Experimental Study on Basalt Fiber Crack Resistance of Asphalt Concrete Based on Acoustic Emission

Abstract

:1. Introduction

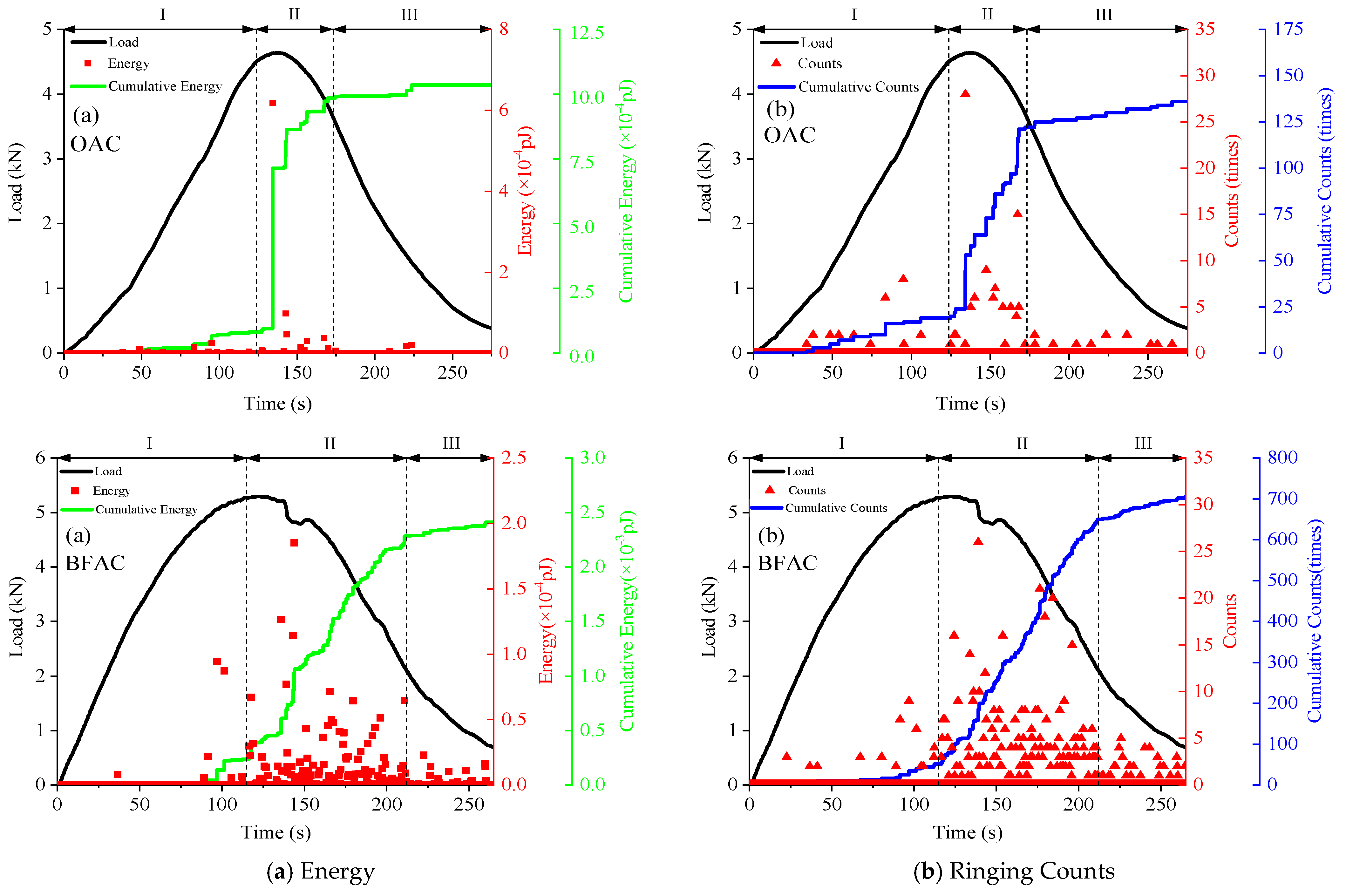

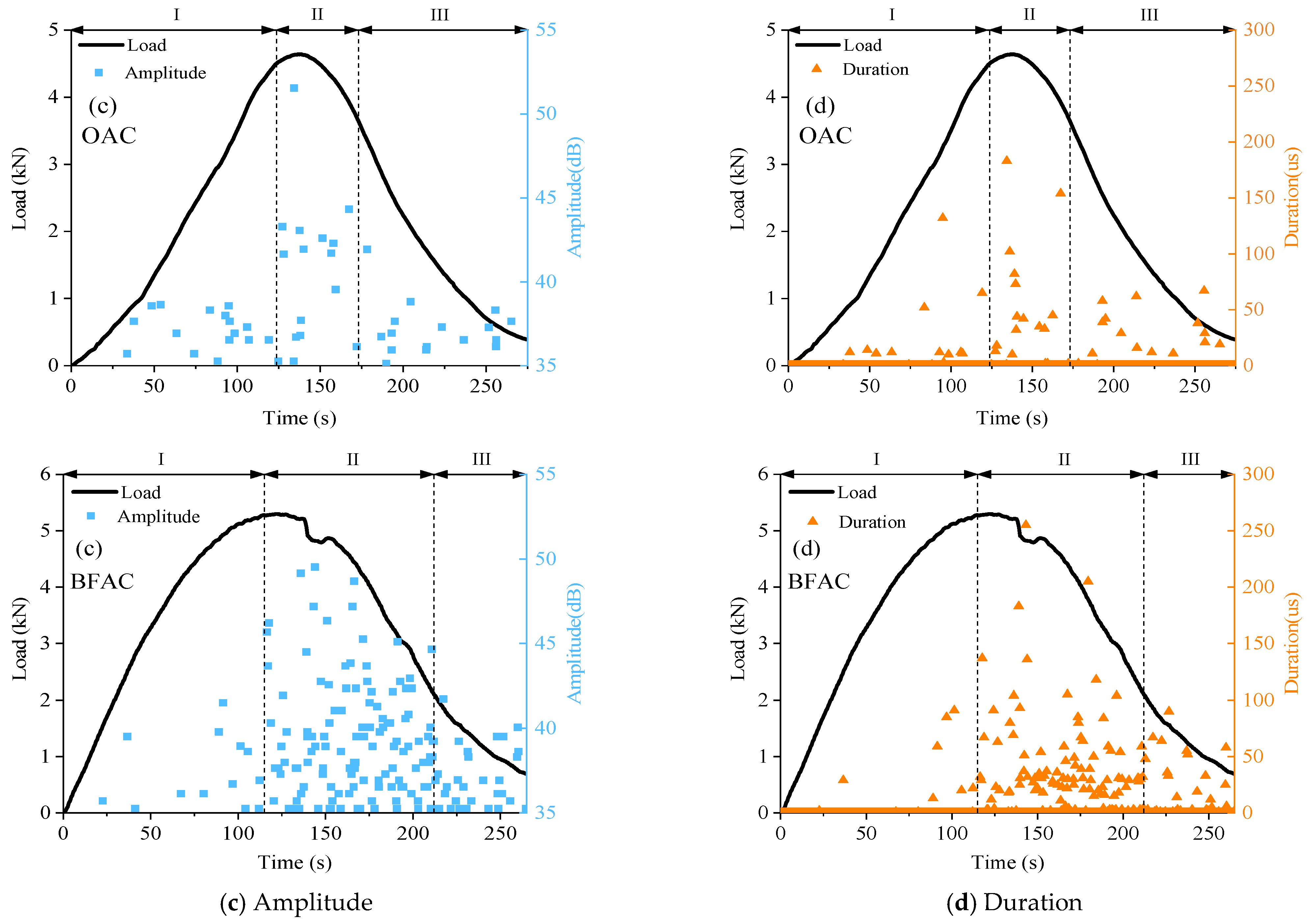

- Study the differences of variation characteristics and laws of AE parameters during the fracture and damage process of OAC and BFAC.

- Study the effect and mechanism of crack resistance of basalt fiber in asphalt concrete damage based on AE parameters.

