Experimental Analysis of NiTi Alloy during Strain-Controlled Low-Cycle Fatigue

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Experimental Conditions

3. Results

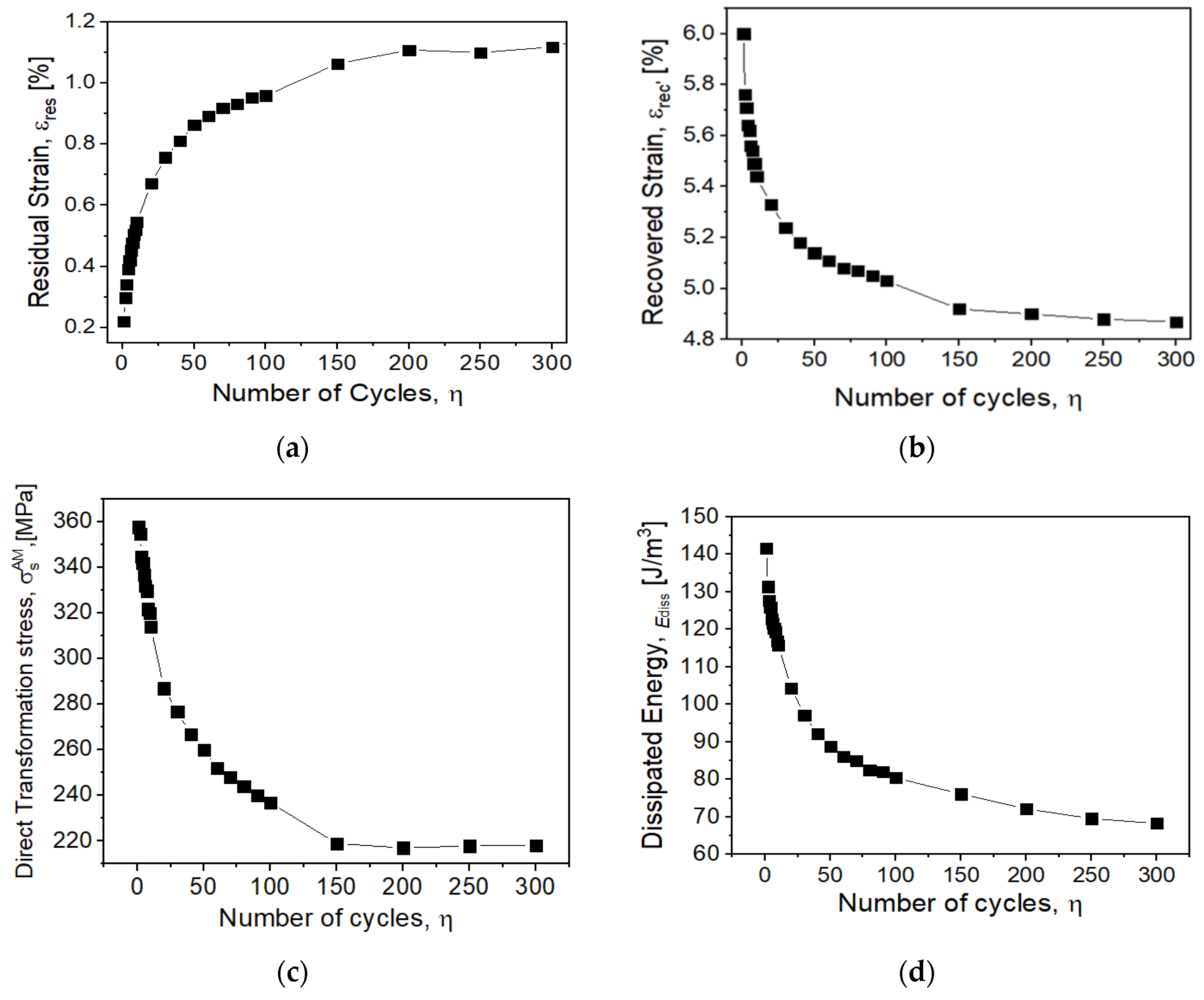

3.1. Functional Behavior

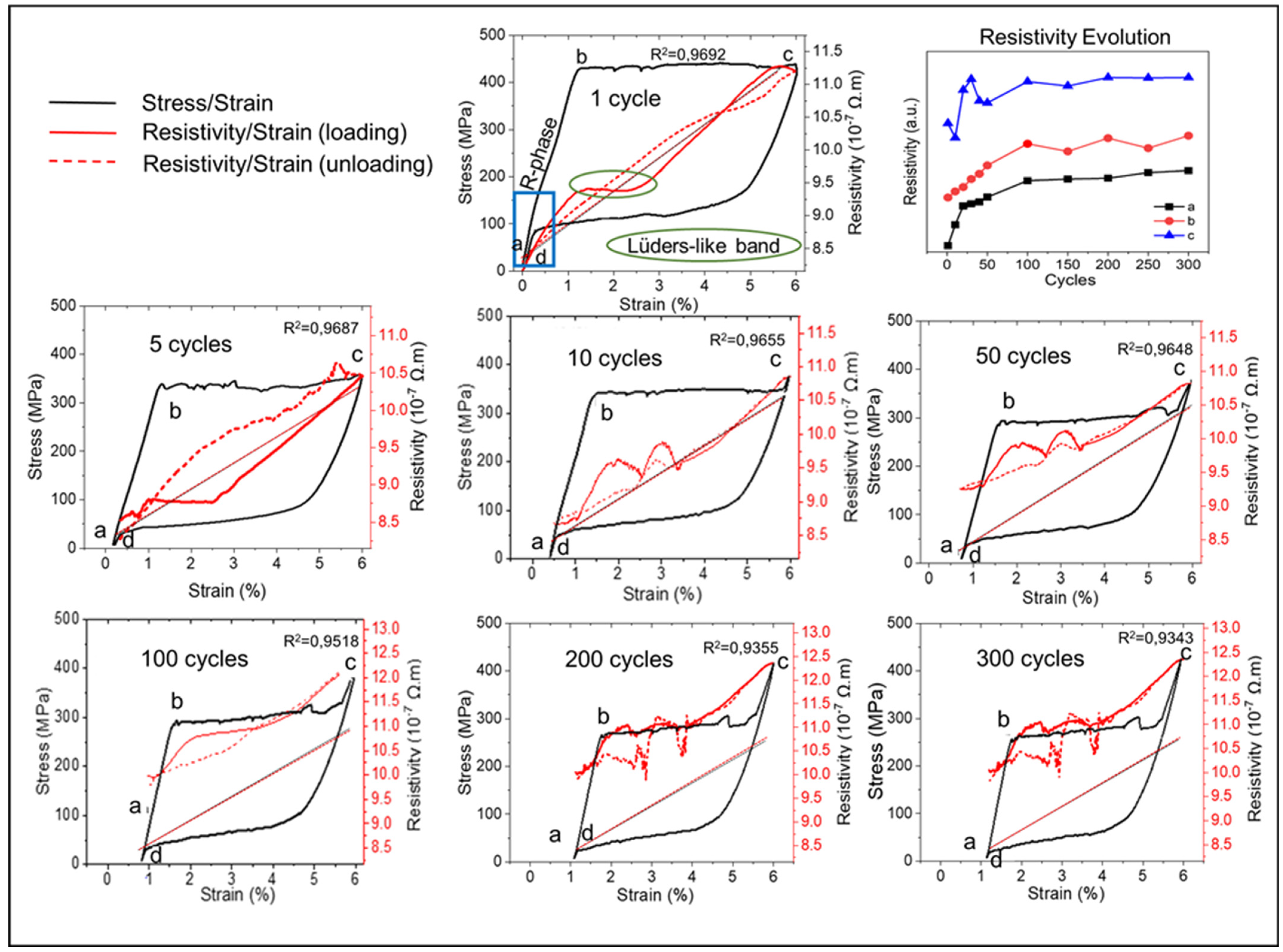

3.2. In Situ Electrical Resistivity versus Low-Cycle Fatigue

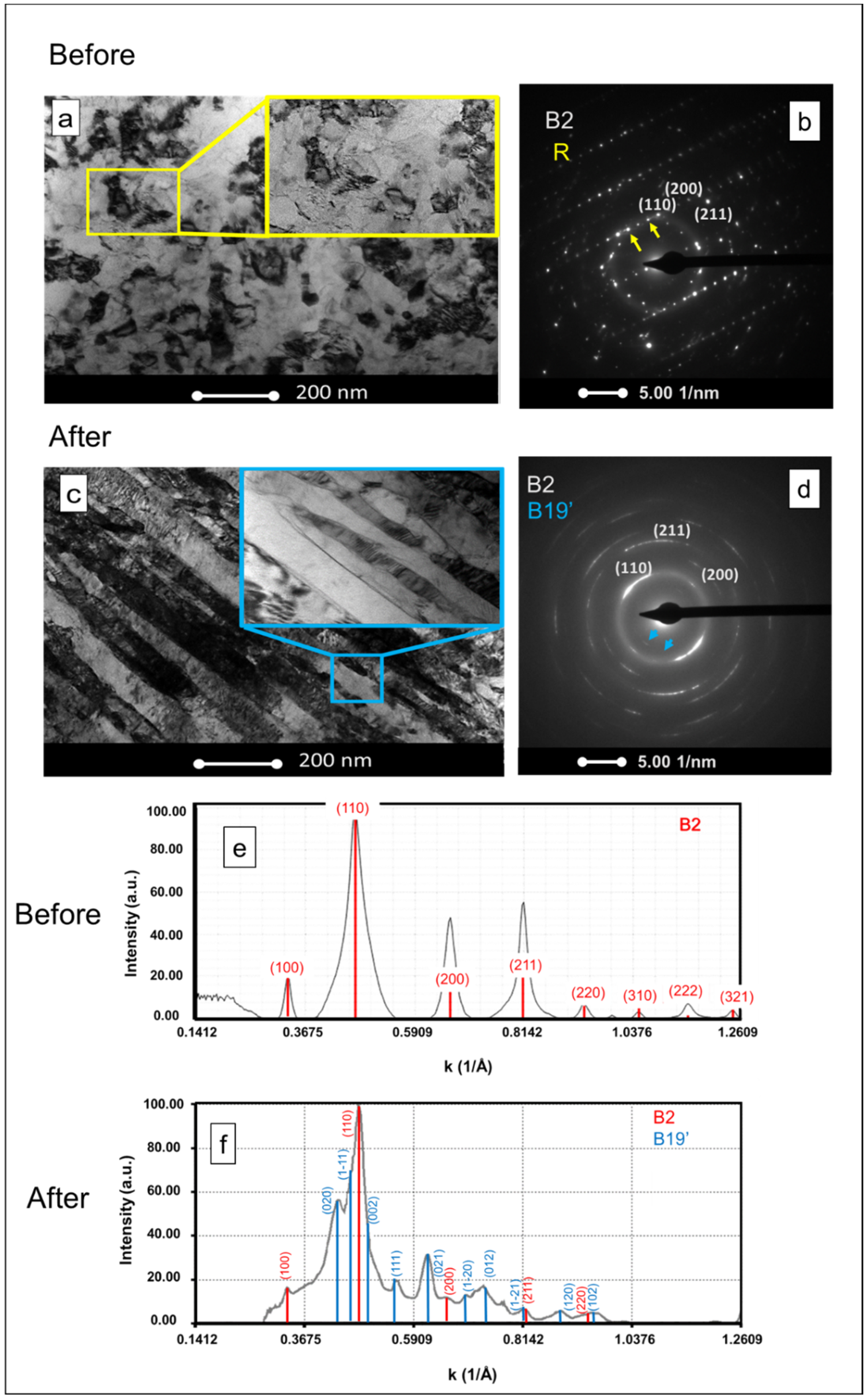

3.3. TEM Analysis

4. Conclusions

- The functional degradation as evidenced by the residual strain evolution is the result of untransformed austenite and remaining martensite formed during cycling; more B2–B19′ interfaces and a higher dislocation density are present in the material as the number of cycles progresses;

