A Robust Numerical Methodology for Fatigue Damage Evolution Simulation in Composites

Abstract

1. Introduction

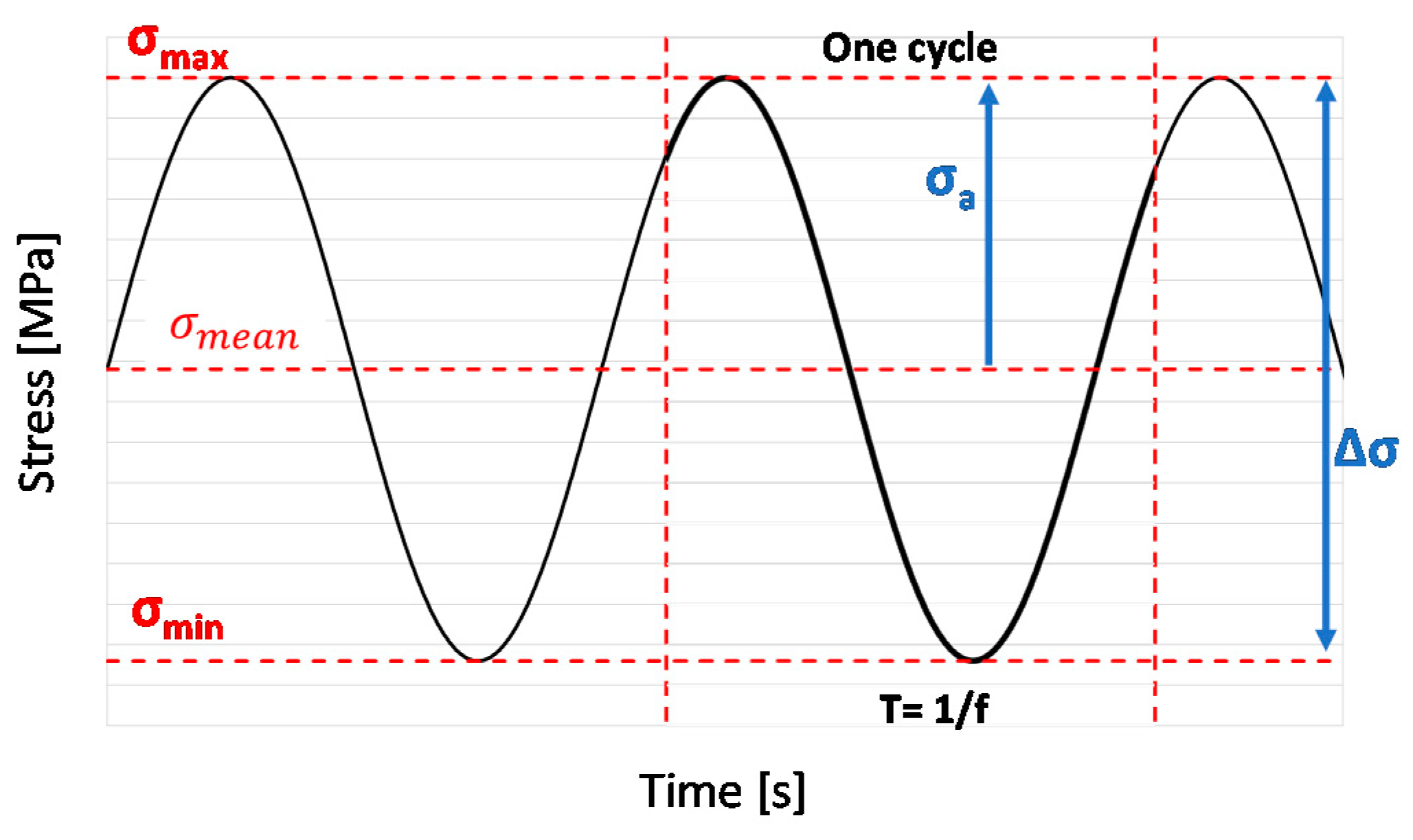

2. Theoretical Background

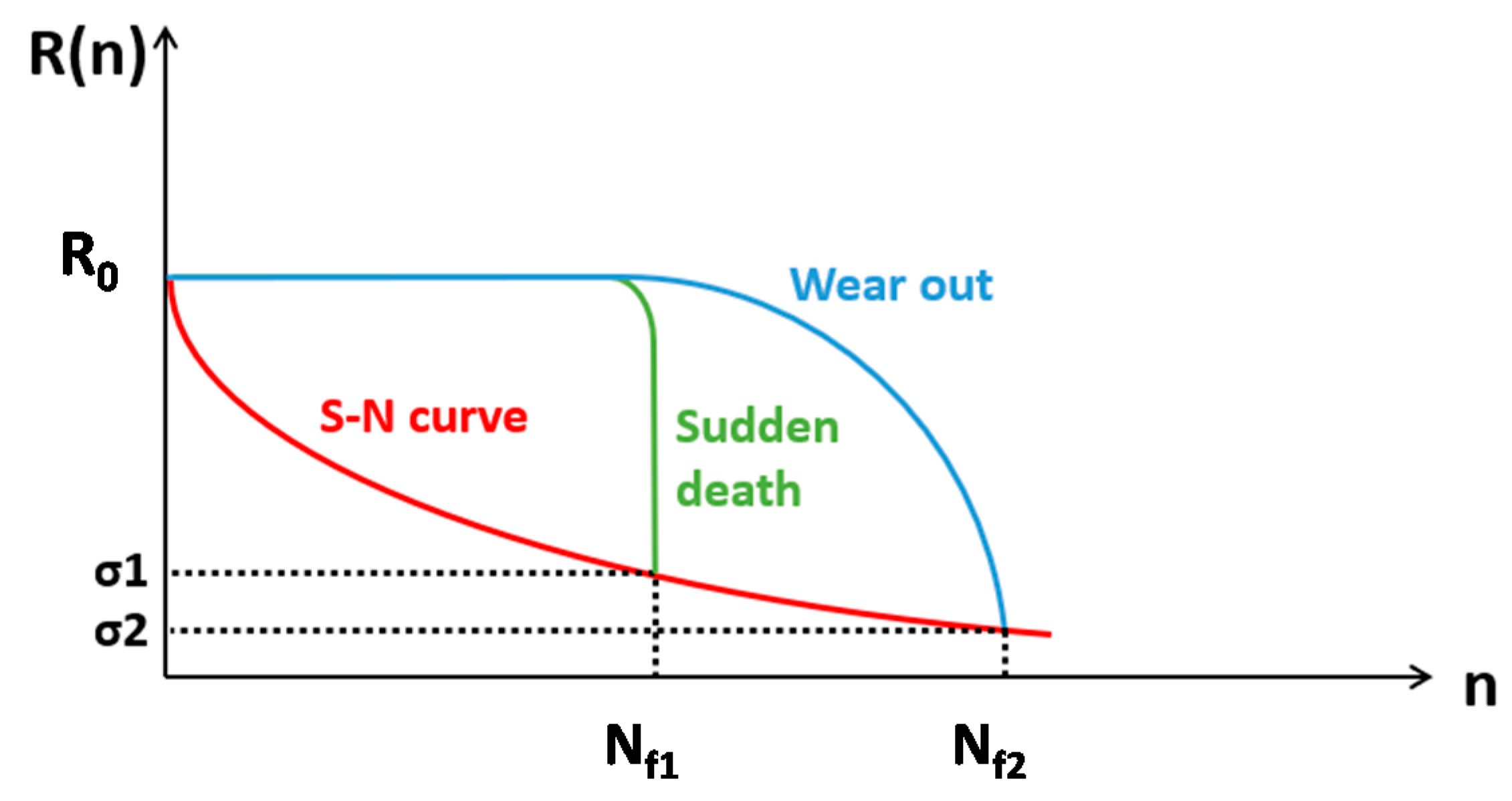

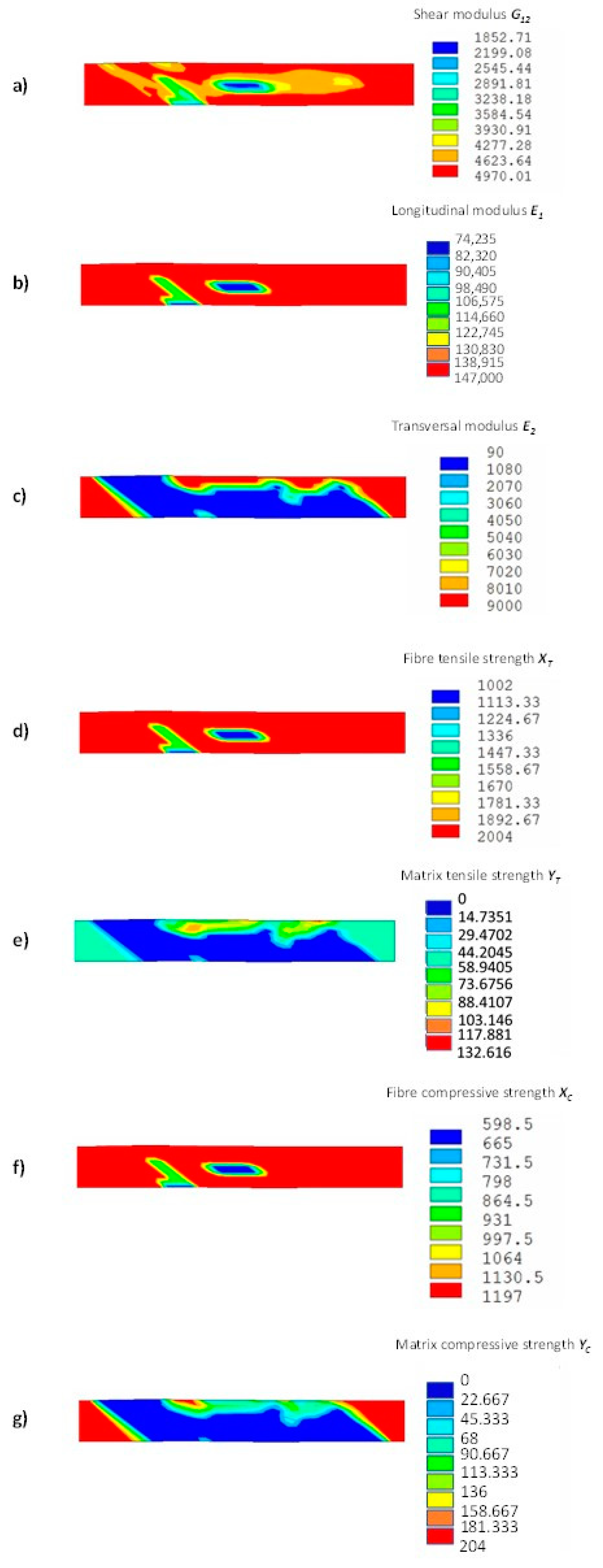

2.1. Wear-Out Model

2.2. Sudden Death Model

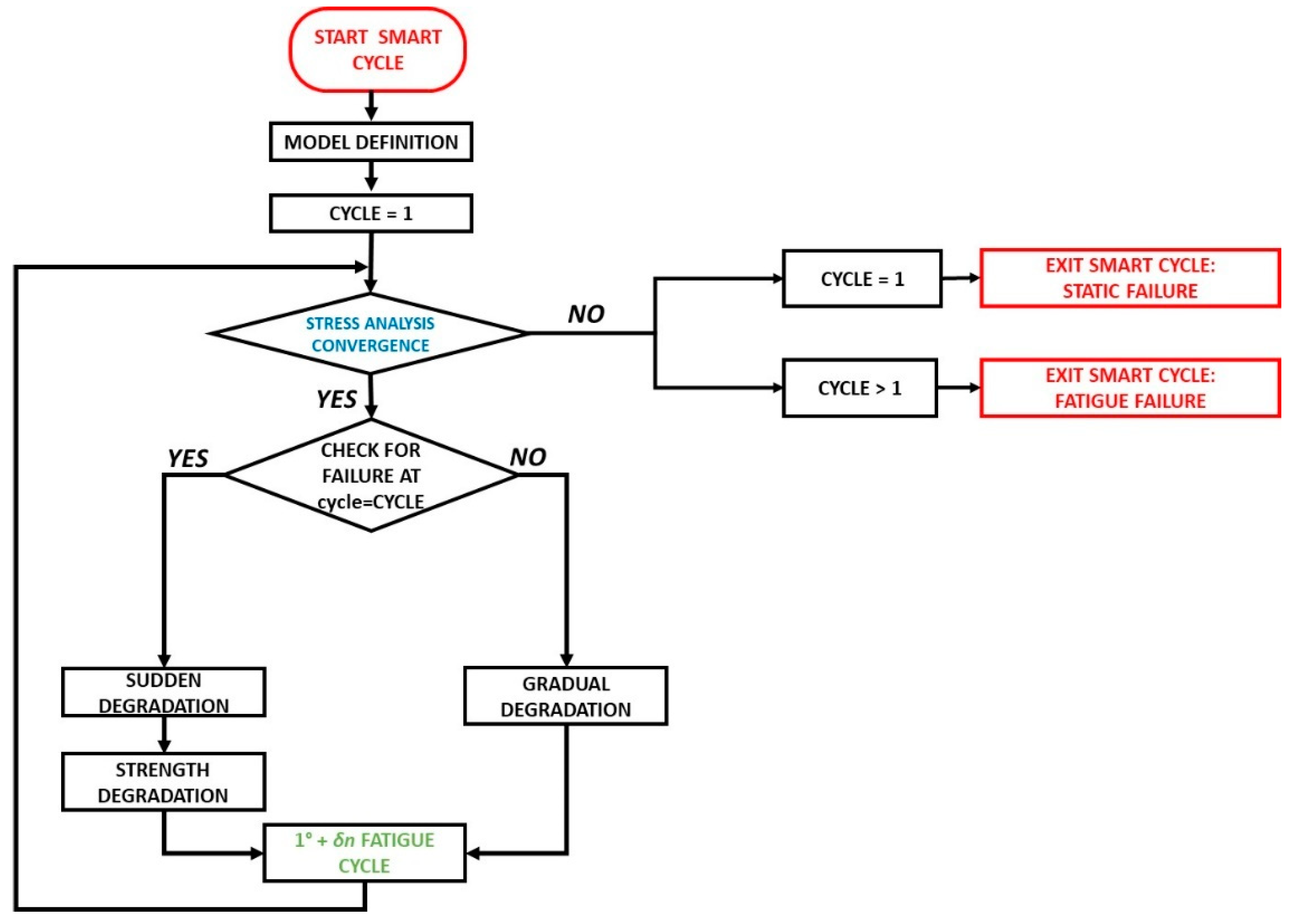

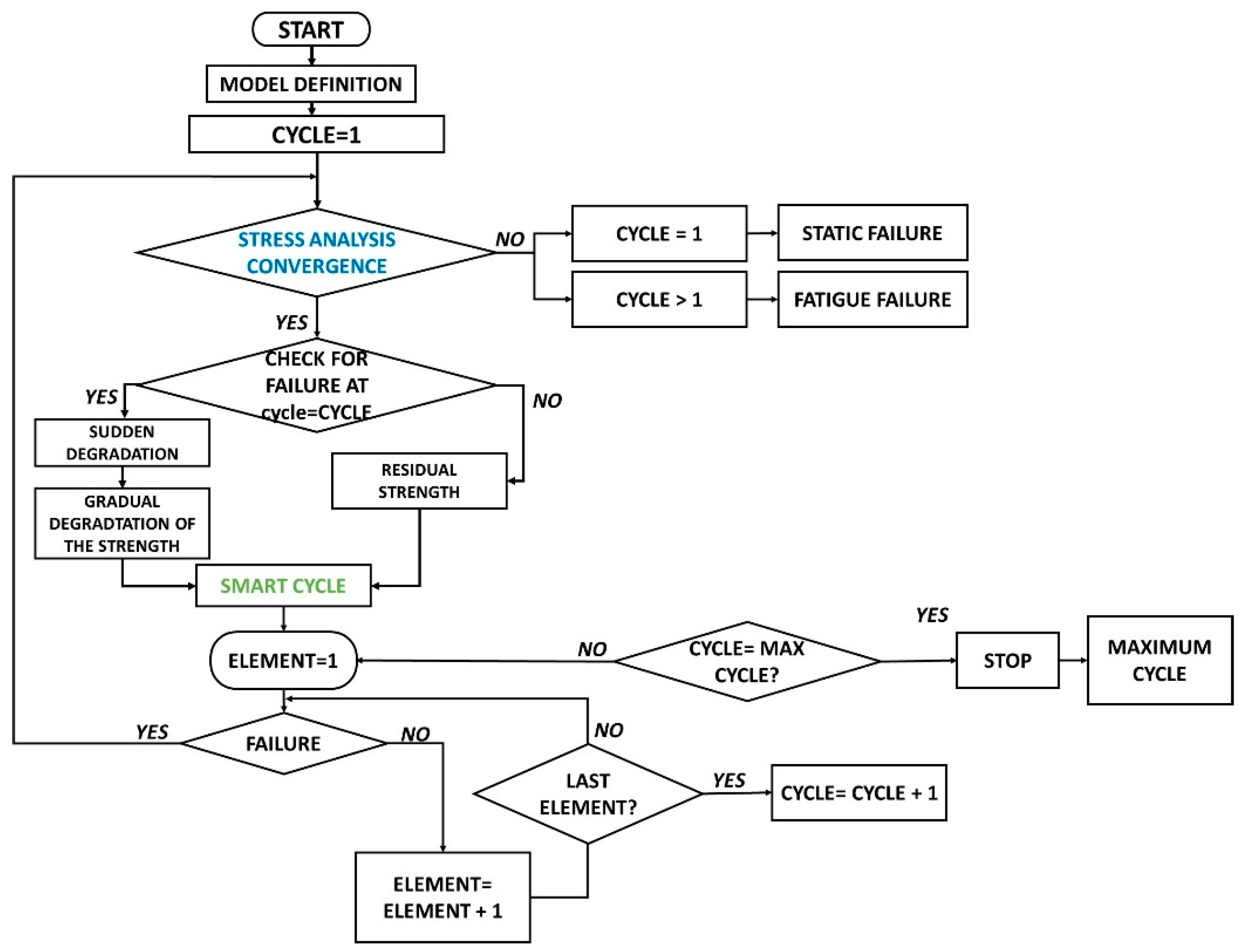

3. Finite Element Model and Smart Cycle Strategy Implementation

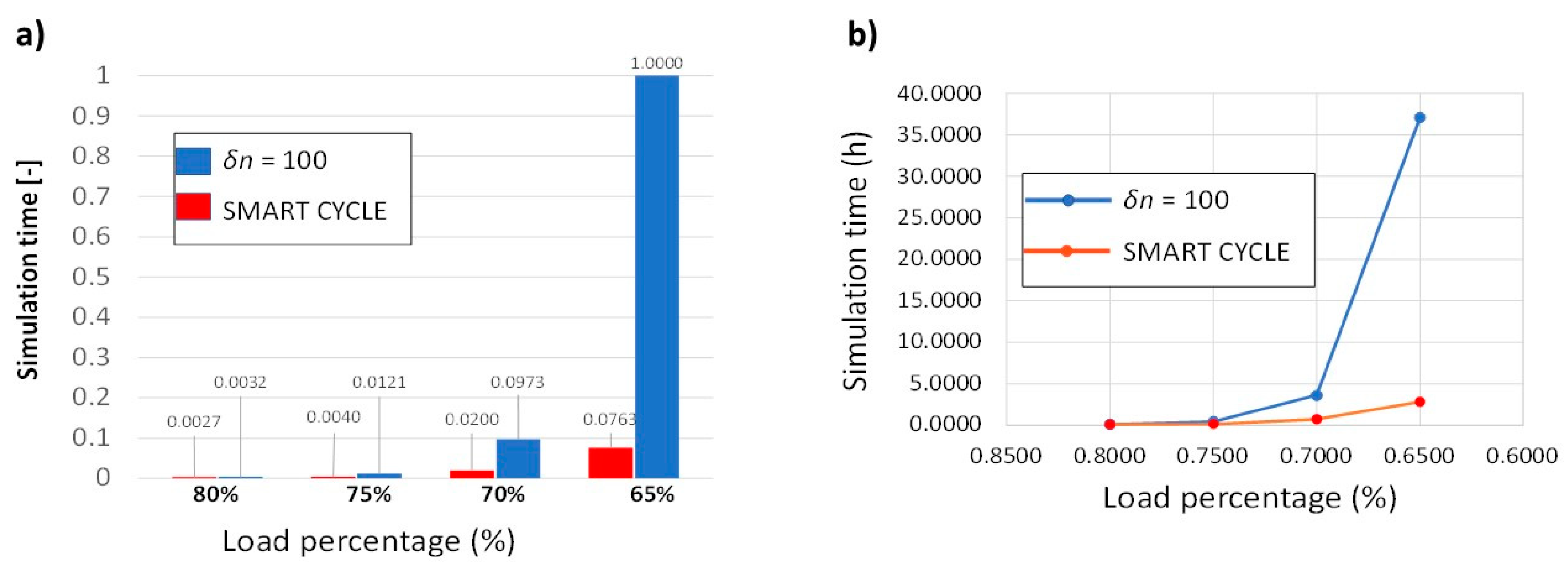

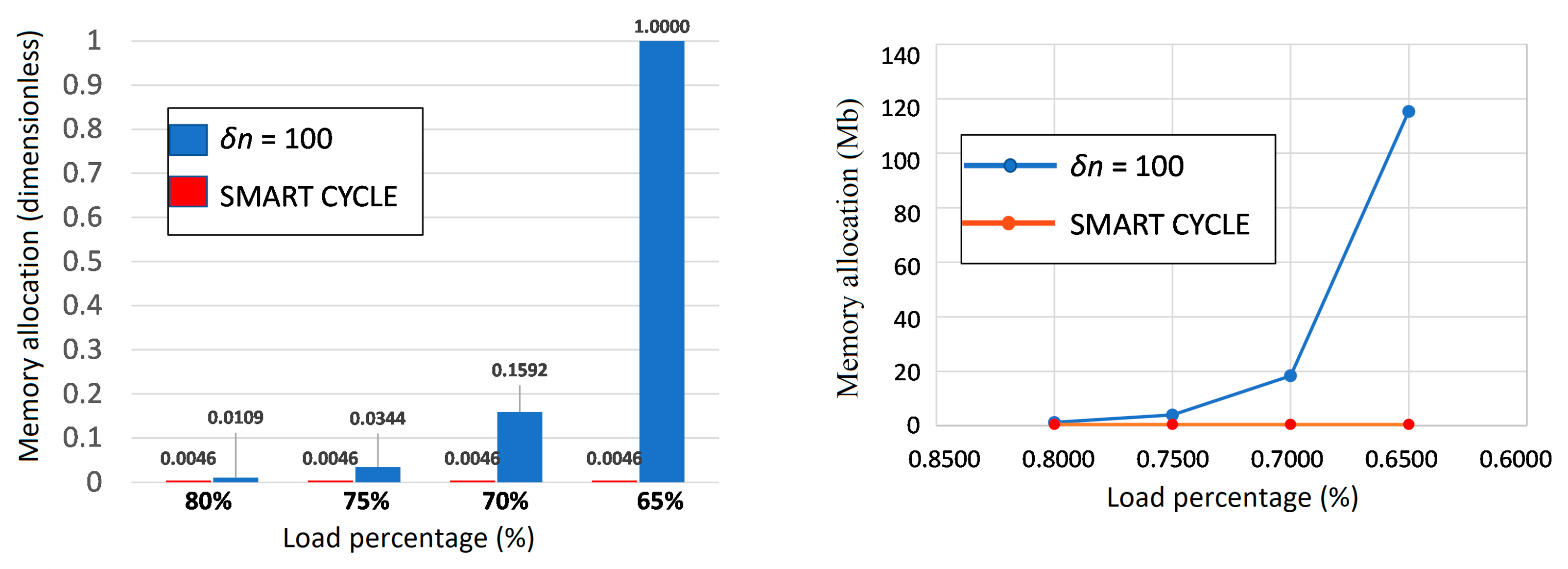

Strategies to Reduce Computational Time

- choose the number of elements where the Hashin criteria needs to be satisfied (default setting is =1) to perform a full numerical analysis with sudden degradation in damaged elements and gradual degradation in all the other elements. This would allow reducing the number of numerical simulations to be performed by grouping the sudden damage for the selected number of elements in one fatigue cycle. This further option would, surely, save additional computational cost but would, probably, cause a decrease in accuracy with an underestimation of the damage evolution;

- choose the ΔN cycles where the check of the Hashin failure criteria is performed (default setting is =1). This would allow speeding up the smart cycle check with a decrease in the computational cost but would also decrease the accuracy in determining sudden damage onset.

