Fracture Behaviour of Real Coarse Aggregate Distributed Concrete under Uniaxial Compressive Load Based on Cohesive Zone Model

Abstract

:1. Introduction

2. Materials and Test

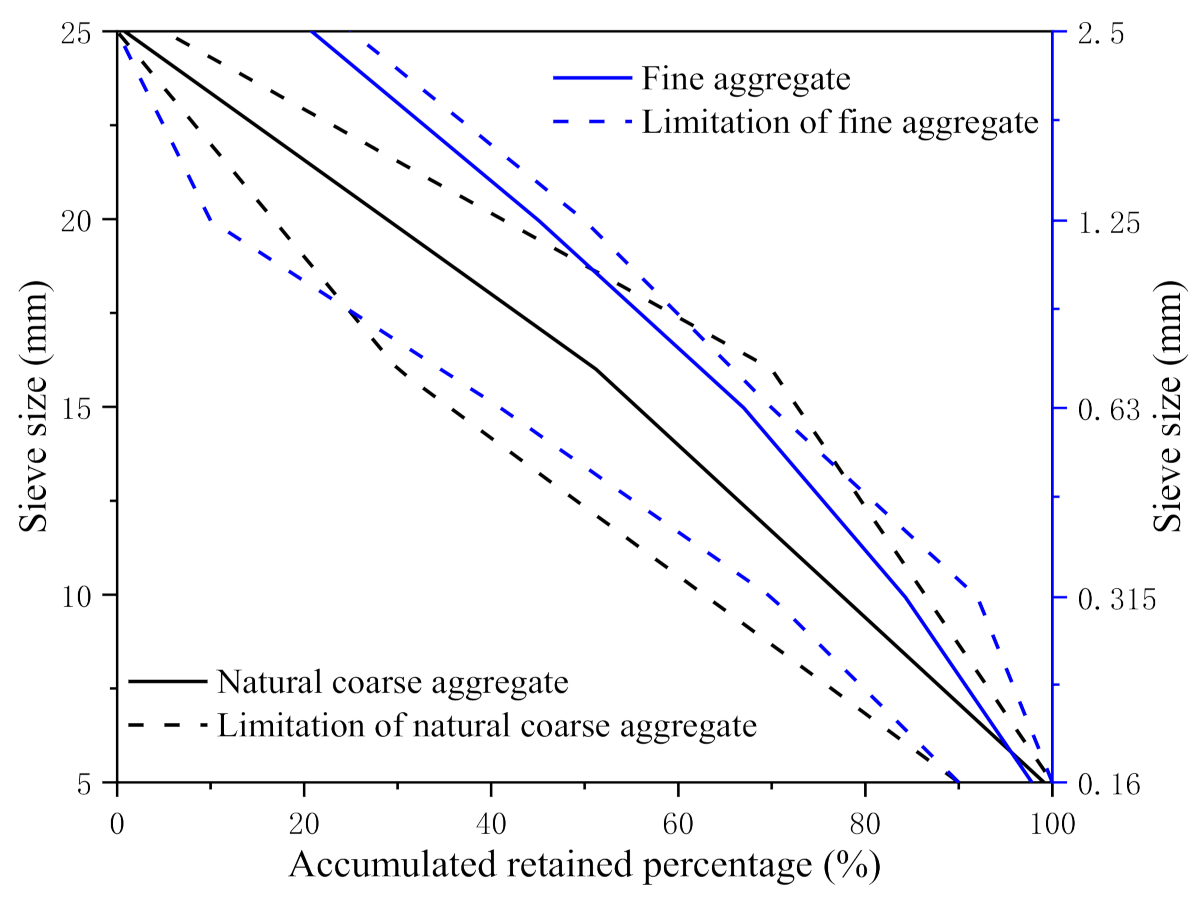

2.1. Experimental Materials

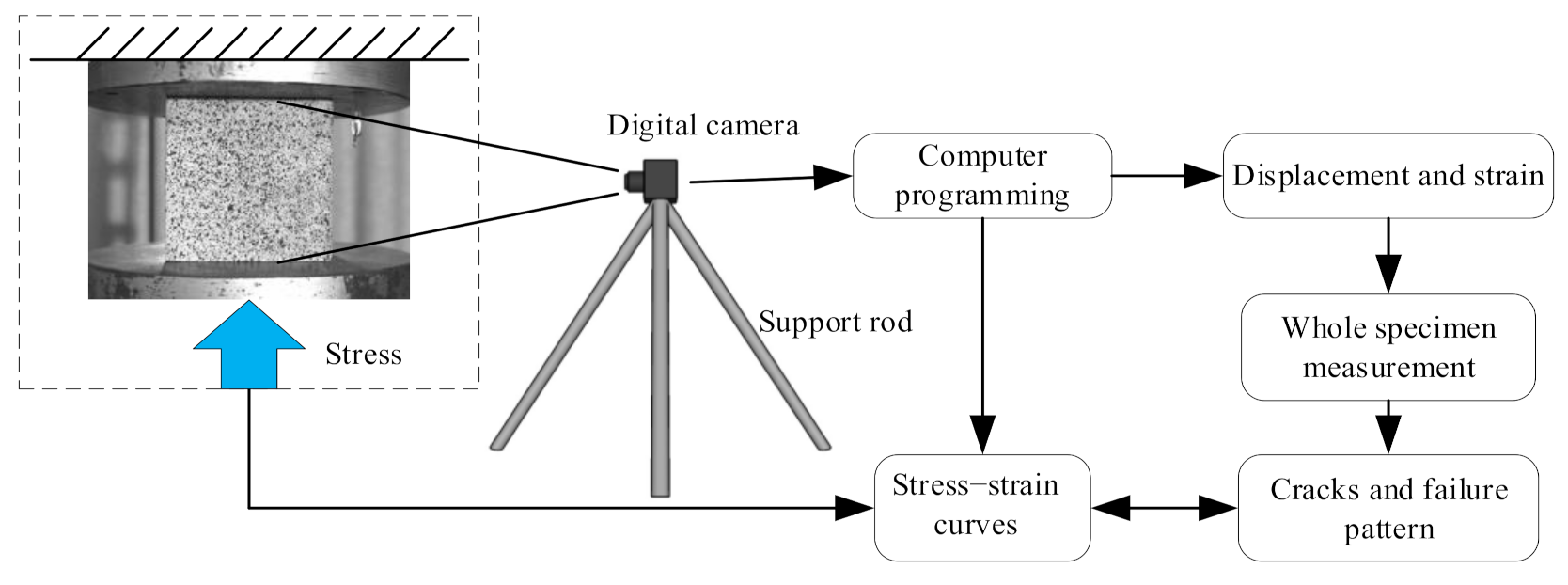

