Durability of Cement and Ash Mortars with Fluidized and Siliceous Fly Ashes Exposed to HCl Acid Environment over a Period of 2 Years

Abstract

1. Introduction

2. Testing Methods

2.1. Determination of Density and Specific Surface Area

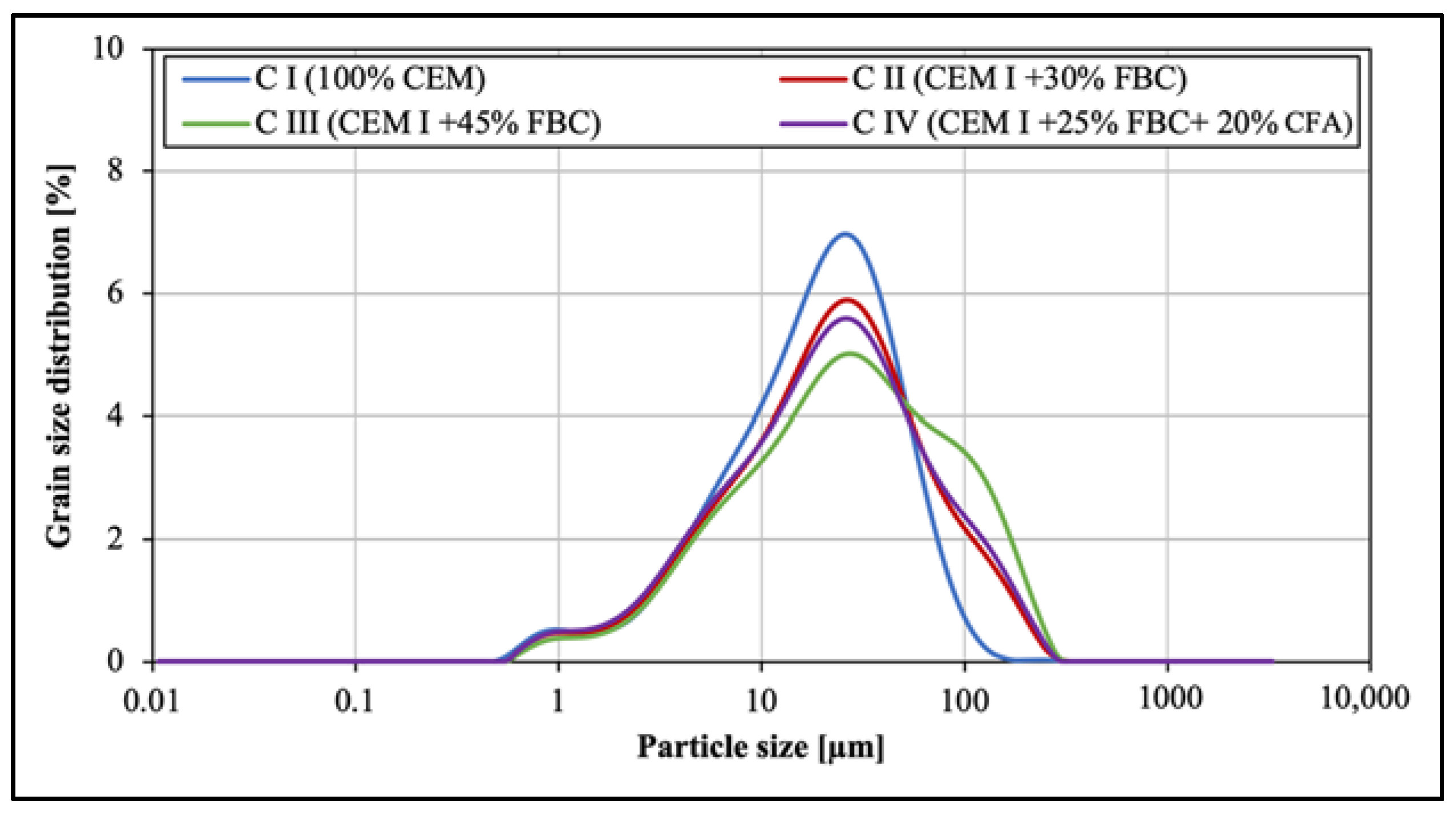

2.2. Analysis of Particle-Size Distribution

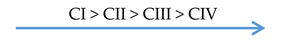

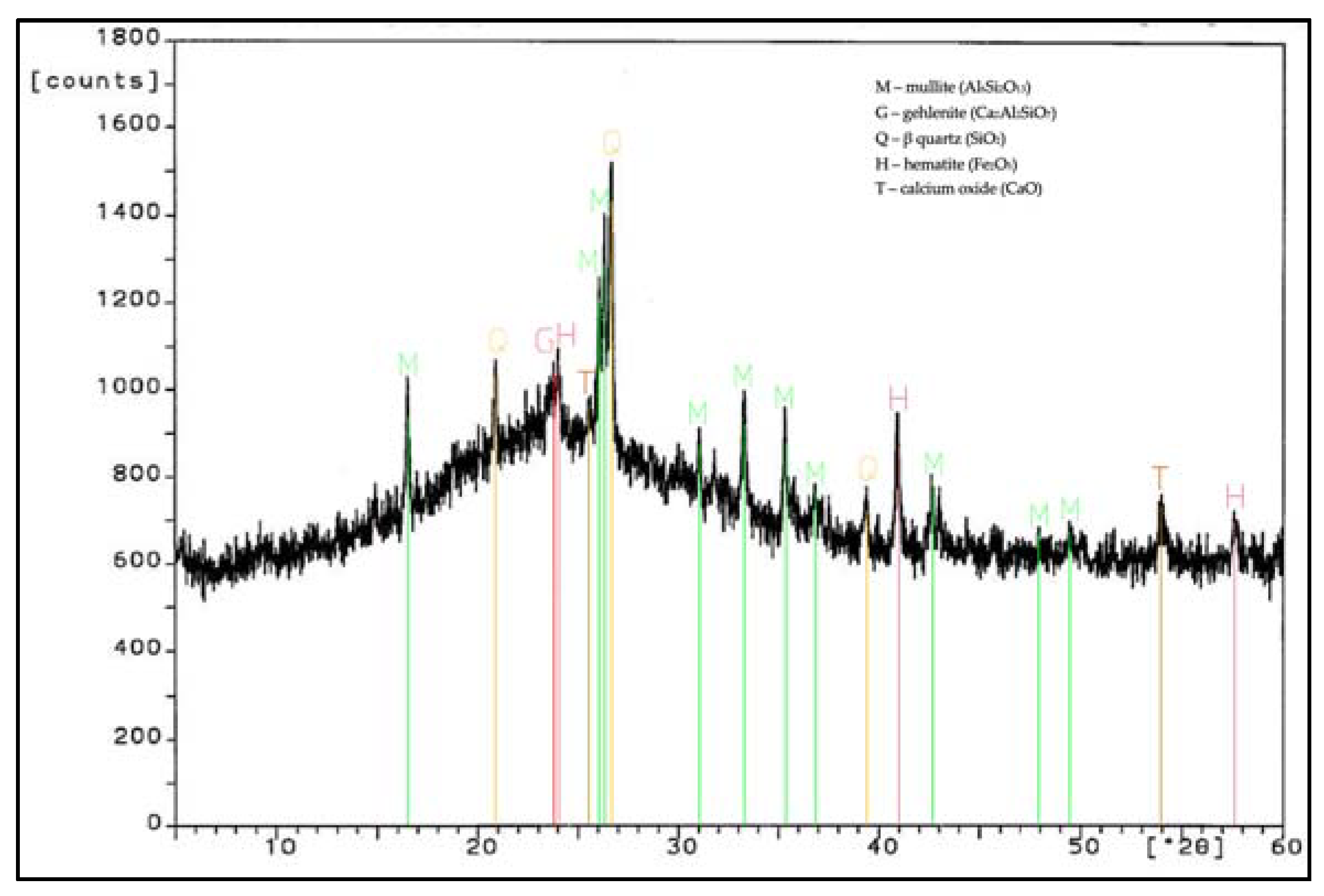

2.3. Determination of Phase Composition

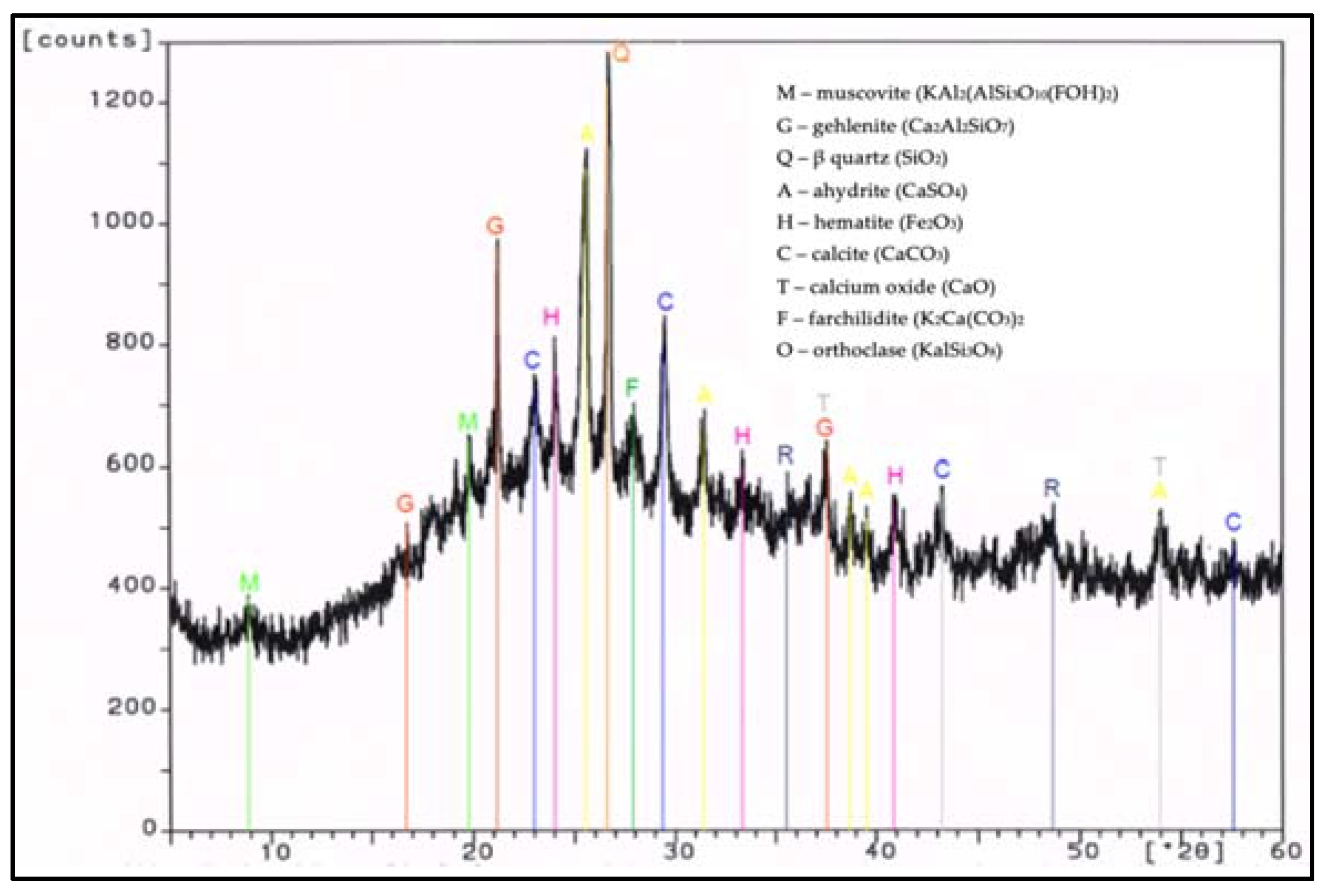

2.4. Determination of Fly-Ash Pozzolanic Activity According to the PN-EN 450-1:2012 Standard ”Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria”

2.5. Pozzolanic-Activity Testing According to the Frattini Method

2.6. Testing Hydration Heat of Binders in Cement–Ash Pastes

2.7. Compressive-Strength Tests of Mortars

2.8. Tests of Mortars’ Linear and Mass Changes

2.9. Tests of Mortars’ Porosity

2.10. Tests of Chemical Composition

3. Physical and Chemical Properties of Cement and FBC and Siliceous Ashes

4. Preparation of Mortars for Durability Tests in an Aggressive Environment

5. Interpretation of Test Results of Cement Binders and Mortar Properties with and without FBC Fly Ash and the Mixture of FBC and Siliceous Fly Ash

