Experimental Method for Tensile Testing of Unidirectional Carbon Fibre Composites Using Improved Specimen Type and Data Analysis

Abstract

:1. Introduction

2. Materials and Methods

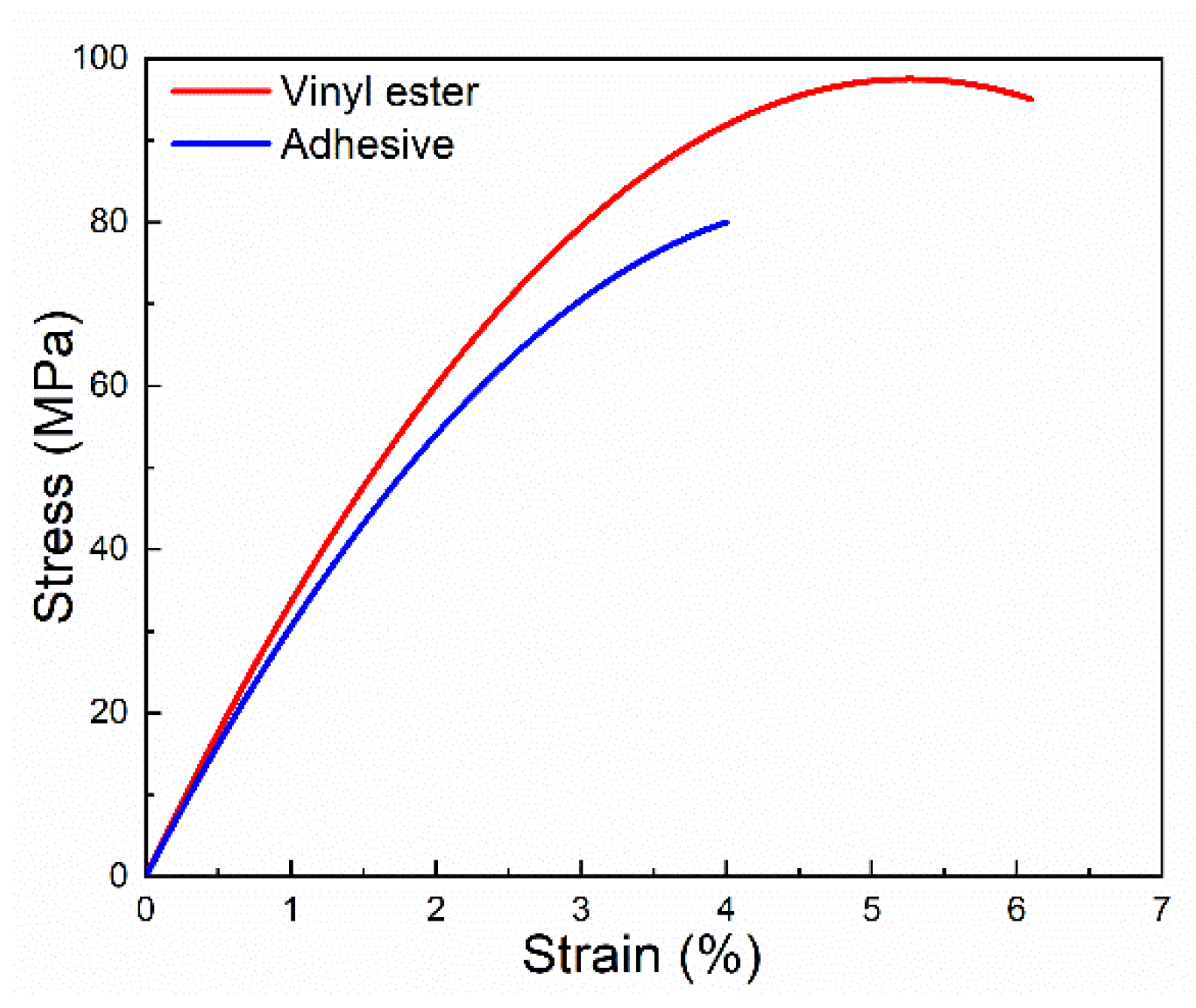

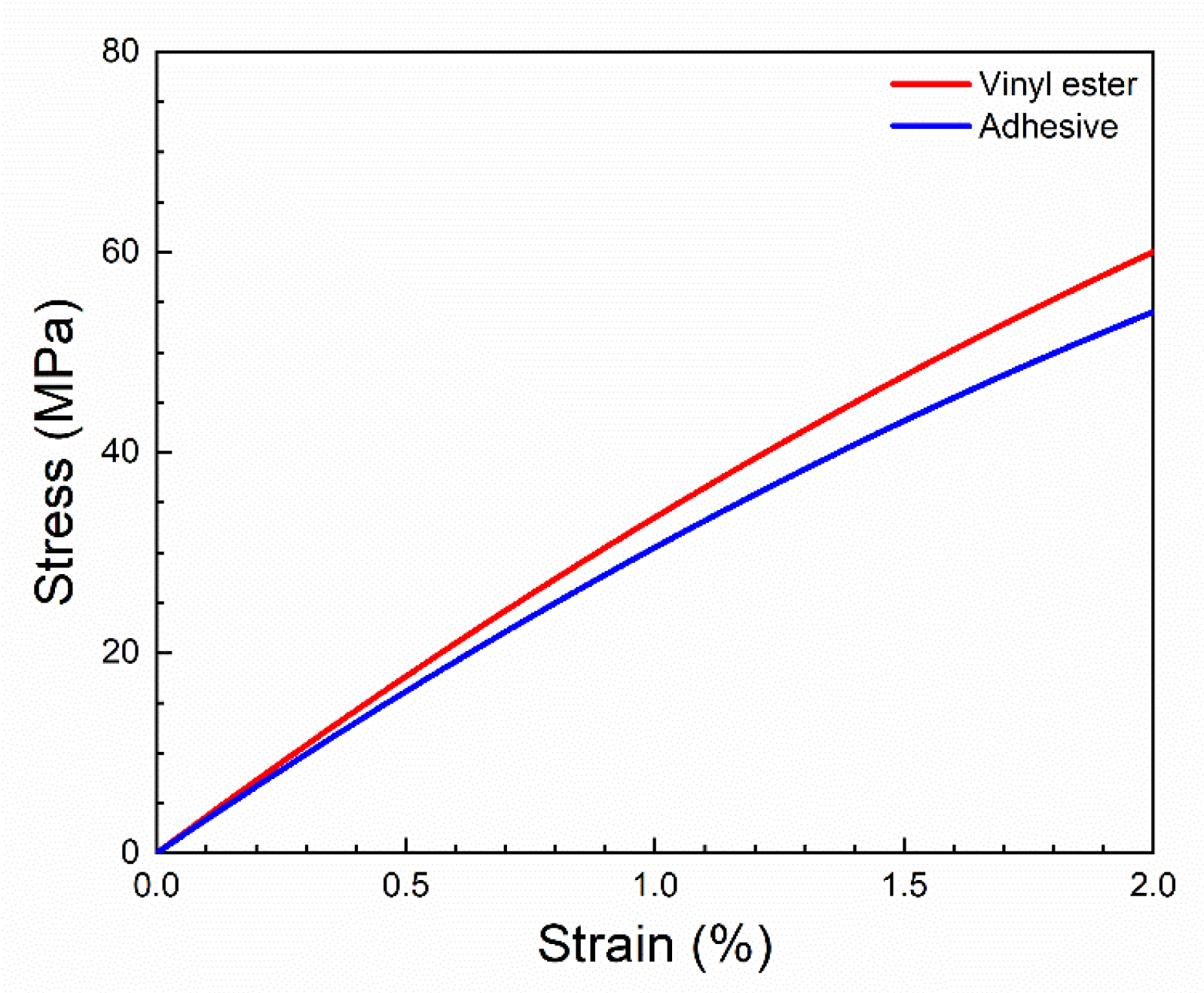

2.1. Protective Layer

