Deformation Behavior and Tensile Properties of the Semi-Equiaxed Microstructure in Near Alpha Titanium Alloy

Abstract

1. Introduction

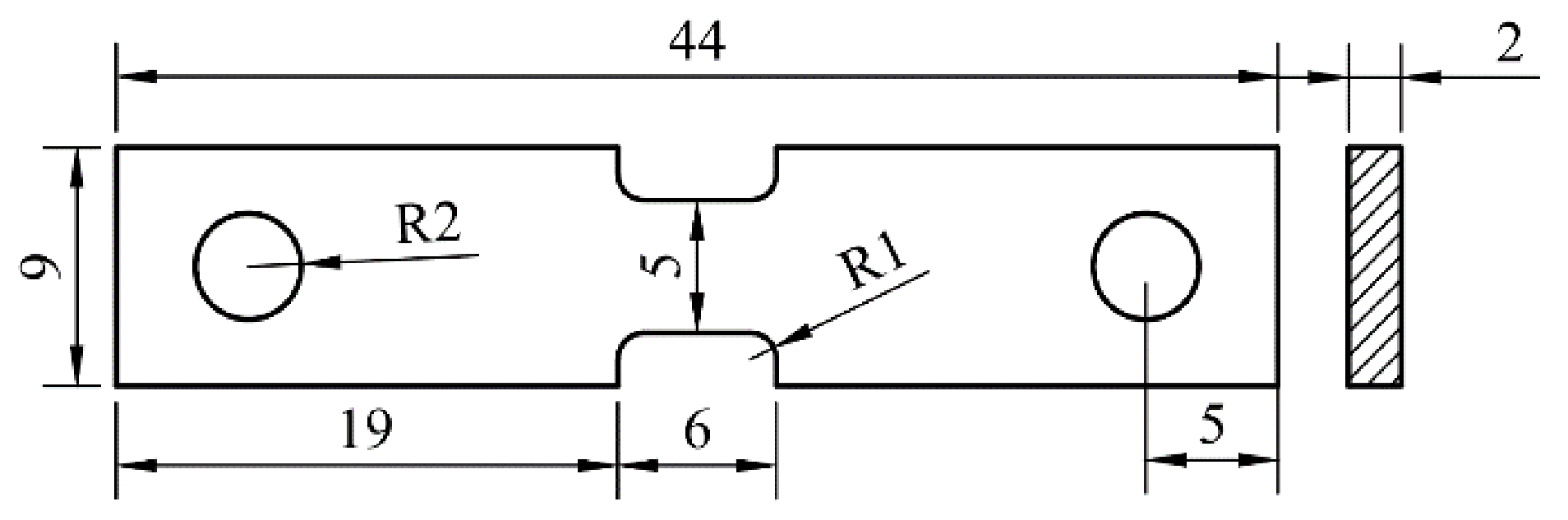

