Parametric Studies of the Load Transfer Platform Reinforcement Interaction with Columns

Abstract

:1. Introduction

2. Numerical Model of Reinforcement and Its Calibration

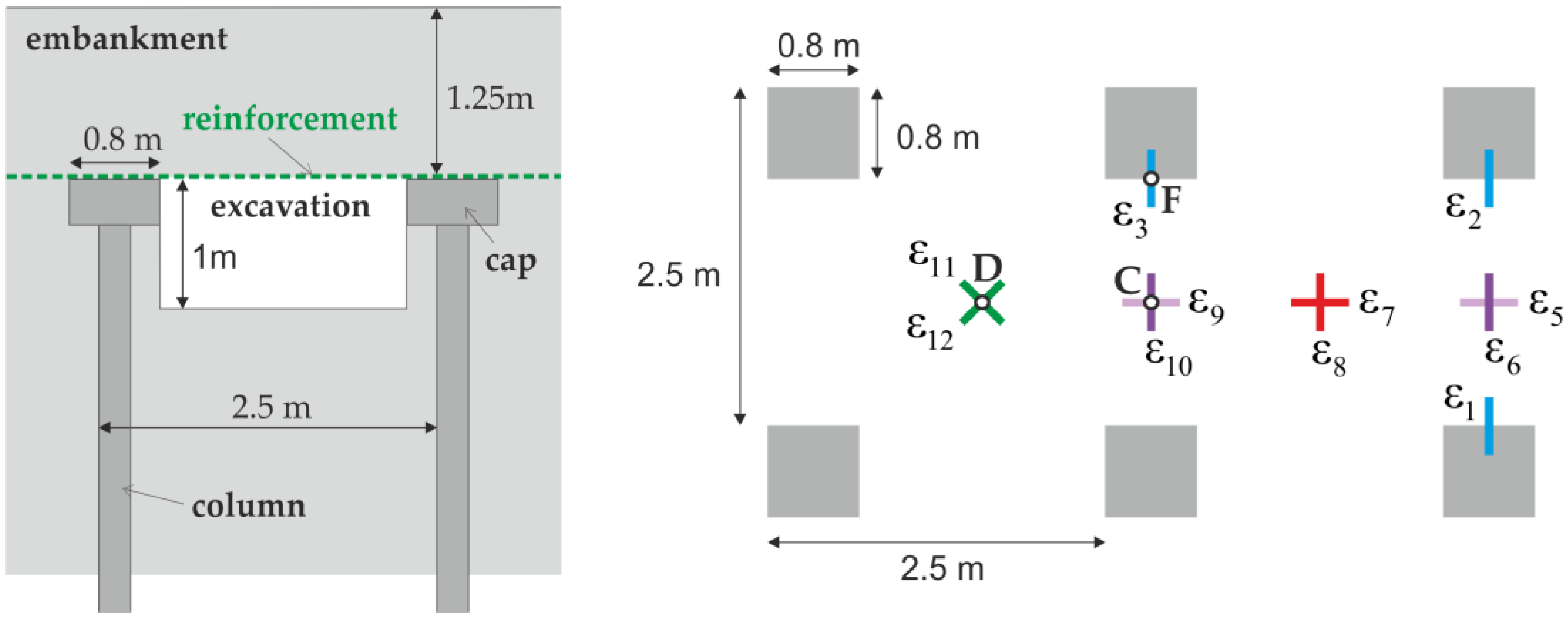

2.1. A Full Scale Experiment

2.2. Results of Strains and Displacement Measurements of the Reinforcement

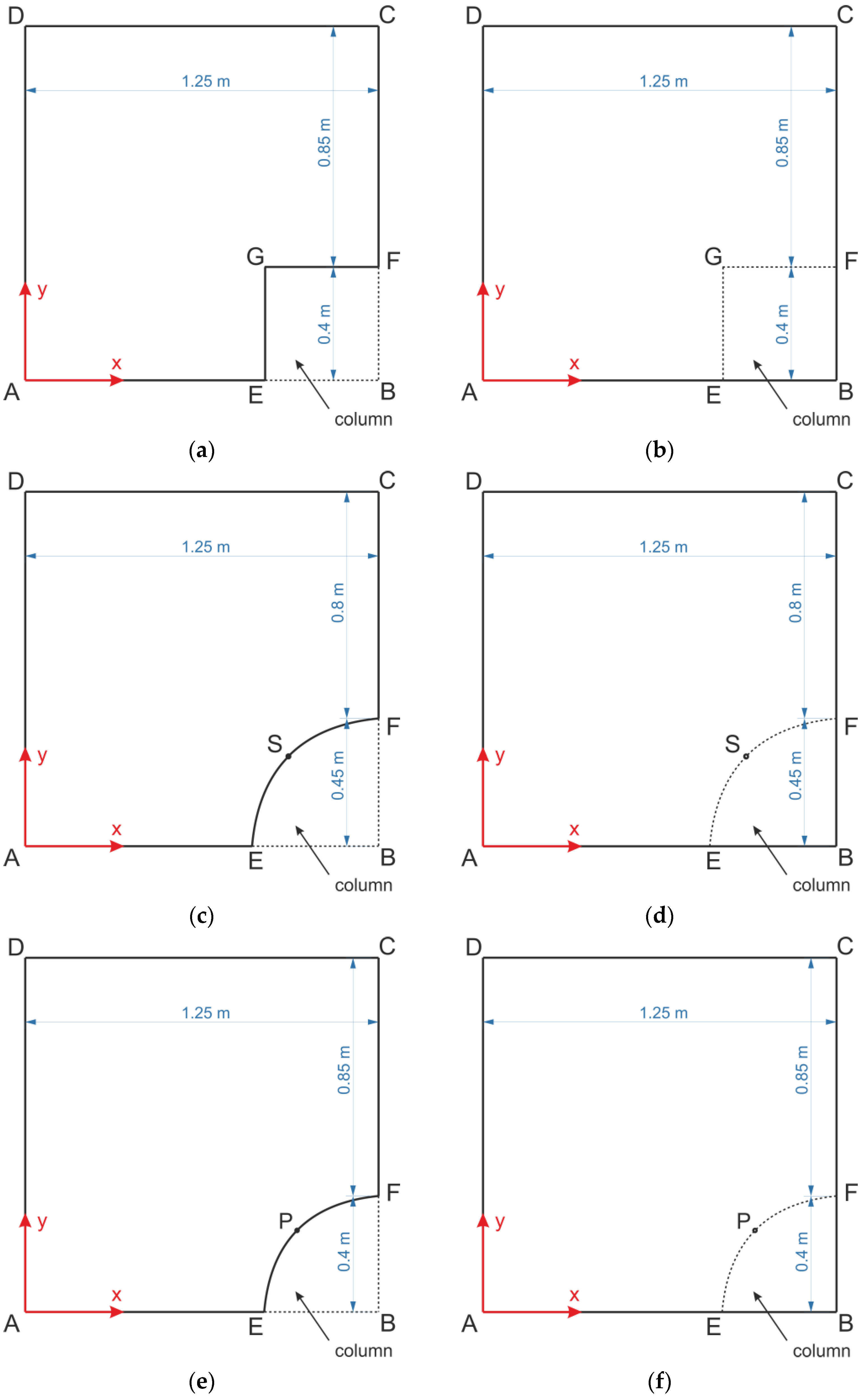

2.3. FEM Numerical Model

2.4. Convergence Analysis

2.5. Calibration of the Model with the Results of Deformation Measurements

3. Research Results and Discussion

3.1. Effect of the Geometric Model on the Obtained Results

3.2. Effect of the Poisson’s Ratio Value

3.3. Effect of Soft Soil Stiffness

3.4. Effect of Load Distribution

- —the maximum value of the load at the top of the pyramid,

- —distance AB (compare Figure 3).

