Application of Ceramic Lattice Structures to Design Compact, High Temperature Heat Exchangers: Material and Architecture Selection

Abstract

:1. Introduction

2. Materials and Methods

2.1. HXs Operating Conditions

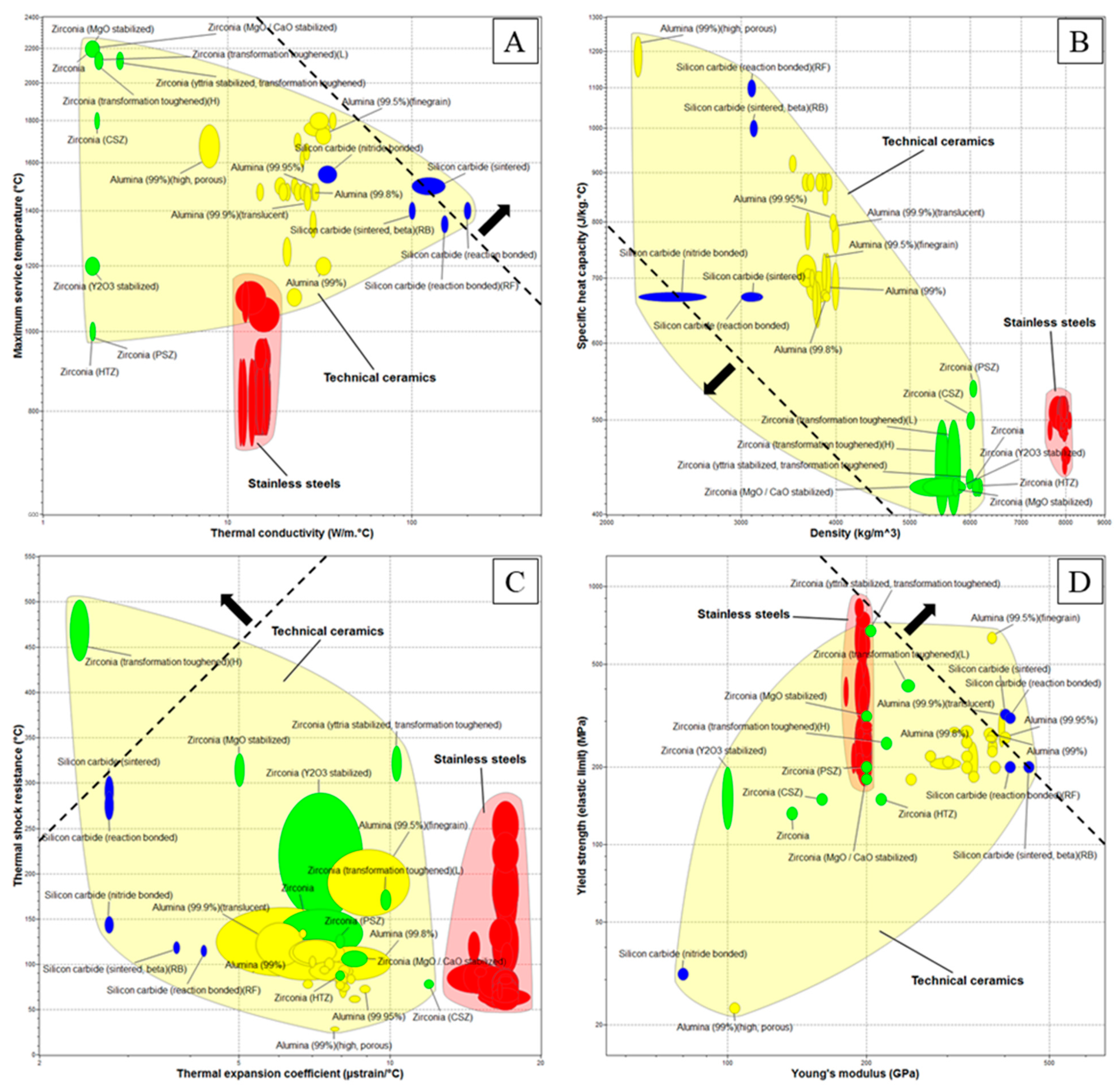

2.2. Ashby-Based Approach

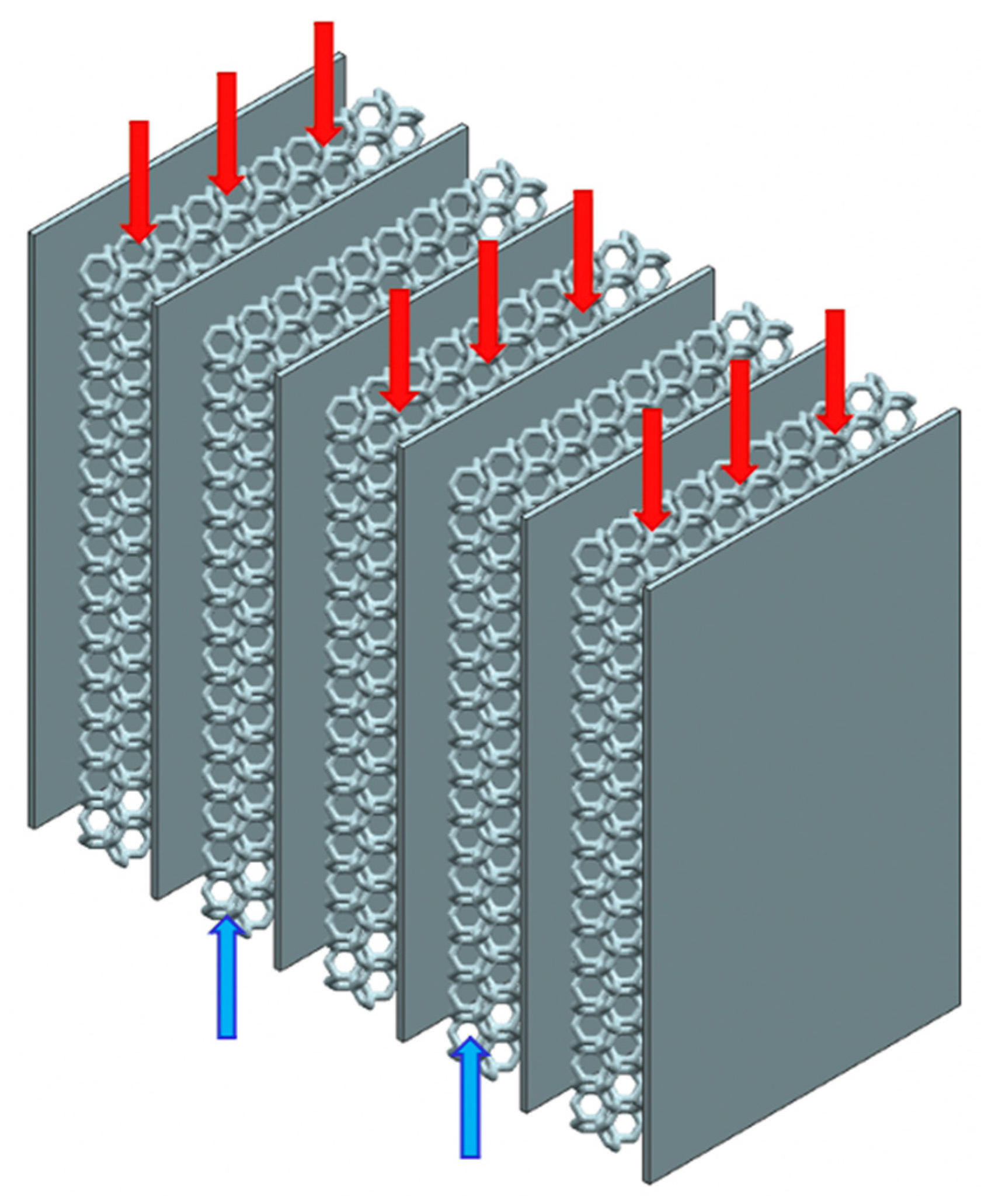

