

- Luo, S.; Qian, Z.; Yang, X.; Lu, Q. Laboratory evaluation of double-layered pavement structures for long-span steel bridge decks. J. Mater. Civ. Eng. 2018, 30, 04018111. [Google Scholar] [CrossRef]

- Jia, H.; Chen, Z.; Kang, Y.; Kang, Y.; Jiao, Z.; Huang, W. Green preparation techniques of high performance epoxy asphalts. J. Southeast Univ. 2008, 38, 496–499. (In Chinese) [Google Scholar]

- Si, J.; Li, Y.; Yu, X. Curing behavior and mechanical properties of an eco-friendly cold-mixed epoxy asphalt. Mater. Struct. 2019, 52, 81. [Google Scholar] [CrossRef]

- Chen, L.; Qian, Z.; Lu, Q. Crack initiation and propagation in epoxy asphalt concrete in the three-point bending test. Road. Mater. Pavement 2014, 15, 507–520. [Google Scholar] [CrossRef]

- Chen, L.; Qian, Z. Rehabilitation of cracking in epoxy asphalt pavement on steel bridge decks. In Proceedings of the 7th RILEM International Conference on Cracking in Pavements, Delft, The Netherlands, 20–22 June 2012; pp. 255–266. [Google Scholar]

- Yang, Y.; Qian, Z.; Song, X. A pothole patching material for epoxy asphalt pavement on steel bridges: Fatigue test and numerical analysis. Constr. Build. Mater. 2015, 94, 299–305. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.; Hu, H. Temperature field characteristic analysis of steel bridge deck during high-temperature asphalt pavement paving. KSCE J. Civ. Eng. 2016, 20, 2811–2821. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.; Hu, J.; Jin, L. Temperature behavior and stability analysis of orthotropic steel bridge deck during gussasphalt pavement paving. J. Bridge Eng. 2018, 23, 04017117. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.; Zheng, D.; Zhang, M. Interlaminar thermal effect analysis of steel bridge deck pavement during gussasphalt mixture paving. Int. J. Pavement Eng. 2019, 20, 1323–1335. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, C.; Feng, D.; Fan, X.; Xie, S. Experimental study on interlayer shear properties of ERS pavement system for long-span steel bridges. Constr. Build. Mater. 2017, 143, 198–209. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, Z.; Cao, R. Research on ERS steel deck pavement techniques. J. Test. Eval. 2012, 40, 1260–1265. [Google Scholar] [CrossRef]

- Qian, Z.; Chen, L.; Wang, Y.; Shen, J. Curing reaction model for epoxy asphalt binder. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2012, 27, 763–767. [Google Scholar] [CrossRef]

- Si, J.; Jia, Z.; Wang, J.; Yu, X.; Li, Y.; Dong, F.; Jiang, R. Comparative analysis of cold-mixed epoxy and epoxy SBS-modified asphalts: Curing rheology, thermal, and mechanical properties. Constr. Build. Mater. 2018, 176, 165–171. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, P.; Pan, Y.; Li, K.; Zhang, Z.; Geng, F. Development of cold-mix high-toughness resin and experimental research into its performance in a steel deck pavement. Constr. Build. Mater. 2020, 235, 117427. [Google Scholar] [CrossRef]

- Fuhaid, A.; Lu, Q.; Luo, S. Laboratory evaluation of biobased epoxy asphalt binder for asphalt pavement. J. Mater. Civ. Eng. 2018, 30, 06018007. [Google Scholar] [CrossRef]

- Ai, T.; Xiang, S.; Wang, Z. Effects of microwave curing on the chemical and physical properties of epoxy asphalt. J. Mater. Civ. Eng. 2016, 28, 06016013. [Google Scholar] [CrossRef]

- Sun, Y.; He, D. High and low-temperature performance evaluation and microanalysis of SMCSBS compound-modified asphalt. Materials 2021, 14, 771. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.; Shi, X.; Zhang, Y.; Ren, H. Developing cold-mixed epoxy resin-based ultra-thin antiskid surface layer for steel bridge deck pavement. Constr. Build. Mater. 2021, 291, 123366. [Google Scholar] [CrossRef]

- Cong, P.; Chen, S.; Yu, J.; Chen, H. Compatibility and mechanical properties of epoxy resin modified asphalt binders. Int. J. Pavement Res. Technol. 2011, 4, 118–123. [Google Scholar] [CrossRef]

- Du, X.; Xu, P.; Cong, P.; Zhou, Z. Compatibilization and toughness modification of linear aliphatic epoxy compound on paving epoxy asphalt. Mater. Struct. 2020, 53, 42. [Google Scholar] [CrossRef]

- Gu, Y.; Tang, B.; He, L.; Yang, F.; Wang, H.; Ling, J. Compatibility of cured phase-inversion waterborne epoxy resin emulsified asphalt. Constr. Build. Mater. 2019, 229, 116942. [Google Scholar] [CrossRef]

