Air Permeability of Maraging Steel Cellular Parts Made by Selective Laser Melting

Abstract

1. Introduction

2. Materials and Methods

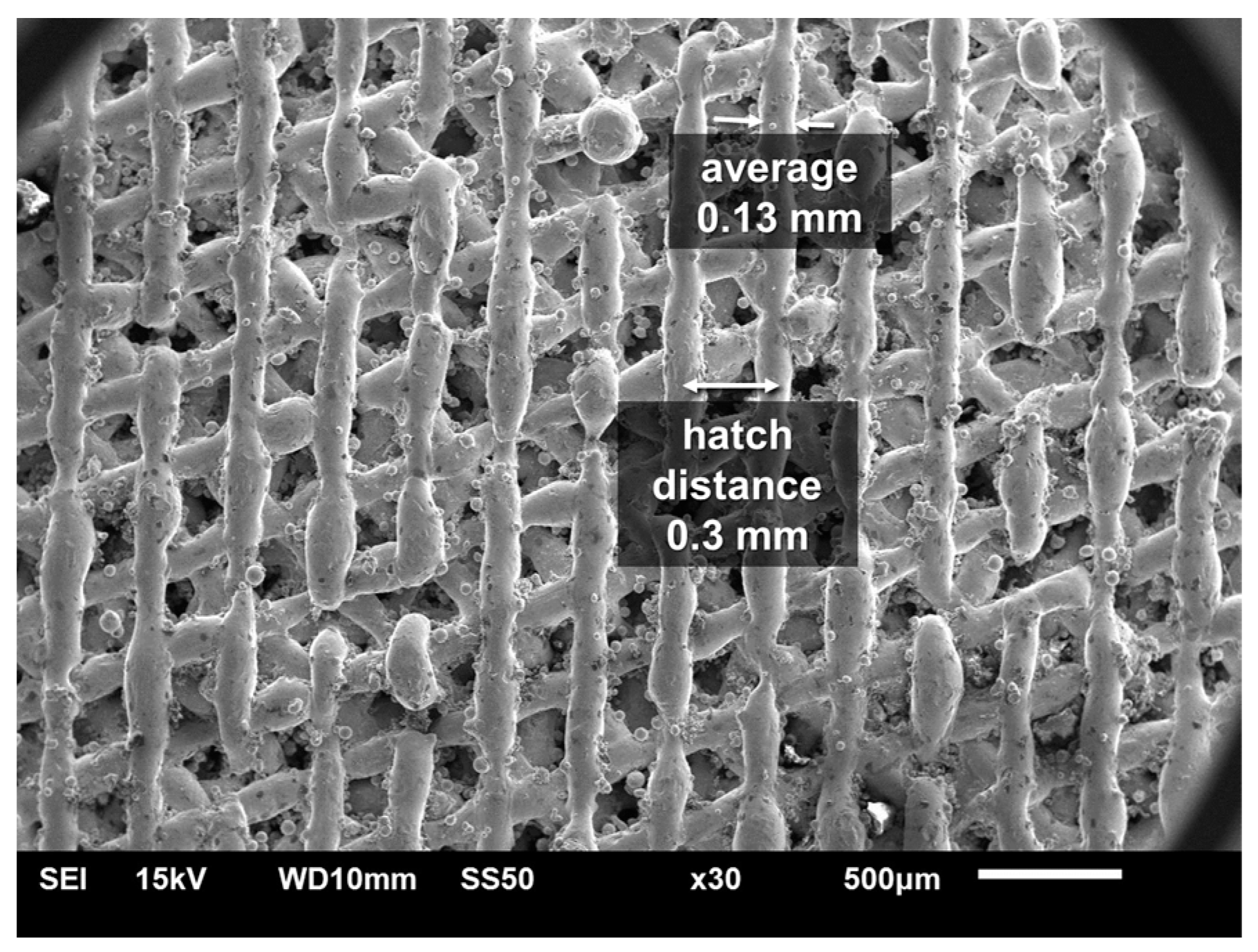