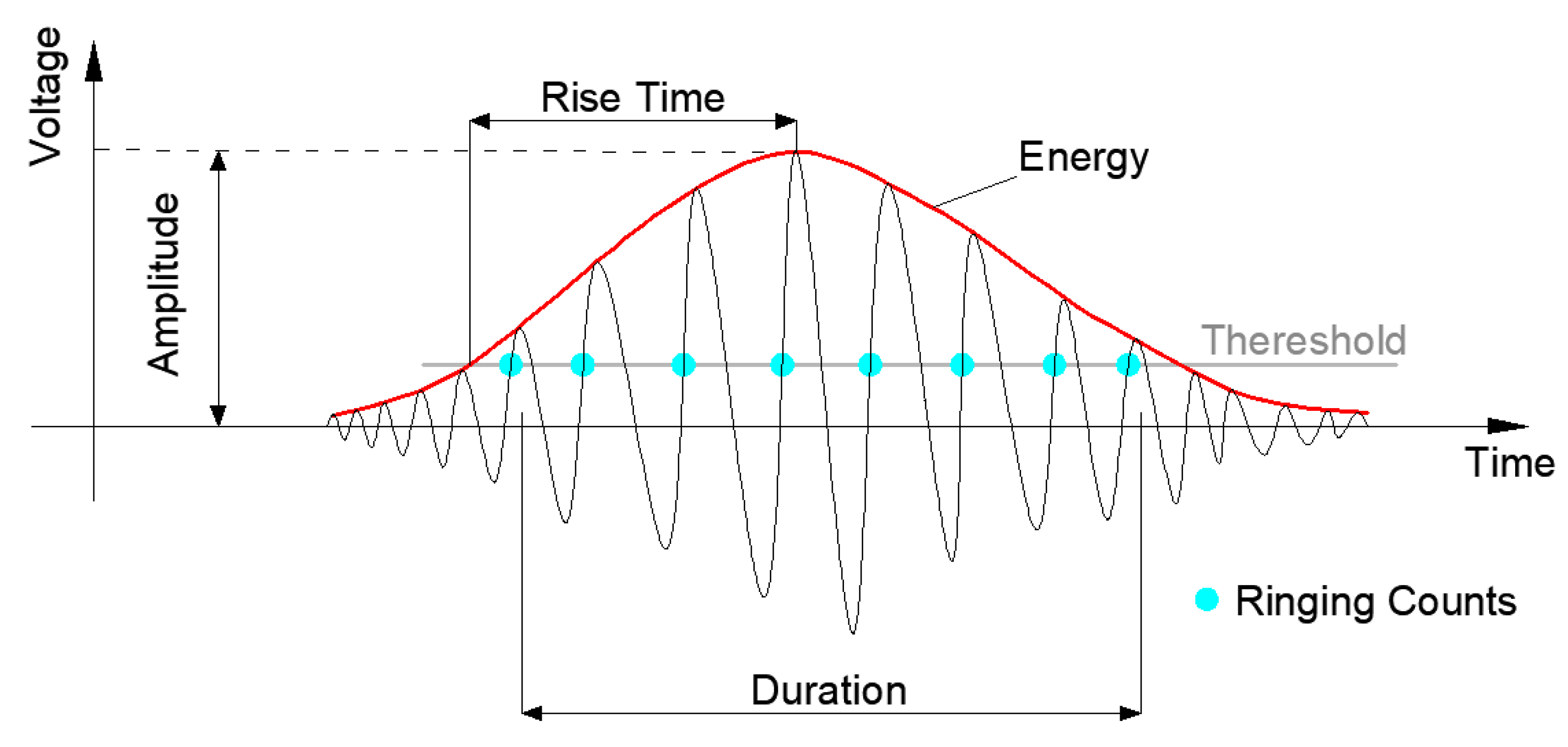

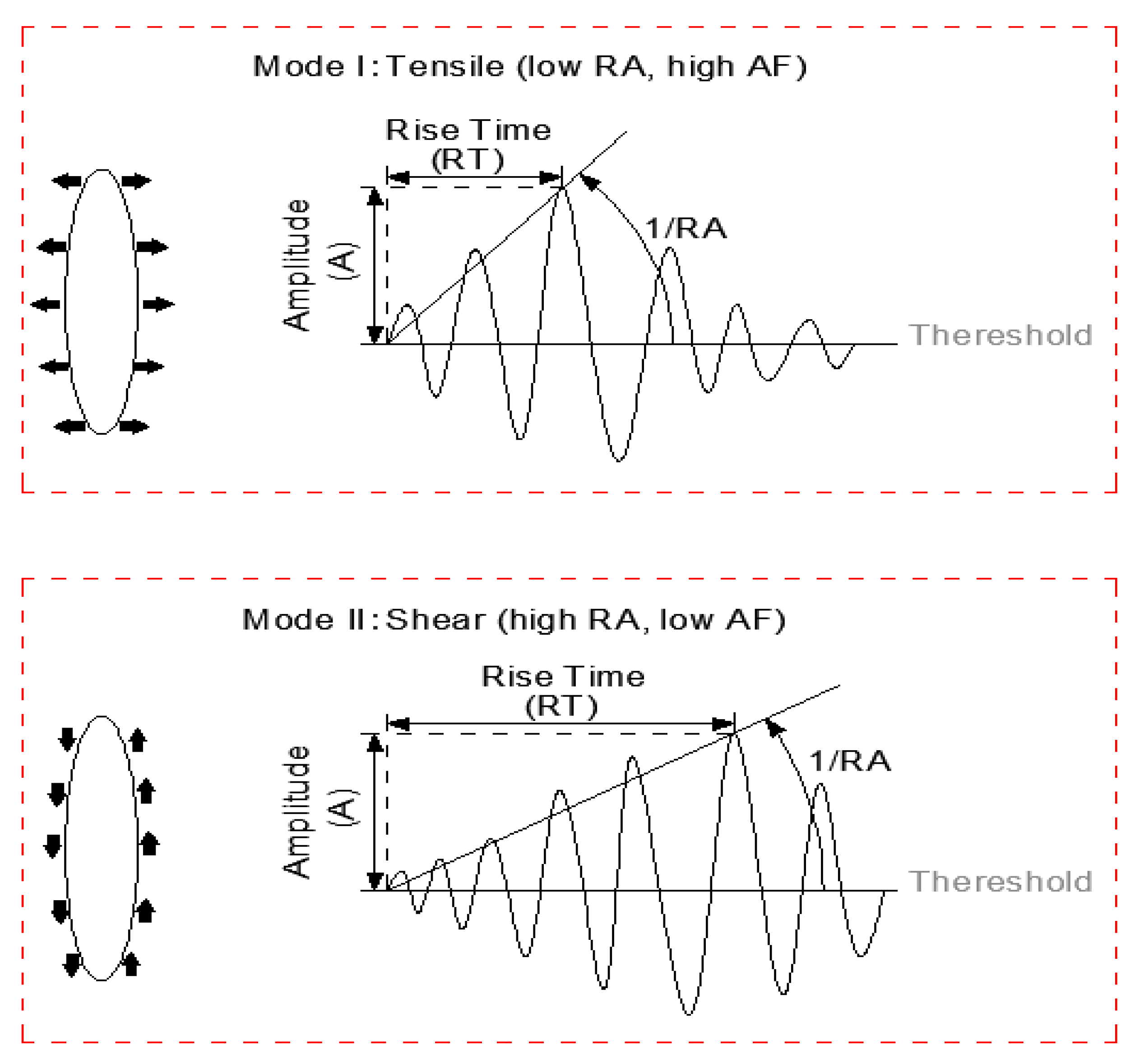

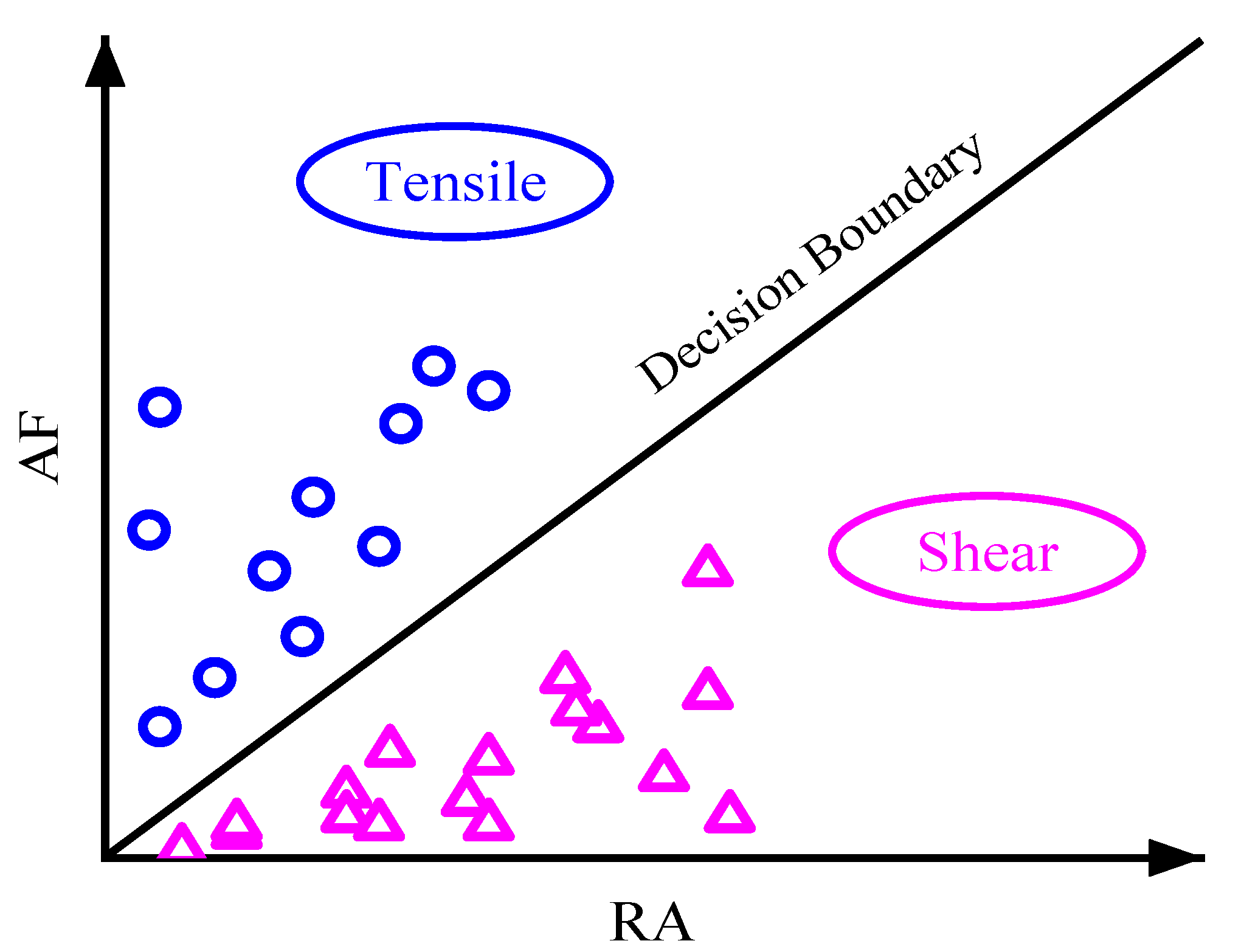

- Explore the cracking mode and crack resistance mechanism of OAC and BFAC by AE parameters Rise Angle (RA) and Average Frequency (AF).