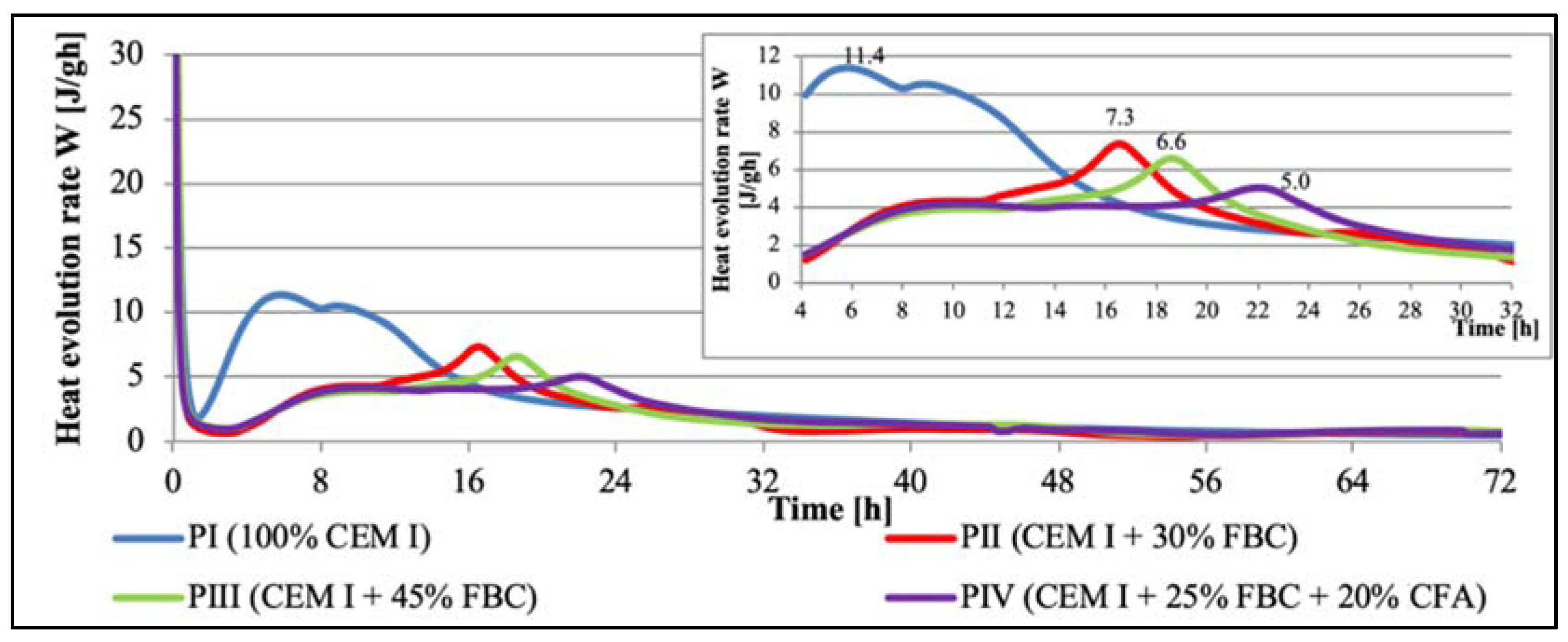

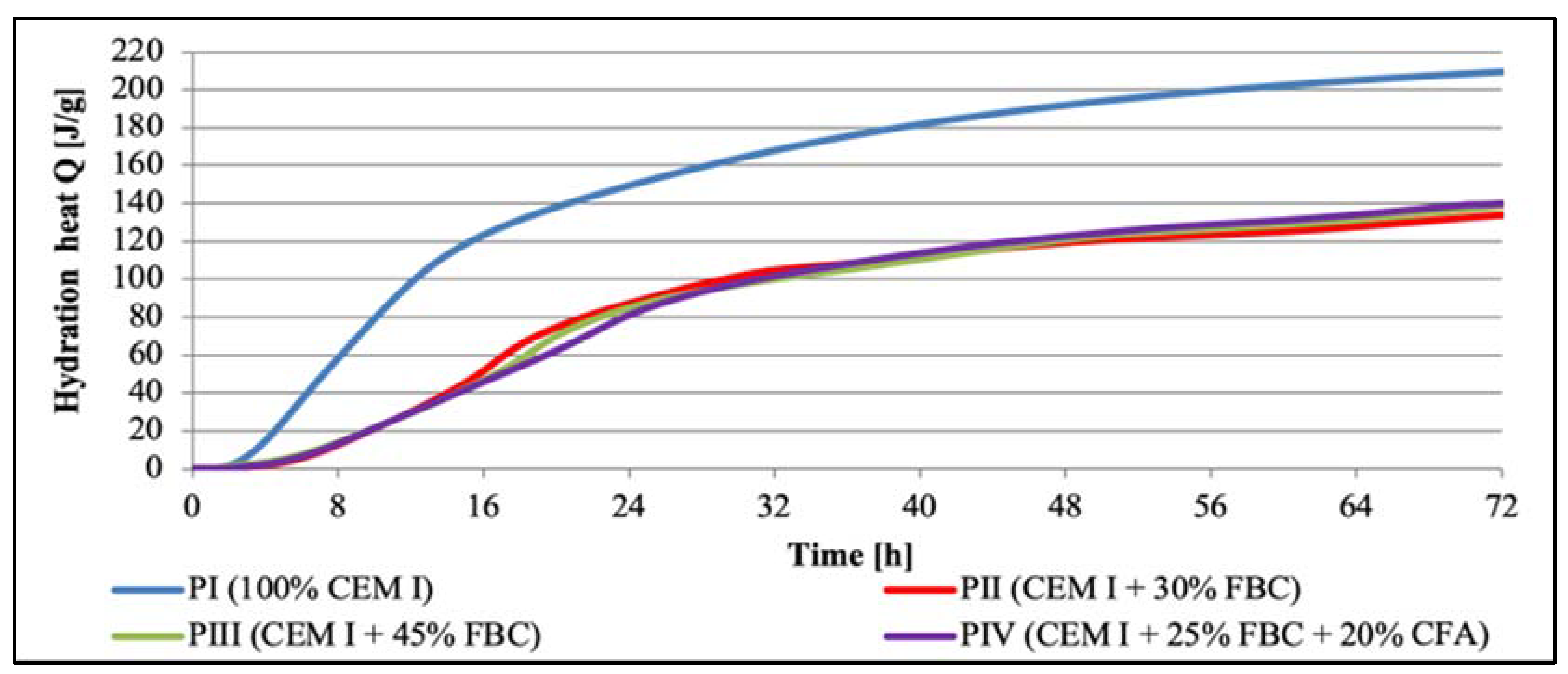

5.1. Results of Hydration Heat Testing

Test Results of Hydration Heat of Cementitious and Cement–Ash Binders in Pastes

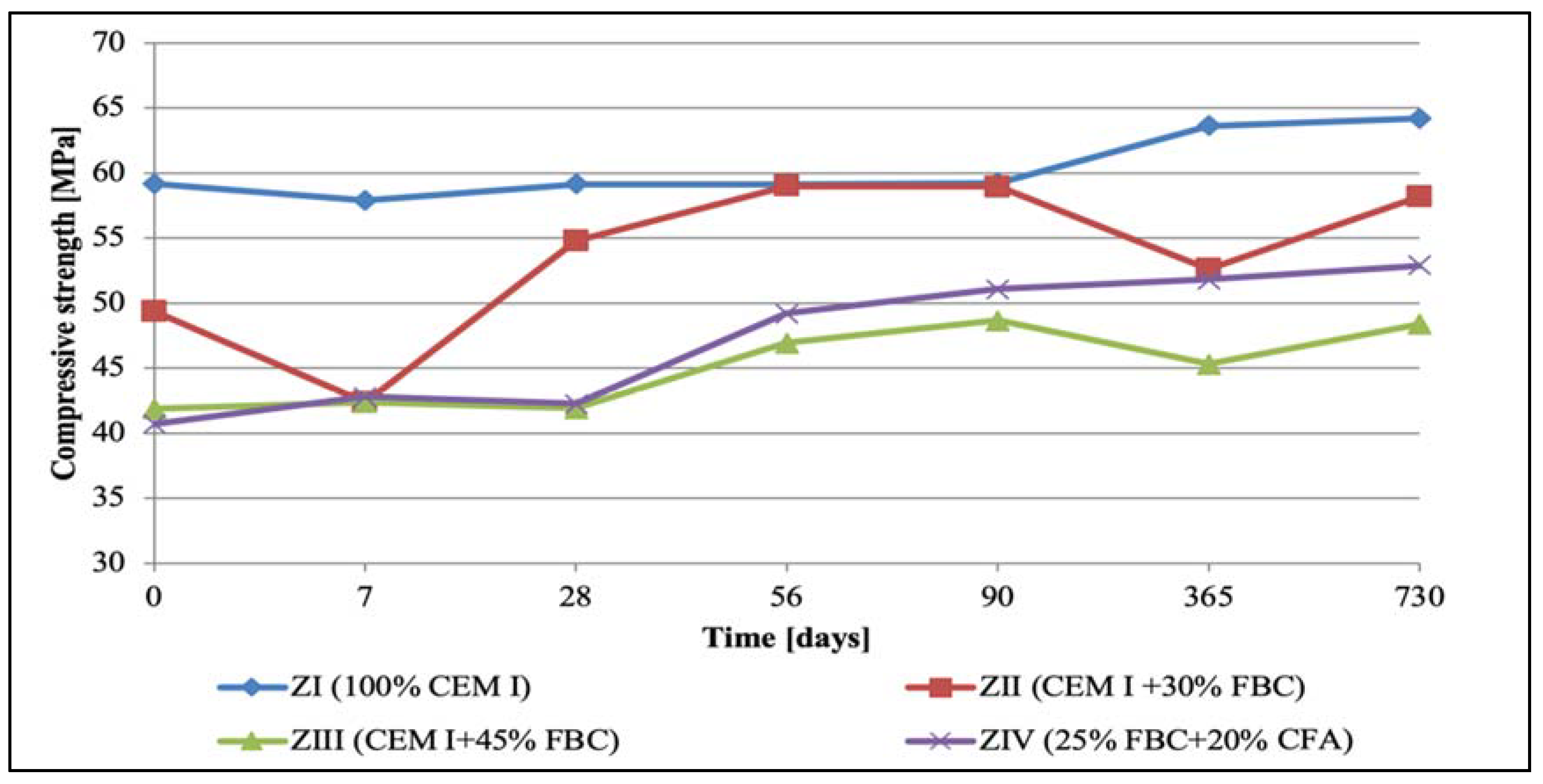

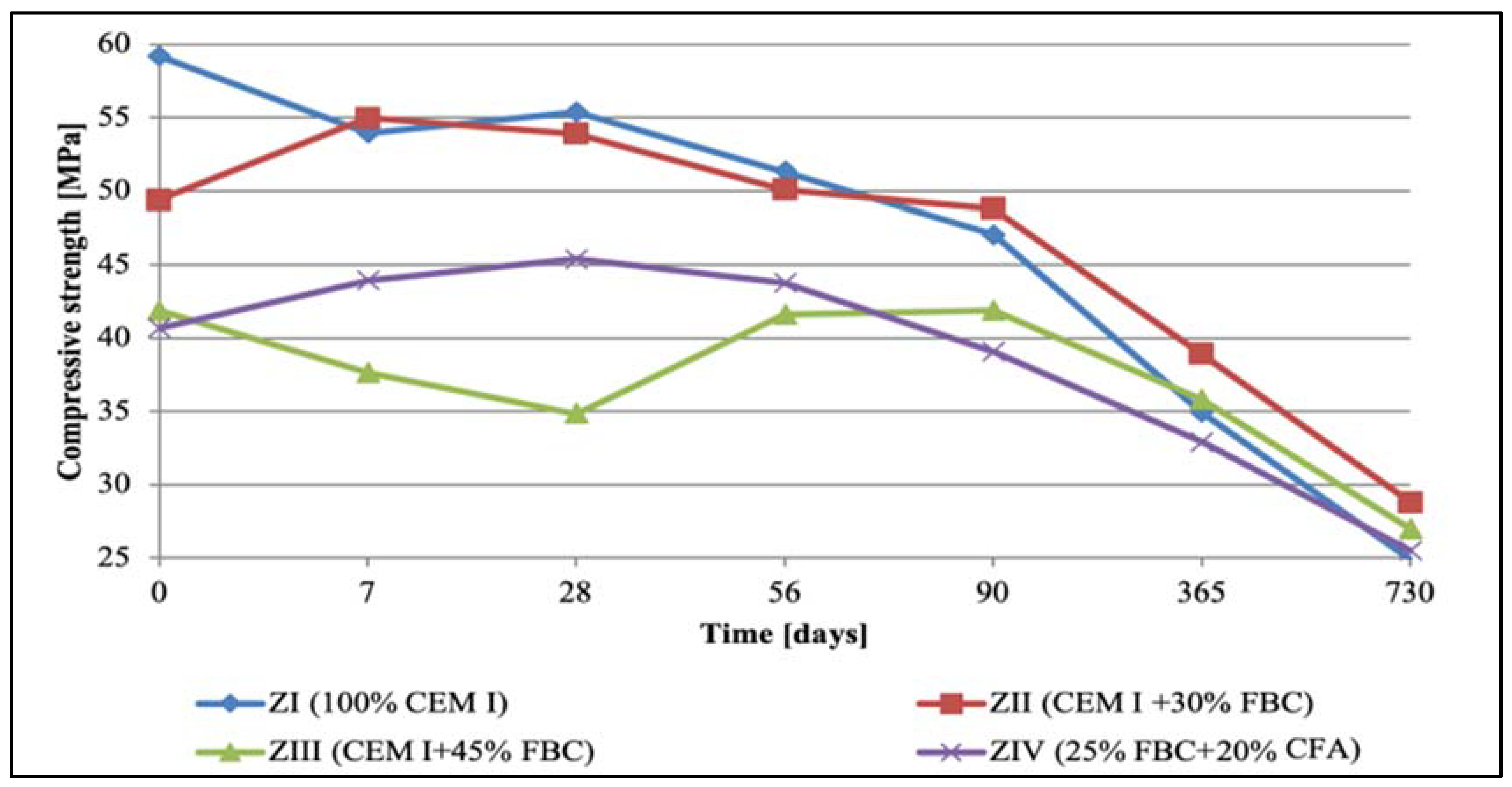

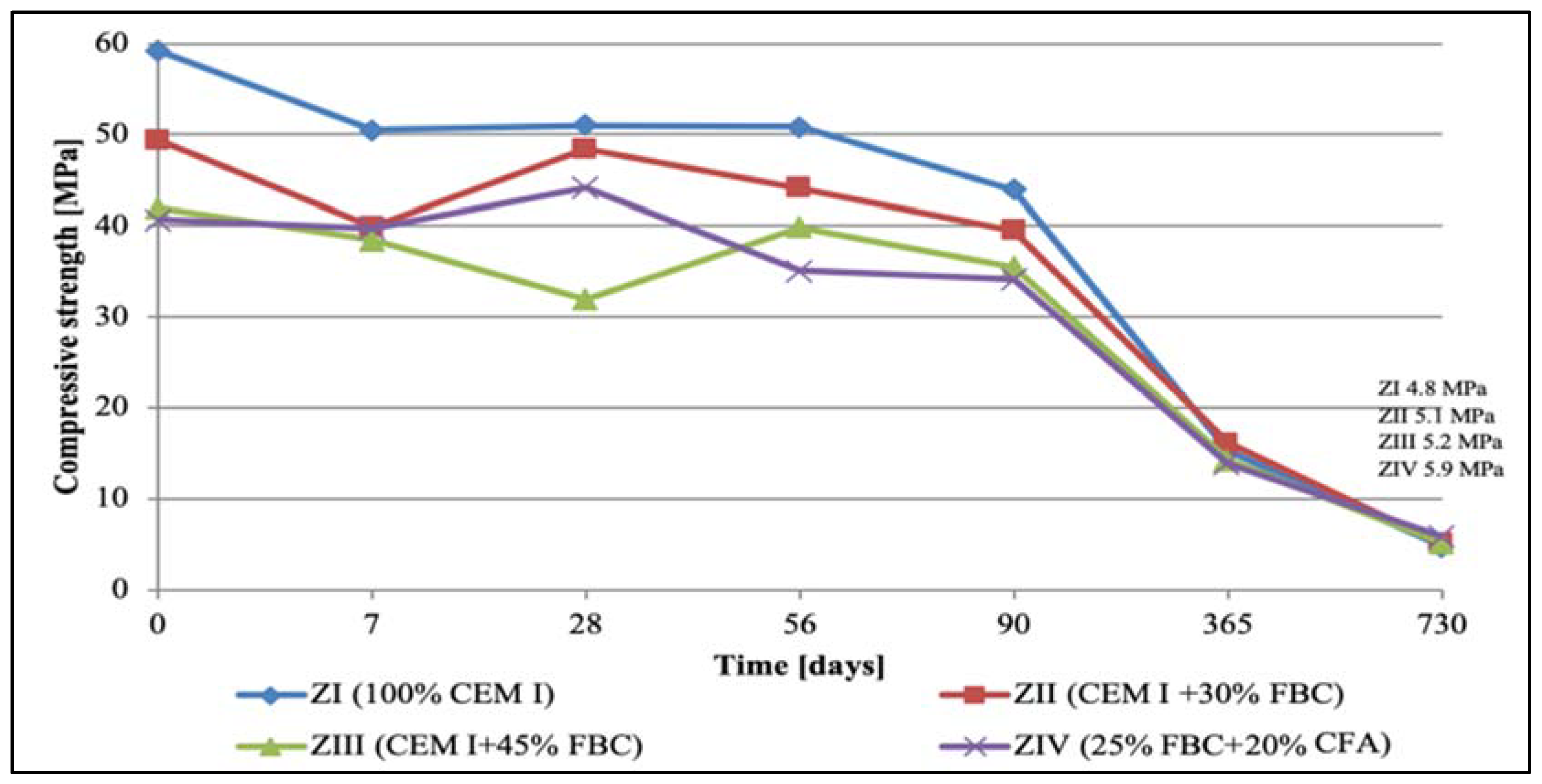

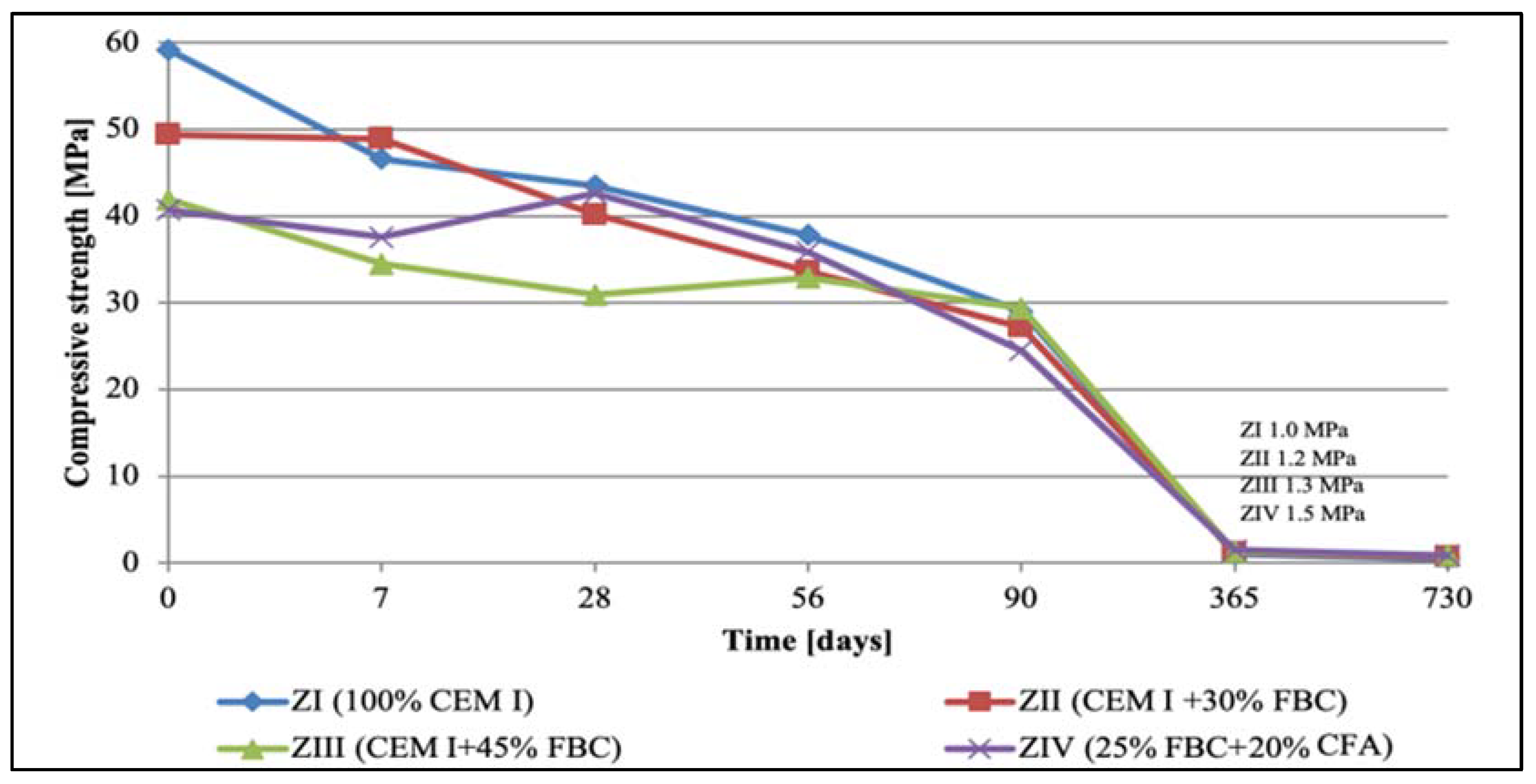

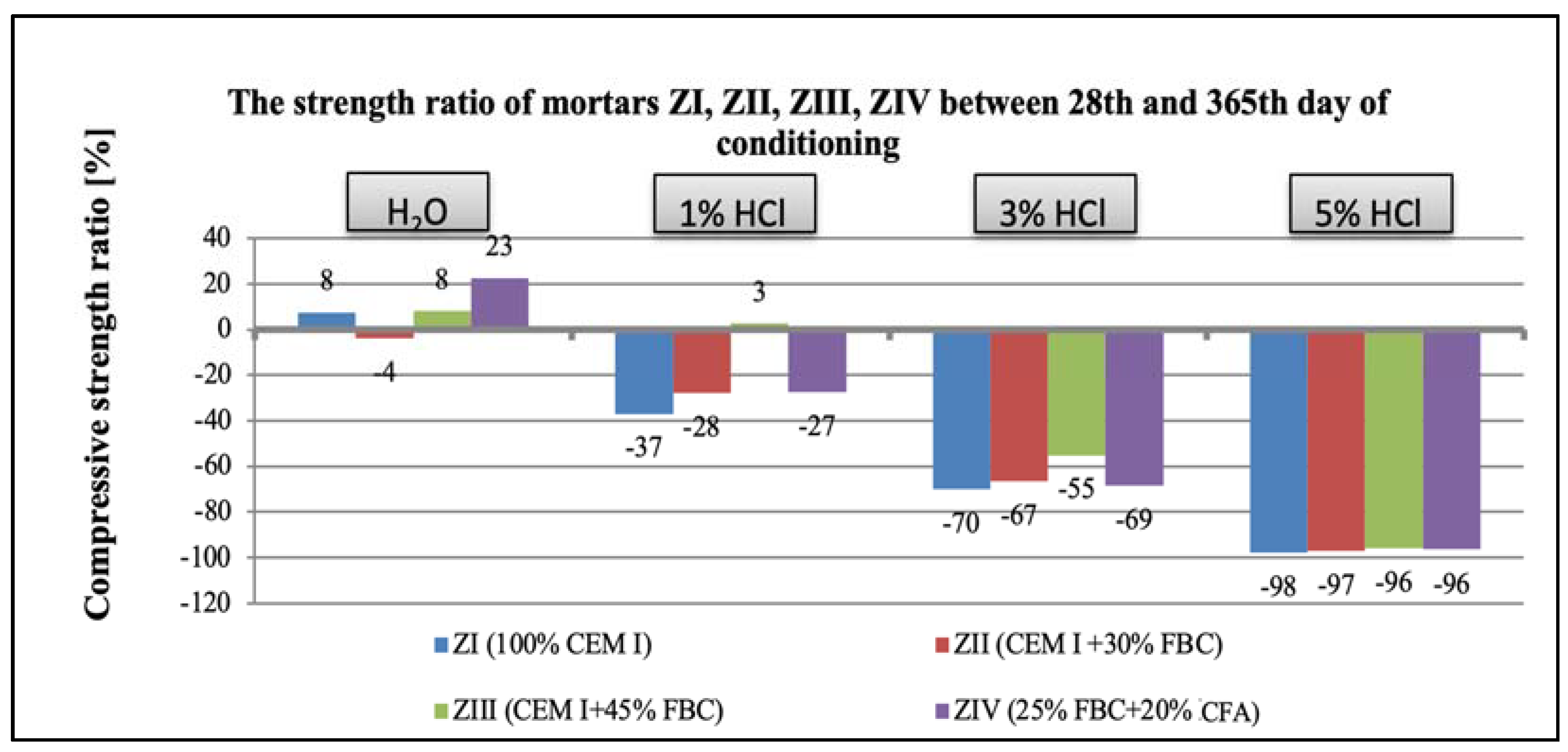

5.2. Results of Compressive-Strength Tests

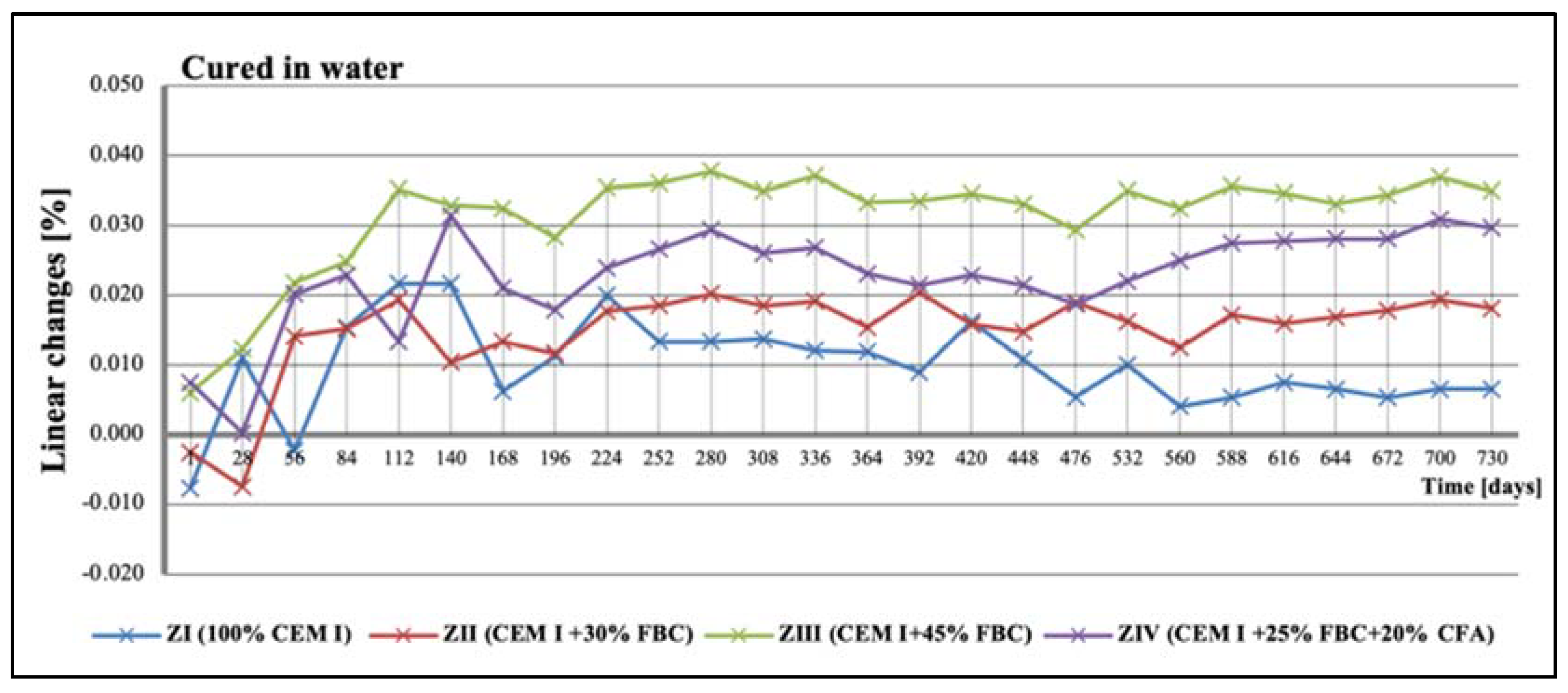

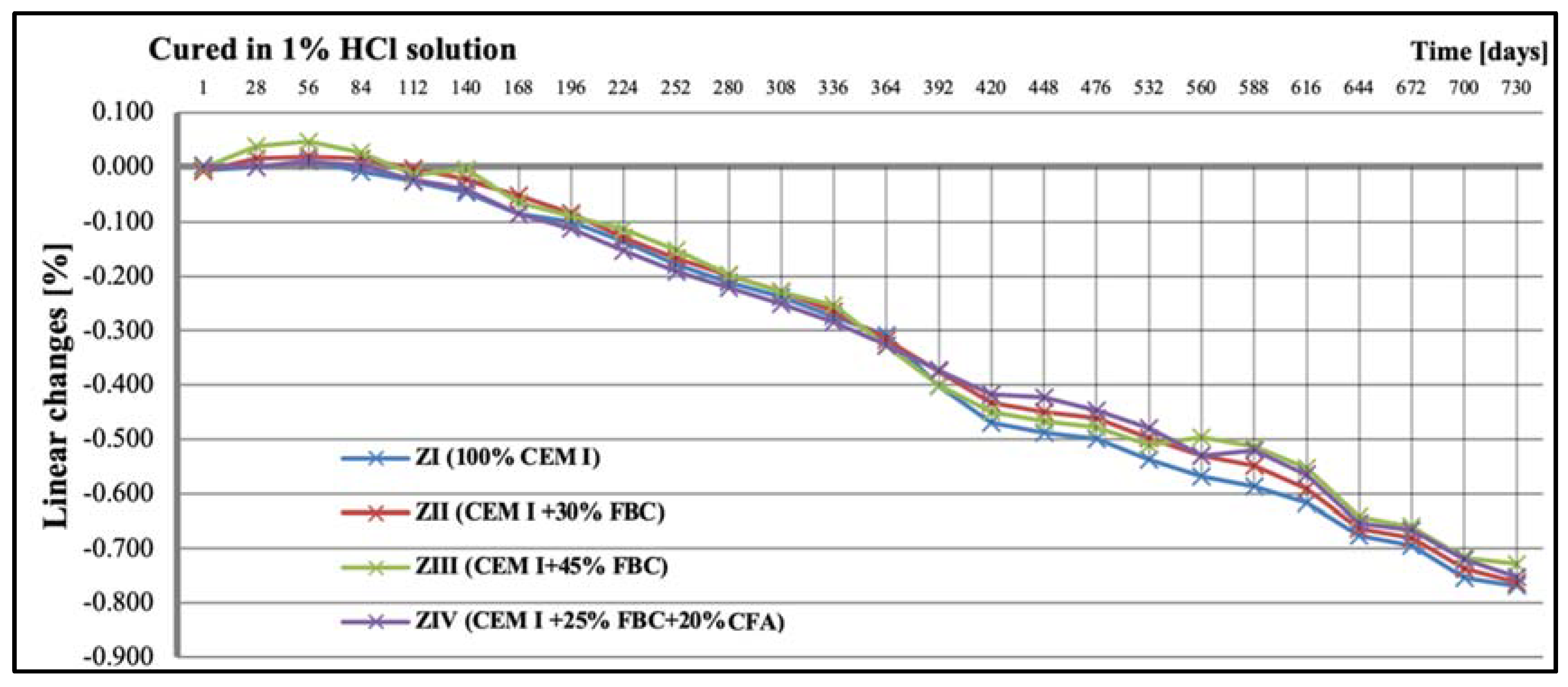

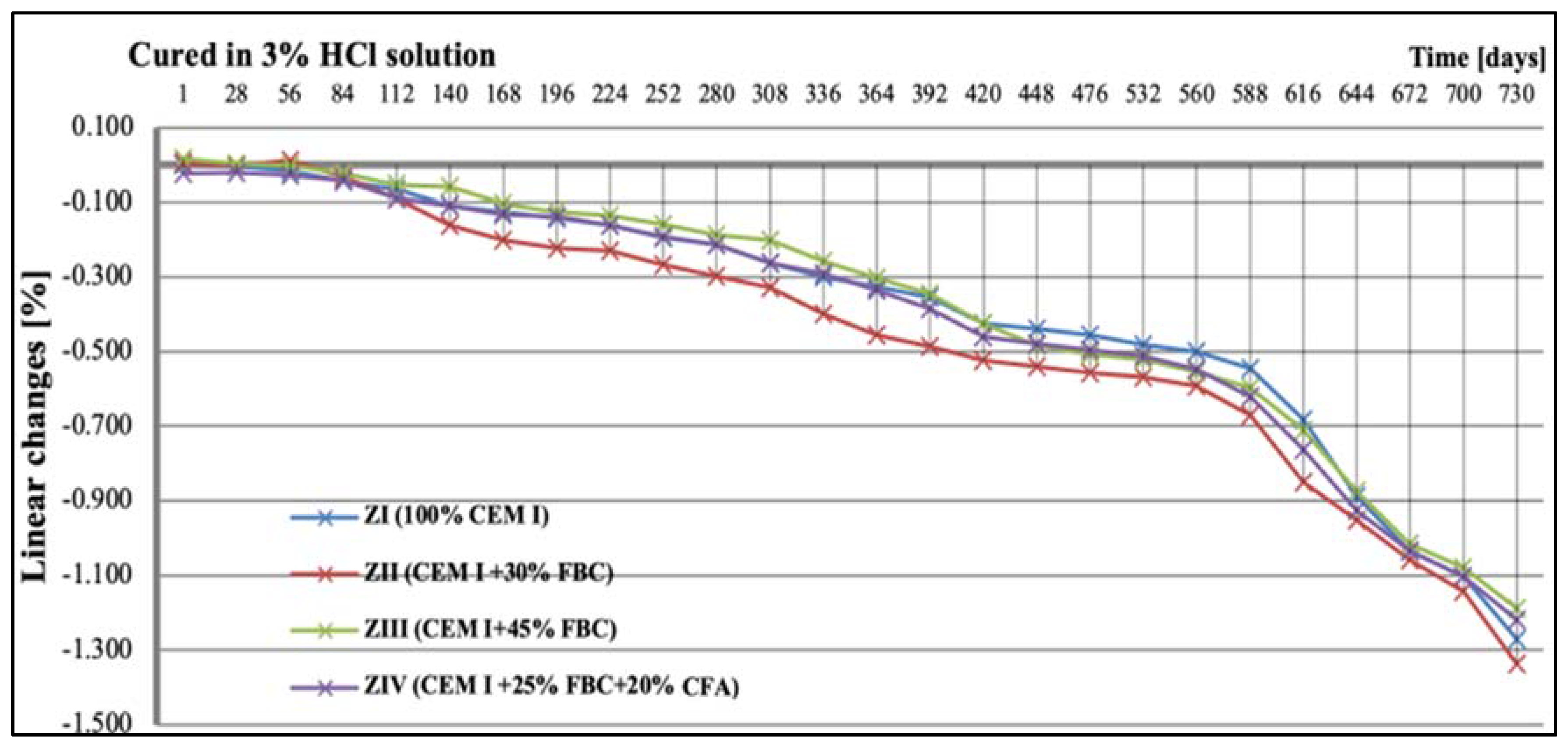

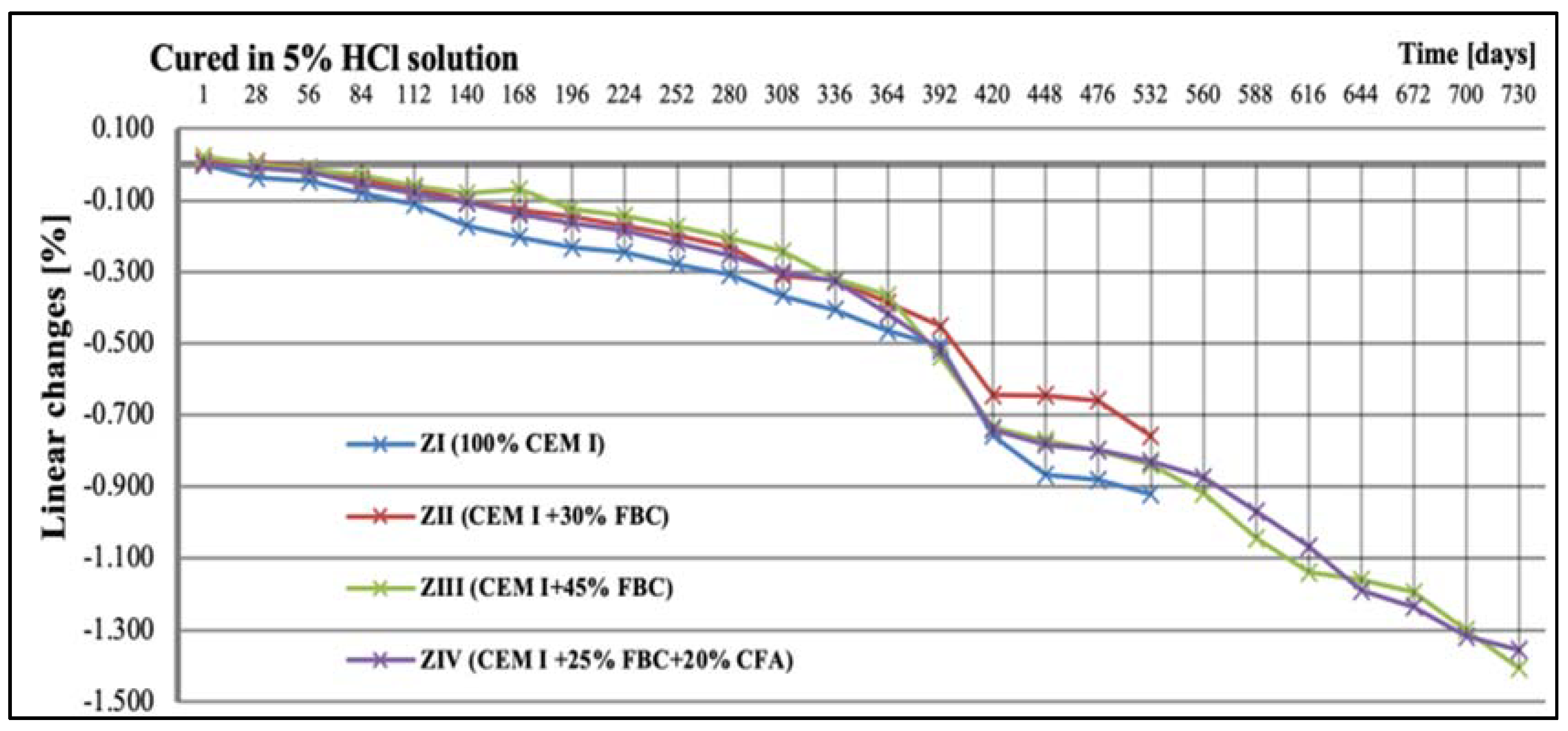

5.3. Test Results of Mortars’ Linear Changes

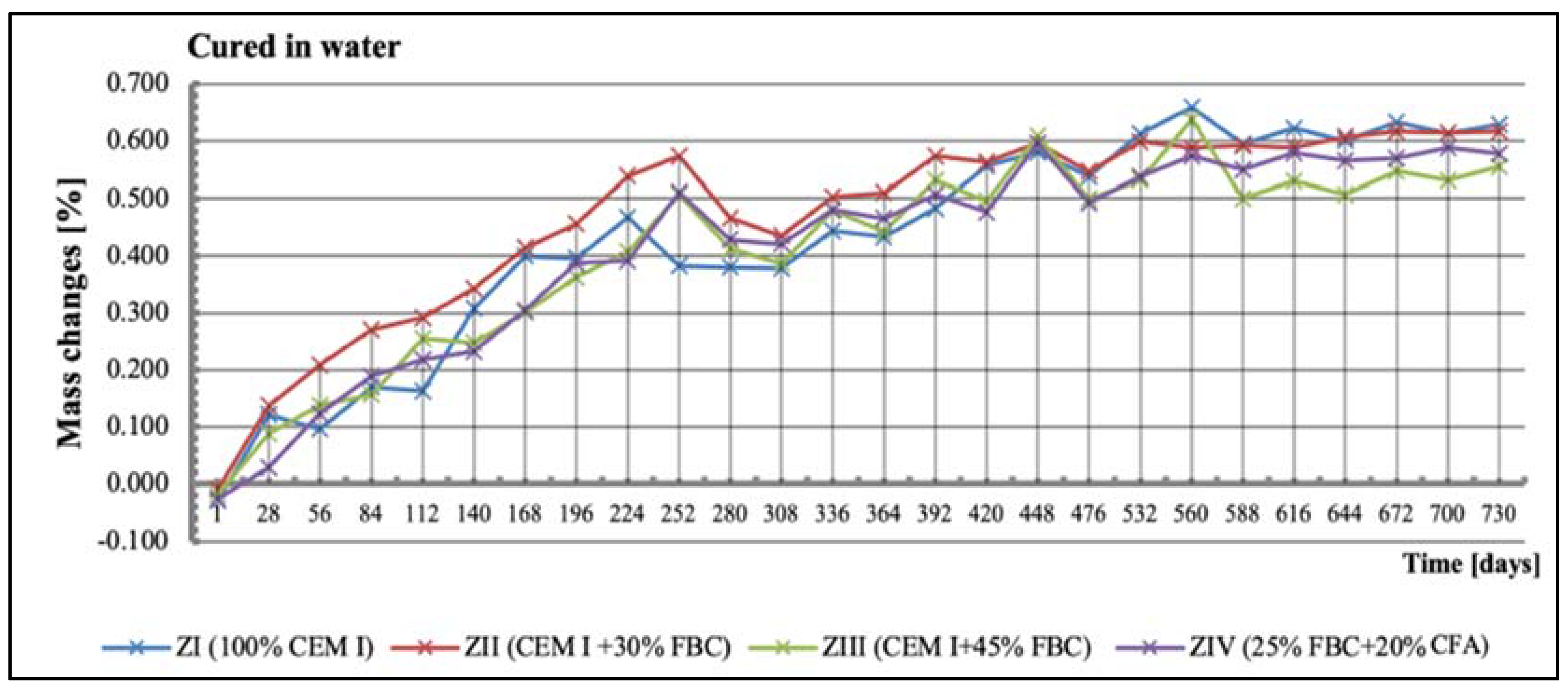

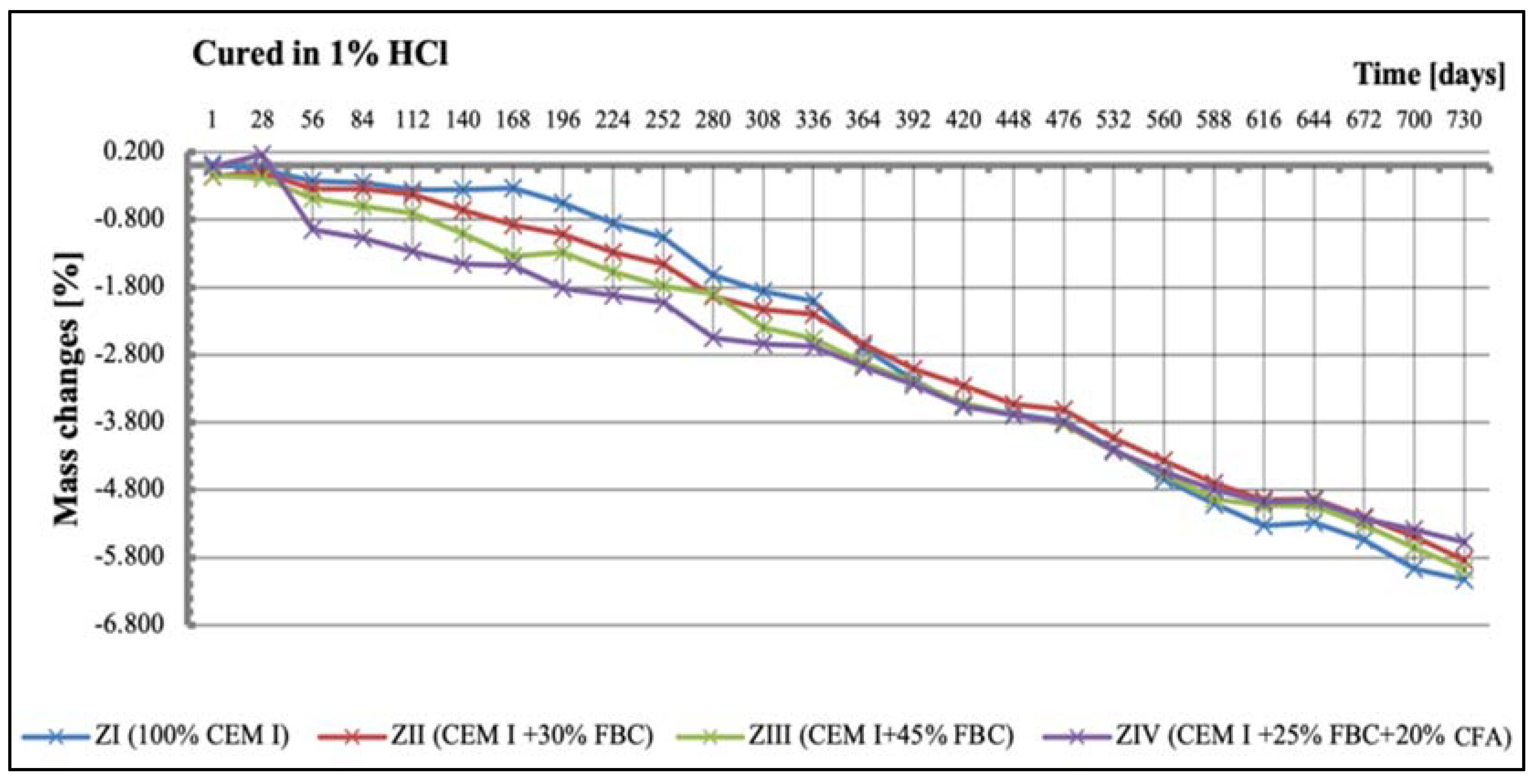

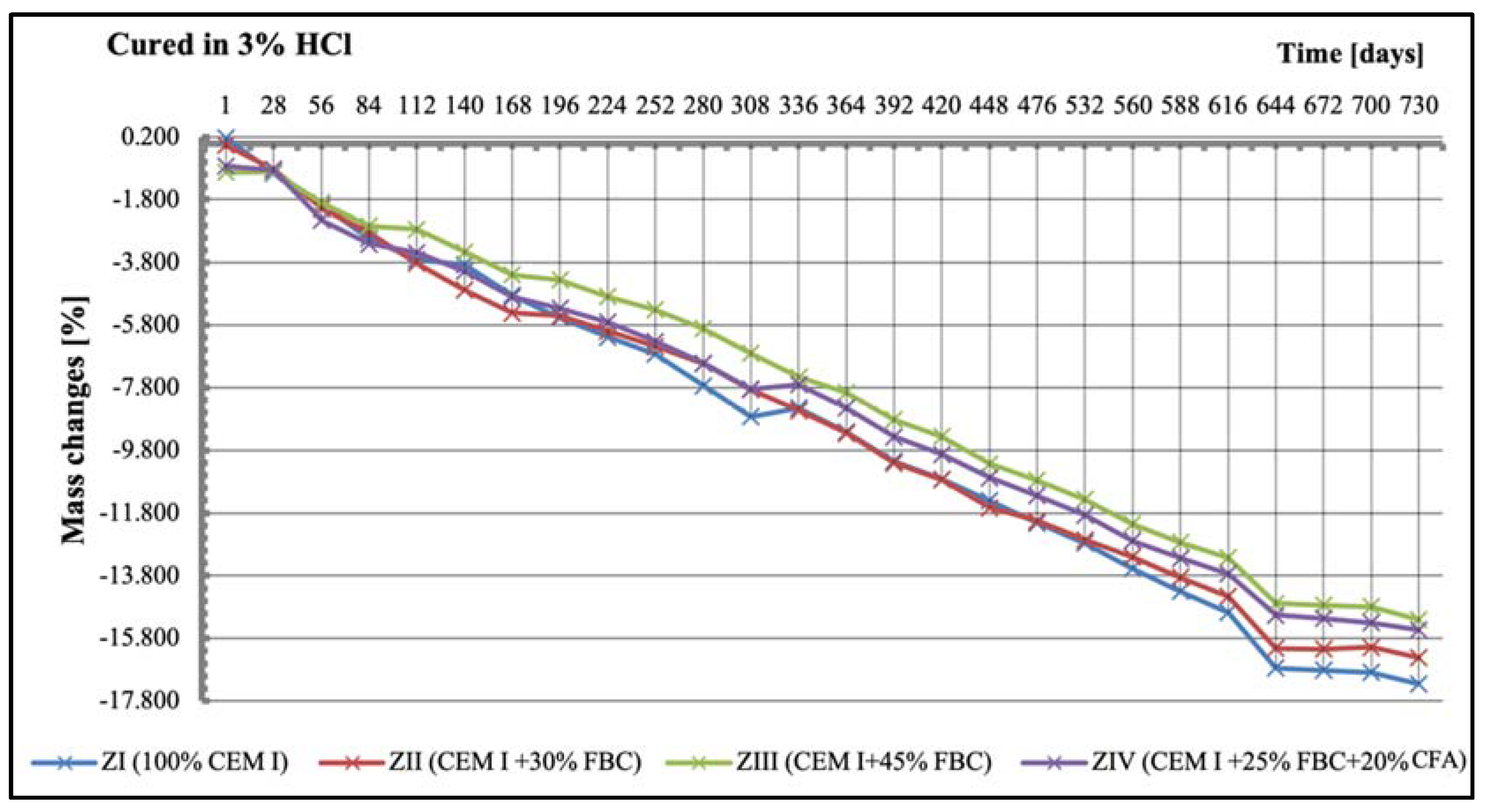

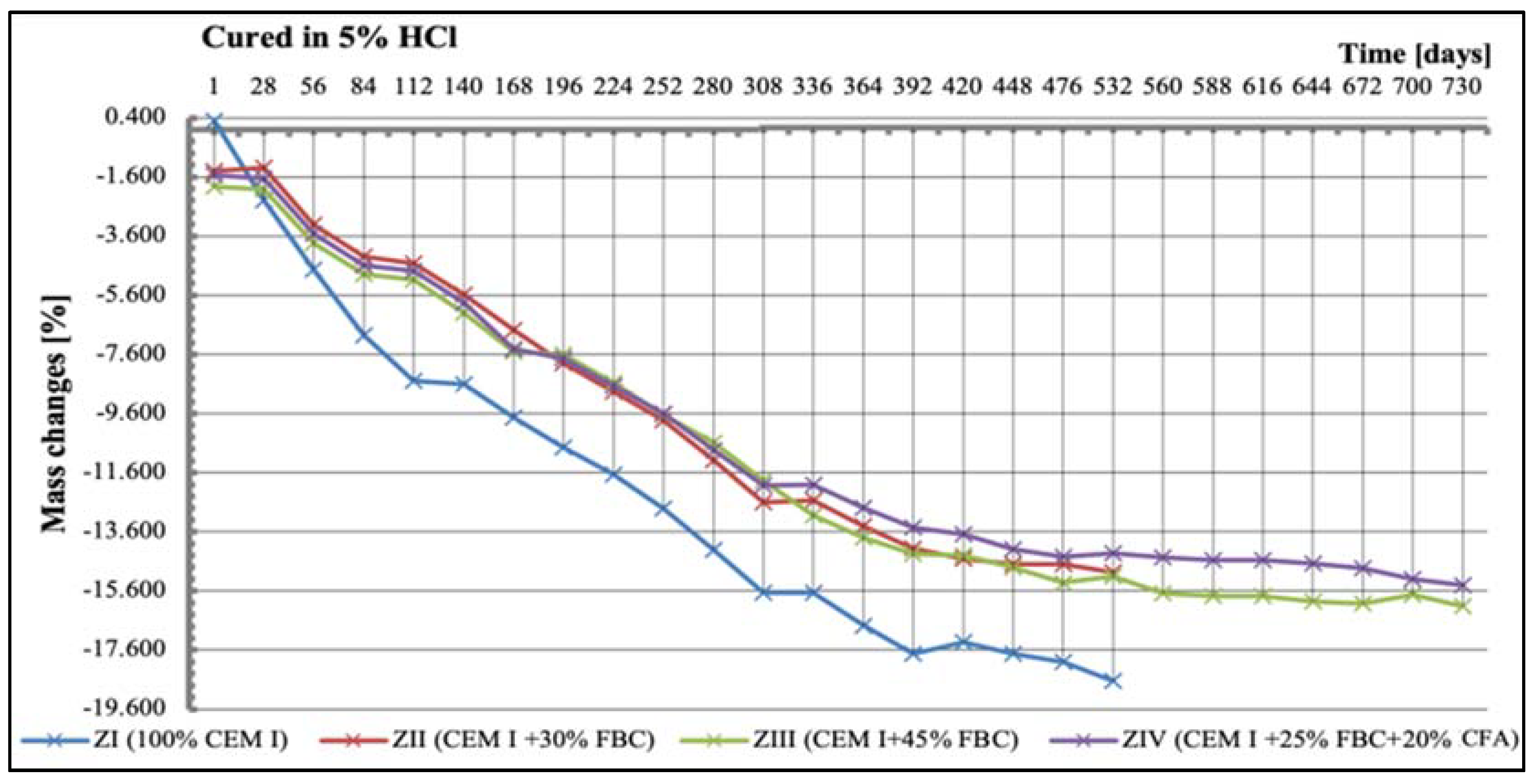

5.4. Test Results of Mortars’ Mass Changes

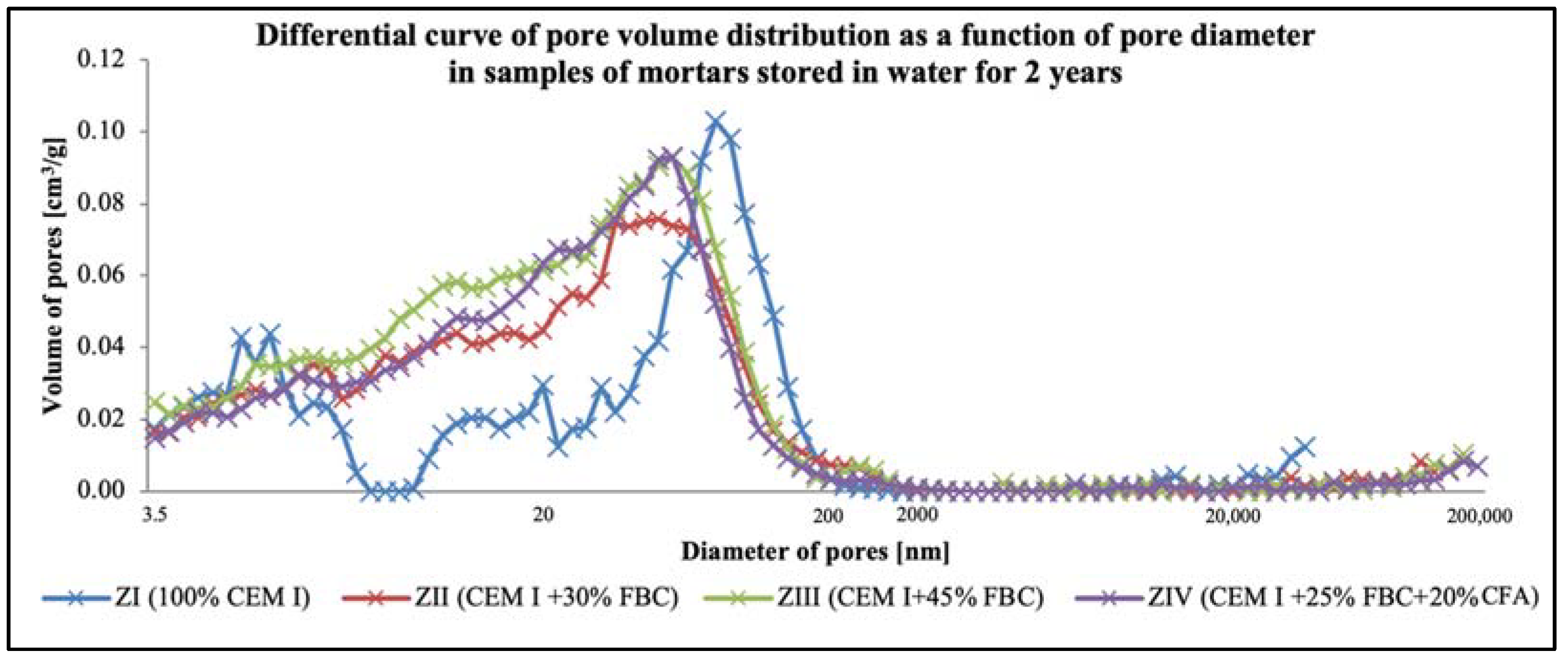

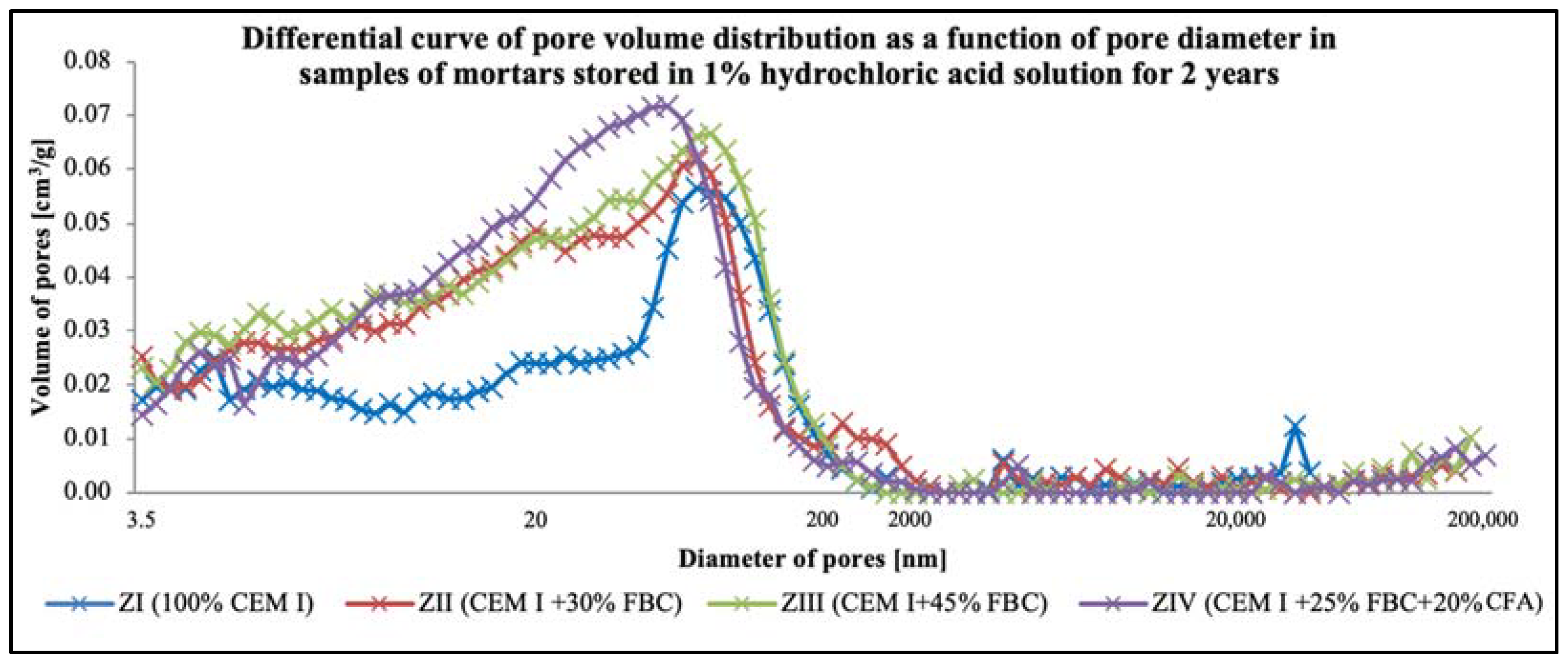

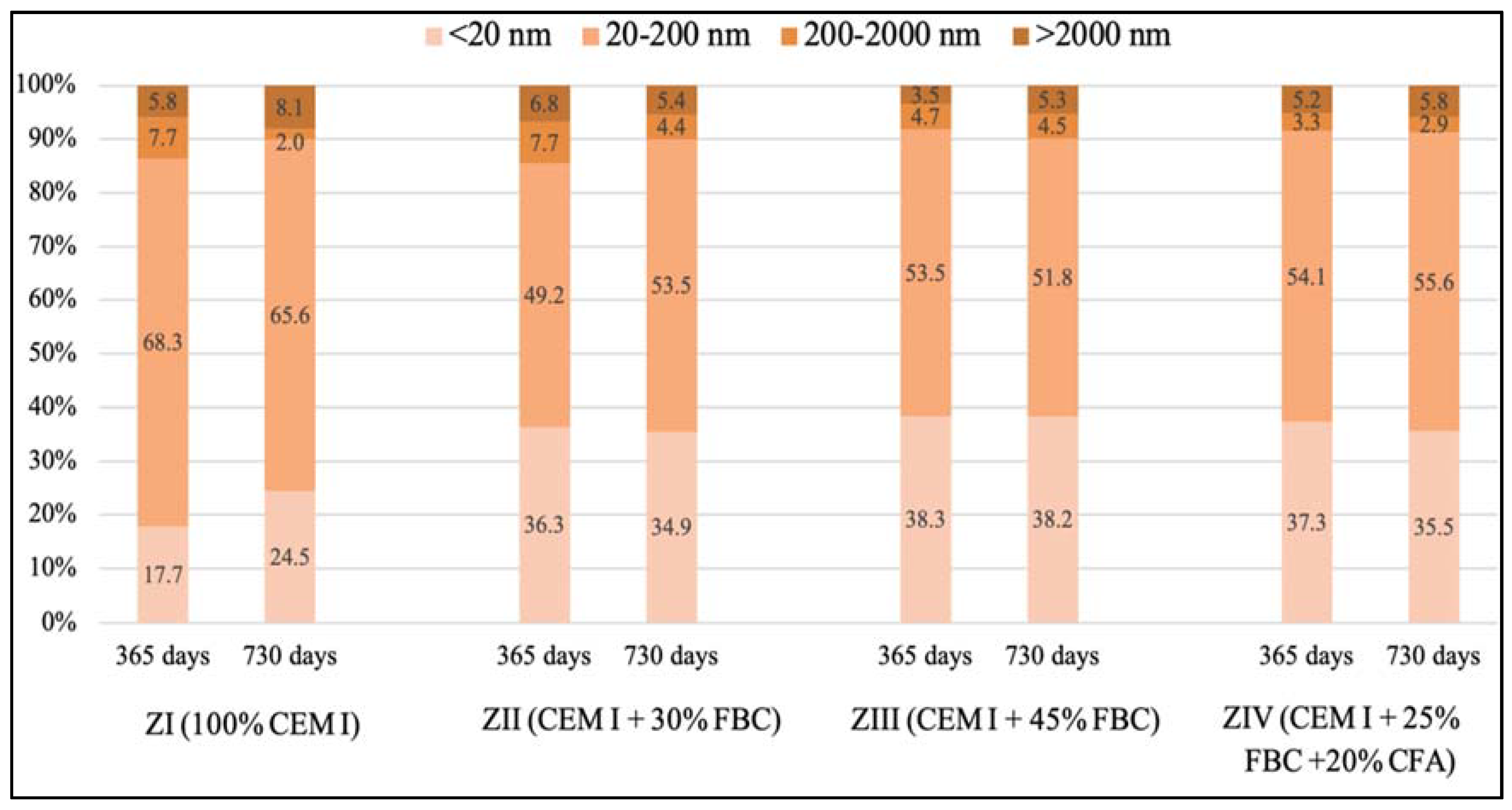

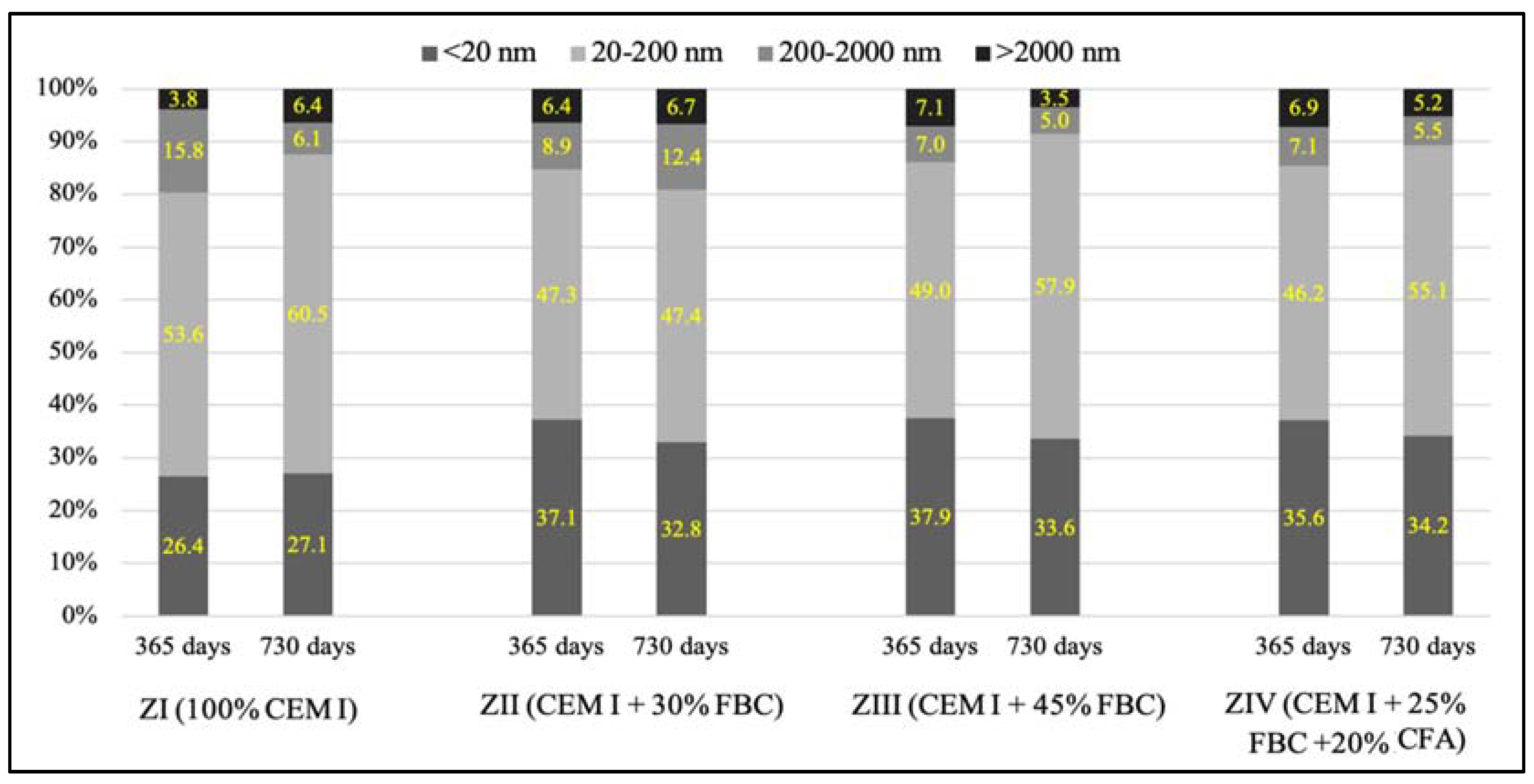

5.5. Results of Mortars’ Porosity Testing

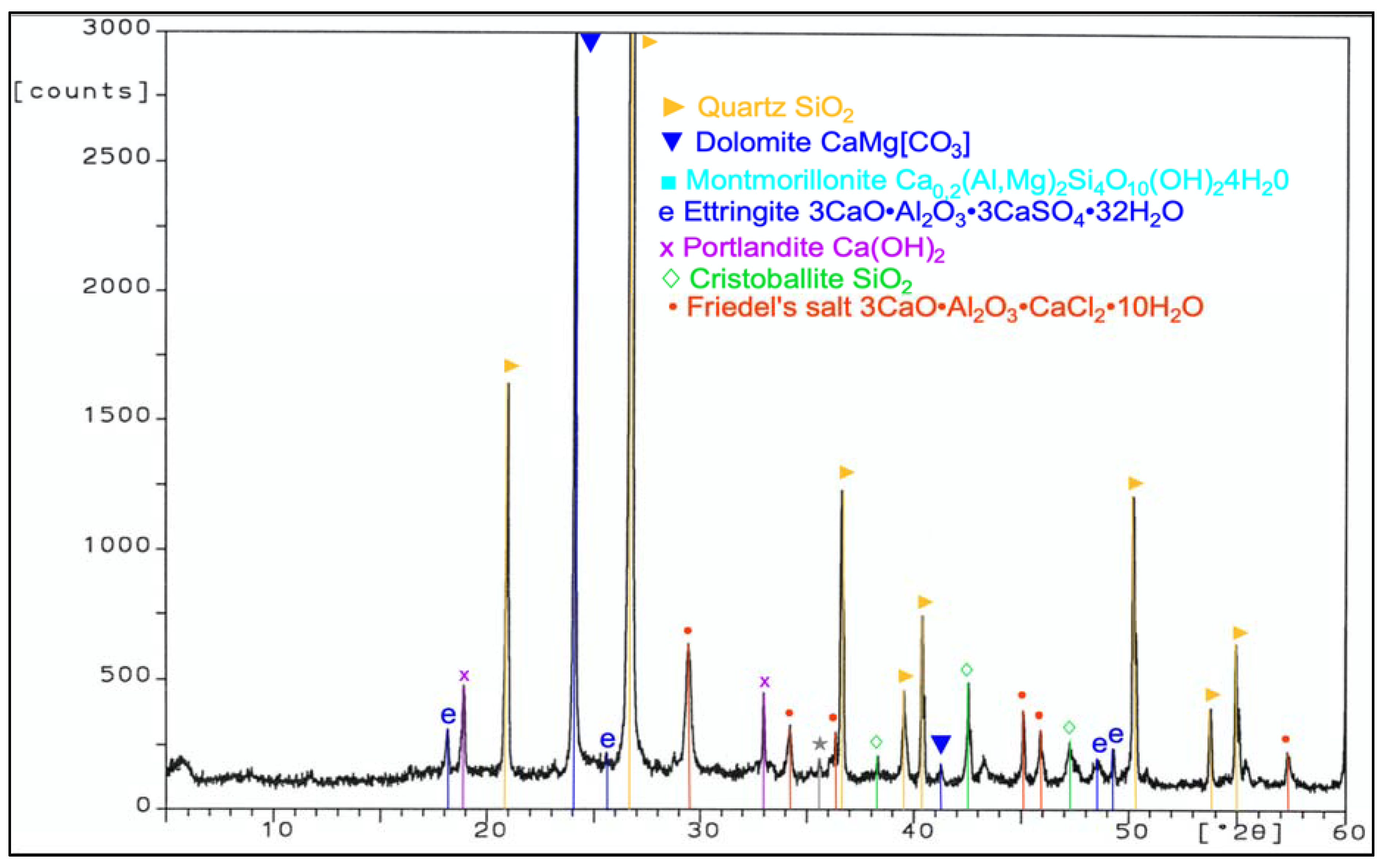

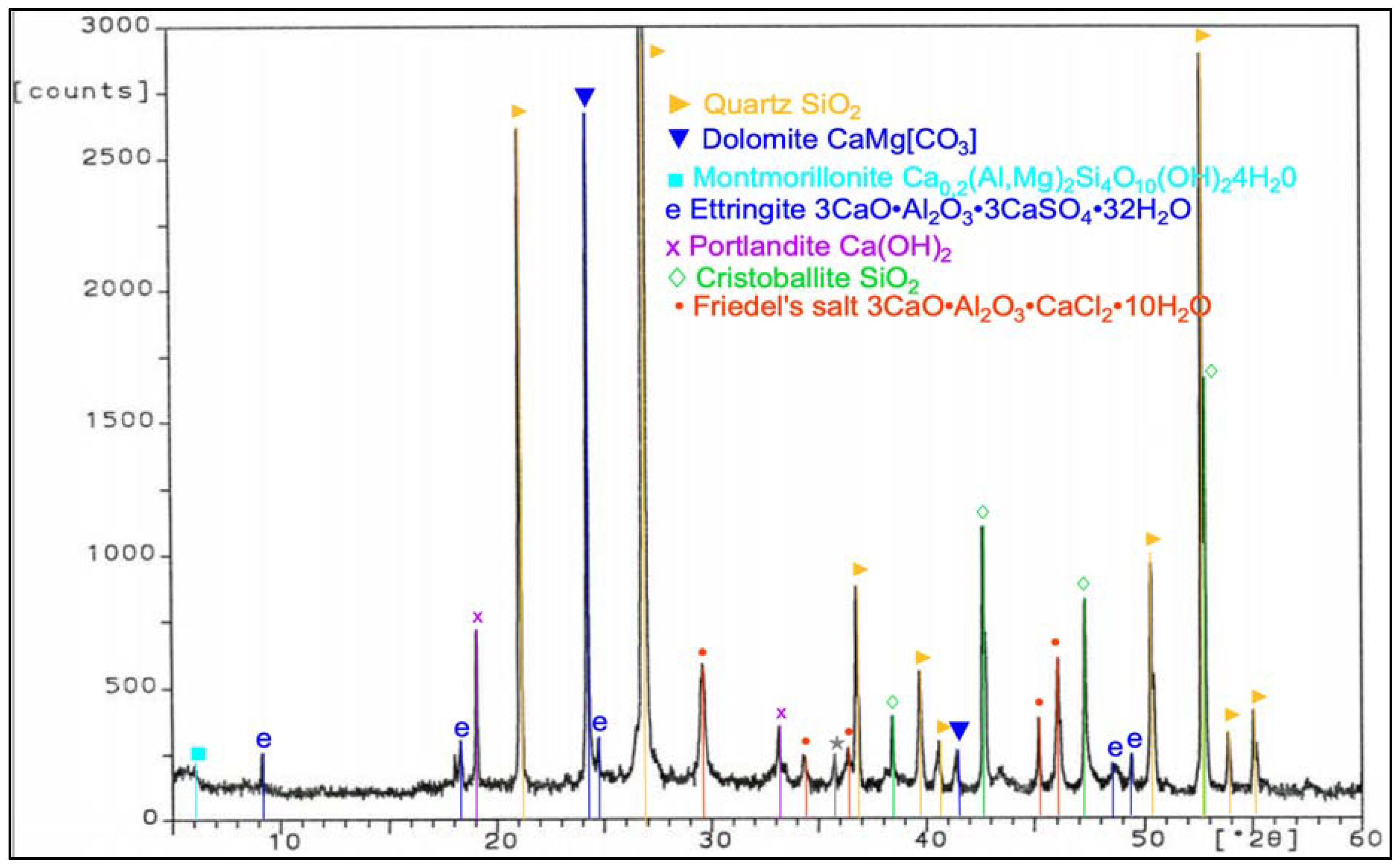

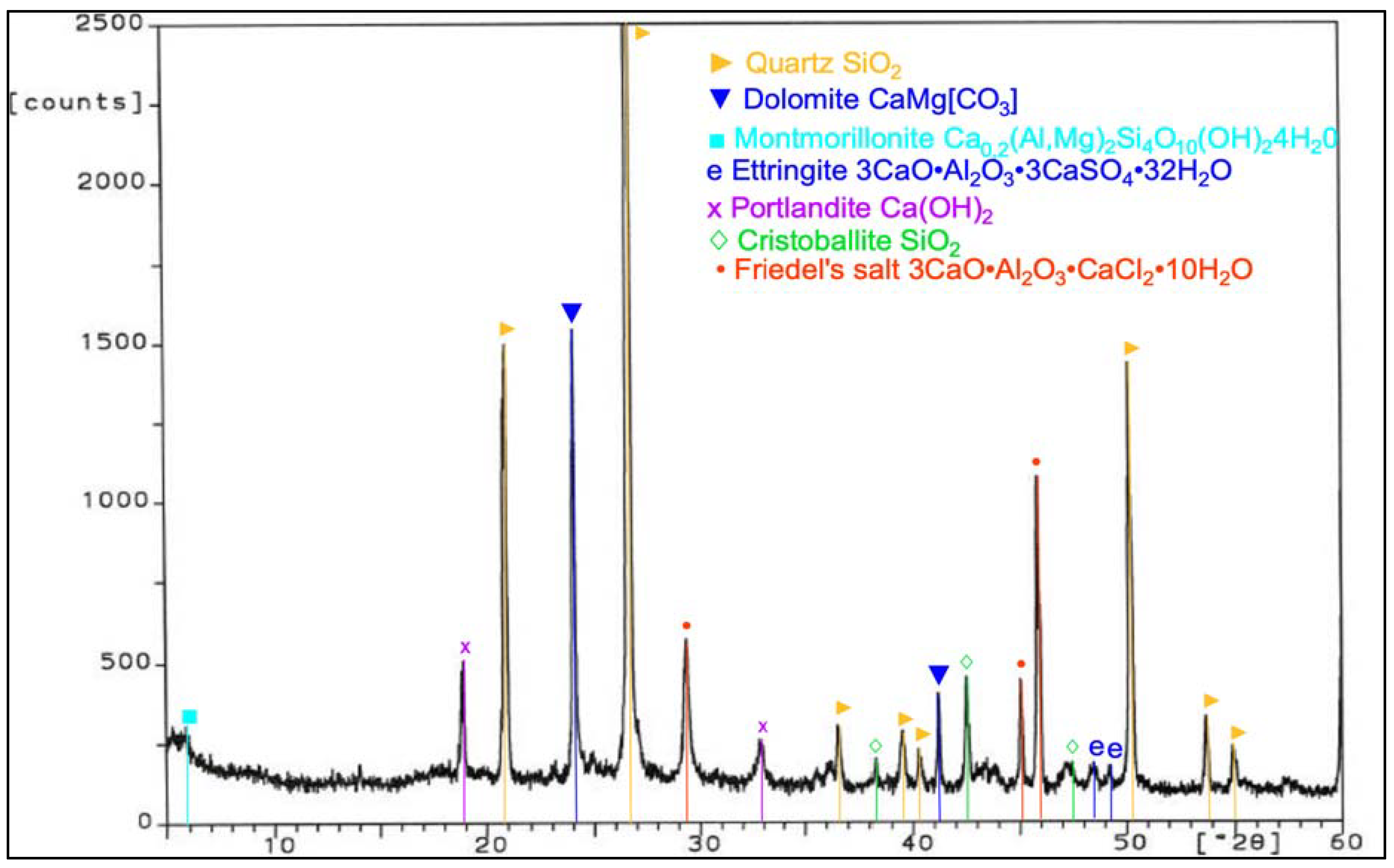

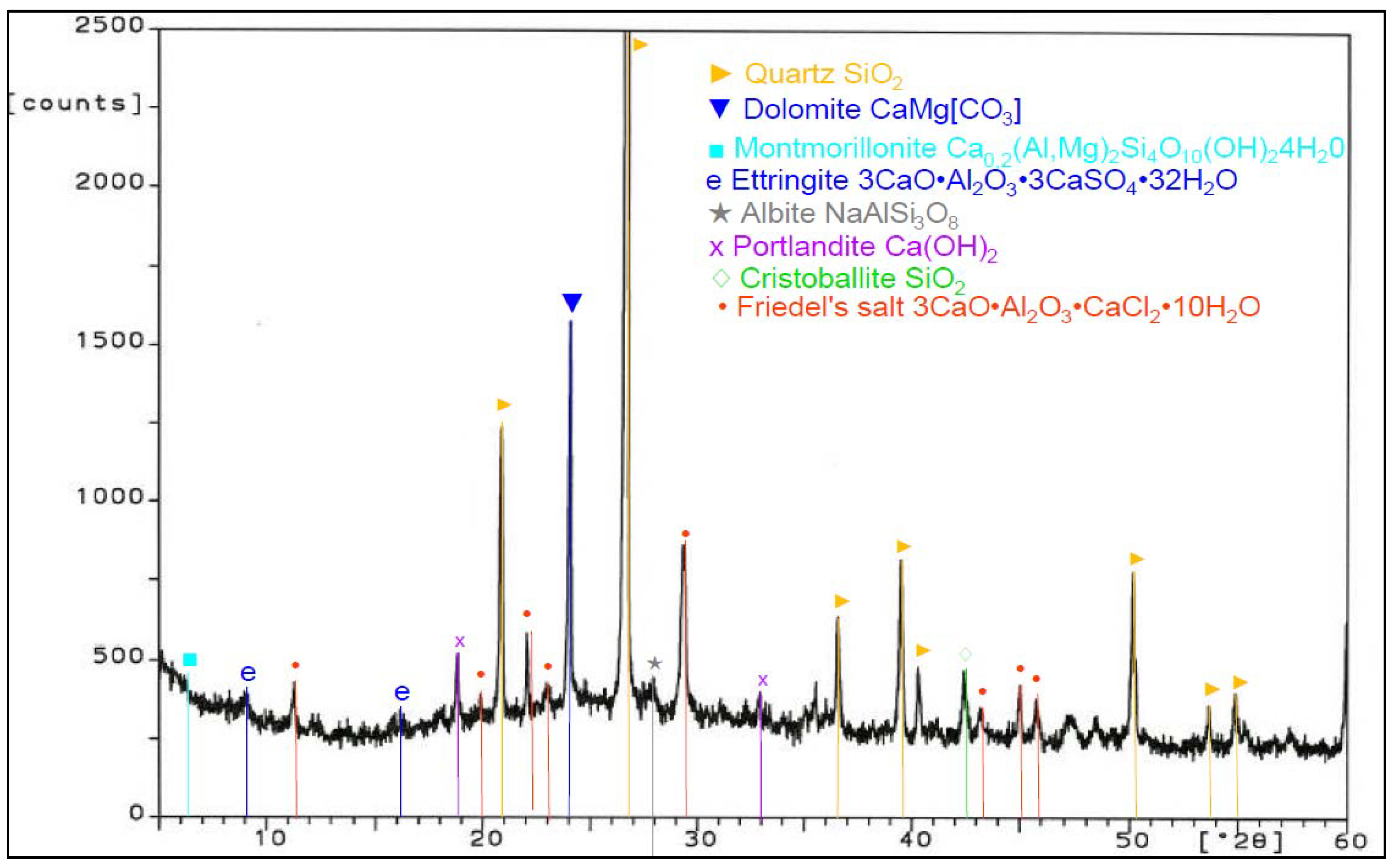

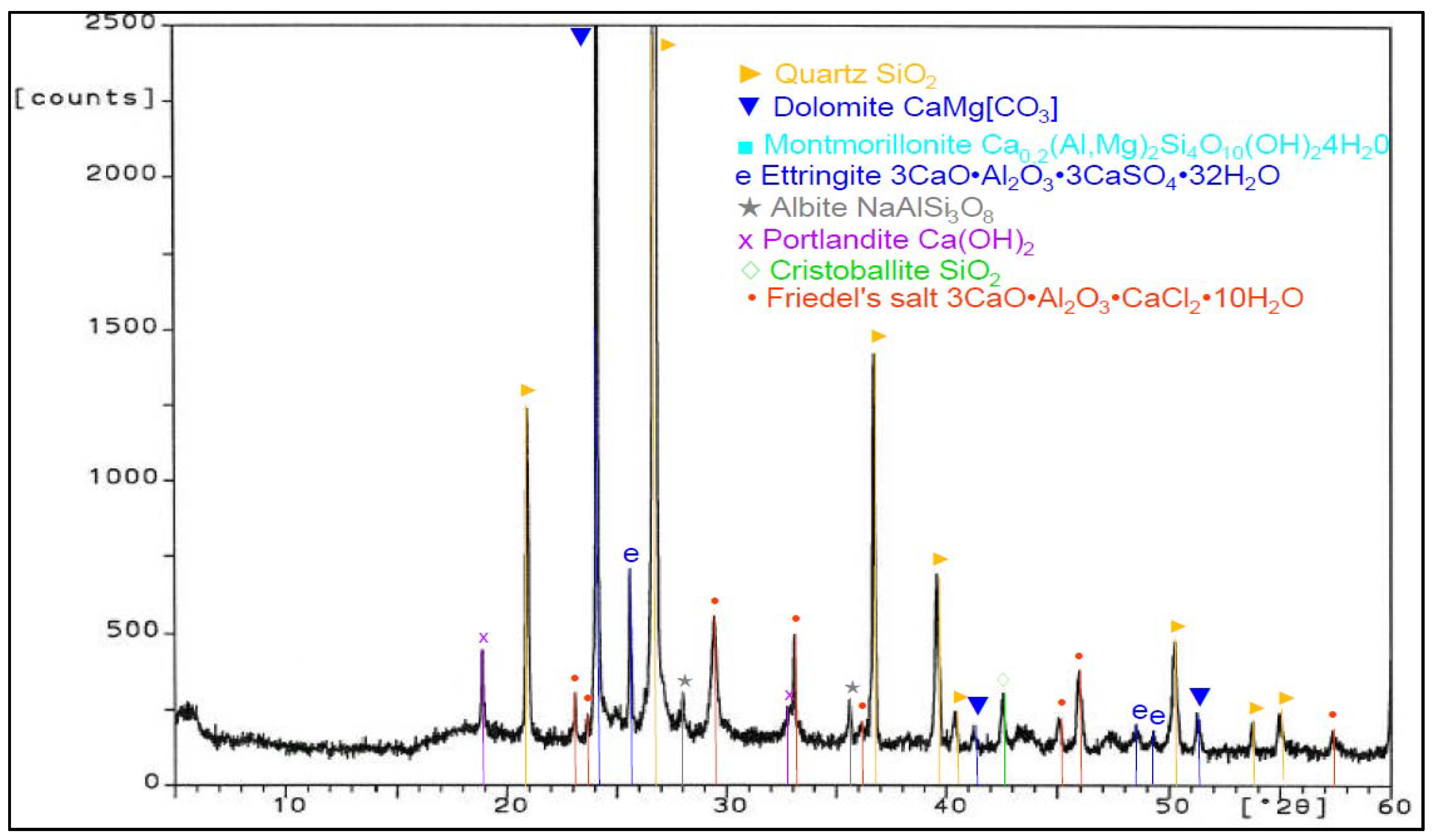

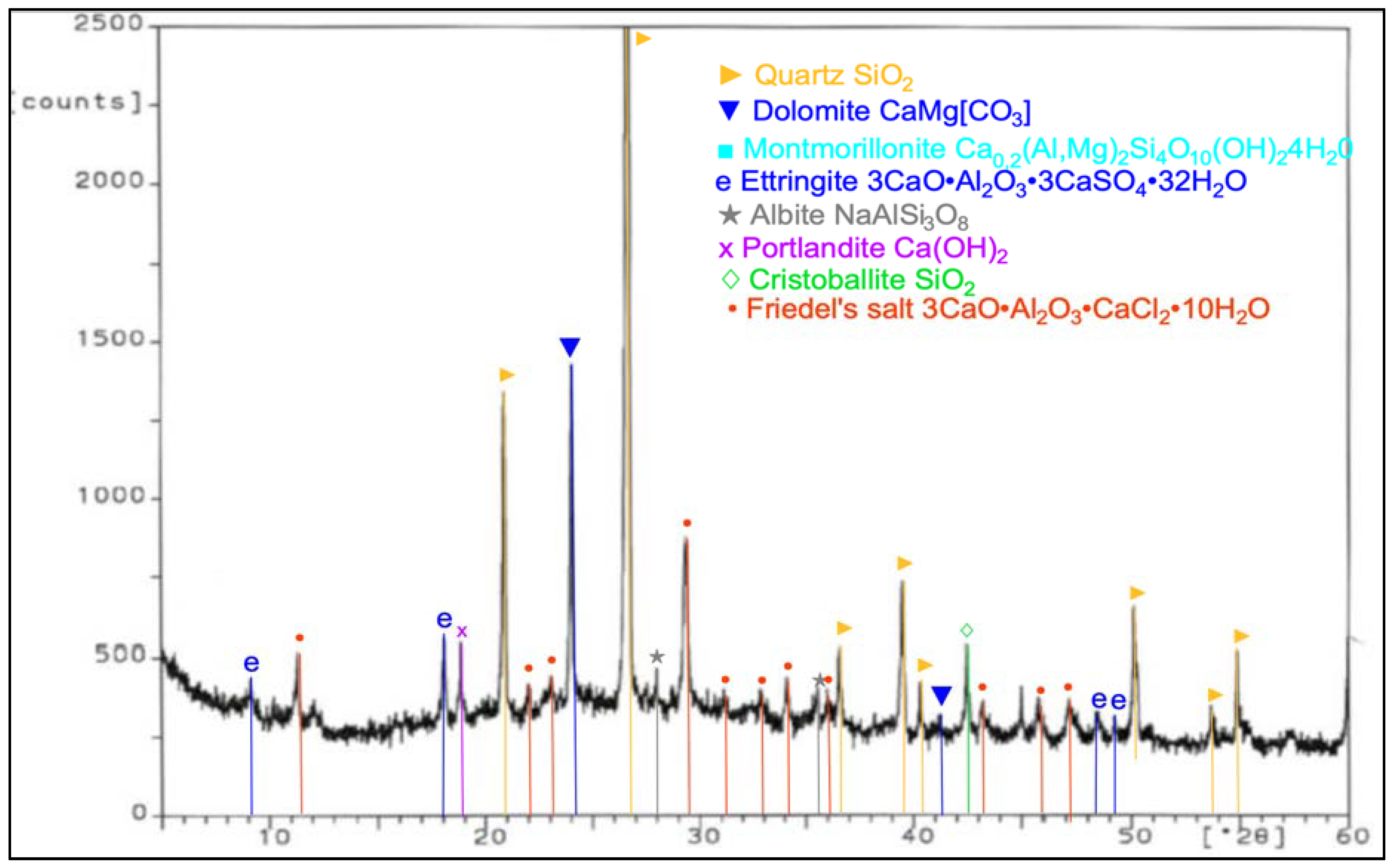

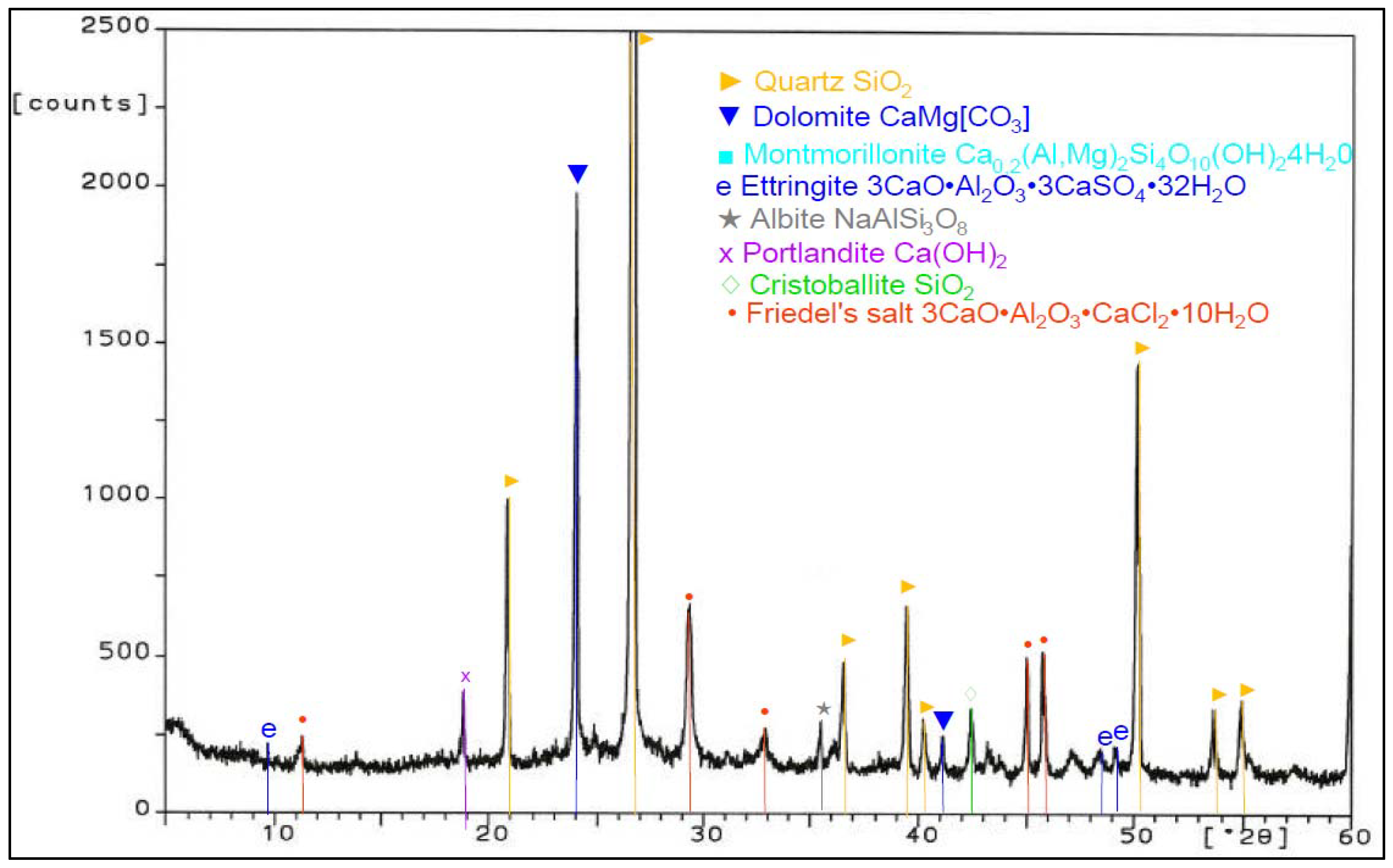

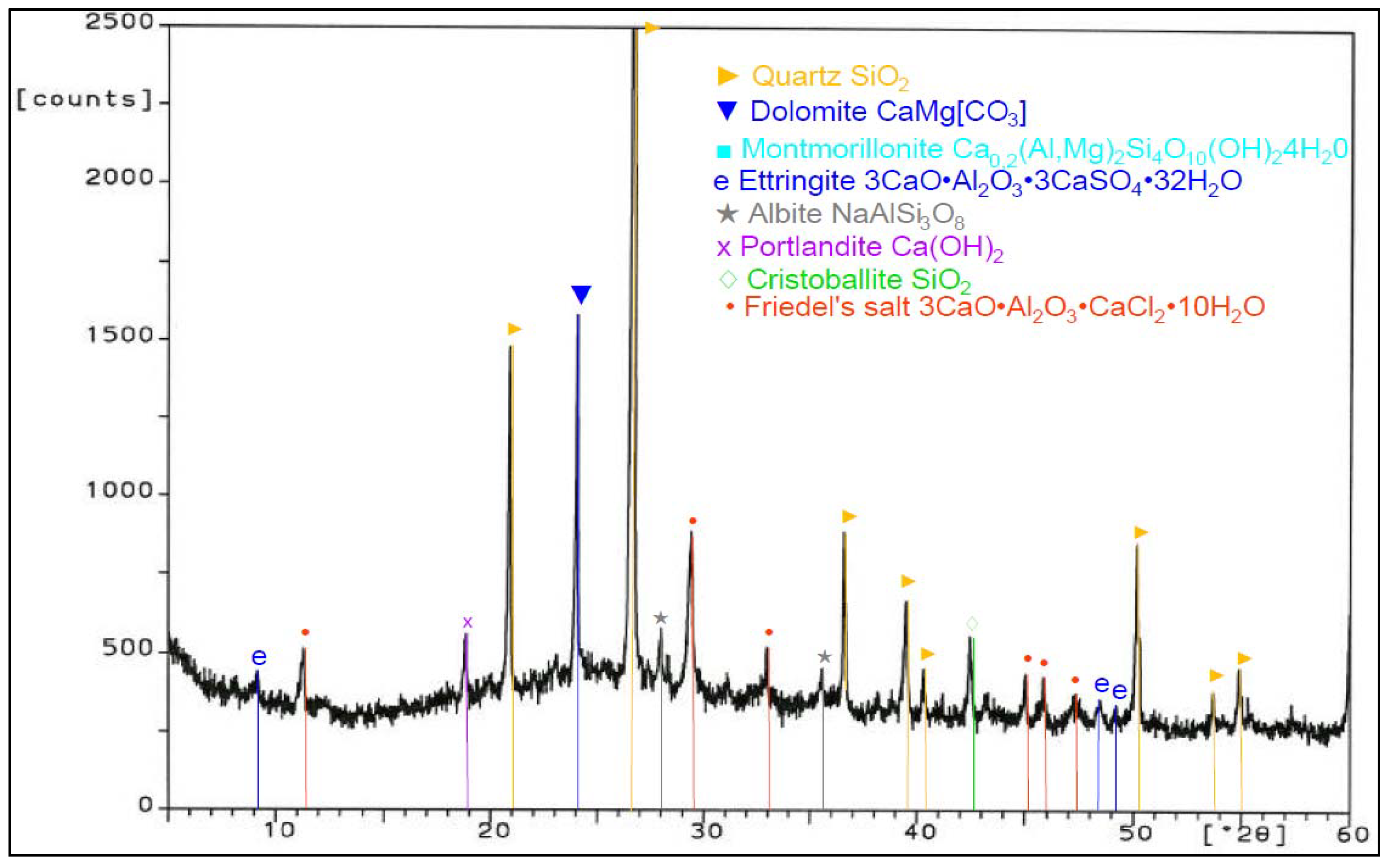

5.6. Results of Phase-Composition Tests of Mortars Determined after 365 and 730 Days of Curing in the 1% HCl Solution

