Author Contributions

Conceptualization, P.J.; methodology, P.J., M.D., A.B., M.Č., software, A.B., D.B.; validation, P.J., A.B.; formal analysis, P.J.; investigation, P.J., M.D., A.B., M.Č.; resources, M.H.; data curation, P.J., D.B.; writing—original draft preparation, P.J.; writing—review and editing, P.J., A.B.; visualization, P.J., M.H., M.D., D.B.; supervision, P.J.; project administration, M.H.; funding acquisition, P.J. All authors have read and agreed to the published version of the manuscript.

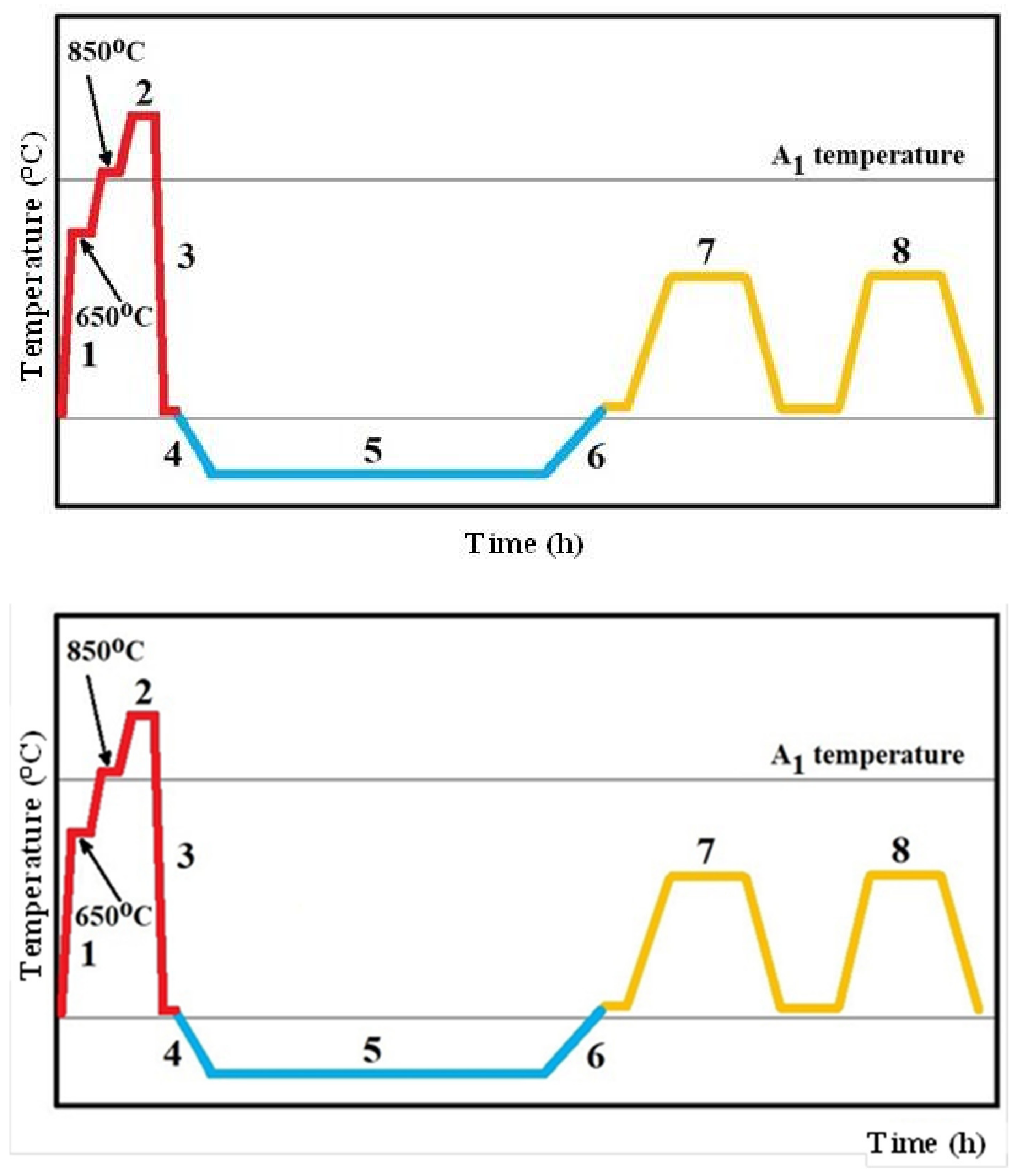

Figure 1.

A schematic of the heat treatment schedules used.

Figure 1.

A schematic of the heat treatment schedules used.

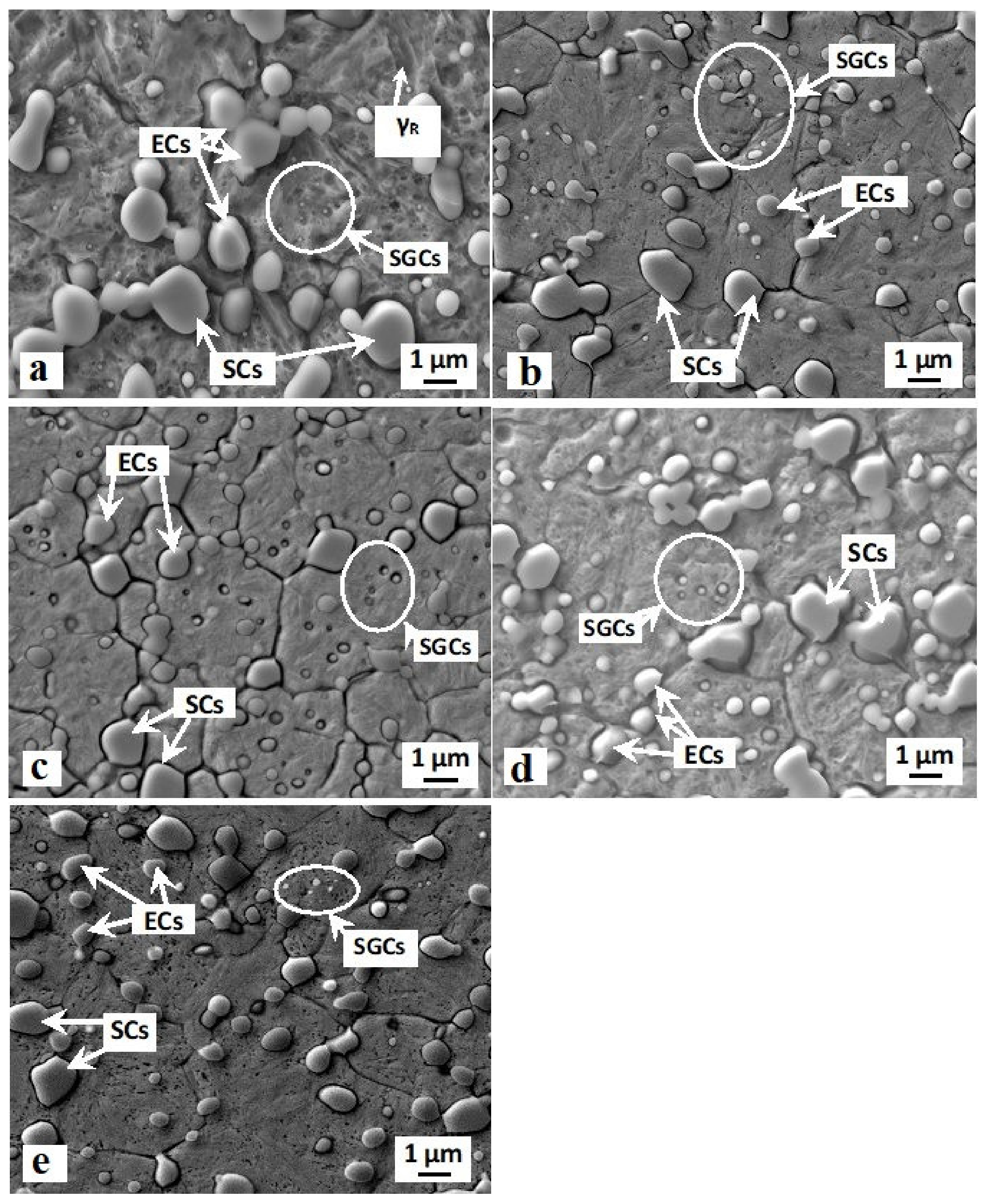

Figure 2.