- —the maximum value of the load at the edges of the column,

- —distance AB (compare Figure 3).

4. Conclusions

- In the case of the arrangement of columns in a square and the absence of soft soil (k = 0 kN/m3), the greatest strains of the reinforcement are located in the direction of diagonals between the columns. This happens regardless of the shape of the column/cap (square, round) and the boundary conditions used. Interestingly, the greatest strains are not always located at the edge of the cap, but at some distance from the cap.

- The stiffness value of a soft soil significantly affects both the value and distribution of strains in the membrane. As the soft soil subgrade reaction coefficient k increases gradually, the highest strain begins to localize around the cap. In the case of round-shaped caps, the leveling of strains around the cap occurs much faster than in the case of square caps. In the case of square caps (variant A2) for the ratio J/k = 3.23, the uniform distribution of the biggest membrane strain around the column can be seen, while in the case of round caps, an almost even distribution of the largest strains of the membrane around the pile cap can be observed for the ratio J/k = 10.77.

- The value of the Poisson’s ratio adopted for the membrane material has an impact on the strain distribution in the reinforcement modeling membrane. This influence is visible both in the case of the strain values at the edge of the column and in the middle of the span between the columns, as well as the location of the maximum strains in relation to the edge of the column.

- In numerical calculations, the manner of implementing the boundary conditions has a significant impact on the values and distributions of individual quantities. Thus, in practical applications, the choice of proper boundary conditions in particular cases is an essential thing.

- The influence of geometry on the deflection values is visible when the soft soil between the columns is characterized by no or low stiffness values. With the increase of the soft soil stiffness (reduction of the ratio of the reinforcement stiffness to the subgrade reaction coefficient), the influence of the geometric variant on the maximum deflection of the membrane is no longer visible. However, the values of strains in the points of maximum deflection remained different, depending on the geometric variant in the entire range of the analyzed ratios of reinforcement stiffness to soft soil stiffness (subgrade reaction k).

- The use of round caps prevents stress concentration in the corners and significant strain values of the reinforcement in these places.

- Proposed load distributions in 3D conditions in the form of a pyramid and an inverse pyramid are original when applied for LTP modelling. The strain distributions and maximum strain values are verified by comparison with experimental data. Both proposed distributions properly model the shape functions in cross-sections CF and DG, but only pyramid shape distribution allows for proper modelling of the strain function in cross-section DC. On the other hand, the values obtained with assumption of the load equivalence are not equal to those observed in the experiment, so the natural consequence may be for example neglecting this assumption and looking for appropriate scaling factors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Białek, K.; Bałachowski, L. Parametry mechaniczne platformy roboczej na podstawie badań DMT. Acta Sci. Pol. Archit. 2016, 15, 31–41. [Google Scholar]

- Sołtys, G.; Brzozowski, T. Analiza wsteczna zachowania się nasypu drogowego posadowionego na kolumnach z warstwą transmisyjną na podstawie długookresowego monitoringu. Acta Sci. Pol. Archit. 2018, 17, 143–155. [Google Scholar] [CrossRef]

- Terzaghi, K. Theoretical Soil Mechanics; Wiley: New York, NY, USA, 1943. [Google Scholar]

- Pham, T.A.; Dias, D. Comparison and evaluation of analytical models for the design of geosynthetic-reinforced and pile-supported embankments. Geotext. Geomembr. 2021, 49, 528–549. [Google Scholar] [CrossRef]

- Rowe, R.K.; Liu, K.-W. Three-dimensional finite element modelling of a full-scale geosynthetic-reinforced, pile-supported embankment. Can. Geotech. J. 2015, 52, 2041–2054. [Google Scholar] [CrossRef]

- Liu, H.L.; Ng, C.W.W.; Fei, K. Performance of a geogrid-reinforced and pile-supported highway embankment over soft clay: Case study. J. Geotech. Geoenvironmental Eng. 2007, 133, 1483–1493. [Google Scholar] [CrossRef]