6. Discussion of Test Results

7. Conclusions

- The increase of the mortars’ curing temperature from 20 to 50 °C affected the increased strength of mortars, which directly resulted from the higher pozzolanic activity of ashes at the elevated temperature;

- Along with increasing content (from 30 to 45% by mass) of FBC fly ash in the cement, the water demand of the binder increased, while the addition of the mixture to cement that, apart from FBC fly ash (25% by mass), also contained siliceous fly ash (20% by mass), resulted in a reduction of the water demand of the cement–ash binder, and improved the performance parameters of the mortars;

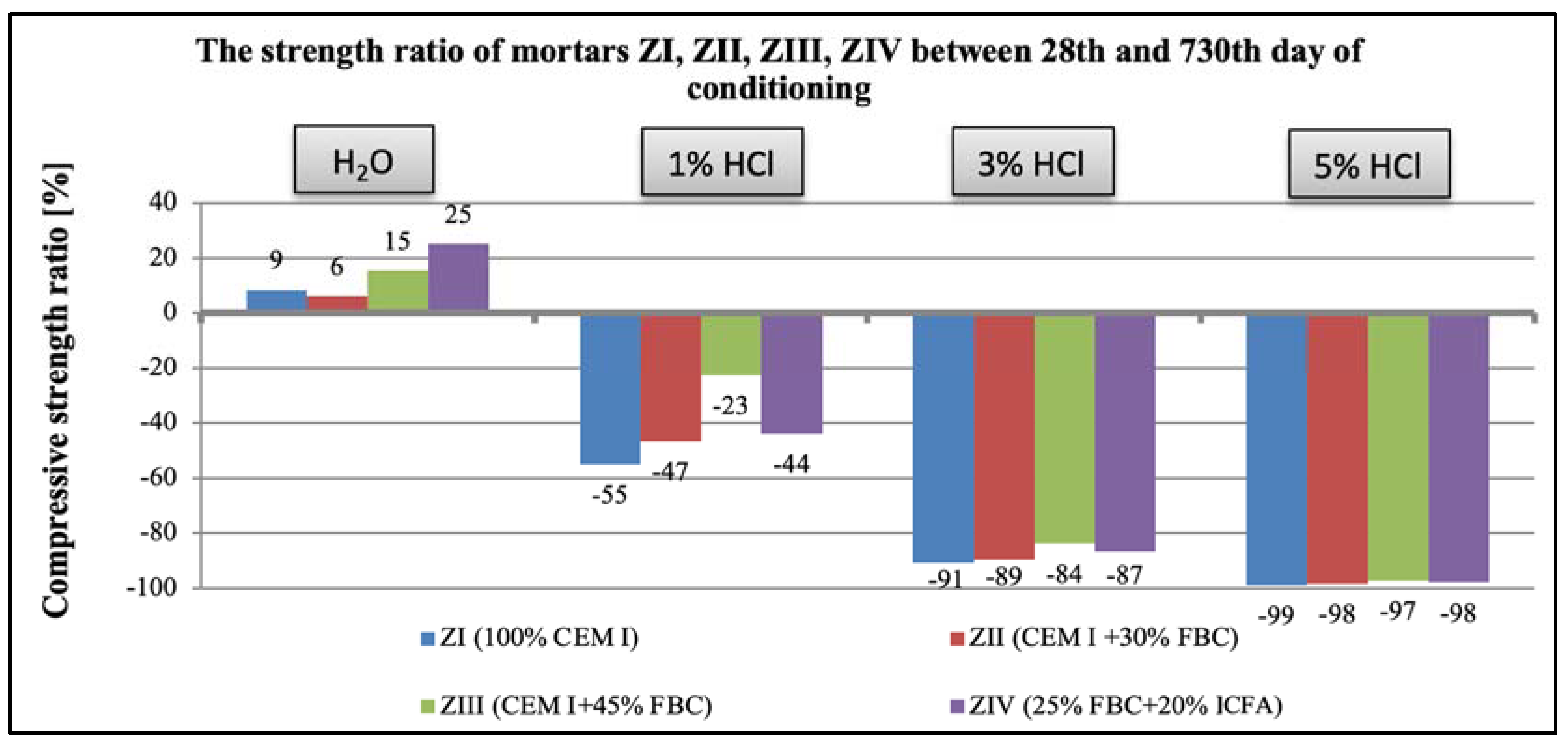

- Application of FBC fly ash and the blend of FBC and siliceous fly ash had a beneficial effect on increasing durability and corrosion resistance of the mortars exposed to HCl solutions (1, 3, and 5%) for a period of 365 days; the above was confirmed by: higher compressive strength, lower linear changes, and reduced mass loss in these mortars compared to the cementitious mortar in the acid-corrosion environment;

- Along with a reduction of total porosity, the compressive strength of mortars tested increased, which was connected with the composition of mortars and the type of pores being formed; the higher the content of FBC fly ash, the higher the content of the mesopores (<50 nm) in the binder was, while the content of pores <200 nm was lower for mortars containing FBC fly ash and the blend of ashes, regardless of the environment in which the mortar was stored;