2. Raw Materials

2.1. Asphalt and Aggregate

2.2. Basalt Fiber

3. Test setup and Methods

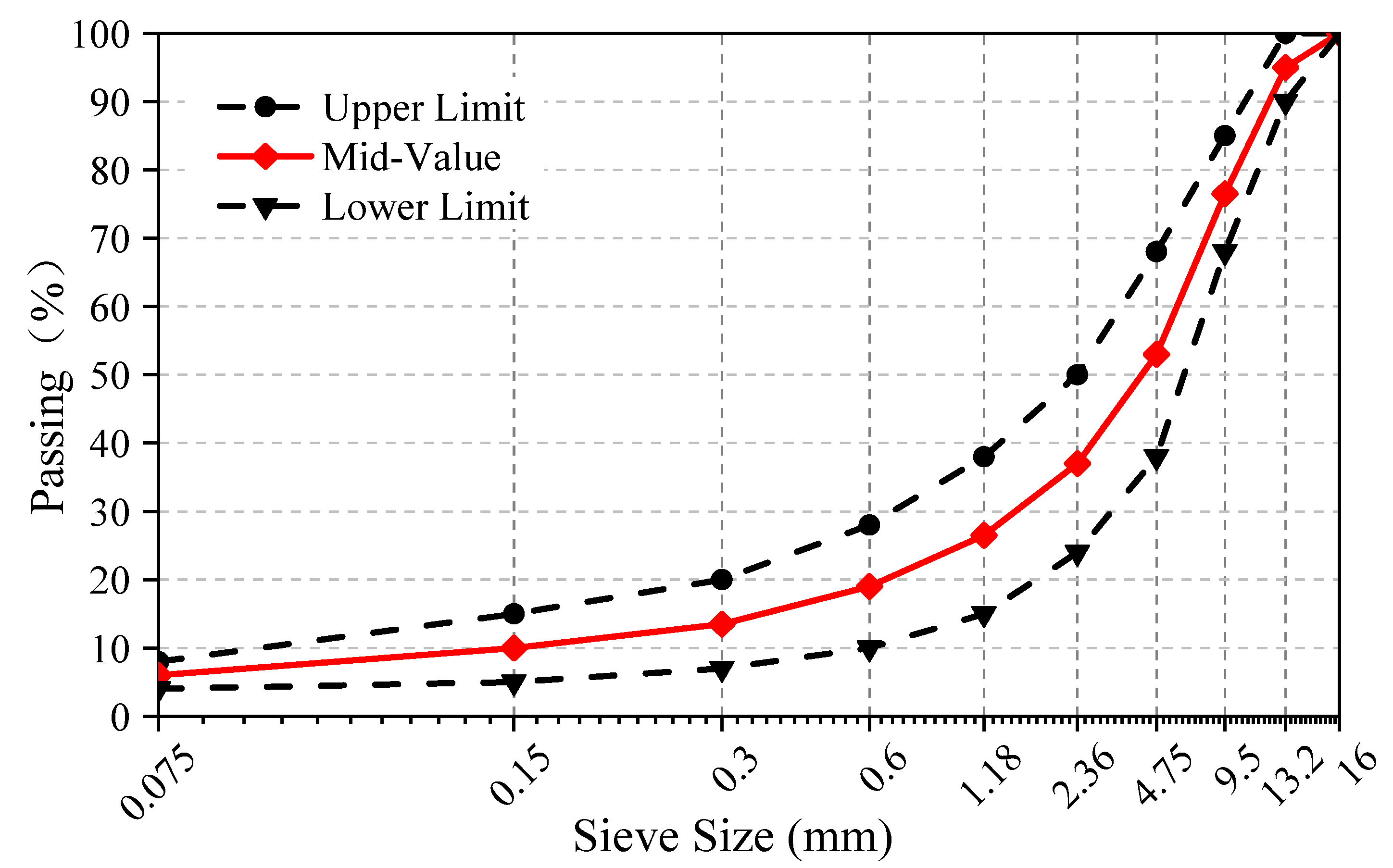

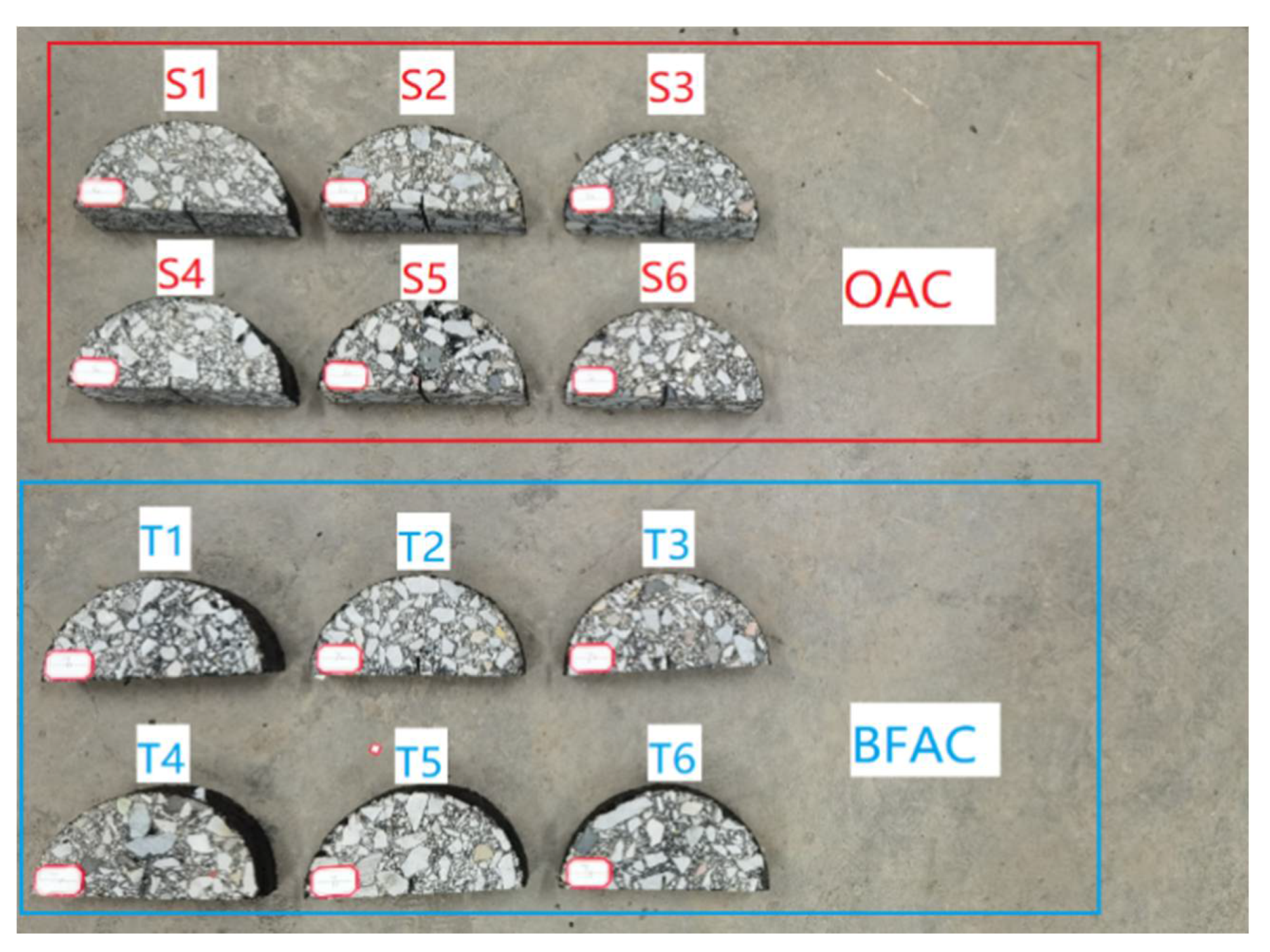

