Fabrication of the Zirconium Diboride-Reinforced Composites by a Combination of Planetary Ball Milling, Turbula Mixing and Spark Plasma Sintering

Abstract

:1. Introduction

2. Test Materials and Methods

- 316 L steel + 5 wt% ZrB2

- 316 L steel + 10 wt% ZrB2

- Dry mixing in a Turbula T-2C mixer (Willy A. Bachofen AG, Muttenz, Switzerland) for 8 h. Steel balls with a diameter of 5 mm were used to homogenize each mixture.

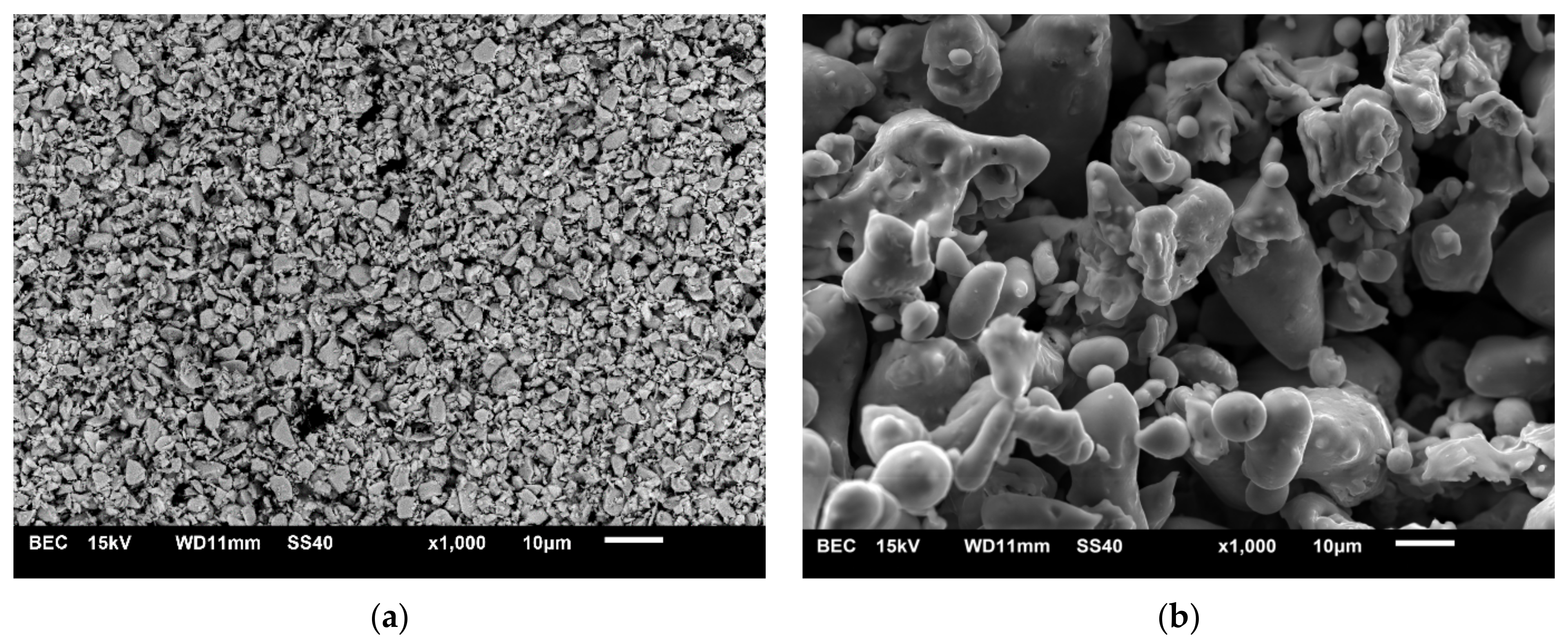

- Milling in a Fritsch Pulverisette 6 planetary mill (Fritsch GmbH -Germany) using a 5 mm diameter milling beaker and balls made of tungsten carbide. The rotational speed of the grinder was 200 rpm and the milling time was 8 h. A solution of polyethylene glycol in ethanol was used as the wetting medium. The milling balls:ground powder weight ratio was 10:1.