2.3. Design

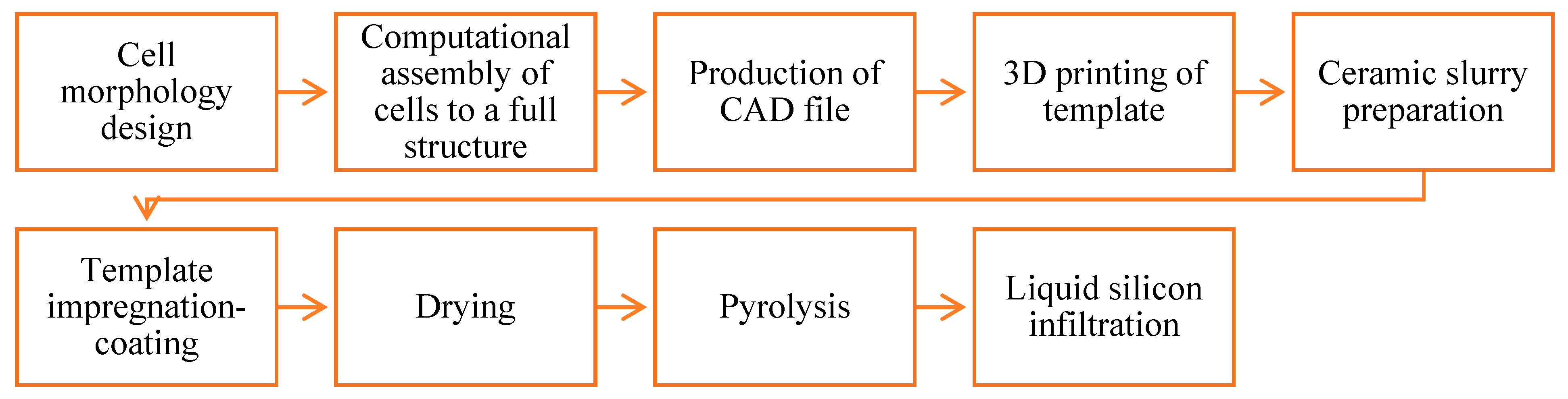

2.4. Additive Manufacturing

2.5. Numerical Simulations

2.5.1. Heat Transfer Characterisation

2.5.2. Friction Factor

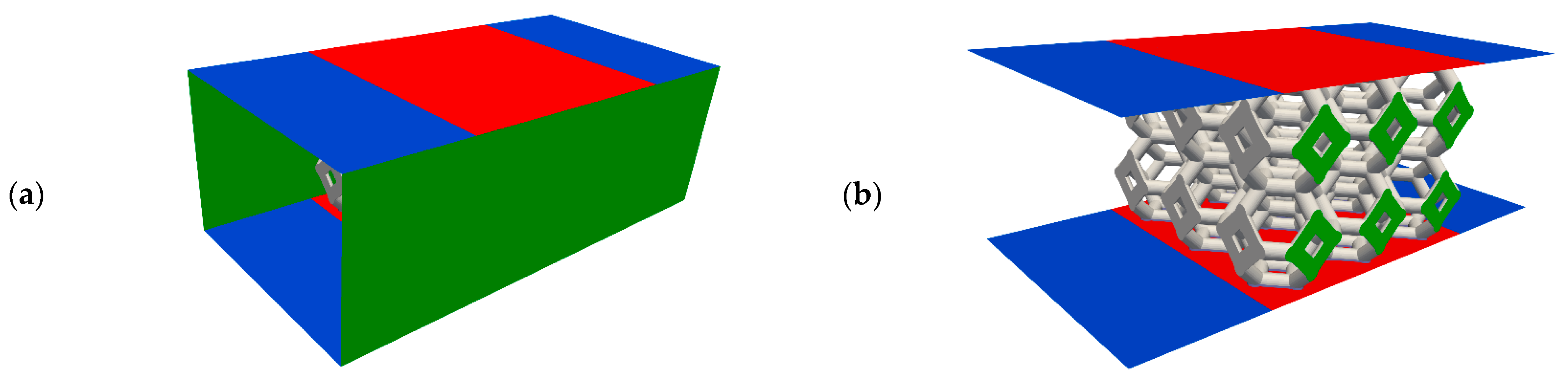

2.5.3. Simulation Domain and Boundary Conditions