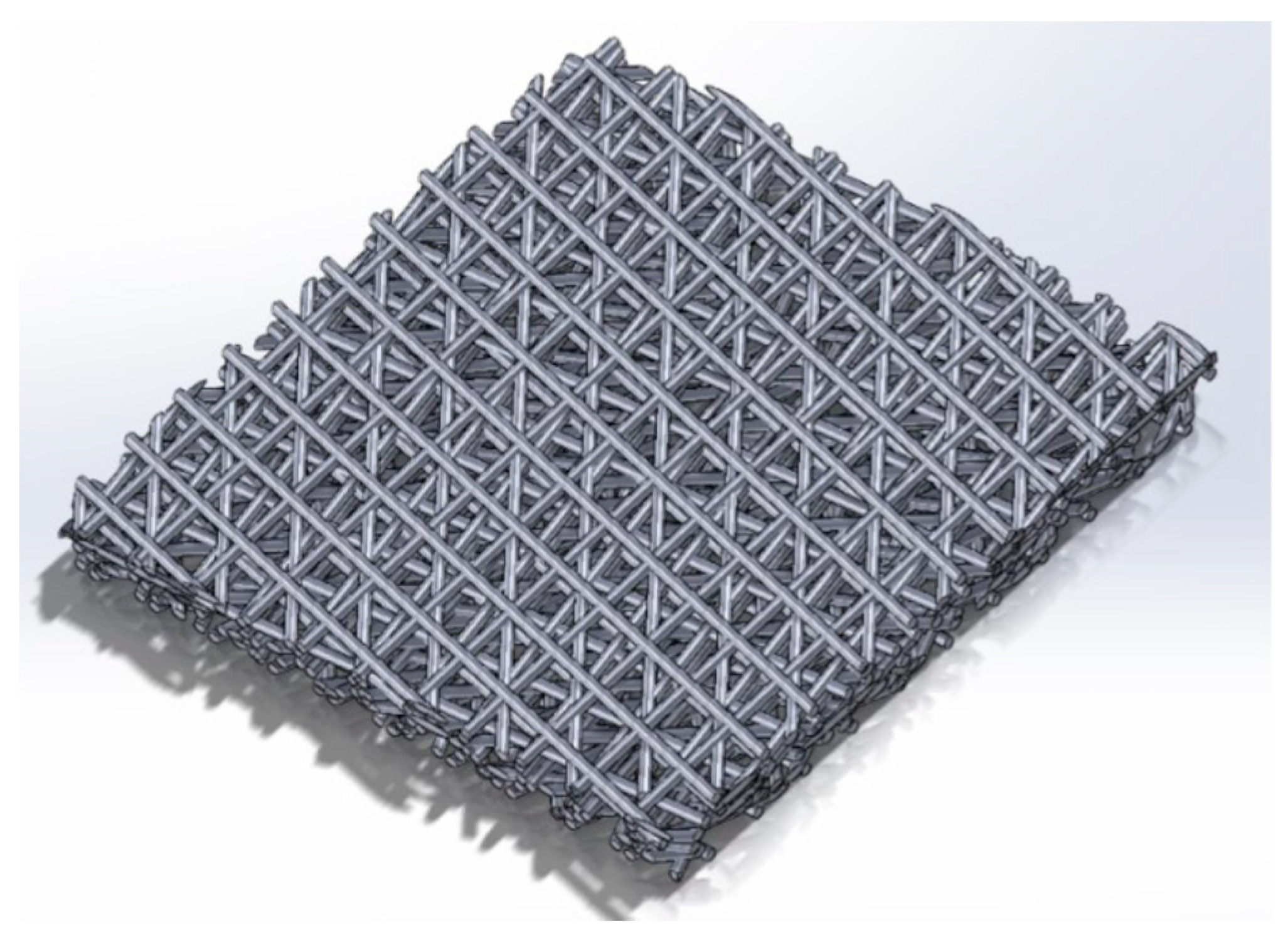

2.1. SLM of Porous Parts

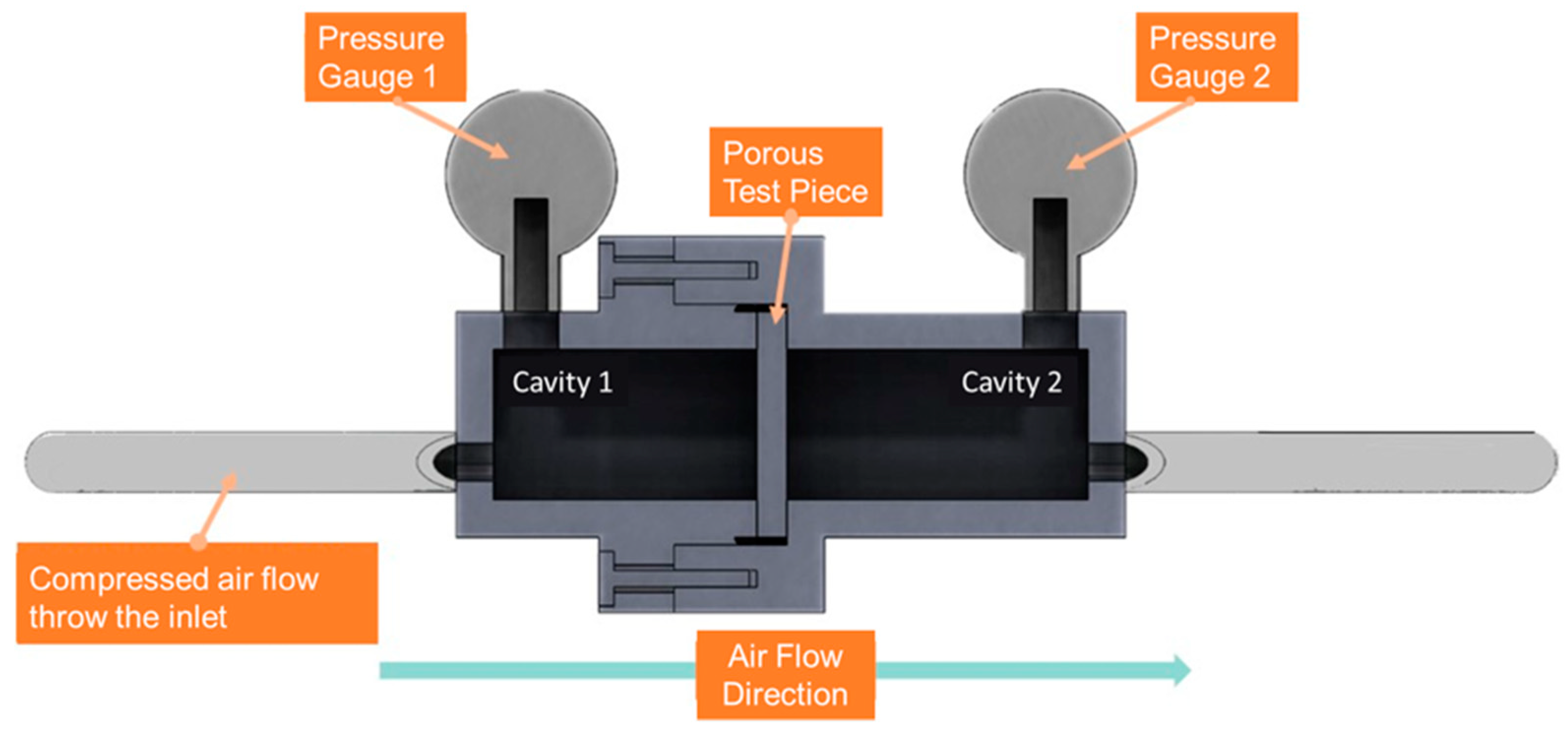

