Influence of Mold and Heat Transfer Fluid Materials on the Temperature Distribution of Large Framed Molds in Autoclave Process

Abstract

:1. Introduction

2. Experiment

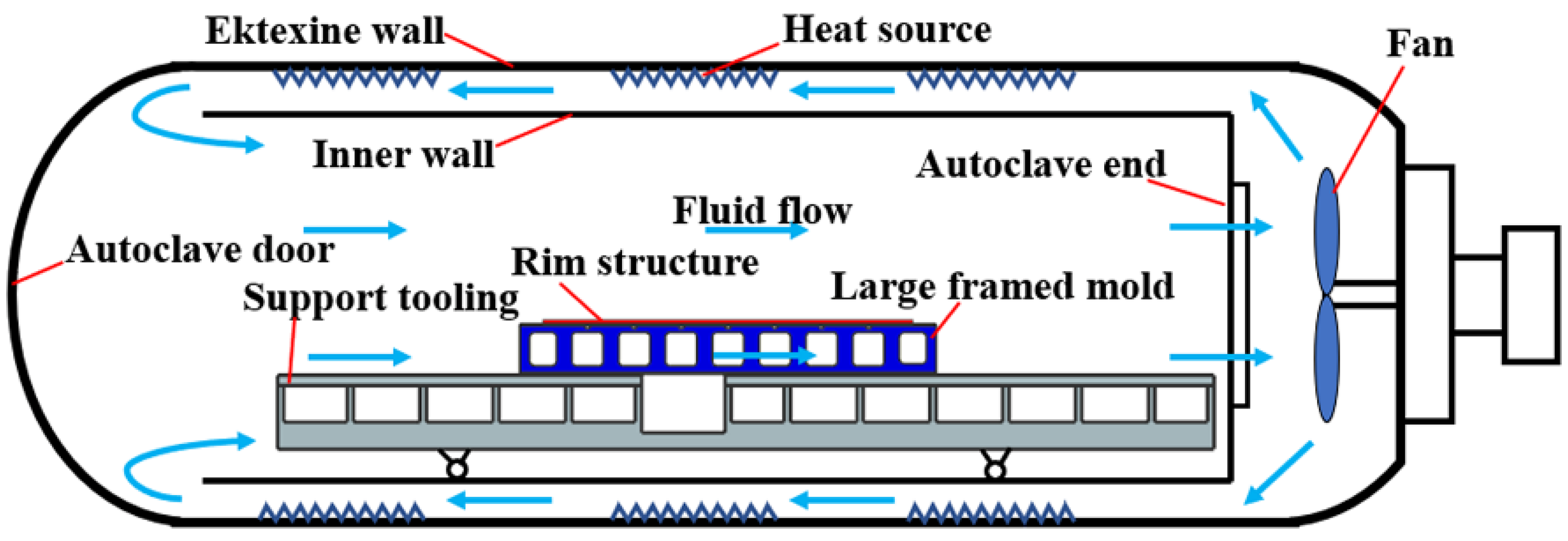

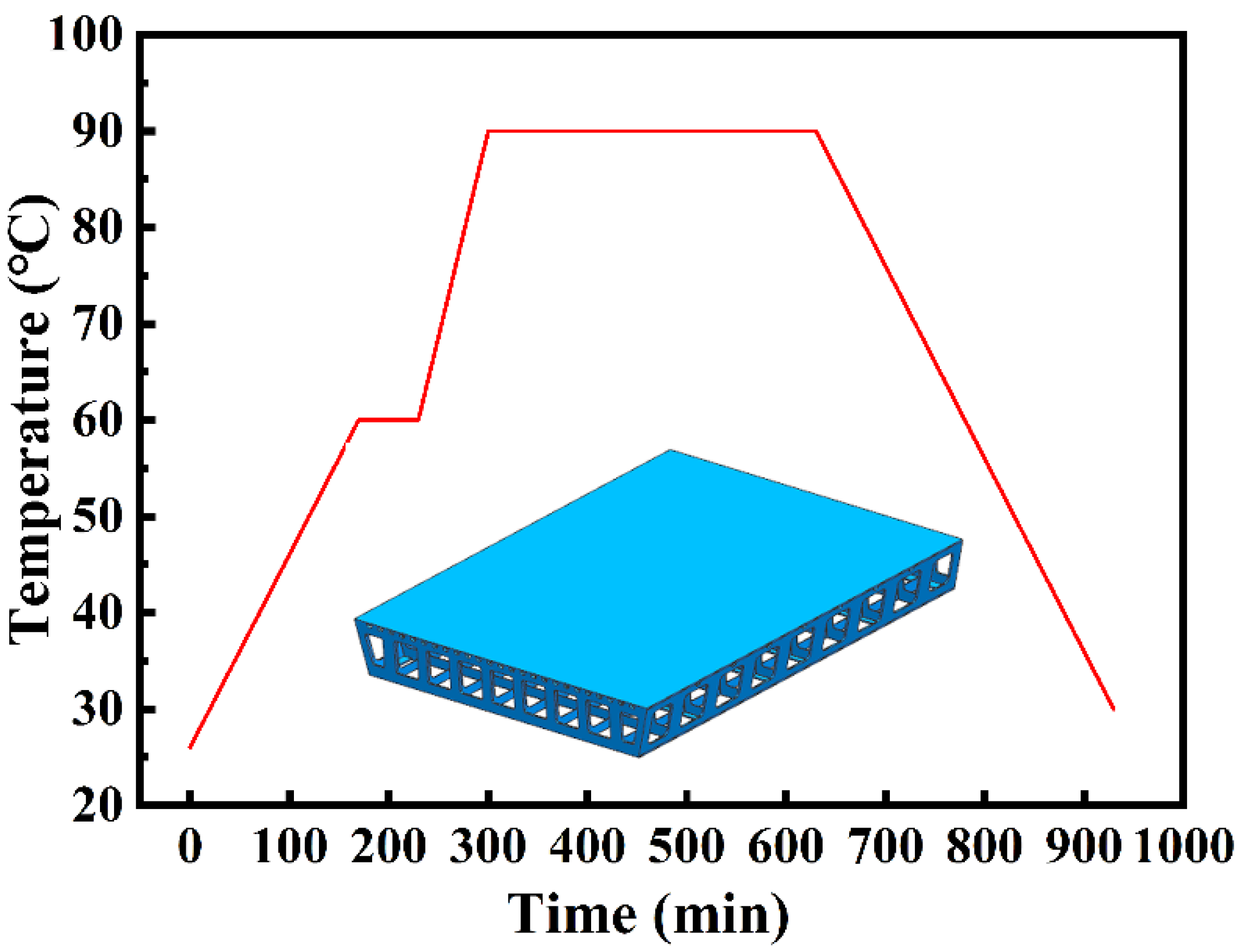

2.1. Temperature Monitoring Experiment

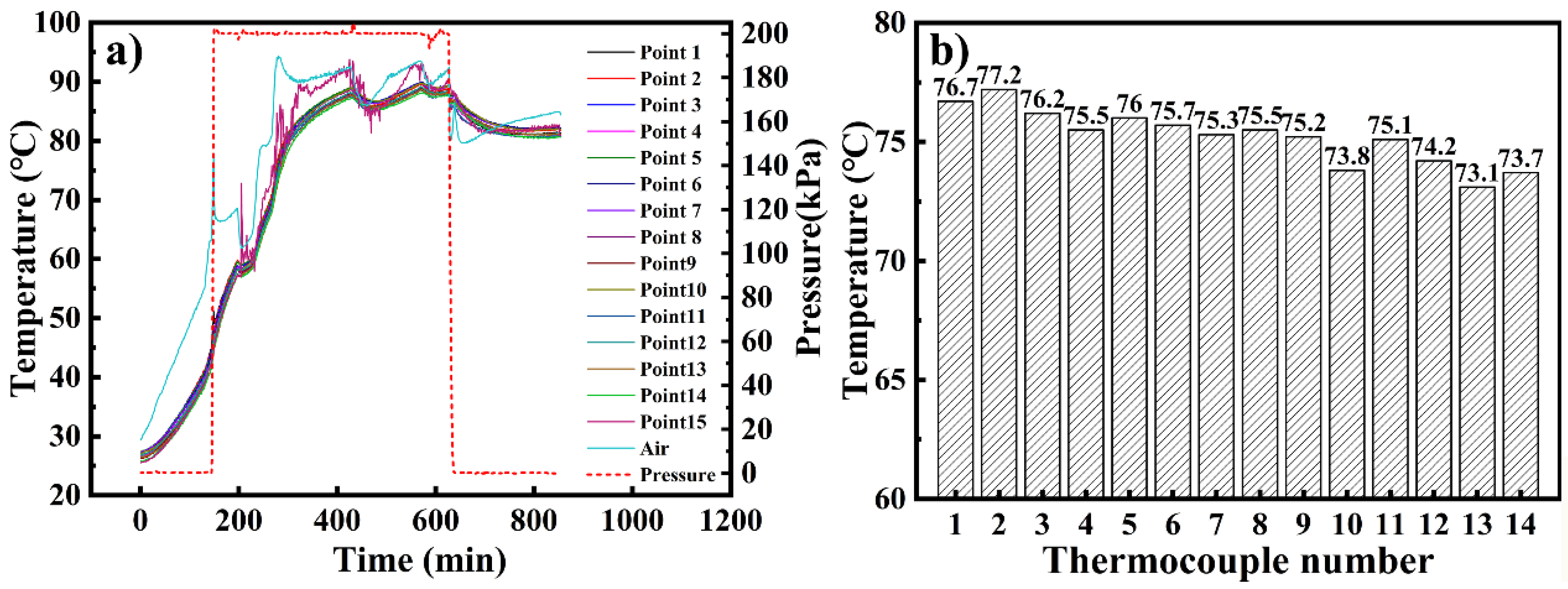

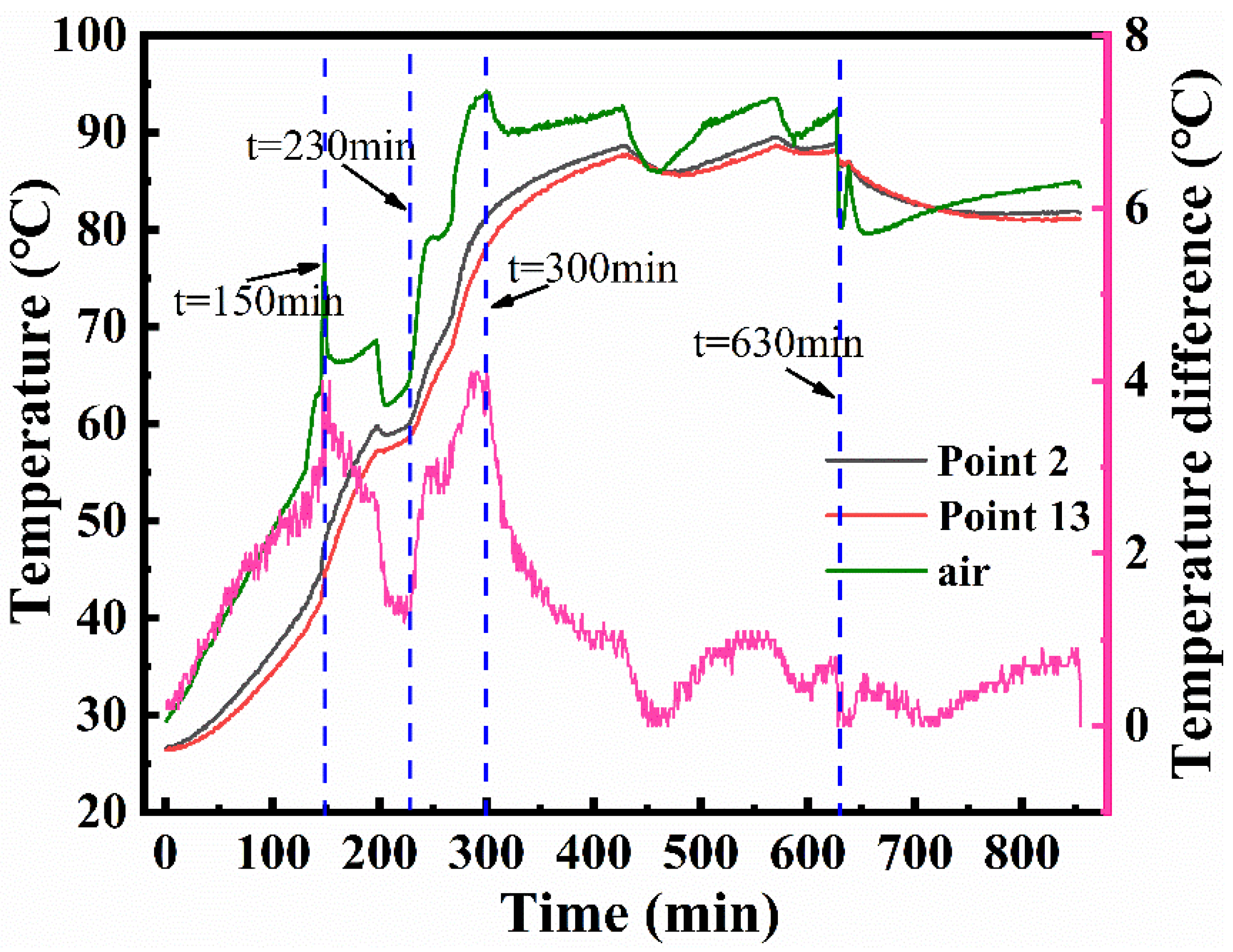

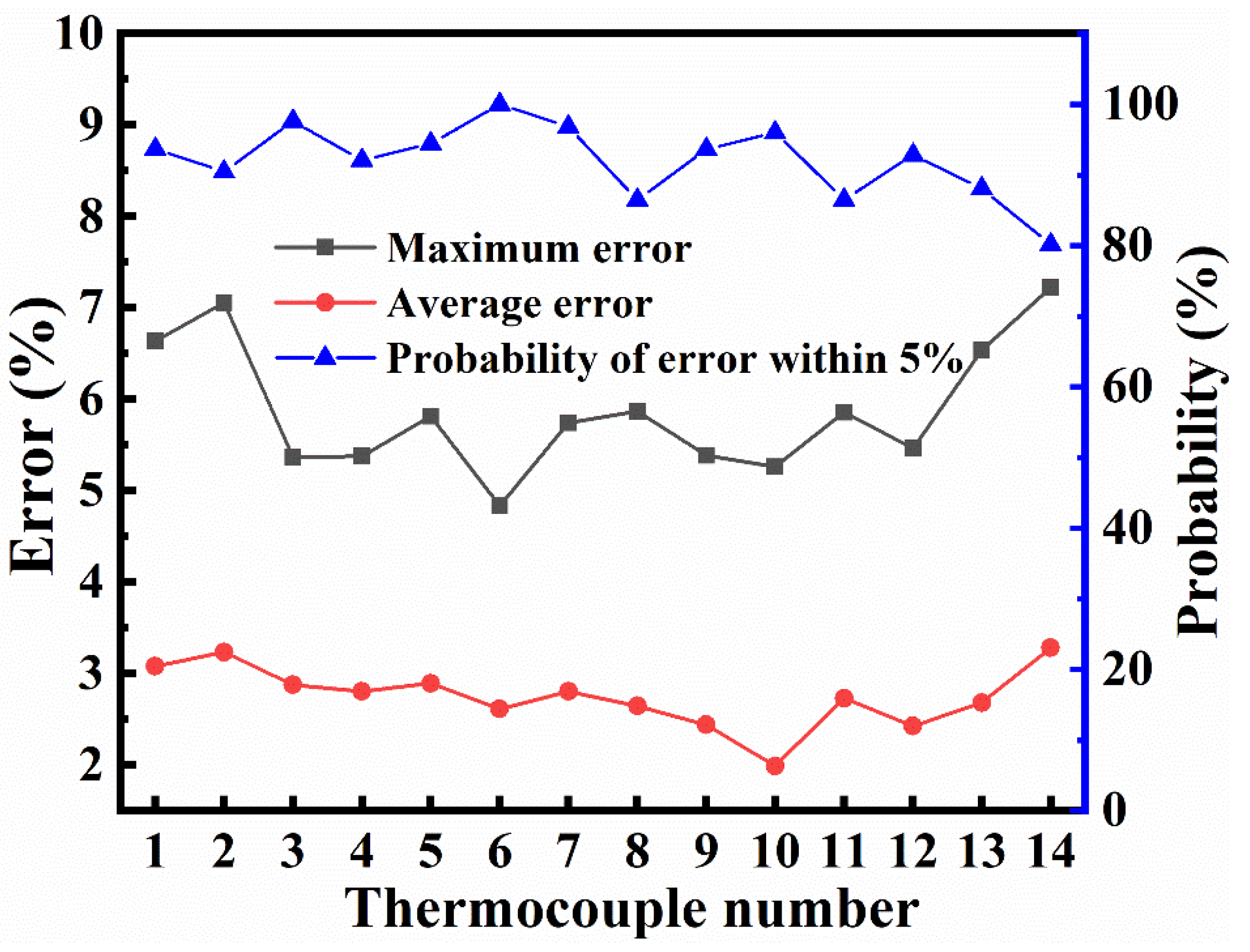

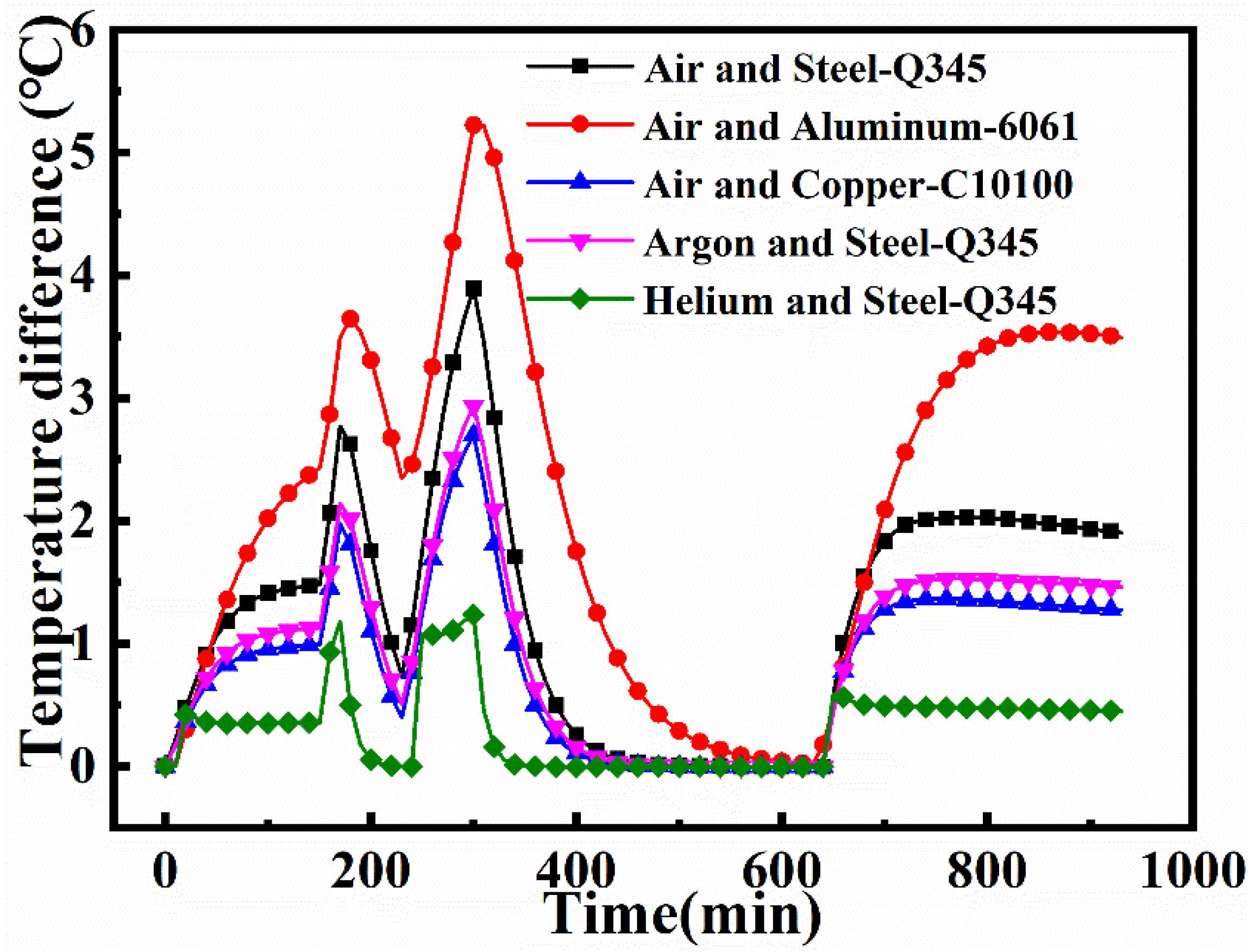

2.2. Experimental Results

3. Simulation and Validation

3.1. Governing Equations

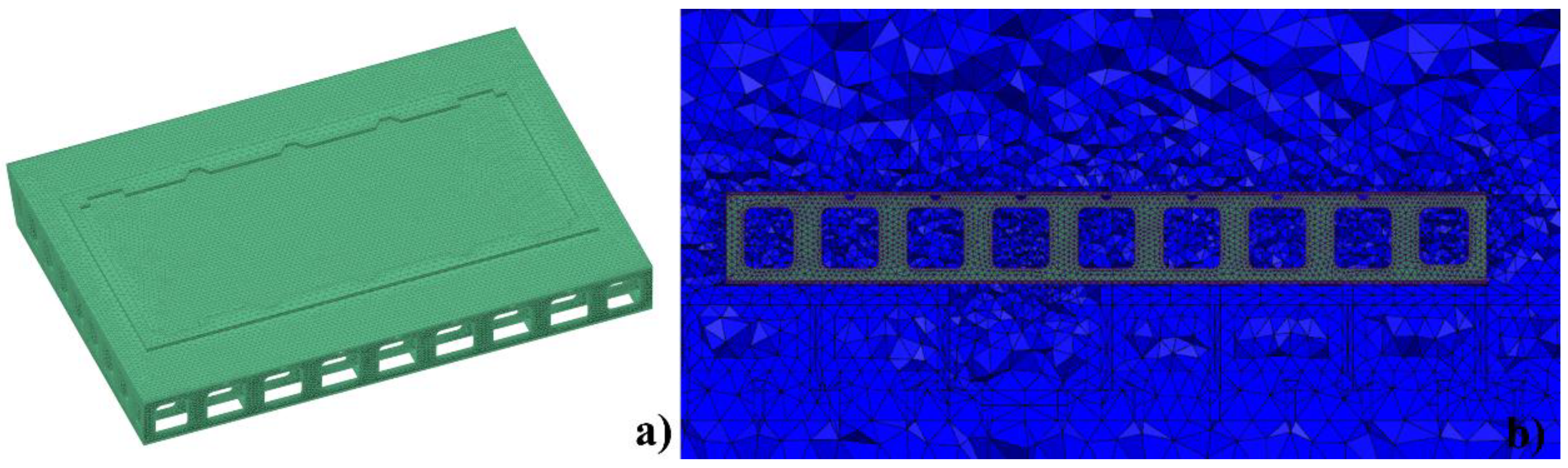

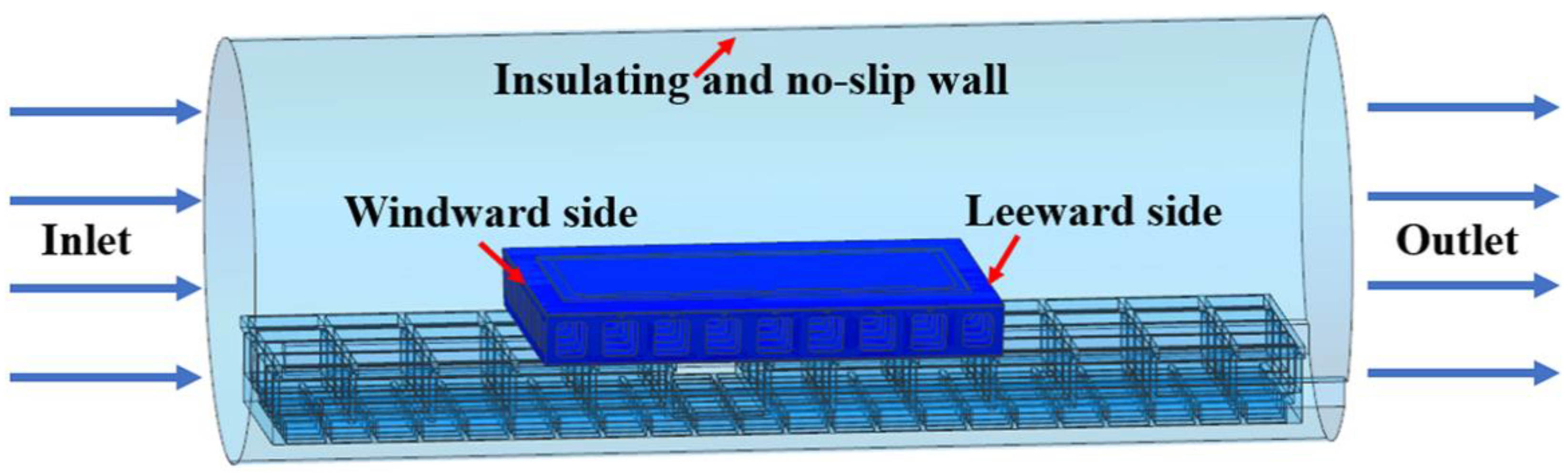

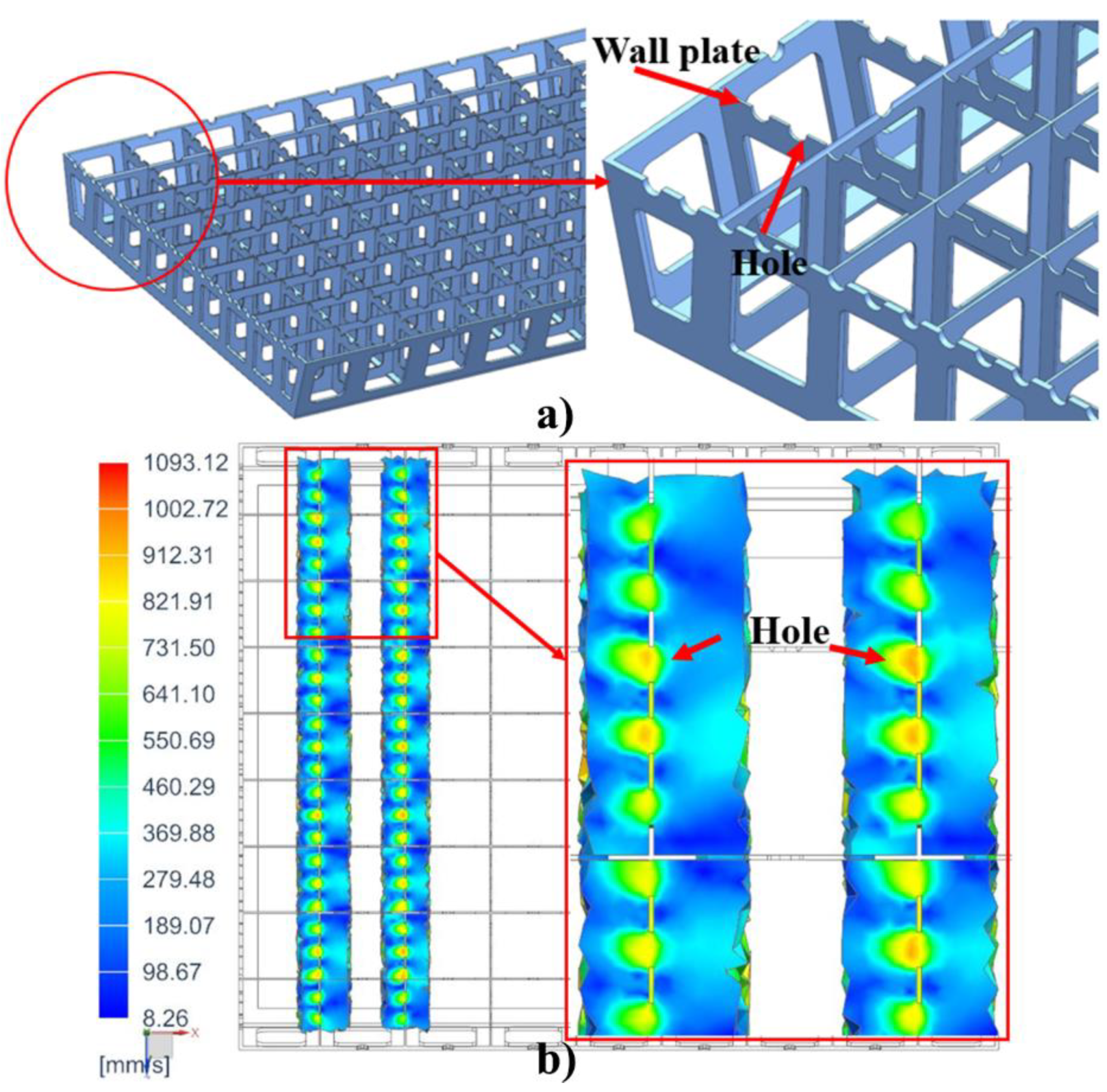

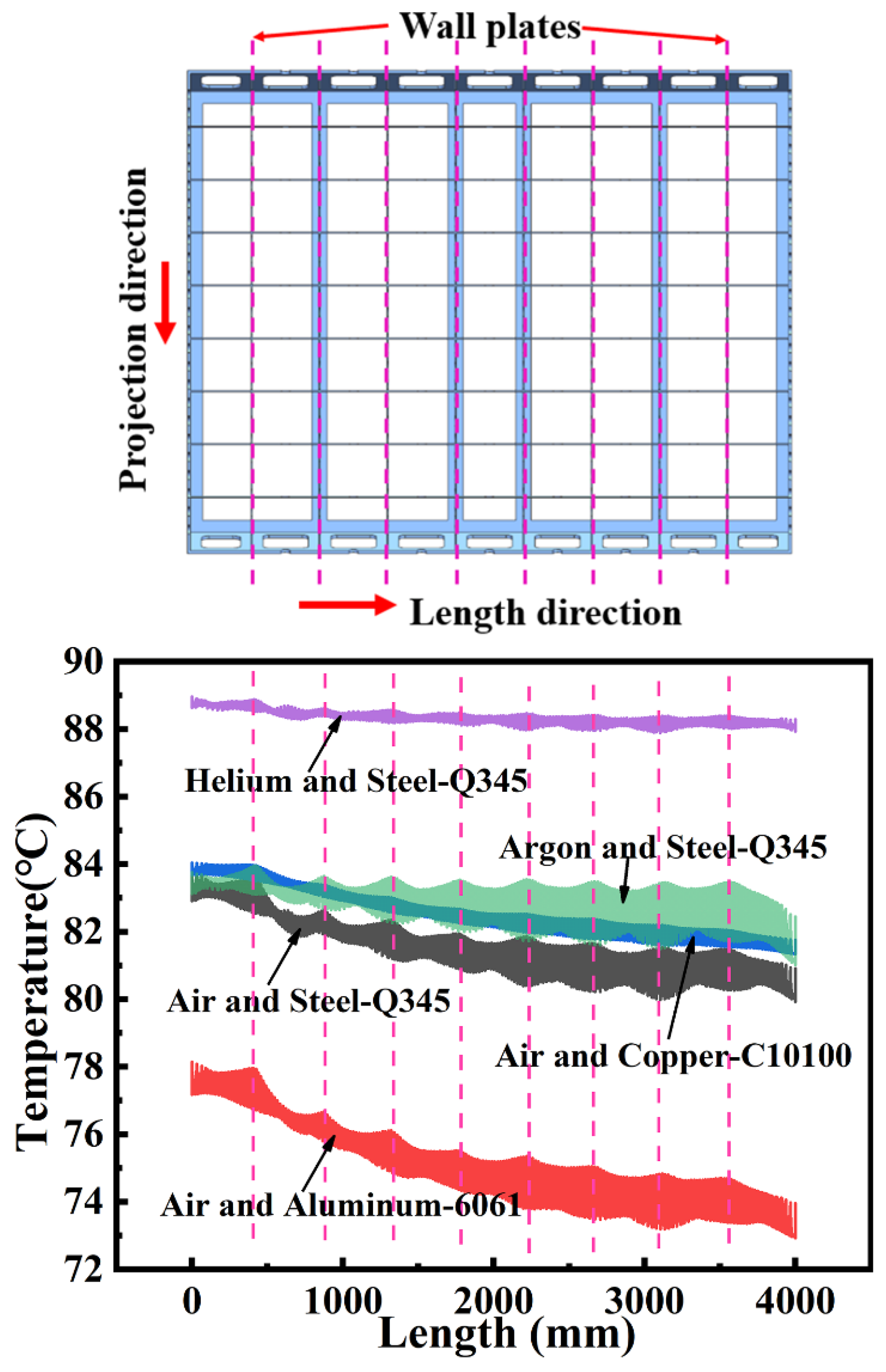

3.2. CFD Model Establishment

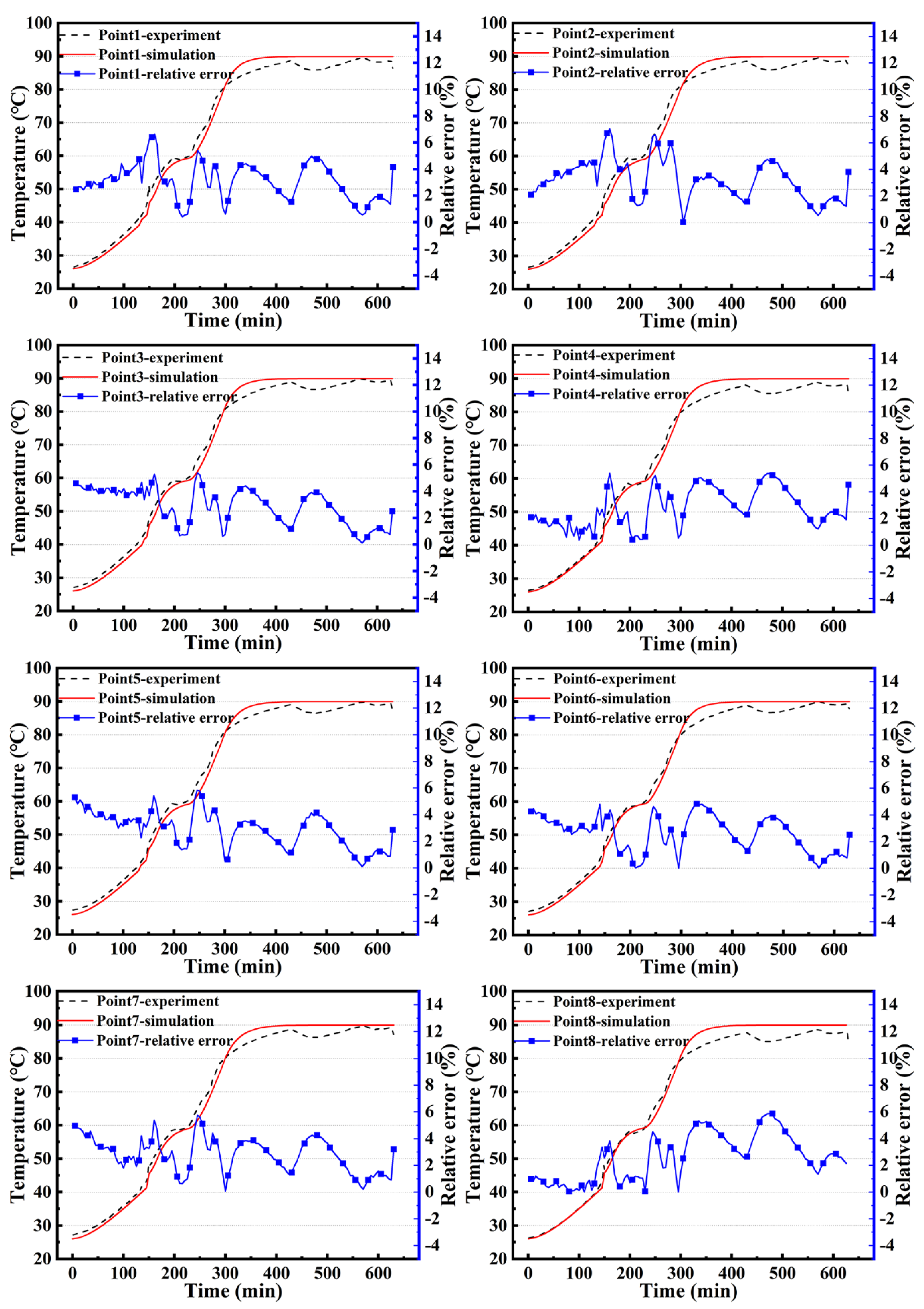