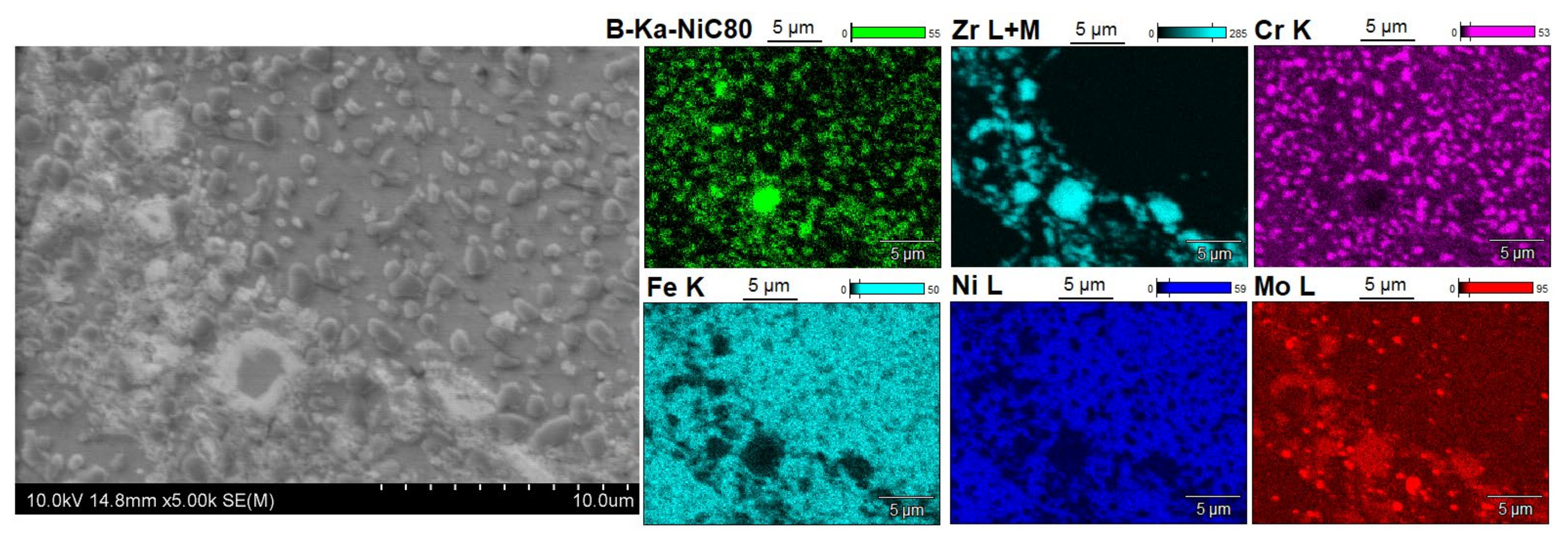

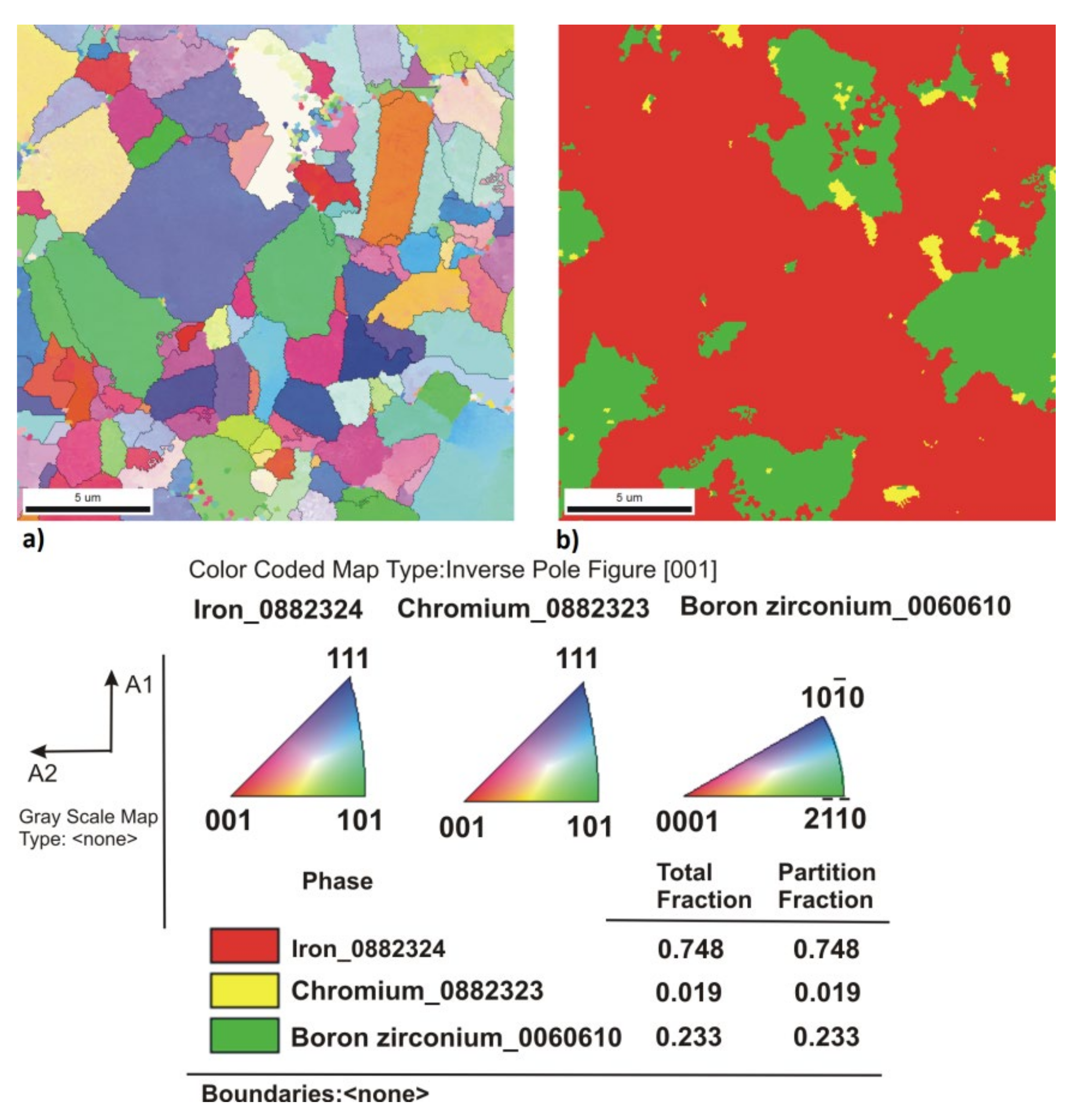

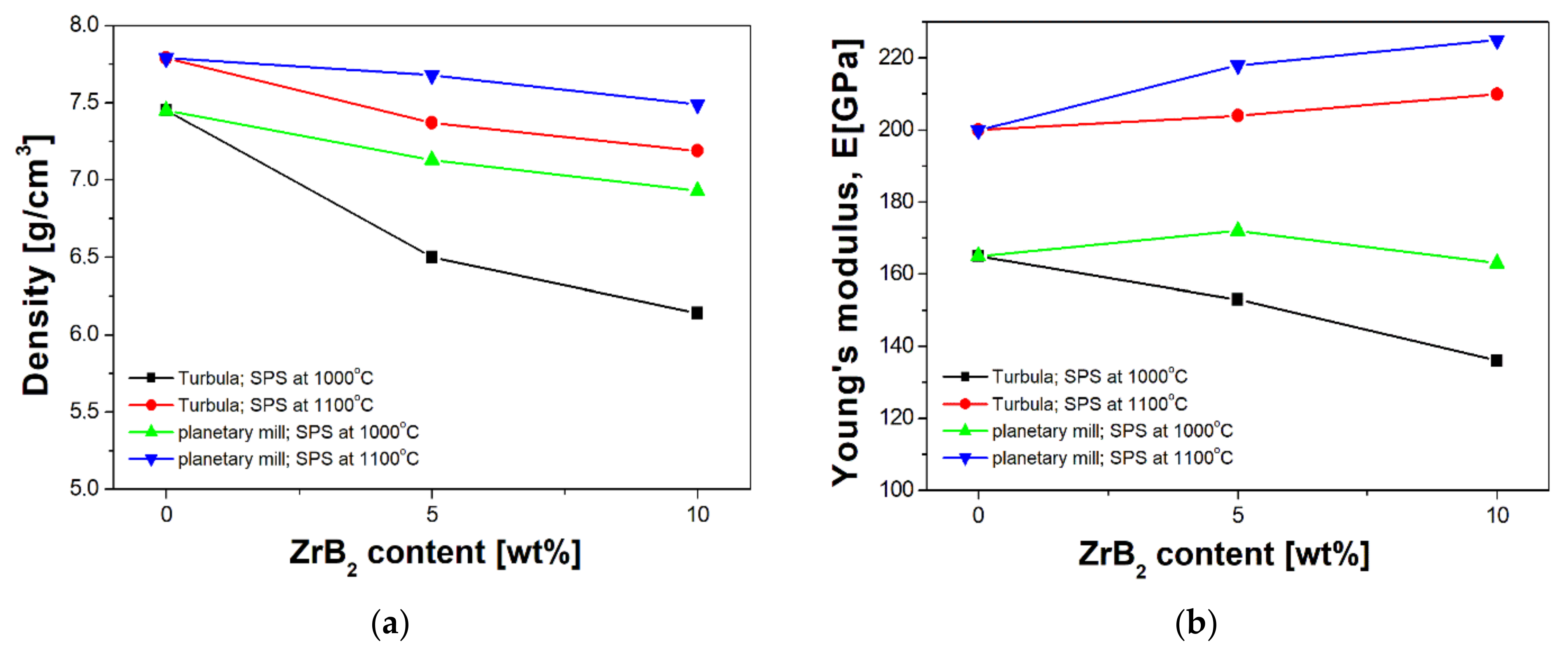

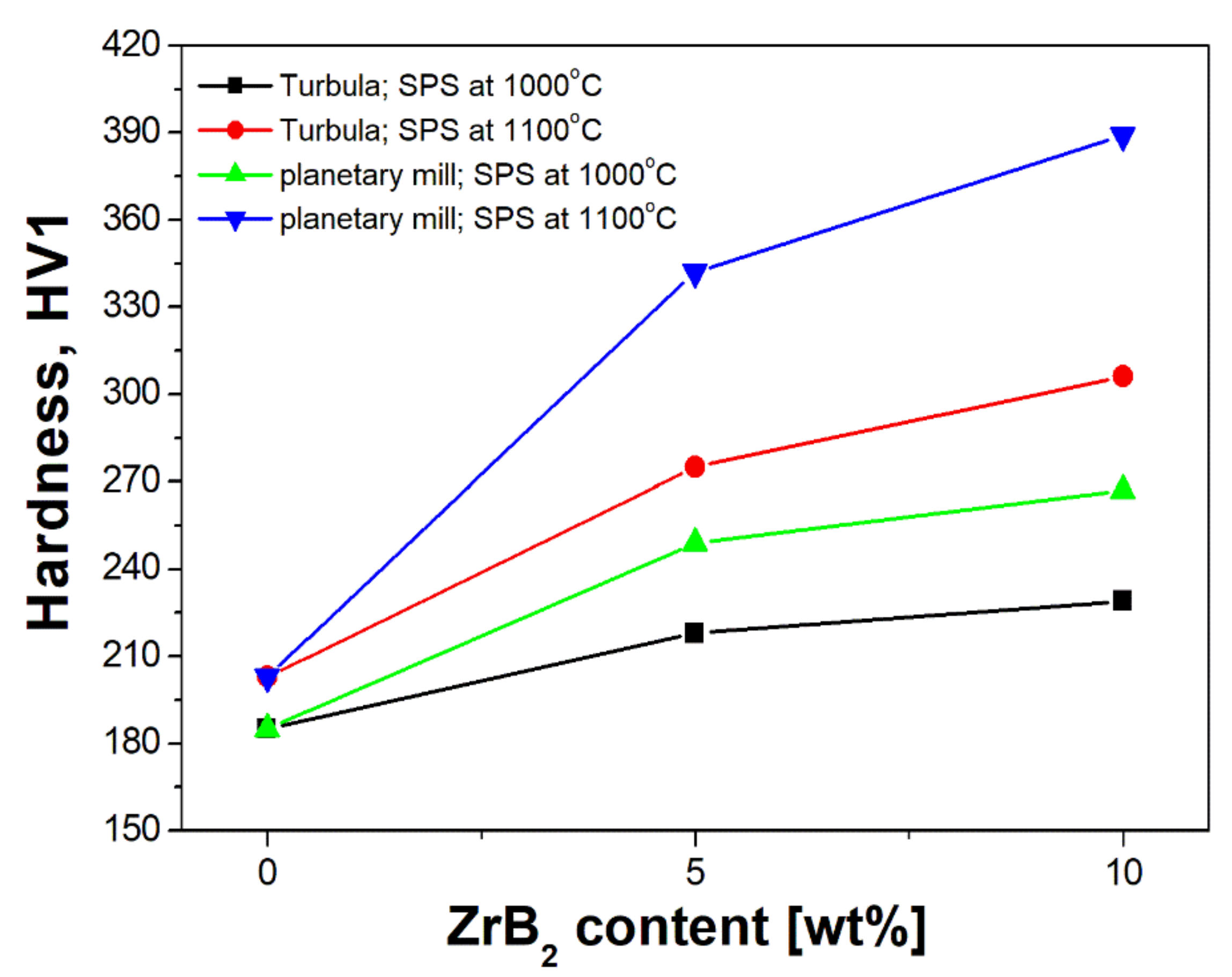

3. Results and Discussion

4. Conclusions

- The test results showed that the sintering temperature of 1000 °C and the SPS method are not sufficient to produce a composite material with high properties.