2.2. Air Permeability Measurement

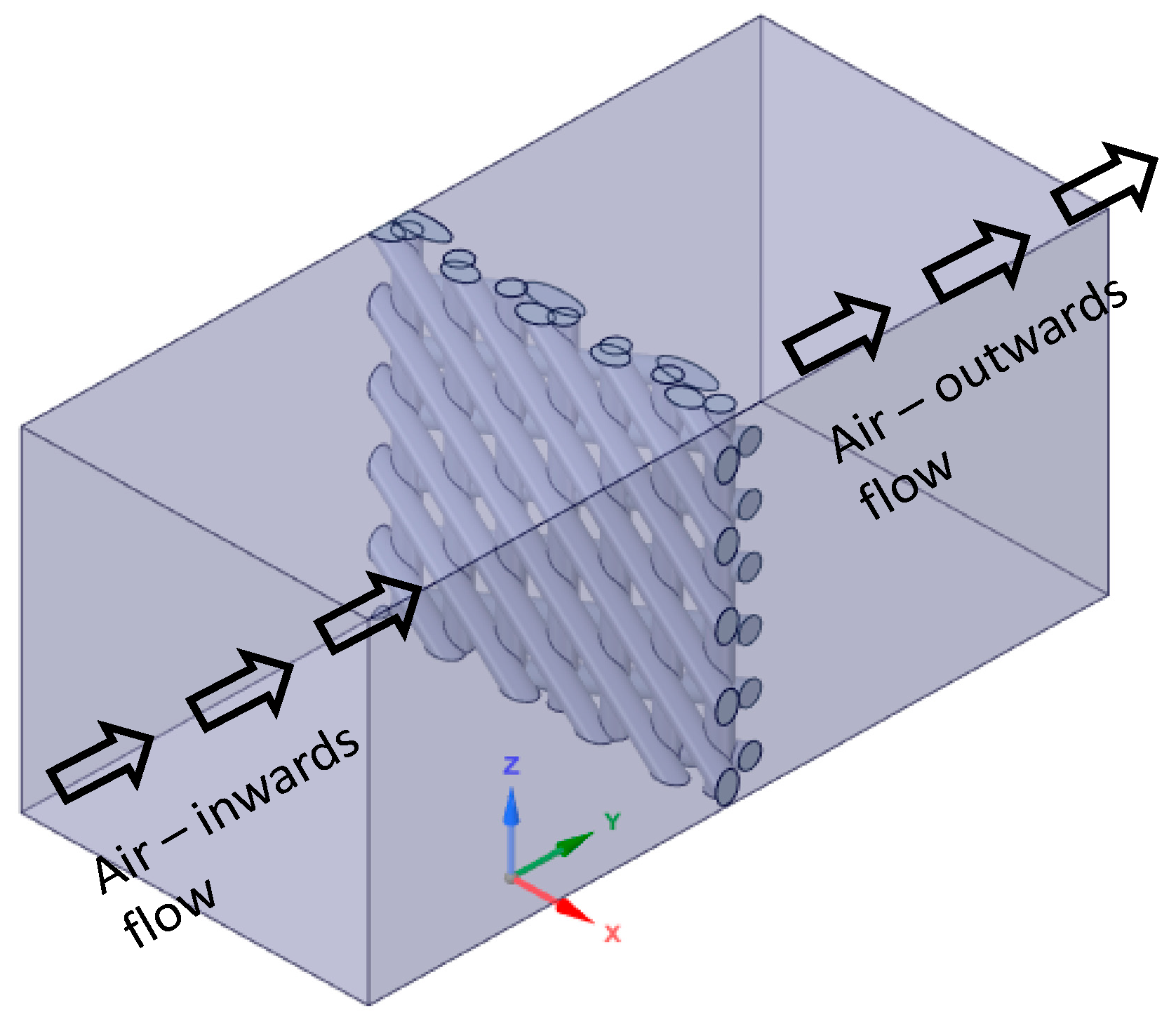