2.5.4. Simulation Parameters, Solution Algorithm and Numerical Setup

3. Results and Discussion

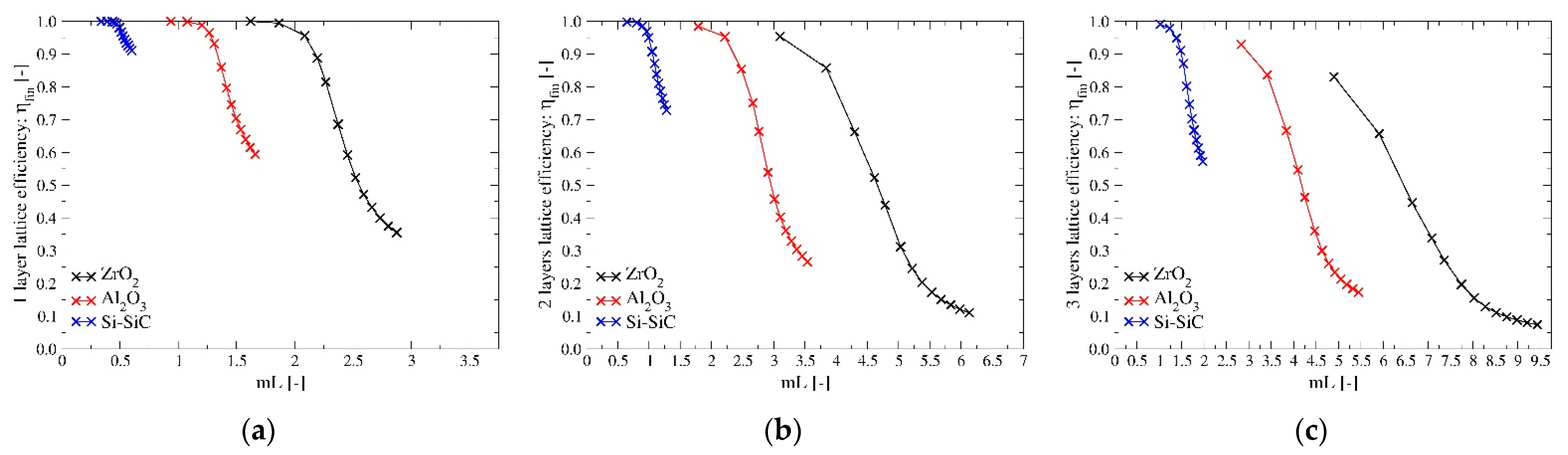

3.1. Material Selection

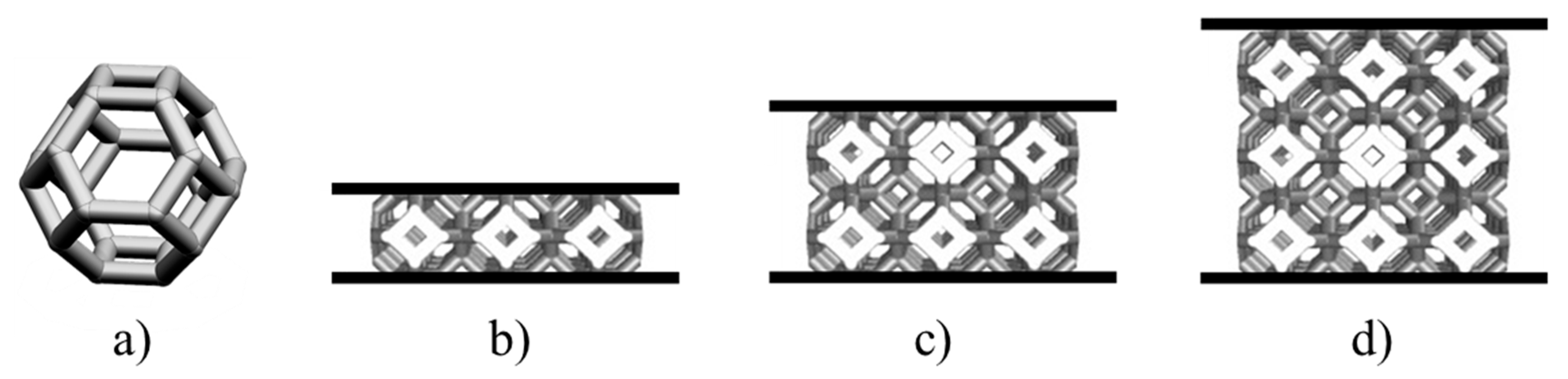

3.2. Lattice Architecture

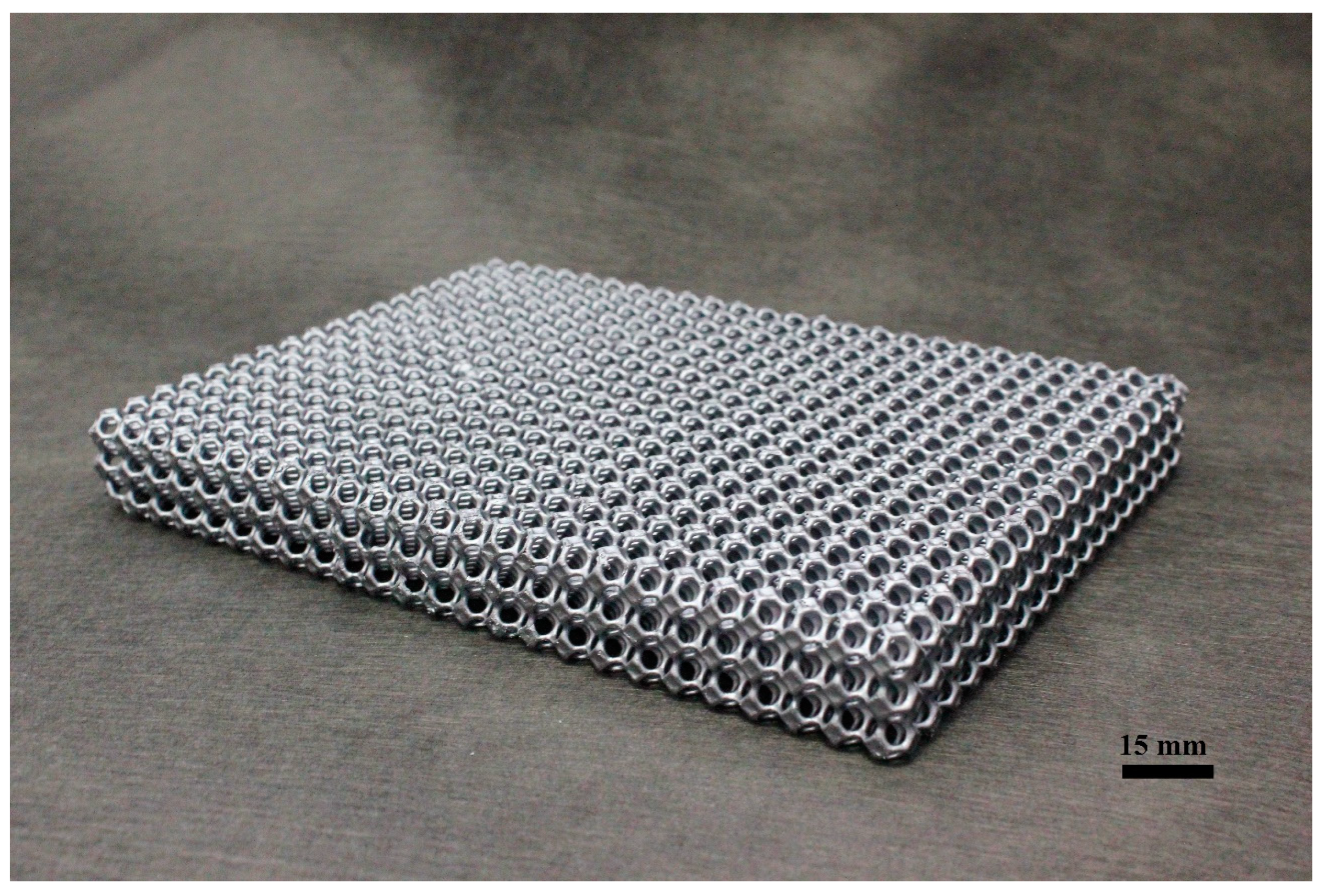

3.3. Replica Method

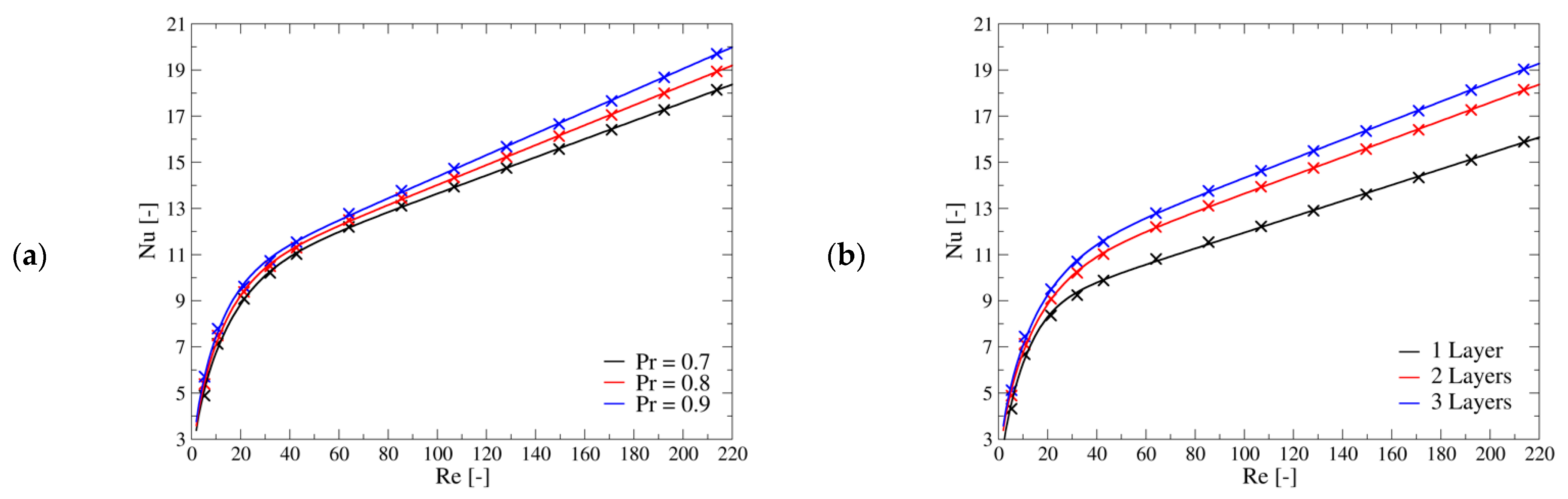