- Zhuang, Y.; Wang, K.Y. Three-dimensional behavior of biaxial geogrid in a piled embankment: Numerical investigation. Can. Geotech. J. 2015, 52, 1629–1635. [Google Scholar] [CrossRef]

- Jamsawang, P.; Yoobanpot, N.; Thanasisathit, N.; Voottipruex, P.; Jongpradist, P. Three-dimensional numerical analysis of a DCM column-supported highway embankment. Comput. Geotech. 2016, 72, 42–56. [Google Scholar] [CrossRef]

- Ghosh, B.; Fatahi, B.; Khabbaz, H.; Nguyen, H.H.; Kelly, R. Field study and numerical modelling for a road embankment built on soft soil improved with concrete injected columns and geosynthetics reinforced platform. Geotext. Geomembr. 2021, 49, 804–824. [Google Scholar] [CrossRef]

- Han, J.; Gabr, M.A. Numerical Analysis of Geosynthetic-Reinforced and Pile-Supported Earth Platforms over Soft Soil. J. Geotech. Geoenviron. Eng. 2002, 128, 44–53. [Google Scholar] [CrossRef]

- Yu, Y.; Bathurst, R.J. Modelling of geosynthetic-reinforced column-supported embankments using 2D full-width model and modified unit cell approach. Geotext. Geomembr. 2017, 45, 103–120. [Google Scholar] [CrossRef]

- Meena, N.K.; Nimbalkar, S.; Fatahi, B.; Yang, G. Effects of soil arching on behavior of pile-supported railway embankment: 2D FEM approach. Comput. Geotech. 2020, 123, 103601. [Google Scholar] [CrossRef]

- Girout, R.; Blanc, M.; Thorel, L.; Dias, D. Geosynthetic reinforcement of pile-supported embankments. Geosynth. Int. 2018, 25, 37–49. [Google Scholar] [CrossRef]

- Dias, D.; Grippon, J. Numerical modelling of a pile-supported embankment using variable inertia piles. Struct. Eng. Mech. 2017, 61, 245–253. [Google Scholar] [CrossRef]

- Jennings, K.; Naughton, P.J. Lateral deformation under the side slopes of Piled embankments. In Proceedings of the Geo-Frontiers 2011: Advances in Geotechnical, Dallas, TX, USA, 13–16 March 2011; Han, J., Alzamora, D.E., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2011. [Google Scholar]

- Jennings, K.; Naughton, P.J. Similitude Conditions Modeling Geosynthetic-Reinforced Piled Embankments Using FEM and FDM Techniques. ISRN Civ. Eng. 2012, 2012, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Han, J. Two-dimensional parametric study of geosynthetic-reinforced column-supported embankments by coupled hydraulic and mechanical modeling. Comput. Geotech. 2010, 37, 638–648. [Google Scholar] [CrossRef]

- Wijerathna, M.; Liyanapathirana, D.S. Numerical issues in modelling DCM column-supported embankments featuring post-yield strain-softening: 2D simplified vs. 3D models. Int. J. Geotech. Eng. 2019, 1–10. [Google Scholar] [CrossRef]

- EBGEO. Recommendations for Design and Analysis of Earth Structures Using Geosynthetic Reinforcements; Ernst & Sohn: Berlin, Germany, 2011; ISBN 978-3-433-60093-1. [Google Scholar]

- Gajewska, B.; Gajewski, M. Approximation Method for Evaluation of Strains and Forces in LTP Reinforcement of Embankments on Columns. IOP Conf. Ser. Mater. Sci. Eng. 2019, 661, 012089. [Google Scholar] [CrossRef]

- Hewlett, W.J.; Randolph, M.F. Analysis of piled embankments. Gr. Eng. 1998, 22, 12–18. [Google Scholar]

- Abusharar, S.W.; Zheng, J.-J.; Chen, B.-G.; Yin, J.-H. A simplified method for analysis of a piled embankment reinforced with geosynthetics. Geotext. Geomembr. 2009, 27, 39–52. [Google Scholar] [CrossRef]