- The obtained test results confirmed the possibility of FBC fly-ash utilization by using it in cement–ash binders and in mixtures with other ash up to 45% by mass; production of cement–ash binders was possible in the strength classes of 32.5 or 42.5 (ZIII and ZIV);

- For mortars with FBC fly ash (ZII and ZIII) cured in water, linear changes and a decrease in strength were observed after both 28 and 365 days of testing, which proved the need to monitor the properties of cement–ash materials over a longer period of time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rovnanikova, P.; Grzeszczyk, S. Resistance of self-compacting concretes on the basis of slag cement (CEM III) to environments containing chlorine ions. Annu. Civ. Eng. 2007, 7, 99–104. [Google Scholar]

- Zivica, V.; Bajza, A. Acidic attack of cement based materials—A review. Part 1. Principle of acidic attack. Constr. Build. Mater. 2001, 15, 331–340. [Google Scholar] [CrossRef]

- Biondini, F.; Vergani, M. Deteriorating beam finite element for nonlinear analysis of concrete structures under corrosion. Struct. Infrastruct. Eng. 2015, 4. [Google Scholar] [CrossRef]

- Blunt, J.; Jen, G.; Ostertag, P. Enhancing corrosion resistance of reinforced concrete structures with hybrid fiber reinforced concrete. Corros. Sci. 2015, 92, 182–191. [Google Scholar] [CrossRef]

