Influence of Water Glass Introduction Methods on Selected Properties of Portland Cement

Abstract

1. Introduction

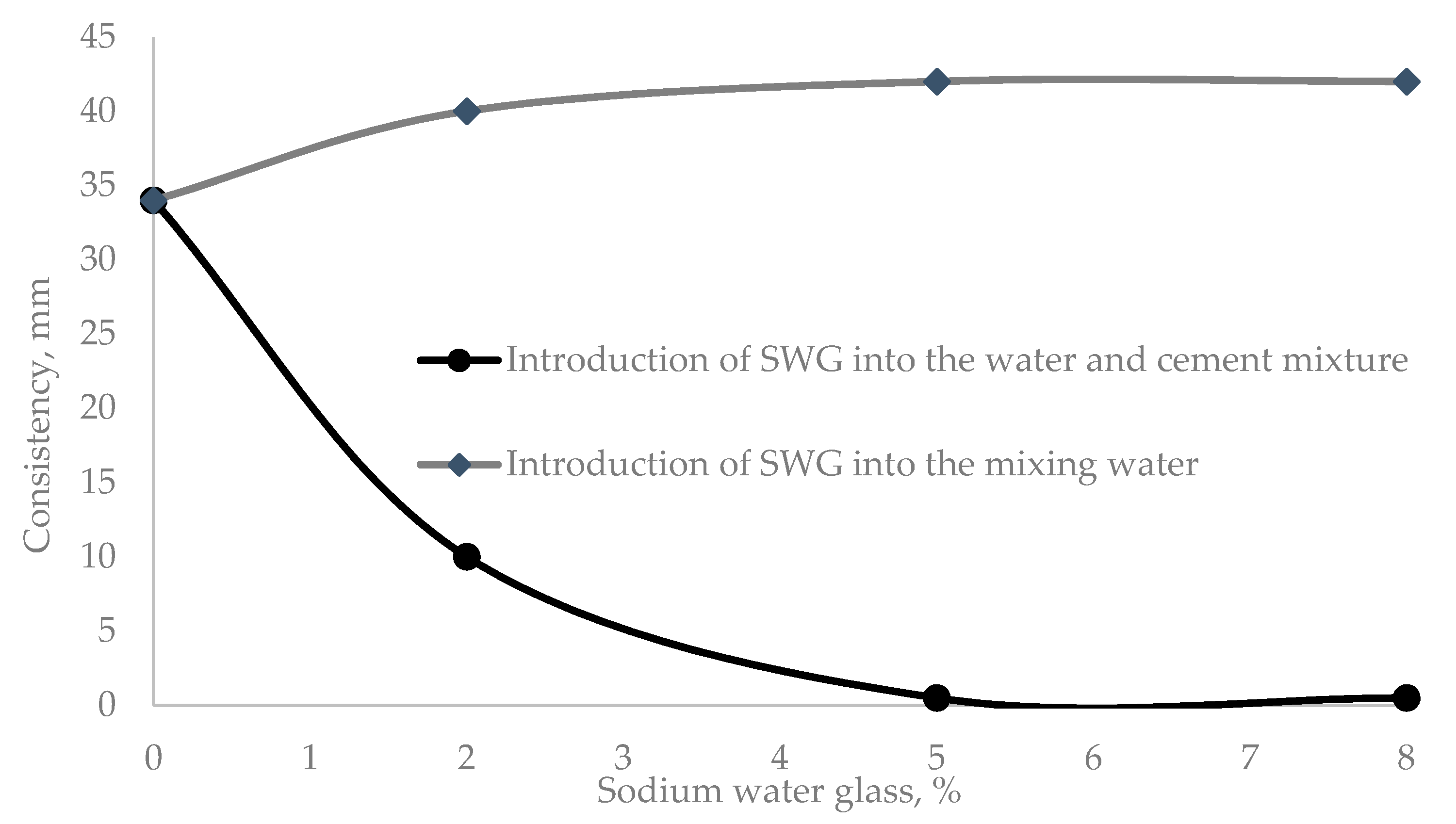

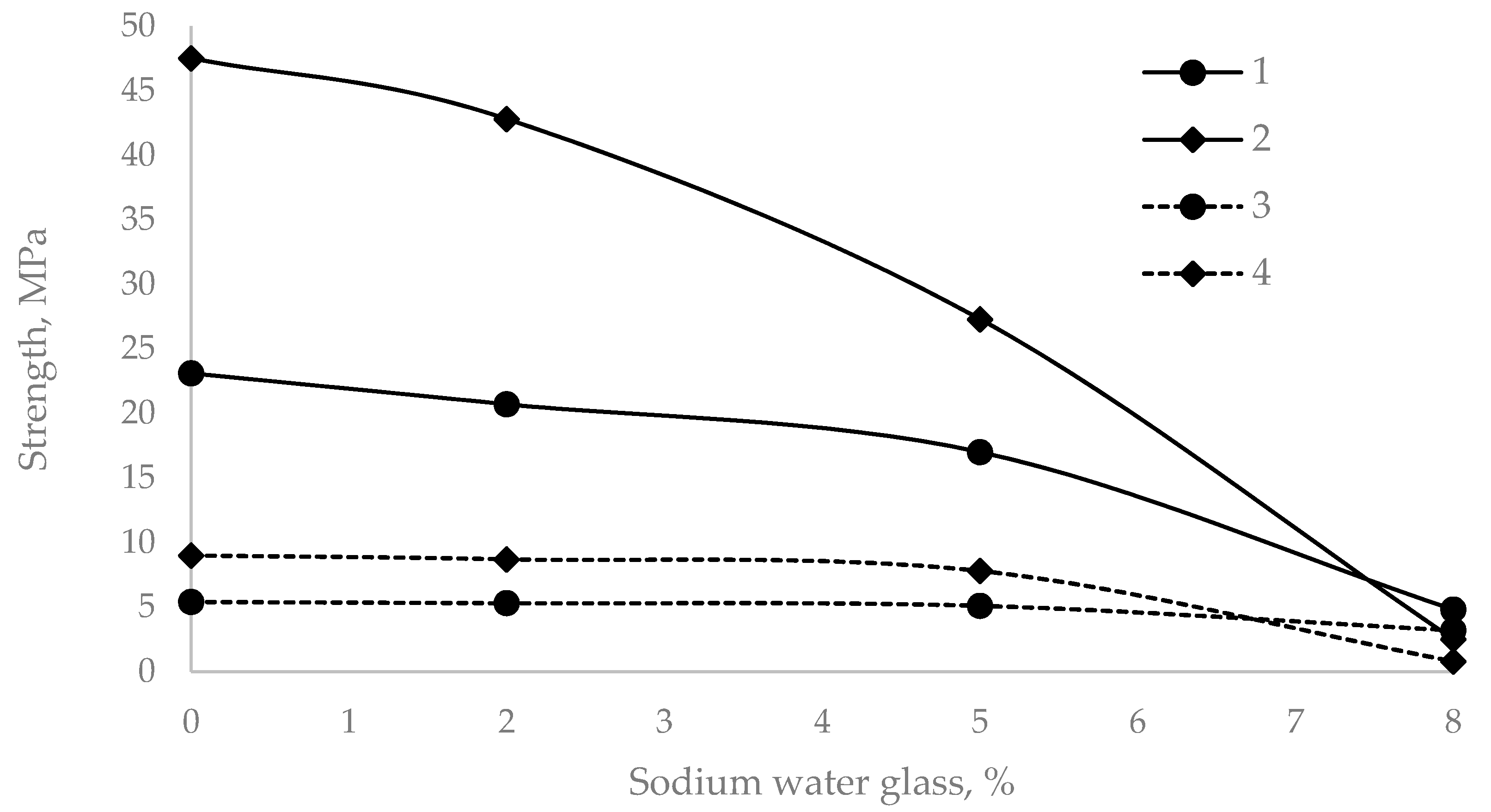

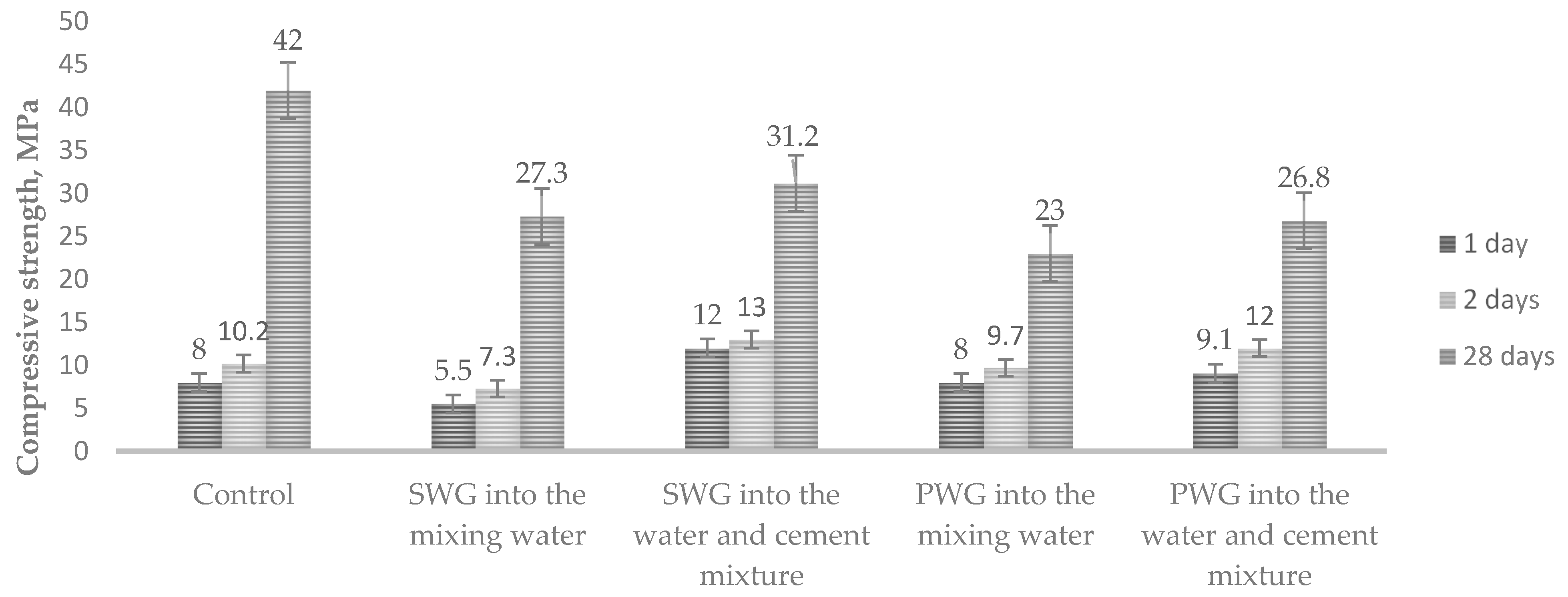

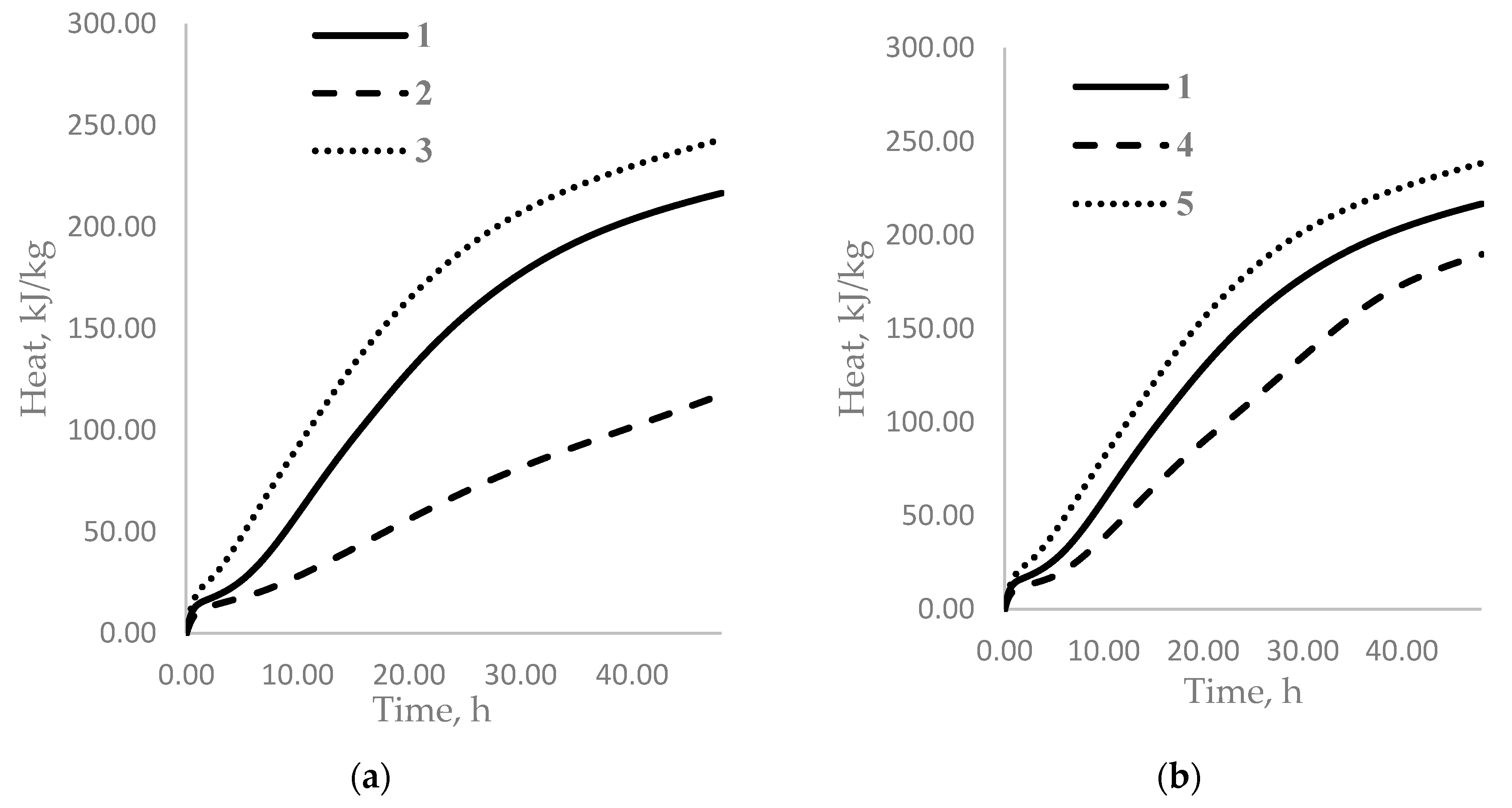

2. Materials and Methods

3. Experimental Section

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramachandran, V.S. Concrete Admixtures Handbook: Properties, Science, and Technology; Noyes Publications: Park Ridge, NJ, USA, 1995. [Google Scholar]

- Neville, A.M. Właściwości Betonu; Polski Cement: Kraków, Poland, 2012. [Google Scholar]