Scanning electron microscopy (SEM) micrographs showing the microstructure of Vanadis 6 ledeburitic steel after conventional room temperature quenching (a) and after SZT at −75 °C (b), −140 °C (c), −196 °C (d), and −269 °C (e).

Figure 2.

Scanning electron microscopy (SEM) micrographs showing the microstructure of Vanadis 6 ledeburitic steel after conventional room temperature quenching (a) and after SZT at −75 °C (b), −140 °C (c), −196 °C (d), and −269 °C (e).

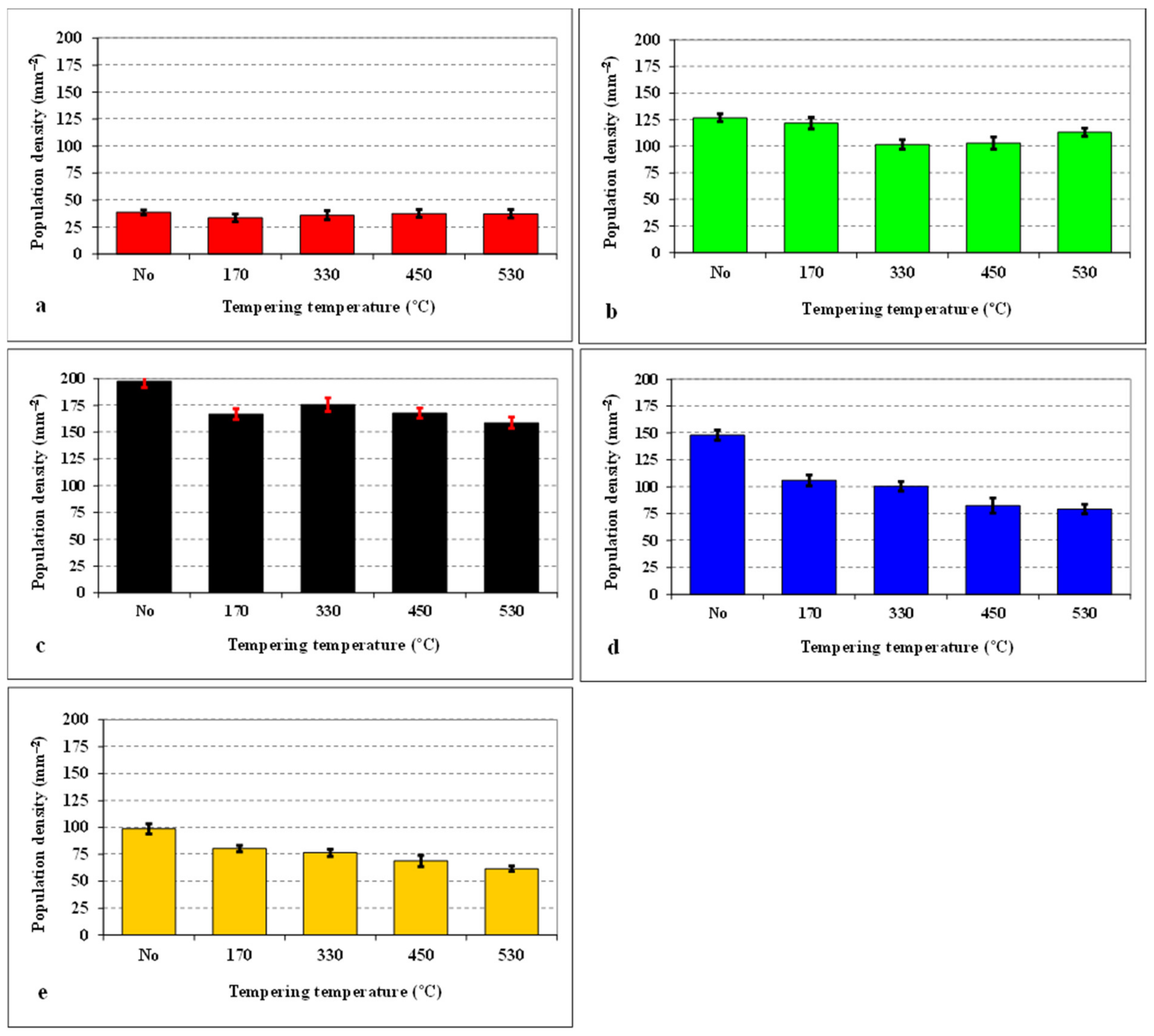

Figure 3.

Population density of small globular carbides (SGCs) for differently sub-zero treated (SZT) specimens as a function of tempering temperature: (a) conventional heat treatment (CHT), (b) SZT −75 °C, (c) SZT −140 °C, (d) SZT −196 °C, (e) SZT −269 °C.

Figure 3.

Population density of small globular carbides (SGCs) for differently sub-zero treated (SZT) specimens as a function of tempering temperature: (a) conventional heat treatment (CHT), (b) SZT −75 °C, (c) SZT −140 °C, (d) SZT −196 °C, (e) SZT −269 °C.

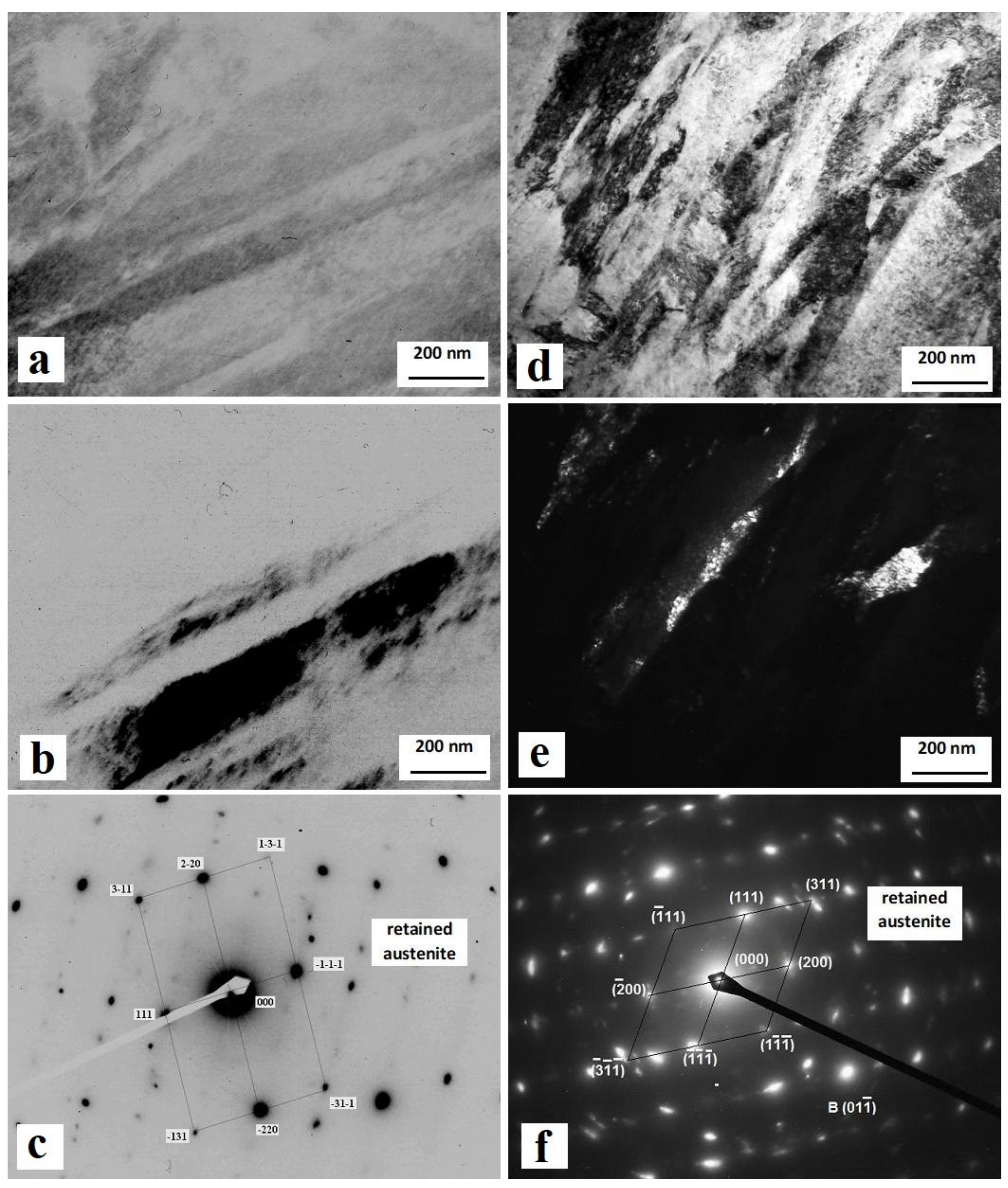

Figure 4.

