Experimental and Numerical Analysis of High-Temperature Superconducting Tapes Modified by Composite Thermal Stabilization Subjected to Thermomechanical Loading

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Methods

2.2.1. Tensile Test

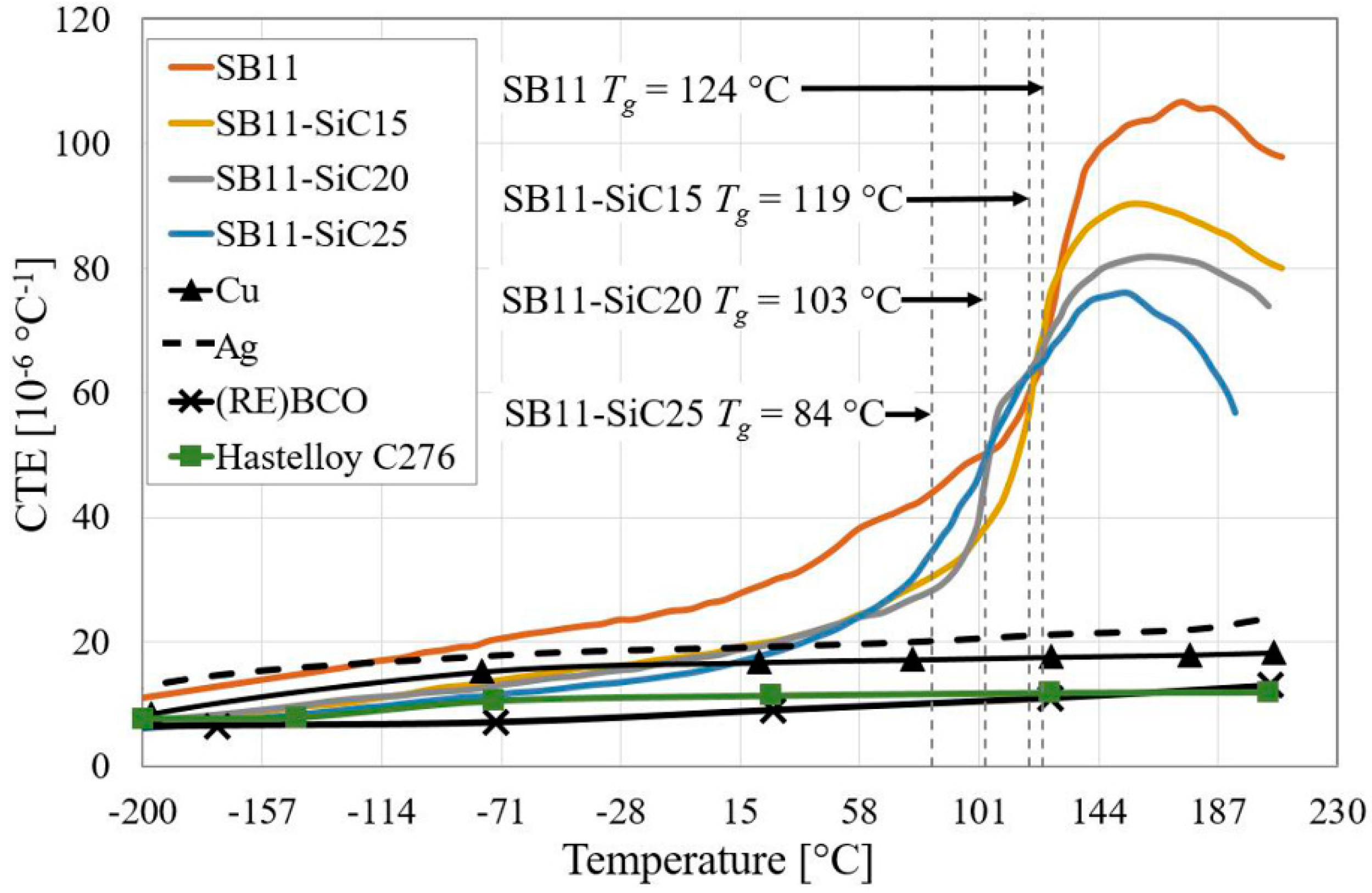

2.2.2. Thermophysical Properties

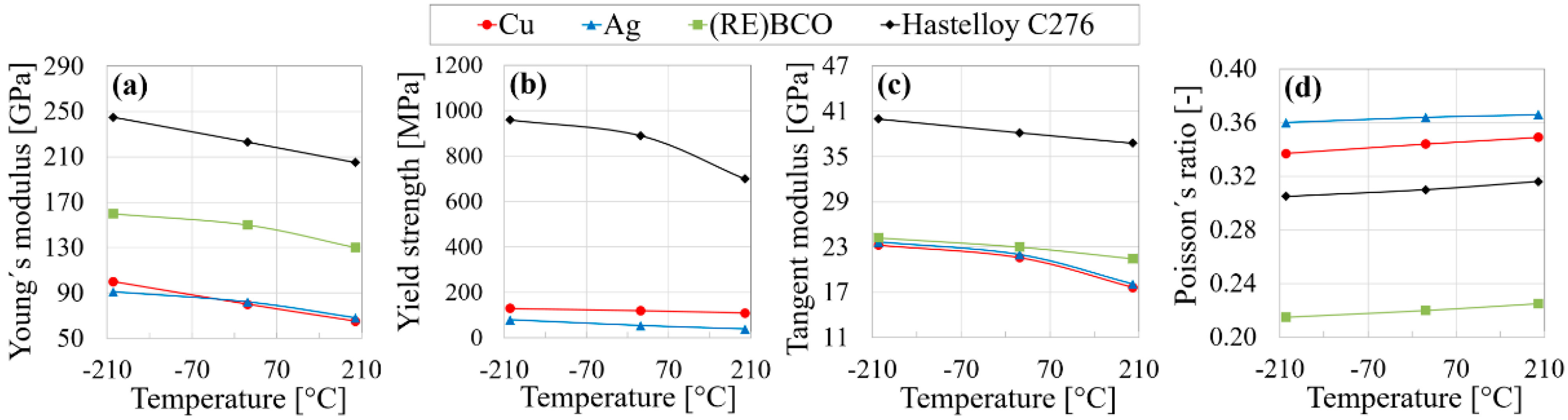

2.2.3. Mechanical Properties

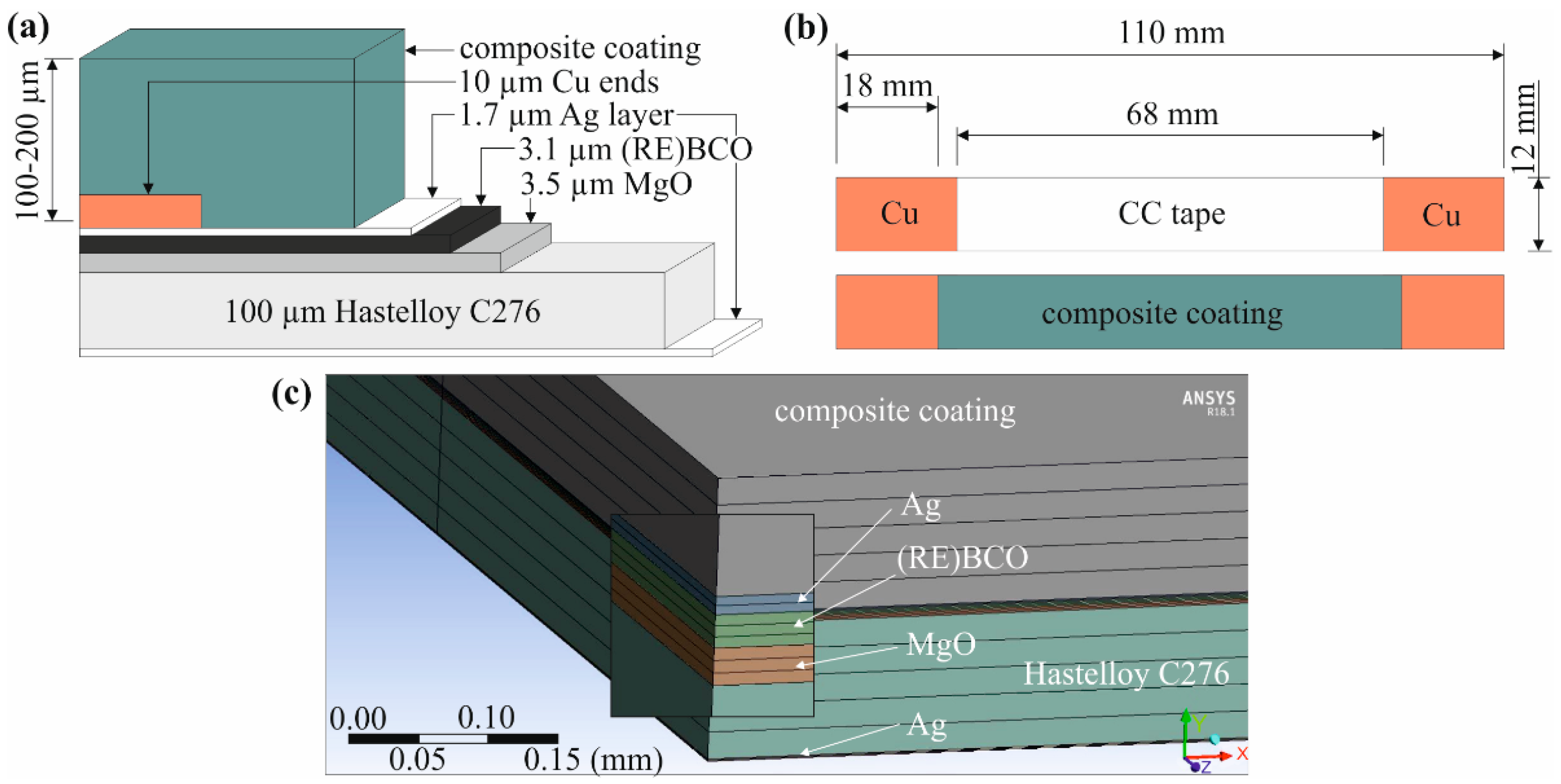

2.2.4. Boundary Conditions for the FEA

3. Results and Discussion

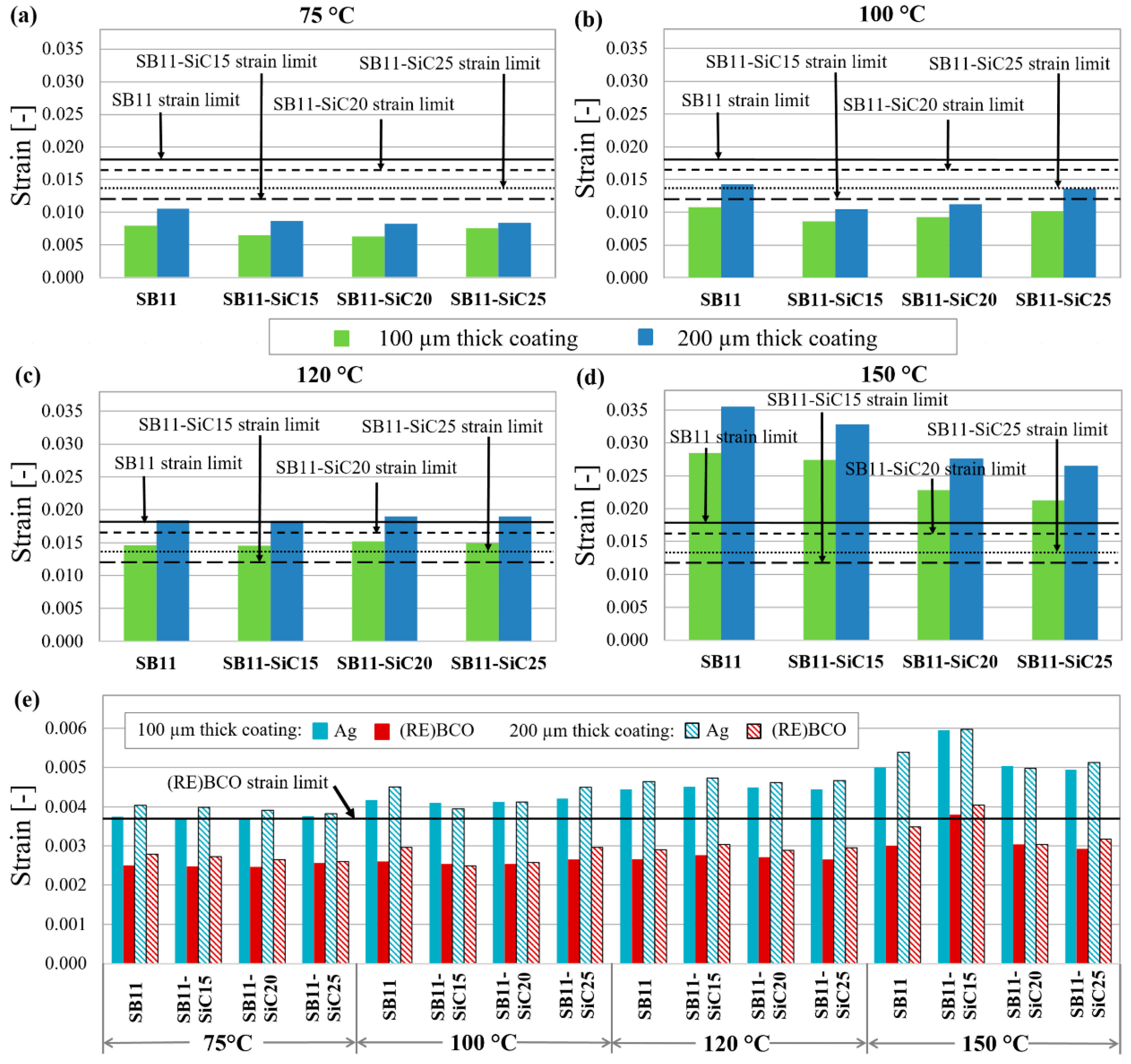