- Zaeske, D. Zur Wirkungsweise von unbewehrten und bewehrten mineralischen Tragschichten über pfahlartigen Gründungselementen. Schr. Geotech. Univ. Kassel 2001, 10, 143. [Google Scholar]

- van Eekelen, S.J.M.; Bezuijen, A.; van Tol, A.F. An analytical model for arching in piled embankments. Geotext. Geomembr. 2013, 39, 78–102. [Google Scholar] [CrossRef]

- Sloan, J.A. Column-supported embankments: Full-scale tests and design recommendations. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2011. [Google Scholar] [CrossRef]

- Van Eekelen, S.J.M. Basal Reinforced Piled Embankments—Experiments, Field Studies and the Development and Validation of a New Analytical Design Model. Ph.D. Thesis, Technical University of Delft, Delft, The Netherlands, 2015. [Google Scholar]

- CUR 226. Design Guideline Basal Reinforced Piled Embankments; SBRCURnet/CRC Press: Delft, The Netherlands, 2016. [Google Scholar]

- BS8006–1. Code of Practice for Strengthened/Reinforced Soils and Other Fills; British Standards Institution: London, UK, 2010. [Google Scholar]

- Drusa, M.; Kais, L.; Vlček, J.; Mečár, M. Piled Embankment Design Comparison. Civ. Environ. Eng. 2015, 11, 76–82. [Google Scholar] [CrossRef] [Green Version]

- Wu, P.C.; Feng, W.Q.; Yin, J.H. Numerical study of creep effects on settlements and load transfer mechanisms of soft soil improved by deep cement mixed soil columns under embankment load. Geotext. Geomembr. 2020, 48, 331–348. [Google Scholar] [CrossRef]

- Gajewska, B.; Gajewski, M. Wpływ rozkładu obciążenia ekwiwalentnego na zachowanie membrany modelującej zbrojenie warstwy transmisyjnej. ACTA Sci. Pol. Archit. Bud. 2020, 19, 41–50. [Google Scholar] [CrossRef]

- Almeida, M.S.S.; Ehrlich, M.; Spotti, A.P.; Marques, M.E.S. Embankment supported on piles with biaxial geogrids. Proc. Inst. Civ. Eng. Geotech. Eng. 2007, 160, 185–192. [Google Scholar] [CrossRef]

- Almeida, M.S.S.; Marques, M.E.S.; Almeida, M.C.F.; Mendonça, M.B. Performance of Two “Low” Piled Embankments with Geogrids at Rio de Janeiro. In Proceedings of the First Pan American Geosynthetics Conference & Exhibition, Cancun, Mexico, 2–5 March 2008. [Google Scholar]

- Hibbitt, Karlsson and Sorensen, Inc. ABAQUS Theory Manual, Version 6.1.; Hibbitt, Karlsson and Sorensen, Inc.: Pawtucket, RI, USA, 2000. [Google Scholar]

- Dassault Systèmes. ABAQUS/Standard User’s Manual; Version 6.11; Dassault Systèmes: Velizy-Villacoublay, France, 2011. [Google Scholar]

- Gajewska, B. Nasypy na Podłożu Wzmocnionym Kolumnami ze Zbrojeniem Warstwy Transmisyjnej; Instytut Badawczy Dróg i Mostów: Warszawa, Poland, 2017. [Google Scholar]

- Koda, E.; Osiński, P.; Kiersnowska, A.; Kawalec, J. Stabilizacja georusztem heksagonalnym podłoża pod trasę narciarską na składowisku. Acta Sci. Pol. Archit. 2016, 15, 185–194. [Google Scholar]

- Zhang, Z.; Wang, M.; Ye, G.B.; Han, J. A novel 2D-3D conversion method for calculating maximum strain of geosynthetic reinforcement in pile-supported embankments. Geotext. Geomembr. 2019, 47, 336–351. [Google Scholar] [CrossRef]

- Dassault Systèmes. ABAQUS Theory Manual; Version 6.11; Dassault Systèmes: Velizy-Villacoublay, France, 2011; Available online: http://130.149.89.49:2080/v6.11/pdf_books/THEORY.pdf (accessed on 17 May 2021).