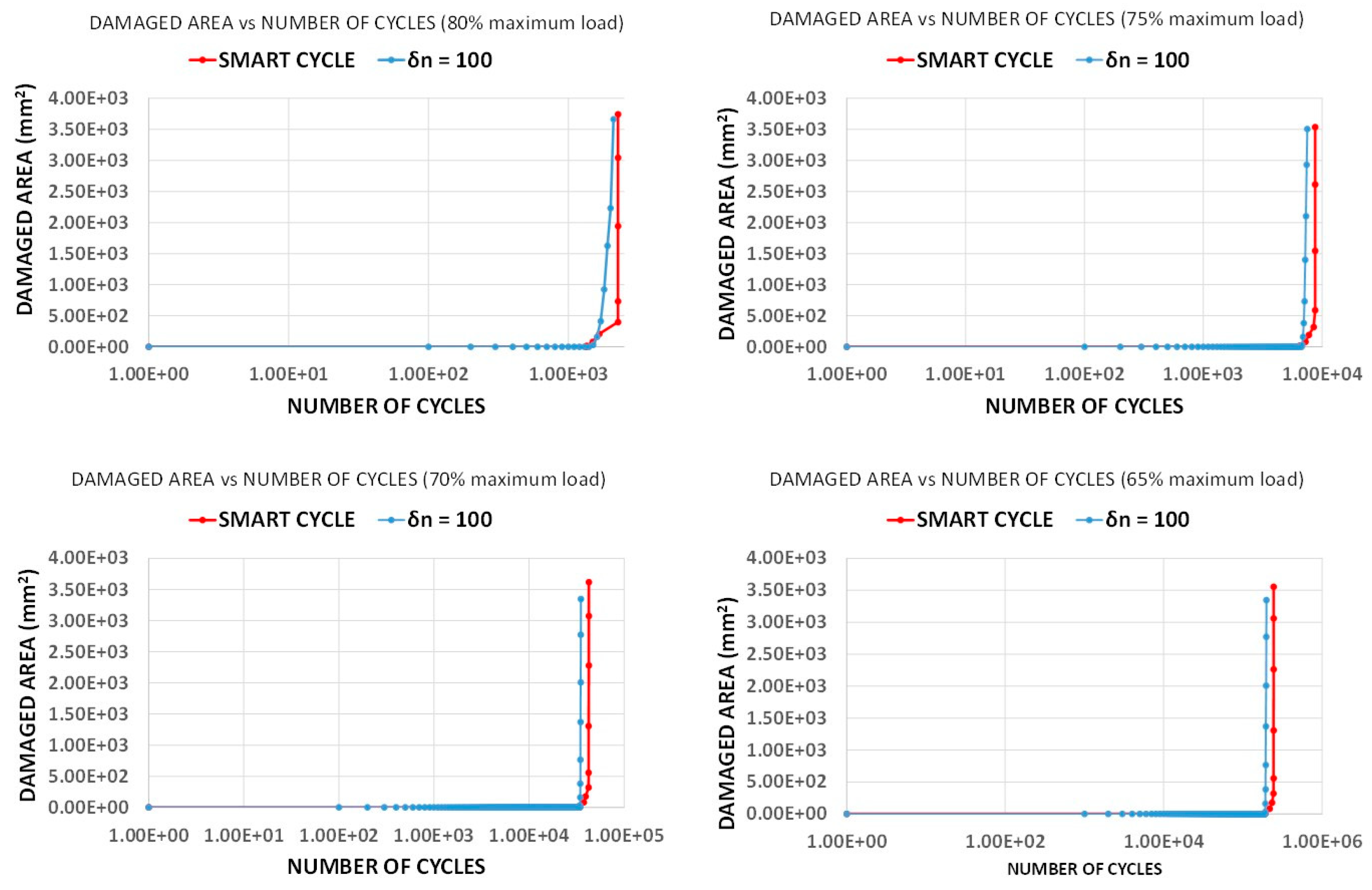

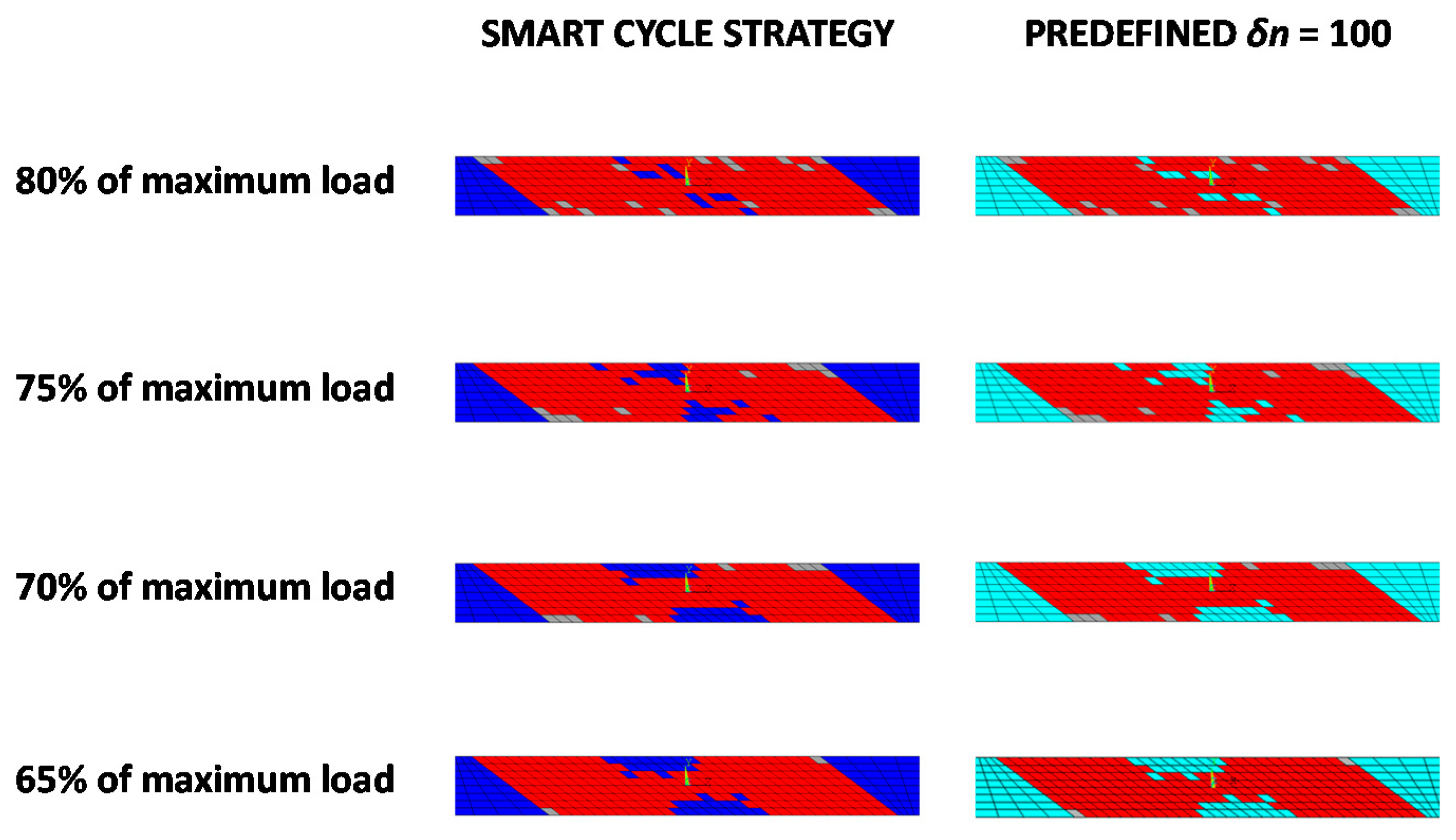

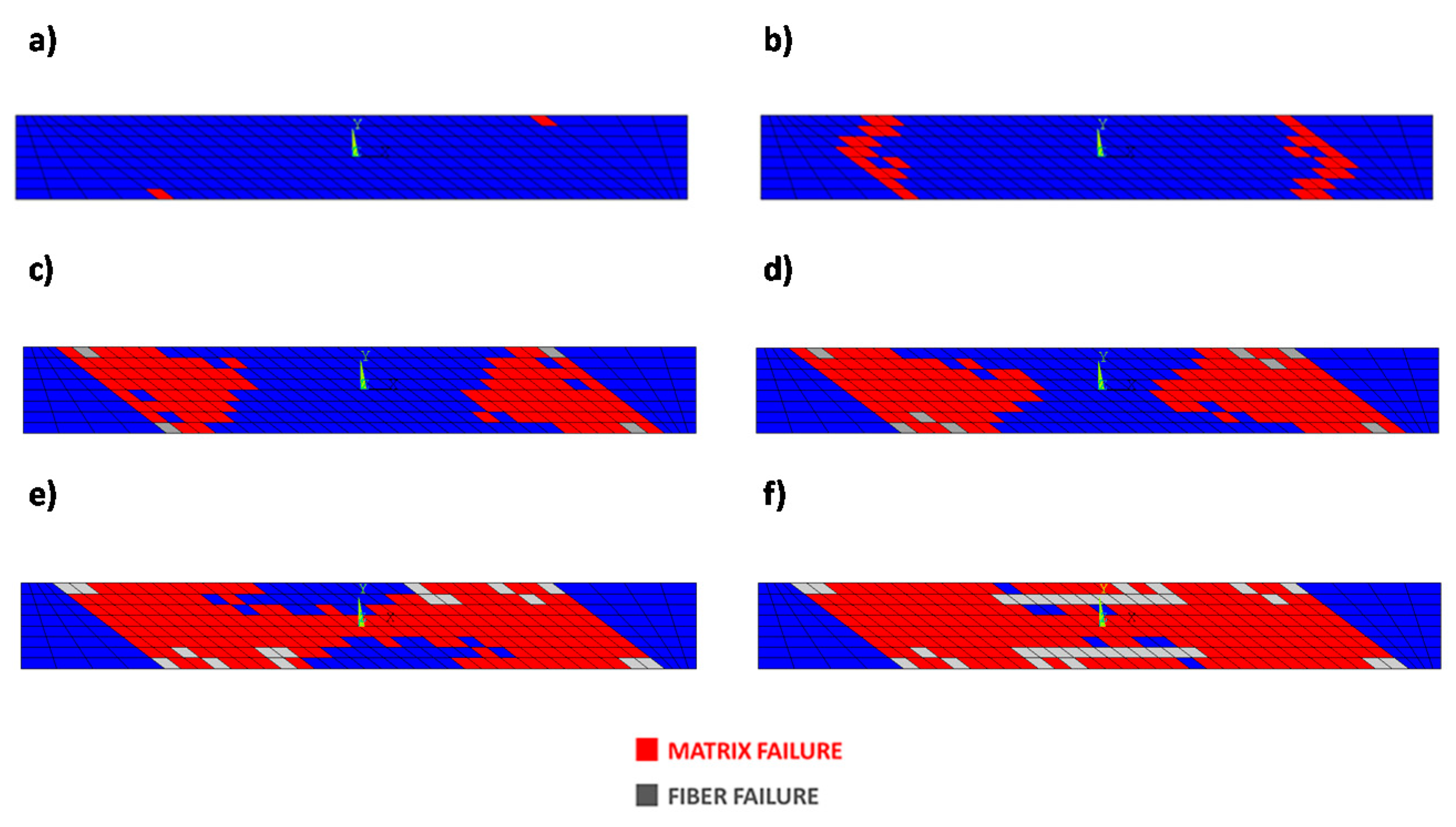

4. Smart Cycle Strategy Validation

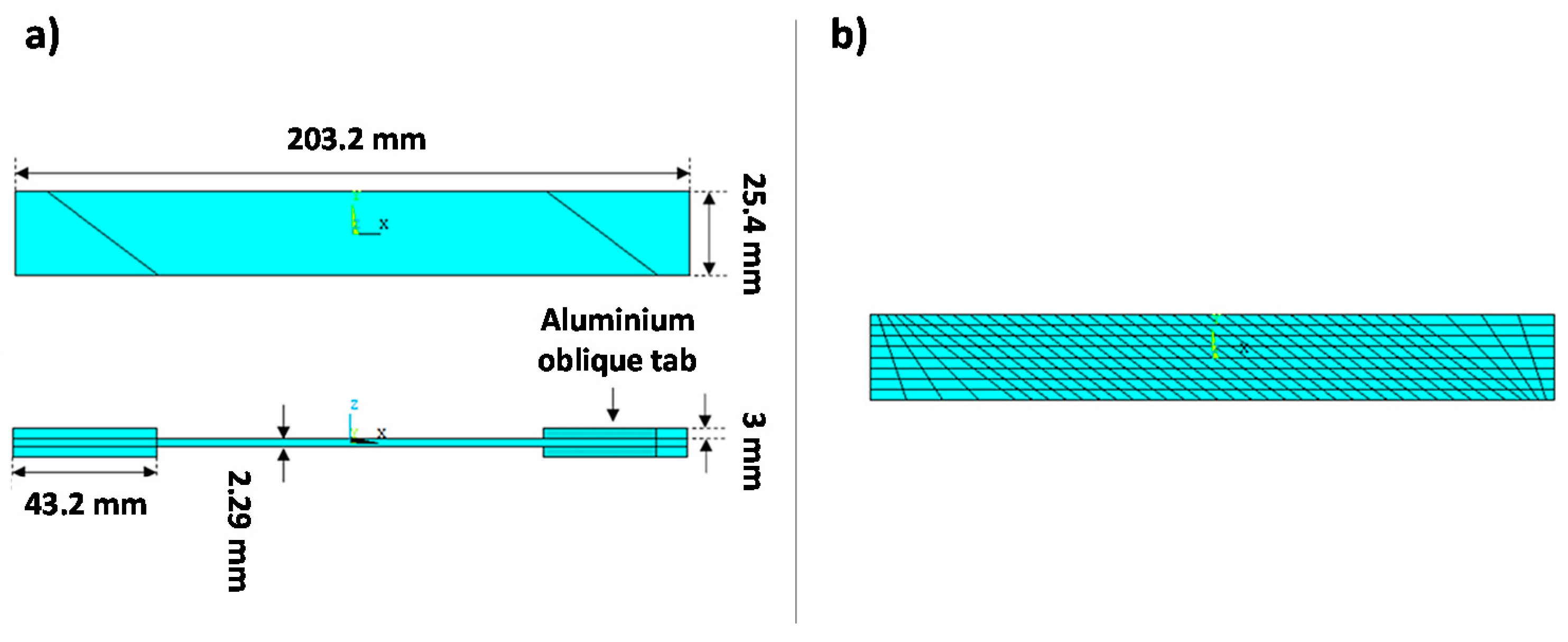

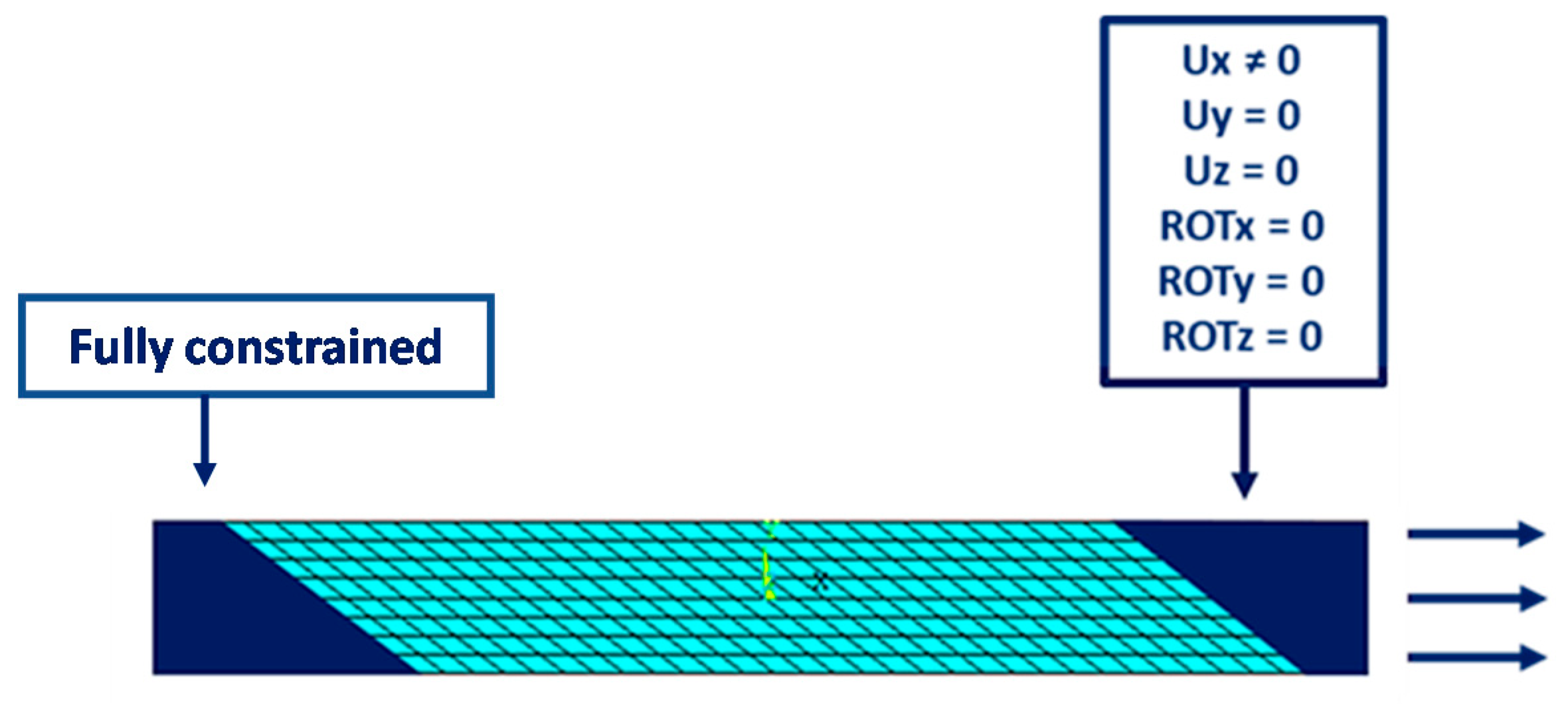

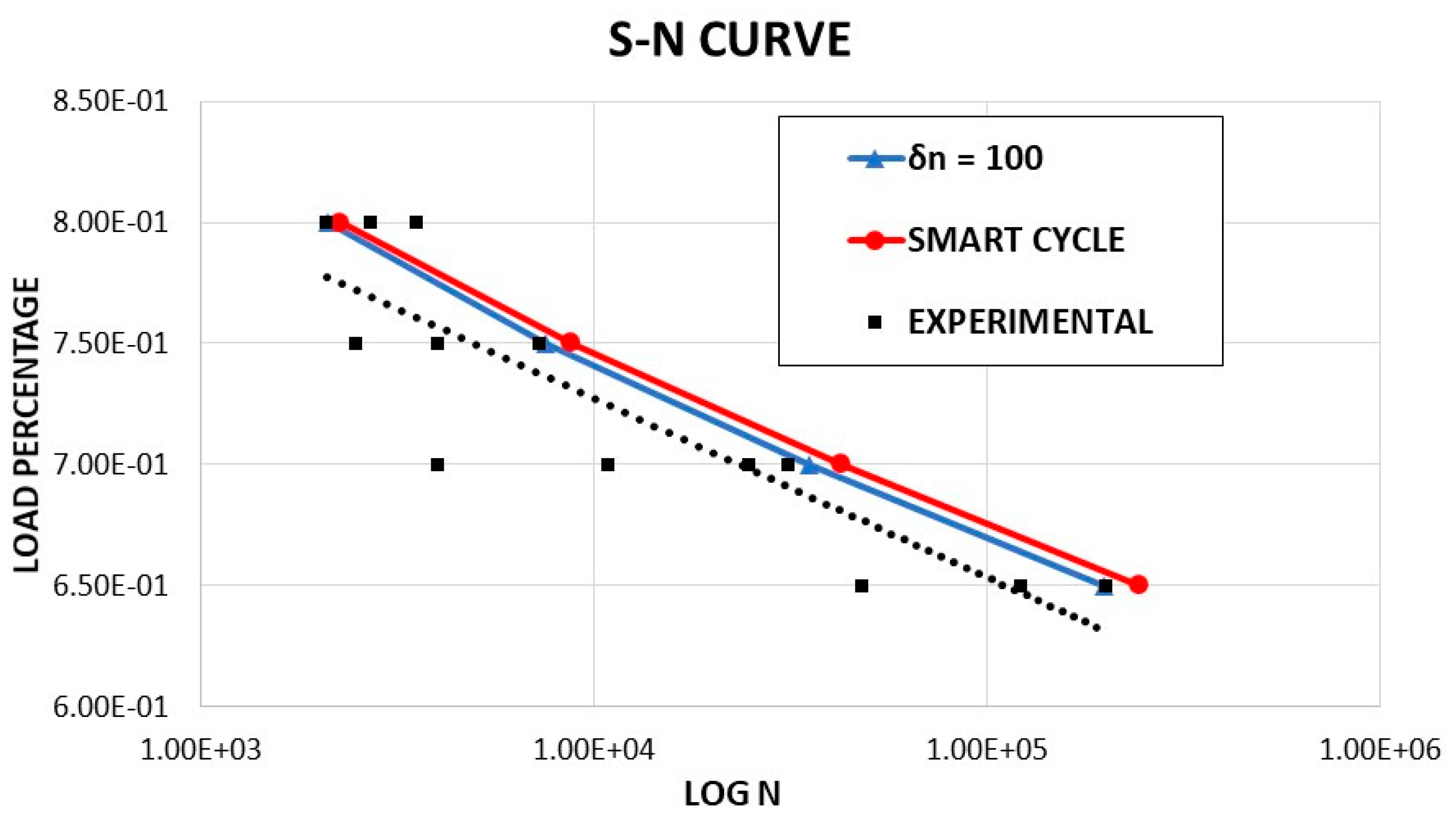