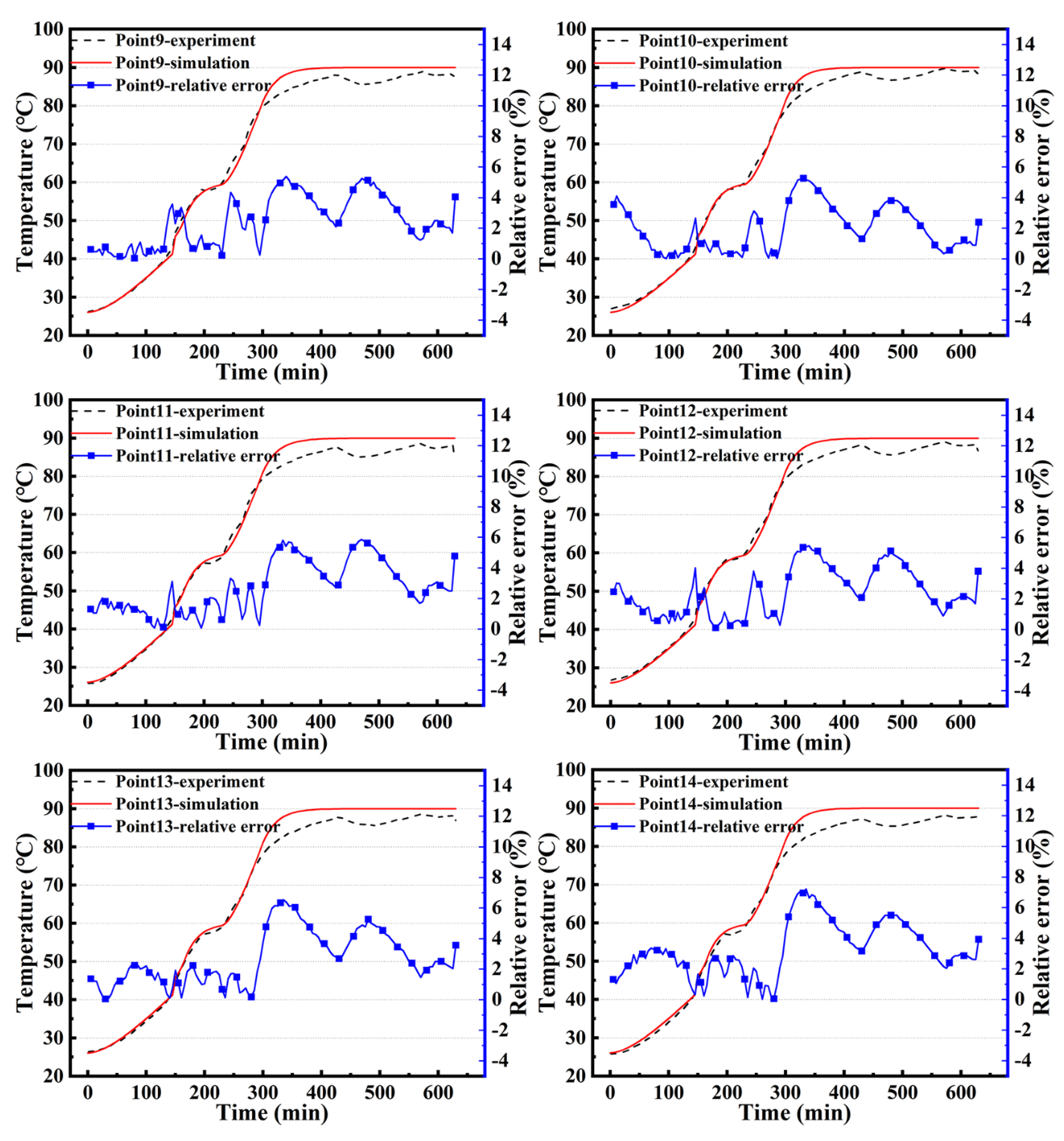

3.3. Model Validation

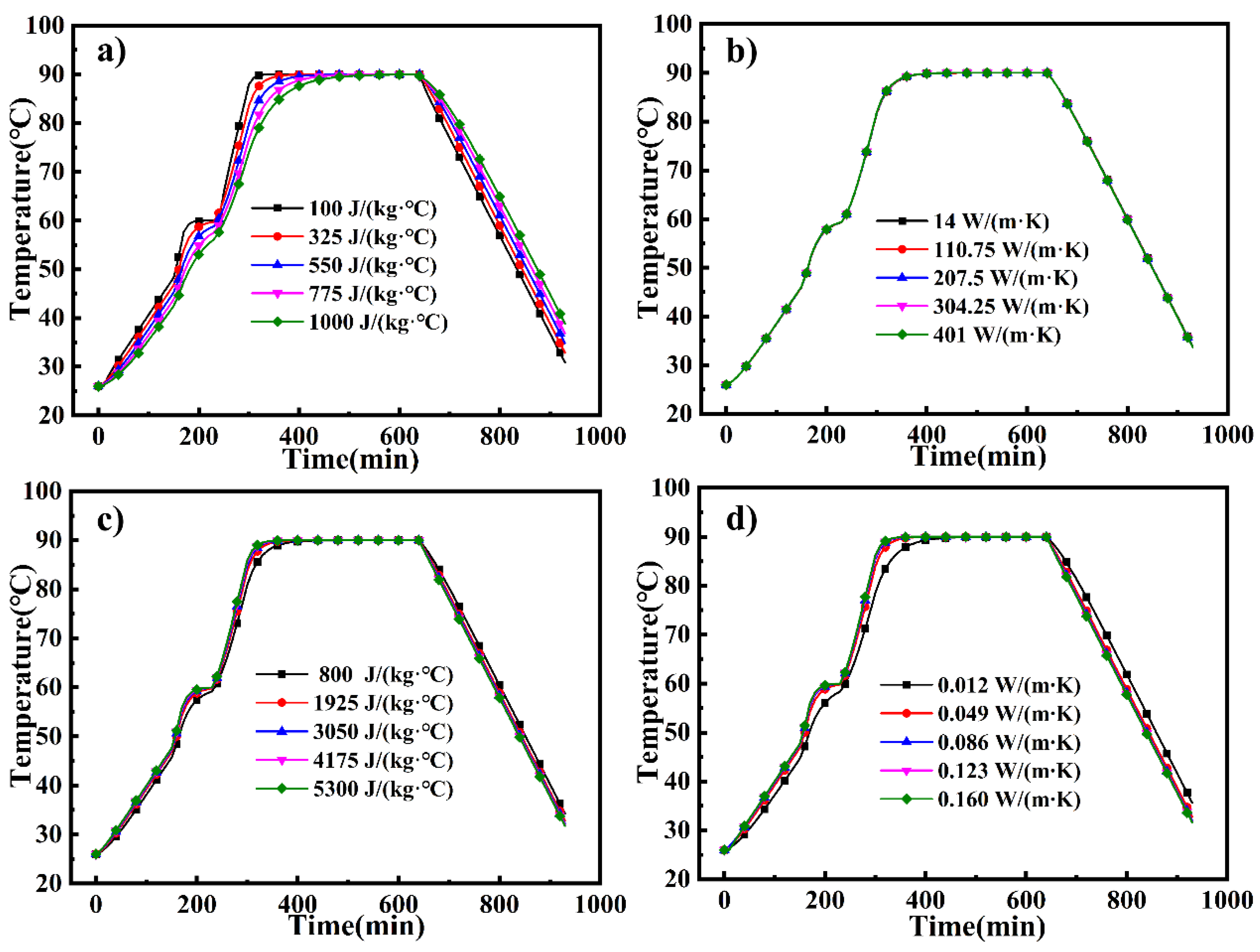

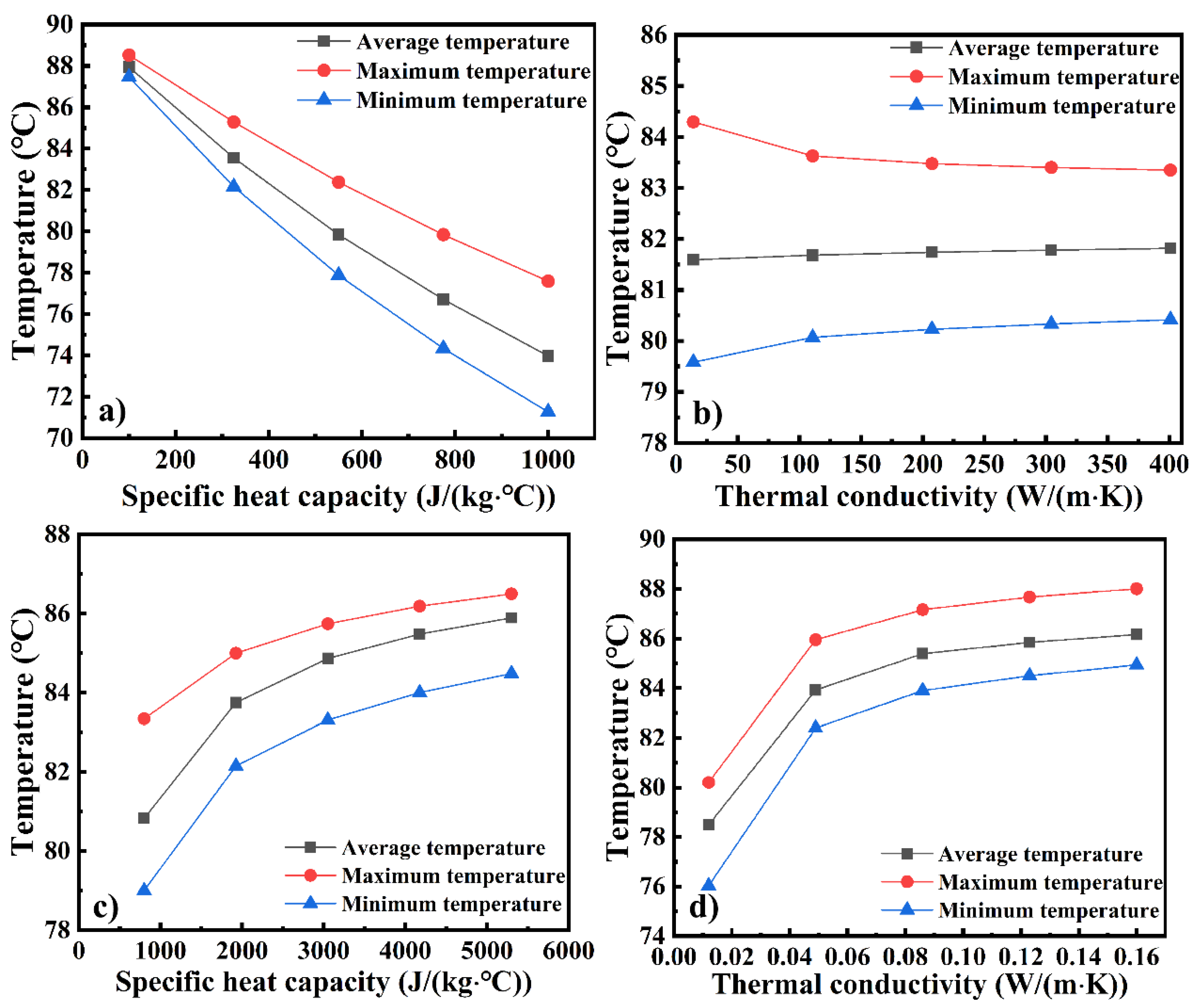

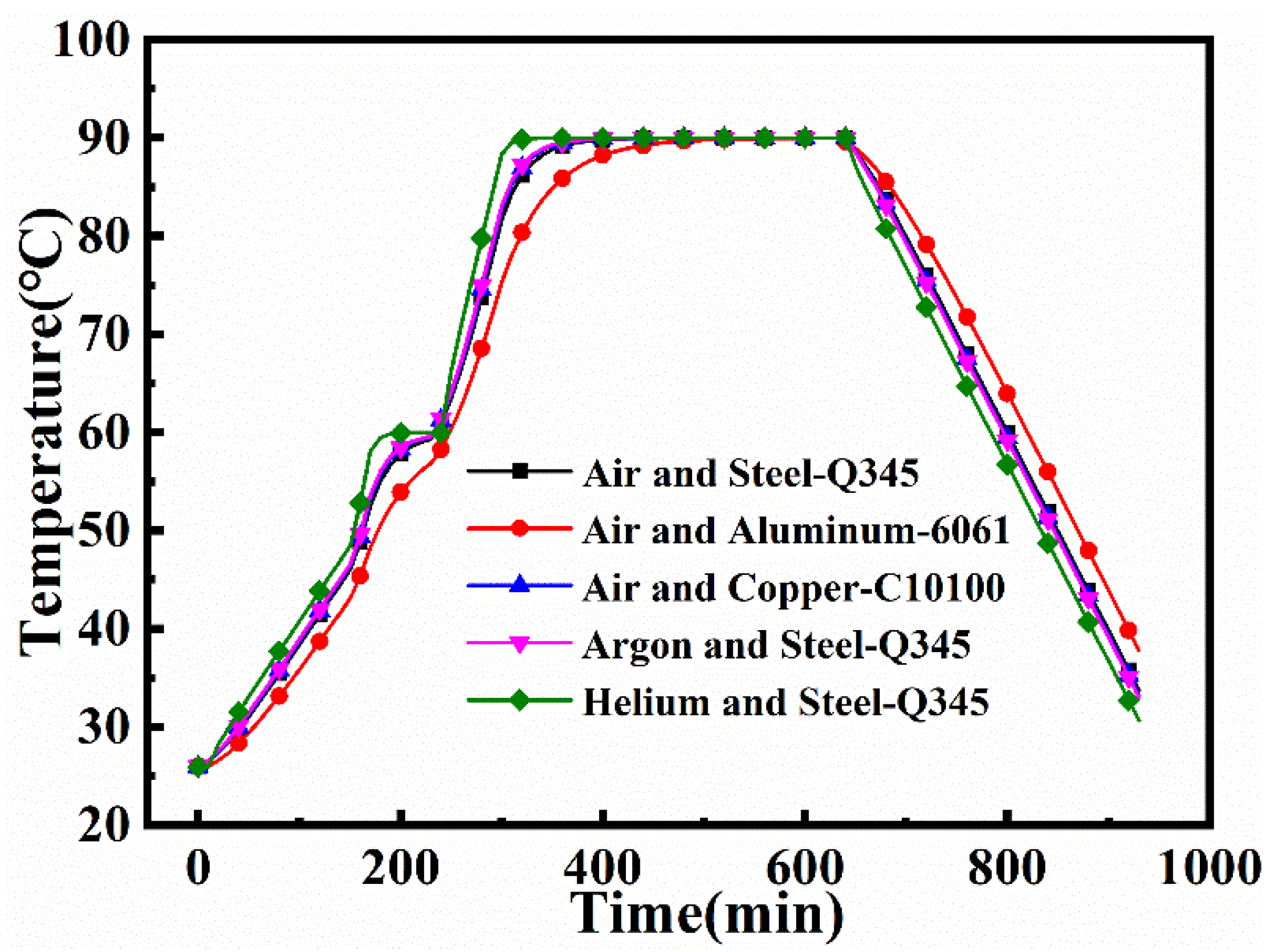

4. Design of Simulations

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Upadhya, A.R.; Dayananda, G.N.; Kamalakannan, G.M.; Setty, J.R.; Daniel, J.C. Autoclaves for Aerospace Applications: Issues and Challenges. Int. J. Aerosp. Eng. 2011, 2011, 1–11. [Google Scholar] [CrossRef]

- Monaghan, M.; Mallon, P. Development of a computer controlled autoclave for forming thermoplastic composites. Compos. Manuf. 1990, 1, 8–14. [Google Scholar] [CrossRef]

- Baran, I.; Cinar, K.; Ersoy, N.; Akkerman, R.; Hattel, J.H. A Review on the Mechanical Modeling of Composite Manufacturing Processes. Arch. Comput. Methods Eng. 2017, 24, 365–395. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Gu, Y.; Li, Y.; Li, M.; Zhang, Z. Role of Tool-Part Interaction in Consolidation of L-Shaped Laminates during Autoclave Process. Appl. Compos. Mater. 2011, 19, 583–597. [Google Scholar] [CrossRef]

- Fernlund, G.; Rahman, N.; Courdji, R.; Bresslauer, M.; Poursartip, A.; Willden, K.; Nelson, K. Experimental and numerical study of the effect of cure cycle, tool surface, geometry, and lay-up on the dimensional fidelity of autoclave-processed composite parts. Compos. Part A Appl. Sci. Manuf. 2002, 33, 341–351. [Google Scholar] [CrossRef]

- Khoun, L.; Centea, T.; Hubert, P. Characterization Methodology of Thermoset Resins for the Processing of Composite Materials—Case Study: CYCOM 890RTM Epoxy Resin. J. Compos. Mater. 2010, 44, 1397–1415. [Google Scholar] [CrossRef]

- Koushyar, H.; Alavi-Soltani, S.; Minaie, B.; Violette, M. Effects of variation in autoclave pressure, temperature, and vacuum-application time on porosity and mechanical properties of a carbon fiber/epoxy composite. J. Compos. Mater. 2012, 46, 1985–2004. [Google Scholar] [CrossRef]

- Ding, A.; Li, S.; Wang, J.; Zu, L. A three-dimensional thermo-viscoelastic analysis of process-induced residual stress in composite laminates. Compos. Struct. 2015, 129, 60–69. [Google Scholar] [CrossRef]

- Maffezzoli, A.; Grieco, A.D. Optimization of Parts Placement in Autoclave Processing of Composites. Appl. Compos. Mater. 2012, 20, 233–248. [Google Scholar] [CrossRef]