Transmission electron microscopy (TEM) micrographs of the CHT specimen (a–c) and the specimen that was subjected to SZT at −196 °C (d–f). (a) Bright-field image showing martensitic needle microstructure with retained austenite at needle interfaces, (b) corresponding dark-field image showing the retained austenite, (c) diffraction patterns of the retained austenite, (d) bright-field image showing martensitic microstructure with a small amount of retained austenite at the interfaces of martensitic domains, (e) corresponding dark-field image, (f) diffraction patterns of the retained austenite.

Figure 4.

Transmission electron microscopy (TEM) micrographs of the CHT specimen (a–c) and the specimen that was subjected to SZT at −196 °C (d–f). (a) Bright-field image showing martensitic needle microstructure with retained austenite at needle interfaces, (b) corresponding dark-field image showing the retained austenite, (c) diffraction patterns of the retained austenite, (d) bright-field image showing martensitic microstructure with a small amount of retained austenite at the interfaces of martensitic domains, (e) corresponding dark-field image, (f) diffraction patterns of the retained austenite.

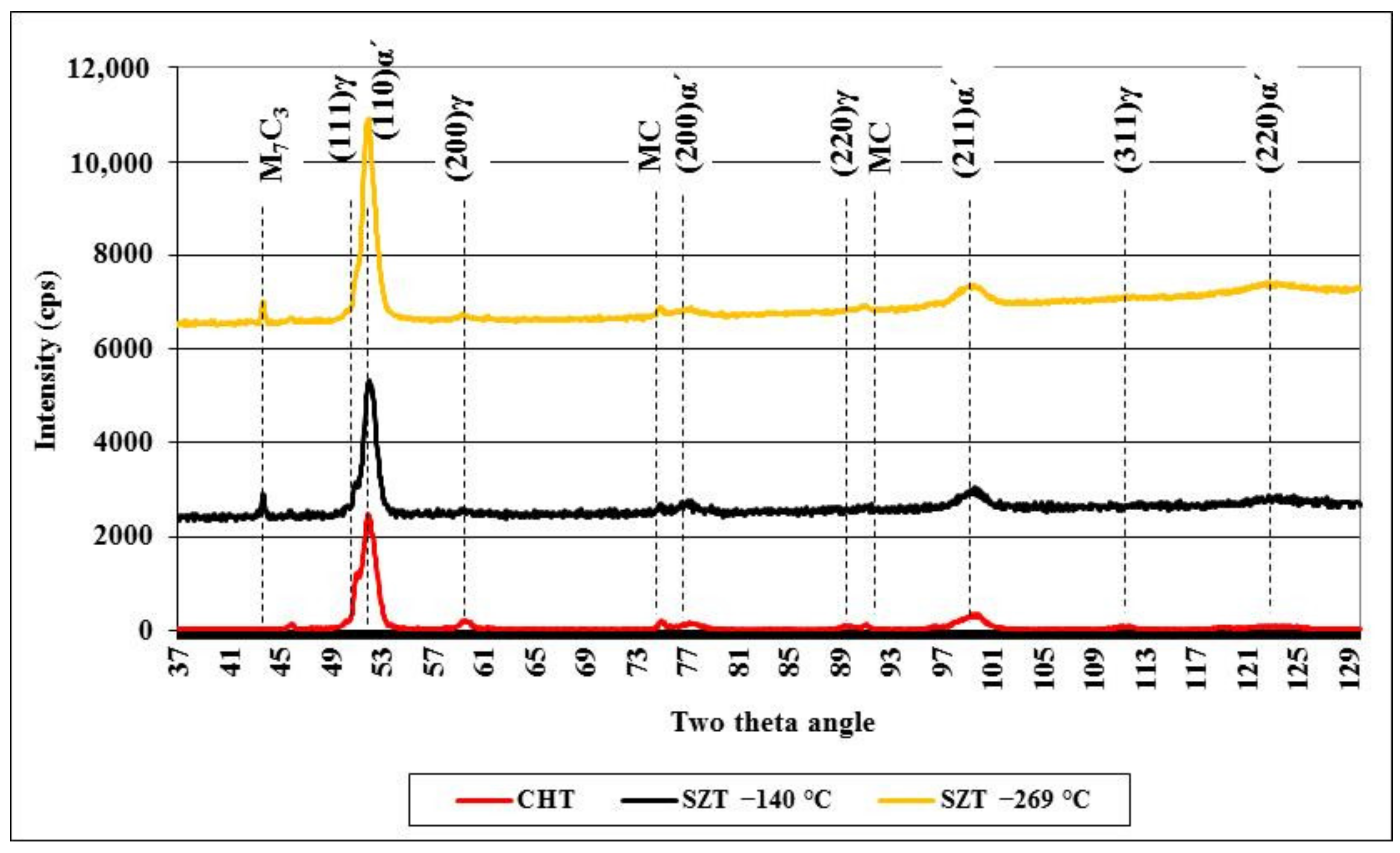

Figure 5.

X-ray diffraction spectra of CHT steel and steel after SZT at −140 and −269 °C.

Figure 5.

X-ray diffraction spectra of CHT steel and steel after SZT at −140 and −269 °C.

Figure 6.

Retained austenite amounts for different SZT specimens, as a function of tempering temperature: (a) CHT, (b) SZT −75 °C, (c) SZT −140 °C, (d) SZT −196 °C, (e) SZT −269 °C.

Figure 6.

Retained austenite amounts for different SZT specimens, as a function of tempering temperature: (a) CHT, (b) SZT −75 °C, (c) SZT −140 °C, (d) SZT −196 °C, (e) SZT −269 °C.