2.2. DIC Program

3. Simulation Program

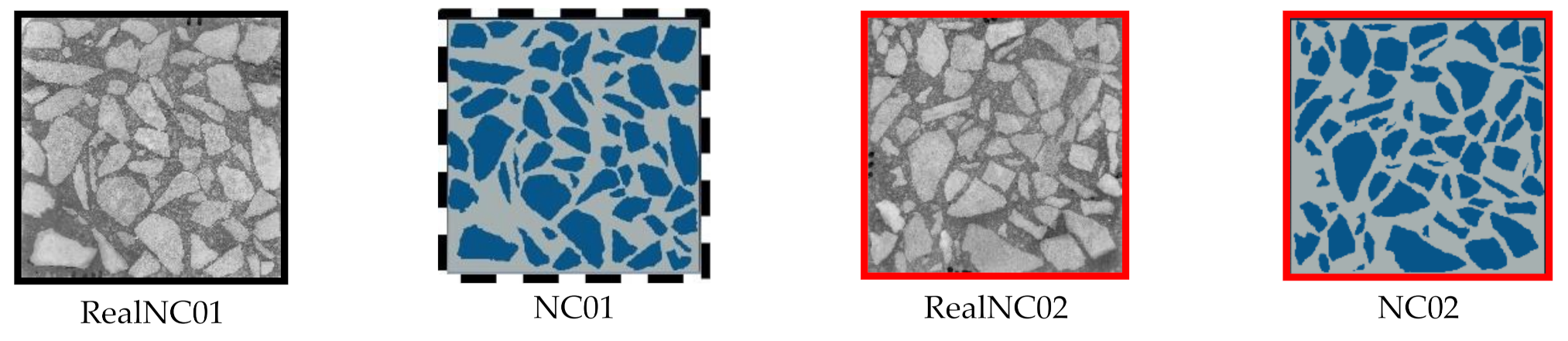

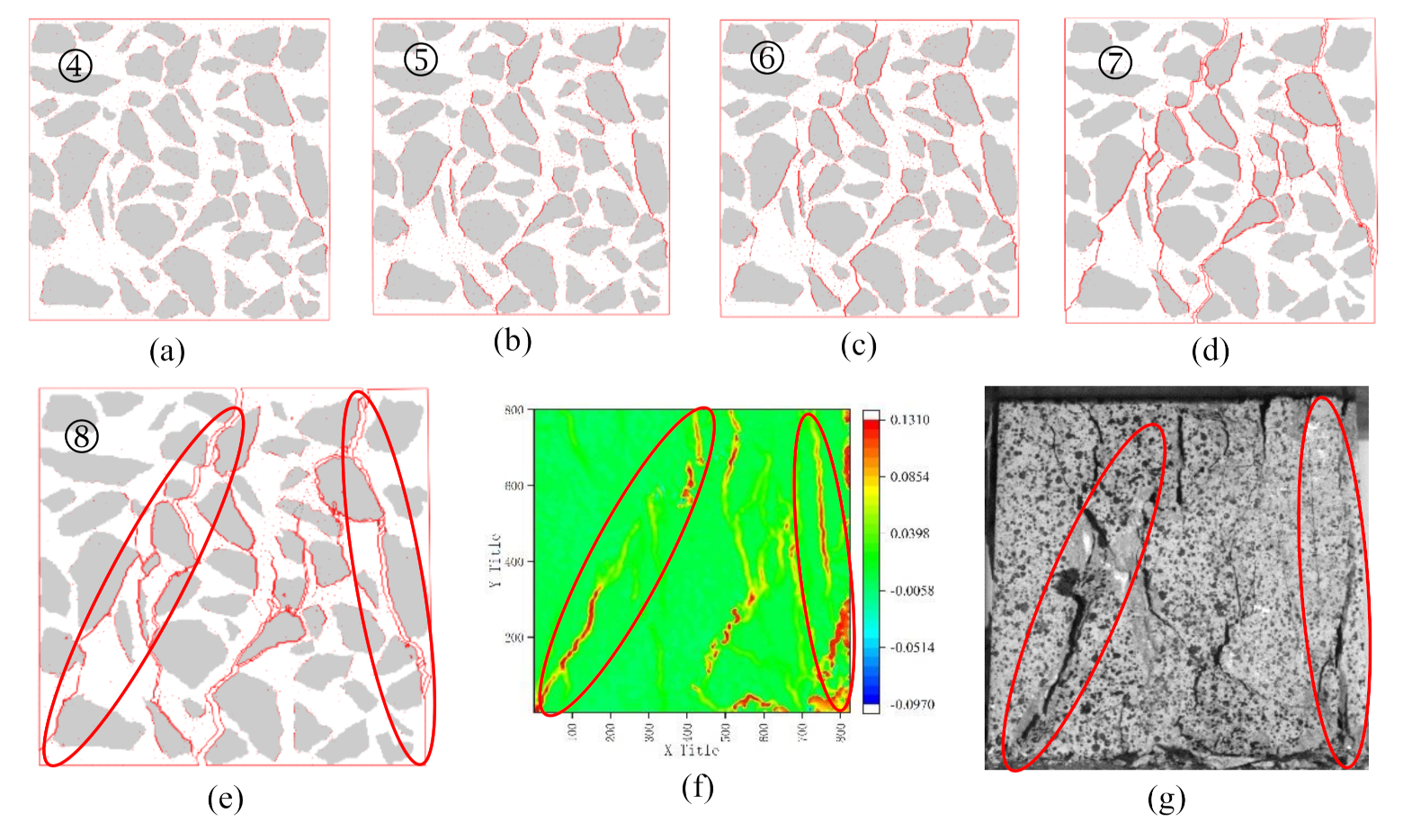

3.1. Modelling

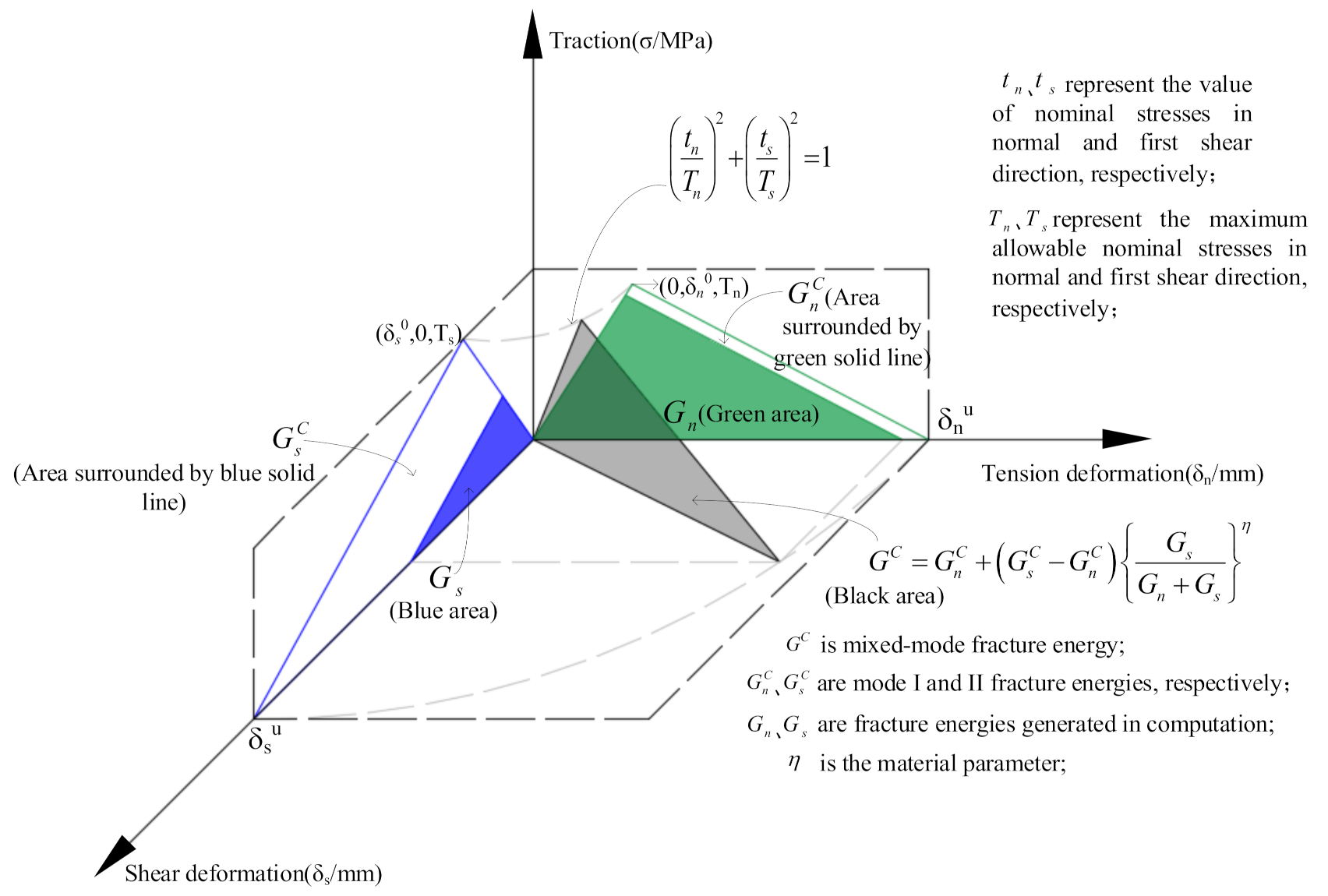

3.2. Material Properties

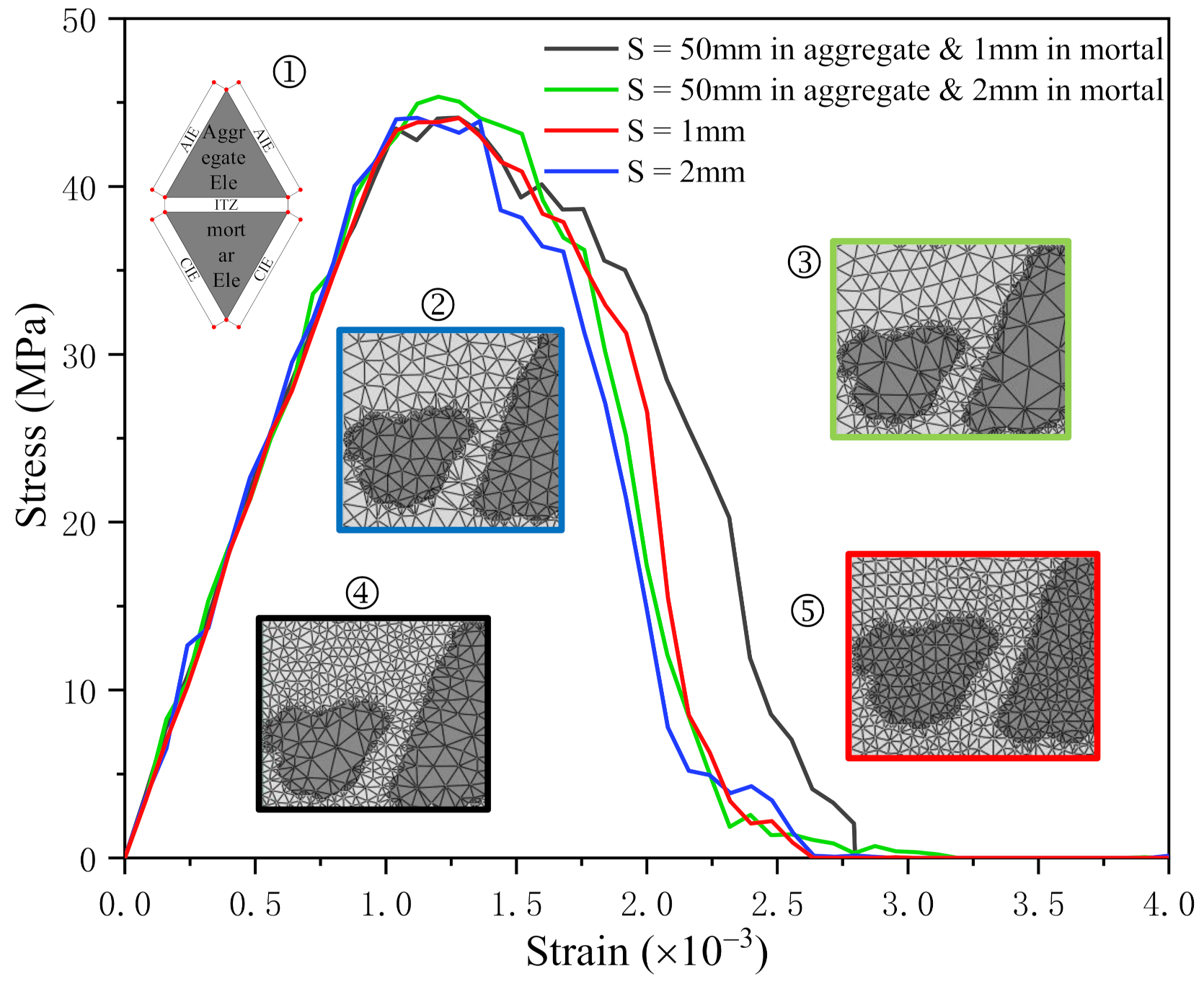

3.3. Mesh Forms and Boundary Condition

- The approximate element size is 1 mm

- The approximate element size is 2 mm

- The approximate size of the cement paste element is 1 mm, and that of the aggregate element is 50 mm

- The approximate size of the cement paste element is 2 mm, and that of the aggregate element is 50 mm