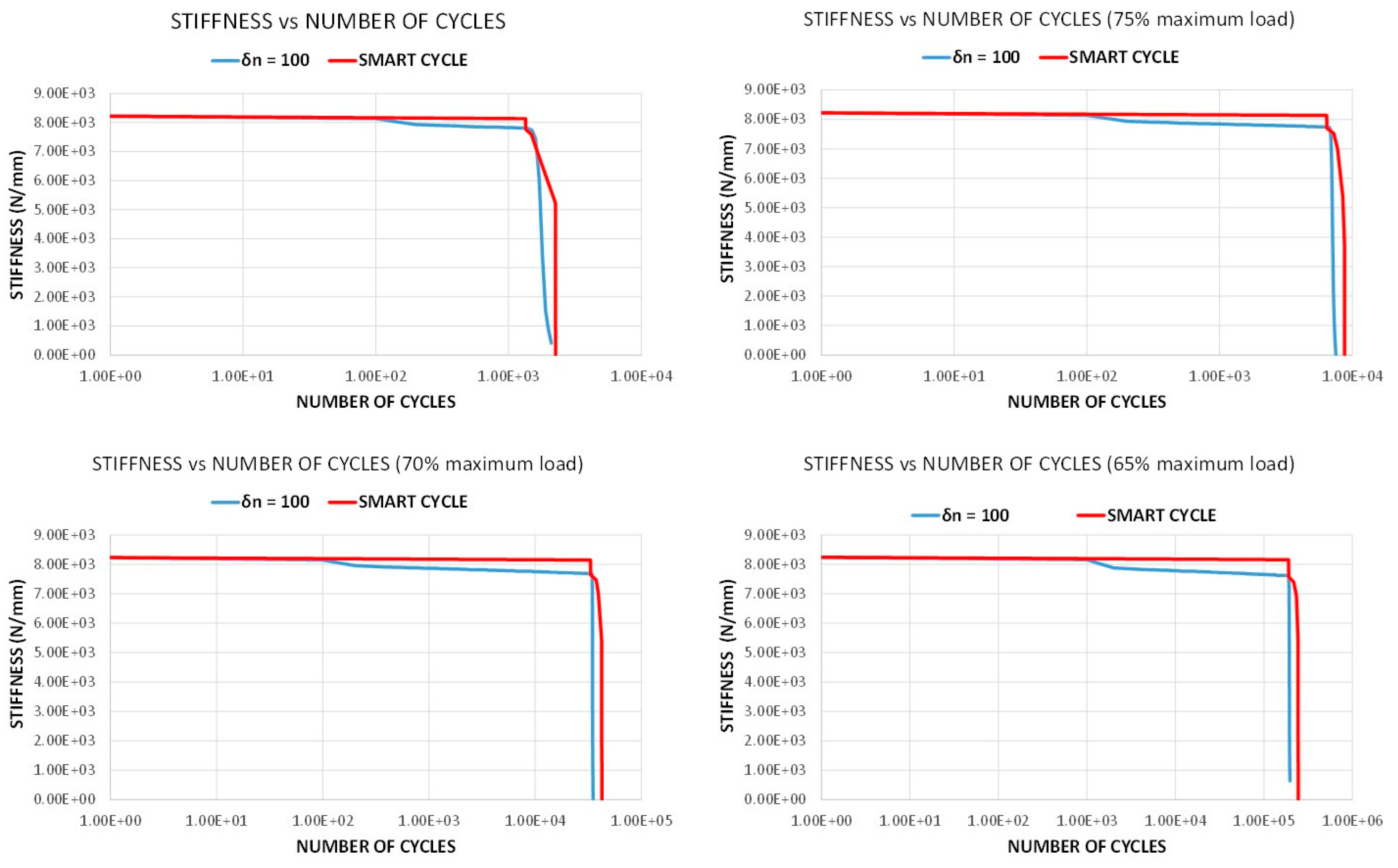

4.1. Off-Axis Tensile Specimen

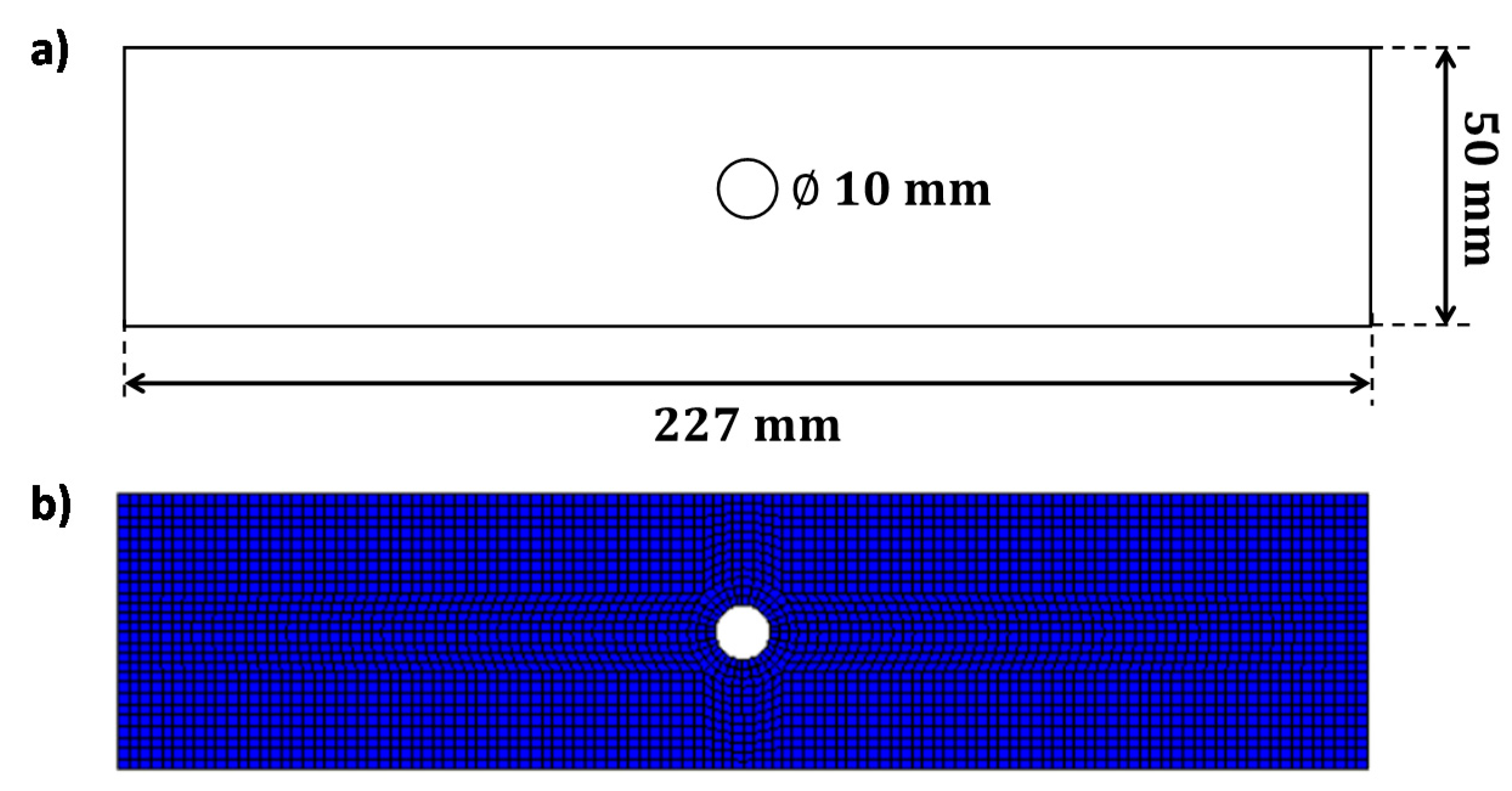

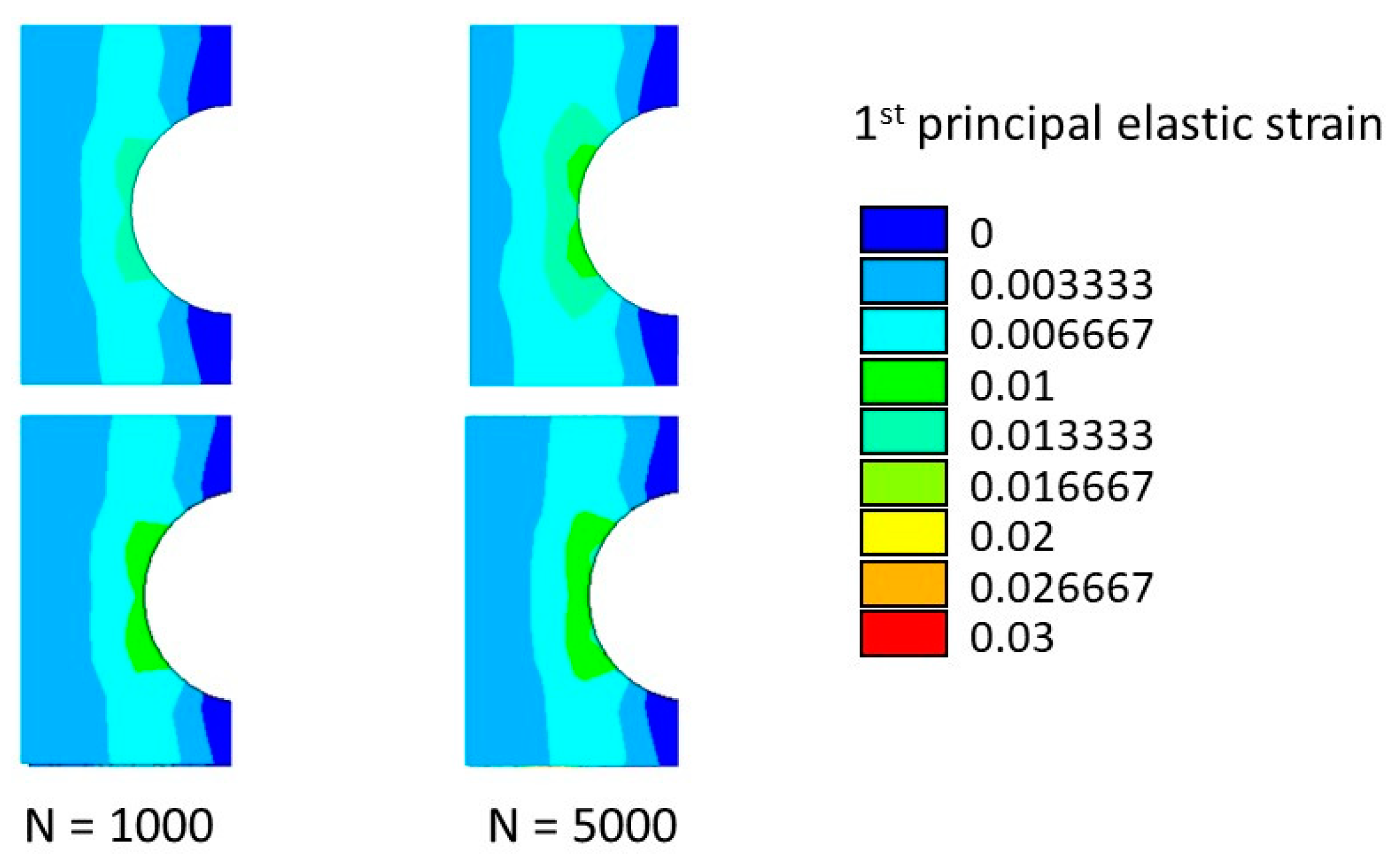

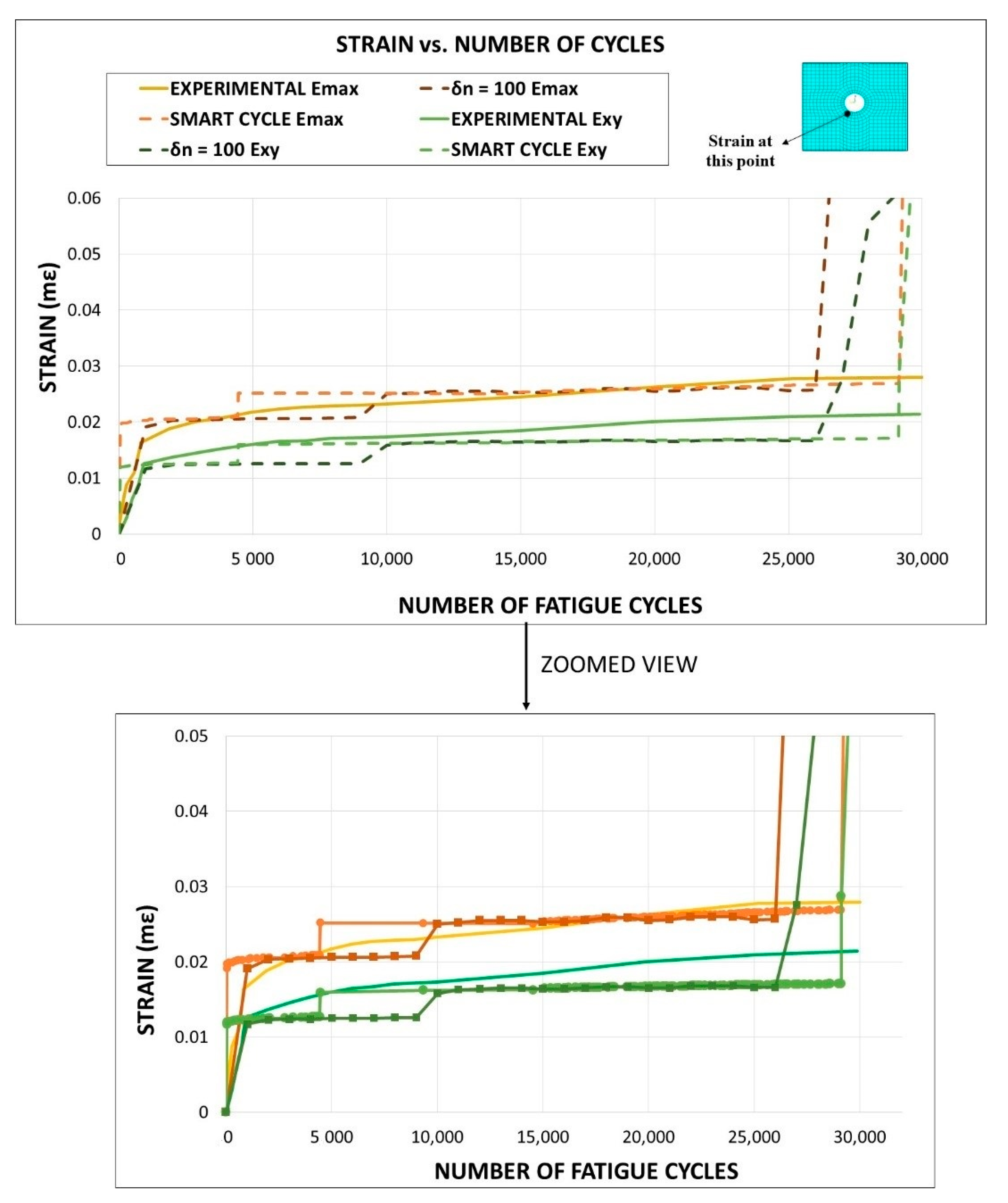

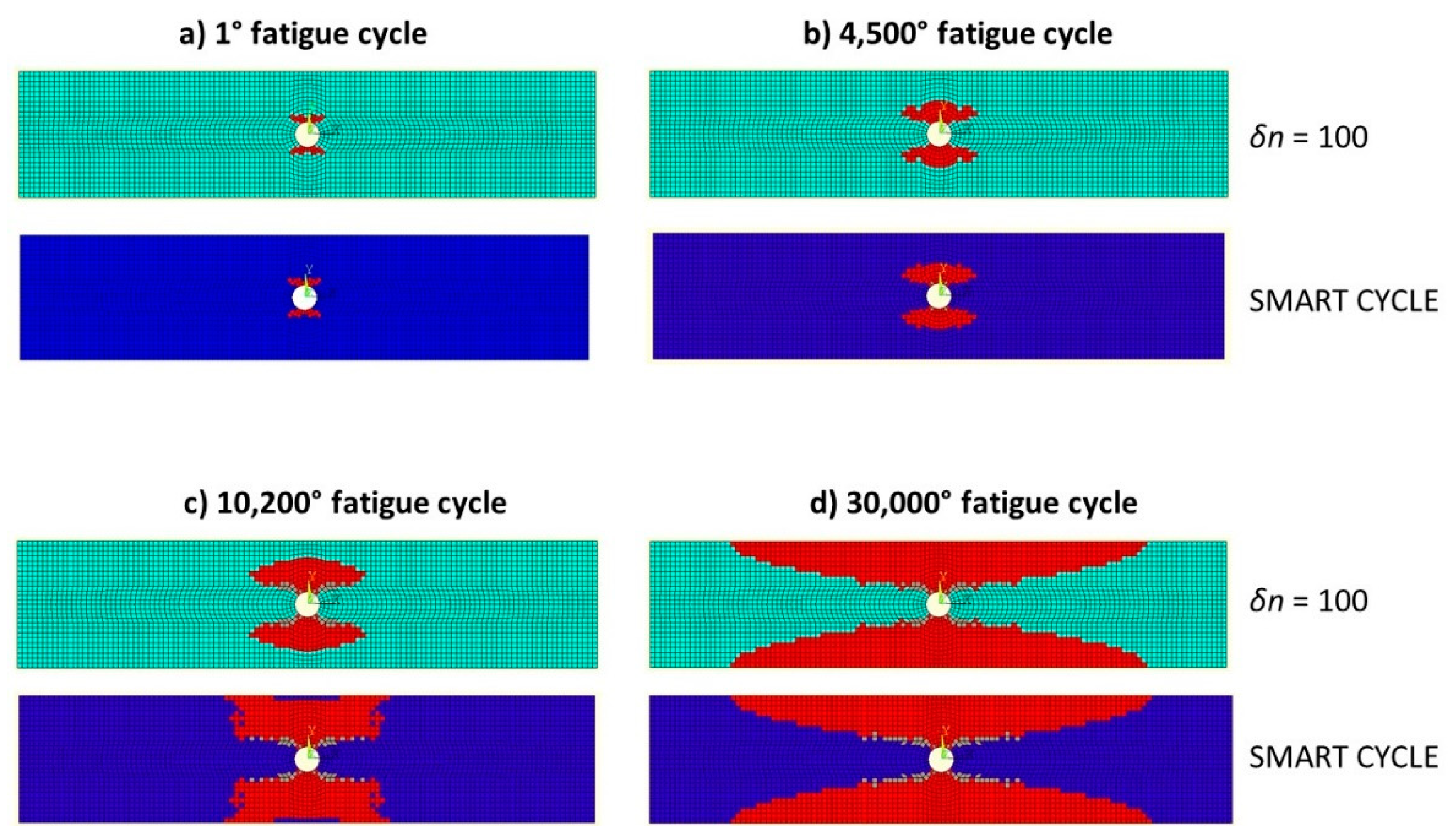

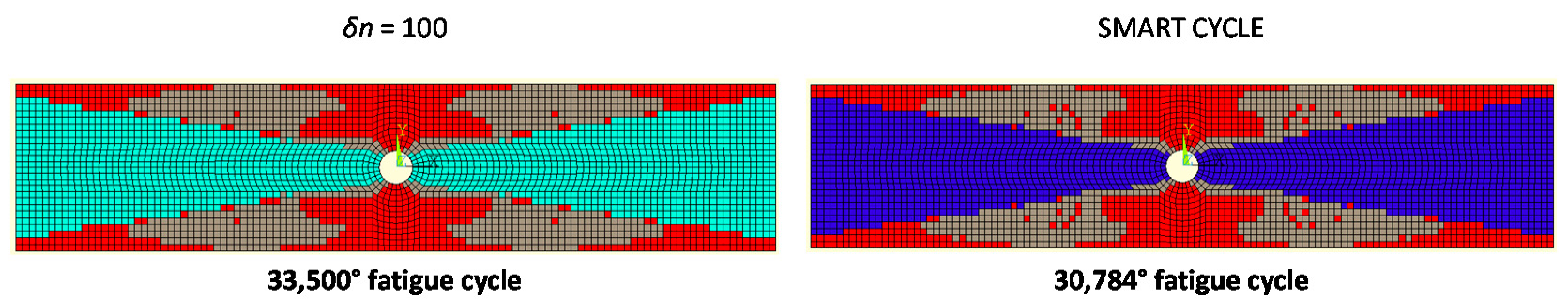