- Castaldo, P.; Palazzo, B.; Mariniello, A. Effects of the axial force eccentricity on the time-variant structural reliability of aging r.c. cross-sections subjected to chloride-induced corrosion. Eng. Struct. 2017, 130, 261–274. [Google Scholar] [CrossRef]

- Michel, A.; Solgaard, A.O.S.; Pease, B.J.; Geiker, M.R.; Stang, H.; Olesen, J.F. Experimental investigation of the relation between damage at the concrete–steel interface and initiation of reinforcement corrosion in plain and fibre reinforced concrete. Corros. Sci. 2013, 77, 308–321. [Google Scholar] [CrossRef]

- Bertolini, L.; Gastaldi, M.; Pedeferri, M.P.; Redaelli, E. Prevention of steel corrosion in concrete exposed to seawater with submerged sacrificial anodes. Corros. Sci. 2002, 44, 1497–1513. [Google Scholar] [CrossRef]

- Maryoto, A. Resistance of concrete with calcium stearate due to chloride attack tested by accelerated corrosion. Procedia Eng. 2017, 171, 511–516. [Google Scholar] [CrossRef]

- Neville, A. Chloride attack of reinforced concrete: An overview. Mater. Struct. 1995, 28. [Google Scholar] [CrossRef]

- Brandt, A.M.; Jóźwiak-Niedźwiedzka, D.; Małolepszy, J.; Marks, M.; Śliwiński, J.; Kasperkiewicz, J. Zastosowanie popiołów lotnych z kotłów fluidalnych w betonach konstrukcyjnych. Kom. Inżynierii Lądowej I Wodnej Pan 2010, 72, 339–351. (In Polish) [Google Scholar]