- John, M.; Scanlon, R.J.R. Accelerating Admixtures for Cold Weather Concreting. Available online: https://www.concreteconstruction.net/how-to/materials/accelerating-admixtures-for-cold-weather-concreting_o (accessed on 10 June 2021).

- Pizoń, J.; Miera, P.; Łaźniewska-Piekarczyk, B. Influence of Hardening Accelerating Admixtures on Properties of Cement with Ground Granulated Blast Furnace Slag. Procedia Eng. 2016, 161, 1070–1075. [Google Scholar] [CrossRef]

- Łukowski, P. Modyfikacja Materiałowa Betonu; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2016. [Google Scholar]

- Cheung, J.; Jeknavorian, A.; Roberts, L.; Silva, D. Impact of admixtures on the hydration kinetics of Portland cement. Cem. Concr. Res. 2011, 41, 1289–1309. [Google Scholar] [CrossRef]

- Chen, C.; Sun, Z. Influence of Aluminum Sulfate on Hydration and Properties of Cement Pastes. J. Adv. Concr. Technol. 2018, 16, 522–530. [Google Scholar] [CrossRef]

- Salvador, R.P.; Cavalaro, S.H.P.; Segura, I.; Figueiredo, A.D.; Pérez, J. Early age hydration of cement pastes with alkaline and alkali-free accelerators for sprayed concrete. Constr. Build. Mater. 2016, 111, 386–398. [Google Scholar] [CrossRef]

- Wang, Y.; He, F.; Wang, J.; Hu, Q. Comparison of Effects of Sodium Bicarbonate and Sodium Carbonate on the Hydration and Properties of Portland Cement Paste. Materials 2019, 12, 1033. [Google Scholar] [CrossRef] [PubMed]

- Pashchenko, A. Teoria Cementa; Budivelnick: Kiev, Ukraine, 1991. [Google Scholar]

- Kurdowski, W. Chemia Cementu i Betonu; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2010. [Google Scholar]

- Massazza, F. Admixtures in concrete. In Advances in Cement Technology; Pergamon Press: New York, NY, USA, 1983; pp. 569–648. [Google Scholar]

