Comparative Life Cycle Analysis of Concrete and Composite Bridges Varying Steel Recycling Ratio

Abstract

:1. Introduction

2. Materials and Methods

2.1. Goal and Scope Definition

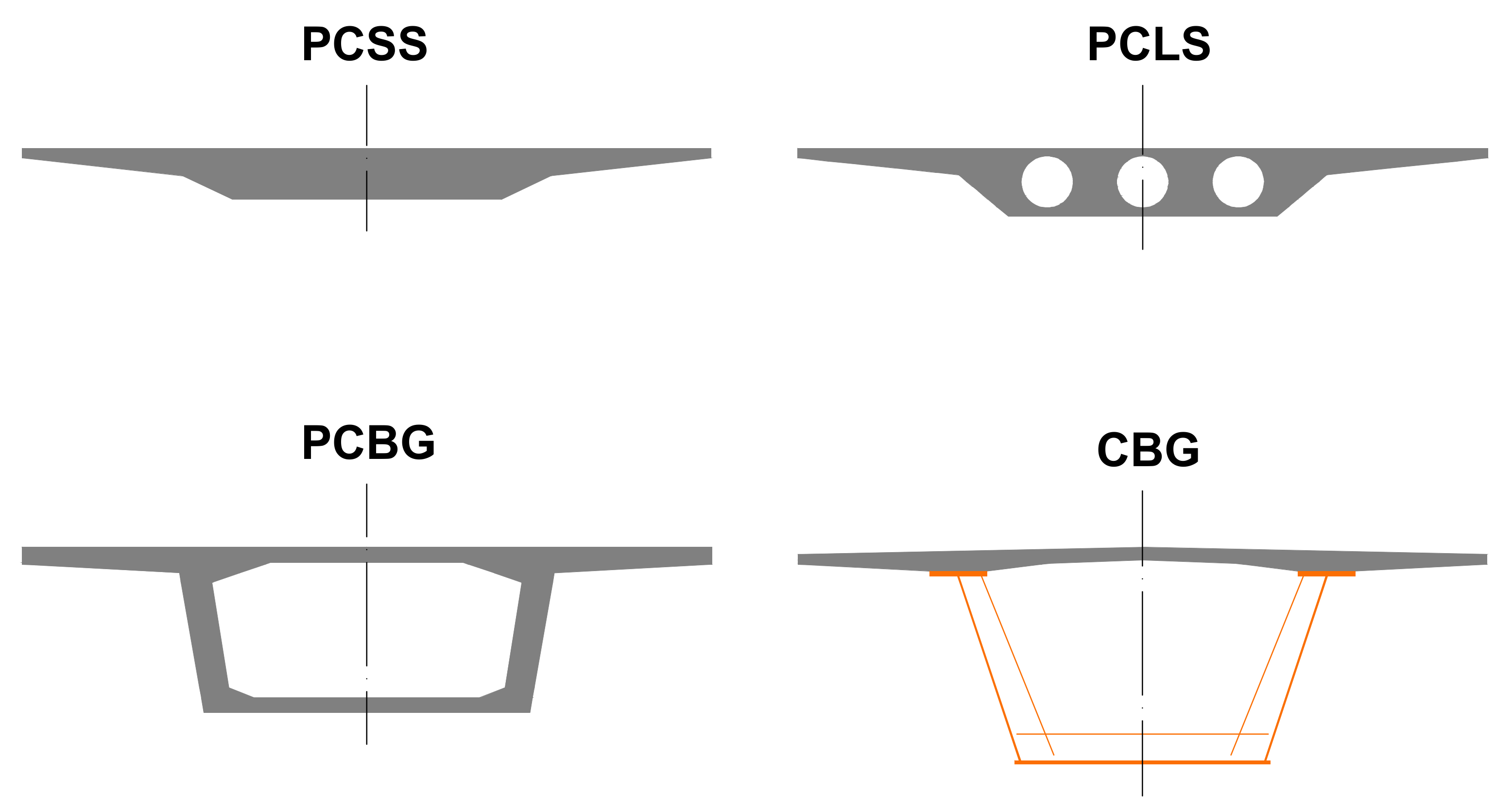

2.1.1. Bridge Deck Type Selection

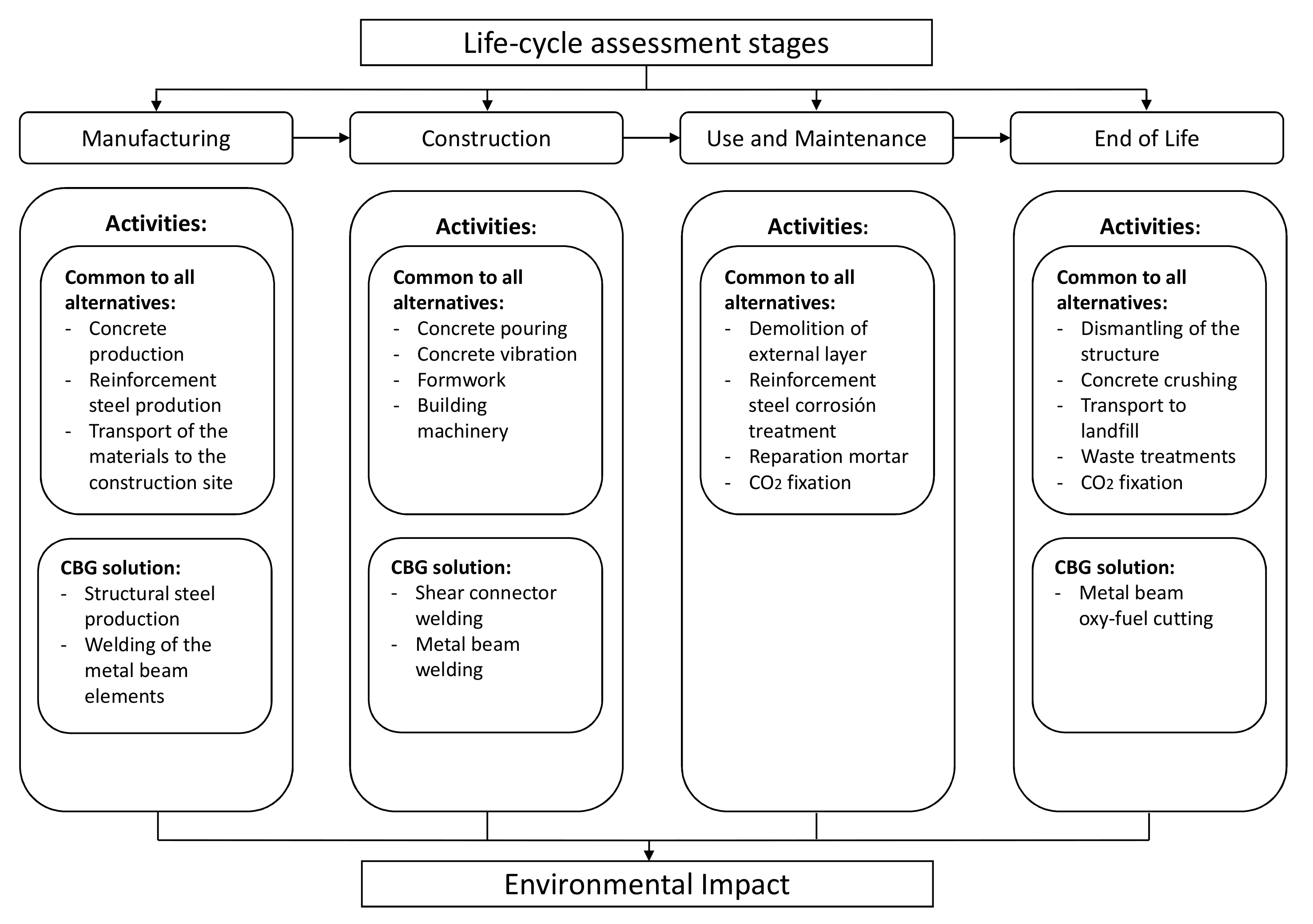

2.1.2. Phases of the Analysis

Manufacturing

Construction

Use and Maintenance

End of Life

2.1.3. Functional Unit

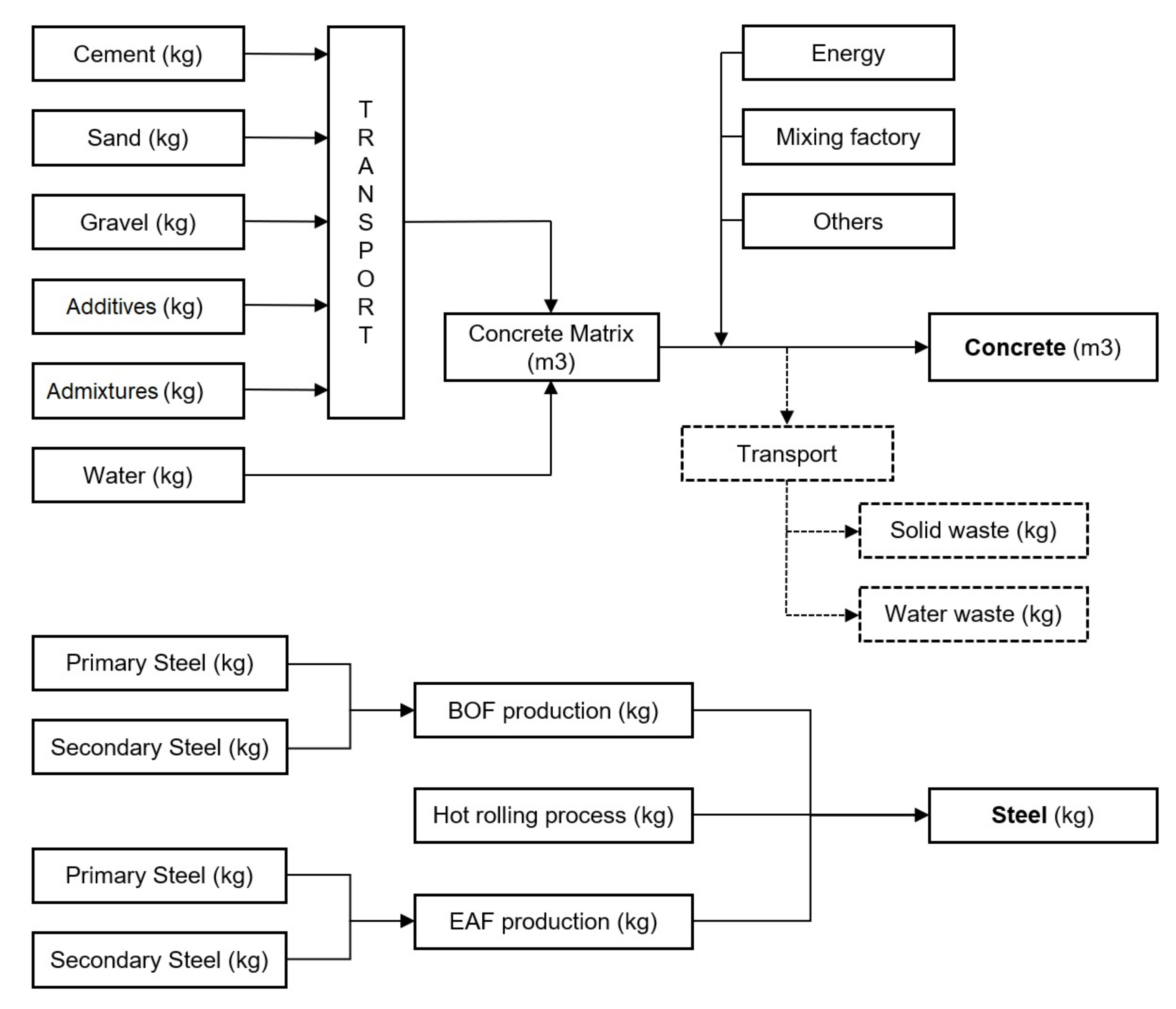

2.2. Inventory Analysis

Software

2.3. Uncertainty