- The electrical resistivity increases linearly with strain; the electrical resistivity at the beginning of each cycle increases with the number of cycles, revealing the presence of a mixture of phases (B2 and B19′);

- During cycling, the resistivity at the beginning of each new loading cycle, as well as the resistivity at the beginning of each upper SIM plateau, gradually change; this shows that NiTi may be effectively used as a crack propagation sensor when inserted inside a component subjected to low-cycle fatigue.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Antonucci, V.; Martone, A. Phenomenology of Shape Memory Alloys. In Shape Memory Alloy Engineering; Butterworth-Heinemann: Oxford, UK, 2015; pp. 33–56. [Google Scholar] [CrossRef]

- Saburi, T. Ti-Ni Shape memory Alloys. In Shape Memory Materials, 1st ed.; Otsuka, K., Ed.; Cambridge University Press: New York, NY, USA, 1998; pp. 49–96. [Google Scholar]

- Schmahl, W.; Khalil-Allafi, J.; Hasse, B.; Wagner, M.; Heckmann, A.; Somsen, C. Investigation of the phase evolution in a super-elastic NiTi shape memory alloy (50.7at.%Ni) under extensional load with synchrotron radiation. Mater. Sci. Eng. A 2004, 378, 81–85. [Google Scholar] [CrossRef]

- Miyazaki, S.; Imai, T.; Igo, Y.; Otsuka, K. Effect of cyclic deformation on the pseudoelasticity characteristics of Ti-Ni alloys. Met. Mater. Trans. A 1986, 17, 115–120. [Google Scholar] [CrossRef]