2.3. Numerical Simulation and Analysis

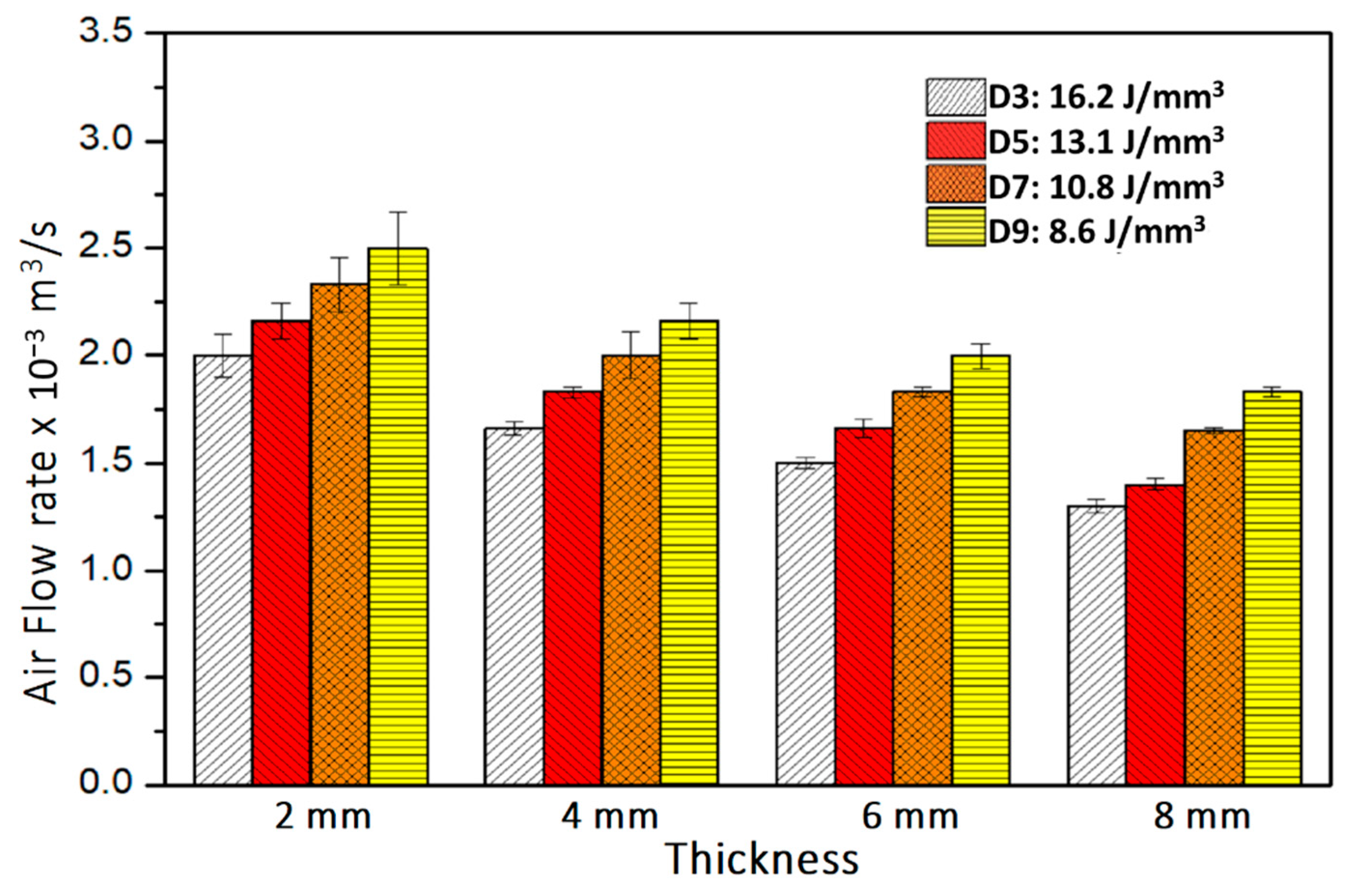