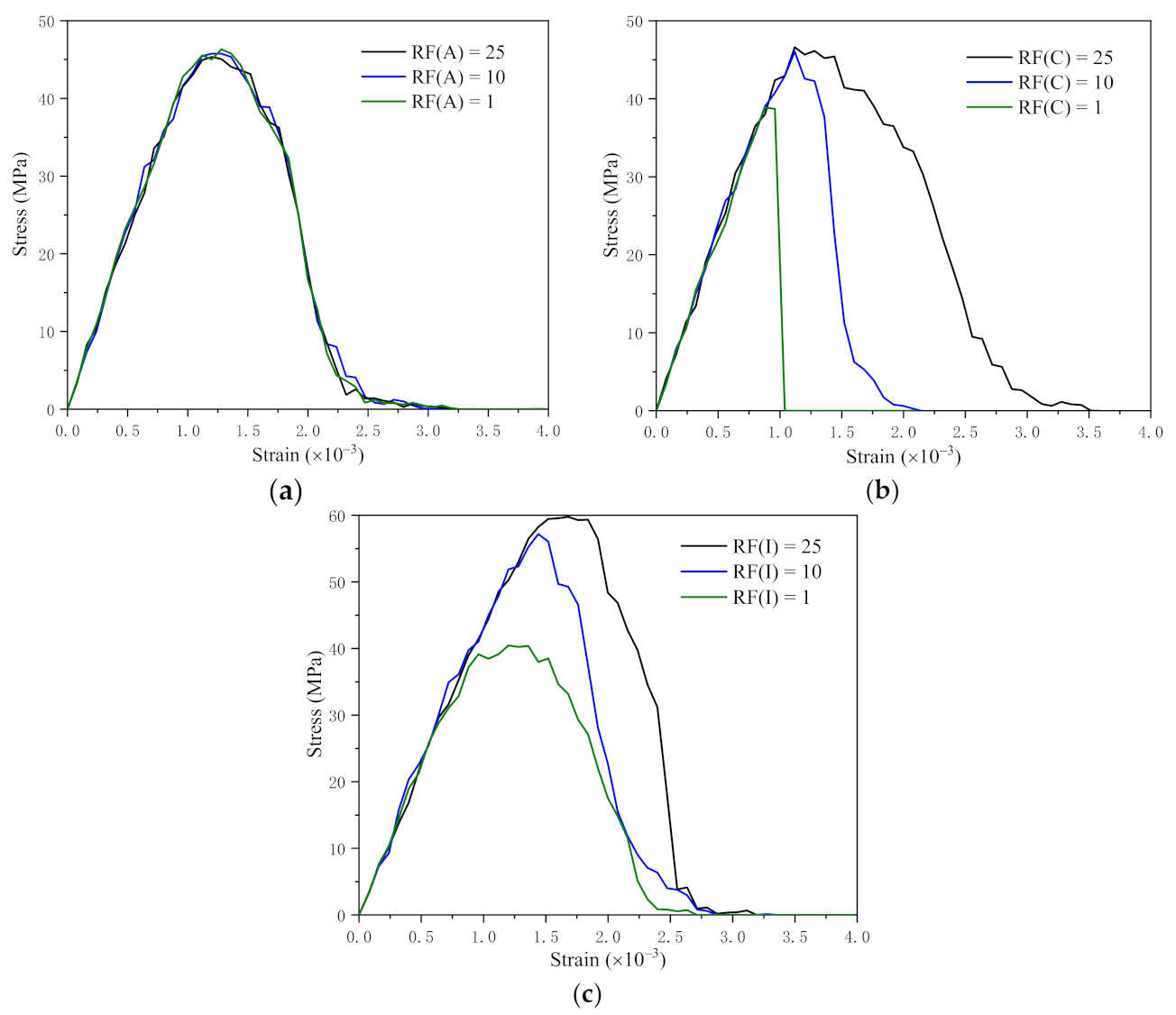

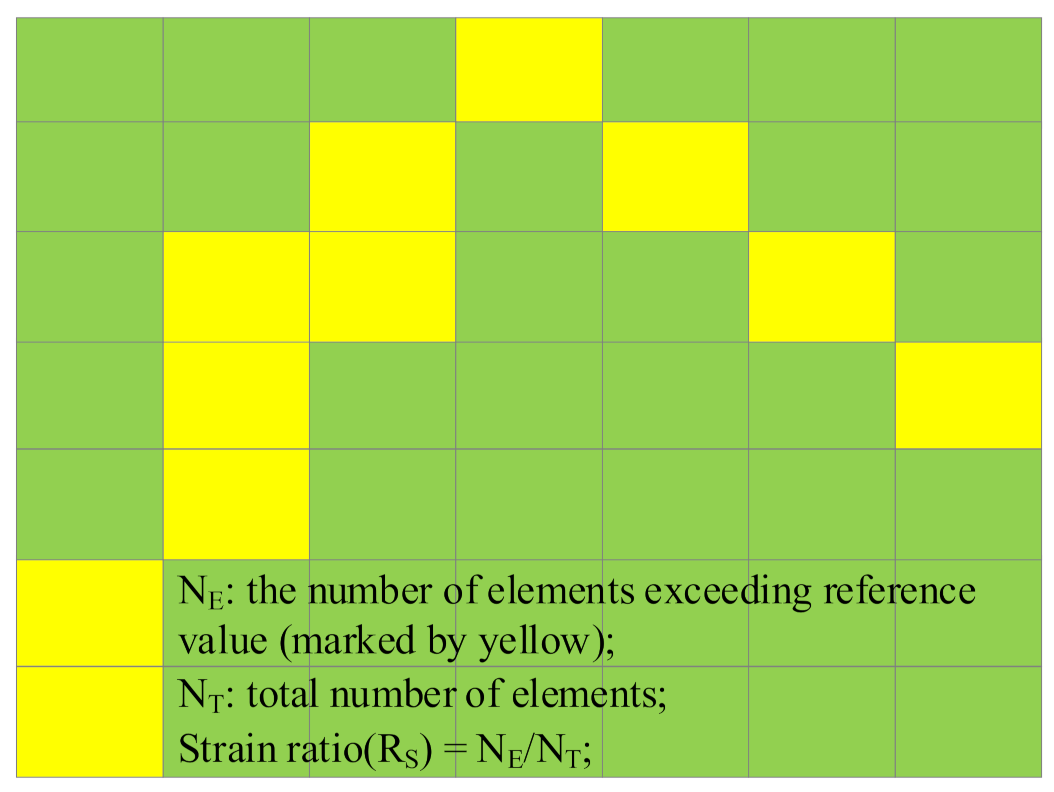

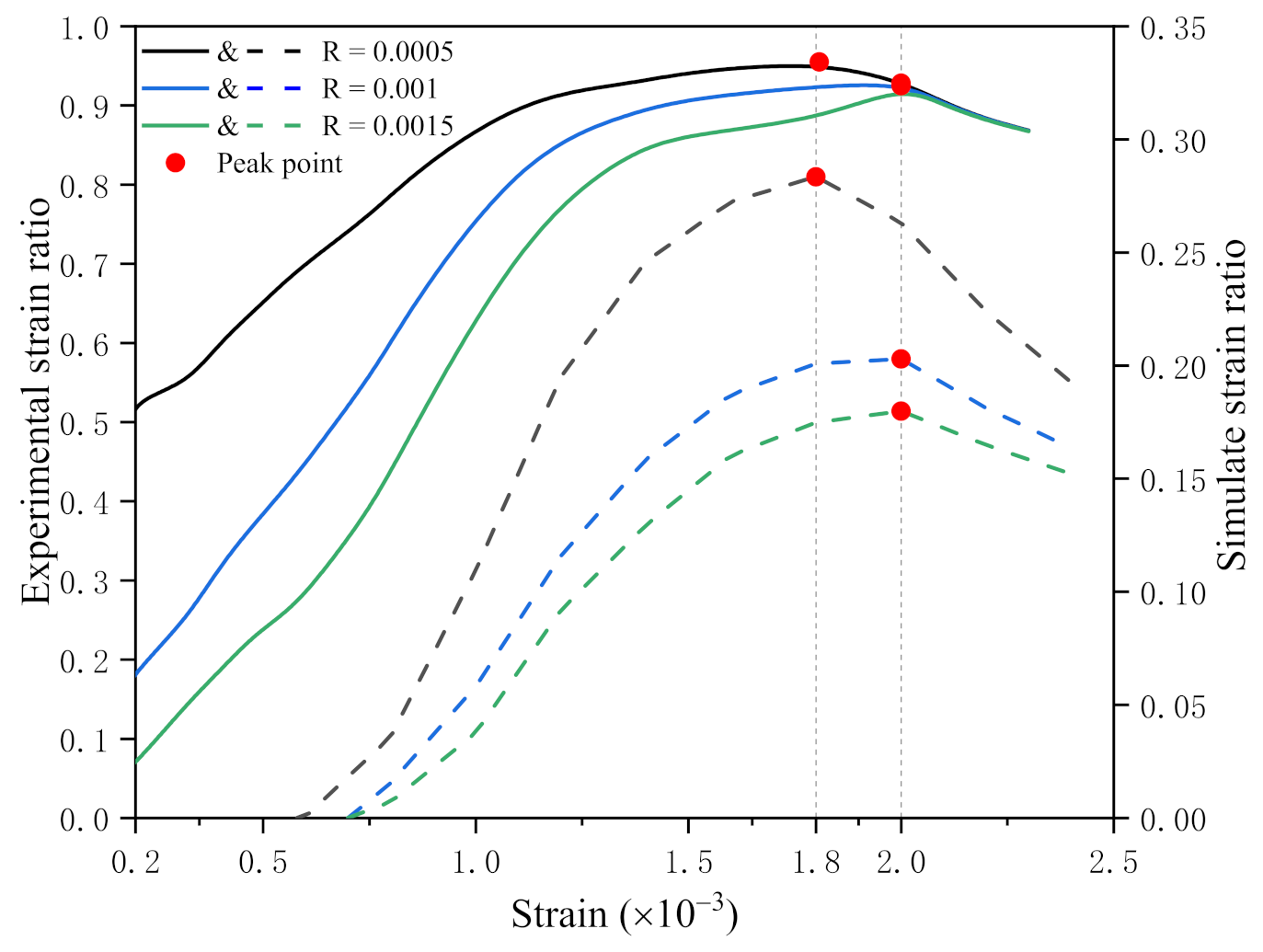

3.4. Parametric Calibration

4. Result Analysis