3.1. Preparation of Specimens

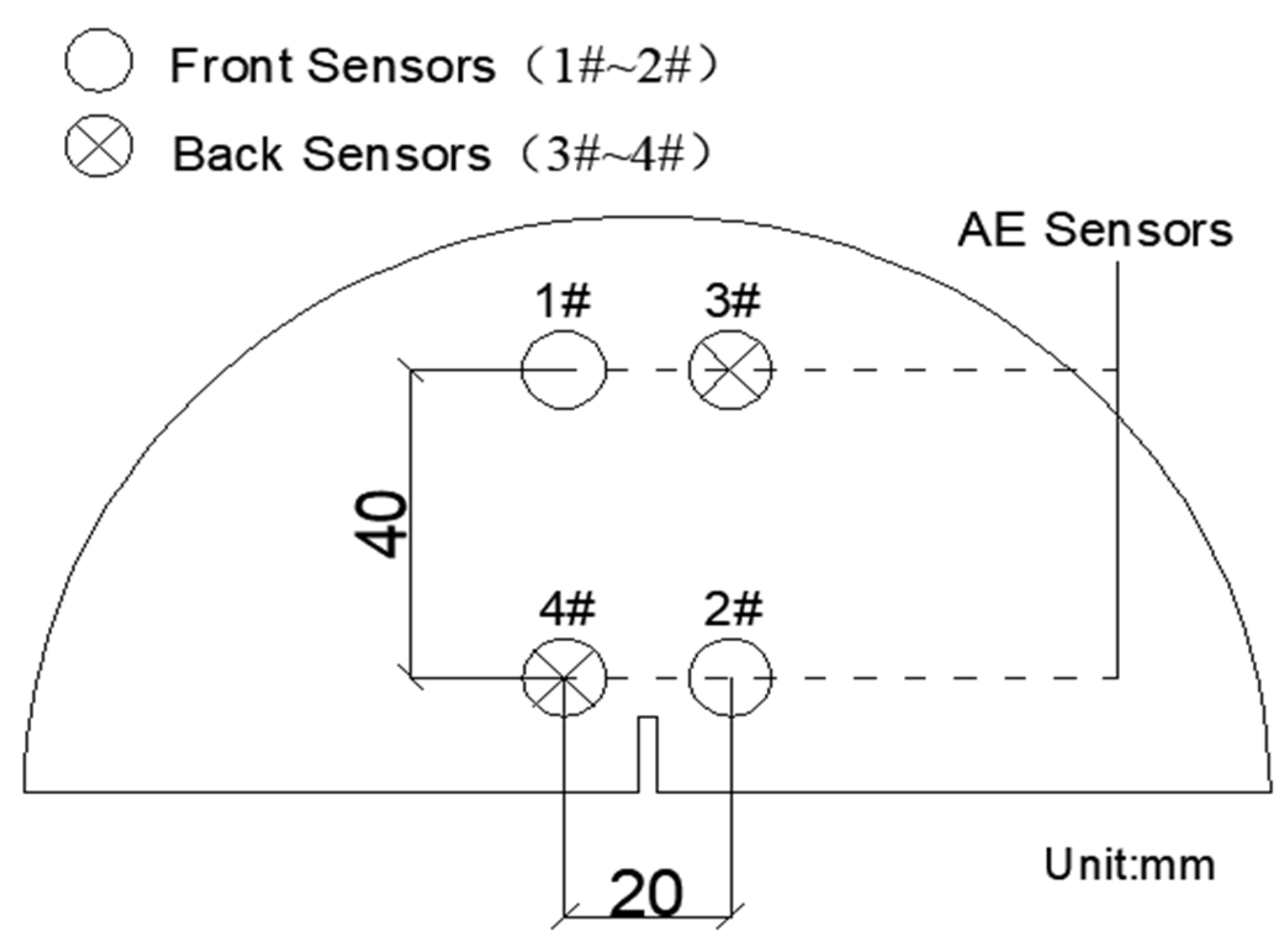

3.2. Test Setup and AE System

3.3. Rise Angle (RA) and Average Frequency (AF)

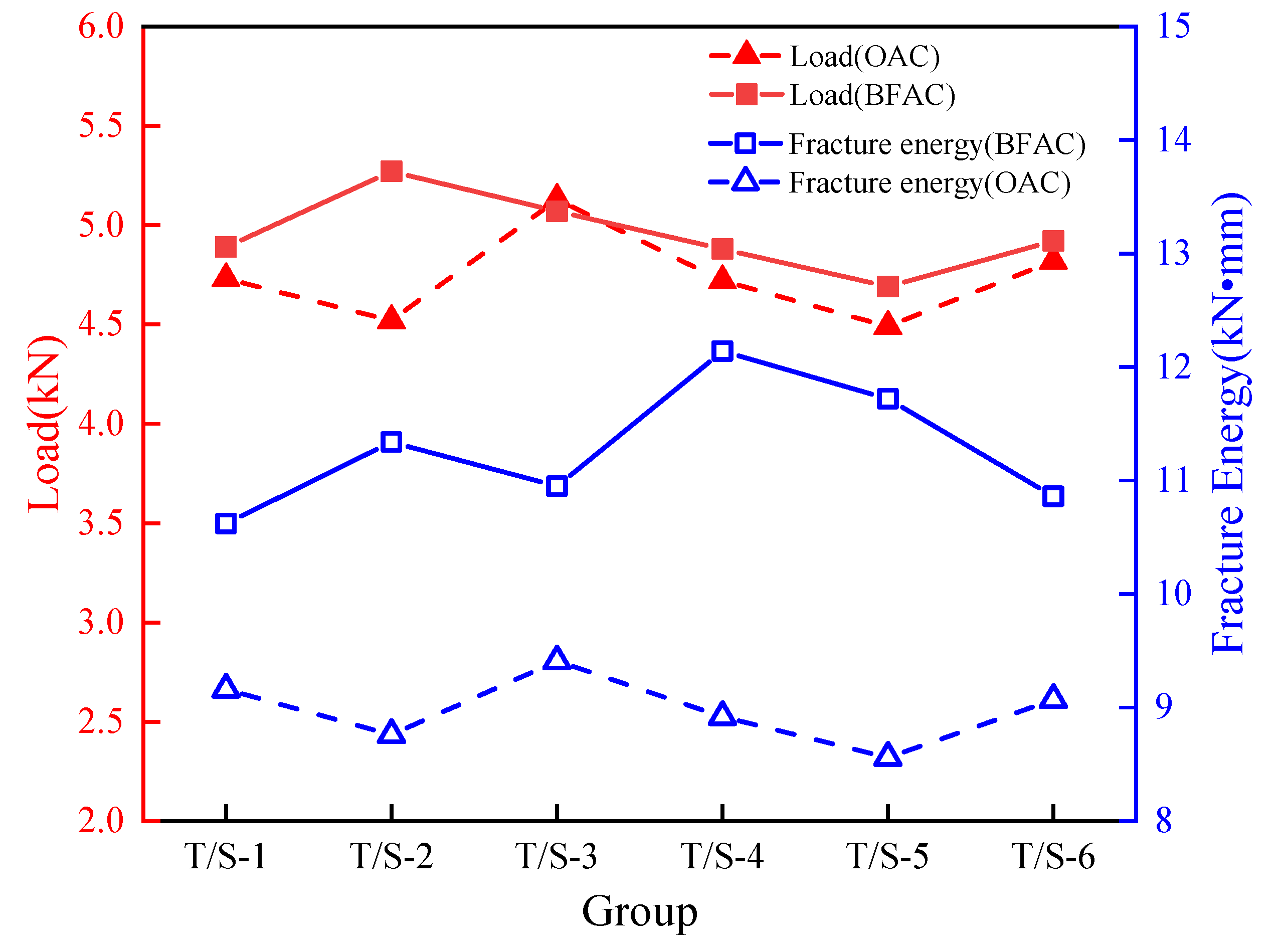