3. Results and Discussion

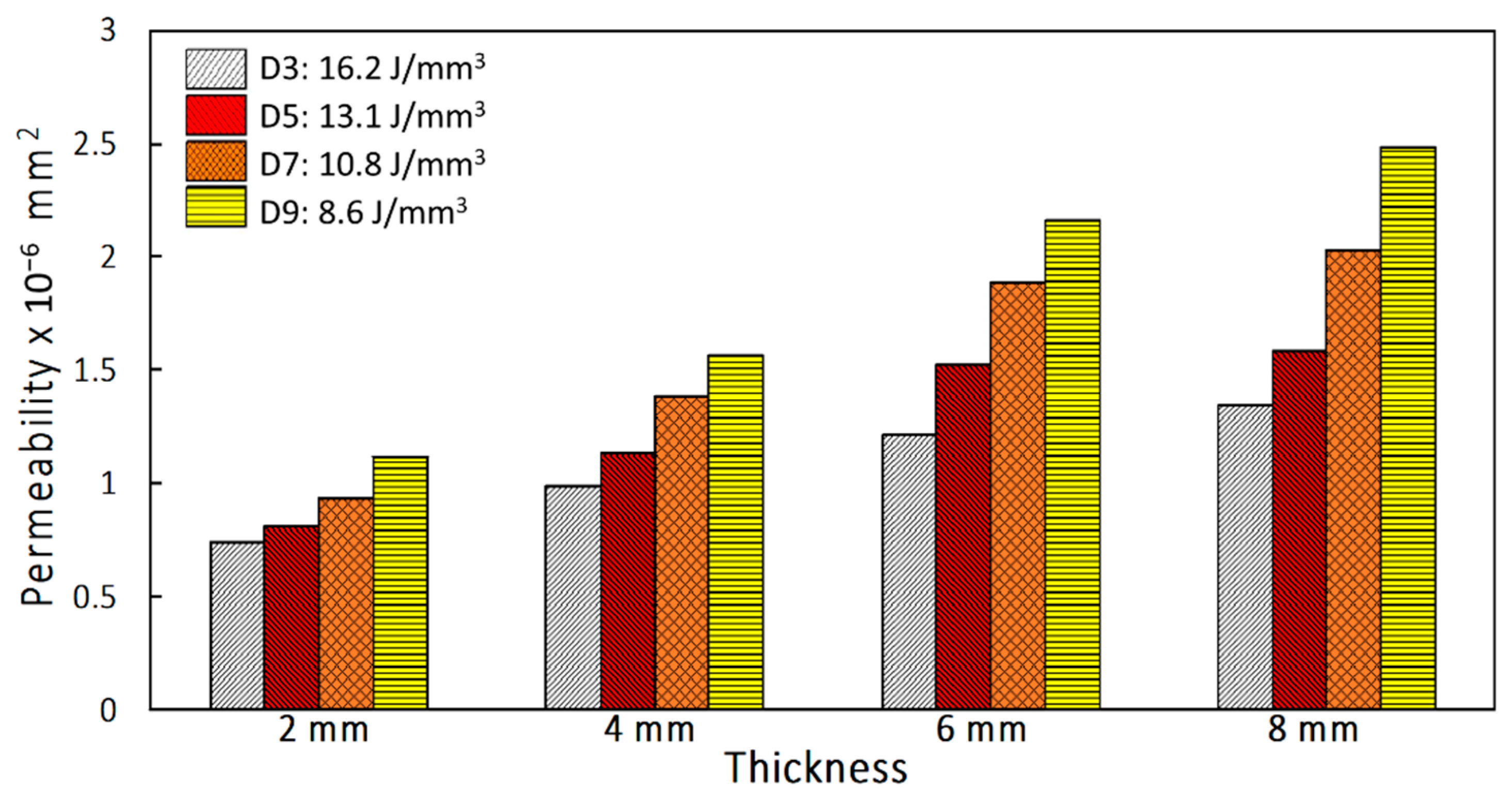