2.4. Bridge Deck Design

2.4.1. Life Cycle Model Description

Manufacturing

Construction

Use and Maintenance

End of Life

2.5. Impact Assessment

2.6. Interpretation

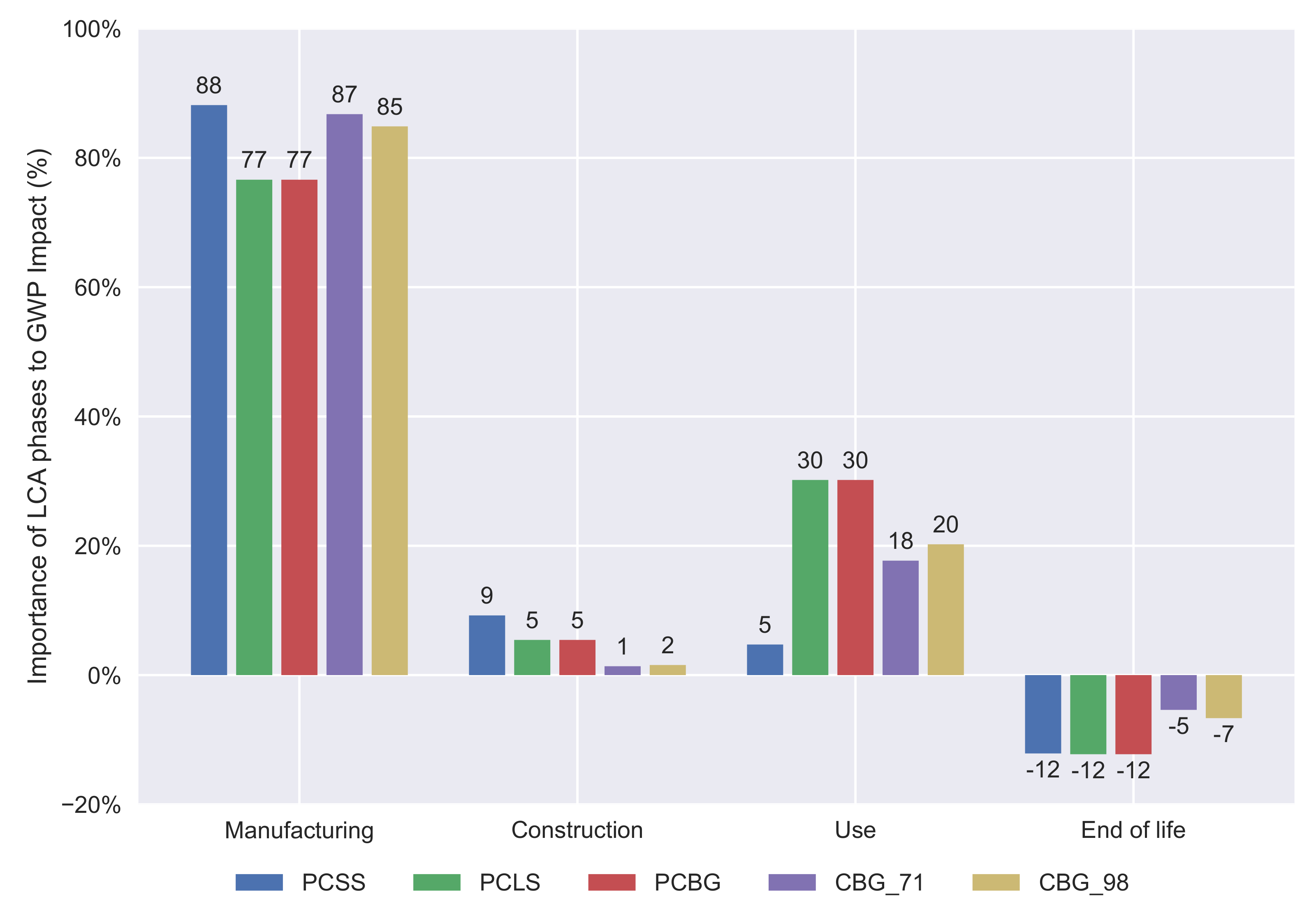

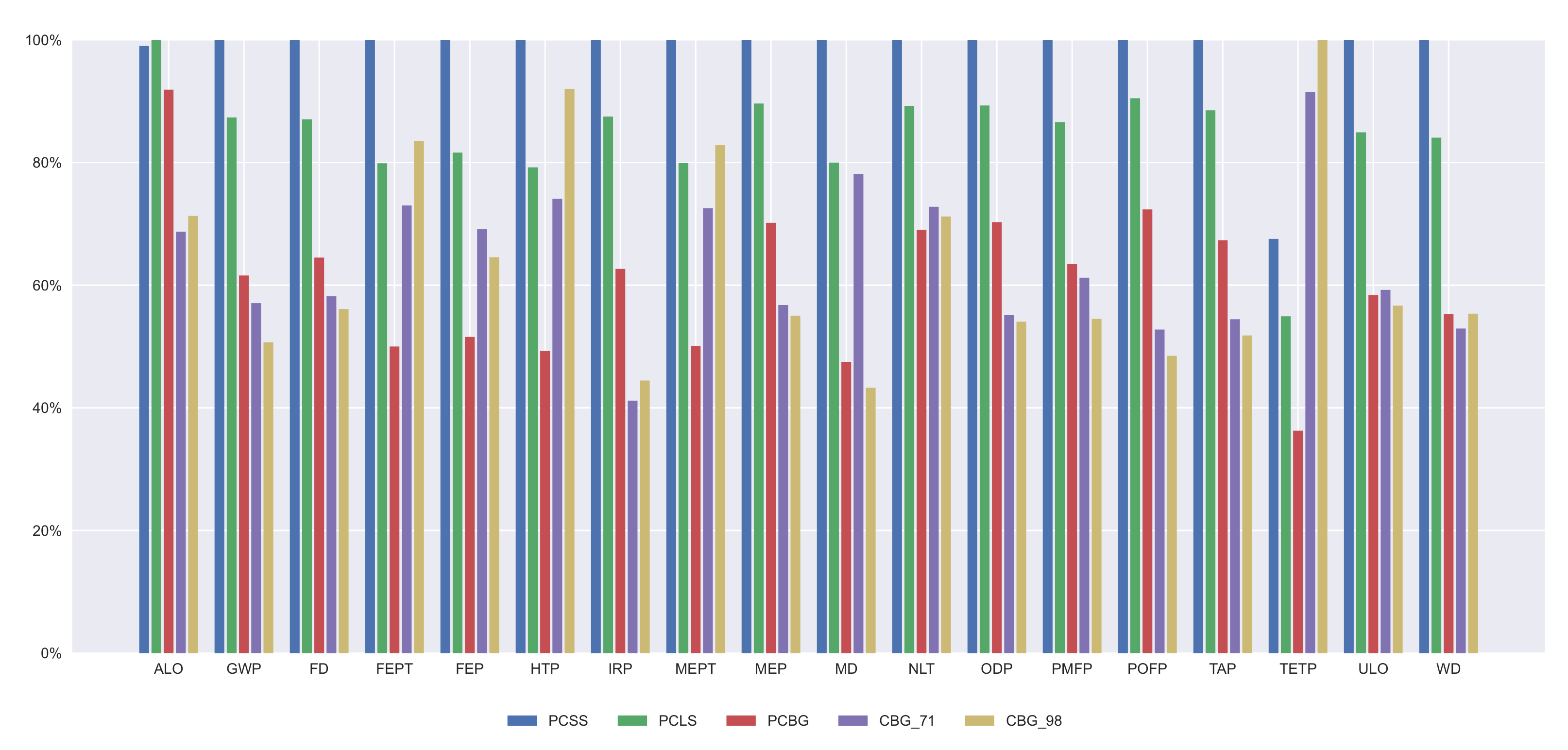

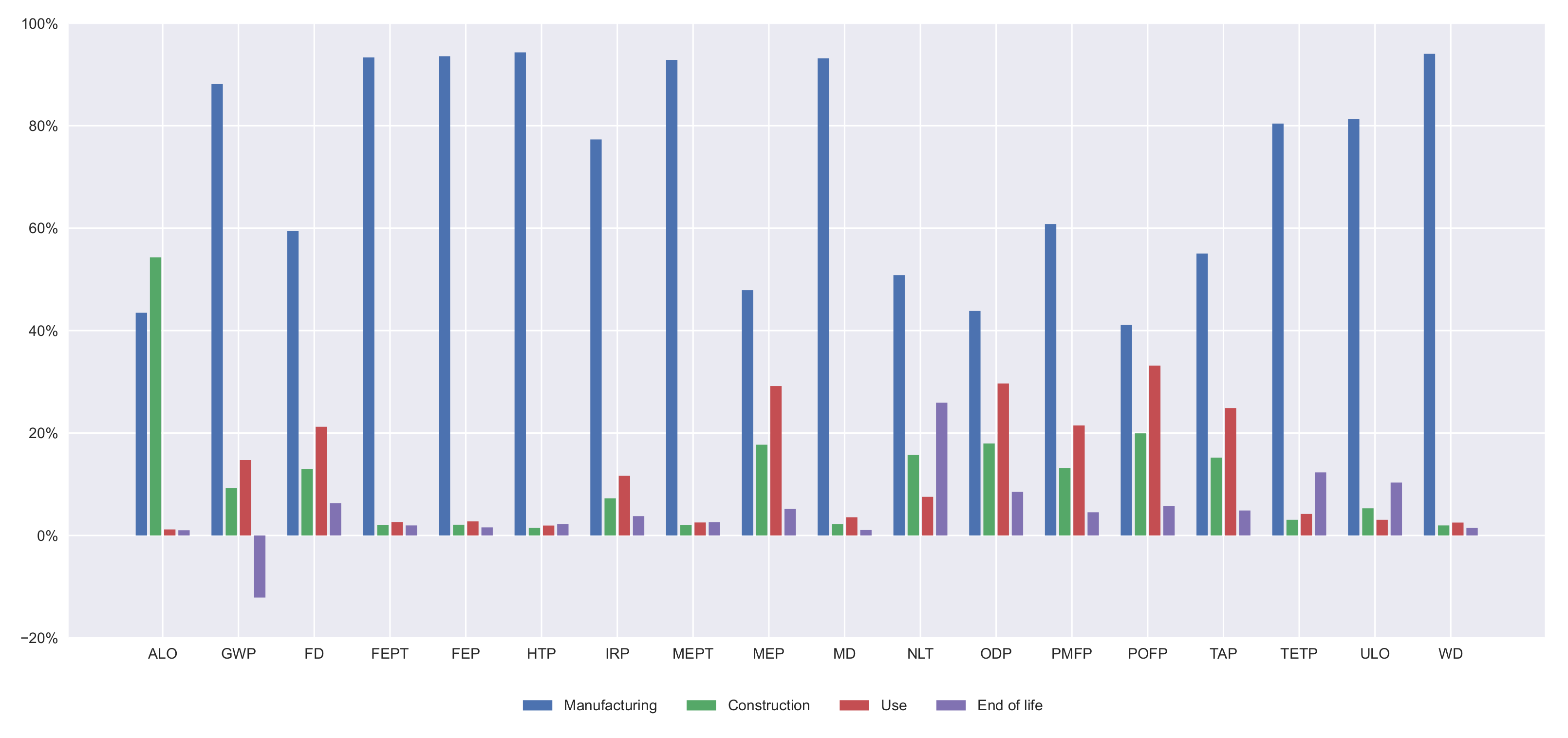

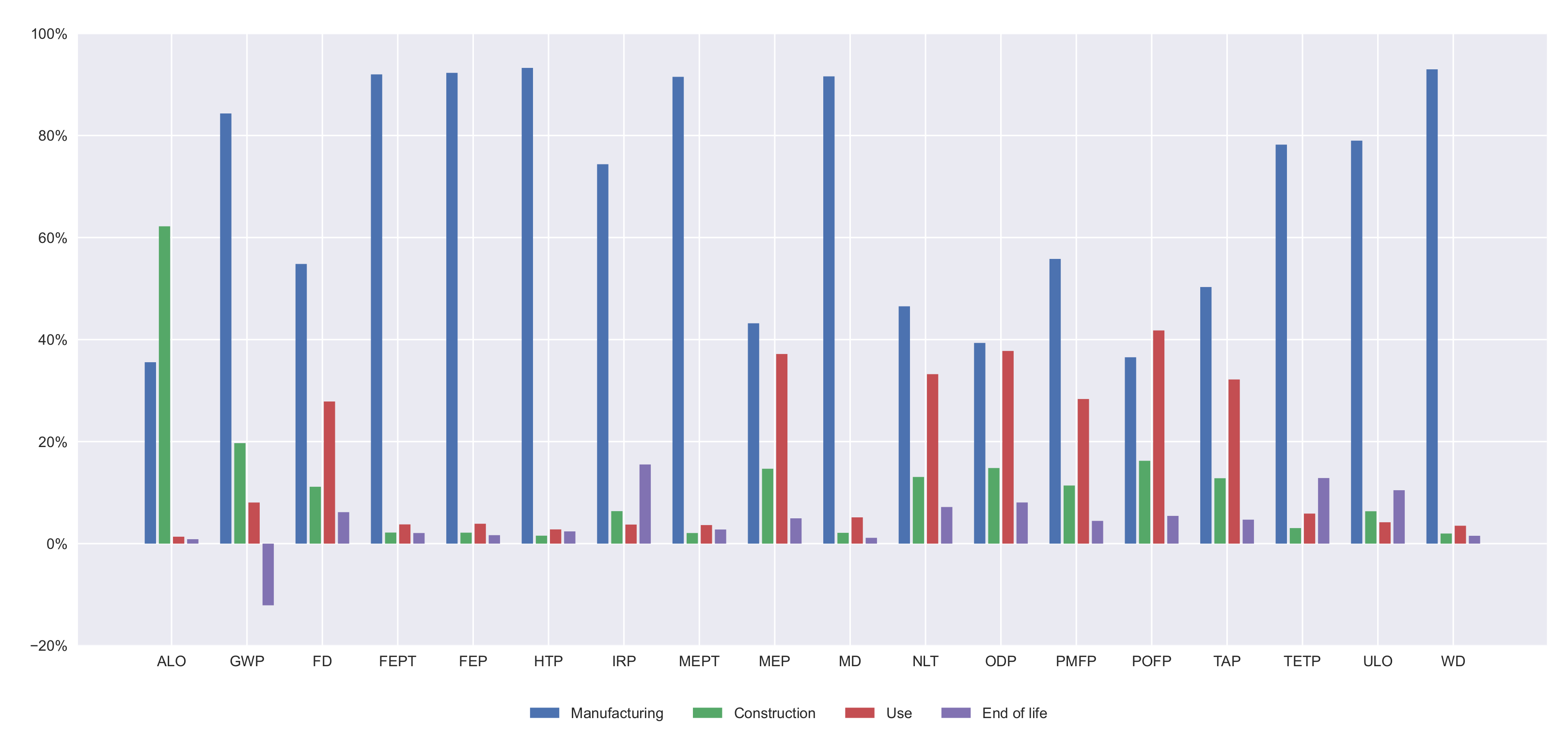

3. Life Cycle Assessment

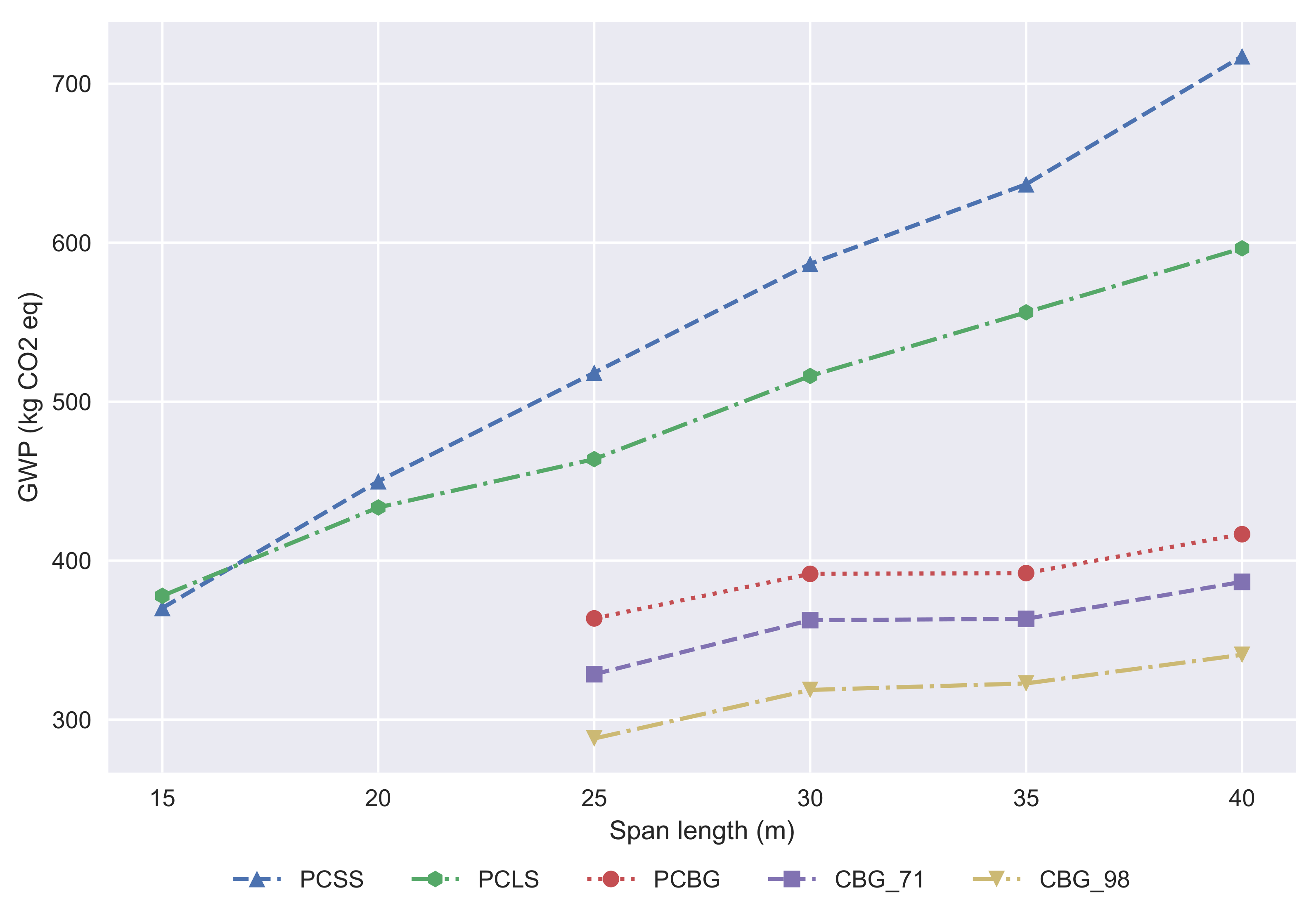

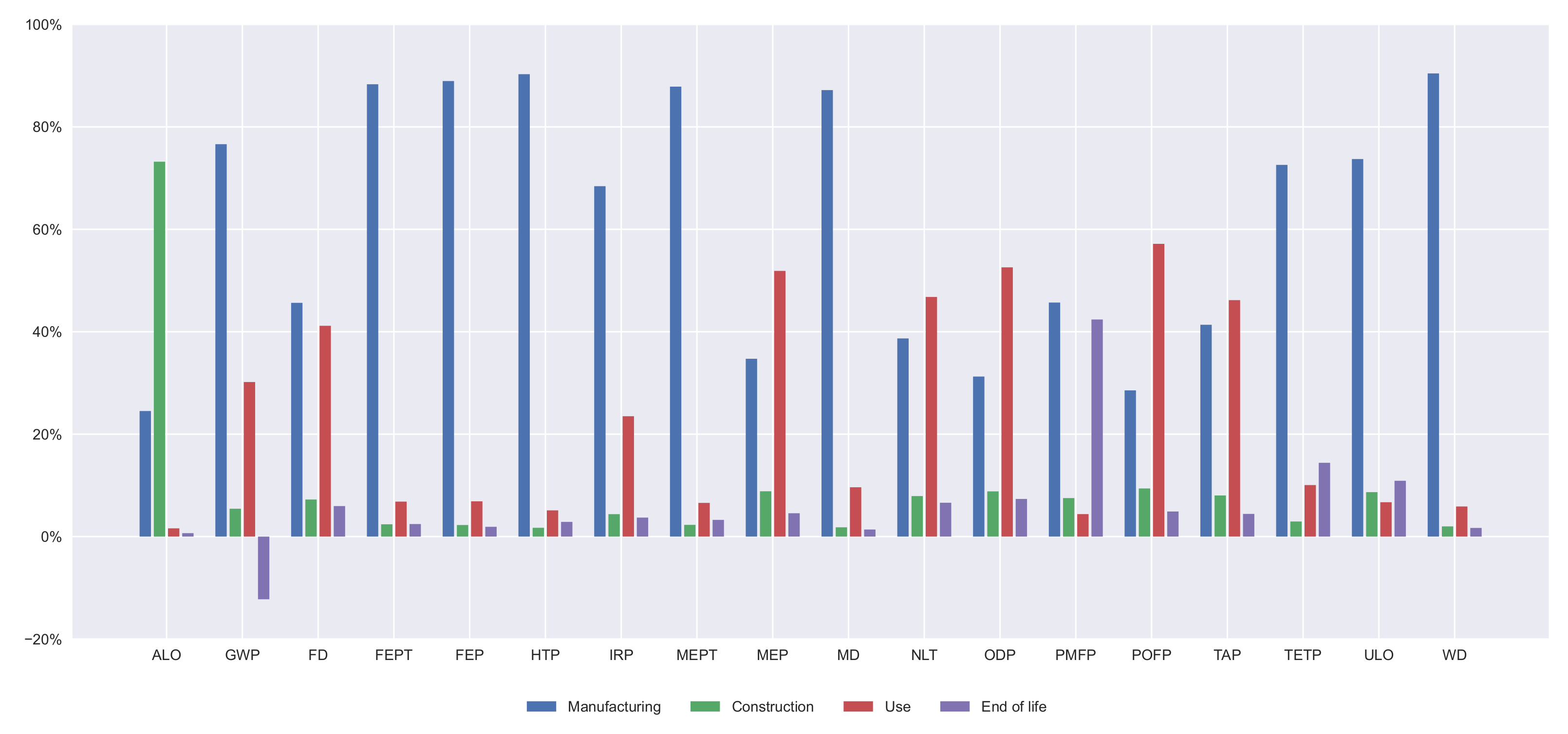

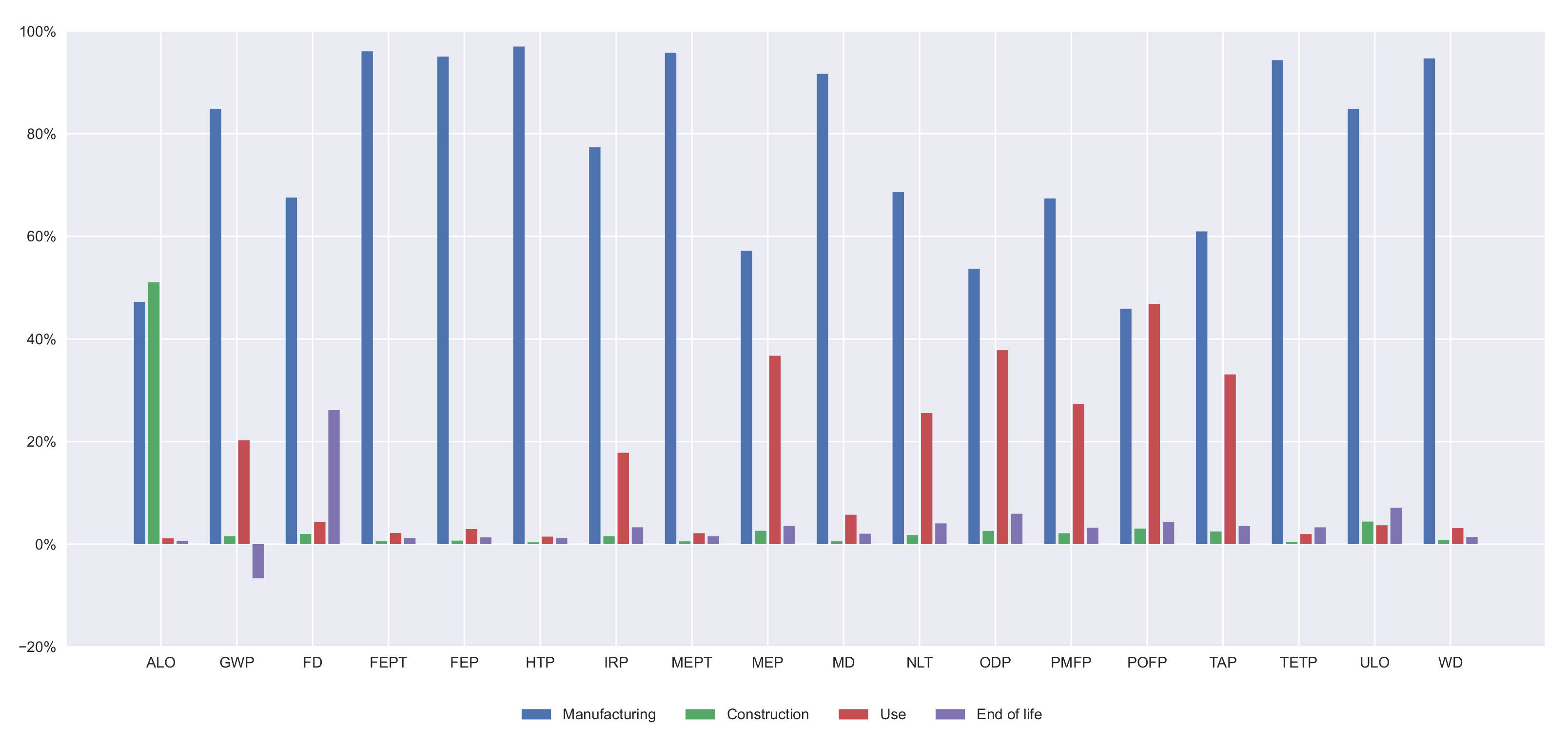