2. Experimental Procedures

3. Results and Discussion

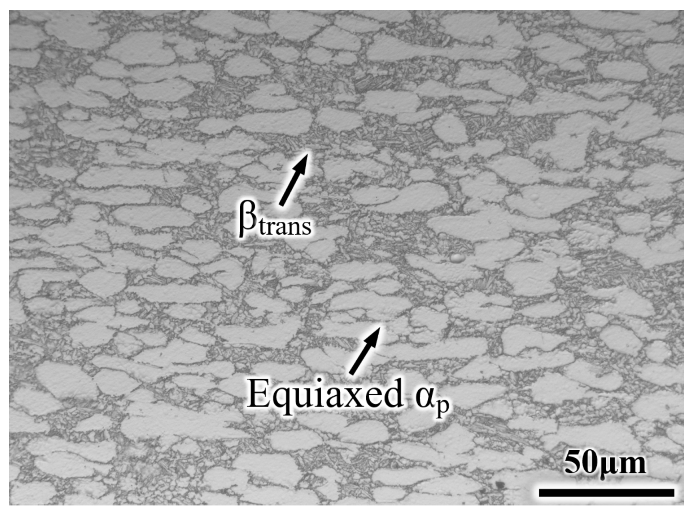

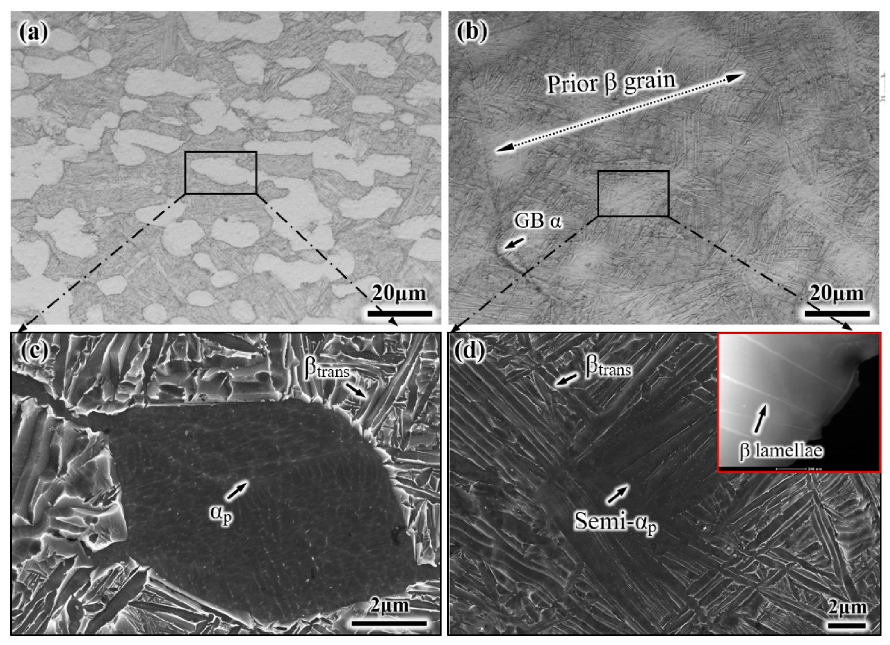

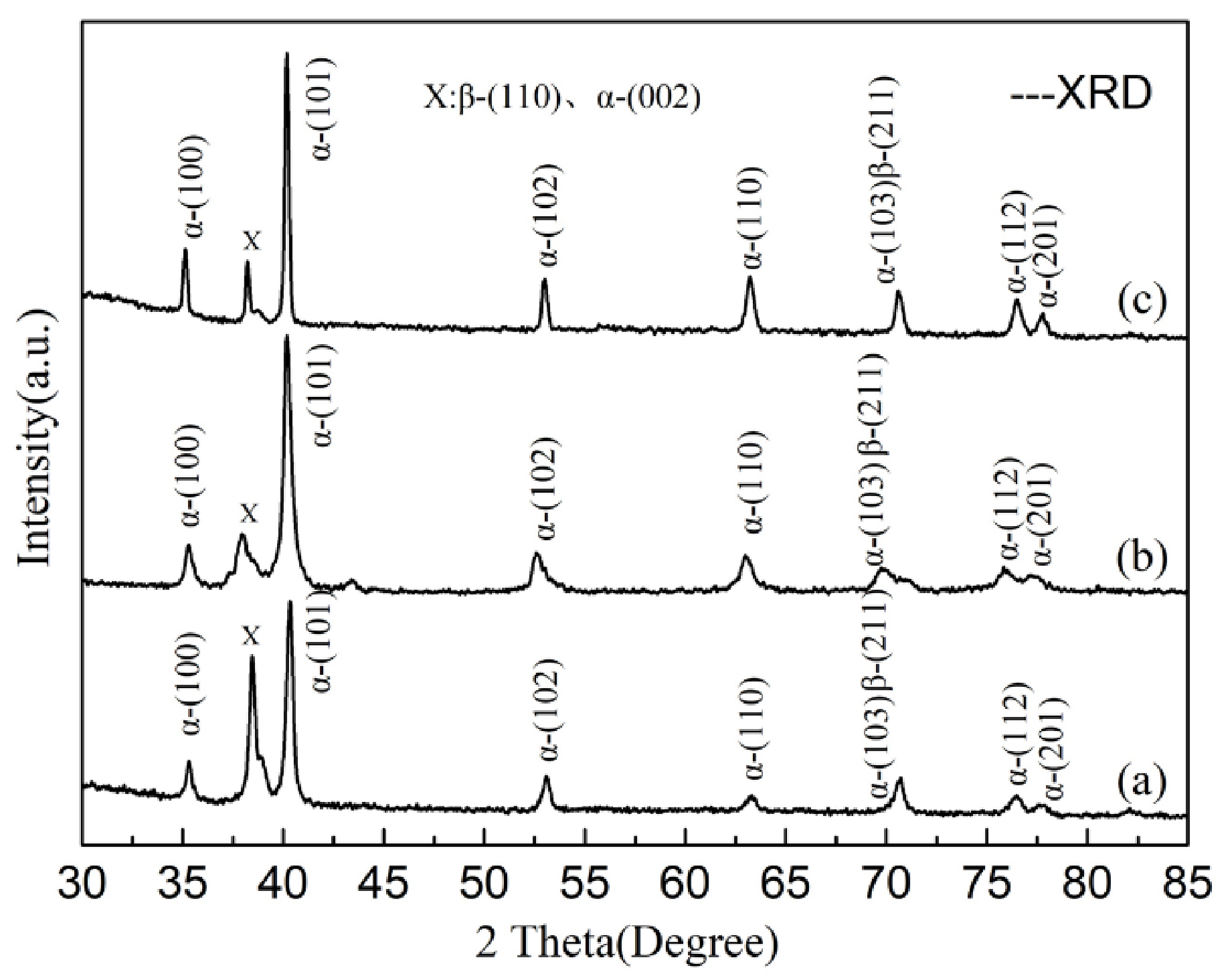