- Jemioło, S.; Gajewski, M. Hipersprężystoplastyczność, 1st ed.; Oficyna Wydawnicza Politechniki Warszawskiej: Warszawa, Poland, 2014; ISBN 978-83-7814-337-6. [Google Scholar]

- Jones, B.M.; Plaut, R.H.; Filz, G.M. Analysis of geosynthetic reinforcement in pile-supported embankments. Part I: 3D plate model. Geosynth. Int. 2010, 17, 59–67. [Google Scholar] [CrossRef]

- Van Eekelen, S.J.M.; Lodder, H.J.; Bezuijen, A. Load distribution on the geosynthetic reinforcement within a piled embankment. In Proceedings of the 15th European Conference on Soil Mechanics and Geotechnical Engineering, Athens, Greece, 12–15 September 2011; Anagnostopoulos, A., Pachakis, M., Tsatsanifos, C., Eds.; IOS Press: Amsterdam, The Netherlands, 2011; pp. 1137–1142. [Google Scholar]

- Fagundes, D.F.; Almeida, M.S.S.; Thorel, L.; Blanc, M. Load transfer mechanism and deformation of reinforced piled embankments. Geotext. Geomembr. 2017, 45, 1–10. [Google Scholar] [CrossRef]

- Filz, G.M.; Sloan, J.A. Load Distribution on Geosynthetic Reinforcement in Column-Supported Embankments. In Proceedings of the Geo-Congress 2013; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 1822–1830. [Google Scholar] [CrossRef]

- Deb, K.; Mohapatra, S.R. Analysis of stone column-supported geosynthetic-reinforced embankments. Appl. Math. Model. 2013, 37, 2943–2960. [Google Scholar] [CrossRef]

- Gajewska, B.; Gajewski, M. Effect of Equivalent Load Distribution on the Accuracy of Mapping the Reinforcement Load Deflection Curve in LTP. Appl. Sci. 2020, 10, 6127. [Google Scholar] [CrossRef]

| At the Edge of the Cap | Between Columns (Caps) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2.05% | 1.73% | 1.50% | 0.51% | 1.50% | 1.14% | 0.97% | 0.32% | 1.36% | 0.25% | 0.63% |

| Axial Spacing of Columns | Head Width | Embankment Height | Volumetric Weight of the Embankment | Internal Friction Angle | Stiffness of the Reinforcement |

|---|---|---|---|---|---|

| 2.5 m | 0.8 m | 1.25 m | 18 kN/m3 | 60° * | 1615 kN/m |

| Variant | A1 | A2 | B1 | B2 | C1 | C2 |

|---|---|---|---|---|---|---|

| Number of elements | 7583 | 18,712 | 7563 | 19,139 | 7708 | 19,131 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gajewska, B.; Gajewski, M.; Lechowicz, Z. Parametric Studies of the Load Transfer Platform Reinforcement Interaction with Columns. Materials 2021, 14, 4015. https://doi.org/10.3390/ma14144015

Gajewska B, Gajewski M, Lechowicz Z. Parametric Studies of the Load Transfer Platform Reinforcement Interaction with Columns. Materials. 2021; 14(14):4015. https://doi.org/10.3390/ma14144015

Chicago/Turabian StyleGajewska, Beata, Marcin Gajewski, and Zbigniew Lechowicz. 2021. "Parametric Studies of the Load Transfer Platform Reinforcement Interaction with Columns" Materials 14, no. 14: 4015. https://doi.org/10.3390/ma14144015

APA StyleGajewska, B., Gajewski, M., & Lechowicz, Z. (2021). Parametric Studies of the Load Transfer Platform Reinforcement Interaction with Columns. Materials, 14(14), 4015. https://doi.org/10.3390/ma14144015