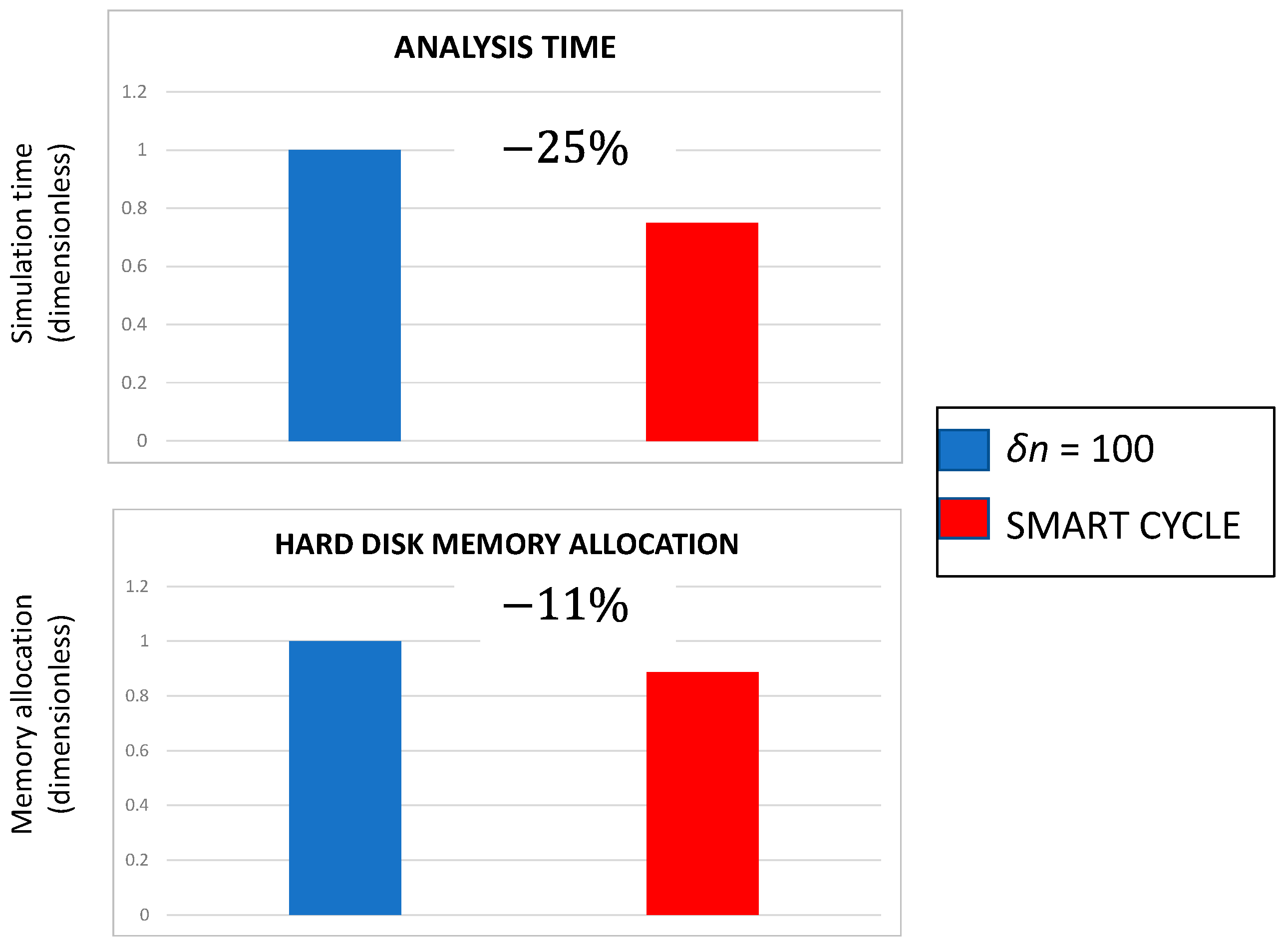

4.2. Cross-Ply Open-Hole Tensile Specimen

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vinson, J.R.; Chou, T.W. Composite Materials and Their Use in Structures; Halsted Press: New York, NY, USA, 1975. [Google Scholar]

- Rana, S.; Fangueiro, R. Advanced Composite Materials for Aerospace Engineering; Woodhead Publishing: Sawstone, UK, 2016; pp. 1–15. [Google Scholar]

- Skoczylas, J.; Samborski, S.; Kłonica, M. The Application of Composite Materials in the Aerospace Industry. J. Technol. Exploit. Mech. Eng. 2019. [Google Scholar] [CrossRef]

- Pinto, F.; Meo, M. Design and Manufacturing of a Novel Shear Thickening Fluid Composite (STFC) with Enhanced out-of-Plane Properties and Damage Suppression. Appl. Compos. Mater. 2017, 24, 643–660. [Google Scholar] [CrossRef]