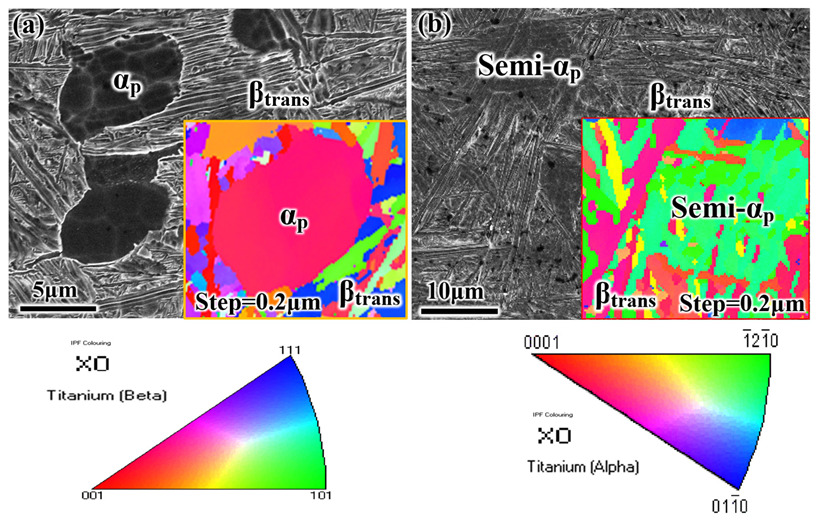

3.1. Microstructural Characteristics

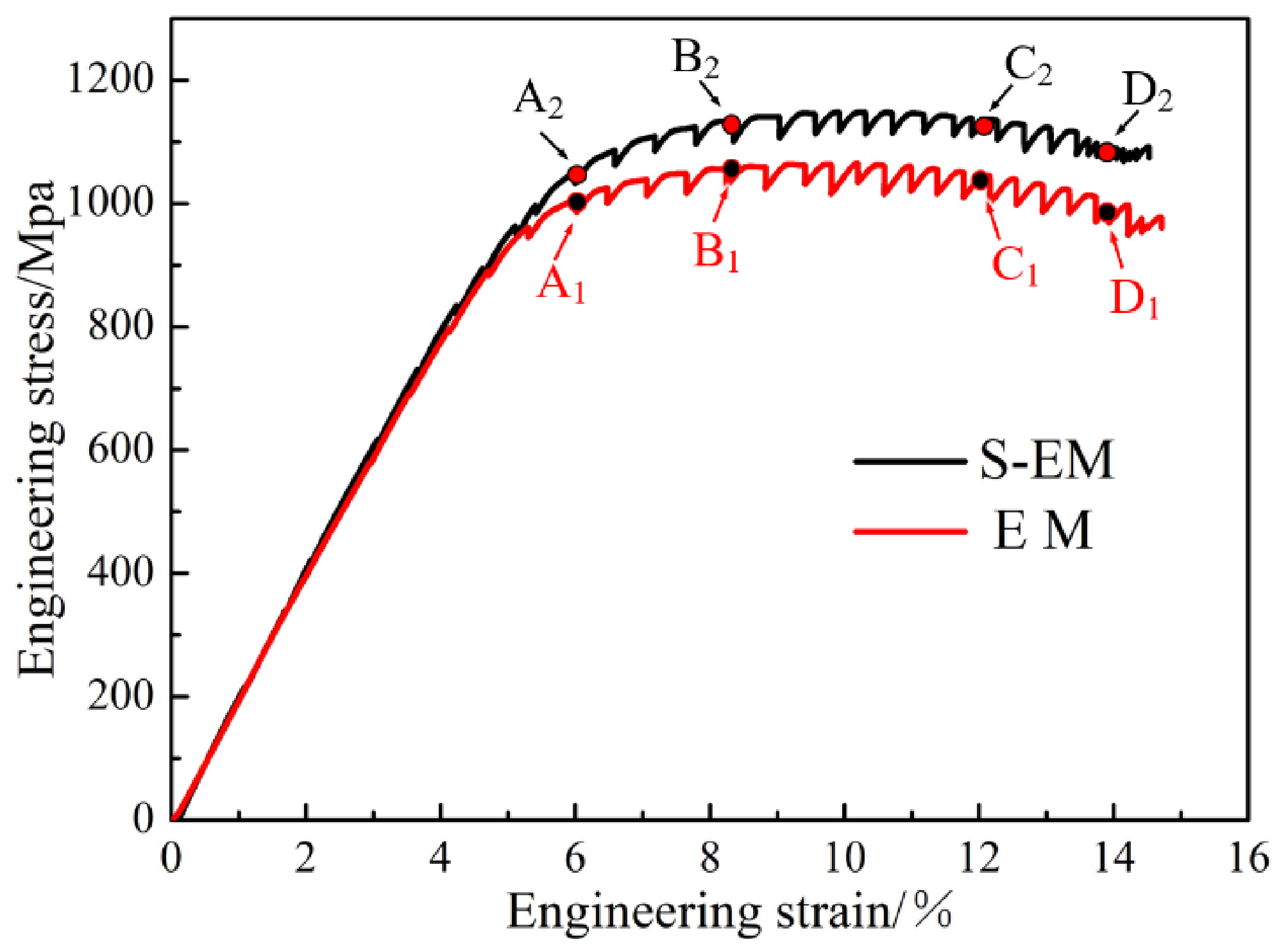

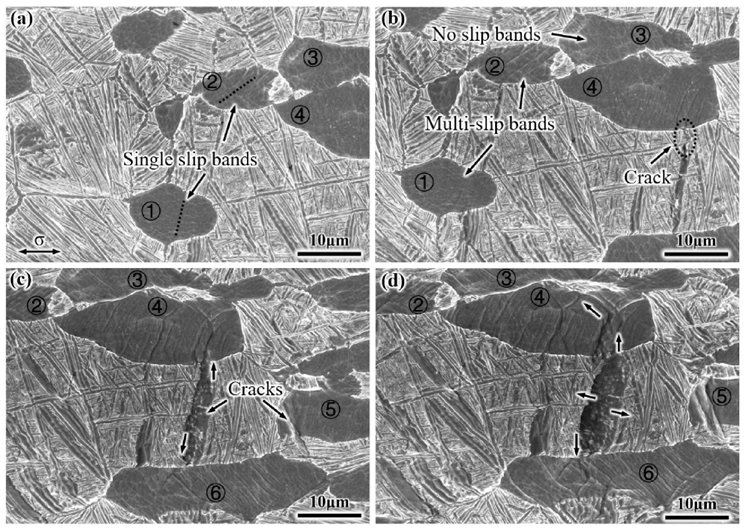