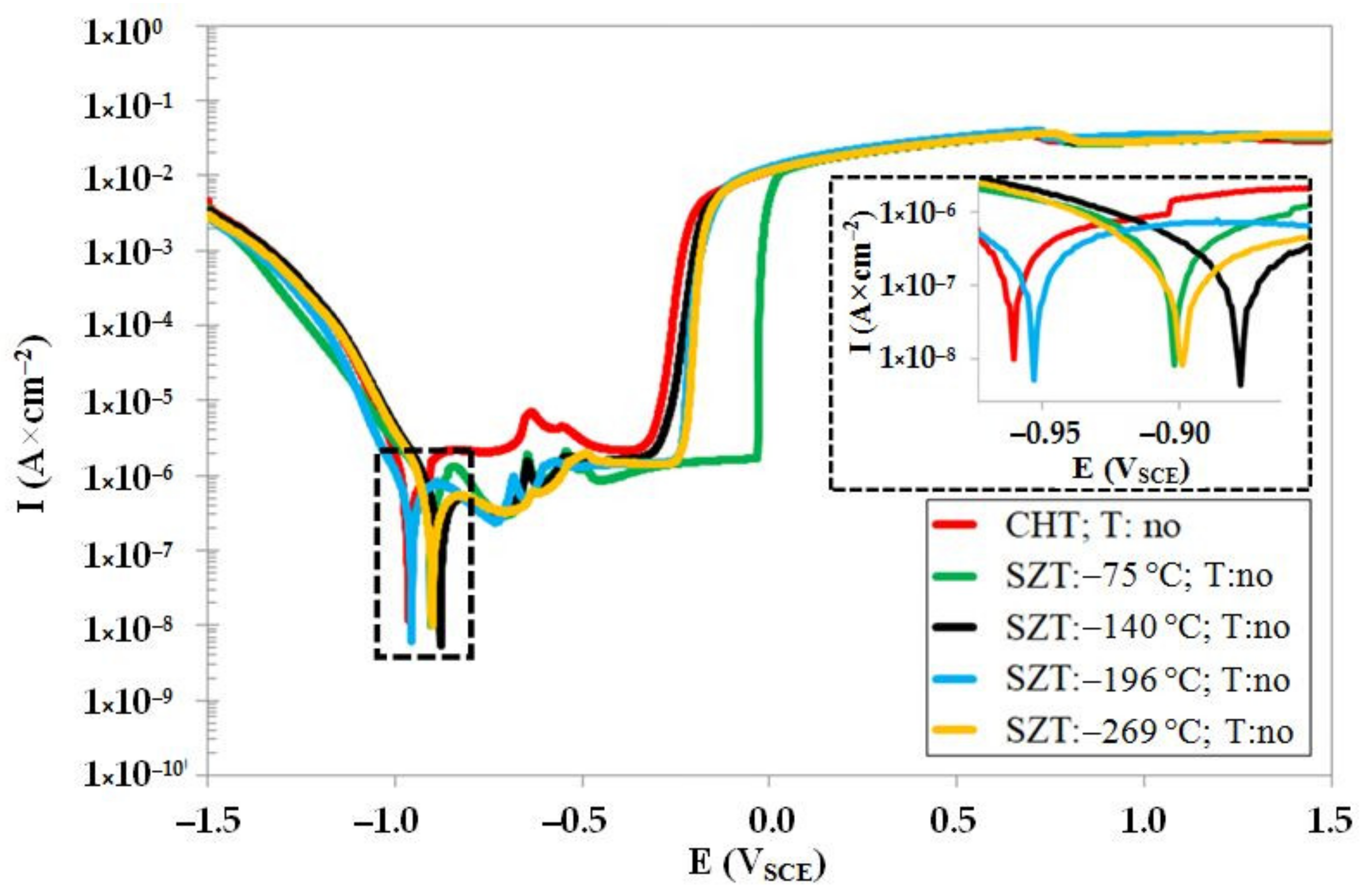

Figure 7.

Potentiodynamic polarisation curves of CHT and different SZT specimens in un-tempered state.

Figure 7.

Potentiodynamic polarisation curves of CHT and different SZT specimens in un-tempered state.

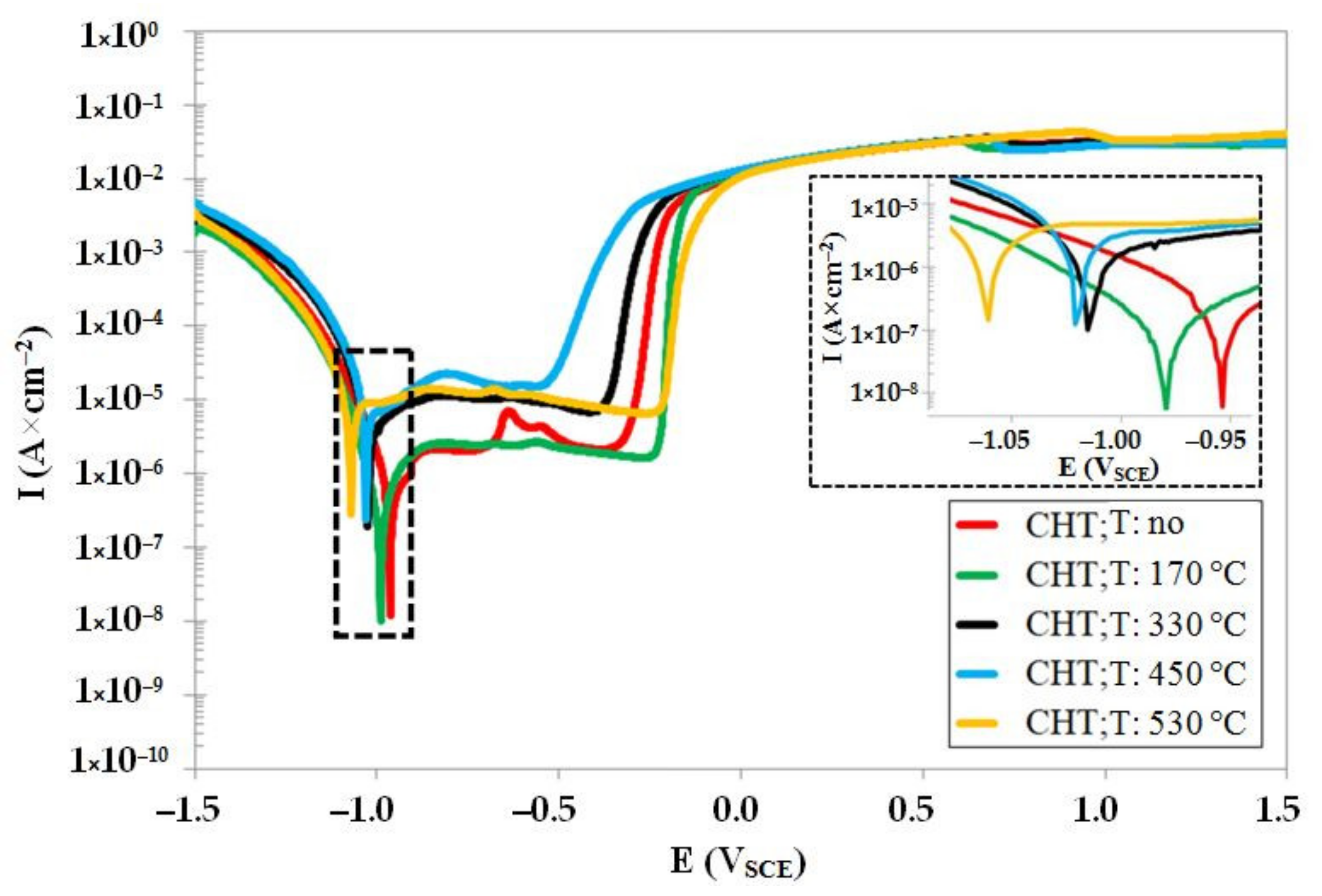

Figure 8.

Potentiodynamic polarisation curves of CHT Vanadis 6 steel in un-tempered state and in the states after different tempering treatments.

Figure 8.

Potentiodynamic polarisation curves of CHT Vanadis 6 steel in un-tempered state and in the states after different tempering treatments.