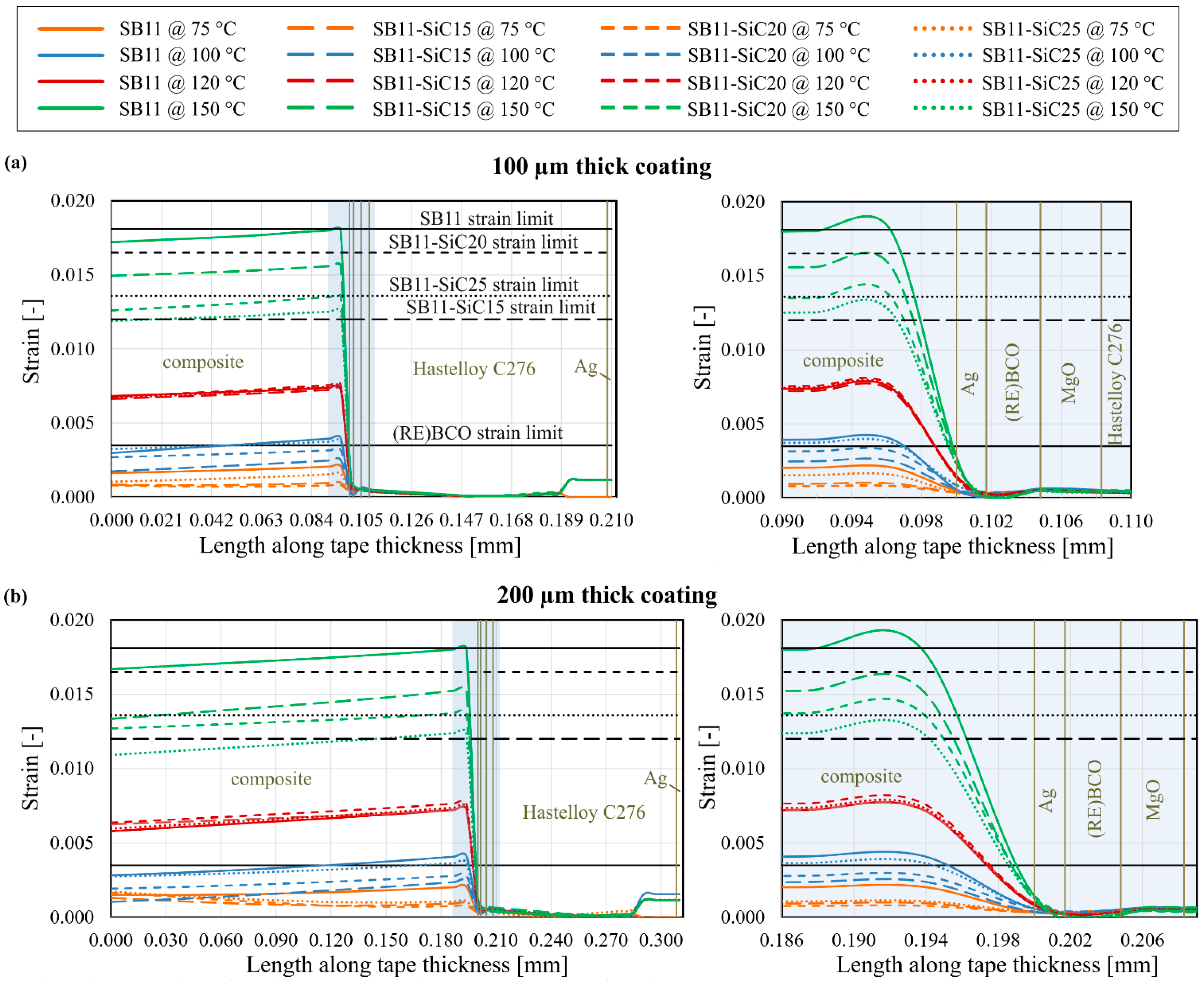

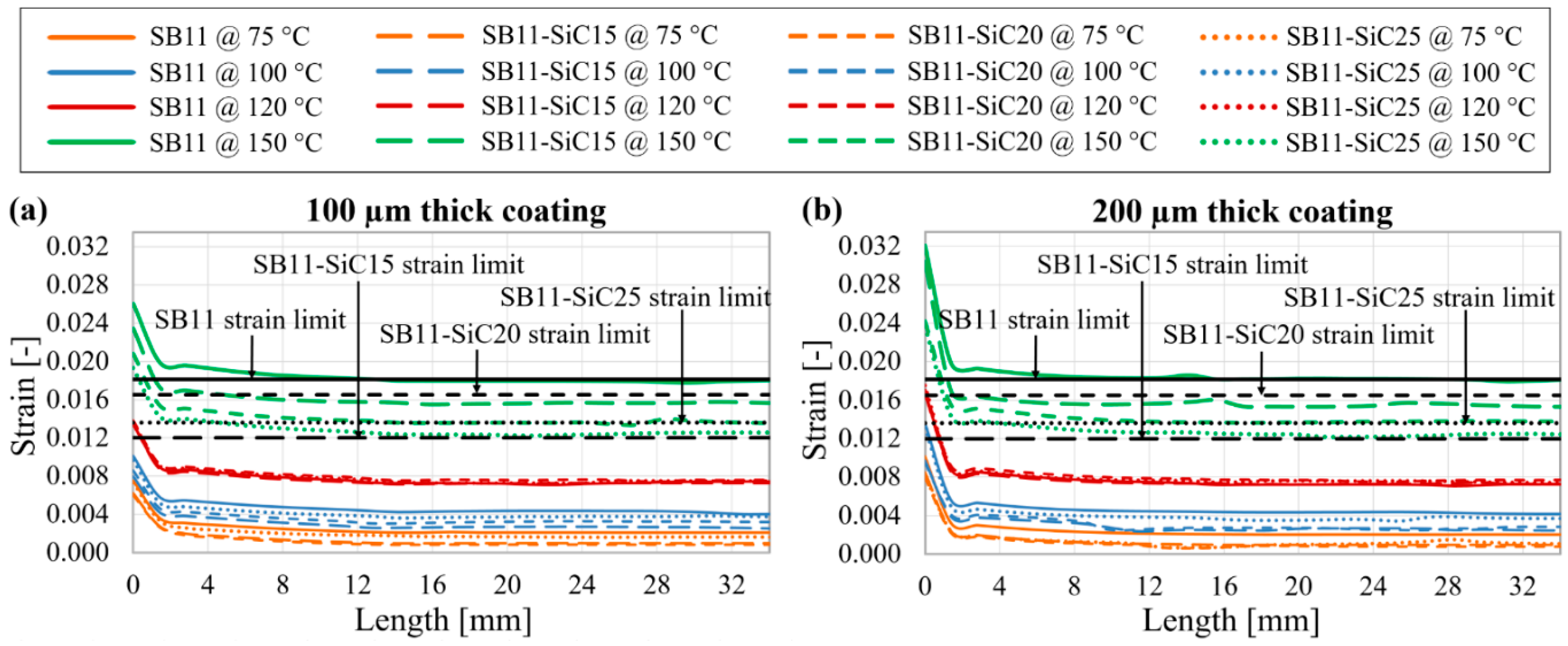

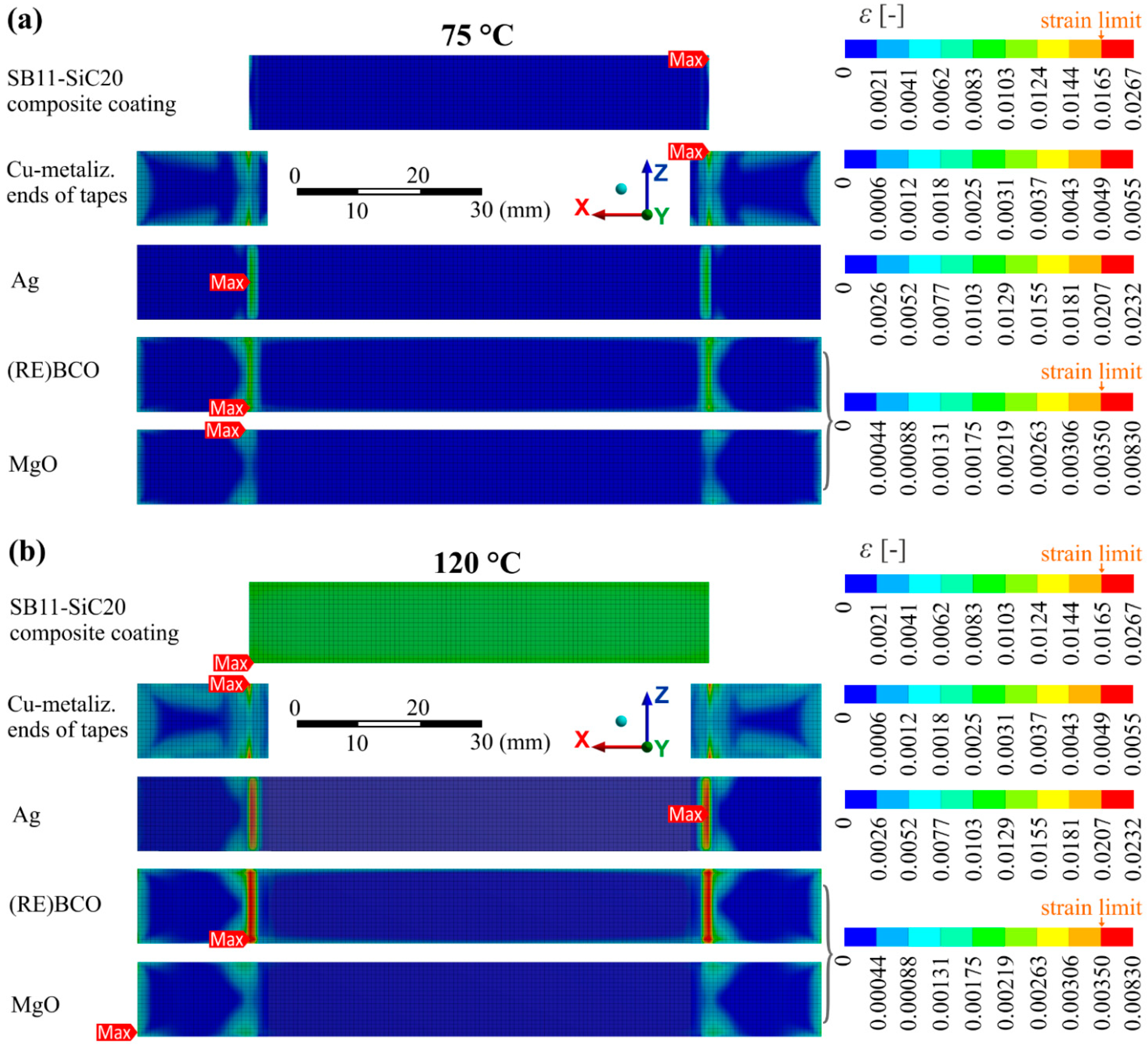

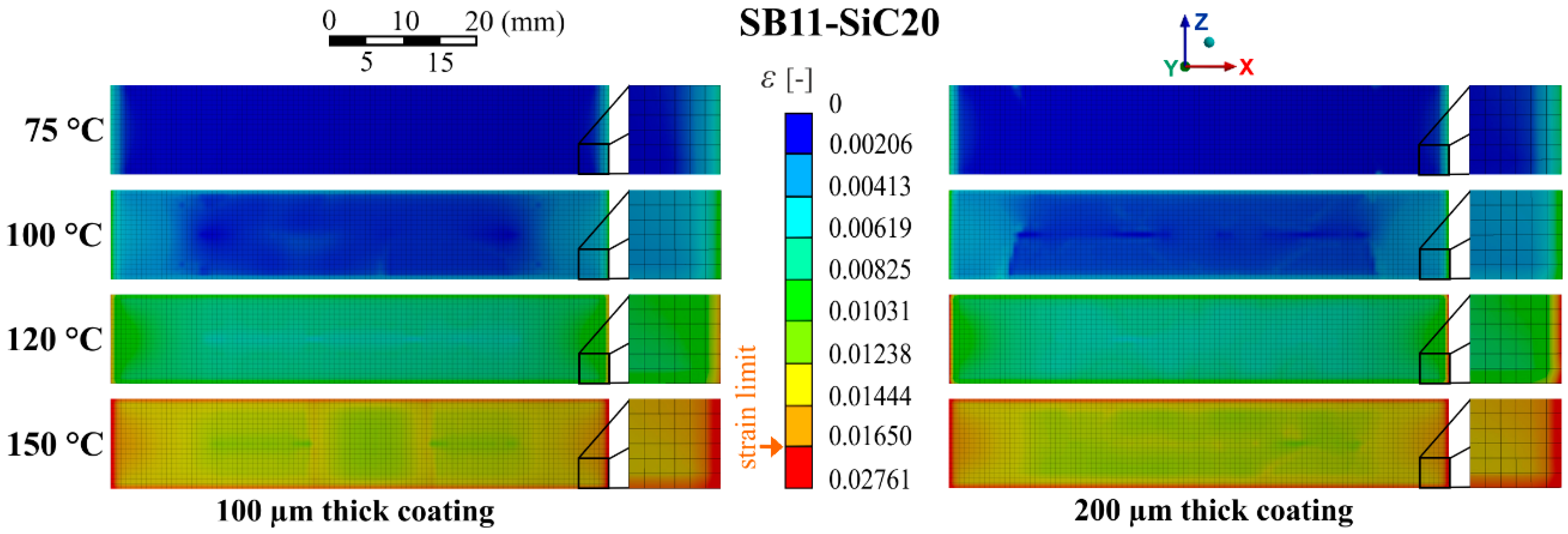

3.1. FEA of the Maximum Strains in the HTS Tapes Modified with the Composite Coating

3.2. FEA of Path Strain Distribution in the HTS Tapes Modified with the Composite Coating

4. Conclusions

- The higher the filler content, the lower the maximal equivalent strain is induced in the whole material volume of the composite layer during the limitation. The trend is disrupted by the composite with the highest SiC content;