- Šittner, P.; Molnárová, O.; Kaderavek, L.; Tyc, O.; Heller, L. Deformation twinning in martensite affecting functional behavior of NiTi shape memory alloys. Materialia 2019, 9, 100506. [Google Scholar] [CrossRef]

- Airoldi, G.; Lodi, D.; Pozzi, M. The Electric Resistance of Shape Memory Alloys in the Pseudoelastic Regime. J. Phys. IV Colloq. 1997, 7, 7. [Google Scholar] [CrossRef][Green Version]

- He, Y.J.; Sun, Q.P. Frequency-dependent temperature evolution in NiTi shape memory alloy under cyclic loading. Smart Mater. Struct. 2010, 19. [Google Scholar] [CrossRef]

- Eggeler, G.; Hornbogen, E.; Yawny, A.; Heckmann, A.; Wagner, M. Structural and functional fatigue of NiTi shape memory alloys. Mater. Sci. Eng. A 2004, 378, 24–33. [Google Scholar] [CrossRef]

- Heller, L.; Seiner, H.; Šittner, P.; Sedlák, P.; Tyc, O.; Kadeřávek, L. On the plastic deformation accompanying cyclic martensitic transformation in thermomechanically loaded NiTi. Int. J. Plast. 2018, 111, 53–71. [Google Scholar] [CrossRef]

- Rohatgi, P. Al-shape memory alloy self-healing metal matrix composite. Mater. Sci. Eng. A 2014, 619, 73–76. [Google Scholar] [CrossRef]

- Sgambitterra, E.; Bruno, L.; Maletta, C. Stress induced martensite at the crack tip in NiTi alloys during fatigue loading. Frat. ed Integrità Strutt. 2014, 8, 167–173. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, S.; Yan, X.; Yue, D.; Sun, R.; Zhou, X. Probabilistic analysis for the functional and structural fatigue of NiTi wires. Mater. Des. 2016, 102, 213–224. [Google Scholar] [CrossRef]

- Tyc, O.; Pilch, J.; Sittner, P. Fatigue of superelastic NiTi wires with different plateau strain. Procedia Struct. Integr. 2016, 2, 1489–1496. [Google Scholar] [CrossRef][Green Version]

- Mammano, G.S.; Dragoni, E. Functional fatigue of Ni–Ti shape memory wires under various loading conditions. Int. J. Fatigue 2014, 69, 71–83. [Google Scholar] [CrossRef]

- Di Cocco, V.; Iacoviello, F.; Maletta, C.; Natali, S. Cyclic microstructural transitions and fracture micromechanisms in a near equiatomic NiTi alloy. Int. J. Fatigue 2014, 58, 136–143. [Google Scholar] [CrossRef]

- Silva, J.D.; Resende, P.; Garcia, P.R.; Lopes, N.; Santos, L.A.; Buono, V.T.L. Fatigue resistance of dual-phase NiTi wires at different maximum strain amplitudes. Int. J. Fatigue 2019, 125, 97–100. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Antonucci, V.; Faiella, G.; Giordano, M.; Mennella, F.; Nicolais, L. Electrical resistivity study and characterization during NiTi phase transformations. Thermochim. Acta 2007, 462, 64–69. [Google Scholar] [CrossRef]

- Otsuka, K.; Sawamura, T.; Shimizu, K. Crystal structure and internal defects of equiatomic TiNi martensite. Phys. Status Solidi 1971, 5, 457–470. [Google Scholar] [CrossRef]

- Maletta, C.; Sgambitterra, E.; Furgiuele, F.; Casati, R.; Tuissi, A. Fatigue properties of a pseudoelastic NiTi alloy: Strain ratcheting and hysteresis under cyclic tensile loading. Int. J. Fatigue 2014, 66, 78–85. [Google Scholar] [CrossRef]

- Kang, G.; Song, D. Review on structural fatigue of NiTi shape memory alloys: Pure mechanical and thermo-mechanical ones. Theor. Appl. Mech. Lett. 2015, 5, 245–254. [Google Scholar] [CrossRef]

- Orgéas, L.; Favier, D. Stress-induced martensitic transformation of a NiTi alloy in isothermal shear, tension and compression. Acta Mater. 1998, 46, 5579–5591. [Google Scholar] [CrossRef]

- Shaw, J.; Kyriakides, S. On the nucleation and propagation of phase transformation fronts in a NiTi alloy. Acta Mater. 1997, 45, 683–700. [Google Scholar] [CrossRef]