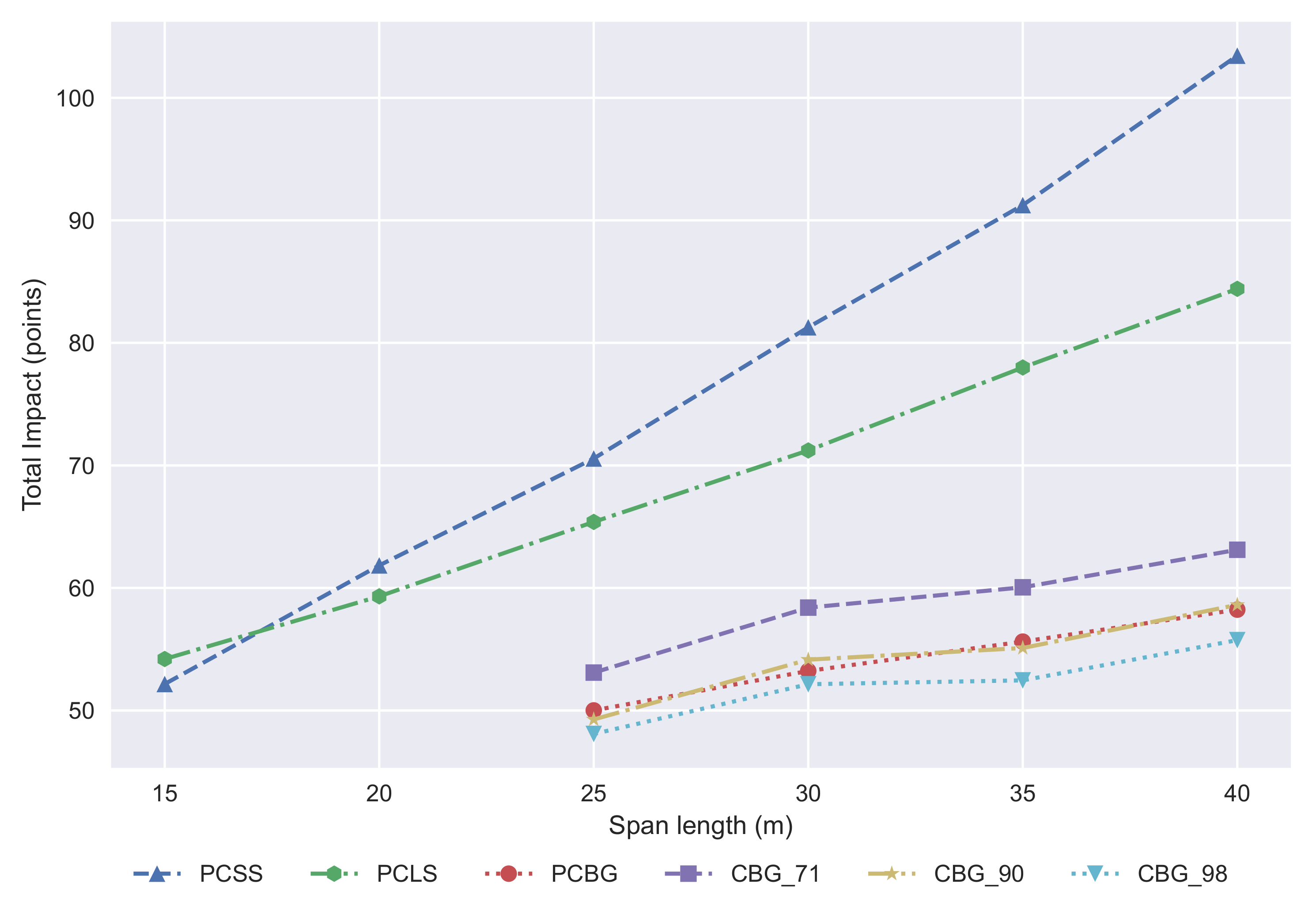

3.1. Midpoint Approach

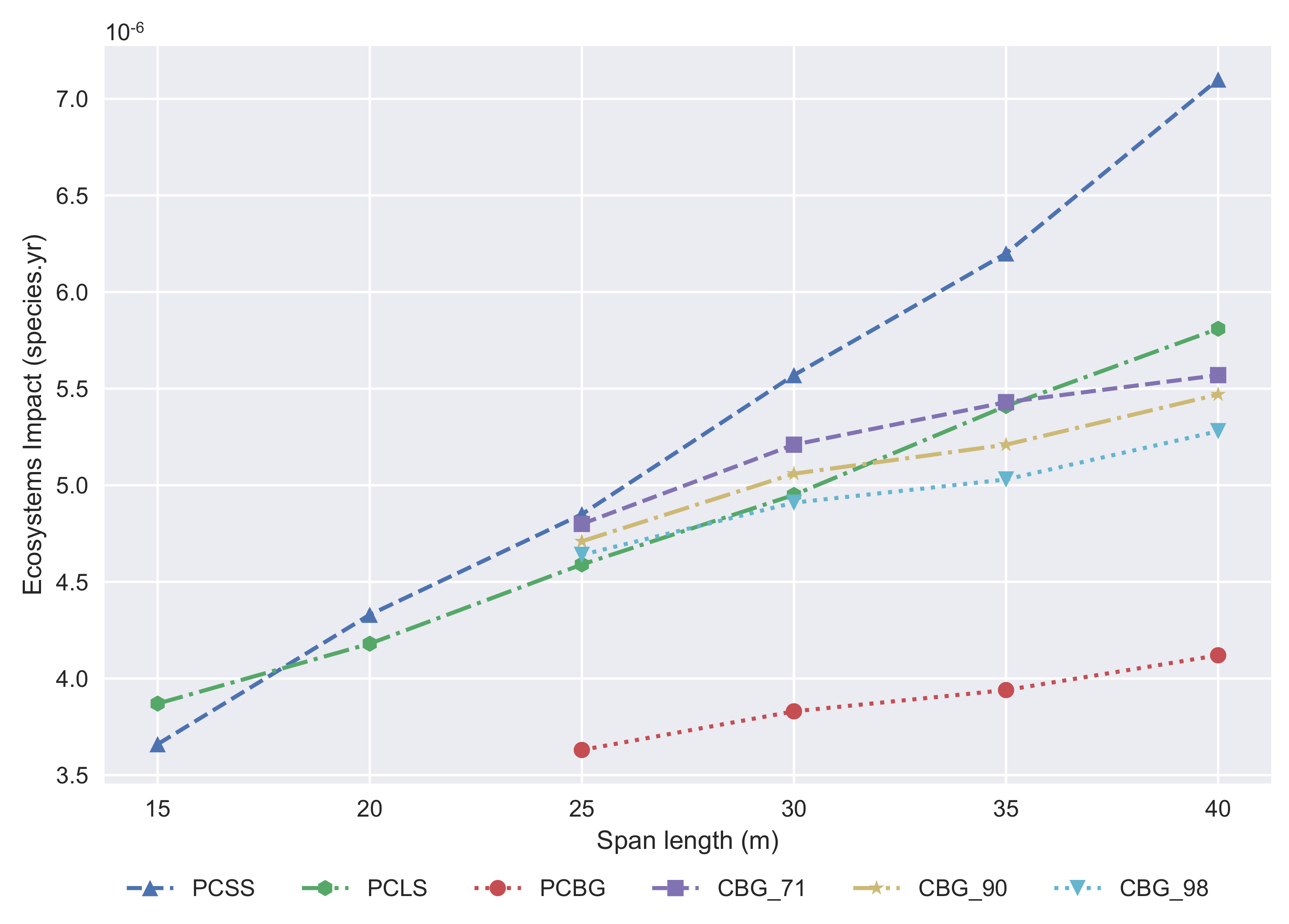

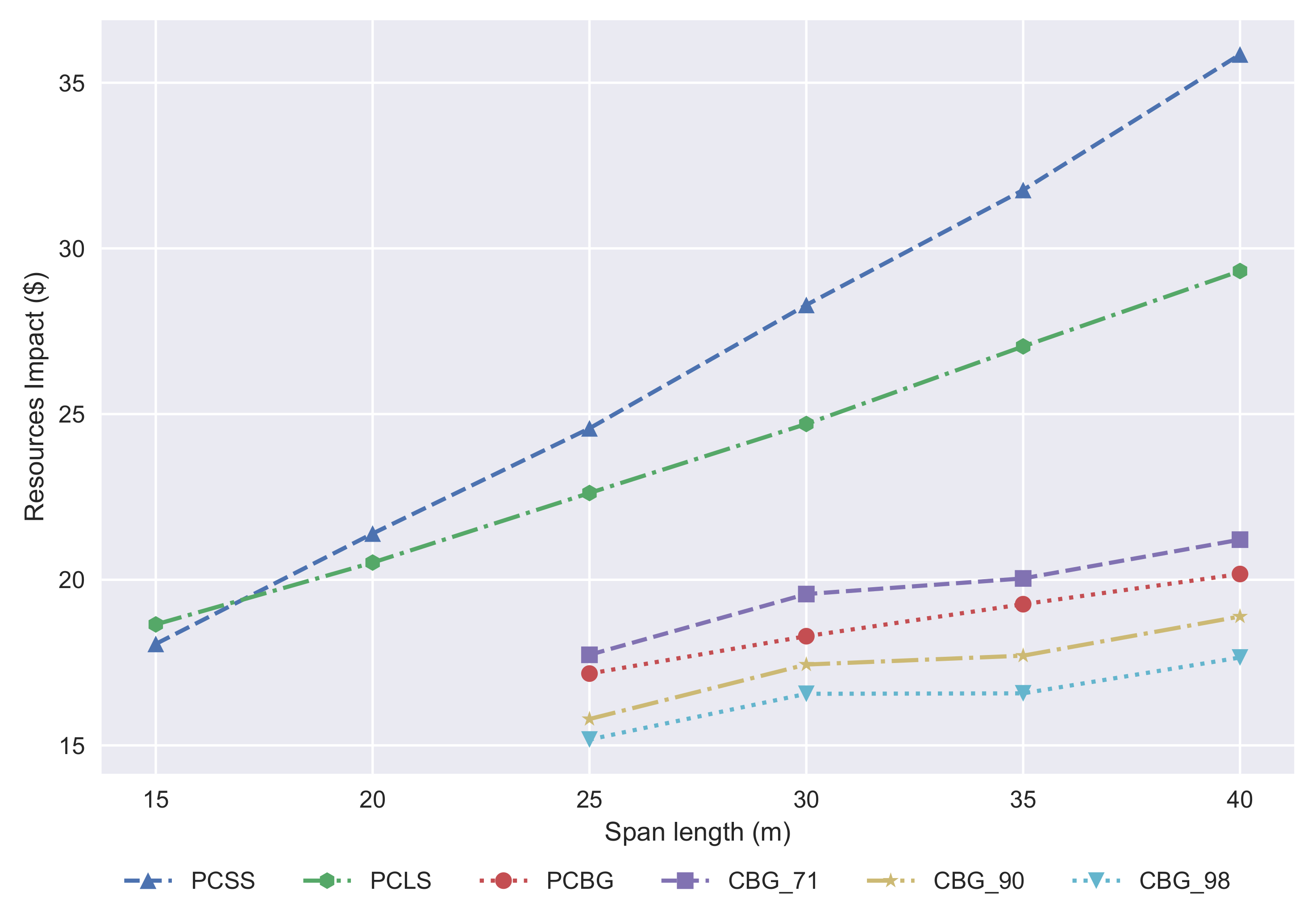

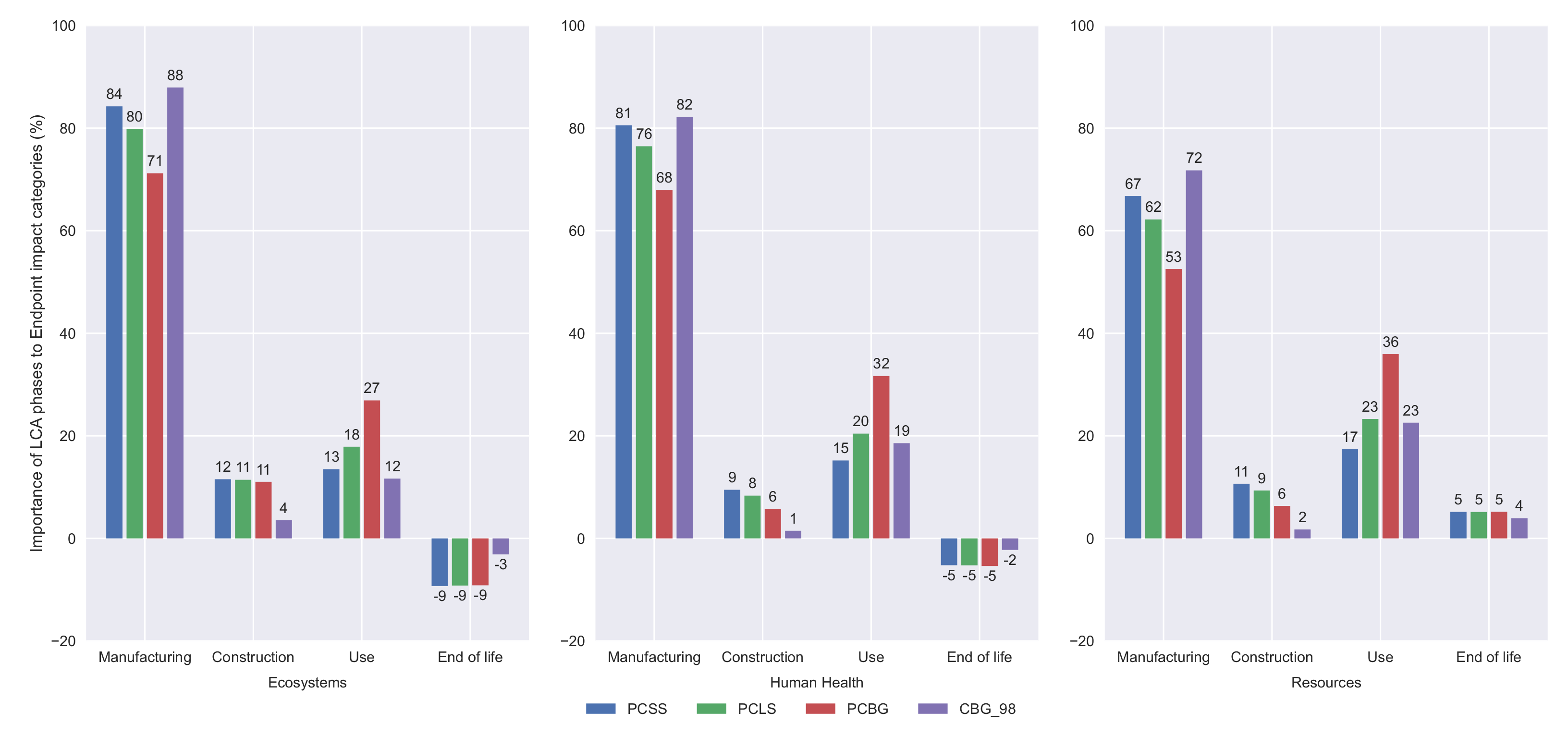

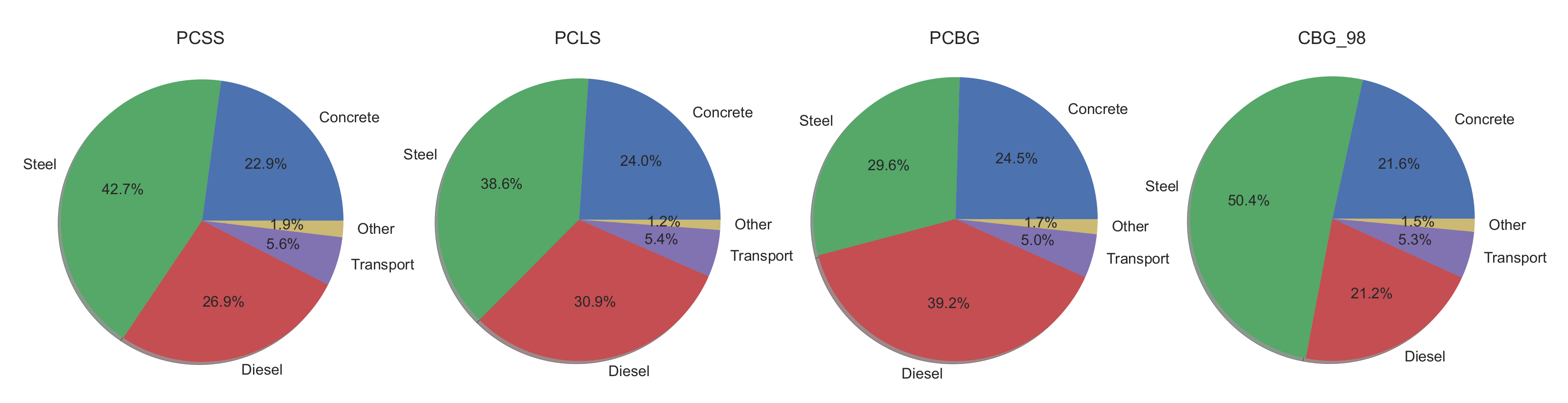

3.2. Endpoint Approach

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Assessment |

| LCIA | LIfe Cycle Inventory Assessment |

| PCSS | Prestressed Concrete Solid Slab |

| PCLS | Prestressed Concrete Lightened Slab |

| PCBG | Prestressed Concrete Box Girder |

| CBG | Composite Box Girder |