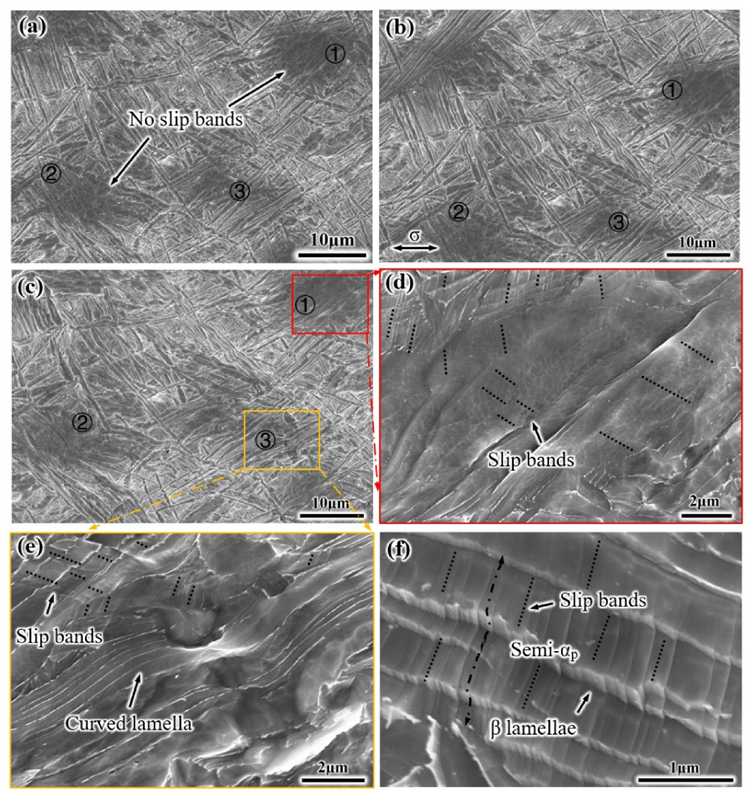

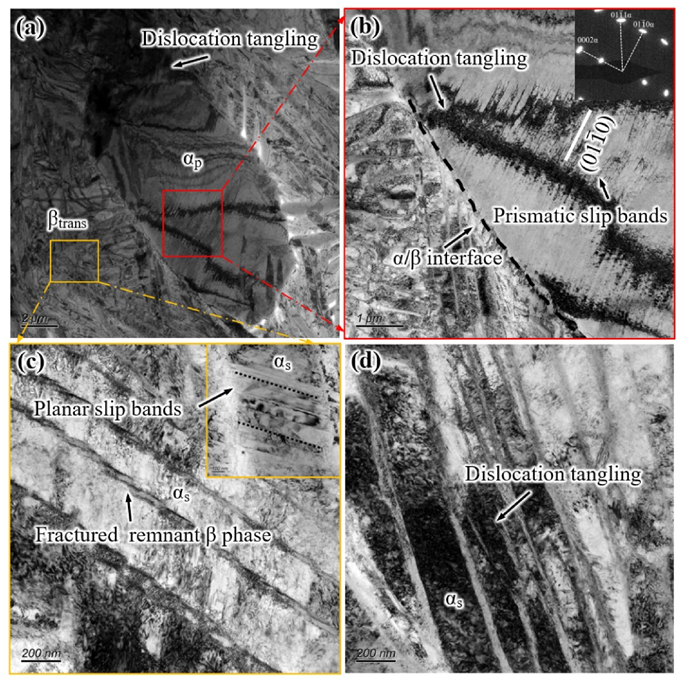

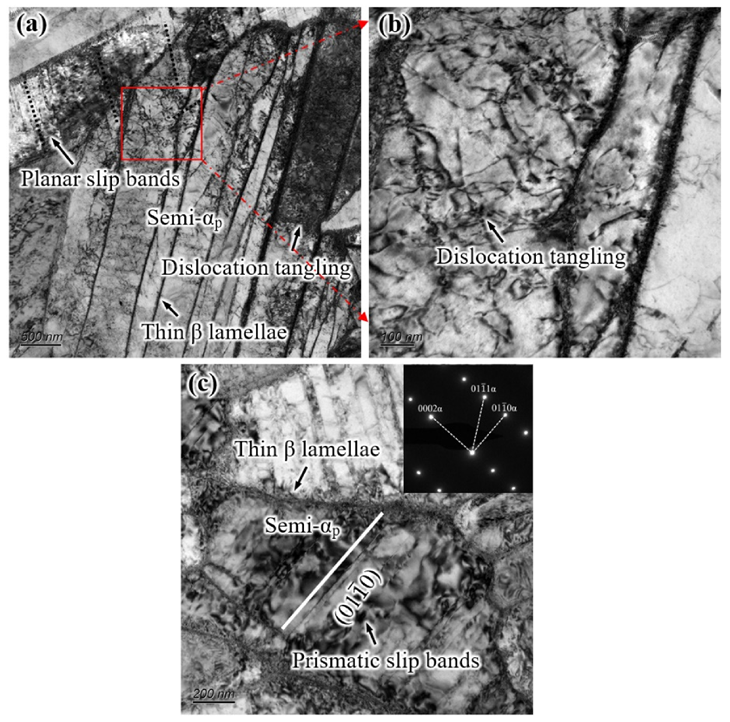

3.2. Research on the Deformation Behavior