- Twigg, G.; Poursartip, A.; Fernlund, G. Tool–part interaction in composites processing. Part II: Numerical modelling. Compos. Part A Appl. Sci. Manuf. 2004, 35, 135–141. [Google Scholar] [CrossRef]

- Vafayan, M.; Ghoreishy, M.H.R.; Abedini, H.; Beheshty, M.H. Development of an optimized thermal cure cycle for a complex-shape composite part using a coupled finite element/genetic algorithm technique. Iran. Polym. J. 2015, 24, 459–469. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.; Xie, F.; Li, M.; Dai, D.; Wang, F. Correlated Rules between Complex Structure of Composite Components and Manufacturing Defects in Autoclave Molding Technology. J. Reinf. Plast. Compos. 2009, 28, 2791–2803. [Google Scholar] [CrossRef]

- Nele, L.; Caggiano, A.; Teti, R. Autoclave Cycle Optimization for High Performance Composite Parts Manufacturing. Procedia CIRP 2016, 57, 241–246. [Google Scholar] [CrossRef]

- Johnston, A. An Integrated Model of the Development of Process-Induced Deformations in Autoclave Processing of Composite Structures; University of British Columbia: Vancouver, BC, Canada, 1997. [Google Scholar]

- Xie, G.N.; Liu, J.; Zang, W.H.; Lorenzini, G.; Biserni, C. Simulation and improvement of temperature distributions of a framed mould during the autoclave composite curing process. J. Eng. Thermophys. 2013, 22, 43–61. [Google Scholar] [CrossRef]

- Dolkun, D.; Wang, H.; Wang, H.; Ke, Y. Influence of Large Framed Mold Placement in Autoclave on Heating Performance. Appl. Compos. Mater. 2020, 27, 811–837. [Google Scholar] [CrossRef]

- Parlevliet, P.; Bersee, H.E.; Beukers, A. Residual stresses in thermoplastic composites—A study of the literature. Part III: Effects of thermal residual stresses. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1581–1596. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, D.G. Development of an Autoclave Cure Cycle with Cooling and Reheating Steps for Thick Thermoset Composite Laminates. J. Compos. Mater. 1997, 31, 2264–2282. [Google Scholar] [CrossRef]

- Park, H.C.; Goo, N.S.; Min, K.J.; Yoon, K.J. Three-dimensional cure simulation of composite structures by the finite element method. Compos. Struct. 2003, 62, 51–57. [Google Scholar] [CrossRef]

- Gopal, A.K.; Adali, S.; Verijenko, V.E. Optimal temperature profiles for minimum residual stress in the cure process of polymer composites. Compos. Struct. 2000, 48, 99–106. [Google Scholar] [CrossRef]