- Talreja, R.; Singh, C.V. Damage and Failure of Composite Materials; Cambridge University Press: Cambridge, UK, 2012; pp. 1–304. [Google Scholar]

- Chamis, C.C. Mechanics of composite materials: Past, present, and future. J. Compos. Technol. Res. 1989, 11, 3–14. [Google Scholar]

- Rohwer, K. Models for Intralaminar damage and failure of fiber composites—A review. Facta Univ. Ser. Mech. Eng. 2016, 14, 1–19. [Google Scholar] [CrossRef]

- Rizzo, F.; D’Agostino, T.; Pinto, F.; Meo, M. High-velocity impact response on advanced hybrid composite structures. Int. Soc. Opt. Eng. 2019, 10973, 109730T. [Google Scholar]

- Lo Cascio, M.; Milazzo, A.; Benedetti, I. Virtual element method for computational homogenization of composite and heterogeneous materials. Compos. Struct. 2020, 232, 111523. [Google Scholar] [CrossRef]

- Sellitto, A.; Riccio, A.; Russo, A.; Zarrelli, M.; Toscano, C.; Lopresto, V. Compressive behaviour of a damaged omega stiffened panel: Damage detection and numerical analysis. Compos. Struct. 2019, 209, 300–316. [Google Scholar] [CrossRef]

- Hill, R. Mathematical Theory of Plasticity; Clarendon: Oxford, UK, 1950; pp. 317–321. [Google Scholar]

- Tsai, S.W.; Wu, E.M. A General Theory of Strength for Anisotropic Materials. J. Compos. Mater. 1971, 5, 58–80. [Google Scholar] [CrossRef]

- Hashin, Z.; Rotem, A. A Fatigue Failure Criterion for Fiber Reinforced Materials. J. Compos. Mater. 1973, 7, 448–464. [Google Scholar] [CrossRef]

- Hashin, Z. Failure Criteria for Unidirectional Fiber Composites. ASME J. Appl. Mech. 1980, 47, 329–334. [Google Scholar] [CrossRef]

- Bak, B.L.V.; Sarrado, C.; Turon, A.; Costa, J. Delamination under fatigue loads in composite laminates: A review on the observed phenomenology and computational methods. Appl. Mech. Rev. 2014, 66, 060803. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Taheri-Behrooz, F. A unified fatigue life model based on energy method. Compos.Struct. 2006, 75, 444–450. [Google Scholar] [CrossRef]

- Ellyin, F.; El-Kadi, H. Predicting crack growth direction in unidirectional composite laminae. Eng. Fract. Mech. 1990, 36, 27–37. [Google Scholar] [CrossRef]

- Ellyin, F.; El-Kadi, H. A fatigue failure criterion for fiber reinforced composite laminae. Compos. Struct. 1990, 15, 61–74. [Google Scholar] [CrossRef]

- Parrinello, F.; Gulizzi, V.; Benedetti, I. A model for low-cycle fatigue in micro-structured materials. Key Eng. Mater. 2020, 827, 134–140. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Fawaz, Z.; Ellyin, F. Fatigue failure model for fibre reinforced materials under general loading conditions. J. Compos. Mater. 1994, 28, 1432–1451. [Google Scholar] [CrossRef]

- Harris, B. Fatigue Behavior of Polymer-Based Composites and Life Prediction Methods; AIB-Vinçotte Leerstoel, 2 maart 1995; Nationaal Fonds voor Wetenschappelijk Onderzoek: Brussels, Belgium, 1985; p. 28. [Google Scholar]

- Adam, T.; Gathercole, N.; Reiter, H.; Harris, B. Life prediction for fatigue of T800/5245 carbon-fibre composites: II. Variable amplitude loading. Int. J. Fatigue 1994, 16, 533–547. [Google Scholar] [CrossRef]

- Gathercole, N.; Reiter, H.; Adam, T.; Harris, B. Life prediction for fatigue of T800/5245 carbon-fibre composites: I. Constant amplitude loading. Int. J. Fatigue 1994, 16, 523–532. [Google Scholar] [CrossRef]

- Salkind, M.J. Fatigue of composites. In Composite Materials Testing and Design (Second Conference); Corten, H.T., Ed.; ASTM STP 497; American Society for Testing and Materials: Baltimore, MD, USA, 1972; pp. 143–169. [Google Scholar]

- Schulte, K. Stiffness reduction and development of longitudinal cracks during fatigue loading of composite laminates. In Mechanical Characterisation of Load Bearing Fibre Composite Laminates, Proceedings of the European Mechanics Colloquium 182, Brussels, Belgium, 29–31 August 1984; Cardon, A.H., Verchery, G., Eds.; Elsevier: Amsterdam, The Netherlands, 1984; pp. 36–54. [Google Scholar]

- Schulte, K.; Baron, C.; Neubert, H.; Bader, M.G.; Boniface, L.; Wevers, M.; Verpoest, I.; de Charentenay, F.X. Damage development in carbon fiber epoxy laminates: Cyclic loading. In Proceedings of the MRS Symposium Advanced Materials for Transport, Strasbourg, France, 26–29 November 1985; p. 8. [Google Scholar]

- Schulte, K.; Reese, E.; Chou, T.-W. Fatigue behaviour and damage development in woven fabric and hybrid fabric composites. In Proceedings of the Sixth International Conference on Composite Materials (ICCM-VI) and Second European Conference on Composite Materials (ECCMII), London, UK, 20–24 July 1987; Matthews, F.L., Buskell, N.C.R., Hodgkinson, J.M., Morton, J., Eds.; Elsevier: Amsterdam, The Netherlands, 1987; Volume 4, pp. 489–499. [Google Scholar]

- Hwang, W.; Han, K.S. Cumulative damage models and multi-stress fatigue life prediction. J. Compos. Mater. 1986, 20, 125–153. [Google Scholar] [CrossRef]

- Hwang, W.; Han, K.S. Fatigue of composites—Fatigue modulus concept and life prediction. J. Compos. Mater. 1986, 20, 154–165. [Google Scholar] [CrossRef]

- Chou, P.C.; Croman, R. Residual Strength in Fatigue Based on the Strength-Life Equal Rank Assumption. J. Compos. Mater. 1978, 12, 177–194. [Google Scholar] [CrossRef]

- Chou, P.C.; Croman, R. Degradation and sudden-death models of fatigue of graphite/epoxy composites. In Composite Materials: Testing and Design (5th Conference) ASTM STP 674; Tsai, S.W., Ed.; American Society for Testing and Materials: Philadelphia, PA, USA, 1979; pp. 431–454. [Google Scholar]

- Shokrieh, M.M. Progressive Fatigue Damage Modeling of Composite Materials. Ph.D. Thesis, McGill University, Montréal, QC, Canada, 1996. [Google Scholar]

- Shokrieh, M.M.; Lessard, L.B. Multiaxial fatigue behavior of unidirectional plies based on uniaxial fatigue experiments—I. Modeling. Int. J. Fatigue 1997, 19, 201–207. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Lessard, L.B. Multiaxial fatigue behavior of unidirectional plies based on uniaxial fatigue experiments—II. Experimental evaluation. Int. J. Fatigue 1997, 19, 209–217. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Lessard, L.B. Residual fatigue life simulation of laminated composites. In Proceedings of the International Conference on Advanced Composites (ICAC 98), Hurghada, Egypt, 15–18 December 1998; pp. 79–86. [Google Scholar]

- Shokrieh, M.M.; Lessard, L.B. Progressive fatigue damage modeling of composite materials, Part I: Modeling. J. Compos. Mater. 2000, 34, 1056–1080. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Lessard, L.B. Progressive fatigue damage modeling of composite materials, Part II: Material characterization and model verification. J. Compos. Mater. 2000, 34, 1081–1116. [Google Scholar] [CrossRef]

- Naderi, M.; Maligno, A.R. Fatigue life prediction of carbon/epoxy laminates by stochastic numerical simulation. Compos. Struct. 2012, 94, 1052–1059. [Google Scholar] [CrossRef]

- Krishnan, A.; Conway, A.; Xiao, X. Assessment of a Progressive Fatigue Damage Model for AS4/3501–6 Carbon Fiber/Epoxy Composites Using Digital Image Correlation. Appl. Compos. Mater. 2019, 26, 1227–1246. [Google Scholar] [CrossRef]

- Khan, A.I.; Venkataraman, S.; Miller, I. Predicting Fatigue Damage of Composites Using Strength Degradation and Cumulative Damage Model. J. Compos. Sci. 2018, 2, 9. [Google Scholar] [CrossRef]

| Failure Modes | Equations | Parameters |

|---|---|---|

| Tensile fiber failure | fiber tensile fatigue strength shear fatigue strength | |

| Compressive fiber failure | fiber compressive fatigue strength | |

| Tensile matrix failure | matrix tensile fatigue strength shear fatigue strength | |

| Compressive matrix failure | matrix compressive fatigue strength |

| Property | Value |  |

| 147,000 MPa | ||

| 9000 MPa | ||

| 5000 MPa | ||

| 3000 MPa | ||

| 0.3 (-) | ||

| 0.42 (-) | ||

| 2004 MPa | ||

| 1197 MPa | ||

| 53 MPa | ||

| 204 MPa | ||

| 137 MPa | ||

| 42 MPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Russo, A.; Sellitto, A.; Curatolo, P.; Acanfora, V.; Saputo, S.; Riccio, A. A Robust Numerical Methodology for Fatigue Damage Evolution Simulation in Composites. Materials 2021, 14, 3348. https://doi.org/10.3390/ma14123348

Russo A, Sellitto A, Curatolo P, Acanfora V, Saputo S, Riccio A. A Robust Numerical Methodology for Fatigue Damage Evolution Simulation in Composites. Materials. 2021; 14(12):3348. https://doi.org/10.3390/ma14123348

Chicago/Turabian StyleRusso, Angela, Andrea Sellitto, Prisco Curatolo, Valerio Acanfora, Salvatore Saputo, and Aniello Riccio. 2021. "A Robust Numerical Methodology for Fatigue Damage Evolution Simulation in Composites" Materials 14, no. 12: 3348. https://doi.org/10.3390/ma14123348

APA StyleRusso, A., Sellitto, A., Curatolo, P., Acanfora, V., Saputo, S., & Riccio, A. (2021). A Robust Numerical Methodology for Fatigue Damage Evolution Simulation in Composites. Materials, 14(12), 3348. https://doi.org/10.3390/ma14123348