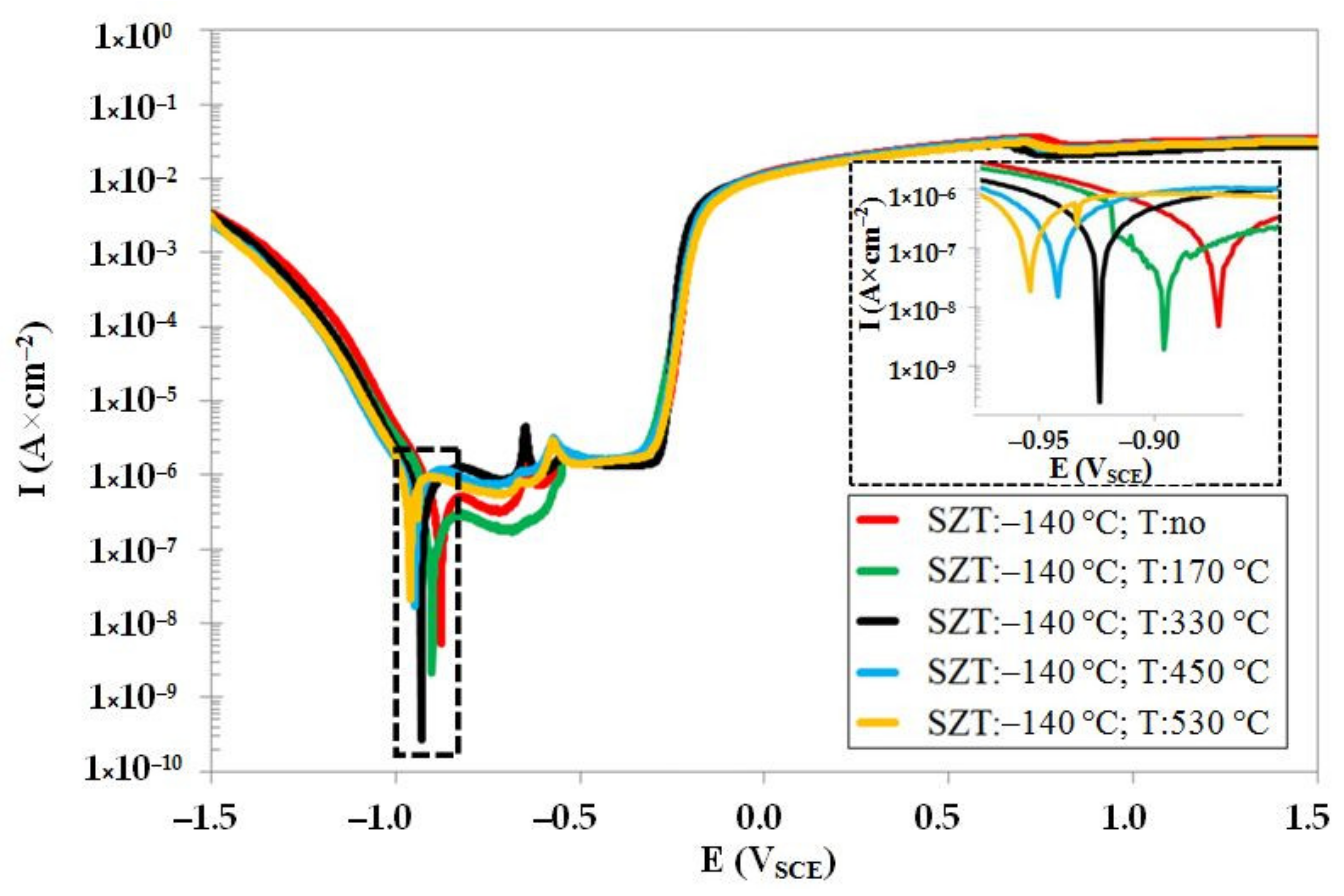

Figure 9.

Potentiodynamic polarisation curves of Vanadis 6 steel subjected to SZT at −140 °C, in un-tempered state and in the states after different tempering treatments.

Figure 9.

Potentiodynamic polarisation curves of Vanadis 6 steel subjected to SZT at −140 °C, in un-tempered state and in the states after different tempering treatments.

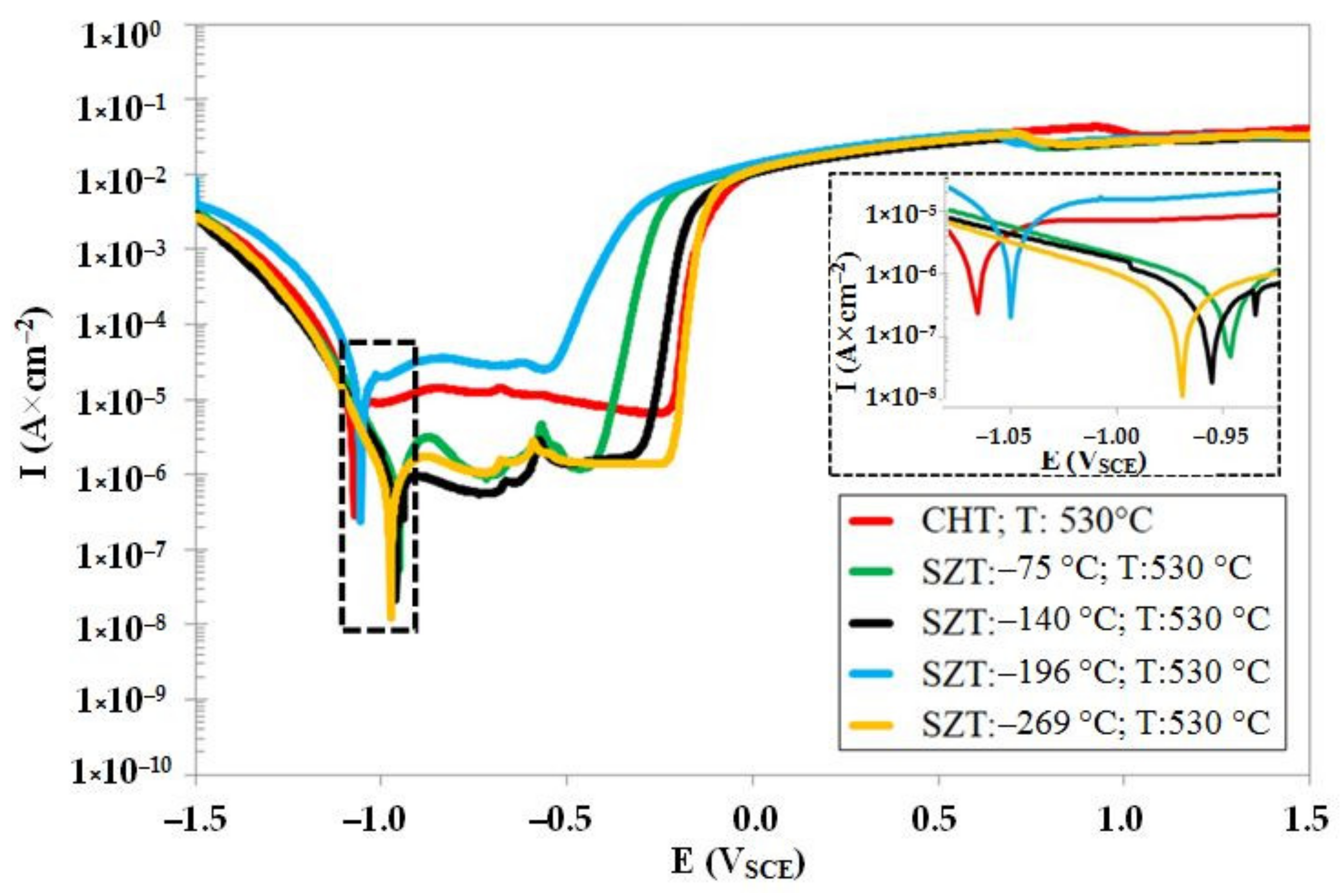

Figure 10.

Potentiodynamic polarisation curves of CHT Vanadis 6 steel, and Vanadis 6 subjected to different SZTs, after tempering at 530 °C.

Figure 10.

Potentiodynamic polarisation curves of CHT Vanadis 6 steel, and Vanadis 6 subjected to different SZTs, after tempering at 530 °C.

Figure 11.

Corrosion rate in dependence on tempering temperature for CHT specimens and for specimens after application of different SZTs.

Figure 11.

Corrosion rate in dependence on tempering temperature for CHT specimens and for specimens after application of different SZTs.