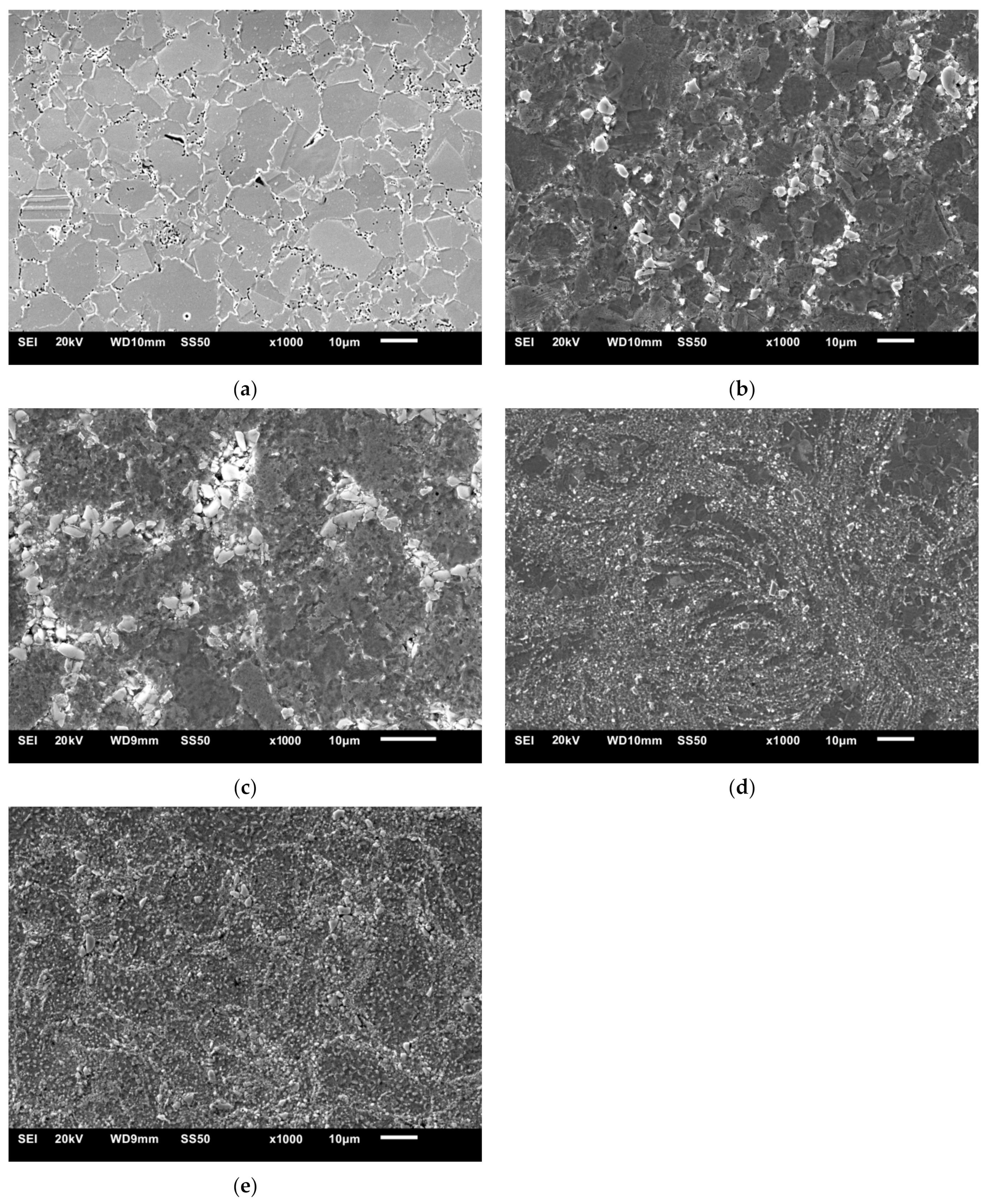

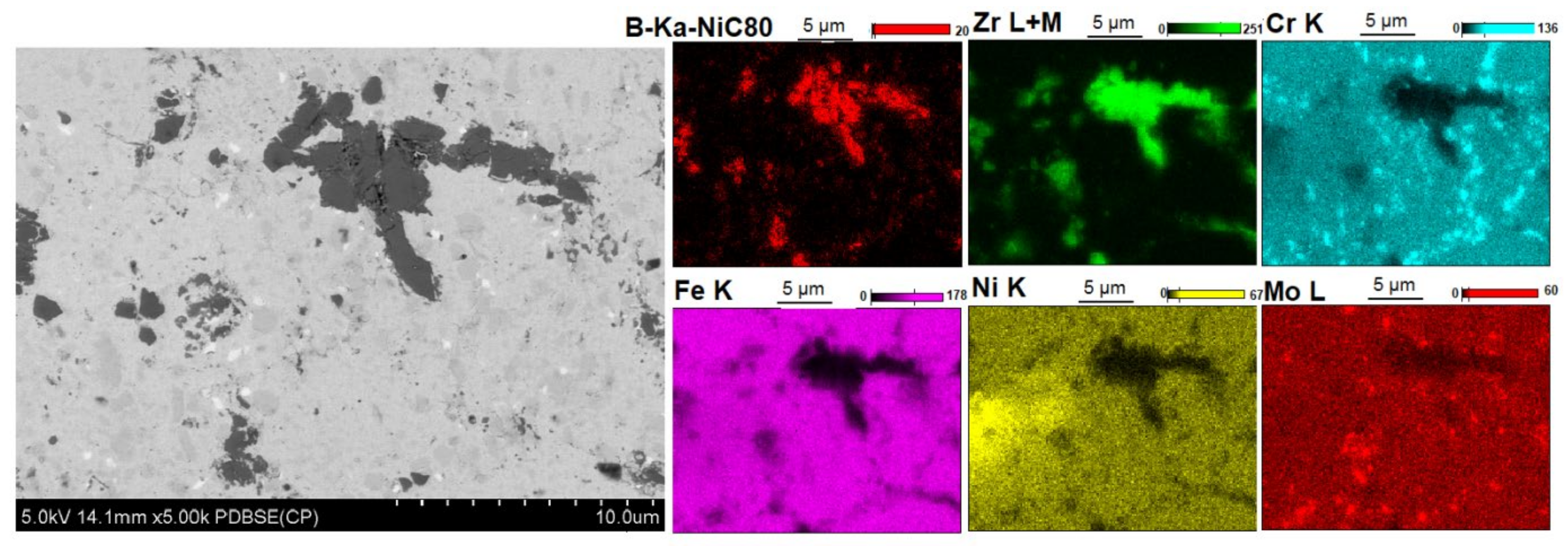

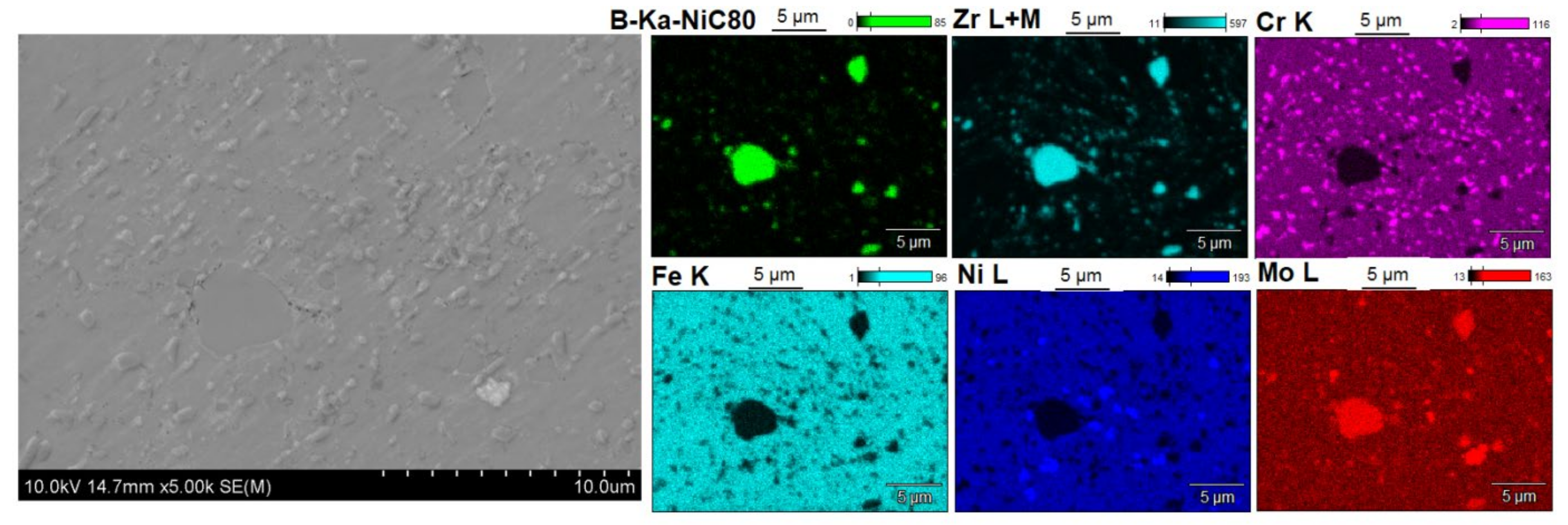

- The microstructure of the sintered composites depends on the method of powder preparation. A heterogeneous distribution of the ZrB2 reinforcing phase in the steel matrix was observed when Turbula mixing was used. Milling in a planetary mill contributed to the refinement and homogeneous dispersion (distribution) of the ZrB2 particles in the matrix. Microstructural examinations additionally revealed the presence of numerous fine precipitates containing chromium and boron.

- The increase in the weight fraction of ZrB2 increased Young’s modulus, hardness and abrasion resistance.

- The method of preparing powders significantly affects the properties of the steel + ZrB2 composites. Milling in a planetary mill is beneficial because all tested composites showed an improvement in density and an increase in Young’s modulus, hardness, strength and wear resistance.