| PRS | Passive Reinforcing Steel |

| ARS | Active Reinforcing Steel |

| BOF | Basic Oxygen Furnace |

| EAF | Electric Arc Furnace |

| ALO | Agricultural Land Occupation |

| GWP | Global Warming Potential |

| FD | Fossil Depletion |

| FEPT | Freshwater Ecotoxicity |

| FEP | Freshwater Eutrophication |

| HTP | Human Toxicity |

| IRP | Ionizing Radiation |

| MEPT | Marine Ecotoxicity |

| MEP | Marine Eutrophication |

| MD | Metal Depletion |

| NLT | Natural Land Transformation |

| OD | Ozone Depletion |

| PMF | Particule Matter Formation |

| POFP | Photochemical Oxidant Formation |

| TAP | Terrestrial Acidification |

| TEPT | Terrestrial Ecotoxicity |

| ULO | Urban Land Occupation |

| WD | Water Depletion |

References

- WCED. Our Common Future; World Commission on Environment and Development: New York, NY, USA, 1987. [Google Scholar]

- Petek Gursel, A.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Årskog, V.; Fossdal, S.; Gjørv, O.E. Life-Cycle Asessment of Repair and Maintenance Systems for Concrete Structures. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004. [Google Scholar]

- Shen, L.Y.; Lu, W.; Yao, H.; Wu, D.H. A computer-based scoring method for measuring the environmental performance of construction activities. Autom. Constr. 2005, 14, 297–309. [Google Scholar] [CrossRef]

- Boesch, M.E.; Hellweg, S. Identifying improvement potentials in cement production with life cycle assessment. Autom. Constr. 2010, 44, 9143–9149. [Google Scholar] [CrossRef]