- Coppola, L. Role of Admixtures in Advanced Concrete Technology. In Proceedings of the Seventh Canmet/ACI International Conference on “Superplasticizers and Other Chemical Admixtures in Concrete”, Berlin, Germany, 20–23 October 2003; pp. 473–495. [Google Scholar]

- Polish Committee for Standardization. PN-EN, 934–2+A1:2012 Admixtures for Concrete, Mortar and Grout—Part 2: Concrete Admixtures—Definitions, Requirements, Conformity, Marking and Labelling; Polish Committee for Standardization: Warsaw, Poland, 2012; p. 24. [Google Scholar]

- Taylor, H.F.W. Cement Chemistry; Thomas Telford Publishing: London, UK, 1997. [Google Scholar]

- Jolicoeur, C.; Simard, M.-A. Chemical admixture-cement interactions: Phenomenology and physico-chemical concepts. Cem. Concr. Compos. 1998, 20, 87–101. [Google Scholar] [CrossRef]

- Chen, G.; Lee, H.; Young, K.L.; Yue, P.L.; Wong, A.; Tao, T.; Choi, K.K. Glass recycling in cement production—An innovative approach. Waste Manag. 2002, 22, 747–753. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Y.; Riefler, C.; Wang, H. Characteristics and pozzolanic reactivity of glass powders. Cem. Concr. Res. 2005, 35, 987–993. [Google Scholar] [CrossRef]

- Schwarz, N.; Neithalath, N. Influence of a fine glass powder on cement hydration: Comparison to fly ash and modeling the degree of hydration. Cem. Concr. Res. 2008, 38, 429–436. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Bouchikhi, A.; Benzerzour, M.; Abriak, N.-E.; Maherzi, W.; Mamindy-Pajany, Y. Study of the impact of waste glasses types on pozzolanic activity of cementitious matrix. Constr. Build. Mater. 2019, 197, 626–640. [Google Scholar] [CrossRef]

- Liu, G.; Florea, M.V.A.; Brouwers, H.J.H. Performance evaluation of sustainable high strength mortars incorporating high volume waste glass as binder. Constr. Build. Mater. 2019, 202, 574–588. [Google Scholar] [CrossRef]

- Park, S.B.; Lee, B.C.; Kim, J.H. Studies on mechanical properties of concrete containing waste glass aggregate. Cem. Concr. Res. 2004, 34, 2181–2189. [Google Scholar] [CrossRef]

- Szewczenko, W.; Kotsay, G. Alkaline Activity of Portland Cement with Additives of Waste Glass. Materials 2021, 14, 1346. [Google Scholar] [CrossRef] [PubMed]

- Shevchenko, V.V. ASR effect in glasses used as additives to Portland cement. Glas. Phys. Chem. 2012, 38, 466–471. [Google Scholar] [CrossRef]

- Shevchenko, V.V.; Kotsai, G.N. Alkaline activity of glass powders used as additives to portland cement. Part I. Glas. Phys. Chem. 2015, 41, 500–502. [Google Scholar] [CrossRef]

- Shevchenko, V.V.; Kotsai, G.N. Nucleator Function of Glass Powders Used as Additives for Portland Cement. Glas. Phys. Chem. 2017, 43, 618–621. [Google Scholar] [CrossRef]

- Shevchenko, V.; Kotsay, G. Effect of Water Glass on Early Hardening of Portland Cement. Procedia Eng. 2017, 172, 977–981. [Google Scholar] [CrossRef]

- Czarnecki, L.; Broniewski, T.; Henning, O. Chemia w Budownictwie; Wydawnictwo Arkady: Warszawa, Poland, 2010. [Google Scholar]

- Kątna, Z. Wpływ szkła wodnego potasowego na parametry zaczynów cementowo-lateksowych. NAFTA-GAZ 2010, 6, 471–476. [Google Scholar]

- Baran, T. Influence of the potassium water glass on Portland cement hydration. Cem. Wapno Bet. 2004, 6, 298–306. [Google Scholar]

- Korneev, V.I.; Danilov, V.V. Zhidkoe i Rastvorimoe Steklo (Liquid Glass); Stroiizdat: St. Petersburg, Russia, 1996. [Google Scholar]

- Kessler, V.G. Sol-Gel Precursors. In The Sol-Gel Handbook; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2015; pp. 195–224. [Google Scholar]

- “RUDNIKI” S.A. Available online: http://www.zchrudniki.com.pl (accessed on 10 June 2021).