4. Crack Resistance Analysis

4.1. Analysis Based on Fracture Energy

4.2. Analysis Based on AE Parameters

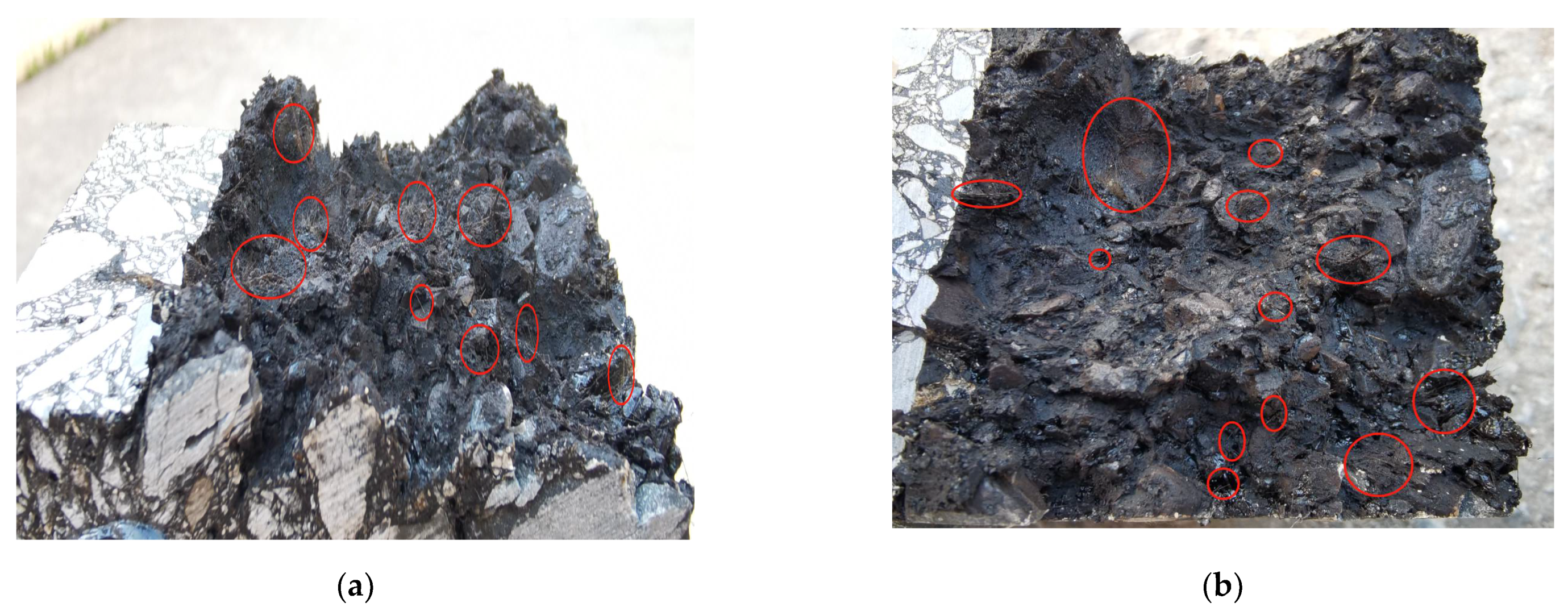

5. Fracture Mode Analysis

6. Conclusions

- (1)