- The strain is distributed unevenly in the composite coating. The highest value is located at the ends of the coating in longitudinal direction. The transverse path showed that it is not exactly at the interface with the Ag layer as expected, but approximately 4–6 µm from this interface;

- Thicker coatings and higher quenching temperatures generate higher strain in all layers of the modified HTS tapes;

- Places with overlapping of more layer edges are the most sensitive to the high strain development. The superconducting layer must bear the strain in this location, which can cause its serious damage. The damaging of such places was also confirmed experimentally;

- The safest strain distribution was achieved with the SB11-SiC20 composite coating of 100 µm thickness and reaching the temperature lower than 120 °C. The calculated quenching temperature was 60 °C higher than the temperature measured in the experimental samples without the Ic degradation. Herewith, the FEA recognized the possibility of using higher electric fields limits (>130 V/m).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Naito, T.; Fujishiro, H.; Yamamura, Y.; Saito, K.; Okamoto, H.; Hayashi, H.; Gosho, Y.; Ohkuma, T.; Shiohara, Y. Specific Heat and Thermal Diffusivity of YBCO Coated Conductors. Phys. Procedia 2012, 36, 1609–1613. [Google Scholar] [CrossRef][Green Version]

- Šouc, J.; Gomory, F.; Solovyov, M.; Vojenčiak, M.; Kujovič, T.; Seiler, E.; Kováč, J.; Frolek, L.; Behúlová, M.; Janovec, J.; et al. CORC-like cable production and characterization of the solenoid made from it. Supercond. Sci. Technol. 2018, 32, 035007. [Google Scholar] [CrossRef]