2.2. Protected Carbon Composites

2.3. Test Specimens

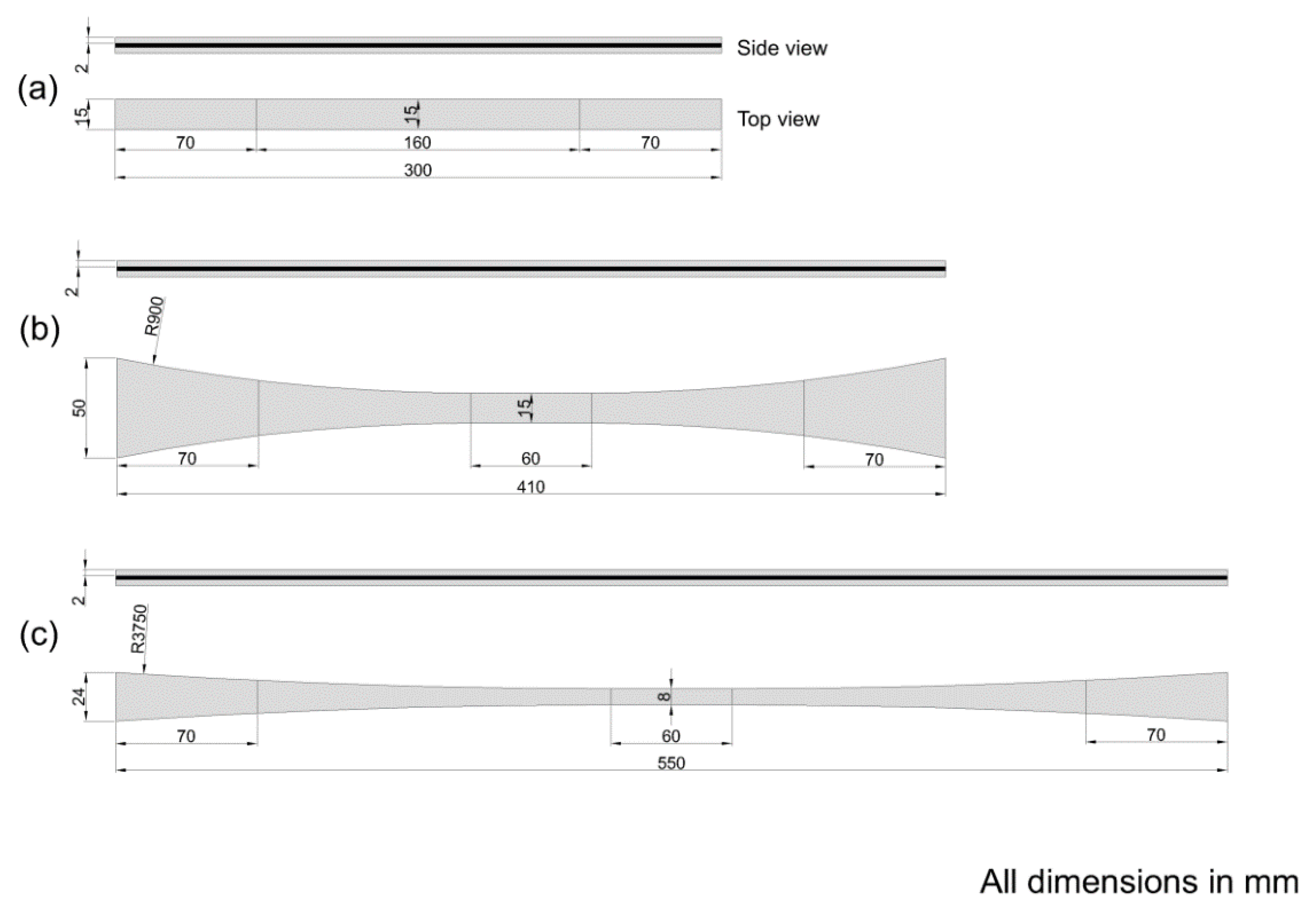

2.3.1. Geometry and Tabs

2.3.2. Preparation

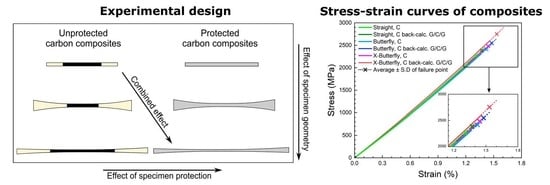

2.3.3. Experimental Design

2.4. Composite Characterization

2.4.1. Fibre Volume Fraction

2.4.2. Composite Volume Fractions