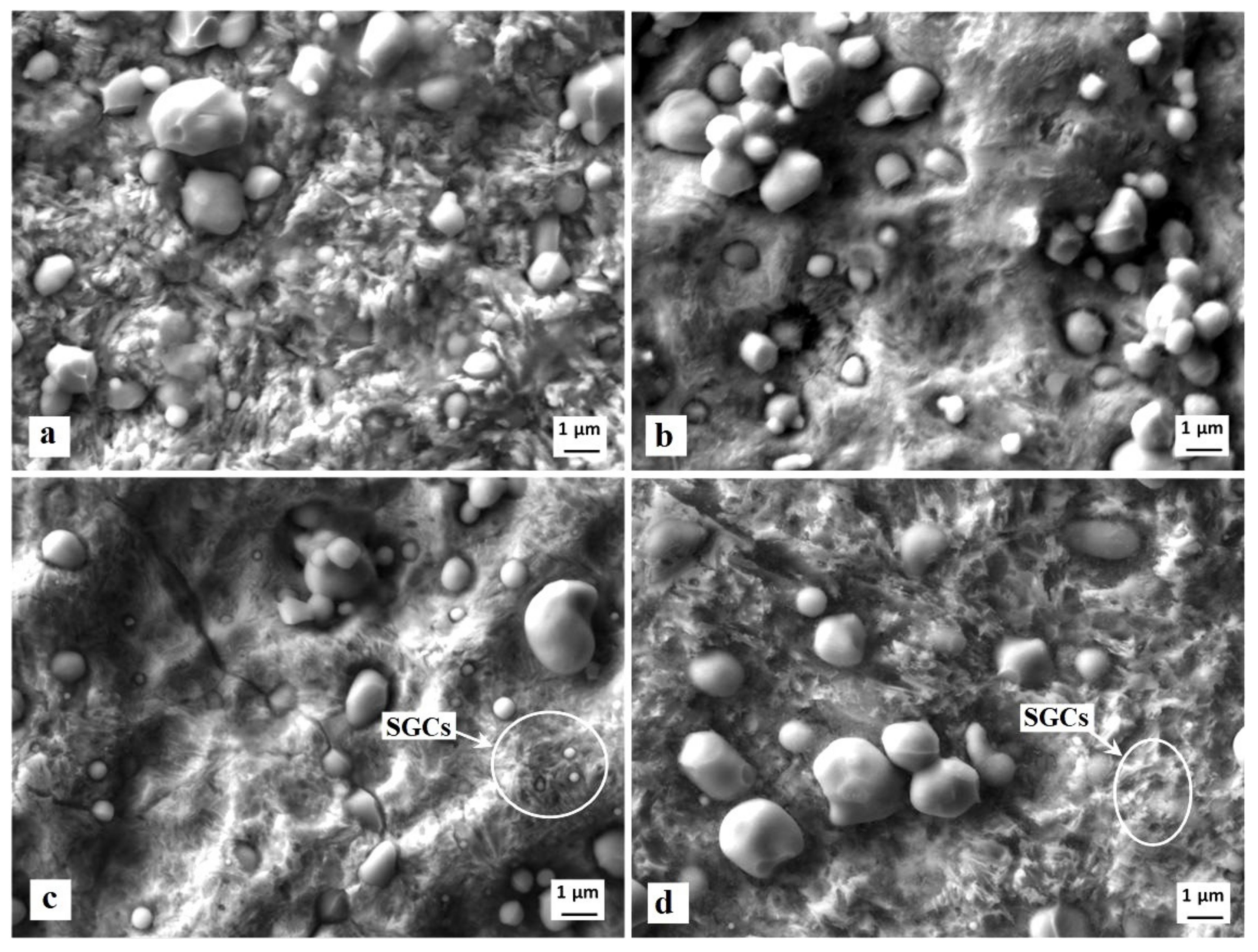

Figure 12.

SEM micrographs showing the surfaces after the potentiodynamic polarisation measurements, CHT (a), CHT + tempering at 530 °C (b), SZT at −140 °C (c), SZT at −140 °C + tempering at 530 °C (d).

Figure 12.

SEM micrographs showing the surfaces after the potentiodynamic polarisation measurements, CHT (a), CHT + tempering at 530 °C (b), SZT at −140 °C (c), SZT at −140 °C + tempering at 530 °C (d).

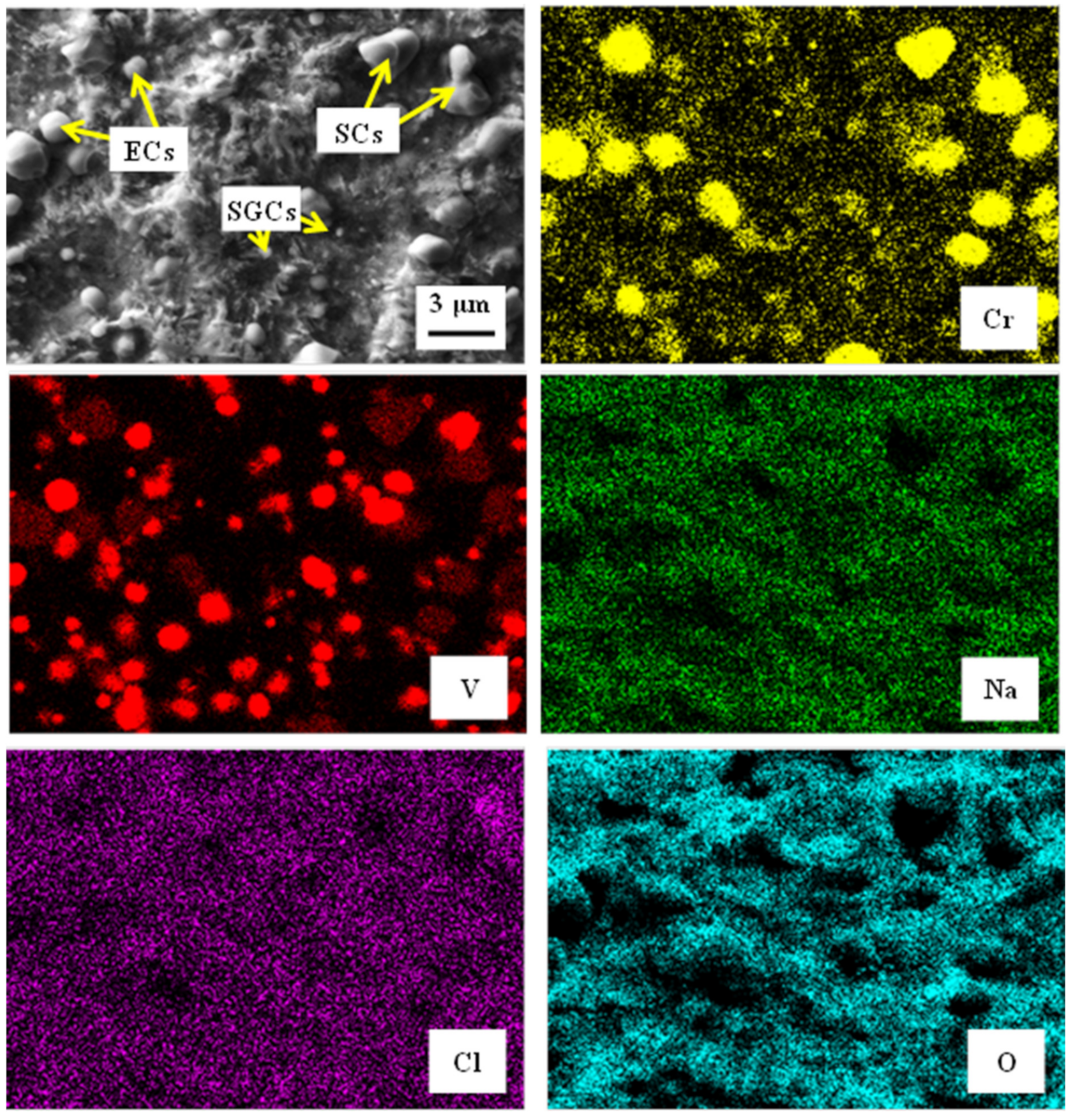

Figure 13.

SEM micrograph showing the surface of the specimen that was subjected to the SZT at −140 °C, after the potentiodynamic polarisation measurements, and corresponding EDS maps of Cr, V, Na, Cl, and O.

Figure 13.

SEM micrograph showing the surface of the specimen that was subjected to the SZT at −140 °C, after the potentiodynamic polarisation measurements, and corresponding EDS maps of Cr, V, Na, Cl, and O.

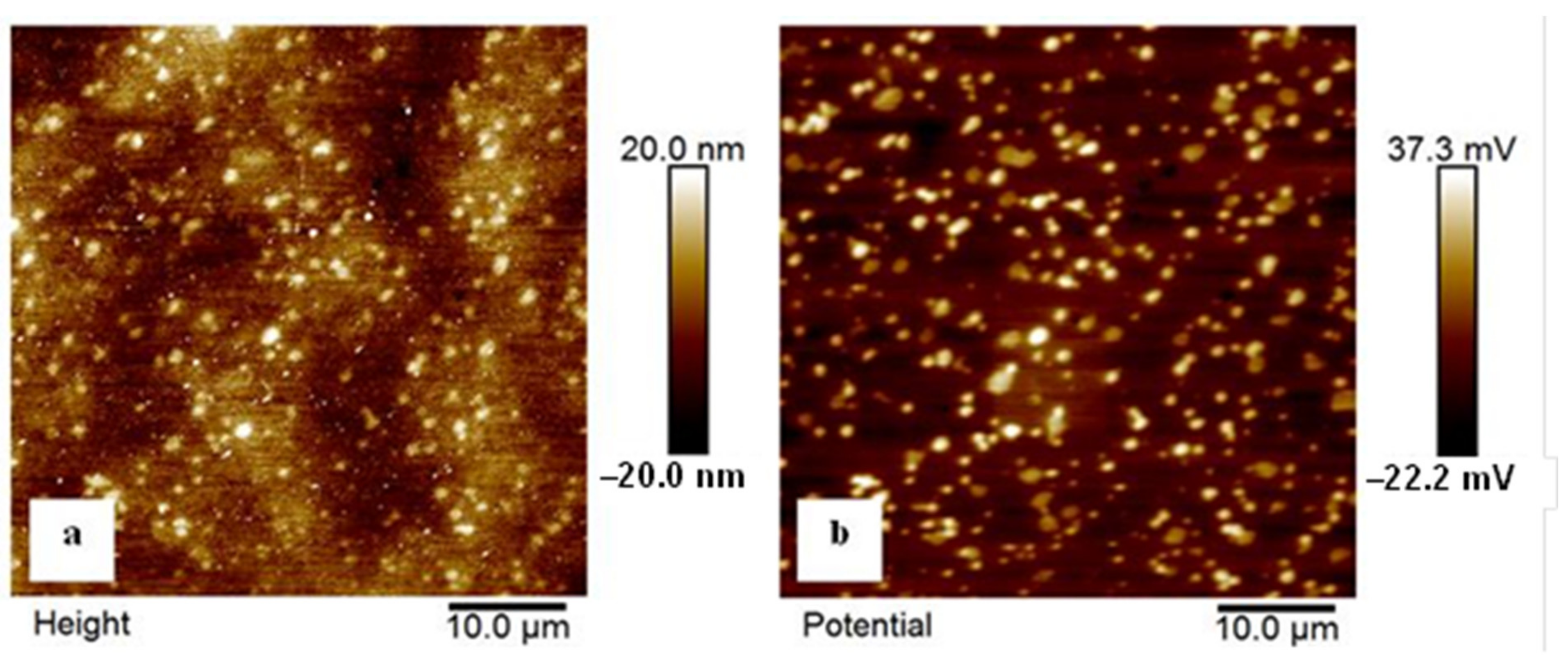

Figure 14.