- Auvergne, R.; Caillol, S.; David, G.; Boutevin, B.; Pascault, J. Biobased thermosetting epoxy: Present and future. Chem. Rev. 2014, 114, 1082–1115. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Chen, R.; Cai, J.; Xi, Z.; Xie, H. Ethylene vinyl acetate copolymer modified epoxy asphalt binders: Phase separation evolution and mechanical properties. Constr. Build. Mater. 2017, 137, 55–65. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Tensile Properties of Plastics (ASTM D638); ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- AASHTO. Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer (AASHTO T316); AASHTO: Washington, DC, USA, 2019. [Google Scholar]

- AASHTO. Standard Method of Test for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (AASHTO T245); AASHTO: Washington, DC, USA, 2014. [Google Scholar]

- Liu, Y.; Qian, Z.; Zheng, D.; Huang, Q. Evaluation of epoxy asphalt-based concrete substructure for high-speed railway ballastless track. Constr. Build. Mater. 2018, 162, 229–238. [Google Scholar] [CrossRef]

- Research Institute of Highway Ministry of Transport. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering (JTG E20-2011); China Communications Press: Beijing, China, 2011.

- Luo, S.; Qian, Z.; Shen, J.; Min, Z. Research on rheological model and construction time range of epoxy asphalt. J. Build. Mater. 2011, 14, 630–633. (In Chinese) [Google Scholar]

- Ministry of Transport of the People’s Republic of China. Specifications for Design and Construction of Pavement on Highway Steel Deck Bridge; JTG/T3364-02; China Communications Press: Beijing, China, 2019.

- Li, X. Preparation and Performance Study on Fast Curing Epoxy Asphalt Material. Master’s Thesis, Southeast University, Nanjing, China, 2015. (In Chinese). [Google Scholar]

- Cheng, D. Preparation and Properties of Epoxy Asphalt Materials Used in Steel Deck Pavement. Master’s Thesis, Chang’an University, Xi’an, China, 2017. (In Chinese). [Google Scholar]

- National Asphalt Pavement Association. Development of Marshall Procedures for Designing Asphalt Paving Mixtures; Information Series 84; National Asphalt Pavement Association: Lanham, MD, USA, 1982. [Google Scholar]

- Wang, G.; Chen, X.; Dong, Q.; Yuan, J.; Hong, Q. Mechanical performance study of pervious concrete using steel slag aggregate through laboratory tests and numerical simulation. J. Clean. Prod. 2020, 262, 121208. [Google Scholar] [CrossRef]

- Chen, T.; Ma, T.; Huang, X.; Ma, S.; Tang, F.; Wu, S. Microstructure of synthetic composite interfaces and verification of mixing order in cold-recycled asphalt emulsion mixture. J. Clean. Prod. 2020, 263, 121467. [Google Scholar] [CrossRef]

- Yang, J.; Li, Z.; Xu, X. Preparation and evaluation of cooling asphalt concrete modified with SBS and tourmaline anion powder. J. Clean. Prod. 2021, 289, 125135. [Google Scholar] [CrossRef]

| The Proportion of Compatilizer (by Mass of Epoxy Resin) (%) | Softening Point (°C) | ||

|---|---|---|---|

| Lower Part of Asphalt-Resin Specimen | Upper Part of Asphalt-Resin Specimen | Difference Value | |

| 0 | 45.2 | 27.3 | 17.9 |

| 10 | 35.5 | 33.3 | 2.2 |

| 15 | 34.9 | 33.6 | 1.3 |

| 20 | 34.3 | 33.9 | 0.4 |

| 30 | 33.9 | 33.3 | 0.6 |

| 40 | 33.6 | 32.8 | 0.8 |

| 50 | 32.7 | 31.7 | 1.0 |

| Curing Agent Types | Ultimate Tensile Strength (MPa) | Elongation at Break (%) | Allowable Construction Duration (25 °C, min) | Fully Cured Time (h) |

|---|---|---|---|---|

| A1 | 5.1 | 120 | 120 | 36 |

| A2 | 5.7 | 104 | 40 | 48 |

| A3 | 4.1 | 75 | 60 | 60 |

| A4 | 2.7 | 67 | 30 | 24 |

| A5 | 8.1 | 34 | 20 | 72 |

| Mass Proportion of A1 and SY Curing Agent | Ultimate Tensile Strength (MPa) | Elongation at Break (%) | Allowable Construction Duration (25 °C, min) | Fully Cured Time (h) |