- Chindaprasirt, P.; Chotithanorm, C.; Cao, H.T.; Sirivivatnanon, V. Influence of fly ash fineness on the chloride penetration of concrete. Constr. Build. Mater. 2007, 21, 356–361. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D. Estimation of chloride migration coefficient in air-entrained concretes containing fluidized bed combustion fly ash. Arch. Civ. Eng. 2012, 58, 25–38. [Google Scholar] [CrossRef]

- Rajczyk, K. Popioły Lotne z Kotłów Fluidalnych i Możliwości ich Uszlachetniania; WYDIS: Opole, Poland, 2012. [Google Scholar]

- Słomka-Słupik, B.; Zybura, A. Doświadczalne badania dekalcyfikacji zaczynu cementowego. In Proceedings of the Dni Betonu Conference, Wisła, Poland, 11–13 October 2010; pp. 787–796. (In Polish). [Google Scholar]

- Haung, P.; Bao, Y.; Yao, Y. Influence of HCl corrosion on the mechanical properties of concrete. Cem. Concr. Res. 2005, 35, 584–589. [Google Scholar] [CrossRef]

- Chandra, S. Hydrochloric acid attack on cement mortar- An analytical study. Cem. Concr. Res. 1988, 18, 193–203. [Google Scholar] [CrossRef]

- Roy, D.M.; Arjunan, P.; Silsbee, M.R. Effect of silica fume, metakaolin, and low-calcium fly ash on chemical resistance of concrete. Cem. Concr. Res. 2001, 31, 1809–1813. [Google Scholar] [CrossRef]

- Kurdowski, W. Cement and Concrete Chemistry; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Sinsiri, T.; Chindaprasirt, P.; Jaturapitakkul, C. Influence of fly ash fineness and shape on the porosity and permeability of blended cement pastes. Int. J. Miner. Metal. Mater. 2010, 17, 683–691. [Google Scholar] [CrossRef]