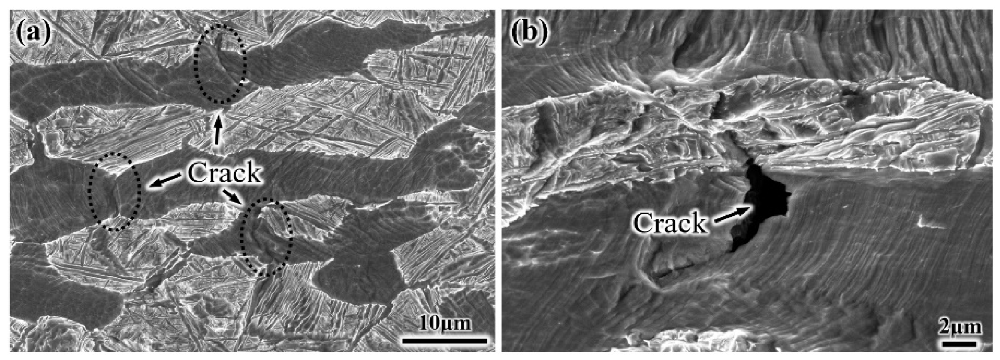

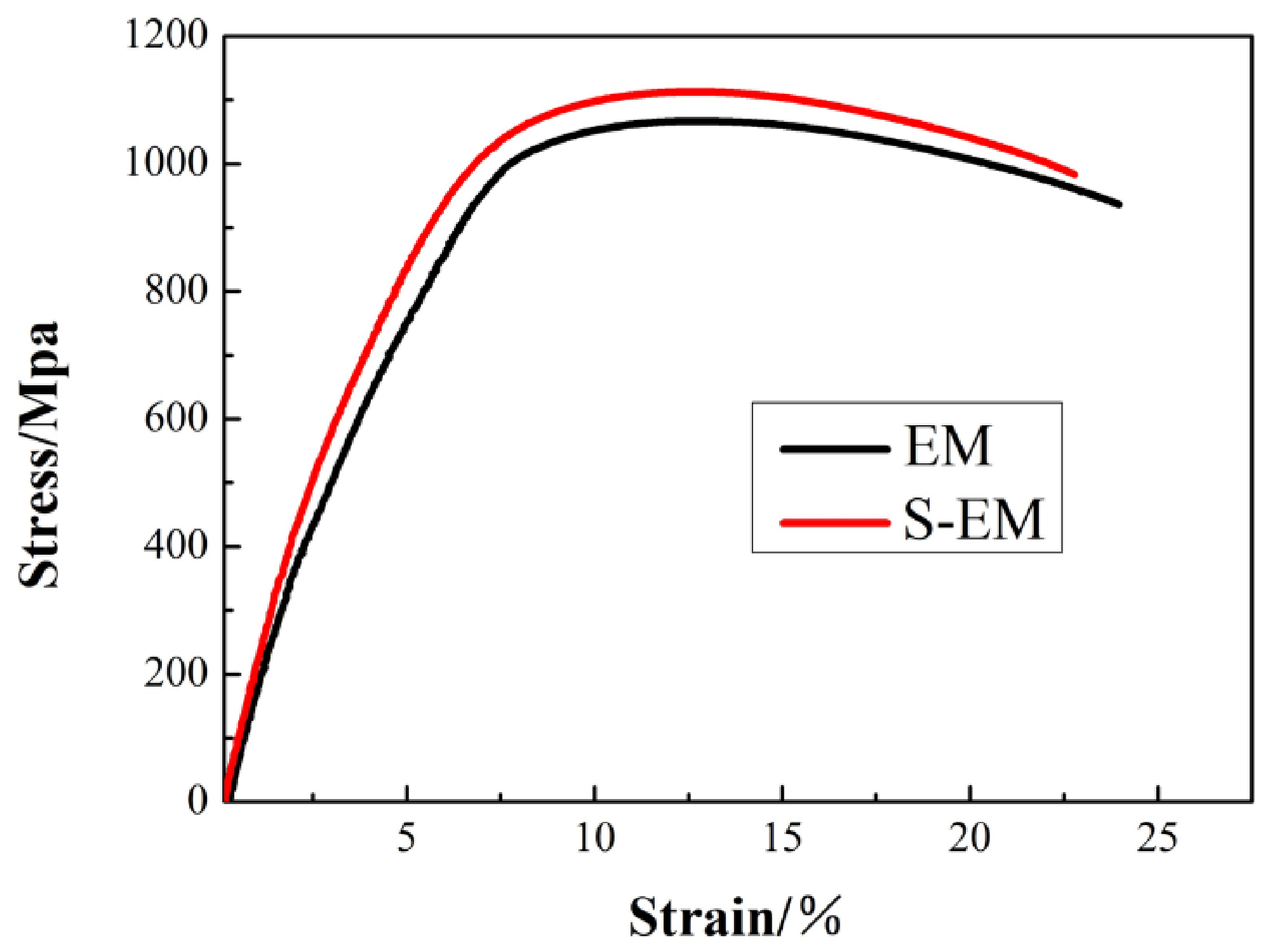

3.3. Tensile Properties and Fracture Characteristics

4. Conclusions

- (1)