- The most advantageous combination of physical, mechanical and tribological properties was obtained for the steel + 10%ZrB2 composites processed by milling in a planetary mill and sintered by SPS at a temperature of 1100 °C for the time of 5 min.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sano, T.; Srivatsan, T.S.; Peretti, M. (Eds.) Advanced Composites for Aerospace, Marine, and Land Applications II; Wiley and Sons, Inc.: Hoboken, NJ, USA, 2015. [Google Scholar]

- Brautman, L.J.; Krock, R.H. Composite Materials; Academic Press: New York, NY, USA, 1975. [Google Scholar]

- Prosviryakov, A.S. SiC content effect on the properties of Cu–SiC composites produced by mechanical alloying. J. Alloy. Compd. 2015, 632, 707–710. [Google Scholar] [CrossRef]

- Pagounis, E.; Lindroos, V.K. Processing and properties of particulate reinforced steel matrix composites. Mater. Sci. Eng. 1998, A246, 221–234. [Google Scholar] [CrossRef]

- Wessley, J.G.J.; Srinivas, S.; Ali, M.D.A. Preparation and characterization of an aluminium 6061 alloy based metal matrix composite. Int. J. Eng. Adv. Technol. 2019, 8, 113–116. [Google Scholar]

- Cao, H.-C.; Liang, Y.-L. Dislocation hardening and phase transformation-induced high ductility in Ti-6Al-4V with a heterogeneous martensitic microstructure under tensile load. J. Alloy. Compd. 2020, 812, 152057. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Hu, X.; Wu, K. Effects of hot extrusion on microstructure and mechanical properties of Mg matrix composite reinforced with deformable TC4 particles. J. Magnes. Alloy. 2020, 8, 421–430. [Google Scholar] [CrossRef]

- Sulima, I.; Boczkal, S.; Jaworska, L. SEM and TEM characterization of microstructure of stainless steel composites reinforced with TiB2. Mater. Charact. 2016, 118, 560–569. [Google Scholar] [CrossRef]

- Cabeza, M.; Feijoo, I.; Merino, P.; Pena, G.; Pérez, M.C.; Cruz, S.; Rey, P. Effect of high energy ball milling on the morphology, microstructure and properties of nano-sized TiC particle-reinforced 6005A aluminium alloy matrix composite. Powder Technol. 2017, 321, 31–43. [Google Scholar] [CrossRef]

- Nourouzi, S.; Damavandi, E.; Rabiee, S.M. Microstructural and mechanical properties of Al-Al2O3 composites focus on experimental techniques. Int. J. Microstruct. Mater. Prop. 2016, 11, 383–398. [Google Scholar]

- Zhang, C.; Zeng, Y.P.; Yao, D.; Yin, J.; Zuo, K.; Xia, Y.; Liang, H. The improved mechanical properties of Al matrix composites reinforced with oriented-Si3N4 whisker. J. Mater. Sci. Technol. 2019, 35, 1345–1353. [Google Scholar] [CrossRef]

- Wang, C.; Lin, H.; Zhang, Z.; Li, W. Fabrication, interfacial characteristics and strengthening mechanisms of ZrB2 microparticles reinforced Cu composites prepared by hot-pressed sintering. J. Alloy. Compd. 2018, 748, 546–552. [Google Scholar] [CrossRef]

- Mondi, R.K.; Golla, B.R. Processing and characterization of super strong and wear resistant Al–5Cu-(0–20 vol%) ZrB2 composites. J. Alloy. Compd. 2020, 814, 152323. [Google Scholar] [CrossRef]

- Sivakumar, S.; Golla, B.R.; Rajulapati, K.V. Influence of ZrB2 hard ceramic reinforcement on mechanical and wear properties of aluminum. Ceram. Int. 2019, 45, 7055–7070. [Google Scholar] [CrossRef]

- Sulima, I.; Hyjek, P.; Jaworska, L.; Perek-Nowak, M. Influence of ZrB2 on Microstructure and Properties of Steel Matrix Composites Prepared by Spark Plasma Sintering. Materaials 2020, 13, 2459. [Google Scholar] [CrossRef] [PubMed]

- Fahrenholtz, W.G.; Hilmas, G.E.; Talmy, I.G.; Zaykoski, J.A. Refractory diborides of zirconium and hafnium. J. Eur. Ceram. Soc. 2007, 90, 1347–1364. [Google Scholar] [CrossRef]

- Chamberlain, A.L.; Fahrenholtz, W.G.; Hilmas, G.E.; Ellerby, D.T. High-strength zirconium diboride-based ceramics. J. Am. Ceram. Soc. 2010, 87, 1170–1172. [Google Scholar] [CrossRef]

- Morz, C. Annual mineral review. Zirconium diboride. Am. Ceram. Soc. Bull. 1995, 74, 165–166. [Google Scholar]

- Durga, V.N.; Bala, K.B.; Gopi, K.M. Impact of dry sliding wear parameters on the wear rate of A7075 based composites reinforced with ZrB2 particulates. J. Mater. Res. Technol. 2021, in press. [Google Scholar]

- Dinaharan, I.; Murugan, N.; Parameswaran, S. Influence of insitu formed ZrB2 particles on microstructure and mechanical properties of AA6061 metal matrix composites. Mater. Sci. Eng. A 2011, 528, 5733–5740. [Google Scholar] [CrossRef]

- Kumar, N.; Gautam, R.K.; Mohan, S. In-situ development of ZrB2 particles and their effect on microstructure and mechanical properties of AA5052 metal matrix composites. Mater. Des. 2015, 80, 129–136. [Google Scholar] [CrossRef]

- Fan, X.; Huang, X.; Liu, Q.; Ding, H.; Wang, H.; Hao, C. The microstructures and properties of in-situ ZrB2 reinforced Cu matrix composites. Results Phys. 2019, 14, 102494. [Google Scholar] [CrossRef]

- Akhtar, F.; Shiju, G. On the processing, microstructure, mechanical and wear properties of cermet/stainless steel layer composites. Acta Mater. 2007, 55, 1467–1477. [Google Scholar]

- Tavares, S.S.M.; Moura, V.; Costa, V.C.; Ferreira, M.L.R.; Pardal, J.M. Microstructural changes and corrosion resistance of AISI 310S steel exposed to 600–800 °C. Mater. Charact. 2009, 60, 573–578. [Google Scholar] [CrossRef]

- Patel, M.; Vaidyanathan, R.M.; Sivaraman, N. Corrosion behavior of sintered 316 L austenitic stainless steel composites. Int. J. Mech. Eng. Technol. 2014, 5, 121–128. [Google Scholar]

- Vardavoullus, M.; Jeandin, M.; Velasco, F.; Torralba, J.M. Dry sliding wear mechanism for P/M austenitic stainless steels and their composites containing Al2O3 and Y2O3 particles. Tribol. Int. 1996, 29, 499–506. [Google Scholar] [CrossRef]

- Feizabadi, J.; Vahdati, K.J.; Haddad, S.M.; Sharifitabar, M.; Sanni, S.A. Fabrication of in situ Al2O3 reinforced nanostructure 304 stainless steel matrix composite by self-propagating high temperature synthesis process. Mater. Des. 2015, 84, 325–330. [Google Scholar] [CrossRef]

- Li, B.; Liu, Y.; Li, J.; Cao, H.; He, L. Effect of sintering process on the microstructures and properties of in situ TiB2–TiC reinforced steel matrix composites produced by spark plasma sintering. J. Mater. Process. Technol. 2010, 210, 91–95. [Google Scholar] [CrossRef]

- Jain, J.; Kar, A.M.; Upadhyaya, A. Effect of YAG addition on sintering of P/M 316 L and 434L stainless steels. Mater. Lett. 2004, 8, 2037–2040. [Google Scholar] [CrossRef]

- Nahme, H. Mechanical property under high dynamic loading and microstructure evaluation of a TiB2 particle-reinforced stainless steel. J. Mater. Sci. 2009, 44, 463–468. [Google Scholar] [CrossRef]

- Shamsuddin, S.; Jamaludin, S.B.; Hussain, Z.; Ahmed, Z.A. The Effects of Al2O3 Amount on the Microstructure and Properties of Fe-Cr Matrix Composites. Metall. Mater. Trans. 2010, 41A, 3452–3457. [Google Scholar] [CrossRef]

- Akhtar, F.; Ali, L.; Peizhong, F.; Shah, J.A. Enhanced sintering, microstructure evolution and mechanical properties of 316 L stainless steel with MoSi2 addition. J. Alloy. Compd. 2011, 509, 8794–8797. [Google Scholar] [CrossRef]

- Ziejewska, C.; Marczyk, J.; Szewczyk-Nykiel, A.; Nykiel, M.; Hebda, M. Influence of size and volume share of WC particles on the properties of sintered metal matrix composites. Adv. Powder Technol. 2019, 30, 835–842. [Google Scholar] [CrossRef]

- Taylor, R.P.; McClain, S.T.; Berrt, J.T. Uncertainty analysis of metal-casting porosity measurements using Archimedes’ principle. Int. J. Cast Met. Res. 1999, 11, 247–257. [Google Scholar] [CrossRef]

- OIM Data Collection, Orientation Imaging Microscopy v7; edition 7.3, EDAX, 2015.