- Lombardo, V.; Barzi, E.; Turrioni, D.; Zlobin, A.V.; Long, N.; Badcock, R. Fabrication, Qualification and Test of High Roebel Coated Conductor Cable for HEP Magnets. IEEE Trans. Appl. Supercond. 2011, 21, 2331–2334. [Google Scholar] [CrossRef]

- Takayasu, M.; Mangiarotti, F.J.; Chiesa, L.; Bromberg, L.; Minervini, J. Conductor Characterization of YBCO Twisted Stacked-Tape Cables. IEEE Trans. Appl. Supercond. 2012, 23, 4800104. [Google Scholar] [CrossRef]

- Tan, Y.X.; Yang, K.; Xiang, B.; Yan, J.; Geng, Y.S.; Liu, Z.Y.; Wang, J.H.; Yanabu, S. Resistive type superconducting fault current limiter and current flowing time. In Proceedings of the 2015 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices (ASEMD), Shanghai, China, 20–23 November 2015; pp. 290–291. [Google Scholar]

- Tixador, P.; Vialle, J.; Badel, A. Operation of an SCFCL at 65 K. IEEE Trans. Appl. Supercond. 2018, 28, 1–5. [Google Scholar] [CrossRef]

- Senatore, C.; Barth, C.; Bonura, M.; Kulich, M.; Mondonico, G. Field and temperature scaling of the critical current density in commercial REBCO coated conductors. Supercond. Sci. Technol. 2015, 29, 014002. [Google Scholar] [CrossRef]

- Markiewicz, W. Protection of HTS Coils in the Limit of Zero Quench Propagation Velocity. IEEE Trans. Appl. Supercond. 2008, 18, 1333–1336. [Google Scholar] [CrossRef]

- Mogro-Campero, A.; Paik, K.W.; Turner, L.G. Degradation of thin films of YBa2Cu3O7 by annealing in air and in vacuum. J. Supercond. Nov. Magn. 1995, 8, 95–98. [Google Scholar] [CrossRef]

- Dhir, V.K. Boiling Heat Transfer. Annu. Rev. Fluid Mech. 1998, 30, 365–401. [Google Scholar] [CrossRef]

- Yazdani-Asrami, M.; Staines, M.; Sidorov, G.; Eicher, A. Heat transfer and recovery performance enhancement of metal and superconducting tapes under high current pulses for improving fault current-limiting behavior of HTS transformers. Supercond. Sci. Technol. 2020, 33, 095014. [Google Scholar] [CrossRef]

- Lacroix, C.; Lapierre, Y.; Coulombe, J.; Sirois, F. High normal zone propagation velocity in second generation high-temperature superconductor coated conductors with a current flow diverter architecture. Supercond. Sci. Technol. 2014, 27, 055013. [Google Scholar] [CrossRef]

- Deutscher, G. High-Voltage Superconducting Fault Current Limiters Based on High-Diffusivity Dielectric Substrates. J. Supercond. Nov. Magn. 2018, 31, 1961–1963. [Google Scholar] [CrossRef]

- De Sousa, W.T.B.; Kudymow, A.; Strauss, S.; Palasz, S.; Elschner, S.; Noe, M. Simulation of the Thermal Performance of HTS Coated Conductors for HVDC SFCL. J. Phys. Conf. Ser. 2020, 1559, 012097. [Google Scholar] [CrossRef]

- Buran, M.; Vojenciak, M.; Mošať, M.; Ghabeli, A.; Solovyov, M.; Pekarčíková, M.; Kopera, L.; Gömöry, F. Impact of a REBCO coated conductor stabilization layer on the fault current limiting functionality. Supercond. Sci. Technol. 2019, 32, 095008. [Google Scholar] [CrossRef]

- Fillers in Action: Reducing the Coefficient of Thermal Expansion of Thermosets—Polymer Innovation Blog. Available online: https://polymerinnovationblog.com/fillers-action-reducing-coefficient-thermal-expansion-thermosets/ (accessed on 2 December 2020).

- Sudheer, M.; Prabhu, R.; Raju, K.; Bhat, T. Effect of Filler Content on the Performance of Epoxy/PTW Composites. Adv. Mater. Sci. Eng. 2014, 2014, 970468. [Google Scholar] [CrossRef]

- Barth, C.; Bagrets, N.; Weiss, K.-P.; Bayer, C.M.; Bast, T. Degradation free epoxy impregnation of REBCO coils and cables. Supercond. Sci. Technol. 2013, 26, 055007. [Google Scholar] [CrossRef]

- Hwang, Y.J.; Kim, J.M.; Kim, L.S.; Jang, J.Y.; Kim, M.; Jeong, S.; Cho, J.Y.; Yi, G.-R.; Choi, Y.S.; Lee, G. Epoxy-based thermally conductive adhesives with effective alumina and boron nitride for superconducting magnet. Compos. Sci. Technol. 2020, 200, 108456. [Google Scholar] [CrossRef]

- Sun, L.; Sneller, A.; Kwon, P. ZrW2O8-containing composites with near-zero coefficient of thermal expansion fabricated by various methods: Comparison and optimization. Compos. Sci. Technol. 2008, 68, 3425–3430. [Google Scholar] [CrossRef]

- Chen, J.; Xing, X.; Sun, C.; Hu, P.; Yu, R.; Wang, A.X.; Li, L. Zero Thermal Expansion in PbTiO3-Based Perovskites. J. Am. Chem. Soc. 2008, 130, 1144–1145. [Google Scholar] [CrossRef] [PubMed]

- Van De Camp, W.; Dhalle, M.; Wessel, W.; Warnet, L.; Atli-Veltin, B.; Van Der Putten, S.; Dam, J.; Ter Brake, H. Cryogenic Fatigue and Stress-strain Behavior of a Fibre Metal Laminate. Phys. Procedia 2015, 67, 1043–1048. [Google Scholar] [CrossRef]