- Taylor, M.; Tam, C.; Gielen, D. Energy Efficiency and CO2 Emissions from the Global Cement Industry, Energy Technology Policy Division; International Energy Agency, Energy Technology Policy Division: Paris, France, 2006. [Google Scholar]

- Collins, F. Inclusion of carbonation during the life cycle of built and recycled concrete: Influence on their carbon footprint. Int. J. Life Cycle Assess. 2010, 15, 549–556. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Frangopol, D.M. Multi-objective design of post-tensioned concrete road bridges using artificial neural networks. Struct. Multidiscip. Optim. 2017, 56, 139–150. [Google Scholar] [CrossRef]

- Yepes, V.; Martí, J.V.; García-Segura, T. Cost and CO2 emission optimization of precast-prestressed concrete U-beam road bridges by a hybrid glowworm swarm algorithm. Autom. Constr. 2015, 49, 123–134. [Google Scholar] [CrossRef]

- Serpell, A.; Kort, J.; Vera, S. Awareness, actions, drivers and barriers of sustainable construction in chile. Technol. Econ. Dev. Econ. 2013, 19, 272–288. [Google Scholar] [CrossRef] [Green Version]

- Sierra, L.A.; Pellicer, E.; Yepes, V. Method for estimating the social sustainability of infrastructure projects. Environ. Impact Assess. Rev. 2017, 65, 41–53. [Google Scholar] [CrossRef] [Green Version]

- Yusof, N.; Zainul Abidin, N.; Zailani, S.H.M.; Govindan, K.; Iranmanesh, M. Linking the environmental practice of construction firms and the environmental behaviour of practitioners in construction projects. J. Clean. Prod. 2016, 121, 64–71. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcala, J.; Pérez-López, E. Hybrid harmony search for sustainable design of post-tensioned concrete box-girder pedestrian bridges. Eng. Struct. 2015, 92, 112–122. [Google Scholar] [CrossRef]

- Marti, J.V.; Yepes, V.; Gonzalez-Vidosa, F. Memetic Algorithm Approach to Designing Precast-Prestressed Concrete Road Bridges with Steel Fiber Reinforcement. J. Struct. Eng. 2015, 141, 04014114. [Google Scholar] [CrossRef] [Green Version]

- Molina-Moreno, F.; García-Segura, T.; Martí, J.V.; Yepes, V. Optimization of buttressed earth-retaining walls using hybrid harmony search algorithms. Eng. Struct. 2017, 134, 205–216. [Google Scholar] [CrossRef]

- Martínez-Muñoz, D.; Martí, J.V.; García, J.; Yepes, V. Embodied Energy Optimization of Buttressed Earth-Retaining Walls with Hybrid Simulated Annealing. Appl. Sci. 2021, 11, 1800. [Google Scholar] [CrossRef]

- Yepes, V.; Alcalá, J.; Perea, C.; González-Vidosa, F. A parametric study of optimum earth-retaining walls by simulated annealing. Eng. Struct. 2008, 30, 821–830. [Google Scholar] [CrossRef]

- Yepes, V.; González-Vidosa, F.; Alcalá, J.; Villalba, P. CO2-Optimization Design of Reinforced Concrete Retaining Walls Based on a VNS-Threshold Acceptance Strategy. J. Comput. Civ. Eng. 2012, 26, 378–386. [Google Scholar] [CrossRef] [Green Version]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Carbon implications of end-of-life management of building materials. Resour. Conserv. Recycl. 2009, 53, 276–286. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life cycle greenhouse gas emissions of blended cement concrete including carbonation and durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Du, G.; Karoumi, R. Life cycle assessment of a railway bridge: Comparison of two superstructure designs. Struct. Infrastruct. Eng. 2013, 9, 1149–1160. [Google Scholar] [CrossRef]

- Du, G.; Safi, M.; Pettersson, L.; Karoumi, R. Life cycle assessment as a decision support tool for bridge procurement: Environmental impact comparison among five bridge designs. Int. J. Life Cycle Assess. 2014, 19, 1948–1964. [Google Scholar] [CrossRef]

- Hettinger, A.; Birat, J.; Hechler, O.; Braun, M. Sustainable Bridges—LCA for a Composite and a Concrete Bridge; Economical Bridge Solutions Based on Innovative Composite Dowels and Integrated Abutments: Ecobridge; Springer Vieweg: Wiesbaden, Germany, 2015. [Google Scholar]

- Salvador, R.; Barros, M.; dos Santos, G.; van Mierlo, K.; Piekarski, C.; de Francisco, A. Towards a green and fast production system: Integrating life cycle assessment and value stream mapping for decision making. Environ. Impact Assess. Rev. 2021, 87, 106519. [Google Scholar] [CrossRef]

- Vitale, P.; Napolitano, R.; Colella, F.; Menna, C.; Asprone, D. Cement-Matrix Composites Using CFRP Waste: A Circular Economy Perspective Using Industrial Symbiosis. Materials 2021, 14, 1484. [Google Scholar] [CrossRef]

- Caneda-Martínez, L.; Monasterio, M.; Moreno-Juez, J.; Martínez-Ramírez, S.; García, R.; Frías, M. Behaviour and Properties of Eco-Cement Pastes Elaborated with Recycled Concrete Powder from Construction and Demolition Wastes. Materials 2021, 14, 1299. [Google Scholar] [CrossRef]

- Jiang, Q.; Wang, F.; Liu, Q.; Xie, J.; Wu, S. Energy Consumption and Environment Performance Analysis of Induction-Healed Asphalt Pavement by Life Cycle Assessment (LCA). Materials 2021, 14, 1244. [Google Scholar] [CrossRef] [PubMed]

- Zastrow, P.; Molina-Moreno, F.; García-Segura, T.; Martí, J.; Yepes, V. Life cycle assessment of cost-optimized buttress earth-retaining walls: A parametric study. J. Clean. Prod. 2017, 140, 1037–1048. [Google Scholar] [CrossRef]

- Pons, J.J.; Penadés-Plà, V.; Yepes, V.; Martí, J.V. Life cycle assessment of earth-retaining walls: An environmental comparison. J. Clean. Prod. 2018, 192, 411–420. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; Martínez-Muñoz, D.; García-Segura, T.; Navarro, I.; Yepes, V. Environmental and Social Impact Assessment of Optimized Post-Tensioned Concrete Road Bridges. Sustainability 2020, 12, 4265. [Google Scholar] [CrossRef]

- Sánchez-Garrido, A.; Navarro, I.; Yepes, V. Neutrosophic multi-criteria evaluation of sustainable alternatives for the structure of single-family homes. Environ. Impact Assess. Rev. 2021, 89, 106572. [Google Scholar] [CrossRef]

- Laiblová, L.; Pešta, J.; Kumar, A.; Hájek, P.; Fiala, C.; Vlach, T.; Kočí, V. Environmental Impact of Textile Reinforced Concrete Facades Compared to Conventional Solutions—LCA Case Study. Materials 2019, 12, 3194. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kvočka, D.; Lešek, A.; Knez, F.; Ducman, V.; Panizza, M.; Tsoutis, C.; Bernardi, A. Life Cycle Assessment of Prefabricated Geopolymeric Façade Cladding Panels Made from Large Fractions of Recycled Construction and Demolition Waste. Materials 2020, 13, 3931. [Google Scholar] [CrossRef]

- Martínez-Muñoz, D.; Martí, J.V.; Yepes, V. Steel-Concrete Composite Bridges: Design, Life Cycle Assessment, Maintenance, and Decision-Making. Adv. Civ. Eng. 2020, 2020, 8823370. [Google Scholar] [CrossRef]

- Rossi, B.; Marquart, S.; Rossi, G. Comparative life cycle cost assessment of painted and hot-dip galvanized bridges. J. Environ. Manag. 2017, 197, 41–49. [Google Scholar] [CrossRef]

- Worldsteel. Life Cycle Inventory Methodology Report for Steel Products; World Steel Association: Brussels, Belgium, 2017. [Google Scholar]

- ISO. Environmental Management, Life Cycle Assessment Principles and Framework (ISO 14040:2006); International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008. Report I: Characterisation; Ministry of Housing, Spatial Planning and Environment (VROM): Den Haag, The Netherlands, 2009; pp. 1–44. [Google Scholar]

- Pang, B.; Yang, P.; Wang, Y.; Kendall, A.; Xie, H.; Zhang, Y. Life cycle environmental impact assessment of a bridge with different strengthening schemes. Int. J. Life Cycle Assess. 2015, 20, 1300–1311. [Google Scholar] [CrossRef]

- Marceau, M.; Nisbet, M.; Vangeem, M. Life Cycle Inventory of Portland Cement Concrete; Report 2137a; Portland Cement Association: Skokie, IL, USA, 2002. [Google Scholar]

- SRI. Construction | SRI—Steel Recycling Institute. Available online: https://www.steelsustainability.org/construction (accessed on 30 January 2021).