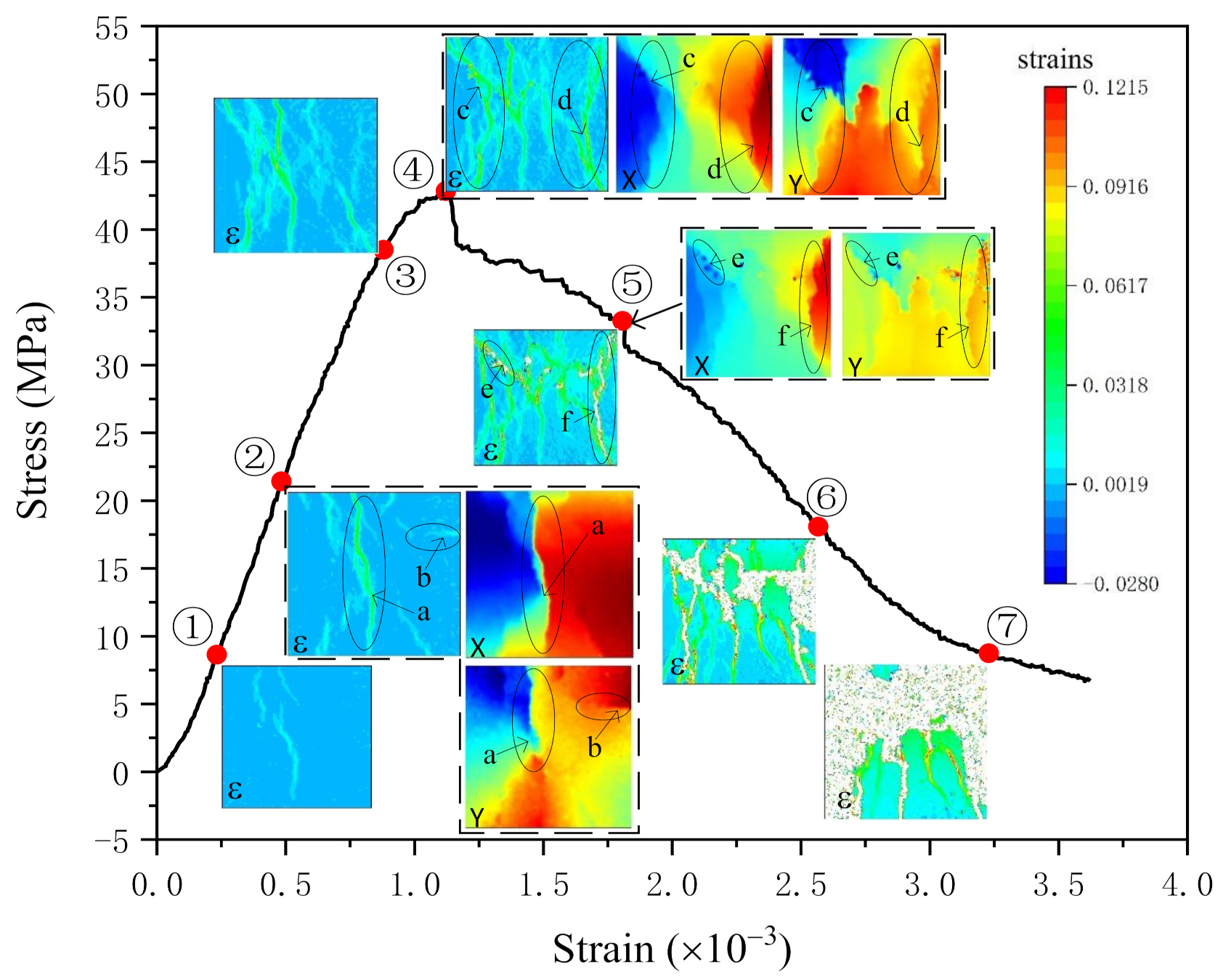

4.1. DIC Result Analysis

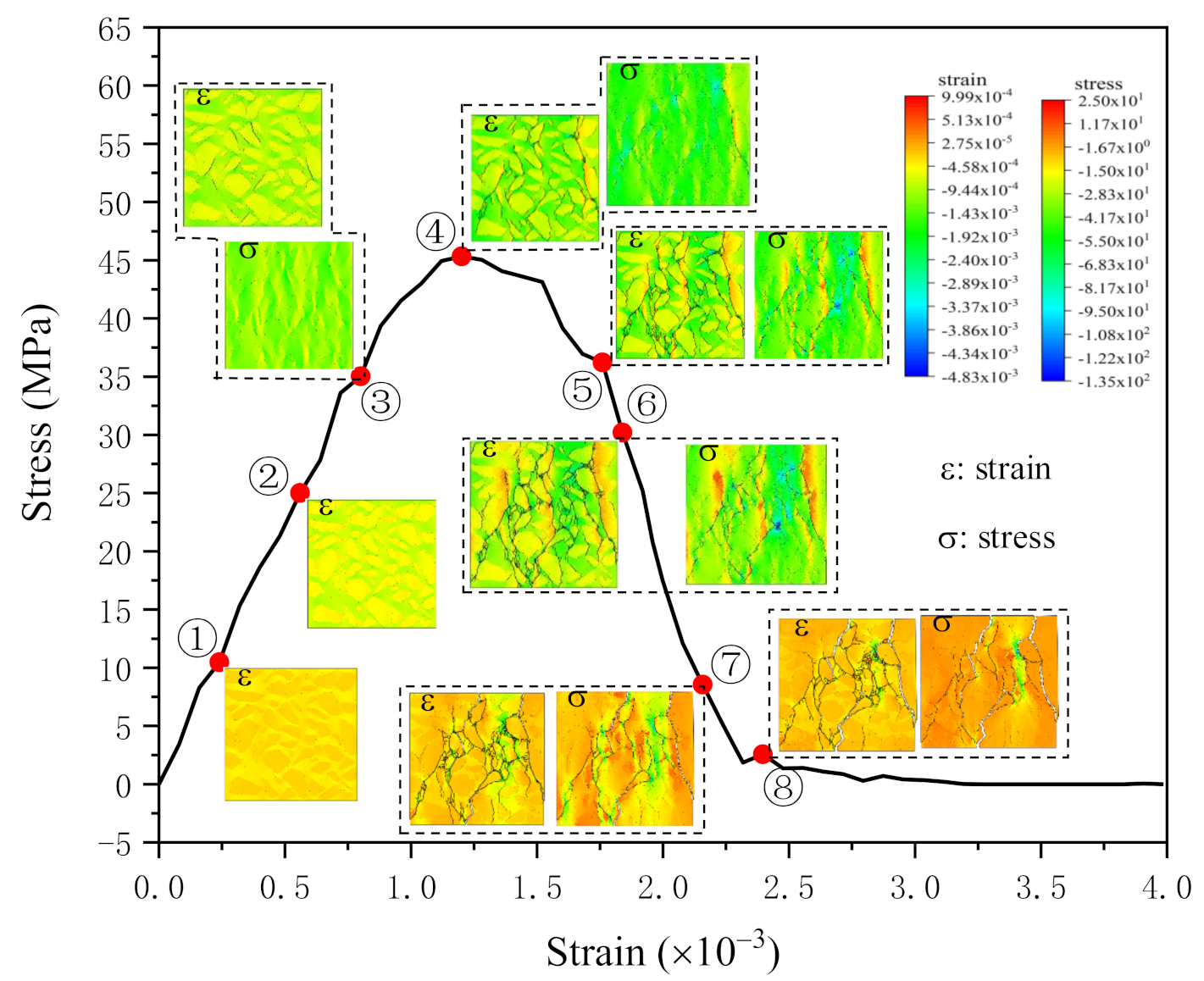

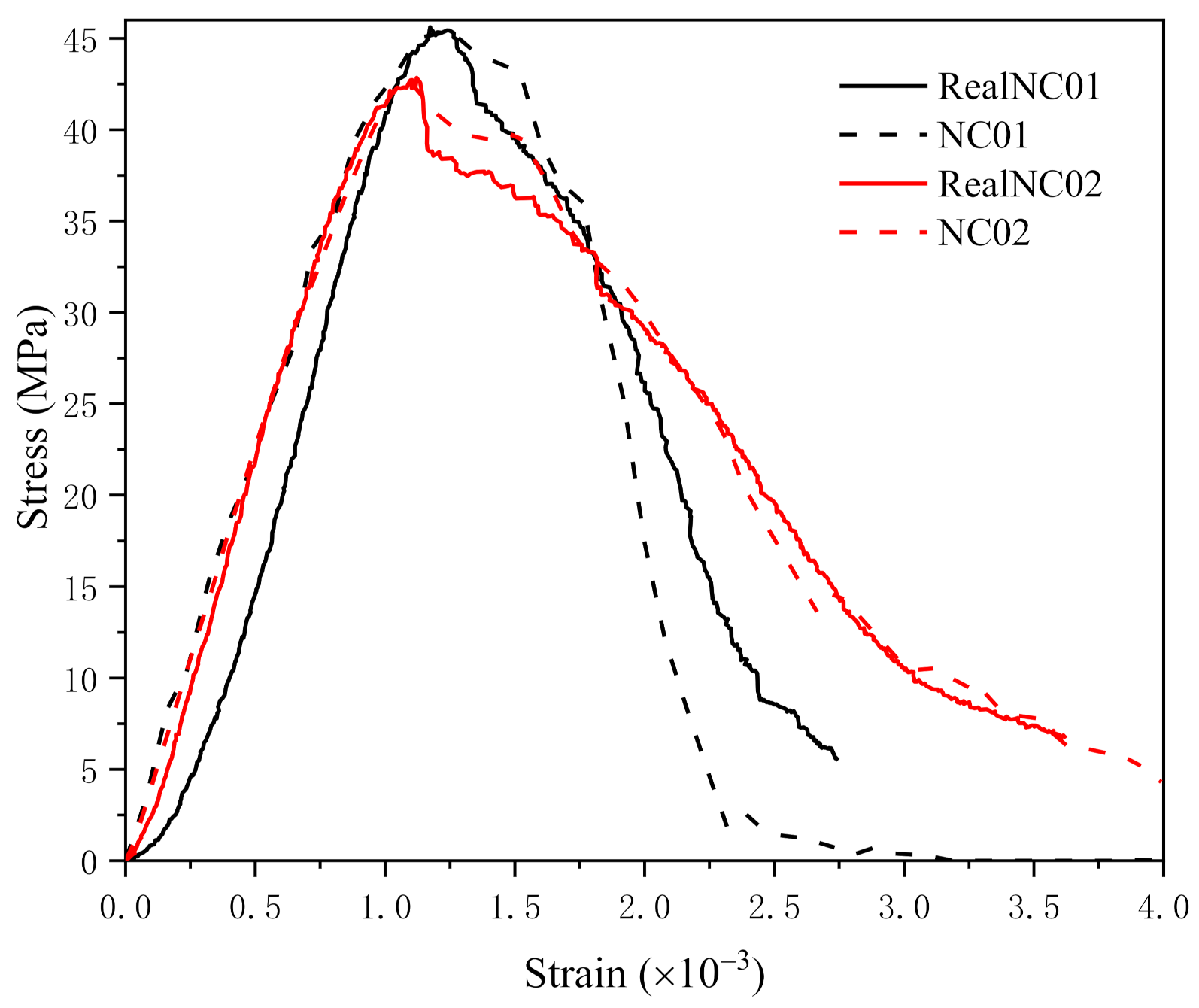

4.2. Simulation Result Analysis

4.3. Comparison between Experimental and Simulation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Notation and abbreviationsThe Abaqus/ Explicit is used in this article | |