- Lea, F.M. The Chemistry of Cement and Concrete, 4th ed.; Edward Arnold Ltd.: London, UK, 1970. [Google Scholar]

- Šebestová, P.; Ćerny, V.; Drochytka, R. Experimental study of autoclaved aerated concrete using circulating fluidized-bed combustion fly ash. Mater. Technol. 2020, 54, 157–161. [Google Scholar] [CrossRef]

- Kurdowski, W. Korozja chlorkowa betonu. Cem. Wapno Beton 2002, 2, 56–60. (In Polish) [Google Scholar]

- Bernardo, G.; Telesca, A.; Valenti, G.L.; Montagnaro, F. Role of ettringite in the reuse of hydrated fly ash from fluidized bed combustion as a sulfur sorbent: A hydration study. Ind. Eng. Chem. Res. 2004, 43, 4054–4059. [Google Scholar] [CrossRef]

- Pacewska, B.; Blonkowski, G.; Wilińska, I. Studies on the pozzolanic and hydraulic properties of fly ashes in model systems. J. Therm. Anal. Calorim. 2008, 94, 469–476. [Google Scholar] [CrossRef]

- Seignol, J.F.; Baghdadi, N.; Toutlemonde, F. A Macroscopic Chemo-Mechanical Model Aimed at Re-Assessment of Delayed Ettringite-Formation Affected Concrete Structures; CTCS’09, Chemo-Mechanical Interaction in Concrete Session; Version 2–10 April 2009. Available online: https://www.researchgate.net/profile/Francois-Toutlemonde/publication/282191780_A_macroscopic_chemo-mechanical_model_aimed_at_re-assessment_of_delayed-ettringite-formation_affected_concrete_structures/links/56938b5608ae0f920dce8a1e/A-macroscopic-chemo-mechanical-model-aimed-at-re-assessment-of-delayed-ettringite-formation-affected-concrete-structures.pdf (accessed on 15 April 2021).