2.4.3. Tensile Properties

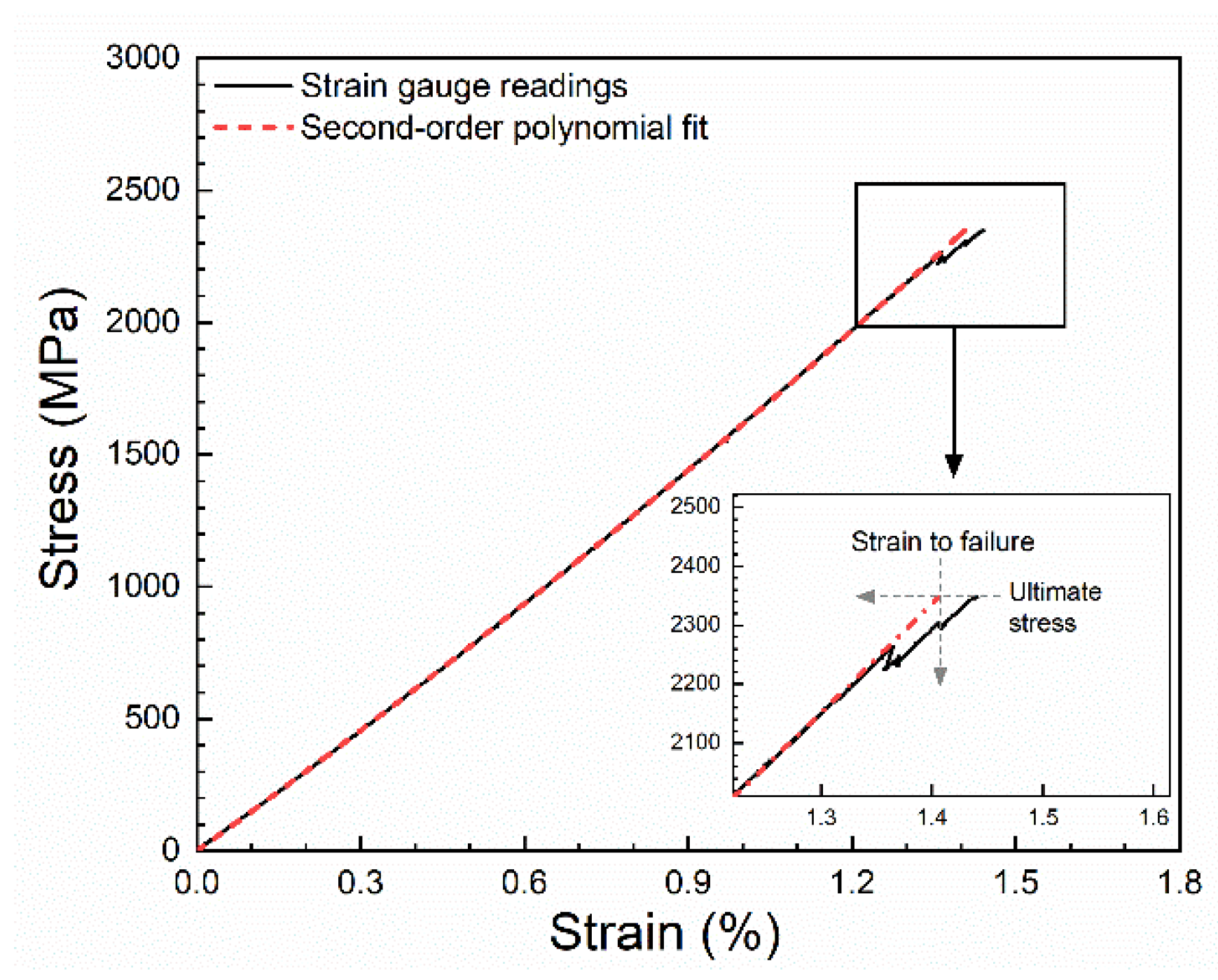

2.5. Stress–Strain Curve Analysis

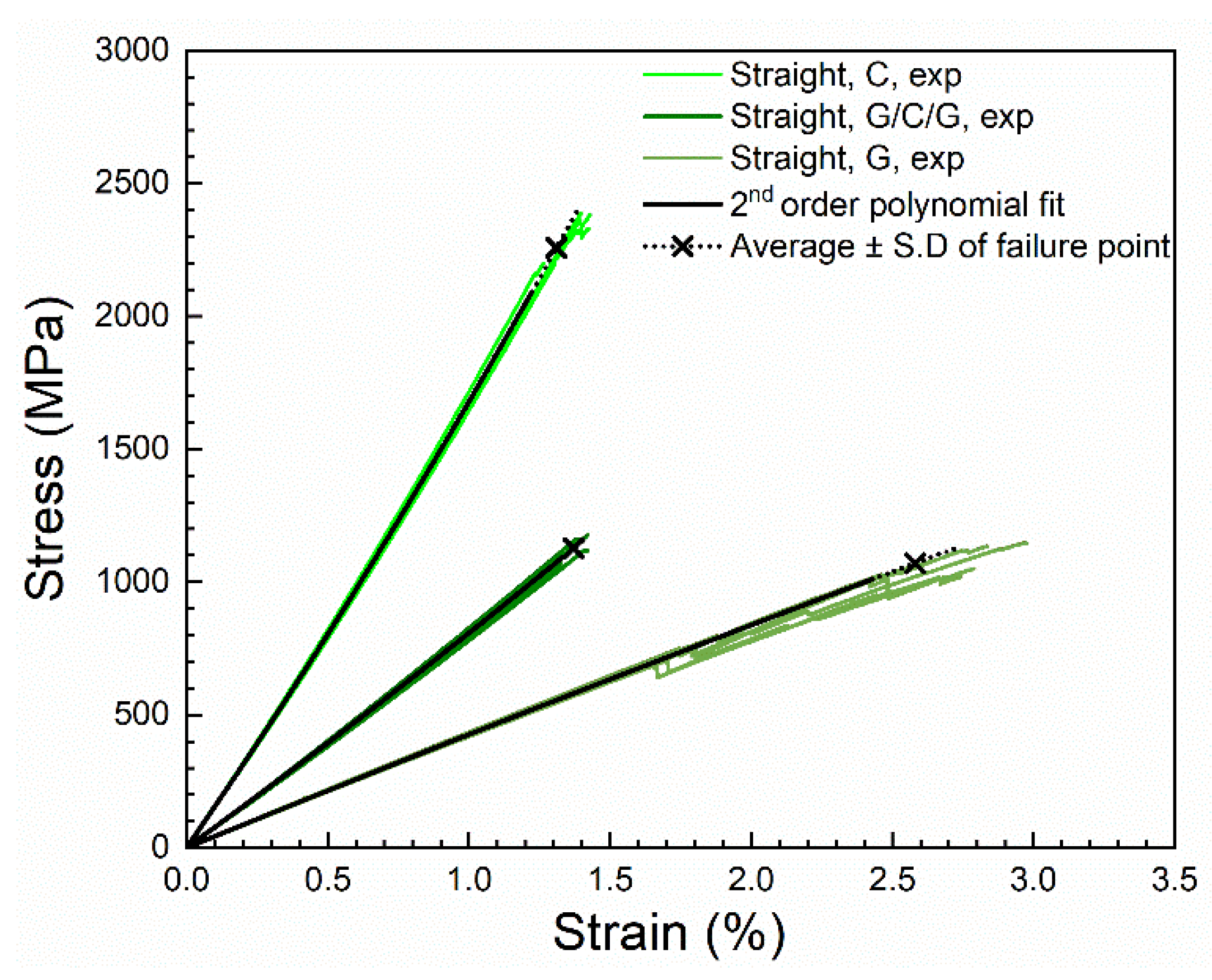

2.5.1. Second-Order Polynomial Fitting

2.5.2. Back-Calculation of Stresses

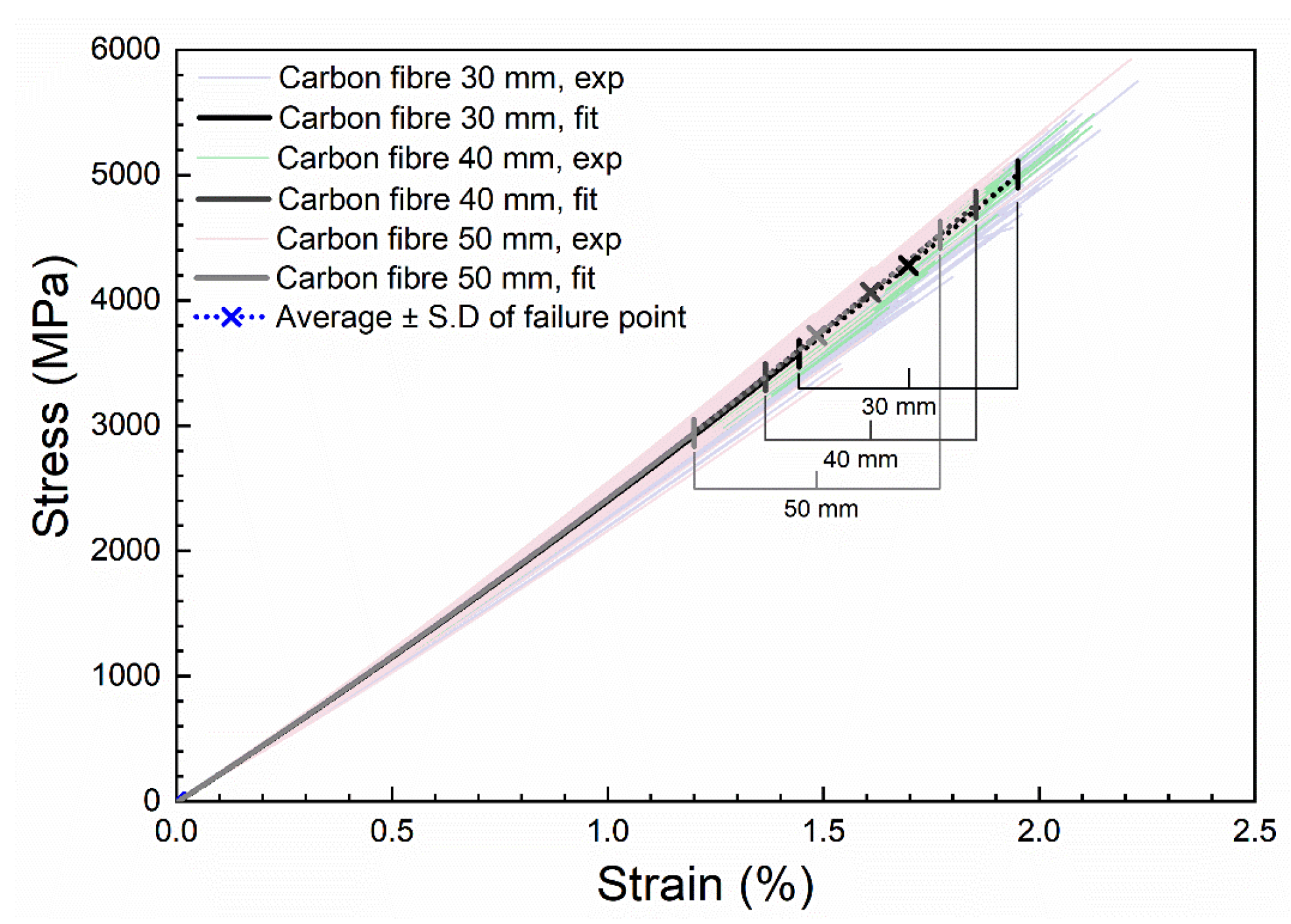

2.6. Single Fibre Tensile Testing