| 2D | Two-dimensional |

| 3D | Three-dimensional |

| FE | Finite element |

| DEM | Discrete element method |

| DIC | Digital image correlation |

| W/C | Water-to-cement ratio |

| DIP | Digital image processing |

| RealNC01/NC02 | Realistic concrete specimen sections |

| NC01/NC02 | Finite element models |

| ITZ | Interface transition zone |

| CIE | Interface element inside cement paste |

| AIE | Interface element inside aggregate |

| CPS3 | 3-node linear plane stress triangle |

| COH2D4 | 4-node two-dimensional cohesive element |

| RF | Ratio of fracture energy |

| RF(A) | Fracture energy ratio of AIEs |

| RF(C) | Fracture energy ratio of CIEs |

| RF(I) | Fracture energy ratio of ITZs |

| Shear mode fracture energy (mode II fracture energy) | |

| Normal mode fracture energy (mode I fracture energy) | |

| X | X-direction displacement contour |

| Y | Y-direction displacement contour |

| ε | Strain |

| σ | Stress tensor |

References

- Snozzi, L.; Caballero, A.; Molinari, J.F. Influence of the meso-structure in dynamic fracture simulation of concrete under tensile loading. Cem. Concr. Res. 2011, 41, 1130–1142. [Google Scholar] [CrossRef] [Green Version]

- Červenka, J.; Červenka, V.; Laserna, S. On crack band model in finite element analysis of concrete fracture in engineering practice. Eng. Fract. Mech. 2018, 197, 27–47. [Google Scholar] [CrossRef]

- Moreno-Juez, J.; Tavares, L.M.; Artoni, R.; Carvalho, R.M.D.D.; Cazacliu, B. Simulation of the Attrition of Recycled Concrete Aggregates during Concrete Mixing. Materials 2021, 14, 3007. [Google Scholar] [CrossRef]

- Pulatsu, B.; Erdogmus, E.; Lourenço, P.B.; Lemos, J.V.; Tuncay, K. Numerical modeling of the tension stiffening in reinforced concrete members via discontinuum models. Comput. Part. Mech. 2021, 8, 423–436. [Google Scholar] [CrossRef]

- Nitka, M.; Tejchman, J. Modelling of concrete behaviour in uniaxial compression and tension with DEM. Granul. Matter 2015, 17, 145–164. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O. A Discrete Numerical Mode for Granular Assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Blais, B.; Vidal, D.; Bertrand, F.; Patience, G.S.; Chaouki, J. Experimental Methods in Chemical Engineering: Discrete Element Method—DEM. Can. J. Chem. Eng. 2019, 97, 1964–1973. [Google Scholar] [CrossRef]

- Durand, R.; da Silva, F.H.B.T. A Coulomb-based model to simulate concrete cracking using cohesive elements. Int. J. Fract. 2019, 220, 17–43. [Google Scholar] [CrossRef]

- Jivkov, A.P.; Engelberg, D.L.; Stein, R.; Petkovski, M. Pore space and brittle damage evolution in concrete. Eng. Fract. Mech. 2013, 110, 378–395. [Google Scholar] [CrossRef]

- Janouchova, E.; Kucerova, A.; Sykora, J.; Vorel, J.; Wan-Wendner, R. Robust probabilistic calibration of a stochastic lattice discrete particle model for concrete. Eng. Struct. 2021, 236, 112000. [Google Scholar] [CrossRef]

- Herrmann, H.; Hansen, A.; Roux, S. Fracture of disordered, elastic lattices in two dimensions. Phys. Rev. B Condens. Matter 1989, 39, 637–648. [Google Scholar] [CrossRef]

- Kikuchi, A.; Kawai, T.; Suzuki, N. The rigid bodies—Spring models and their applications to three-dimensional crack problems. Comput. Struct. 1992, 44, 469–480. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modéer, M.; Petersson, P.E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–781. [Google Scholar] [CrossRef]

- Kim, Y.-R.; de Freitas, F.A.C.; Jung, J.S.; Sim, Y. Characterization of bitumen fracture using tensile tests incorporated with viscoelastic cohesive zone model. Constr. Build. Mater. 2015, 88, 1–9. [Google Scholar] [CrossRef]

- Elices, M.; Guinea, G.; Sánchez, F.J.; Planas, J. The cohesive zone model: Advantages, limitations and challenges. Eng. Fract. Mech. 2002, 69, 137–163. [Google Scholar] [CrossRef]

- Wiltman, F.H. Structure of concrete with respect to crack formation. Fract. Mech. Concr. 1983, 43, 6. [Google Scholar]

- Xiong, X.; Xiao, Q. Meso-Scale Simulation of Concrete Based on Fracture and Interaction Behavior. Appl. Sci. 2019, 9, 2986. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Xu, W.; Li, Y. Random aggregate model for mesoscopic structures and mechanical analysis of fully-graded concrete. Comput. Struct. 2016, 177, 103–113. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, Q.; Keer, L.M.; Yao, Y.; Huang, Y. The multi-factor effect of tensile strength of concrete in numerical simulation based on the Monte Carlo random aggregate distribution. Constr. Build. Mater. 2018, 165, 585–595. [Google Scholar] [CrossRef]

- Yu, Q.; Chen, Z.; Yang, J.; Rong, K. Numerical Study of Concrete Dynamic Splitting Based on 3D Realistic Aggregate Mesoscopic Model. Materials 2021, 14, 1948. [Google Scholar] [CrossRef]

- Ma, Y.; Huang, H. DEM analysis of failure mechanisms in the intact Brazilian test. Int. J. Rock Mech. Min. Sci. 2018, 102, 109–119. [Google Scholar] [CrossRef]

- Mora, C.; Kwan, A.; Chan, H. Particle size distribution analysis of coarse aggregate using digital image processing. Cem. Concr. Res. 1998, 28, 921–932. [Google Scholar] [CrossRef]

- Yang, R.; Buenfeld, N.R. Binary segmentation of aggregate in SEM image analysis of concrete. Cem. Concr. Res. 2001, 31, 437–441. [Google Scholar] [CrossRef]

- Garboczi, E.J.; Cheok, G.S.; Stone, W.C. Using LADAR to characterize the 3-D shape of aggregates: Preliminary results. Cem. Concr. Res. 2006, 36, 1072–1075. [Google Scholar] [CrossRef]

- Sun, H.; Gao, Y.; Zheng, X.; Chen, Y.; Jiang, Z.; Zhang, Z. Meso-Scale Simulation of Concrete Uniaxial Behavior Based on Numerical Modeling of CT Images. Materials 2019, 12, 3403. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.-J.; Li, B.-B.; Wu, J.-Y. X-ray computed tomography images based phase-field modeling of mesoscopic failure in concrete. Eng. Fract. Mech. 2019, 208, 151–170. [Google Scholar] [CrossRef]

- Yue, Q.; Wang, L.; Liu, F.; Xiao, A.N. Numerical Study on Damage Process of Recycled Aggregate Concrete by Real Meso-scale Model. J. Build. Mater. 2016, 19, 221–228. [Google Scholar]

- Trawiński, W.; Bobiński, J.; Tejchman, J. Two-dimensional simulations of concrete fracture at aggregate level with cohesive elements based on X-ray μCT images. Eng. Fract. Mech. 2016, 168, 204–226. [Google Scholar] [CrossRef]