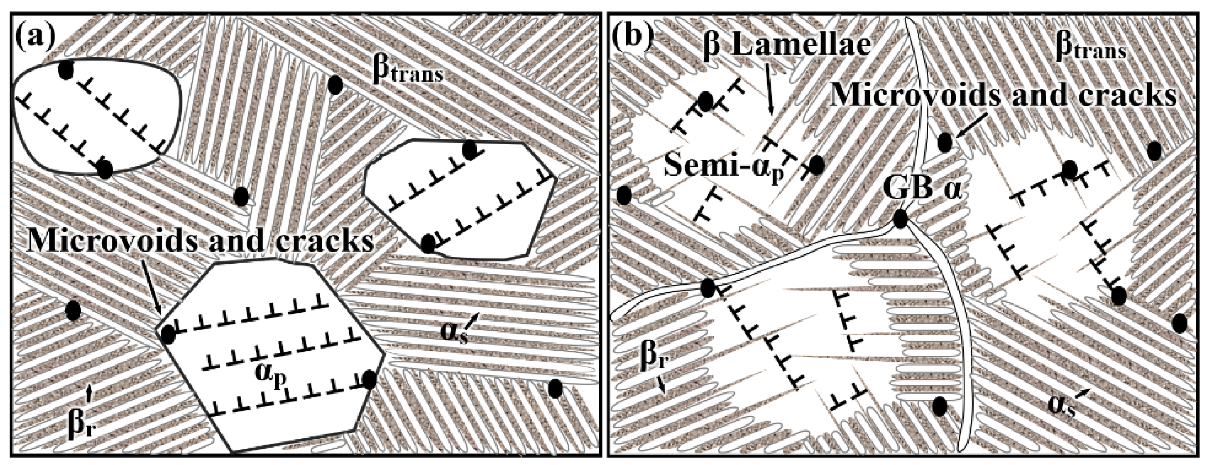

- In the S-EM, the distinct αp/βtrans interface in the bimodal microstructure primarily disappears, and the thin β lamellae grow through the equiaxed αp phase, leading to partial division of the equiaxed αp phase by the thin β lamellae.

- (2)

- The S-EM effectively suppress the formation of dense slip bands in the semi-equiaxed αp phase, so the stress concentration at the blurry semi-αp/βtrans interface in the S-EM has been reduced, and the semi-equiaxed αp phase and βtrans microstructure have better deformation compatibility. In addition, the tensile strength of the S-EM is higher than that of the EM due to the thin β lamellae hindering the movement of dislocations within the semi-equiaxed αp phase in the S-EM.

- (3)

- In the S-EM, the prismatic slip and dislocation tangling between the thin β lamellae are the main deformation modes of the semi-equiaxed αp phase. The deformation of the βtrans microstructure in the S-EM is mainly affected by planar slip and dislocation tangling in the αs lamellae.

- (4)

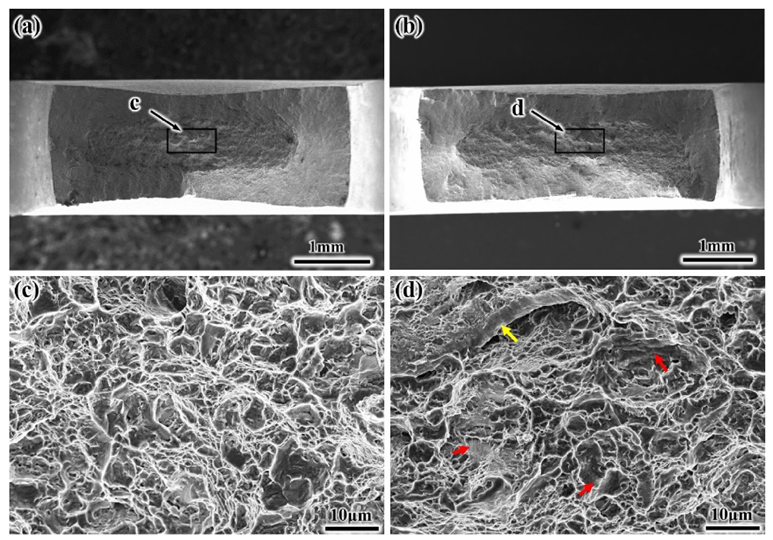

- The tensile fracture failures of both EM and S-EM in TA19 alloy show a mixture fracture mode. Compared to the EM, S-EM samples have shallower dimples and more cleavage facets, which leads to the proportion of brittle fracture mechanism of S-EM is slightly larger than EM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rezaee, M.; Zarei-Hanzaki, A.; Mohamadizadeh, A.; Ghasemi, E. High-temperature flow characterization and microstructural evolution of Ti6242 alloy: Yield drop phenomenon. Mater. Sci. Eng. A 2016, 673, 346–354. [Google Scholar] [CrossRef]

- Gao, P.F.; Lei, Z.N.; Li, Y.K.; Zhan, M. Low-cycle fatigue behavior and property of TA15 titanium alloy with tri-modal microstructure. Mater. Sci. Eng. A 2018, 736, 1–11. [Google Scholar] [CrossRef]