3. Results and Discussion

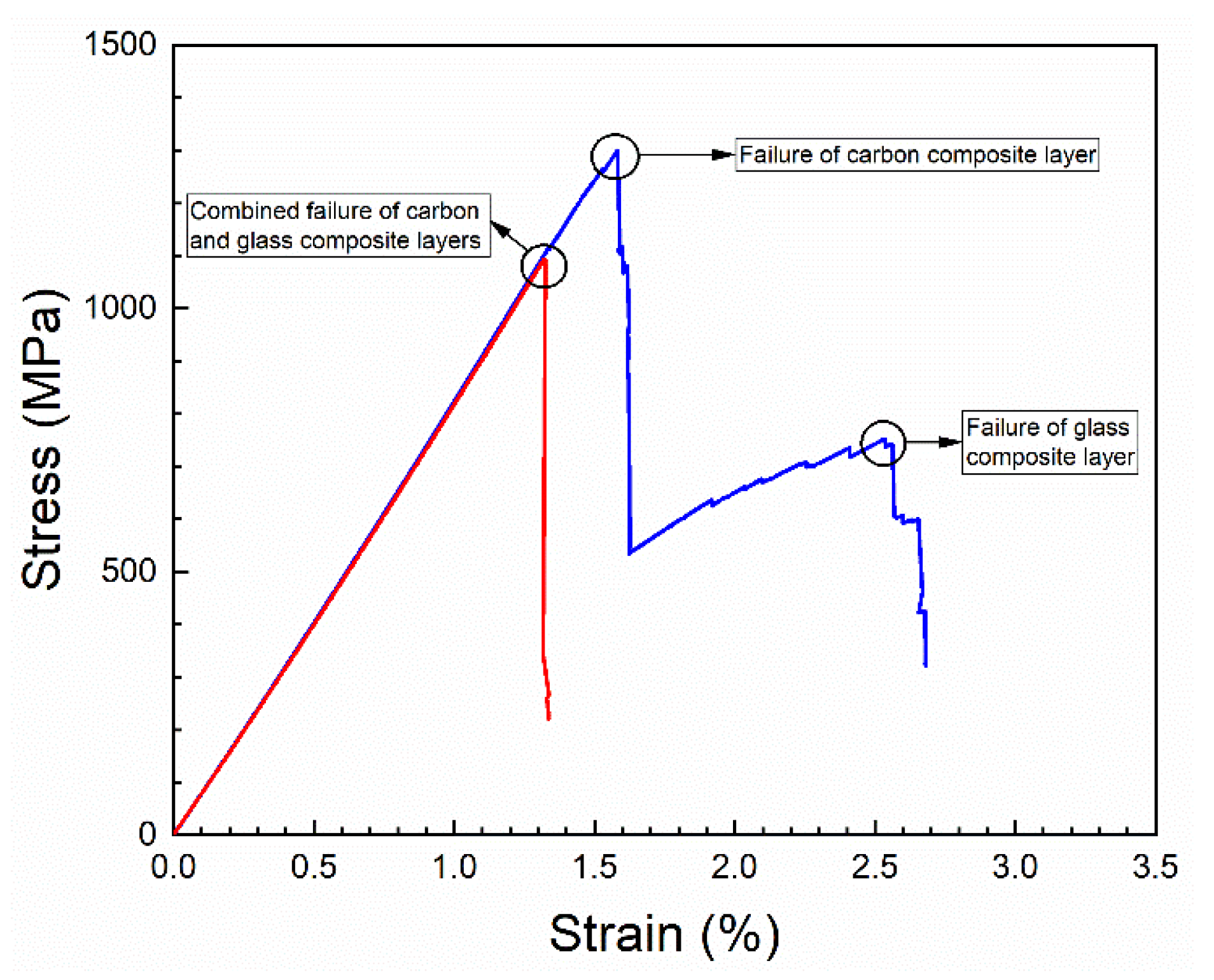

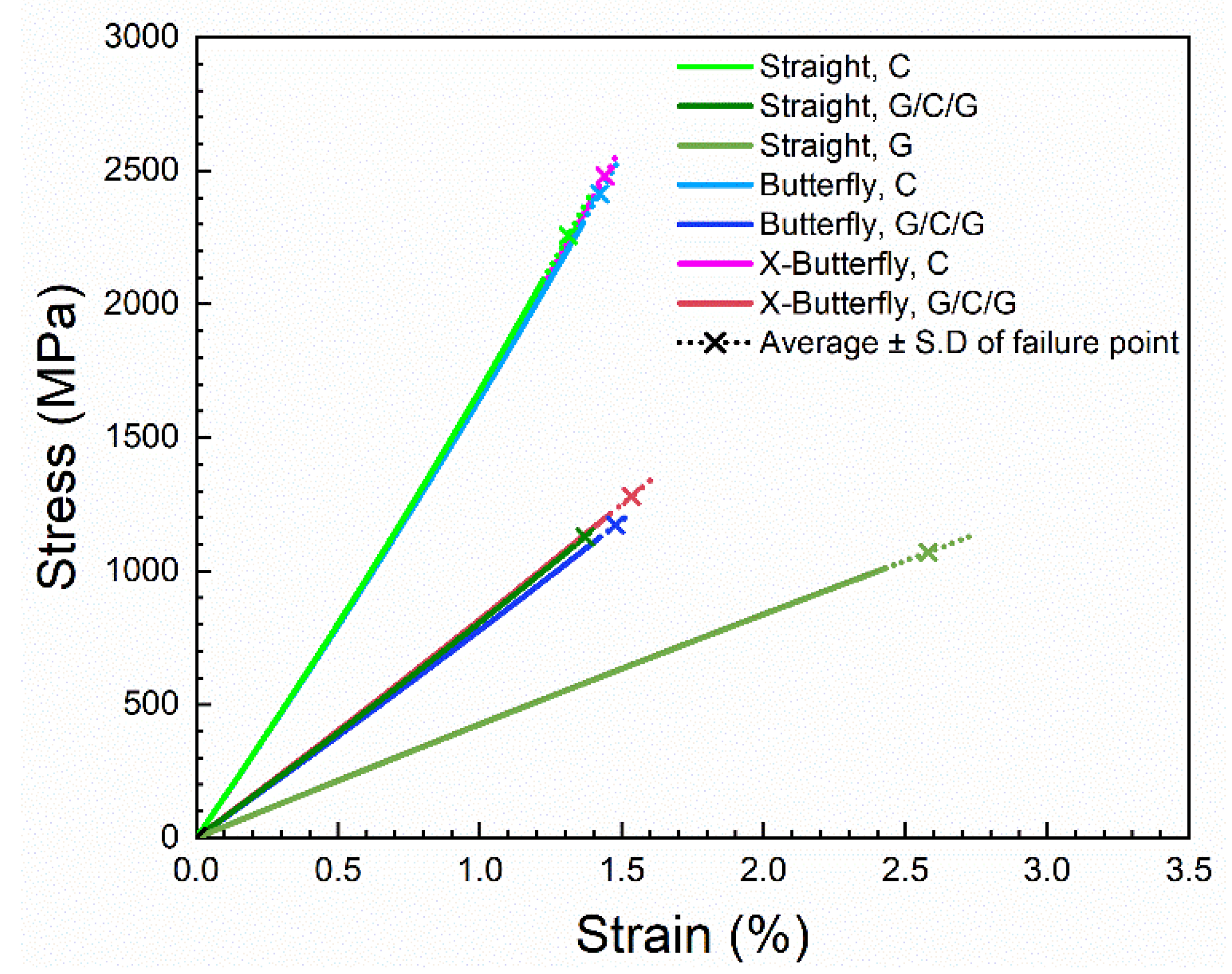

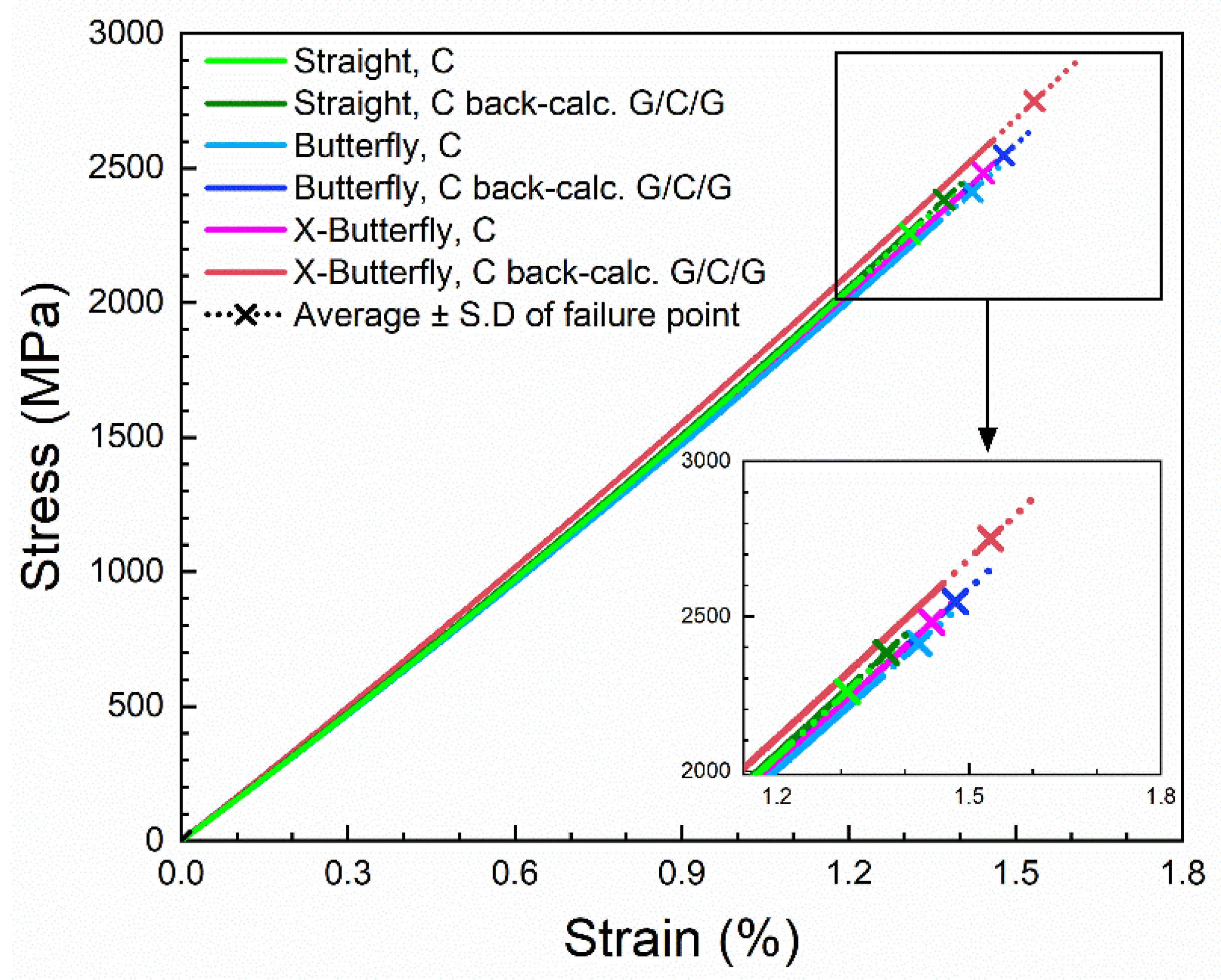

3.1. Analysis of Stress–strain Curves

- Single failure mode, where failure of the central carbon composite layer is leading to immediate failure of the protective glass composite layers.

- Double failure mode, where failure of the central carbon composite layer is leading to a drop of load, and the load is then carried by the protective glass composite layers until their failure at a later stage of the tensile test.