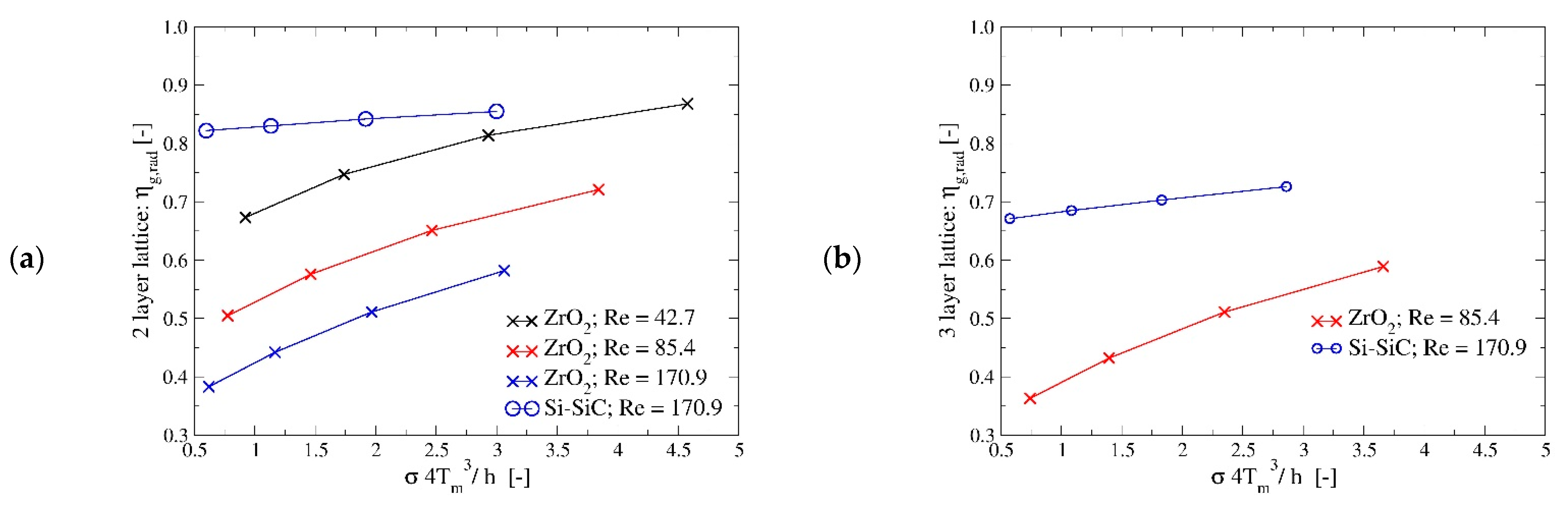

3.4. Heat Transfer Characterisation of the Lattice Architecture

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rashidi, S.; Kashefi, M.H.; Kim, K.C.; Samimi-Abianeh, O. Potentials of porous materials for energy management in heat exchangers—A comprehensive review. Appl. Energy 2019, 243, 206–232. [Google Scholar] [CrossRef]

- Son, K.N.; Weibel, J.A.; Kumaresan, V.; Garimella, S.V. Design of multifunctional lattice-frame materials for compact heat exchangers. Int. J. Heat Mass Transf. 2017, 115, 619–629. [Google Scholar] [CrossRef] [Green Version]