- Tarzimoghadam, Z.; Sandlöbes, S.; Pradeep, K.G.; Raabe, D. Microstructure design and mechanical properties in a near-α Ti–4Mo alloy. Acta Mater. 2015, 97, 291–304. [Google Scholar] [CrossRef]

- Bobbili, R.; Madhu, V. Flow and fracture characteristics of near alpha titanium alloy. J. Alloys Compd. 2016, 684, 162–170. [Google Scholar] [CrossRef]

- Jia, W.; Zeng, W.; Yu, H. Effect of aging on the tensile properties and microstructures of a near-alpha titanium alloy. Mater. Des. 2014, 58, 108–115. [Google Scholar] [CrossRef]

- Gao, P.F.; Qin, G.; Wang, X.X.; Li, Y.X.; Zhan, M.; Li, G.J.; Li, J.S. Dependence of mechanical properties on the microstructural parameters of TA15 titanium alloy with tri-modal microstructure. Mater. Sci. Eng. A 2019, 739, 203–213. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Zhang, C.J.; Guo, C.X.; Zhang, S.Z.; Feng, H.; Chen, C.Y.; Zhang, H.Z.; Cao, P. Microstructural manipulation and improved mechanical properties of a near α titanium alloy. Mater. Sci. Eng. A 2020, 771, 138569. [Google Scholar] [CrossRef]

- Huang, C.W.; Zhao, Y.Q.; Xin, S.W.; Zhou, W.; Li, Q.; Zeng, W. Effect of microstructure on torsion properties of Ti–5Al–5Mo–5V–3Cr–1Zr alloy. J. Alloys Compd. 2017, 693, 582–591. [Google Scholar] [CrossRef]

- Tan, C.; Sun, Q.; Xiao, L.; Zhao, Y.; Sun, J. Characterization of deformation in primary α phase and crack initiation and propagation of TC21 alloy using in-situ SEM experiments. Mater. Sci. Eng. A 2018, 725, 33–42. [Google Scholar] [CrossRef]

- Shao, H.; Zhao, Y.; Ge, P.; Zeng, W. Crack initiation and mechanical properties of TC21 titanium alloy with equiaxed microstructure. Mater. Sci. Eng. A 2013, 586, 215–222. [Google Scholar] [CrossRef]

- Huang, C.; Zhao, Y.; Xin, S.; Zhou, W.; Li, Q.; Zeng, W.; Tan, C. High cycle fatigue behavior of Ti–5Al–5Mo–5V–3Cr–1Zr titanium alloy with bimodal microstructure. J. Alloys Compd. 2017, 695, 1966–1975. [Google Scholar] [CrossRef]

- Yang, Y.; Jiang, Z.; Wang, C.; Hu, H.B.; Tang, T.G.; Zhang, H.S.; Fu, Y.N. Effects of the phase interface on initial spallation damage nucleation and evolution in dual phase titanium alloy. Mater. Sci. Eng. A 2018, 731, 385–393. [Google Scholar] [CrossRef]

- Huang, C.; Zhao, Y.; Xin, S.; Tan, C.; Zhou, W.; Li, Q.; Zeng, W. Effect of microstructure on high cycle fatigue behavior of Ti–5Al–5Mo–5V–3Cr–1Zr titanium alloy. Int. J. Fatigue 2017, 94, 30–40. [Google Scholar] [CrossRef]

- Sadeghpour, S.; Abbasi, S.M.; Morakabati, M.; Bruschi, S. Correlation between alpha phase morphology and tensile properties of a new beta titanium alloy. Mater. Des. 2017, 121, 24–35. [Google Scholar] [CrossRef]

- Attallah, M.M.; Preuss, M.; Boonchareon, C.; Steuwer, A.; Daniels, J.E.; Hughes, D.J.; Dungey, C.; Baxter, G.J. Microstructural and Residual Stress Development due to Inertia Friction Welding in Ti-6246. Metall. Mater. Trans. A 2012, 43, 3149–3161. [Google Scholar] [CrossRef]

- Wang, G.; Chen, Z.; Li, J.; Liu, J.; Wang, Q.; Yang, R. Microstructure and Mechanical Properties of Electron Beam Welded Titanium Alloy Ti-6246. J. Mater. Sci. Technol. 2018, 34, 570–576. [Google Scholar] [CrossRef]

- Xu, P.; Zhou, L.; Han, M.; Wei, Z.; Liang, Y. Flash-butt welded Ti6242 joints preserved base-material strength and ductility. Mater. Sci. Eng. A 2020, 774, 138915. [Google Scholar] [CrossRef]

- Han, M.; Xu, P.; Wan, M.; Liang, Y.; Du, J. Semi-equiaxed Structure and Tensile Properties of TA19 Titanium Alloy. Rare Met. Mater. Eng. 2018, 47, 3768–3775. [Google Scholar]

- ASTM International. Standard Guide for Preparation of Metallographic Specimens; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Steel, S.; Axial, C.; Application, F. E8/E8M Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Qin, D.; Lu, Y.; Guo, D.; Zheng, L.; Liu, Q.; Zhou, L. Tensile deformation and fracture of Ti–5Al–5V–5Mo–3Cr–1.5Zr–0.5Fe alloy at room temperature. Mater. Sci. Eng. A 2013, 587, 100–109. [Google Scholar] [CrossRef]