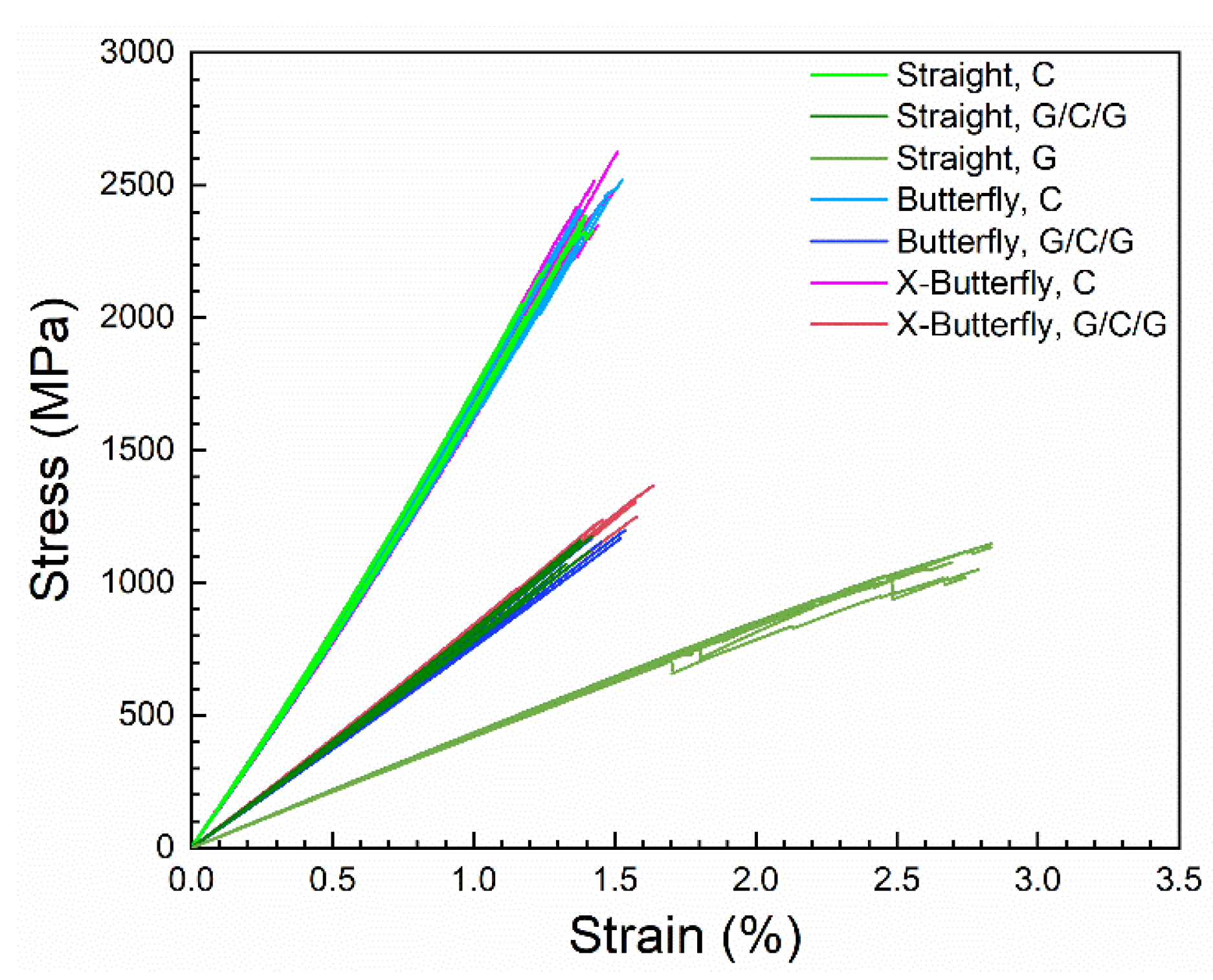

3.2. Effect of Specimen Geometry

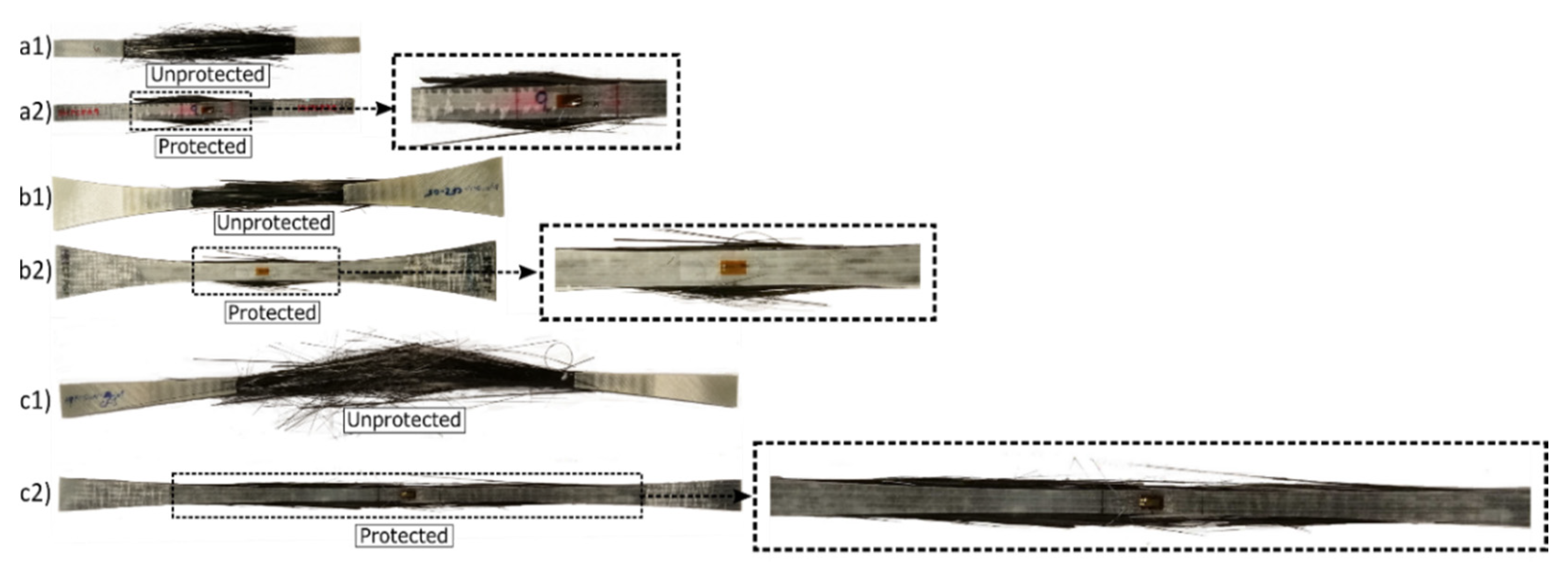

3.3. Effect of Specimen Protection

3.4. Combined Effect of Specimen Geometry and Protection

4. Conclusions

- An excellent agreement is found between the experimental stress–strain curves and the second-order polynomial fitted curves. Accordingly, it is demonstrated that the fitted stress–strain curves can be used as practical operational curves for further analysis.

- A good agreement between back-calculated stress–strain curves of protected carbon composites and measured stress–strain curves of unprotected carbon composites is found. Similarly, a good agreement is found between back-calculated stress–strain curves of carbon fibres and measured stress–strain curves of single carbon fibres. Only the failure points differ between the curves. Altogether, this validates the efficacy of the applied analysis of stress–strain curves and method of back-calculation.

- Initial stiffness (E0) that takes into account the shape of the whole stress–strain curve was determined based on the practical operational stress–strain curves. Initial Stiffness of unprotected carbon composites with the three different specimen geometries were found to be identical at 153 GPa. This is expected since a change in specimen geometry should have no effect on the determined stiffness.

- Comparing butterfly specimens to straight-sided ones, the effect of changing specimen geometry was an increase in strain to failure from 1.31 to 1.42%. For the elongated X-butterfly specimens, strain to failure was furthermore increased to 1.44%.

- It can be speculated that the non-identical tested materials volume of the three different specimen geometries in itself may result in variation of strain to failure due to a materials size effect. Based on Weibull model calculations, it is found that the potential size effect phenomenon is relatively small compared to the effect of specimen geometry.

- The protected carbon composites showed higher strain to failure compared to the unprotected carbon composites. The relative increment of strain to failure was in the range of 4–6% for the three specimen geometries. The largest difference was seen for the X-butterfly specimens where the strain to failure was increased from 1.44 to 1.53%.

- An extensive broom-like failure mode was observed for all specimens. In the protected specimens, however, failure was observed to be more restricted in the gauge section. This observation indicates that the protective layers help promote failure of the carbon composite in the gauge section.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Material | ||||||

|---|---|---|---|---|---|---|

| Epoxy adhesive | 3.3 | 80 | 0.040 | 0.0015 | 3.4 | −70.3 |