- Cement Ożarów. Available online: http://ozarow.com.pl (accessed on 10 June 2021).

- Polish Committee for Standardization. PN-EN, 196–3:2016-12 Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- Polish Committee for Standardization. PN-EN, 196–1:2016 Methods of Testing Cement. Determination of Strength; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- Polish Committee for Standardization. PN-EN ISO, 148–1:2016 Charpy Pendulum Impact Test—Part 1: Test Method; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- Shevchenko, V.V.; Kotsay, G.N. Influence of Glass Powder Additives on the Hydration Process of Portland Cement. Glas. Phys. Chem. 2020, 46, 653–656. [Google Scholar] [CrossRef]

- Baliński, A. O strukturze Uwodnionego Krzemianu Sodu Jako Spoiwa mas Formierskich; Instytut Odlewnictwa: Kraków, Poland, 2009. [Google Scholar]

- Yu, I. Orlov on the Glass Formation in the Na2O–SiO2–H2O System. Glas. Phys. Chem. 2002, 28, 281–287. [Google Scholar]

- Shevchenko, V.V.; Kotsay, G.N. The Effect of Additives of Water-Soluble Glass on the Extraction of Alkali from Portland Cement. Glas. Phys. Chem. 2019, 45, 596–598. [Google Scholar] [CrossRef]

| WG | Chemical Composition of Water Glass, wt % | Siliceous Module | ||

|---|---|---|---|---|

| SiO2 | Na2O | K2O | ||

| Sodium | 26.14 | 7.86 | - | 3.32 |

| Potassium | 23.56 | - | 6.58 | 3.58 |

| Chemical Composition, wt % | Phase Composition 1, wt % | Blaine Surface (cm2/g) | ||

|---|---|---|---|---|

| CaO | 64.23 | Alite (s) | 60.40 | 3380 |

| SiO2 | 21.75 | Belite (b) | 17.42 | |

| Al2O3 | 3.54 | Tricalcium aluminate | 3.47 | |

| Fe2O3 | 3.50 | Tetracalcium aluminoferrite | 10.60 | |

| Na2Oeq | 0.71 | Gypsum | 5.25 | |

| MgO | 0.80 | |||

| SO3 | 2.44 | |||

| Los of ignition | 3.03 | |||

| N Position | Composition | Introduction of WG |

|---|---|---|

| 1 | 100% CEM | - |

| 2 | 100% CEM + 5% sodium water glass (SWG) | Into the mixing water |

| 3 | Into the water and cement mixture | |

| 4 | 100% CEM + 5% potassium water glass (PWG) | Into the mixing water |

| 5 | Into the water and cement mixture |

| N Position | Setting Time, min | |

|---|---|---|

| Initial | Final | |

| 1 | 370 | 410 |

| 2 | 500 | 680 |

| 3 | 280 | 320 |

| 4 | 410 | 490 |

| 5 | 330 | 380 |

| N | Maximum Rate of Heat Evolution, W/kg | ||

|---|---|---|---|

| Pre-Induction Stage of Hydration | Induction Stage of Hydration | Post-Induction Stage of Hydration | |

| 1 | 8.18 | 0.62 | 2.16 |

| 2 | 4.54 | 0.41 | 0.81 |

| 3 | 10.45 | 1.36 | 2.51 |

| 4 | 5.35 | 0.43 | 1.25 |

| 5 | 9.24 | 1.14 | 2.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szewczenko, W.; Kotsay, G. Influence of Water Glass Introduction Methods on Selected Properties of Portland Cement. Materials 2021, 14, 3257. https://doi.org/10.3390/ma14123257

Szewczenko W, Kotsay G. Influence of Water Glass Introduction Methods on Selected Properties of Portland Cement. Materials. 2021; 14(12):3257. https://doi.org/10.3390/ma14123257

Chicago/Turabian StyleSzewczenko, Wiktor, and Galyna Kotsay. 2021. "Influence of Water Glass Introduction Methods on Selected Properties of Portland Cement" Materials 14, no. 12: 3257. https://doi.org/10.3390/ma14123257

APA StyleSzewczenko, W., & Kotsay, G. (2021). Influence of Water Glass Introduction Methods on Selected Properties of Portland Cement. Materials, 14(12), 3257. https://doi.org/10.3390/ma14123257