- International Standard. Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Friction and Wear Characteristics of Monolithic Ceramics by Ball-On-Disc Method; ISO 20808:2016(E); International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Kang, S.L. Sintering: Densification, Grain Growth and Microstructure; Elsevier Bitterworth-Heinemann: Burlington, MA, USA, 2005. [Google Scholar]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 464, 1–184. [Google Scholar] [CrossRef]

- Kulecki, P.; Lichańska, E. The effect of poweder ball milling on themicrostructure and mechanical properties of sintered Fe-Cr-Mo-Mn-(Cu) steel. Powder Metall. Prog. 2017, 17, 82–92. [Google Scholar] [CrossRef] [Green Version]

- Suryanarayana, C.; Ivanov, E.; Boldyrev, V.V. The science and technology of mechanical alloying. Mater. Sci. Eng. 2001, A304–306, 151–158. [Google Scholar] [CrossRef]

- Sulima, I. Role of boron addition on the consolidation and properties of steel composites prepared by SPS. Bull. Mater. Sci. 2015, 38, 1831–1841. [Google Scholar] [CrossRef]

- Molinari, A.; Straffelini, G.; Pieczonka, T.; Kazior, J. Persistent liquid phase sintering of 316 L stainless steel. Int. J. Power Metall. 1998, 34, 21–28. [Google Scholar]

- Molinari, A.; Menapace, C.; Kazior, J.; Pieczonka, T. Liquid phase sintering of boron alloyed austenitic stainless steel. Mater. Sci. 2007, 534–536, 553–556. [Google Scholar]

- CRC. Materials Science and Engineering Handbook, 3rd ed.; James, F., Ed.; Shackelford and William Alexander CRC Press: Boca Raton, FL, USA, 2001; p. 509. [Google Scholar]

- McGuire, M.F. Stainless Steels for Design Engineers; ASM International: Materials Park, OH, USA, 2008; pp. 69–78. [Google Scholar]

- Salur, E.; Acarer, M.; Savkliyildiz, I. Improving mechanical properties of nano-sized TiC particle reinforced AA7075 Al alloy composites produced by ball milling and hot pressing. Mater. Today Commun. 2021, 27, 102202. [Google Scholar] [CrossRef]

- Zhang, B.; Bi, G.; Wang, P.; Bai, J.; Chew, Y.; Nai, M.S. Microstructure and mechanical properties of Inconel 625/nano-TiB2 composite fabricated by LAAM. Mater. Des. 2016, 111, 70–79. [Google Scholar] [CrossRef]

- Tjong, S.C.; Lau, K.C. Abrasion resistance of stainless-steel composites reinforced with hard TiB2 particles. Compos. Sci. Technol. 2000, 60, 1141–1146. [Google Scholar] [CrossRef]

- Ni, Z.F.; Sun, Y.S.; Xue, F.; Bai, J.; Lu, Y.J. Microstructure and properties of austenitic stainless steel reinforced with in situ TiC particulate. Mater. Des. 2011, 32, 1462–1467. [Google Scholar] [CrossRef]

- Unifantowicz, P.; Oksiuta, Z.; Olier, P.; Carlan, Y.; Baluc, N. Microstructure and mechanical properties of an ODS RAF steel fabricated by hot extrusion or hot isostatic pressing. Fusion Eng. Des. 2011, 86, 2413–2416. [Google Scholar] [CrossRef] [Green Version]

- Sulima, I.; Kowalik, R. Corrosion behaviors, mechanical properties and microstructure of the steel matrix composites fabricated b HP-HT method. Mater. Sci. Eng. A 2015, 639, 671–680. [Google Scholar] [CrossRef]

- Matin, A.; Saniee, F.F.; Abedi, H.R. Microstructure and mechanical properties of Mg/SiC and AZ80/SiC nano-composites fabricated through stir casting method. Mater. Sci. Eng. A 2015, 625, 81–88. [Google Scholar] [CrossRef]

- Srivastava, S.A.; Das, K. The abrasive wear resistance of TiC and (Ti,W)C-reinforced Fe–17Mn austenitic steel matrix composites. Tribol. Int. 2010, 43, 944–950. [Google Scholar] [CrossRef]

- Velasco, F.; Lima, W.M.; Anton, N.; Abenojar, J.; Torralba, J.M. Effect of intermetallic particles on wear behaviour of stainless steel matrix composites. Tribol. Int. 2003, 36, 547–551. [Google Scholar] [CrossRef]

| Chemical Composition, wt% | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cr | Ni | Mo | Mn | Si | S | P | C | Fr |