- Pelanconi, M.; Barbato, M.; Zavattoni, S.; Vignoles, G.L.; Ortona, A. Thermal design, optimization and additive manufacturing of ceramic regular structures to maximize the radiative heat transfer. Mater. Des. 2019, 163, 107539. [Google Scholar] [CrossRef]

- Ho, J.Y.; Leong, K.C.; Wong, T.N. Additively-manufactured metallic porous lattice heat exchangers for air-side heat transfer enhancement. Int. J. Heat Mass Transf. 2020, 150, 119262. [Google Scholar] [CrossRef]

- Sommers, A.; Wang, Q.; Han, X.; T’Joen, C.; Park, Y.; Jacobi, A. Ceramics and ceramic matrix composites for heat exchangers in advanced thermal systems—A review. Appl. Therm. Eng. 2010, 30, 1277–1291. [Google Scholar] [CrossRef]

- Chandran, R.B.; De Smith, R.M.; Davidson, J.H. Model of an integrated solar thermochemical reactor/reticulated ceramic foam heat exchanger for gas-phase heat recovery. Int. J. Heat Mass Transf. 2015, 81, 404–414. [Google Scholar] [CrossRef] [Green Version]

- Ashby, M.F. The properties of foams and lattices. Philos. Trans. R. Soc. A 2006, 364, 15–30. [Google Scholar] [CrossRef]

- Pelanconi, M.; Ortona, A. Nature-inspired, ultra-lightweight structures with gyroid cores produced by additive manufacturing and reinforced by unidirectional carbon fiber ribs. Materials 2019, 12, 4134. [Google Scholar] [CrossRef] [Green Version]

- Ortona, A.; Yoon, D.H.; Fend, T.; Feckler, G.; Smirnova, O. Tubular Si-infiltrated SiCf/SiC composites for solar receiver application–Part 2: Thermal performance analysis and prediction. Sol. Energy Mater. Sol. Cells 2015, 140, 382–387. [Google Scholar] [CrossRef]

- Pelanconi, M.; Rezaei, E.; Ortona, A. Cellular ceramic architectures produced by hybrid additive manufacturing: A review on the evolution of their design. J. Ceram. Soc. Jpn. 2020, 128, 595–604. [Google Scholar] [CrossRef]

- Pelanconi, M.; Ortona, A. Review on the design approaches of cellular architectures produced by additive manufacturing. In Industrializing Additive Manufacturing. AMPA 2020; Meboldt, M., Klahn, C., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Abu Al-Rub, R.K. MSLattice: A free software for generating uniform and graded lattices based on triply periodic minimal surfaces. Mater. Des. Process. Commun. 2020, e205. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A.; Ashby, M.F. Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids 2001, 49, 1747–1769. [Google Scholar] [CrossRef] [Green Version]

- Rezaei, E.; Barbato, M.; Gianella, S.; Ortona, A.; Haussener, S. Pressure drop and convective heat transfer in different SiSiC structures fabricated by indirect additive manufacturing. J. Heat Transf. 2020, 142, 032702. [Google Scholar] [CrossRef]

- Rezaei, E.; Barbato, M.; Ortona, A.; Haussener, S. Design and optimization of a high-temperature latent heat storage unit. Appl. Energy 2020, 261, 114330. [Google Scholar] [CrossRef]

- Pusterla, S.; Barbato, M.; Ortona, A.; D’Angelo, C. Numerical study of cell morphology effects on convective heat transfer in reticulated ceramics. Int. J. Heat Mass Transf. 2012, 55, 7902–7910. [Google Scholar] [CrossRef]

- Vignoles, G.L.; Ortona, A. Numerical study of effective heat conductivities of foams by coupled conduction and radiation. Int. J. Therm. Sci. 2016, 109, 270–278. [Google Scholar] [CrossRef] [Green Version]

- Ashby, M.F.; Johnson, K. Materials and Design: The Art and Science of Material Selection in Product Design; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Gianella, S.; Gaia, D.; Ortona, A. High temperature applications of Si—SiC cellular ceramics. Adv. Eng. Mater. 2012, 14, 1074–1081. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Pelanconi, M.; Ortona, A.; Abu Al-Rub, R.K. Additive manufacturing of architected catalytic ceramic substrates based on triply periodic minimal surfaces. J. Am. Ceram. Soc. 2019, 102, 6176–6193. [Google Scholar] [CrossRef]

- Papetti, V.; Eggenschwiler, P.D.; Torre, A.D.; Lucci, F.; Ortona, A.; Montenegro, G. Additive manufactured open cell polyhedral structures as substrates for automotive catalysts. Int. J. Heat Mass Transf. 2018, 126, 1035–1047. [Google Scholar] [CrossRef]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Felzmann, R.; Gruber, S.; Mitteramskogler, G.; Tesavibul, P.; Boccaccini, A.R.; Liska, R.; Stampfl, J. Lithography-based additive manufacturing of cellular ceramic structures. Adv. Eng. Mater. 2012, 14, 1052–1058. [Google Scholar] [CrossRef]

- Wilkes, J.; Hagedorn, Y.C.; Meiners, W.; Wissenbach, K. Additive manufacturing of ZrO2-Al2O3 ceramic components by selective laser melting. Rapid Prototyp. J. 2013, 19, 51–57. [Google Scholar] [CrossRef]

- Ortona, A.; D’Angelo, C.; Gianella, S.; Gaia, D. Cellular ceramics produced by rapid prototyping and replication. Mater. Lett. 2012, 80, 95–98. [Google Scholar] [CrossRef]