- Kalia, S.; Fu, S.-Y. Polymers at Cryogenic Temperatures; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Pekarčíková, M.; Mišík, J.; Drienovský, M.; Krajčovič, J.; Vojenčiak, M.; Búran, M.; Mošať, M.; Húlan, T.; Skarba, M.; Cuninková, E.; et al. Composite Heat Sink Material for Superconducting Tape in Fault Current Limiter Applications. Materials 2020, 13, 1832. [Google Scholar] [CrossRef] [PubMed]

- Pekarčíková, M.; Drienovský, M.; Krajčovič, J.; Mišík, J.; Cuninková, E.; Húlan, T.; Bošák, O.; Vojenčiak, M. Analysis of thermo-physical properties of materials suitable for thermal stabilization of superconducting tapes for high-voltage superconducting fault current limiters. J. Therm. Anal. Calorim. 2019, 138, 4375–4383. [Google Scholar] [CrossRef]

- Lord, J.D.; Morrell, R. Measurement Good Practice Guide No. 98 Elastic Modulus Measurement. 100. Available online: https://www.npl.co.uk/special-pages/guides/gpg98_elastic (accessed on 10 January 2021).

- Swenson, C.A. Linear thermal expansivity (1.5–300 K) and heat capacity (1.2–90 K) of Stycast 2850FT. Rev. Sci. Instruments 1997, 68, 1312–1315. [Google Scholar] [CrossRef]

- White, G.K. Thermal expansion of reference materials: Copper, silica and silicon. J. Phys. D Appl. Phys. 1973, 6, 2070–2078. [Google Scholar] [CrossRef]

- Wang, K.; Reeber, R. Thermal Expansion of Copper. High Temp. Mater. Sci. 1996, 35, 181–186. [Google Scholar]

- Smith, D.; Fickett, F. Low-Temperature Properties of Silver. J. Res. Natl. Inst. Stand. Technol. 1995, 100, 119–171. [Google Scholar] [CrossRef] [PubMed]

- Joshi, R.H.; Thakore, B.Y.; Vyas, P.R.; Jani, A.R.; Bhatt, N.K. High-temperature thermodynamics of silver: Semi-empirical approach. Chin. Phys. B 2017, 26, 116502. [Google Scholar] [CrossRef]

- Zeisberger, M.; Latka, I.; Ecke, W.; Habisreuther, T.; Litzkendorf, D.; Gawalek, W. Measurement of the thermal expansion of melt-textured YBCO using optical fibre grating sensors. Supercond. Sci. Technol. 2005, 18, S202–S205. [Google Scholar] [CrossRef]

- Nagel, P.; Pasler, V.; Meingast, C.; Rykov, A.I.; Tajima, S. Anomalously Large Oxygen-Ordering Contribution to the Thermal Expansion of Untwinned YBa2Cu3O6.95 Single Crystals: A Glasslike Transition near Room Temperature. Phys. Rev. Lett. 2000, 85, 2376–2379. [Google Scholar] [CrossRef]

- Sugano, M.; Shikimachi, K.; Hirano, N.; Nagaya, S. The reversible strain effect on critical current over a wide range of temperatures and magnetic fields for YBCO coated conductors. Supercond. Sci. Technol. 2010, 23, 085013. [Google Scholar] [CrossRef]

- Tao, L.; Sun, Z.; Min, W.; Ou, H.; Qi, L.; Yu, M. Improving the Toughness of Thermosetting Epoxy Resins via Blending Triblock Copolymers. RSC Adv. 2020, 10, 1603–1612. [Google Scholar] [CrossRef]

- Li, J.; Peng, C.; Li, Z.; Wu, Z.; Li, S. The improvement in cryogenic mechanical properties of nano-ZrO2/epoxy composites via surface modification of nano-ZrO2. RSC Adv. 2016, 6, 61393–61401. [Google Scholar] [CrossRef]

- Chowdhury, H.; Rahman, M.M.; Uddin, T. Improvement of mechanical properties of polypropylene composite using filler, modifier and reinforcement. J. Phys. Conf. Ser. 2018, 1086, 012003. [Google Scholar] [CrossRef]

- Ilin, K.; Yagotintsev, K.A.; Zhou, C.; Gao, P.; Kosse, J.; Otten, S.J.; Wessel, W.A.J.; Haugan, T.J.; Van Der Laan, D.C.; Nijhuis, A. Experiments and FE modeling of stress–strain state in ReBCO tape under tensile, torsional and transverse load. Supercond. Sci. Technol. 2015, 28, 055006. [Google Scholar] [CrossRef]

- Wakamoto, K.; Mochizuki, Y.; Otsuka, T.; Nakahara, K.; Namazu, T. Temperature Dependence on Tensile Mechanical Properties of Sintered Silver Film. Materials 2020, 13, 4061. [Google Scholar] [CrossRef] [PubMed]

- Huo, Y.; Lee, C.C. The growth and stress vs. strain characterization of the silver solid solution phase with indium. J. Alloys Compd. 2016, 661, 372–379. [Google Scholar] [CrossRef]

- Tseng, Y.-W.; Hung, F.-Y.; Lui, T.-S. Microstructure, tensile and electrical properties of gold-coated silver bonding wire. Microelectron. Reliab. 2015, 55, 608–612. [Google Scholar] [CrossRef]

- Rajaguru, P.; Lu, H.; Bailey, C. Sintered silver finite element modelling and reliability based design optimisation in power electronic module. Microelectron. Reliab. 2015, 55, 919–930. [Google Scholar] [CrossRef][Green Version]

- Allen, N.C.; Chiesa, L.; Takayasu, M. Combined Tension-Torsion Effects on 2G REBCO Tapes for Twisted Stacked-Tape Cabling. IEEE Trans. Appl. Supercond. 2015, 25, 4800805. [Google Scholar] [CrossRef]