- Guo, Z.-S.; Du, S.; Zhang, B. Temperature field of thick thermoset composite laminates during cure process. Compos. Sci. Technol. 2005, 65, 517–523. [Google Scholar] [CrossRef]

- Aleksendrić, D.; Carlone, P.; Ćirović, V. Optimization of the Temperature-Time Curve for the Curing Process of Thermoset Matrix Composites. Appl. Compos. Mater. 2016, 23, 1047–1063. [Google Scholar] [CrossRef]

- Struzziero, G.; Skordos, A. Multi-objective optimisation of the cure of thick components. Compos. Part A Appl. Sci. Manuf. 2017, 93, 126–136. [Google Scholar] [CrossRef] [Green Version]

- Weber, T.A.; Arent, J.-C.; Münch, L.; Duhovic, M.; Balvers, J.M. A fast method for the generation of boundary conditions for thermal autoclave simulation. Compos. Part A Appl. Sci. Manuf. 2016, 88, 216–225. [Google Scholar] [CrossRef]

- Slesinger, N.; Shimizu, T.; Arafath, A.R.A. Heat transfer coefficient distribution inside an autoclave. In Proceedings of the 17th International Conference on Composite Material ICCM, Edinburgh, UK, 27–31 July 2009. [Google Scholar]

- Hudek, M.E. Examination of Heat Transfer during Autoclave Processing of Polymer Composites; University of Manitoba: Winnipeg, MB, Canada, 2002. [Google Scholar]

- Duval, M. Investigation and Modelling of the Heat Transfer Process in Carbon Fibre/Epoxy Composite Tools; Carleton University: Ottawa, ON, Canada, 2018. [Google Scholar]

- Gao, Y.; Qu, C.H. Numerical simulation about heat-fluid coupling in autoclaves. Ind. Furn. 2012, 4, 37–39. [Google Scholar]

- Yue, G.; Zhang, B.; Du, S.H. Influence of the mould on curing induced shape distortion for resin matrix thermosetting composites. Fiber Reinf. Plast. Compos. 2010, 5, 63–65. [Google Scholar]

- Zhang, C.H. Curing Temperature Field Tradeoff Design Method of Large Scale Composite Material Structure in Autoclave Process; Harbin Institute of Technology: Harbin, China, 2009. [Google Scholar]

- Kluge, N.; Lundström, S.; Ljung, A.-L.; Westerberg, L.; Nyman, T. An experimental study of temperature distribution in an autoclave. J. Reinf. Plast. Compos. 2016, 35, 566–578. [Google Scholar] [CrossRef]

- Kluge, J.N.E.; Lundström, S.; Westerberg, L.; Nyman, T. Modelling heat transfer inside an autoclave: Effect of radiation. J. Reinf. Plast. Compos. 2016, 35, 1126–1142. [Google Scholar] [CrossRef]

- Chen, F.; Zhan, L.; Xu, Y. Simulation of mold temperature distribution in a running process autoclave. Iran. Polym. J. 2015, 24, 927–934. [Google Scholar] [CrossRef]

- Chen, F.; Zhan, L.; Li, S. Refined simulation of temperature distribution in molds during autoclave process. Iran. Polym. J. 2016, 25, 775–785. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, L.; Zhu, W.; Xu, Q.; Ke, Y. Design optimization of molds for autoclave process of composite manufacturing. J. Reinf. Plast. Compos. 2017, 36, 1564–1576. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, W.; Wang, Q.; Xu, Q.; Ke, Y. A heat-balance method for autoclave process of composite manufacturing. J. Compos. Mater. 2018, 53, 641–652. [Google Scholar] [CrossRef]

- Han, N.; An, L.; Fan, L.; Hua, L.; Gao, G. Research on Temperature Field Distribution in a Frame Mold during Autoclave Process. Materials 2020, 13, 4020. [Google Scholar] [CrossRef] [PubMed]

- Bohne, T.; Frerich, T.; Jendrny, J.; Jürgens, J.-P.; Ploshikhin, V. Simulation and validation of air flow and heat transfer in an autoclave process for definition of thermal boundary conditions during curing of composite parts. J. Compos. Mater. 2018, 52, 1677–1687. [Google Scholar] [CrossRef]

- Guo, Z.; Tao, W.; Shah, R. The field synergy (coordination) principle and its applications in enhancing single phase convective heat transfer. Int. J. Heat Mass Transf. 2005, 48, 1797–1807. [Google Scholar] [CrossRef]

- Ghalandari, M.; Koohshahi, E.M.; Mohamadian, F.; Shamshirband, S.; Chau, K.W. Numerical simulation of nanofluid flow inside a root canal. Eng. Appl. Comput. Fluid Mech. 2019, 13, 254–264. [Google Scholar] [CrossRef]

| Metal | Metal Grade | Density | Thermal Conductivity | Specific Heat Capacity |

|---|---|---|---|---|

| g/cm3 | W/(m∙K) | J/(kg∙°C) | ||

| Q345 (China) | 7.829 | 54.6 | 434 | |

| AISI 310 | 7.93 | 14 | 500 | |

| AISI 410 | 7.73 | 24.2 | 460 | |

| Steel | AISI 304 | 7.90 | 16.3 | 500 |

| AISI 1005 | 7.87 | 56 | 481 | |

| AISI 1008HR | 7.87 | 65.2 | 481 | |

| AISI 4340 | 7.85 | 44.5 | 475 | |

| 2014 | 2.79 | 154.25 | 880 | |

| Aluminum | 5086 | 2.66 | 117 | 900 |

| 6061 | 2.71 | 154.25 | 896 | |

| A356 | 2.67 | 151 | 963 | |

| Copper | C10100 | 8.92 | 387 | 385 |

| Fluid | Density | Thermal Conductivity | Specific Heat Capacity |

|---|---|---|---|

| kg/m3 | W/(m∙K) | J/(kg∙°C) | |

| Air | 1.2041 | 0.0263 | 1007 |

| Argon (Ar) | 1.78 | 0.0154 | 2951 |

| Carbon dioxide (CO2) | 1.5362 | 0.02047 | 900 |

| Nitrogen (N2) | 1.142 | 0.0262 | 1042 |

| Oxygen (O2) | 1.3007 | 0.02676 | 920.3 |

| Helium (He) | 0.1625 | 0.152 | 5193 |

| Specific Heat Capacity of the Mold | Thermal Conductivity of the Mold | Specific Heat Capacity of the Fluid | Thermal Conductivity of the Fluid |

|---|---|---|---|

| J/(kg∙°C) | W/(m∙K) | J/(kg∙°C) | W/(m∙K) |

| 100–1000 | 54.6 | 1007 | 0.0263 |

| 434 | 14–401 | 1007 | 0.0263 |

| 434 | 54.6 | 800–5300 | 0.0263 |

| 434 | 54.6 | 1007 | 0.012–0.16 |

| Case | Mold | Fluid |

|---|---|---|

| 1 | Steel-Q345 | Air |

| 2 | Aluminum-6061 | Air |

| 3 | Copper-C10100 | Air |

| 4 | Steel-Q345 | Argon |

| 5 | Steel-Q345 | Helium |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Zhang, B.; Luo, L.; Lin, T.; Xue, X. Influence of Mold and Heat Transfer Fluid Materials on the Temperature Distribution of Large Framed Molds in Autoclave Process. Materials 2021, 14, 4311. https://doi.org/10.3390/ma14154311

Zhang G, Zhang B, Luo L, Lin T, Xue X. Influence of Mold and Heat Transfer Fluid Materials on the Temperature Distribution of Large Framed Molds in Autoclave Process. Materials. 2021; 14(15):4311. https://doi.org/10.3390/ma14154311

Chicago/Turabian StyleZhang, Guowei, Boming Zhang, Ling Luo, Ting Lin, and Xiangchen Xue. 2021. "Influence of Mold and Heat Transfer Fluid Materials on the Temperature Distribution of Large Framed Molds in Autoclave Process" Materials 14, no. 15: 4311. https://doi.org/10.3390/ma14154311

APA StyleZhang, G., Zhang, B., Luo, L., Lin, T., & Xue, X. (2021). Influence of Mold and Heat Transfer Fluid Materials on the Temperature Distribution of Large Framed Molds in Autoclave Process. Materials, 14(15), 4311. https://doi.org/10.3390/ma14154311