- Pelanconi, M.; Colombo, P.; Ortona, A. Additive manufacturing of silicon carbide by selective laser sintering of PA12 powders and polymer infiltration and pyrolysis. J. Eur. Ceram. Soc. 2021. [Google Scholar] [CrossRef]

- Incropera, F.P.; Lavine, A.S.; Bergman, T.L.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: New York, NY, USA, 2007. [Google Scholar]

- Contestabile, F.; Cornolti, L.; Zavattoni, S.; Barbato, M.C. An advanced wall treatment for a 1D model of packed bed thermal energy storage systems. J. Energy Storage 2019, 26, 100918. [Google Scholar] [CrossRef]

- Torre, A.D.; Montenegro, G.; Onorati, A.; Khadilkar, S.; Icarelli, R. Multi-Scale CFD Modeling of Plate Heat Exchangers Including Offset-Strip Fins and Dimple-Type Turbulators for Automotive Applications. Energies 2019, 12, 2965. [Google Scholar] [CrossRef] [Green Version]

- Kays, W.M.; London, A.L. Compact Heat Exchangers; OSTI.GOV: Oak Ridge, TN, USA, 1984. [Google Scholar]

- Seguin, D.; Montillet, A.; Comiti, J.; Huet, F. Experimental characterization of flow regimes in various porous media—II: Transition to turbulent regime. Chem. Eng. Sci. 1998, 53, 3897–3909. [Google Scholar] [CrossRef]

- CRC. CRC Handbook of Chemistry and Physics; Lide, D.R., Ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- EngiCer SA. Material Data Sheet: SiSiC. Available online: http://www.engicer.com/wp-content/uploads/materialdatasheet/EngiCer_Material_Data_Sheet_SiSiC.pdf (accessed on 30 April 2021).

- Howel, J.R.; Siegel, R.; Menguc, M.P. Thermal Radiation Heat Transfer, 5th ed.; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Orszag, S.A. Accurate solution of the Orr-Sommerfeld stability equation. J. Fluid Mech. 1971, 50, 689–703. [Google Scholar] [CrossRef] [Green Version]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. Turbul. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- Weller, H.G.; Tabor, G.; Jasak, H.; Fureby, C. A tensorial approach to computational continuum mechanics using object-oriented techniques. Comput. Phys. 1998, 12, 620–631. [Google Scholar] [CrossRef]

- OpenCFD. OpenFOAM Documentation. Available online: https://www.openfoam.com/documentation/user-guide/standard-solvers.php (accessed on 30 April 2021).

- Jasak, H. Error analysis and Estimation for the Finite Volume Method with Applications to Fluid Flows. Ph.D. Thesis, University of London, London, UK, 1996. [Google Scholar]

- ANSYS Academic Research. ANSYS Fluent Theory Guide, Release 20.1; ANSYS, Inc.: Canonsburg, PA, USA, 2018. [Google Scholar]

- Jacobson, N.S.; Myers, D.L.; Harder, B.J. Active oxidation of silicon carbide. Mater. High. Temp. 2012, 29, 193–198. [Google Scholar] [CrossRef]

- Jennings, H.M.; Dalgleish, B.J.; Pratt, P.L. Reactions between silicon and nitrogen. J. Mater. Sci. 1988, 23, 2573–2583. [Google Scholar] [CrossRef]

- Lichko, T.; Kryl, Y.A.; Rymar, V.E. High-temperature reaction between silicon carbide and nitrogen under pressure. Powder Metall. Met. Ceram. 1993, 32, 281–285. [Google Scholar] [CrossRef]

- Ferrari, L.; Barbato, M.C.; Ortona, A.; D’Angelo, C. Convective heat transfer in cellular ceramic: A 3D numerical solution. In Proceedings of the International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Florida, FL, USA, 14–16 July 2014. [Google Scholar]

- Bianchi, G.; Gianella, S.; Ortona, A. Design and additive manufacturing of periodic ceramic architectures. J. Ceram. Sci. Technol 2017, 8, 59–66. [Google Scholar]

- Scheffler, M.; Colombo, P. (Eds.) Cellular Ceramics: Structure, Manufacturing, Properties and Applications; John Wiley & Sons: New York, NY, USA, 2006. [Google Scholar]

- Eggenschwiler, P.D.; Tsinoglou, D.N.; Seyfert, J.; Bach, C.; Vogt, U.; Gorbar, M. Ceramic foam substrates for automotive catalyst applications: Fluid mechanic analysis. Exp. Fluids 2009, 47, 209–222. [Google Scholar] [CrossRef]

- Wu, Z.; Caliot, C.; Bai, F.; Flamant, G.; Wang, Z.; Zhang, J.; Tian, C. Experimental and numerical studies of the pressure drop in ceramic foams for volumetric solar receiver applications. Appl. Energy 2010, 87, 504–513. [Google Scholar] [CrossRef]