| 17.20 | 12.32 | 2.02 | 0.43 | 0.89 | 0.03 | 0.028 | 0.027 | balance |

| Wear Test Conditions | |

|---|---|

| Temperature, T | 23 °C |

| ball | Al2O3 |

| ball diameter, d | 3.175 mm |

| load applied, Fn | 5 N |

| friction track diameter, r | 5.0 mm |

| sliding speed, v | 0.1 m/s |

| total sliding distance, L | 1000 m |

| test duration, t | 10,000 s |

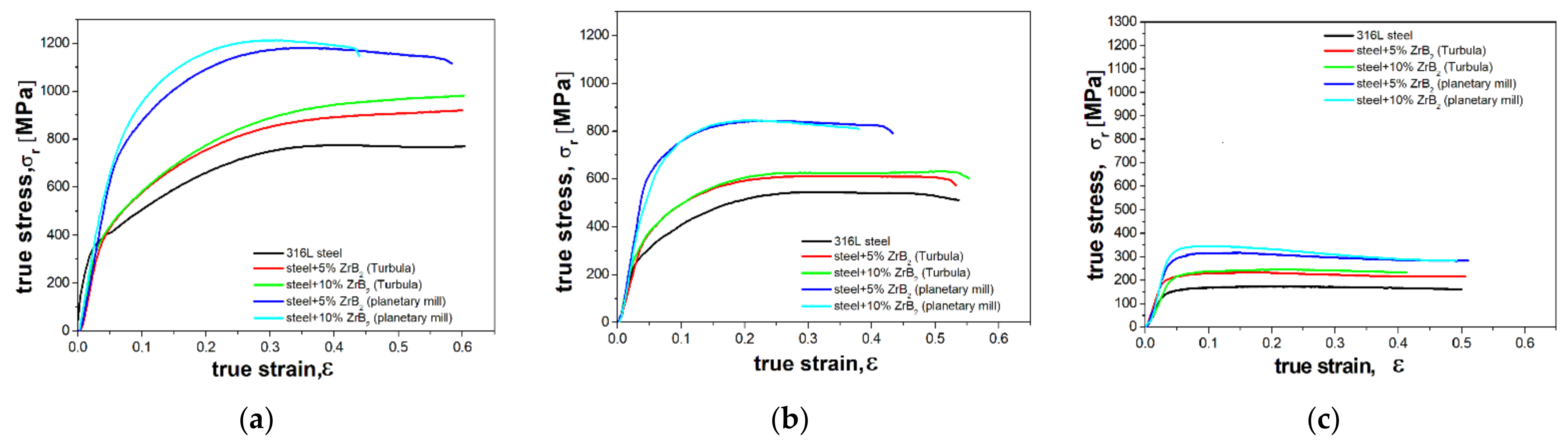

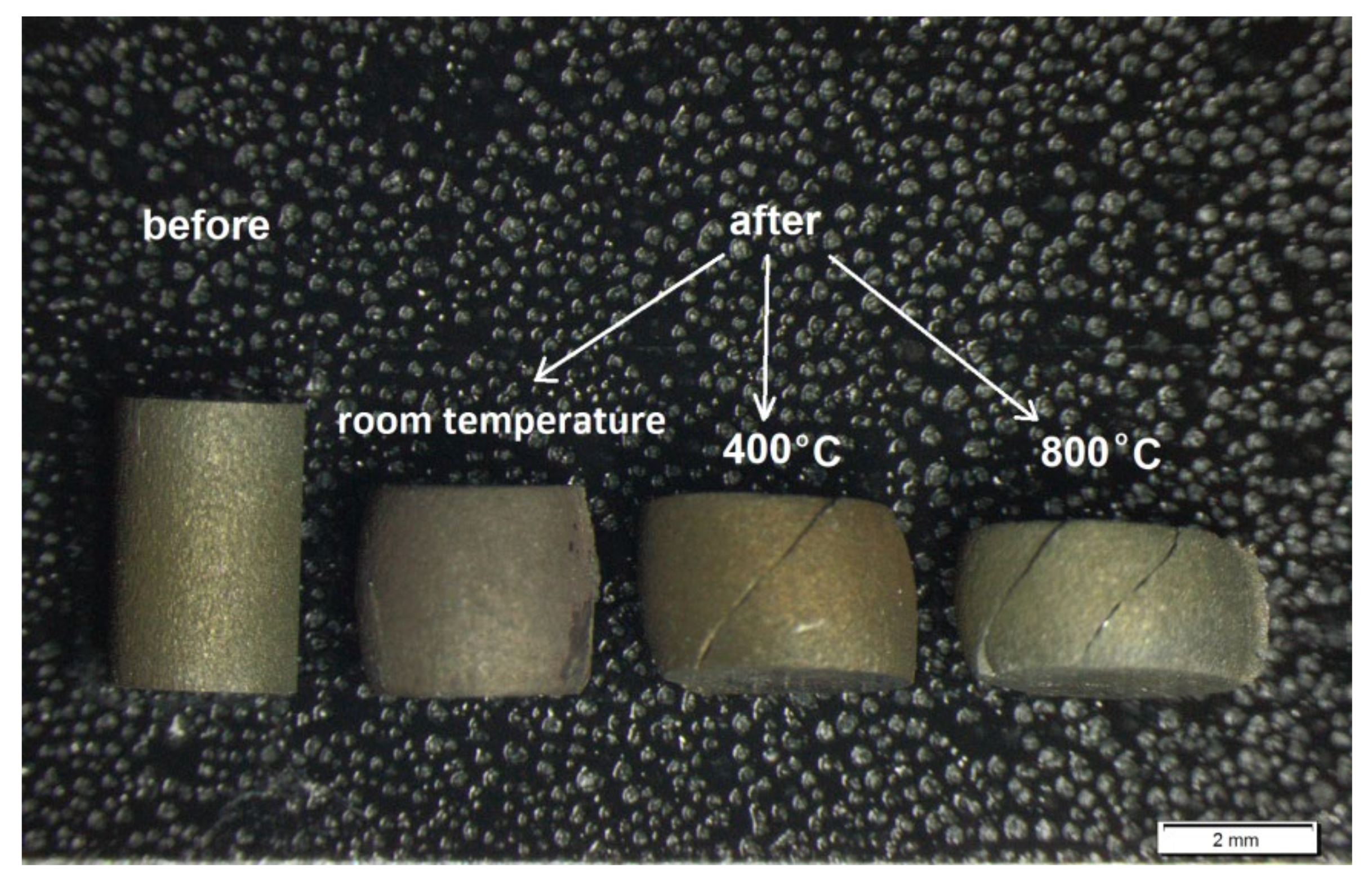

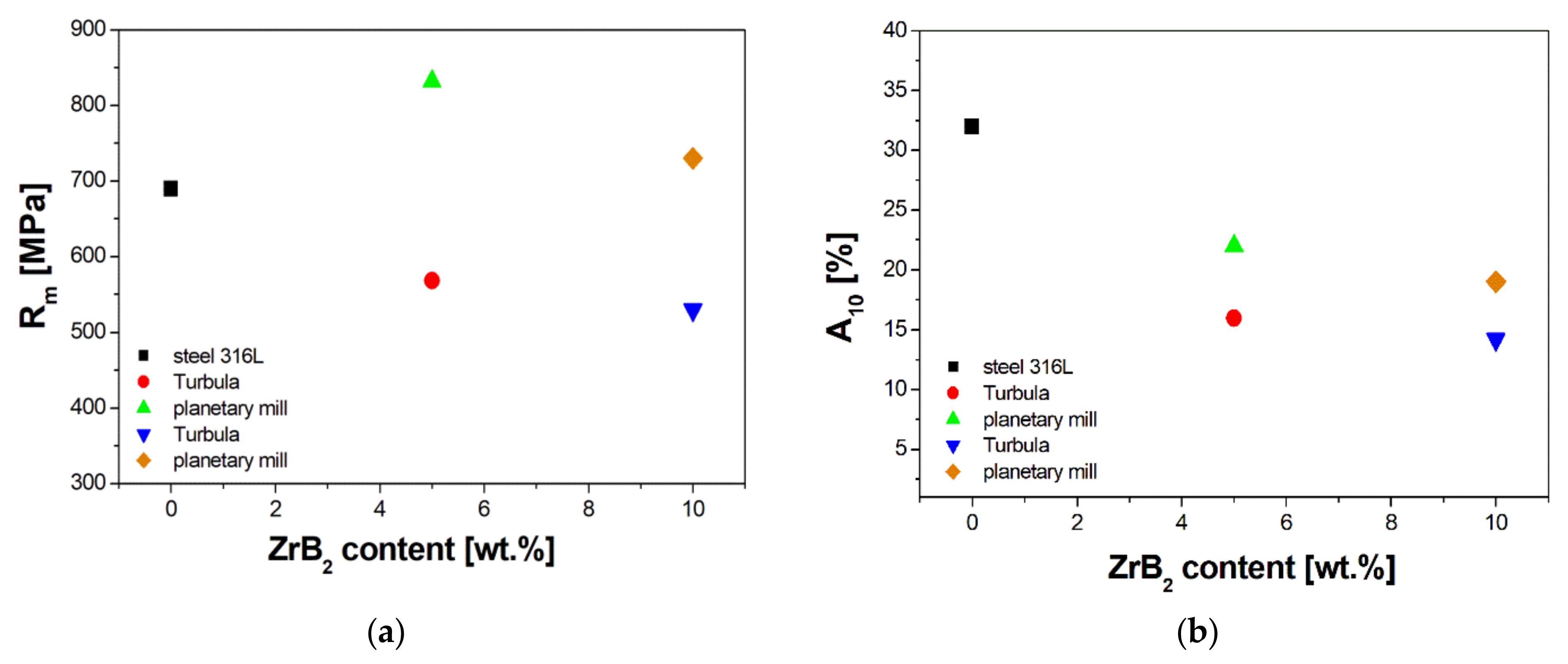

| Sintered Materials | Tensile Strength Rm [MPa] | Elongation A10 [%] | Compressive Strength σc [MPa] | ||