KPFM images of the examined steel sample that was subjected to the SZT at −140 °C. (a) Topography and (b) work function mapping. Image size 50 × 50 μm2.

Figure 14.

KPFM images of the examined steel sample that was subjected to the SZT at −140 °C. (a) Topography and (b) work function mapping. Image size 50 × 50 μm2.

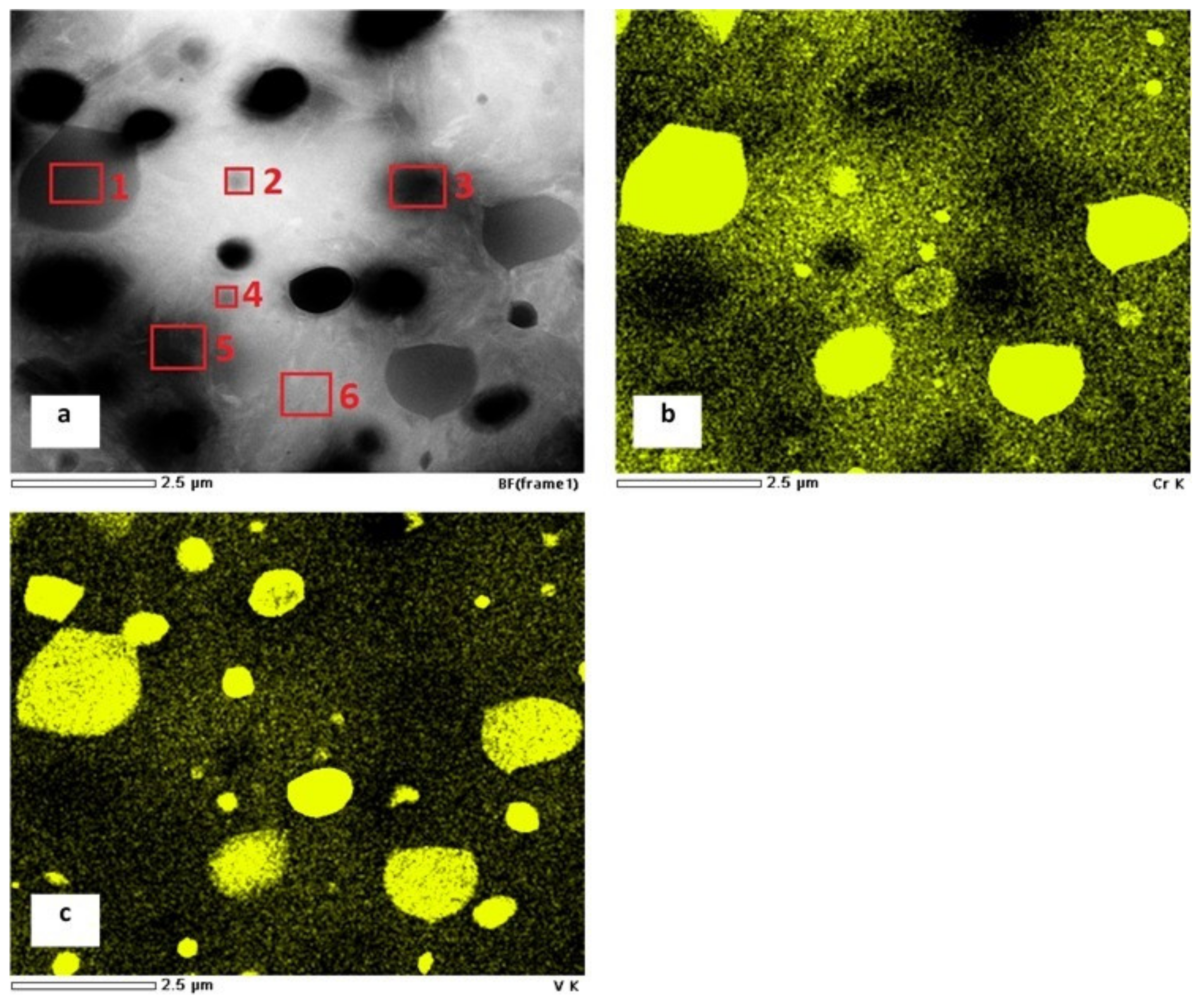

Figure 15.

TEM micrograph showing the carbides in martensitic matrix of the specimen after quenching followed by SZT at −140 °C (a), EDS map of Cr (b), EDS map of V (c). The sites of semi-quantitative EDS measurements are labelled and numbered in the TEM image (a).

Figure 15.

TEM micrograph showing the carbides in martensitic matrix of the specimen after quenching followed by SZT at −140 °C (a), EDS map of Cr (b), EDS map of V (c). The sites of semi-quantitative EDS measurements are labelled and numbered in the TEM image (a).