- Mayeur, J.R.; McDowell, D.L. A three-dimensional crystal plasticity model for duplex Ti–6Al–4V. Int. J. Plast. 2007, 23, 1457–1485. [Google Scholar] [CrossRef]

- Tan, C.; Li, X.; Sun, Q.; Xiao, L.; Zhao, Y.; Sun, J. Effect of α-phase morphology on low-cycle fatigue behavior of TC21 alloy. Int. J. Fatigue 2015, 75, 1–9. [Google Scholar] [CrossRef]

- Gao, P.; Cai, Y.; Zhan, M.; Fan, X.; Lei, Z. Crystallographic orientation evolution during the development of tri-modal microstructure in the hot working of TA15 titanium alloy. J. Alloys Compd. 2018, 741, 734–745. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Morgan, J.T.; Malas, J.C.; Frazier, W.G.; Prasad, Y.V.R.K. Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti–6Al–4V. Mater. Sci. Eng. A 2000, 279, 289–299. [Google Scholar] [CrossRef]

- Chong, Y.; Deng, G.; Gao, S.; Yi, J.; Shibata, A.; Tsuji, N. Yielding nature and Hall-Petch relationships in Ti-6Al-4V alloy with fully equiaxed and bimodal microstructures. Scr. Mater. 2019, 172, 77–82. [Google Scholar] [CrossRef]

- Yu, H.; Xin, Y.; Wang, M.; Liu, Q. Hall-Petch relationship in Mg alloys: A review. J. Mater. Sci. Technol. 2018, 34, 248–256. [Google Scholar] [CrossRef]

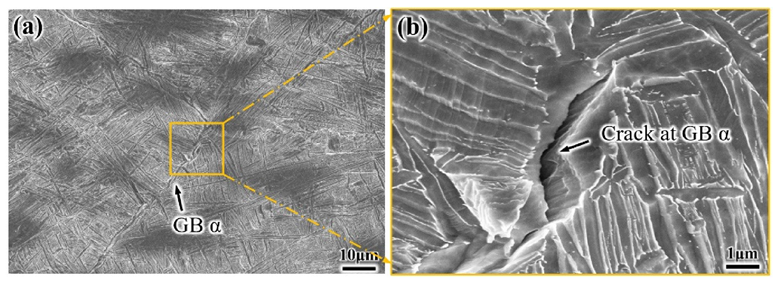

- Liu, C.; Lu, Y.; Tian, X.; Liu, D. Influence of continuous grain boundary α on ductility of laser melting deposited titanium alloys. Mater. Sci. Eng. A 2016, 661, 145–151. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, K.; Zhou, Y.; Zhu, X.; Xin, R.; Liu, Q. Crystallographic orientation dependent crack nucleation during the compression of a widmannstätten-structure α/β titanium alloy. Scr. Mater. 2018, 156, 110–114. [Google Scholar] [CrossRef]

- Liu, R.; Hui, S.; Ye, W.; Yu, Y.; Fu, Y.; Song, X.; Deng, X. Tensile and fracture properties of Ti-62A alloy plate with different microstructures. Rare Met. 2012, 31, 420–423. [Google Scholar] [CrossRef]

| Al | Sn | Zr | Mo | W | Si | Ti |

|---|---|---|---|---|---|---|

| 6.61 | 1.75 | 4.12 | 1.91 | 0.32 | 0.10 | Bal. |

| Microstructure | αp (vol %) | αp Diameter (μm) | αs Length (μm) | αs Width (nm) | GB α (vol %) | GB α Width (nm) |

|---|---|---|---|---|---|---|

| EM | 42 ± 2 | 12 ± 1 | 10 ± 1 | 400 ± 20 | 0.3 | 420 ± 30 |

| S-EM | 41 ± 2 | 13 ± 1 | 11 ± 1 | 410 ± 20 | 1.2 | 850 ± 30 |

| Microstructure | YS/Mpa | UTS/Mpa | El/% | RA/% |

|---|---|---|---|---|

| EM | 984 | 1067 | 23.9 | 32.9 |

| S-EM | 1022 | 1113 | 22.8 | 30.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, M.; Lin, T.; Zhou, L.; Li, W.; Liang, Y.; Han, M.; Liang, Y. Deformation Behavior and Tensile Properties of the Semi-Equiaxed Microstructure in Near Alpha Titanium Alloy. Materials 2021, 14, 3380. https://doi.org/10.3390/ma14123380

Luo M, Lin T, Zhou L, Li W, Liang Y, Han M, Liang Y. Deformation Behavior and Tensile Properties of the Semi-Equiaxed Microstructure in Near Alpha Titanium Alloy. Materials. 2021; 14(12):3380. https://doi.org/10.3390/ma14123380

Chicago/Turabian StyleLuo, Minglang, Tingyi Lin, Lei Zhou, Wei Li, Yilong Liang, Moliu Han, and Yu Liang. 2021. "Deformation Behavior and Tensile Properties of the Semi-Equiaxed Microstructure in Near Alpha Titanium Alloy" Materials 14, no. 12: 3380. https://doi.org/10.3390/ma14123380

APA StyleLuo, M., Lin, T., Zhou, L., Li, W., Liang, Y., Han, M., & Liang, Y. (2021). Deformation Behavior and Tensile Properties of the Semi-Equiaxed Microstructure in Near Alpha Titanium Alloy. Materials, 14(12), 3380. https://doi.org/10.3390/ma14123380