| Vinyl ester matrix | 3.6 | 95 | 0.061 | 0.0015 | 3.7 | −70.4 |

References

- Kant, M.E.; Crabtree, J.D.; Young, S.; Penumadu, D. Concept of limit stress for the tensile behavior of carbon fibre composite tows. Compos. B. Eng. 2020, 201, 108384. [Google Scholar] [CrossRef]

- Markussen, C.M.; Madsen, B.; Lilholt, H.; Andersen, L.T. Impact of non-hookean behaviour on mechanical performance of hybrid composites. In Proceedings of the 20th International Conference on Composite Materials ICCM20 Secretariat, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Wisnom, M.R.; Maheri, M.R. Tensile strength of unidirectional carbon fibre-epoxy from tapered specimens. In Proceedings of the 2nd European Conference on Composites Testing and Standardisation, Hamburg, Germany, 13 September 1994; pp. 239–247. [Google Scholar]

- Maheri, M.R. An improved method for testing unidirectional FRP composites in tension. Compos. Struct. 1995, 33, 27–34. [Google Scholar] [CrossRef]

- Matsuo, T.; Hojo, M.; Kageyama, K. Influence of gripping method on tensile properties of unidirectional thermoplastic CFRP—Round-robin activity for international standardization in Japan. J. Compos. Mater. 2019, 53, 4161–4171. [Google Scholar] [CrossRef]

- De Baere, I.; Van Paepegem, W.; Degrieck, J. On the design of end tabs for quasi-static and fatigue testing of fibre-reinforced composites. Polym. Compos. 2009, 30, 381–390. [Google Scholar] [CrossRef]

- Kulakov, V.L.; Tarnopol’skii, Y.M.; Arnautov, A.K.; Rytter, J. Stress-strain state in the zone of load transfer in a composite specimen under uniaxial tension. Mech. Compos. Mater. 2004, 40, 91–100. [Google Scholar] [CrossRef]

- Portnov, G.G.; Kulakov, V.L.; Arnautov, A.K. A refined stress-strain analysis in the load transfer zone of flat specimens of high-strength unidirectional composites in uniaxial tension—1. Theoretical analysis. Mech. Compos. Mater. 2006, 42, 547–554. [Google Scholar] [CrossRef]

- De Baere, I.; Van Paepegem, W.; Hochard, C.; Degrieck, J. On the tension–tension fatigue behaviour of a carbon reinforced thermoplastic part II: Evaluation of a dumbbell-shaped specimen. Polym. Test. 2011, 30, 663–672. [Google Scholar] [CrossRef] [Green Version]

- Adams, D.O.; Adams, D.F. Tabbing Guide for Composite Test Specimens; Office of Aviation Research: Washington, DC, USA, 2002; DOT/FAA/AR-02/106. [Google Scholar]

- Kumagai, S.; Shindo, Y.; Horiguchi, K.; Takeda, T. Mechanical characterization of CFRP woven laminates between room temperature and 4 K. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2003, 46, 359–364. [Google Scholar] [CrossRef] [Green Version]

- Zangenberg, J. The effects of Fibre Architecture on Fatigue Life-Time of Composite Materials. Ph.D. Thesis, Technical University of Denmark, Lyngby, Denmark, September 2013. DTU Wind Energy, PhD-0018 (EN). [Google Scholar]