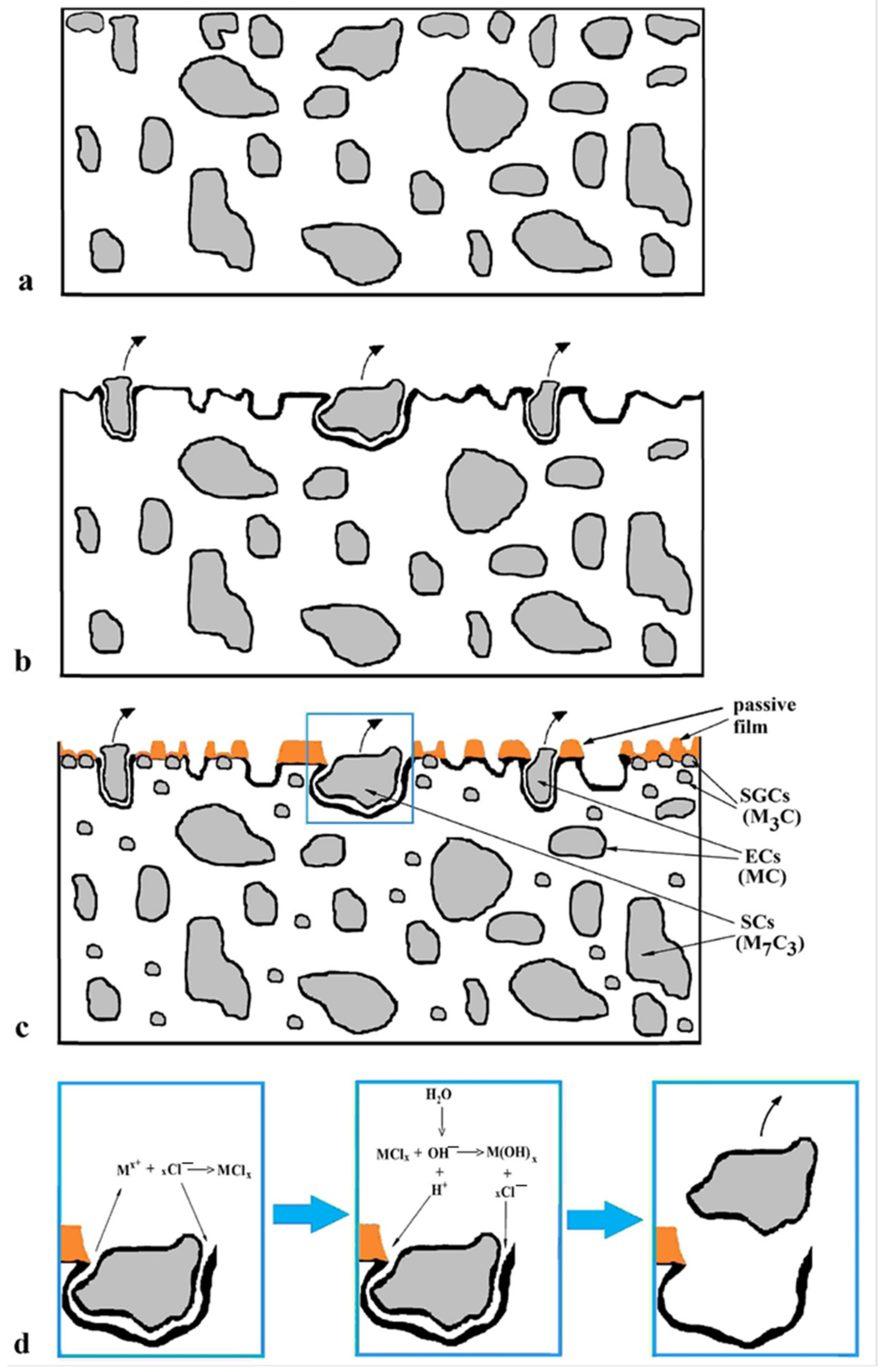

Figure 16.

A schematic of the corrosion attack of the Vanadis 6 steel: before testing (a), after testing, CHT steel (b), SZT steel—overview (c), detail from (d).

Figure 16.

A schematic of the corrosion attack of the Vanadis 6 steel: before testing (a), after testing, CHT steel (b), SZT steel—overview (c), detail from (d).

Table 1.

Chemical composition of the experimental steel.

Table 1.

Chemical composition of the experimental steel.

| Element (Mass %) | C | Si | Mn | Cr | V | Mo | Fe |

|---|

| Content | 2.1 | 1.0 | 0.4 | 6.8 | 5.4 | 1.5 | balance |

Table 2.

The mass percentage, f, atomic weight, W, most common valance, n, electron equivalents of the main elements in the Vanadis 6 steel, Q, and calculated electron equivalent of the steel, Qtotal, as well as its equivalent weight, Ew.

Table 2.

The mass percentage, f, atomic weight, W, most common valance, n, electron equivalents of the main elements in the Vanadis 6 steel, Q, and calculated electron equivalent of the steel, Qtotal, as well as its equivalent weight, Ew.

| Element | f (Mass %) | W (g) | n (-) | Q = (n × f)/W |

|---|

| C | 2.1 | 12.0107 | 4 | 0.699376389 |

| Si | 1.0 | 28.0855 | 4 | 0.142422246 |

| Mn | 0.4 | 54.9380 | 2 | 0.014561857 |

| Cr | 6.8 | 51.9961 | 3 | 0.392337118 |

| Mo | 1.5 | 95.9400 | 6 | 0.093808630 |

| V | 5.4 | 50.9415 | 5 | 0.530019729 |

| Fe | 82.8 | 55.8450 | 3 | 4.448025786 |

| Qtotal | 6.320551755 |

| EW | 15.821403555 |

Table 3.

Corrosion current, Icorr, corrosion potential, Ecorr, and pitting potential, Epit, values acquired from corrosion tests in 3.5 mass % NaCl water solution, for CHT and different SZT specimens in the prior-to-tempering state.

Table 3.

Corrosion current, Icorr, corrosion potential, Ecorr, and pitting potential, Epit, values acquired from corrosion tests in 3.5 mass % NaCl water solution, for CHT and different SZT specimens in the prior-to-tempering state.

| Heat Treatment | Icorr (A·cm−2) | Ecorr (V) | Epit (V) |

|---|

| CHT, un-tempered | 1.54 × 10−7 | −0.964 | −0.264 |

| SZT −75 °C, un-tempered | 9.82 × 10−8 | −0.903 | −0.026 |

| SZT −140 °C, un-tempered | 1.02 × 10−8 | −0.878 | −0.221 |

| SZT −196 °C, un-tempered | 4.41 × 10−8 | −0.956 | −0.188 |

| SZT −269 °C, un-tempered | 4.82 × 10−8 | −0.901 | −0.179 |

Table 4.

Corrosion current, Icorr, corrosion potential, Ecorr, and pitting potential, Epit, values acquired from corrosion tests in 3.5 mass % NaCl water solution, for CHT and differently tempered specimens.

Table 4.

Corrosion current, Icorr, corrosion potential, Ecorr, and pitting potential, Epit, values acquired from corrosion tests in 3.5 mass % NaCl water solution, for CHT and differently tempered specimens.

| Heat Treatment | Icorr (A·cm−2) | Ecorr (V) | Epit (V) |

|---|

| CHT, un-tempered | 1.54 × 10−7 | −0.964 | −0.264 |

| CHT, tempered at 170 °C | 1.21 × 10−7 | −0.990 | −0.189 |

| CHT, tempered at 330 °C | 1.74 × 10−6 | −1.031 | −0.283 |

| CHT, tempered at 450 °C | 2.32 × 10−6 | −1.035 | −0.395 |

| CHT, tempered at 530 °C | 2.49 × 10−6 | −1.072 | −0.142 |

Table 5.

Corrosion current, Icorr, corrosion potential, Ecorr, and pitting potential, Epit, values acquired from corrosion tests in 3.5 mass % NaCl water solution, for specimens after SZT at −140 °C and different tempering regimes.

Table 5.

Corrosion current, Icorr, corrosion potential, Ecorr, and pitting potential, Epit, values acquired from corrosion tests in 3.5 mass % NaCl water solution, for specimens after SZT at −140 °C and different tempering regimes.

| Heat Treatment | Icorr (A·cm−2) | Ecorr (V) | Epit (V) |

|---|

| SZT −140 °C, un-tempered | 1.02 × 10−8 | −0.878 | −0.221 |

| SZT −140 °C, tempered at 170 °C | 5.17 × 10−8 | −0.902 | −0.219 |

| SZT −140 °C, tempered at 330 °C | 1.13 × 10−7 | −0.930 | −0.232 |

| SZT −140 °C, tempered at 450 °C | 1.88 × 10−7 | −0.948 | −0.230 |

| SZT −140 °C, tempered at 530 °C | 2.52 × 10−7 | −0.961 | −0.198 |

Table 6.

Corrosion current, Icorr, corrosion potential, Ecorr, and pitting potential, Epit, values acquired from corrosion tests in 3.5 mass % NaCl water solution, for CHT and different SZT specimens, after tempering at 530 °C.

Table 6.

Corrosion current, Icorr, corrosion potential, Ecorr, and pitting potential, Epit, values acquired from corrosion tests in 3.5 mass % NaCl water solution, for CHT and different SZT specimens, after tempering at 530 °C.

| Heat Treatment | Icorr (A·cm−2) | Ecorr (V) | Epit (V) |

|---|

| CHT, tempered at 530 °C | 2.49 × 10−6 | −1.072 | −0.142 |

| SZT −75 °C, tempered at 530 °C | 4.61 × 10−7 | −0.952 | −0.262 |

| SZT −140 °C, tempered at 530 °C | 2.52 × 10−7 | −0.961 | −0.198 |

| SZT −196 °C, tempered at 530 °C | 1.27 × 10−6 | −1.065 | −0.372 |

| SZT −269 °C, tempered at 530 °C | 1.70 × 10−7 | −0.975 | −0.145 |

Table 7.

Recorded values of EDS measurements from sites in

Figure 16a.

Table 7.

Recorded values of EDS measurements from sites in

Figure 16a.

| Site No. | Chemical Composition (mass %) |

|---|

| Si | V | Cr | Fe | Mo |

|---|

| 1 | - | 12.8 | 37.8 | 47.1 | 2.3 |

| 2 | - | 73.4 | 17.7 | 8.9 | - |

| 3 | 0.5 | 0.5 | 5.4 | 92.4 | 1.2 |

| 4 | 0.2 | 16.2 | 7.4 | 74.8 | 1.4 |

| 5 | 0.5 | 0.7 | 5.7 | 91.6 | 1.5 |

| 6 | 0.5 | 0.6 | 5.6 | 92.4 | 0.9 |