- The AE technology can effectively reflect the influence of basalt fibers on the damage of asphalt concrete material from the microscopic level, and basalt fibers played a role in the stage lag behind the specimen itself, bearing the load. So they had no improvement effect on the bending failure load.

- (2)

- The whole process of OAC and BFAC fracture damage can be divided into three stages based on AE parameters: microcrack initiation stage, rapid fracture stage, and residual stage. Among the three stages, the second stage had the greatest difference between OAC and BFAC. In this stage, the AE parameter of BFAC had larger values, more quantities, more dense occurrence, and evener distribution, which is also the main stage when basalt fibers played the role of crack resistance and toughening.

- (3)

- The fracture modes analysis shows that RA and AF values can more intuitively and deeply reflect the fracture modes inside material. The existence of basalt fibers made the shear events increase significantly and fracture modes more abundant; furthermore, the tensile fracture tendency was reduced and the effect of basalt fibers on crack resistance and toughness was reflected from the side.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| OAC | Ordinary asphalt concrete |

| BFAC | Basalt fiber asphalt concrete |

| AE | Acoustic emission |

| RA | Rise Angle |

| AF | Average Frequency |

References

- Son, S.; Said, I.M.; Al-Qadi, I.L. Fracture properties of asphalt concrete under various displacement conditions and temperatures. Constr. Build. Mater. 2019, 222, 332–341. [Google Scholar] [CrossRef]

- Alaswadko, N.; Hassan, R.; Meyer, D.; Mohammed, B. Probabilistic prediction models for crack initiation and progression of spray sealed pavements. Int. J. Pavement Eng. 2019, 20, 1–12. [Google Scholar] [CrossRef]

- Liu, Z.H.; Chen, C.Y.; Qin, R.J. Research to performance of basalt fibre strengthen sbs modified asphalt mixture. Adv. Mater. Res. 2012, 446, 191–195. [Google Scholar] [CrossRef]

- Zheng, Y.; Cai, Y.; Zhang, G.; Fang, H. Fatigue property of basalt fiber-modified asphalt mixture under complicated environment. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2014, 29, 996–1004. [Google Scholar] [CrossRef]

- Morova, N. Investigation of usability of basalt fibers in hot mix asphalt concrete. Constr. Build. Mater. 2013, 47, 175–180. [Google Scholar] [CrossRef]

- Li, Z.; Shen, A.; Wang, H.; Guo, Y.; Wu, H. Effect of basalt fiber on the low-temperature performance of an asphalt mixture in a heavily frozen area. Constr. Build. Mater. 2020, 253, 119080. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, W.; Gong, Y.; Wang, S.; Yang, S.; Sun, X. Comparative study on the damage characteristics of asphalt mixtures reinforced with an eco-friendly basalt fiber under freeze-thaw cycles. Materials 2018, 11, 2488. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Celauro, C.; Pratico, F.G. Asphalt mixtures modified with basalt fibres for surface courses. Constr. Build. Mater. 2018, 170, 245–253. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, Z.; Liu, P.; Li, Y.; Hu, J.; Gao, Y.; Li, X. Influence of basalt fiber on mode I and II fracture properties of asphalt mixture at medium and low temperatures. Theor. Appl. Fract. Mech. 2020, 112, 102884. [Google Scholar] [CrossRef]

- Tripathi, R.; Srivastava, M.; Hloch, S.; Adamčík, P.; Chattopadhyaya, S.; Das, A.K. Monitoring of acoustic emission during the disintegration of rock. Procedia Eng. 2016, 149, 481–488. [Google Scholar] [CrossRef] [Green Version]

- D’Angela, D.; Ercolino, M. Acoustic emission entropy as a fracture-sensitive feature for real-time assessment of metal plates under fatigue loading. Procedia Struct. Integr. 2019, 18, 570–576. [Google Scholar]

- Xie, C.; Yuan, L.; Zhao, M.; Jia, Y. Study on failure mechanism of porous concrete based on acoustic emission and discrete element method. Constr. Build. Mater. 2020, 235, 117409. [Google Scholar] [CrossRef]

- Fan, Z.; Sun, Y. Detecting and evaluation of fatigue damage in concrete with industrial computed tomography technology. Constr. Build. 2019, 223, 794–805. [Google Scholar] [CrossRef]

- Pazdera, L.; Cajka, R.; Topolář, L.; Matečková, P.; Bilek, V.; Sucharda, O. Measurement and utilization of acoustic emission for the analysis and monitoring of concrete slabs on the subsoil. Period. Polytech. Civil. Eng. 2019, 63, 608–620. [Google Scholar] [CrossRef]

- Verstrynge, E.; Lacidogna, G.; Accornero, F.; Tomor, A. A review on acoustic emission monitoring for damage detection in masonry structures. Constr. Build. Mater. 2020, 268, 121089. [Google Scholar] [CrossRef]

- Zhou, Z.; Rui, Y.; Cai, X.; Lu, J. Constrained total least squares method using TDOA measurements for jointly estimating acoustic emission source and wave velocity. Measurement 2021, 182, 109758. [Google Scholar] [CrossRef]

- Qiu, X.; Wang, Y.; Xu, J.; Xiao, S.; Li, C. Acoustic emission propagation characteristics and damage source localization of asphalt mixtures. Constr. Build. Mater. 2020, 252, 119086. [Google Scholar] [CrossRef]