- Whitaker, S. The Forchheimer equation: A theoretical development. Transp. Porous Media 1996, 25, 27–61. [Google Scholar] [CrossRef]

| HX | Side | Parameter | Design Specification |

|---|---|---|---|

| Inert gas circuit heat exchanger | Cold side | Composition of the fluid to be heated [-] | N2 |

| Inlet temperature [°C] | 600 | ||

| Mass flow rate [kg/h] | 100 | ||

| Outlet target temperature [°C] | 1150 | ||

| Working pressure [bar] | <2 | ||

| Hot side | Composition of the fluid [-] | N2 + O2 wt% N2 ≈ 99.9 wt% O2 ≈ 0.1 | |

| Inlet temperature [°C] | 1200 | ||

| Mass flow rate [kg/h] | 100 | ||

| Outlet target temperature [°C] | Result of the design | ||

| Working pressure [bar] | <2 | ||

| Steam generation circuit heat exchanger | Cold side | Composition of the fluid to be heated [-] | H2O |

| Inlet temperature [°C] | 300 | ||

| Mass flow rate [kg/h] | 10 | ||

| Outlet target temperature [°C] | 800 | ||

| Working pressure [bar] | <2 | ||

| Hot side | Composition of the fluid [-] | H2O + H2 + N2 wt% H2O ≈ 94.6 wt% H2 ≈ 0.6 wt% N2 ≈ 4.8 | |

| Inlet temperature [°C] | 900 | ||

| Mass flow rate [kg/h] | 10.35 | ||

| Outlet target temperature [°C] | Result of the design | ||

| Working pressure [bar] | <2 |

| Pros | Cons |

|---|---|

|

|

| Lattice Structure | Total Surface [m2] | Lattice Surface /Total Surface [−] | Total Surface/Surface with No Lattice [−] | Specific Surface [1/m] | Porosity [−] |

|---|---|---|---|---|---|

| 1-layer (1 × 3 × 3) | 1.8335 × 10−3 | 0.706 | 2.53 | 759.7 | 0.847 |

| 2-layers (2 × 3 × 3) | 3.0284 × 10−3 | 0.760 | 4.17 | 641.9 | 0.844 |

| 3-layers (3 × 3 × 3) | 4.3266 × 10−3 | 0.832 | 5.96 | 615.6 | 0.839 |

| Field | Inlet | Outlet | Lattice Surface (Grey Colour) | Central Box Top and Bottom Patches (Red Colour) | Development Region Top and Bottom Patches (Blue Colour) |

|---|---|---|---|---|---|

| Velocity | Parabolic profile | Zero gradient | No-slip | No-slip | No-slip |

| Temperature | Fixed value | Zero gradient | Fixed value/interface fluid solid | Zero gradient | Fixed value |

| Pressure | Fixed value | Zero gradient | Fixed flux pressure | Fixed flux pressure | Fixed flux pressure |

| Lattice Structure | α | β | γ | δ | λ | Maximum Relative Error [%] | Average Relative Error [%] |

|---|---|---|---|---|---|---|---|

| 1 layer (1 × 3 × 3) | 8.510 | 0.0804 | 0.5344 | 0.0438 | 0.682 | 6.37 | 0.92 |

| 2 layers (2 × 3 × 3) | 9.708 | 0.0503 | 0.4165 | 0.0502 | 0.679 | 5.66 | 0.62 |

| 3 layers (3 × 3 × 3) | 10.197 | 0.0528 | 0.4108 | 0.0526 | 0.677 | 5.90 | 0.62 |

| Lattice Structure | Maximum Relative Error Equation (16) [%] | Maximum Relative Error Equation (17) [%] | |||||

|---|---|---|---|---|---|---|---|

| 1 layer (1 × 3 × 3) | 325.3 | 4.672 | 301.2 | 10.457 | −1.210 | 14.10 | 3.90 |

| 2 layers (2 × 3 × 3) | 329.8 | 3.891 | 319.7 | 6.316 | −0.507 | ||

| 3 layers (3 × 3 × 3) | 318.5 | 3.872 | 308.6 | 6.253 | −0.498 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pelanconi, M.; Zavattoni, S.; Cornolti, L.; Puragliesi, R.; Arrivabeni, E.; Ferrari, L.; Gianella, S.; Barbato, M.; Ortona, A. Application of Ceramic Lattice Structures to Design Compact, High Temperature Heat Exchangers: Material and Architecture Selection. Materials 2021, 14, 3225. https://doi.org/10.3390/ma14123225

Pelanconi M, Zavattoni S, Cornolti L, Puragliesi R, Arrivabeni E, Ferrari L, Gianella S, Barbato M, Ortona A. Application of Ceramic Lattice Structures to Design Compact, High Temperature Heat Exchangers: Material and Architecture Selection. Materials. 2021; 14(12):3225. https://doi.org/10.3390/ma14123225

Chicago/Turabian StylePelanconi, Marco, Simone Zavattoni, Luca Cornolti, Riccardo Puragliesi, Edoardo Arrivabeni, Luca Ferrari, Sandro Gianella, Maurizio Barbato, and Alberto Ortona. 2021. "Application of Ceramic Lattice Structures to Design Compact, High Temperature Heat Exchangers: Material and Architecture Selection" Materials 14, no. 12: 3225. https://doi.org/10.3390/ma14123225

APA StylePelanconi, M., Zavattoni, S., Cornolti, L., Puragliesi, R., Arrivabeni, E., Ferrari, L., Gianella, S., Barbato, M., & Ortona, A. (2021). Application of Ceramic Lattice Structures to Design Compact, High Temperature Heat Exchangers: Material and Architecture Selection. Materials, 14(12), 3225. https://doi.org/10.3390/ma14123225