- Hammervold, J.; Reenaas, M.; Brattebø, H. Environmental Life Cycle Assessment of Bridges. J. Bridge Eng. 2013, 18, 153–161. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V. Multiobjective optimization of post-tensioned concrete box-girder road bridges considering cost, CO2 emissions, and safety. Eng. Struct. 2016, 125, 325–336. [Google Scholar] [CrossRef]

- Lagerblad, B. Carbon Dioxide Uptake during Concrete Life Cycle—State of the Art; Swedish Cement and Concrete Research Institute: Boras, Sweden, 2005. [Google Scholar]

- Penadés-Plà, V.; Martí, J.V.; García-Segura, T.; Yepes, V. Life-Cycle Assessment: A Comparison between Two Optimal Post-Tensioned Concrete Box-Girder Road Bridges. Sustainability 2017, 9, 1864. [Google Scholar] [CrossRef] [Green Version]

- MFOM. Instrucción de Hormigón Estructural (EHE-08); Ministerio de Fomento: Madrid, Spain, 2011. [Google Scholar]

- Ciroth, A. ICT for environment in life cycle applications openLCA—A new open source software for Life Cycle Assessment. Int. J. Life Cycle Assess. 2007, 12, 209. [Google Scholar] [CrossRef]

- Frischknecht, R.; Rebitzer, G. The ecoinvent database system: A comprehensive web-based LCA database. J. Clean. Prod. 2005, 13, 1337–1343. [Google Scholar] [CrossRef]

- Pascual-González, J.; Guillén-Gosálbez, G.; Mateo-Sanz, J.M.; Jiménez-Esteller, L. Statistical analysis of the ecoinvent database to uncover relationships between life cycle impact assessment metrics. J. Clean. Prod. 2016, 112, 359–368. [Google Scholar] [CrossRef]

- Larsen, S. Inclusion of uncertainty in Environmental Impact Assessment in Greenland. Environ. Impact Assess. Rev. 2021, 89, 106583. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Peng, Y.; Feng, Y.; Mao, C. Reprint of: Uncertainty analysis for measuring greenhouse gas emissions in the building construction phase: A case study in China. J. Clean. Prod. 2017, 163, S420–S432. [Google Scholar] [CrossRef]

- Ciroth, A.; Muller, S.; Weidema, B.; Lesage, P. Empirically based uncertainty factors for the pedigree matrix in ecoinvent. Int. J. Life Cycle Assess. 2016, 21, 1338–1348. [Google Scholar] [CrossRef]

- Yepes, V.; Díaz, J.; González-Vidosa, F.; Alcalá, J. Statistical Characterization of Prestressed Concrete Road Bridge Decks. Rev. Construcción 2009, 8, 95–108. [Google Scholar]

- MFOM. Obras de Paso de Nueva Construcción; Ministerio de Fomento: Madrid, Spain, 2000. [Google Scholar]

- Zhang, Y.; Mao, Y.; Jiao, L.; Shuai, C.; Zhang, H. Eco-efficiency, eco-technology innovation and eco-well-being performance to improve global sustainable development. Environ. Impact Assess. Rev. 2021, 89, 106580. [Google Scholar] [CrossRef]

- Catalonia Institute of Construction Technology. BEDEC ITEC Materials Database. Available online: https://metabase.itec.cat/vide/es/bedec (accessed on 11 January 2021).

- Yi, S.; Kurisu, K.; Hanaki, K. Life cycle impact assessment and interpretation of municipal solid waste management scenarios based on the midpoint and endpoint approaches. Int. J. Life Cycle Assess. 2011, 16, 652–668. [Google Scholar] [CrossRef]

- Khatri, P.; Jain, S.; Pandey, S. A cradle-to-gate assessment of environmental impacts for production of mustard oil using life cycle assessment approach. J. Clean. Prod. 2017, 166, 988–997. [Google Scholar] [CrossRef]

| Unit | 15 | 20 | 25 | 30 | 35 | 40 | |

|---|---|---|---|---|---|---|---|

| PCSS | |||||||

| Concrete HP-40 | m³ | 0.473 | 0.561 | 0.649 | 0.738 | 0.826 | 0.914 |

| Reinforcement Steel | kg | 51.728 | 61.380 | 71.033 | 80.686 | 90.339 | 99.992 |

| Prestressed Reinforcement Steel | kg | 9.223 | 17.133 | 25.043 | 32.953 | 40.863 | 48.773 |

| Formwork | m² | 1.500 | 1.500 | 1.500 | 1.500 | 1.500 | 1.500 |

| PCLS | |||||||

| Concrete HP-40 | m³ | 0.509 | 0.557 | 0.605 | 0.654 | 0.702 | 0.750 |

| Reinforcement Steel | kg | 52.165 | 57.109 | 62.052 | 66.996 | 71.939 | 76.883 |

| Prestressed Reinforcement Steel | kg | 5.069 | 10.914 | 16.759 | 22.604 | 28.449 | 34.294 |

| Formwork | m² | 1.700 | 1.700 | 1.700 | 1.700 | 1.700 | 1.700 |

| PCBG | |||||||

| Concrete HP-40 | m³ | 0.441 | 0.461 | 0.482 | 0.503 | 0.523 | 0.544 |

| Reinforcement Steel | kg | 28.790 | 32.601 | 36.632 | 40.884 | 45.356 | 50.048 |

| Prestressed Reinforcement Steel | kg | 3.042 | 4.917 | 6.792 | 8.667 | 10.542 | 12.417 |

| Formwork | m² | 1.900 | 1.900 | 1.900 | 1.900 | 1.900 | 1.900 |

| CBG | |||||||

| Concrete HA-30 | m³ | 0.220 | 0.230 | 0.240 | 0.250 | 0.261 | 0.272 |

| Reinforcement Steel | kg | 20.976 | 22.250 | 23.603 | 25.037 | 26.559 | 28.173 |

| Structural Steel | kg | 59.400 | 63.700 | 68.175 | 81.000 | 80.600 | 88.375 |

| Shear Connector Steel | kg | 0.310 | 0.346 | 0.381 | 0.423 | 0.437 | 0.494 |

| Formwork | m² | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Concrete | |||

|---|---|---|---|

| Material | Unit | HA-30 | HP-40 |

| Gravel | kg | 1110.00 | 829.00 |

| Sand | kg | 730.00 | 1102.00 |

| Cement | kg | 300.00 | 320.00 |

| Water | kg | 201.00 | 160.00 |

| Superplasticizer | kg | 0.27 | 5.00 |

| PCSS | PCLS | PCBG | CBG_98 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Acronym | Unit | Mean | cv (%) | Mean | cv (%) | Mean | cv (%) | Mean | cv (%) |

| ALO | m2*a | 31.35 | 59.31% | 31.67 | 63.27% | 29.09 | 71.18% | 22.583 | 55.17% |

| GWP | kg CO2 eq | 636.76 | 45.72% | 556.19 | 44.00% | 392.14 | 40.28% | 322.776 | 35.37% |

| FD | kg oil eq | 148.79 | 26.09% | 129.51 | 24.25% | 95.97 | 20.58% | 83.494 | 26.26% |

| FEPT | kg 1,4-DB eq | 7.53 | 41.45% | 6.01 | 40.54% | 3.76 | 39.15% | 6.285 | 43.37% |

| FEP | kg P eq | 0.16 | 40.84% | 0.13 | 39.08% | 0.08 | 37.43% | 0.100 | 37.76% |

| HTP | kg 1,4-DB eq | 276.00 | 44.56% | 218.63 | 44.03% | 135.98 | 42.66% | 253.954 | 47.37% |

| IRP | kg U235 eq | 56.39 | 44.71% | 49.34 | 44.12% | 35.33 | 40.17% | 25.067 | 31.96% |

| MEPT | kg 1,4-DB eq | 7.41 | 40.88% | 5.92 | 39.98% | 3.71 | 38.60% | 6.140 | 43.13% |

| MEP | kg N eq | 0.14 | 23.59% | 0.13 | 21.70% | 0.10 | 17.53% | 0.079 | 24.98% |

| MD | kg Fe eq | 98.26 | 50.78% | 78.60 | 47.04% | 46.66 | 44.54% | 42.531 | 35.66% |

| NLT | m2 | 0.13 | 25.82% | 0.12 | 24.29% | 0.09 | 20.45% | 0.094 | 39.37% |

| ODP | kg CFC-11 eq | 0.00 | 19.32% | 0.00 | 17.68% | 0.00 | 14.55% | 0.000 | 21.31% |

| PMFP | kg PM10 eq | 1.74 | 27.47% | 1.51 | 24.64% | 1.10 | 20.31% | 0.948 | 26.43% |

| POFP | kg NMVOC | 3.63 | 19.95% | 3.29 | 17.87% | 2.63 | 14.03% | 1.761 | 18.52% |

| TAP | kg SO2 eq | 2.90 | 26.53% | 2.57 | 24.56% | 1.95 | 20.35% | 1.504 | 24.73% |

| TETP | kg 1,4-DB eq | 0.08 | 33.95% | 0.07 | 33.60% | 0.04 | 32.70% | 0.122 | 48.71% |

| ULO | m2*a | 7.18 | 34.96% | 6.10 | 34.11% | 4.19 | 33.32% | 4.070 | 32.24% |

| WD | m3 | 1540.31 | 45.90% | 1294.58 | 45.72% | 851.61 | 44.25% | 852.564 | 38.79% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Muñoz, D.; Martí, J.V.; Yepes, V. Comparative Life Cycle Analysis of Concrete and Composite Bridges Varying Steel Recycling Ratio. Materials 2021, 14, 4218. https://doi.org/10.3390/ma14154218

Martínez-Muñoz D, Martí JV, Yepes V. Comparative Life Cycle Analysis of Concrete and Composite Bridges Varying Steel Recycling Ratio. Materials. 2021; 14(15):4218. https://doi.org/10.3390/ma14154218

Chicago/Turabian StyleMartínez-Muñoz, David, Jose V. Martí, and Víctor Yepes. 2021. "Comparative Life Cycle Analysis of Concrete and Composite Bridges Varying Steel Recycling Ratio" Materials 14, no. 15: 4218. https://doi.org/10.3390/ma14154218

APA StyleMartínez-Muñoz, D., Martí, J. V., & Yepes, V. (2021). Comparative Life Cycle Analysis of Concrete and Composite Bridges Varying Steel Recycling Ratio. Materials, 14(15), 4218. https://doi.org/10.3390/ma14154218