- Sedmák, P.; Sittner, P.; Pilch, J.; Curfs, C. Instability of cyclic superelastic deformation of NiTi investigated by synchrotron X-ray diffraction. Acta Mater. 2015, 94, 257–270. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Guo, W.-G. Superelastic and cyclic response of NiTi SMA at various strain rates and temperatures. Mech. Mater. 2006, 38, 463–474. [Google Scholar] [CrossRef]

- Cho, H.; Yamamoto, T.; Takeda, Y.; Suzuki, A.; Sakuma, T. Exploitation of shape memory alloy actuator using resistance feedback control and its development. Prog. Nat. Sci. 2010, 20, 97–103. [Google Scholar] [CrossRef]

- Sittner, P.; Sedlák, P.; Landa, M.; Novak, V.; Lukas, P. In situ experimental evidence on R-phase related deformation processes in activated NiTi wires. Mater. Sci. Eng. A 2006, 438–440, 579–584. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Humbeeck, J. Lüders-like deformation associated with martensite reorientation in NiTi. Scr. Mater. 1998, 39, 1047–1055. [Google Scholar] [CrossRef]

- Zheng, L.; He, Y.; Moumni, Z. Effects of Lüders-like bands on NiTi fatigue behaviors. Int. J. Solids Struct. 2016, 83, 28–44. [Google Scholar] [CrossRef]

- Stroz, D. TEM studies of the R-phase transformation in a NiTi shape memory alloy after thermo-mechanical treatment. Mater. Chem. Phys. 2003, 81, 460–462. [Google Scholar] [CrossRef]

- Racek, J.; Duchoň, J.; Vronka, M.; Cieslar, M. TEM observation of twins in surface grains of superelastic NiTi wire after cyclic loading. Mater. Sci. Eng. A 2020, 782, 139271. [Google Scholar] [CrossRef]

| Stress (MPa) | Strain (%) | Resistivity (10−7 Ω·m) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cycle/Points | a | b | c | d | a | b | c | d | a | b | c | d |

| 1 | 0.00 | 362.00 | 386.00 | 0.00 | 0.00 | 1.25 | 6.00 | 0.20 | 8.16 | 9.36 | 11.21 | 8.29 |

| 5 | 0.00 | 328.10 | 349.80 | 0.00 | 0.34 | 1.37 | 6.00 | 0.38 | 8.28 | 8.77 | 10.42 | 8.29 |

| 10 | 0.00 | 314.00 | 349.01 | 0.00 | 0.50 | 1.68 | 6.00 | 0.50 | 8.68 | 9.51 | 10.85 | 9.05 |

| 50 | 0.00 | 310.80 | 406.92 | 0.00 | 0.80 | 1.72 | 6.00 | 0.90 | 9.37 | 10.16 | 11.72 | 9.37 |

| 100 | 0.00 | 237.00 | 321.00 | 0.00 | 0.97 | 1.96 | 6.00 | 1.00 | 9.78 | 10.70 | 12.25 | 9.83 |

| 200 | 0.00 | 217.00 | 319.00 | 0.00 | 1.14 | 2.00 | 6.00 | 1.12 | 9.84 | 10.84 | 12.35 | 9.85 |

| 300 | 0.00 | 216.00 | 327.00 | 0.00 | 1.20 | 2.15 | 6.00 | 1.25 | 10.03 | 10.90 | 12.35 | 10.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lima, P.C.; Rodrigues, P.F.; Ramos, A.S.; da Costa, J.D.M.; Braz Fernandes, F.M.; Vieira, M.T. Experimental Analysis of NiTi Alloy during Strain-Controlled Low-Cycle Fatigue. Materials 2021, 14, 4455. https://doi.org/10.3390/ma14164455

Lima PC, Rodrigues PF, Ramos AS, da Costa JDM, Braz Fernandes FM, Vieira MT. Experimental Analysis of NiTi Alloy during Strain-Controlled Low-Cycle Fatigue. Materials. 2021; 14(16):4455. https://doi.org/10.3390/ma14164455

Chicago/Turabian StyleLima, Pedro Cunha, Patrícia Freitas Rodrigues, Ana Sofia Ramos, José D. M. da Costa, Francisco Manuel Braz Fernandes, and Maria Teresa Vieira. 2021. "Experimental Analysis of NiTi Alloy during Strain-Controlled Low-Cycle Fatigue" Materials 14, no. 16: 4455. https://doi.org/10.3390/ma14164455

APA StyleLima, P. C., Rodrigues, P. F., Ramos, A. S., da Costa, J. D. M., Braz Fernandes, F. M., & Vieira, M. T. (2021). Experimental Analysis of NiTi Alloy during Strain-Controlled Low-Cycle Fatigue. Materials, 14(16), 4455. https://doi.org/10.3390/ma14164455