- Korkiakoski, S.; Brøndsted, P.; Sarlin, E.; Saarela, O. Influence of specimen type and reinforcement on measured tension-tension fatigue life of unidirectional GFRP laminates. Int. J. Fatigue 2016, 85, 114–129. [Google Scholar] [CrossRef] [Green Version]

- Cz’el, G.; Jalalvand, M.; Wisnom, M.R. Hybrid specimens eliminating stress concentrations in tensile and compressive testing of unidirectional composites. Compos. Part. A Appl. Sci. Manuf. 2016, 91, 436–447. [Google Scholar] [CrossRef] [Green Version]

- Wisnom, M.R.; Czel, G.; Swolfs, Y.; Jalalvand, M.; Verpoest, I.; Larissa, G. Hybrid effects in thin ply carbon/glass unidirectional laminates: Accurate experimental determination and prediction. Compos. Part. A Appl. Sci. Manuf. 2016, 88, 131–139. [Google Scholar] [CrossRef] [Green Version]

- Tahir, M.M.; Wang, W.-X.; Matsubara, T. A novel tab for tensile testing of unidirectional thermoplastic composites. J. Thermoplast. Compos. Mater. 2019, 32, 37–51. [Google Scholar] [CrossRef]

- Technical Committee. Plastics—Determination of Tensile Properties—Part 5: Test Conditions for Unidirectional Fibre-Reinforced Plastic Composites; ISO 527-5:2009; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- ASTM International. D3039/D3039M-17 Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Madsen, B.; Andersen, T.L.; Lilholt, H. Volumetric Composition: Fibre Content and Porosity. In Handbook of Green Materials. Biobased Composite Materials, Their Processing, Properties, and Industrial Applications; World Scientific Publishing: Singapore, 2014; Volume 4, Chapter 10; pp. 137–153. [Google Scholar]

- Kelly, A.; Macmillan, N.H. Strong Solids, 3rd ed.; Oxford University Press and Macmillan: Oxford, UK, 1986. [Google Scholar]

- Jalalvand, M.; Czel, G.; Wisnom, M.R. Numerical modelling of the damage modes in UD thin carbon/glass hybrid laminates. Compos. Sci. Technol. 2014, 94, 39–47. [Google Scholar] [CrossRef] [Green Version]

- Kumar, R.; Mikkelsen, L.P.; Lilholt, H.; Madsen, B. Datasets from tensile testing of unidirectional carbon fiber composites using different specimen types. Zenodo 2021. [Google Scholar] [CrossRef]

- Weibull, W.A. Statistical Theory of the Strength of Materials; Royal Swedish Academy of Engineering Sciences: Stockholm, Sweden, 1939. [Google Scholar]

- Wisnom, M.R.; Khan, B.; Hallett, S.R. Size effects in unnotched tensile strength of unidirectional and quasi-isotropic carbon/epoxy composites. Compos. Struct. 2008, 84, 21–28. [Google Scholar] [CrossRef]

- Kumar, R.; Mikkelsen, L.P.; Lilholt, H.; Madsen, B. Probability of failure in composites: Stress state model for non-straight sided specimen. in preparation.

- Greenhalgh, E.S. Failure Analysis and Fractography of Polymer Composites; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing Limited: Sawston, UK, 2009. [Google Scholar]

- Kumar, R.; Mikkelsen, L.P.; Lilholt, H.; Madsen, B. Understanding the mechanical response of glass and carbon fibres: Stress-strain analysis and modulus determination. In Proceedings of the 41st Risø International Symposium on Materials Science: “Materials and Design for Next Generation Wind Turbine Blades”, Roskilde, Denmark, 7–10 September 2020; Volume 942, p. 012033. [Google Scholar] [CrossRef]

- Ji, X.; Wang, C.; Francis, B.A.P.; Chia, E.S.M.; Zheng, L.; Yang, J.; Joshi, S.C.; Chen, Z. Mechanical and interfacial properties characterisation of single carbon fs for composite applications. Exp. Mech. 2015, 55, 1057–1065. [Google Scholar] [CrossRef]

- Kumar, R.; Mikkelsen, L.P.; Lilholt, H.; Madsen, B. Single fiber tensile test-glass and carbon fibers. Zenodo 2020. [Google Scholar] [CrossRef]

| Specimen Geometries | Composite Volume Fractions | ||

|---|---|---|---|

| VC | VG | VA | |

| Straight | 31.0 ± 0.01 | 66.6 ± 0.2 | 2.4 ± 0.2 |

| Butterfly | 29.6 ± 0.01 | 67.4 ± 0.2 | 3.0 ± 0.3 |

| X-Butterfly | 31.1 ± 0.01 | 67.6 ± 0.2 | 1.3 ± 0.2 |

| Carbon Composite | Specimen Geometry | ||

|---|---|---|---|

| Straight-Sided | Butterfly | X-Butterfly | |

| Unprotected, C | 153 ± 3 | 153 ± 3 | 153 ± 4 |

| Protected, G/C/G | 77 ± 2 | 75 ± 1 | 79 ± 1 |

| Carbon Composite | Specimen Geometry | ||

|---|---|---|---|

| Straight-Sided | Butterfly | X-Butterfly | |

| Unprotected, C | 1.31 ± 0.09 | 1.42 ± 0.06 | 1.44 ± 0.04 |

| Protected, G/C/G | 1.37 ± 0.04 | 1.48 ± 0.06 | 1.53 ± 0.07 |

| Gauge length (mm) | 30 | 40 | 50 |

| Strain to failure (%) | 1.69 ± 0.25 | 1.60 ± 0.24 | 1.48 ± 0.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, R.; Mikkelsen, L.P.; Lilholt, H.; Madsen, B. Experimental Method for Tensile Testing of Unidirectional Carbon Fibre Composites Using Improved Specimen Type and Data Analysis. Materials 2021, 14, 3939. https://doi.org/10.3390/ma14143939

Kumar R, Mikkelsen LP, Lilholt H, Madsen B. Experimental Method for Tensile Testing of Unidirectional Carbon Fibre Composites Using Improved Specimen Type and Data Analysis. Materials. 2021; 14(14):3939. https://doi.org/10.3390/ma14143939

Chicago/Turabian StyleKumar, Rajnish, Lars P. Mikkelsen, Hans Lilholt, and Bo Madsen. 2021. "Experimental Method for Tensile Testing of Unidirectional Carbon Fibre Composites Using Improved Specimen Type and Data Analysis" Materials 14, no. 14: 3939. https://doi.org/10.3390/ma14143939

APA StyleKumar, R., Mikkelsen, L. P., Lilholt, H., & Madsen, B. (2021). Experimental Method for Tensile Testing of Unidirectional Carbon Fibre Composites Using Improved Specimen Type and Data Analysis. Materials, 14(14), 3939. https://doi.org/10.3390/ma14143939