- Behnia, B.; Reis, H. Self-healing of thermal cracks in asphalt pavements. Constr. Build. Mater. 2019, 218, 316–322. [Google Scholar] [CrossRef]

- Qiu, X.; Xu, J.; Xiao, S.; Yang, Q. Acoustic emission parameters and waveforms characteristics of fracture failure process of asphalt mixtures. Constr. Build. Mater. 2019, 215, 135–147. [Google Scholar] [CrossRef]

- Qiu, X.; Xu, J.; Xu, W.; Xiao, S.; Wang, F.; Yuan, J. Characterization of fatigue damage mechanism of asphalt mixtures with acoustic emission. Constr. Build. Mater. 2020, 240, 117961. [Google Scholar] [CrossRef]

- Qiu, X.; Xu, J.; Xu, W.; Yang, Q.; Wang, F.; Yuan, J. Diagnosis of damage evolution process for asphalt mixtures using pattern recognition with acoustic emission signals. Constr. Build. Mater. 2021, 280, 122536. [Google Scholar] [CrossRef]

- Cai, X.; Fu, L.; Zhang, J.; Chen, X.; Yang, J. Damage analysis of semi-flexible pavement material under axial compression test based on acoustic emission technique. Constr. Build. Mater. 2020, 239, 117773. [Google Scholar] [CrossRef]

- Jiao, Y.; Fu, L.; Shan, W.; Liu, S. Damage fracture characterization of pervious asphalt considering temperature effect based on acoustic emission parameters. Eng. Fract. Mech. 2018, 210, 147–159. [Google Scholar] [CrossRef]

- Jiao, Y.; Liu, S.; Fu, L.; Shan, W. Fracture monitoring of SBS and crumb rubber modified porous asphalt mixtures under compression and splitting testing using acoustic emission technique. J. Mater. Civ. Eng. 2019, 31, 04019063. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, Y.; Zhang, M.; Fu, L.; Zhang, L. Investigation of fracture modes in pervious asphalt under splitting and compression based on acoustic emission monitoring. Eng. Fract. Mech. 2019, 211, 209–220. [Google Scholar] [CrossRef]

- Arnold, J.W.; Behnia, B.; McGovern, M.E.; Hill, B.; Buttlar, W.G.; Reis, H. Quantitative evaluation of low-temperature performance of sustainable asphalt pavements containing recycled asphalt shingles (RAS). Constr. Build. Mater. 2014, 58, 1–8. [Google Scholar] [CrossRef]

- Yang, K.; Li, D.; He, Z.; Zhou, H.; Li, J. Study on acoustic emission characteristics of low-temperature asphalt concrete cracking damage. Materials 2021, 14, 881. [Google Scholar] [CrossRef]

- Silva, J.D.A.A.E.; Rodrigues, J.K.G.; de Carvalho, M.W.; Lucena, L.C.D.F.L.; Cavalcante, E.H. Mechanical performance of asphalt mixtures using polymer-micronized PET-modified binder. Road Mater. Pavement Des. 2018, 19, 1001–1009. [Google Scholar] [CrossRef]

- Polaczyk, P.; Ma, Y.; Xiao, R.; Hu, W.; Jiang, X.; Huang, B. Characterization of aggregate interlocking in hot mix asphalt by mechanistic performance tests. Road Mater. Pavement Des. 2021, 22, 498–513. [Google Scholar] [CrossRef]

- Zhu, B.; Liu, H.; Li, W.; Wu, C.; Chai, C. Fracture behavior of permeable asphalt mixtures with steel slag under low temperature based on acoustic emission technique. Sensors 2020, 20, 5090. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Ling, T.Q.; Huang, Z.H. Experiment study on crack resistance performance of asphalt pavement stress-absorbing layer based on fracture energy. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2012, 31, 966–969. (In Chinese) [Google Scholar]

- Rasheed, M.A.; Prakash, S.S.; Gangadharan, R. Acoustic emission characterization of hybrid fiber reinforced cellular concrete under direct shear loads. Nondestruct. Eval. 2019, 38, 17. [Google Scholar] [CrossRef]

- Wu, J.; Chen, Z.; Feng, M.; Wang, Y.; Han, G. The length of pre-existing fissure effects on the dilatancy behavior, acoustic emission, and strength characteristics of cracked sandstone under different confining pressures. Environ. Earth Sci. 2018, 77, 1–14. [Google Scholar] [CrossRef]

- Mclaskey, G.C.; Glaser, S.D.; Grosse, C.U. Beamforming array techniques for acoustic emission monitoring of large concrete structures. J. Sound. Vib. 2010, 329, 2384–2394. [Google Scholar] [CrossRef]

- Lu, Y.; Li, W.; Wang, L.; Meng, X.; Wang, B.; Zhang, K.; Zhang, X. In-situ microscale visualization experiments on microcracking and microdeformation behaviour around a pre-crack tip in a three-point bending sandstone. Int. J. Rock Mech. Min. Sci. 2019, 114, 175–185. [Google Scholar] [CrossRef]

| Index | Diameter (um) | Specific Gravity (g/cm3) | Tensile Strength (Mpa) | Elasticity Modulus (Gpa) | Elongation (%) |

|---|---|---|---|---|---|

| Value | 13 | 2.7–3.1 | 2700 | 65 | 2.5–2.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; He, Z.; Li, D.; Xu, H.; Kong, L. Experimental Study on Basalt Fiber Crack Resistance of Asphalt Concrete Based on Acoustic Emission. Materials 2021, 14, 4096. https://doi.org/10.3390/ma14154096

Yang K, He Z, Li D, Xu H, Kong L. Experimental Study on Basalt Fiber Crack Resistance of Asphalt Concrete Based on Acoustic Emission. Materials. 2021; 14(15):4096. https://doi.org/10.3390/ma14154096

Chicago/Turabian StyleYang, Kang, Zhaoyi He, Dongxue Li, Hao Xu, and Lin Kong. 2021. "Experimental Study on Basalt Fiber Crack Resistance of Asphalt Concrete Based on Acoustic Emission" Materials 14, no. 15: 4096. https://doi.org/10.3390/ma14154096

APA StyleYang, K., He, Z., Li, D., Xu, H., & Kong, L. (2021). Experimental Study on Basalt Fiber Crack Resistance of Asphalt Concrete Based on Acoustic Emission. Materials, 14(15), 4096. https://doi.org/10.3390/ma14154096