|---|---|---|---|---|

| 5:5 | 1.7 | 320 | 30 | 12 |

| 6:4 | 2.1 | 284 | 50 | 16 |

| 7:3 | 2.6 | 256 | 60 | 16 |

| 8:2 | 3.1 | 184 | 80 | 20 |

| 9:1 | 3.8 | 146 | 100 | 20 |

| 10:0 | 5.1 | 120 | 120 | 36 |

| Property | Mass Ratio (Epoxy Resin: Curing Agent) | Mass Ratio of 70# Asphalt to Epoxy Asphalt (%) | |||

|---|---|---|---|---|---|

| 50 | 60 | 70 | 80 | ||

| Tensile strength (MPa) | 1:0.4 | 1.89 | 1.32 | 1.05 | – |

| 1:0.6 | 2.74 | 1.84 | 1.17 | – | |

| 1:0.8 | 4.12 | 3.42 | 2.36 | – | |

| 1:1 | 3.80 | 2.56 | 1.93 | 1.26 | |

| Elongation at break (%) | 1:0.4 | 266 | 289 | 356 | – |

| 1:0.6 | 187 | 274 | 322 | – | |

| 1:0.8 | 103 | 174 | 235 | – | |

| 1:1 | 146 | 214 | 254 | 303 | |

| Formula No. | Component Proportion of Epoxy Asphalt | |

|---|---|---|

| Mass Ratio (Epoxy Resin: Curing Agent) | Mass Ratio of 70# Asphalt to Epoxy Asphalt (%) | |

| I | 1:0.6 | 50 |

| II | 1:0.8 | 50 |

| III | 1:0.8 | 60 |

| IV | 1:0.8 | 70 |

| V | 1:1 | 50 |

| VI | 1:1 | 60 |

| Property | Formula No. | Curing Period | |||||

|---|---|---|---|---|---|---|---|

| 8 h | 10 h | 12 h | 16 h | 20 h | 24 h | ||

| Marshall stability (kN) | III | 13.26 | 28.20 | 44.32 | 50.23 | 54.4 | 54.64 |

| IV | 12.8 | 24.21 | 40.27 | 42.31 | 44.76 | 44.86 | |

| VI | 10.14 | 20.32 | 42.10 | 47.43 | 48.46 | 48.64 | |

| Property | Test Value | |||

|---|---|---|---|---|

| CHES Epoxy Asphalt | KD-BEP Epoxy Asphalt | 2910-Type Epoxy Asphalt | Cold Mix Epoxy Asphalt | |

| Tensile strength (MPa) | 3.42 | 2.6 | 3.86 | 4.62 |

| Elongation at break (%) | 174 | 226 | 244 | 88 |

| Water absorption rate (%, 7 days, 20 °C) | 0.12 | 0.15 | 0.05 | 0.13 |

| Time until viscosity increased to 1Pa·s (min) | 80 | >120 | 59 | 67 |

| Performance | Test Value | Criterions [32] | |||

|---|---|---|---|---|---|

| CHES EAC | Cold Mix EAC | KD-BEP EAC | 2910-Type EAC | ||

| Dynamic stability (cycle/mm, 70 °C) | 26,400 | 24,020 | 32,373 | 29,523 | ≥6000 |

| Flexural strength (MPa, −10 °C) | 19.22 | 20.52 | 18.29 | 18.80 | – |

| Flexural stiffness (MPa, −10 °C) | 4953 | 4869 | 5685 | 5275 | – |

| Flexural strain at failure (με, −10 °C) | 3880 | 4214 | 3218 | 3564 | ≥3000 |

| Residual Marshall stability (%) | 93.5 | 91.3 | 91.1 | 90.2 | ≥85 |

| TSR (%) | 89.1 | 86.3 | 86.5 | 85.6 | ≥80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Qian, Z.; Wang, Y.; Xue, Y. Development and Laboratory Evaluation of a Cold Mix High-Early-Strength Epoxy Asphalt Concrete for Steel Bridge Deck Pavements. Materials 2021, 14, 4555. https://doi.org/10.3390/ma14164555

Liu Y, Qian Z, Wang Y, Xue Y. Development and Laboratory Evaluation of a Cold Mix High-Early-Strength Epoxy Asphalt Concrete for Steel Bridge Deck Pavements. Materials. 2021; 14(16):4555. https://doi.org/10.3390/ma14164555

Chicago/Turabian StyleLiu, Yang, Zhendong Qian, Yongning Wang, and Yongchao Xue. 2021. "Development and Laboratory Evaluation of a Cold Mix High-Early-Strength Epoxy Asphalt Concrete for Steel Bridge Deck Pavements" Materials 14, no. 16: 4555. https://doi.org/10.3390/ma14164555

APA StyleLiu, Y., Qian, Z., Wang, Y., & Xue, Y. (2021). Development and Laboratory Evaluation of a Cold Mix High-Early-Strength Epoxy Asphalt Concrete for Steel Bridge Deck Pavements. Materials, 14(16), 4555. https://doi.org/10.3390/ma14164555