- Vojenciak, M.; Mosat’, M.; Pekarčíková, M.; Michalcova, E.; Mišík, J. Advanced superconducting tapes for high voltage fault current limiters. In Proceedings of the 2018 ELEKTRO, Mikulov, Czech Republic, 21–23 May 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Otten, S.; Kario, A.; Kling, A.; Goldacker, W. Bending properties of different REBCO coated conductor tapes and Roebel cables AtT = 77 K. Supercond. Sci. Technol. 2016, 29, 125003. [Google Scholar] [CrossRef]

- Gömöry, F.; Šouc, J. Stability of DC transport in HTS conductor with local critical current reduction. Supercond. Sci. Technol. 2021, 34, 025005. [Google Scholar] [CrossRef]

| Sample | System Composition | Density [kg/m3] |

|---|---|---|

| SB11 | Stycast 2850FT/catalyst 11 | 2271 ± 7 |

| SB11-SiC15 | Stycast 2850FT/catalyst 11 + 15 vol.% SiC | 2390 ± 3 |

| SB11-SiC20 | Stycast 2850FT/catalyst 11 + 20 vol.% SiC | 2691 ± 4 |

| SB11-SiC25 | Stycast 2850FT/catalyst 11 + 25 vol.% SiC | 2992 ± 6 |

| Composite | Experiment | Extrapolation | ||||

|---|---|---|---|---|---|---|

| E [GPa] | ν [-] | UTS [MPa] | E [GPa] | ν [-] | UTS [MPa] | |

| −120 °C | −200 °C | |||||

| SB11 | 21.32 ± 2.00 | 0.367 ± 0.010 | 44.00 ± 2.19 | 27.12 | 0.360 | 57.00 |

| SB11-SiC15 | 24.11 ± 0.67 | 0.361 ± 0.010 | 54.84 ± 7.40 | 31.80 | 0.342 | 70.52 |

| SB11-SiC20 | 26.42 ± 3.41 | 0.351 ± 0.005 | 59.47 ± 1.79 | 34.15 | 0.341 | 80.43 |

| SB11-SiC25 | 29.80 ± 2.17 | 0.340 ± 0.020 | 65.50 ± 6.49 | 40.23 | 0.333 | 86.46 |

| RT | ||||||

| SB11 | 5.40 ± 1.72 | 0.369 ± 0.003 | 19.96 ± 3.50 | |||

| SB11-SiC15 | 8.66 ± 3.98 | 0.365 ± 0.006 | 24.74 ± 1.87 | |||

| SB11-SiC20 | 10.94 ± 7.35 | 0.360 ± 0.006 | 34.59 ± 2.72 | |||

| SB11-SiC25 | 15.61 ± 2.48 | 0.352 ± 0.004 | 35.93 ± 2.31 | |||

| 100 °C | 150 °C | |||||

| SB11 | 0.52 ± 0.27 | 0.382 ± 0.010 | 4.56 ± 0.08 | 0.15 | 0.384 | 1.50 |

| SB11-SiC15 | 1.06 ± 0.05 | 0.377 ± 0.006 | 7.21 ± 0.81 | 0.40 | 0.382 | 3.00 |

| SB11-SiC20 | 0.63 ± 0.31 | 0.371 ± 0.003 | 5.69 ± 0.86 | 0.20 | 0.376 | 2.00 |

| SB11-SiC25 | 0.50 ± 0.30 | 0.363 ± 0.010 | 4.20 ± 0.72 | 0.10 | 0.367 | 1.45 |

| Sample | Elongation at Break [-] | ||

|---|---|---|---|

| −120 °C | RT | 100 °C | |

| SB11 | 0.00208 ± 0.00011 | 0.00504 ± 0.00197 | 0.01810 ± 0.00526 |

| SB11-SiC15 | 0.00202 ± 0.00053 | 0.00417 ± 0.00132 | 0.01200 ± 0.00158 |

| SB11-SiC20 | 0.00199 ± 0.00027 | 0.00326 ± 0.00172 | 0.01650 ± 0.00600 |

| SB11-SiC25 | 0.00186 ± 0.00106 | 0.00181 ± 0.00102 | 0.01360 ± 0.00672 |

| CTE [10−6/°C] | SB11 | SB11-SiC15 | SB11-SiC20 | SB11-SiC25 |

|---|---|---|---|---|

| 22 °C | 29.3 | 19.7 | 19.4 | 17.7 |

| 75 °C | 41.6 | 28.1 | 26.9 | 29.2 |

| 100 °C | 49.9 | 36.6 | 38.5 | 48.5 |

| 120 °C | 61.0 | 62.0 | 66.5 | 64.9 |

| 150 °C | 101.0 | 90.2 | 81.3 | 76.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cuninková, E.; Pekarčíková, M.; Skarba, M.; Krajčovič, J.; Pašák, M. Experimental and Numerical Analysis of High-Temperature Superconducting Tapes Modified by Composite Thermal Stabilization Subjected to Thermomechanical Loading. Materials 2021, 14, 3579. https://doi.org/10.3390/ma14133579

Cuninková E, Pekarčíková M, Skarba M, Krajčovič J, Pašák M. Experimental and Numerical Analysis of High-Temperature Superconducting Tapes Modified by Composite Thermal Stabilization Subjected to Thermomechanical Loading. Materials. 2021; 14(13):3579. https://doi.org/10.3390/ma14133579

Chicago/Turabian StyleCuninková, Eva, Marcela Pekarčíková, Michal Skarba, Jozef Krajčovič, and Matej Pašák. 2021. "Experimental and Numerical Analysis of High-Temperature Superconducting Tapes Modified by Composite Thermal Stabilization Subjected to Thermomechanical Loading" Materials 14, no. 13: 3579. https://doi.org/10.3390/ma14133579

APA StyleCuninková, E., Pekarčíková, M., Skarba, M., Krajčovič, J., & Pašák, M. (2021). Experimental and Numerical Analysis of High-Temperature Superconducting Tapes Modified by Composite Thermal Stabilization Subjected to Thermomechanical Loading. Materials, 14(13), 3579. https://doi.org/10.3390/ma14133579