- Ren, W.; Yang, Z.; Sharma, R.; Zhang, C.; Withers, P.J. Two-dimensional X-ray CT image based meso-scale fracture modelling of concrete. Eng. Fract. Mech. 2015, 133, 24–39. [Google Scholar] [CrossRef]

- Chu, T.C.; Ranson, W.F.; Sutton, M.A. Applications of digital-image-correlation techniques to experimental mechanics. Exp. Mech. 1985, 25, 232–244. [Google Scholar] [CrossRef]

- Yue, Z.Q.; Chen, S.; Tham, L.G. Finite element modeling of geomaterials using digital image processing. Comput. Geotech. 2003, 30, 375–397. [Google Scholar] [CrossRef]

- Jiang, Y.U.; Tian, P.; Qin, Y. An Analytical Survey on Generation Methods of Meso-level Aggregate Models for Concrete. Mater. Rev. 2016, 30, 102–108. [Google Scholar]

- Barrioulet, M.; Saada, R.; Ringot, E. A quantitative structural study of fresh cement paste by image analysis part 1: Image processing. Cem. Concr. Res. 1991, 21, 835–843. [Google Scholar] [CrossRef]

- López, C.M.; Carol, I.; Aguado, A. Meso-structural study of concrete fracture using interface elements. I: Numerical model and tensile behavior. Mater. Struct. 2008, 41, 583–599. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.; Park, R. Theoretical Stress-Strain Model for Confined Concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef] [Green Version]

- Durand, R.; da Silva, F.H.B.T. Three-dimensional modeling of fracture in quasi-brittle materials using plasticity and cohesive finite elements. Int. J. Fract. 2021, 228, 45–70. [Google Scholar] [CrossRef]

- López, C.M.; Carol, I.; Aguado, A. Meso-structural study of concrete fracture using interface elements. II: Compression, biaxial and Brazilian test. Mater. Struct. 2008, 41, 601–620. [Google Scholar] [CrossRef]

- Alfano, G. On the influence of the shape of the interface law on the application of cohesive-zone models. Compos. Sci. Technol. 2006, 66, 723–730. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiao, Y.; Wu, Q.; Xue, Y. A multi-state progressive cohesive law for the prediction of unstable propagation and arrest of Mode-I delamination cracks in composite laminates. Eng. Fract. Mech. 2021, 248, 107684. [Google Scholar] [CrossRef]

- Benzeggagh, M.L.; Kenane, M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 1996, 56, 439–449. [Google Scholar] [CrossRef]

- Naga Satish Kumar, C.; Gunneswara Rao, T.D. Punching shear resistance of concrete slabs using mode-II fracture energy. Eng. Fract. Mech. 2012, 83, 75–85. [Google Scholar] [CrossRef]

- Wang, X.F.; Yang, Z.J.; Yates, J.R.; Jivkov, A.P.; Zhang, C. Monte Carlo simulations of mesoscale fracture modelling of concrete with random aggregates and pores. Constr. Build. Mater. 2015, 75, 35–45. [Google Scholar] [CrossRef]

- Wu, Z.; Cui, W.; Fan, L.; Liu, Q. Mesomechanism of the dynamic tensile fracture and fragmentation behaviour of concrete with heterogeneous mesostructure. Constr. Build. Mater. 2019, 217, 573–591. [Google Scholar] [CrossRef]

- Hao, Y.; Hao, H. Finite element modelling of mesoscale concrete material in dynamic splitting test. Adv. Struct. Eng. 2016, 19, 1027–1039. [Google Scholar] [CrossRef]

- Xiangqian, F.; Shengtao, L.; Xudong, C.; Saisai, L.; Yuzhu, G. Fracture behaviour analysis of the full-graded concrete based on digital image correlation and acoustic emission technique. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1274–1289. [Google Scholar] [CrossRef]

- Yuan, H.; Luo, G.; Liu, C.; Zeng, L. Interfacial properties of CFRP sheets and concrete subjected to variable amplitude fatigue loading. Struct. Concr. 2021, 1, 1–19. [Google Scholar] [CrossRef]

- Qing-Lei, Y.U.; Tang, C.A.; Zhu, W.C.; Tang, S.B. Digital image-based numerical simulation on failure process of concrete. Eng. Mech. 2008, 25, 72–78. [Google Scholar]

| Type | Fineness Modulus | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Tight Density (kg/m3) | Water Absorption (%) | Dust Content (%) |

|---|---|---|---|---|---|---|

| FA | 3.09 | 2620 | 1623 | 1718 | 0.59 | 0.8 |

| Type | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Crushing Index (%) | Water Absorption (%) | Dust Content (%) | Elongated and Flaky Particle (%) |

|---|---|---|---|---|---|---|

| NCA | 2708 | 1436 | 12.37 | 0.39 | 1.12 | 7.1 |

| No. | W/C | Water (kg/m3) | Cement (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) |

|---|---|---|---|---|---|

| NC | 0.5 | 203 | 406 | 730 | 1046 |

| Parts | Density (kg/m3) | Elastic Modulus (GPa) | Poisson’s Ratio | Maximum Nominal Stress in Normal/Shear Direction (MPa) | Normal/Shear Mode Fracture Energy (N/mm) | B-K Criterion Material Parameter |

|---|---|---|---|---|---|---|

| Aggregate | 2708 | 75 | 0.16 | - | - | - |

| Mortar | 2400 | 35 | 0.20 | - | - | - |

| AIEs | 2600 | 103 | - | 10/90 | 400/10,000 | 1.2 |

| CIEs | 2400 | 103 | - | 5/35 | 0.2/4 | 1.2 |

| ITZs | 2300 | 103 | - | 3/12 | 0.04/0.12 | 1.2 |

| Elements Size (mm) | Solid Element (CPS3) | Cohesive Element (COH2D4) |

|---|---|---|

| 1 | 30,624 | 40,496 |

| 2 | 19,603 | 26,901 |

| 50 in aggregate, 1 in cement paste | 24,341 | 31,442 |

| 50 in aggregate, 2 in cement paste | 17,033 | 25,441 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ying, J.; Guo, J. Fracture Behaviour of Real Coarse Aggregate Distributed Concrete under Uniaxial Compressive Load Based on Cohesive Zone Model. Materials 2021, 14, 4314. https://doi.org/10.3390/ma14154314

Ying J, Guo J. Fracture Behaviour of Real Coarse Aggregate Distributed Concrete under Uniaxial Compressive Load Based on Cohesive Zone Model. Materials. 2021; 14(15):4314. https://doi.org/10.3390/ma14154314

Chicago/Turabian StyleYing, Jingwei, and Jin Guo. 2021. "Fracture Behaviour of Real Coarse Aggregate Distributed Concrete under Uniaxial Compressive Load Based on Cohesive Zone Model" Materials 14, no. 15: 4314. https://doi.org/10.3390/ma14154314

APA StyleYing, J., & Guo, J. (2021). Fracture Behaviour of Real Coarse Aggregate Distributed Concrete under Uniaxial Compressive Load Based on Cohesive Zone Model. Materials, 14(15), 4314. https://doi.org/10.3390/ma14154314