- Bland, A.E.; Jones, C.E.; Rose, J.G.; Jarrett, M.N. Production of No-Cement Concretes Utilizing Fluid Bed Combustion Waste and Power Plant Fly Ash. In Proceedings of the Ninth International Conference on FBC, Boston, MA, USA, 3–7 May 1987; Mustonen, J.R., Ed.; ASME: New York, NY, USA, 1987; pp. 947–953. [Google Scholar]

- Rajczyk, K.; Giergiczny, E.; Glinicki, M.A. Use of DTA in the investigations of fly ashes from fluidized bed boilers. J. Therm. Anal. Calorim. 2004, 77, 165–170. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Thaiwitchareon, S.; Kaewpirom, S.; Rattanasak, U. Controlling ettringite formation in FBC fly ash geopolymer concrete. Cem. Concr. Compos. 2013, 31, 24–28. [Google Scholar] [CrossRef]

- Janowska-Renkas, E.; Kowalska, J.; Kaliciak, A.; Janus, G. The resistance of mortars with fluidized beds boiler fly ashes and conventional fly ashes to acid corrosion. Annu. Civ. Eng. 2016, 16, 101–109. [Google Scholar]

- Shen, Y.; Qian, J.; Zhang, Z. Investigations of anhydrite in CFBC fly ash as cement retarders. Constr. Build. Mater. 2013, 40, 672–678. [Google Scholar] [CrossRef]

- Gazdiča, D.; Fridrichováa, M.; Kulíseka, K.; Vehovská, L. The potential use of the FBC ash for the preparation of blended cements. Procedia Eng. 2017, 180, 1298–1305. [Google Scholar] [CrossRef]

- Conn, R.E.; Sellakumar, K.; Bland, A.E. Utilization of CFB fly ash for construction applications. In Proceedings of the 15th International Conference on Fluidized Bed Combustion, Savannah, GA, USA, 16–19 May 1999. [Google Scholar]

- Chugh, Y.P.; Patwardhan, A.; Kumar, S. Demonstration of CFB ash as a cement substitute in concrete pier foundations for photo-voltaic power system at SIUC. In Proceedings of the World of Coal Ash Conference (WOCA), Covington, KY, USA, 7–10 May 2007. [Google Scholar]

- Glinicki, M.A.; Zieliński, M. Air void system in concrete containing circulating fluidized bed combustion fly ash. Mater. Struct. 2008, 41, 681–687. [Google Scholar] [CrossRef]

- Zieliński, M. Effects of FBC fly ash on mechanical properties and durability of concrete. In Proceedings of the US-Poland Workshop on Diagnostics of Concrete Materials and Structures for Infrastructure Facilities, Warsaw, Poland, 17–18 May 2004; pp. 159–165. [Google Scholar]

- Stevens, W.; Robl, T.; Mahboub, K. The cementitious and pozzolanic properties of fluidized bed combustion fly ash. In Proceedings of the World of Coal Ash Conference (WOCA), Lexington, KY, USA, 4–7 May 2009. [Google Scholar]

- Feldman, R.F.; Carette, G.G.; Malhotra, V.M. Studies on mechanics of development of physical and mechanical properties of high-volume fly ash-cement pastes. Cem. Concr. Compos. 1990, 12, 245–251. [Google Scholar] [CrossRef]

- Zeng, Q.; Li, K.; Fen-Chong, T.; Dangla, P. Pore structure characterization of cement pastes blended with high-volume fly-ash. Cem. Concr. Res. 2012, 42, 194–204. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, C.; Sun, W. Fly ash effects: II. The active effect of fly ash. Cem. Concr. Res. 2004, 34, 2057–2060. [Google Scholar] [CrossRef]

- Singh, P.; Shah, N.D.; Majumdar, P.K. Influence of flyash on fineness, porosity and permeability of flyash blended cement paste. Int. Res. J. Eng. Technol. 2018, 5, 1056–1058. [Google Scholar]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on microstructure of blended cement paste. Constr. Build. Mater. 2017, 21, 1534–1541. [Google Scholar] [CrossRef]

- Roszczynialski, W., Jr.; Stępień, P.; Tkaczewska, E.; Roszczynialski, W. The reliability of pozzolanic activity assessment methods in testing different fly ashes. Cem. Wapno Beton 2014, 5, 323–333. [Google Scholar]

- Murugan, M.; En-Hua, Y.; Cise, U. Resistance of graphene oxide-modified cement pastes to hydrochloric acid attack. Constr. Build. Mater. 2021, 273, 1534–1541. [Google Scholar] [CrossRef]

- Pavlik, V. Corrosion of hardened cement paste by acetic and nitric acids part I: Calculation of corrosion depth. Cem. Concr. Res. 1994, 24, 551–562. [Google Scholar] [CrossRef]

- Grzeszczyk, S.; Janowska-Renkas, E.; Kowalska, J. Rheological properties of fluidized bed boilers fly ash. Annu. Civ. Eng. 2013, 13, 63–66. [Google Scholar]

- Dąbrowska, M.; Giergiczny, Z. Chemical resistance of mortars made of cement with calcareous fly ash. Roads Bridges 2014, 12. [Google Scholar] [CrossRef]

- Janowska-Renkas, E.; Kowalska, J.; Kaliciak, A.; Janus, G. Cement-fly ash mortars durability, with fly ash from fluidized bed boilers and conventional combustion, exposed to aggressive environment influence. MATEC Web Conf. 2018, 174. [Google Scholar] [CrossRef][Green Version]

- Pytel, Z. Properties of cements containing ashes from fluidised bed combustion installations. In Proceedings of the Dni Betonu Conference, Szczyrk, Poland, 8–10 October 2002; pp. 476–477. [Google Scholar]

- Janowska-Renkas, E.; Kaliciak, A. Impact of Fly Ashes from Combustion in Fluidized Bed Boilers and Siliceous Fly Ashes on Durability of Mortars Exposed to Seawater and Carbonation Process. Materials 2021, 14, 2345. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S.; Zhou, J. Experimental study and analytical model for pore structure of hydrated cement paste. Appl. Clay Sci. 2014, 101, 159–167. [Google Scholar] [CrossRef]

- Lin, K.-L.; Cheng, T.-W.; Ho, C.-H.; Chang, Y.-M.; Lo, K.-W. Utilization of Circulating Fluidized Bed Fly Ash as Pozzolanic Material. Open Civ. Eng. J. 2017, 11, 176–186. [Google Scholar] [CrossRef][Green Version]

- Zhao, J.; Li, D.; Liao, S.; Wang, D.; Wang, H.; Yan, P. Influence of mechanical grinding on pozzolanic characteristics of circulating fluidized bed fly ash (CFA) and resulting consequences on hydration and hardening properties of blended cement. J. Therm. Anal. Calorim. 2018, 132, 1459–1470. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, G.; Wang, D.; Liao, S.; Zhai, M. The hydration properties of blended cement containing ultrafine fly ash with particle size less than 17 μm from the circulating fluidized bed combustion of coal gangue. J. Therm. Anal. Calorim. 2020, 139, 2971–2984. [Google Scholar] [CrossRef]

- Kurdowski, W. Podstawy Chemiczne Mineralnych Materiałów Budowlanych i ich Właściwości; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2018. [Google Scholar]

- Tracz, T.; Zdeb, T. Effect of hydration and carbonation progress on the porosity and permeability of cement pastes. Materials 2019, 12, 192. [Google Scholar] [CrossRef]

- Allahverdi, A.; Škvára, F. Acidic corrosion oh hydrated cement based materials. Part 1—Mechanism of the phenomenon. Ceramics 2000, 44, 114–120. [Google Scholar] [CrossRef]

- Schwotzer, M.; Scherer, T.; Gerdes, A. Immediate impact on the rim zone of cement based materials due to chemical attack: A focused ion beam study. Mat. Char. 2015, 99, 77–83. [Google Scholar] [CrossRef]

- Mona, Z.; Khashaya, J.; Farshad, R. Properties and durability of concrete containing fluidized bed combustion (FBC) fly ash. Constr. Build. Mater. 2020, 258. [Google Scholar] [CrossRef]

| Constituent [%] | Cement CEM I 42.5 R | Fly Ash from Fluidized Bed Combustion (FBC) | Siliceous Fly Ash (CFA) |

|---|---|---|---|

| Loss on ignition | 2.57 | 4.30 | 1.81 |

| Insoluble matter | 0.46 | - | - |

| SiO2 | 19.79 | 39.26 | 40.20 |

| Fe2O3 | 2.98 | 3.79 | 2.00 |

| Al2O3 | 5.76 | 29.37 | 6.00 |

| CaO | 62.28 | 12.04 | 43.20 |

| MgO | 1.71 | 1.79 | 4.70 |

| SO3 | 2.62 | 3.13 | 0.10 |

| K2O | - | 1.01 | - |

| Na2O | 0.75 | 1.49 | - |

| Specific surface area according to Blaine (cm2/g) | 3570 | 8300 | 3800 |

| Fly Ash from Fluidized Bed Combustion (FBC) | Siliceous Fly Ash (CFA) | Mixture Of Fluidized (FBC) And Siliceous (CFA) Fly Ash | |

|---|---|---|---|

| Pozzolanic activity (%) | 104.2 ± 2.7 | 78.2 ± 3.3 | 89.0 ± 3.5 |

| Name of Sample | CI (100% CEM I) | CII (CEM I + 30% FBC) | CIII (CEM I + 45% FBC) | CIV (CEM I + 25% FBC + 20% CFA) |

|---|---|---|---|---|

| Density (g/cm3) | 3.04 ± 0.08 | 2.94 ± 0.06 | 3.03 ± 0.05 | 2.76 ± 0.07 |

| Specific surface area (cm2/g) | 3570 ± 70 | 3940 ± 90 | 3990 ± 70 | 3920 ± 60 |

| Type of Mortar | CEM I 42.5 R (g) | FBC (g) | CFA (g) | Sand (g) | Water (g) | w/b |

|---|---|---|---|---|---|---|

| ZI (100% CEM I) | 450 | - | - | 216 | 0.48 | |

| ZII (CEM I + 30% FBC) | 346 | 104 | - | 1350 | 255 | 0.57 |

| ZIII (CEM I + 45% FBC) | 310 | 140 | - | 276 | 0.61 | |

| ZIV (CEM I + 25% FBC + 20% CFA) | 310 | 77.8 | 62.2 | 247 | 0.55 |

| Type of Binder | Particle-Size Distribution [%] | |||

|---|---|---|---|---|

| <10 µm | 10–50 µm | 50–100 µm | >100 µm | |

| CI (100% CEM I) | 26.53 | 61.96 | 10.58 | 0.93 |

| CII (CEM I + 30% FBC) | 25.12 | 53.34 | 14.00 | 7.54 |

| CIII (CEM I + 45% FBC) | 22.94 | 46.64 | 17.24 | 13.16 |

| CIV (CEM I + 25% FBC + 20% CFA) | 26.00 | 51.21 | 14.26 | 8.54 |

| Type of Cement Pastes | 12 h | 24 h | 48 h | 72 h |

|---|---|---|---|---|

| PI (100% CEM I) | 97.9 | 149.3 | 191.7 | 209.3 |

| PII (CEM I + 30% FBC) | 29.6 | 81.0 | 122.5 | 139.9 |

| PIII (CEM I + 45% FBC) | 29.3 | 84.8 | 120.8 | 138.3 |

| PIV (CEM I + 25% FBC + 20% CFA) | 29.9 | 87.2 | 119.3 | 133.7 |

| Cement–Fly-Ash Paste | PI (100% CEM I) | PII (CEM I + 30% FBC) | PIII (CEM I + 45% FBC) | PIV (CEM I + 25% FBC + 20% CFA) |

|---|---|---|---|---|

| Maximum reaction rate of W (J/g h) | 11.4 | 7.3 | 6.6 | 5.0 |

| Time (h) | 5.8 | 16.4 | 18.8 | 22.3 |

| Type of Mortar | ZI (100% CEM I) | ZII (CEM I + 30% FBC) | ZIII (CEM I + 45% FBC) | ZIV (CEM I + 25% FBC + 20% CFA) |

|---|---|---|---|---|

| Compressive strength (MPa) | 2.3 | 1.8 | 1.4 | 1.3 |

| Time (days) | Environment | ZI (100% CEM I) | ZII (CEM I + 30% FBC) | ZIII (CEM I + 45% FBC) | ZIV (CEM I + 25% FBC + 20% CFA) |

|---|---|---|---|---|---|

| 365 | H2O |  |  |  |  |

| No degradation | No degradation | No degradation | No degradation | ||

| 1% HCl |  |  |  |  | |

| 14.5 cm2 | 14.9 cm2 | 15.6 cm2 | Rusty rim on the surface | ||

| 3% HCl |  |  |  |  | |

| 7.60 cm2 | 8.24 cm2 | 9.36 cm2 | 8.72 cm2 | ||

| 5% HCl |  |  |  |  | |

| 1.86 cm2 | 1.96 cm2 | 2.04 cm2 | 2.01 cm2 | ||

| 730 | H2O |  |  |  |  |

| No degradation | No degradation | No degradation | No degradation | ||

| 1% HCl |  |  |  |  | |

| 12.34 cm2 | 13.04 cm2 | 13.85 cm2 | 13.44 cm2 | ||

| 3% HCl |  |  |  |  | |

| Total degradation of section | Total degradation of section | 0.52 cm2 | Total degradation of section | ||

| 5% HCl |  |  |  |  | |

| Total degradation of section | Total degradation of section | Total degradation of section | Total degradation of section |

| Type of Mortar | Apparent Density (g/cm3) | Total Porosity (%) | Percentage of Pores [%] | ||||

|---|---|---|---|---|---|---|---|

| <20 nm | 20–200 nm | 200–2000 nm | 2000–20,000 nm | <20,000 nm | |||

| H2O (365 days) | |||||||

| ZI (100% CEM I) | 2.12 | 11.4 | 17.7 | 68.3 | 7.7 | 0.4 | 5.4 |

| ZII (CEM I + 30% FBC) | 2.10 | 16.7 | 36.3 | 49.2 | 7.7 | 2.2 | 4.6 |

| ZIII (CEM I + 45% FBC) | 2.07 | 17.0 | 38.3 | 53.5 | 4.7 | 0.9 | 2.6 |

| ZIV (CEM I + 25% FBC + 20% CFA) | 2.11 | 16.3 | 37.3 | 54.1 | 3.3 | 0.6 | 4.6 |

| H2O (730 days) | |||||||

| ZI (100% CEM I) | 2.18 | 13.1 | 24.5 | 65.6 | 2.0 | 0.3 | 7.8 |

| ZII (CEM I + 30% FBC) | 2.15 | 15.2 | 34.9 | 53.5 | 4.4 | 0.2 | 5.2 |

| ZIII (CEM I + 45% FBC) | 2.1 | 17.3 | 38.2 | 51.8 | 4.5 | 0.7 | 4.6 |

| ZIV (CEM I + 25% FBC + 20% CFA) | 2.12 | 15.3 | 35.5 | 55.6 | 2.9 | 0.6 | 5.2 |

| 1% HCl solution (365 days) | |||||||

| ZI (100% CEM I) | 2.15 | 22.6 | 26.4 | 53.6 | 15.8 | 2.5 | 1.3 |

| ZII (CEM I + 30% FBC) | 2.10 | 19.7 | 37.1 | 47.3 | 8.9 | 1.8 | 4.6 |

| ZIII (CEM I + 45% FBC) | 2.08 | 16.8 | 37.9 | 49.0 | 7.0 | 2.5 | 3.6 |

| ZIV (CEM I + 25% FBC + 20% CFA) | 2.09 | 17.1 | 35.6 | 46.2 | 7.1 | 4.2 | 6.7 |

| 1% HCl solution (730 days) | |||||||

| ZI (100% CEM I) | 2.17 | 11.3 | 27.1 | 60.5 | 6.1 | 1.9 | 4.5 |

| ZII (CEM I + 30% FBC) | 2.14 | 15.1 | 32.8 | 47.4 | 12.4 | 2.6 | 4.1 |

| ZIII (CEM I + 45% FBC) | 2.06 | 15.3 | 33.6 | 57.9 | 5.0 | 0.9 | 2.6 |

| ZIV (CEM I + 25% FBC + 20% CFA) | 2.14 | 14.8 | 34.2 | 55.1 | 5.5 | 0.8 | 4.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janowska-Renkas, E.; Kaliciak, A.; Janus, G.; Kowalska, J. Durability of Cement and Ash Mortars with Fluidized and Siliceous Fly Ashes Exposed to HCl Acid Environment over a Period of 2 Years. Materials 2021, 14, 3229. https://doi.org/10.3390/ma14123229

Janowska-Renkas E, Kaliciak A, Janus G, Kowalska J. Durability of Cement and Ash Mortars with Fluidized and Siliceous Fly Ashes Exposed to HCl Acid Environment over a Period of 2 Years. Materials. 2021; 14(12):3229. https://doi.org/10.3390/ma14123229

Chicago/Turabian StyleJanowska-Renkas, Elżbieta, Agnieszka Kaliciak, Grzegorz Janus, and Jolanta Kowalska. 2021. "Durability of Cement and Ash Mortars with Fluidized and Siliceous Fly Ashes Exposed to HCl Acid Environment over a Period of 2 Years" Materials 14, no. 12: 3229. https://doi.org/10.3390/ma14123229

APA StyleJanowska-Renkas, E., Kaliciak, A., Janus, G., & Kowalska, J. (2021). Durability of Cement and Ash Mortars with Fluidized and Siliceous Fly Ashes Exposed to HCl Acid Environment over a Period of 2 Years. Materials, 14(12), 3229. https://doi.org/10.3390/ma14123229