|---|---|---|---|---|---|

| Room Temperature | 400 °C | 800 °C | |||

| 316 L steel | 690 | 32 | 774 | 545 | 167 |

| steel + 5%ZrB2 (Turbula) | 568 | 14.3 | 919 | 608 | 234 |

| steel + 10%ZrB2 (Turbula) | 530 | 21 | 980 | 639 | 245 |

| steel + 5%ZrB2 (planetary mill) | 832 | 21.7 | 1164 | 837 | 317 |

| steel + 10%ZrB2 (planetary mill) | 730 | 15.7 | 1238 | 848 | 326 |

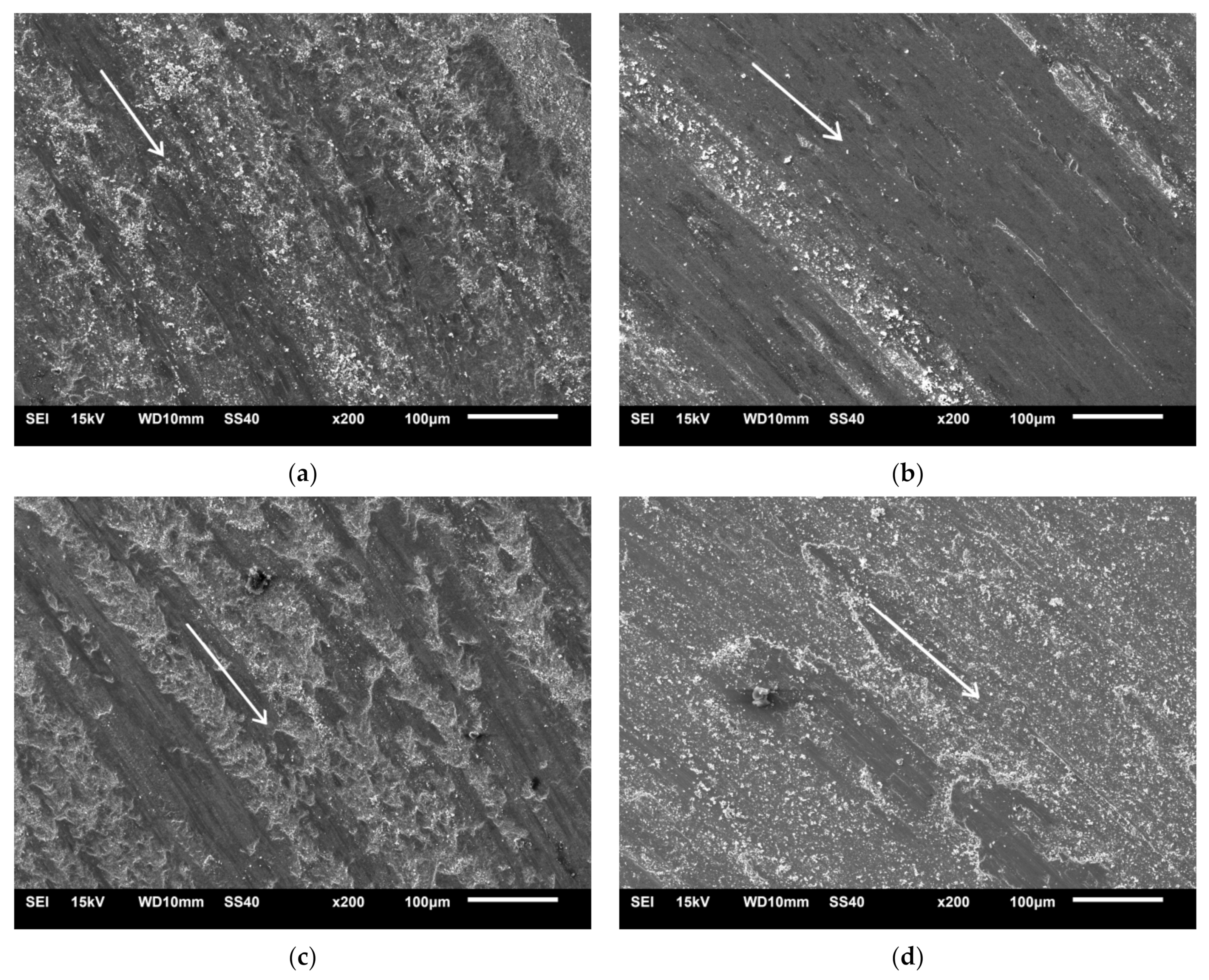

| Sintered Materials | Coefficient of Friction µ [-] | Specific Wear Rate Wv [mm3/Nm] |

|---|---|---|

| 316 L steel | 0.64 | 32.5 × 10−6 |

| steel + 5%ZrB2 (Turbula) | 0.55 | 24.6 × 10−6 |

| steel + 10%ZrB2 (Turbula) | 0.47 | 16.9 × 10−6 |

| steel + 5%ZrB2 (planetary mill) | 0.51 | 19.4 × 10−6 |

| steel + 10%ZrB2 (planetary mill) | 0.40 | 13.1 × 10−6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sulima, I.; Hyjek, P.; Podsiadło, M. Fabrication of the Zirconium Diboride-Reinforced Composites by a Combination of Planetary Ball Milling, Turbula Mixing and Spark Plasma Sintering. Materials 2021, 14, 4056. https://doi.org/10.3390/ma14144056

Sulima I, Hyjek P, Podsiadło M. Fabrication of the Zirconium Diboride-Reinforced Composites by a Combination of Planetary Ball Milling, Turbula Mixing and Spark Plasma Sintering. Materials. 2021; 14(14):4056. https://doi.org/10.3390/ma14144056

Chicago/Turabian StyleSulima, Iwona, Paweł Hyjek, and Marcin Podsiadło. 2021. "Fabrication of the Zirconium Diboride-Reinforced Composites by a Combination of Planetary Ball Milling, Turbula Mixing and Spark Plasma Sintering" Materials 14, no. 14: 4056. https://doi.org/10.3390/ma14144056

APA StyleSulima, I., Hyjek, P., & Podsiadło, M. (2021). Fabrication of the Zirconium Diboride-Reinforced Composites by a Combination of Planetary Ball Milling, Turbula Mixing and Spark Plasma Sintering. Materials, 14(14), 4056. https://doi.org/10.3390/ma14144056