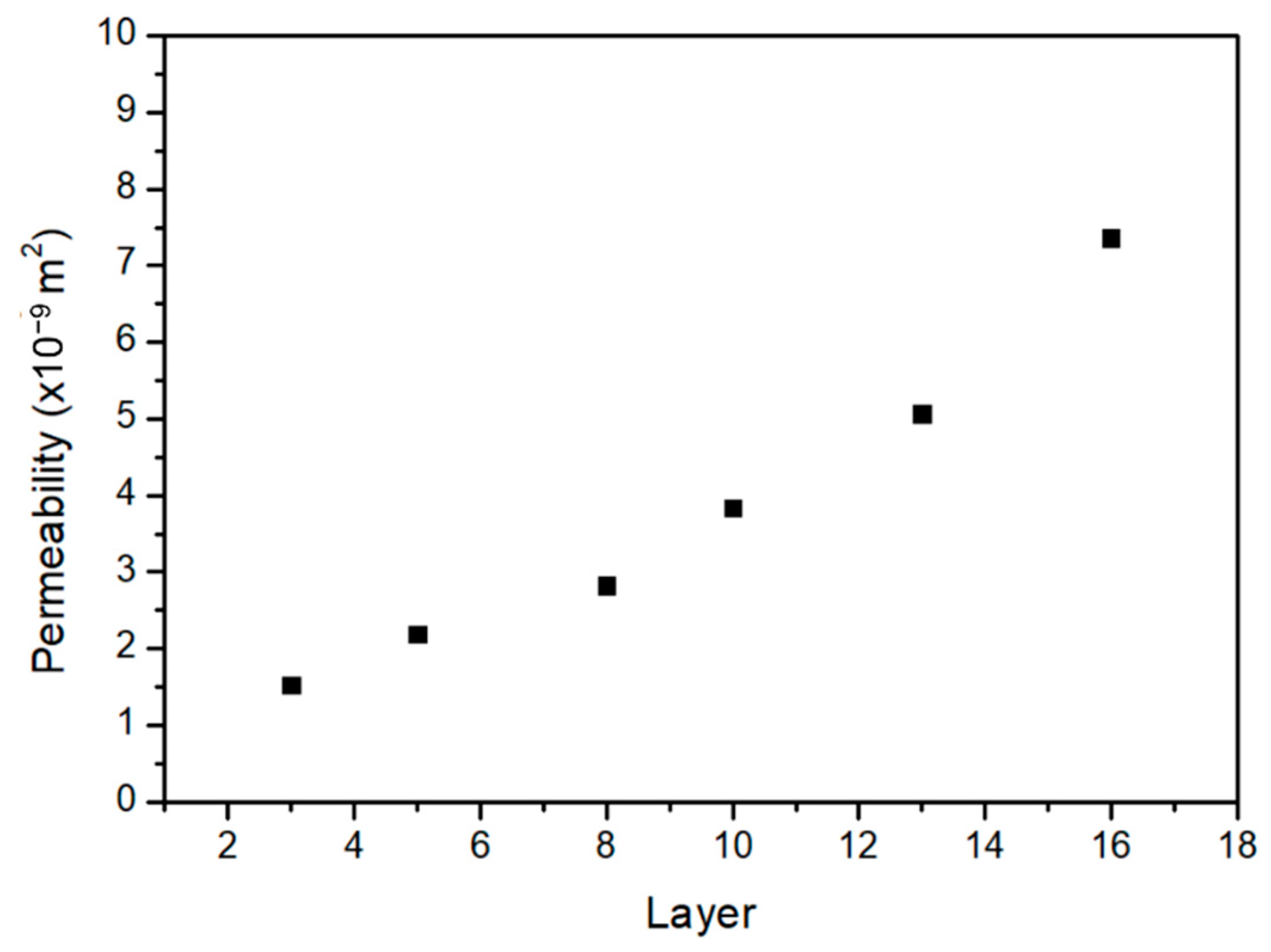

3.1. Effects of Energy Density and Thickness on Sample Porosity

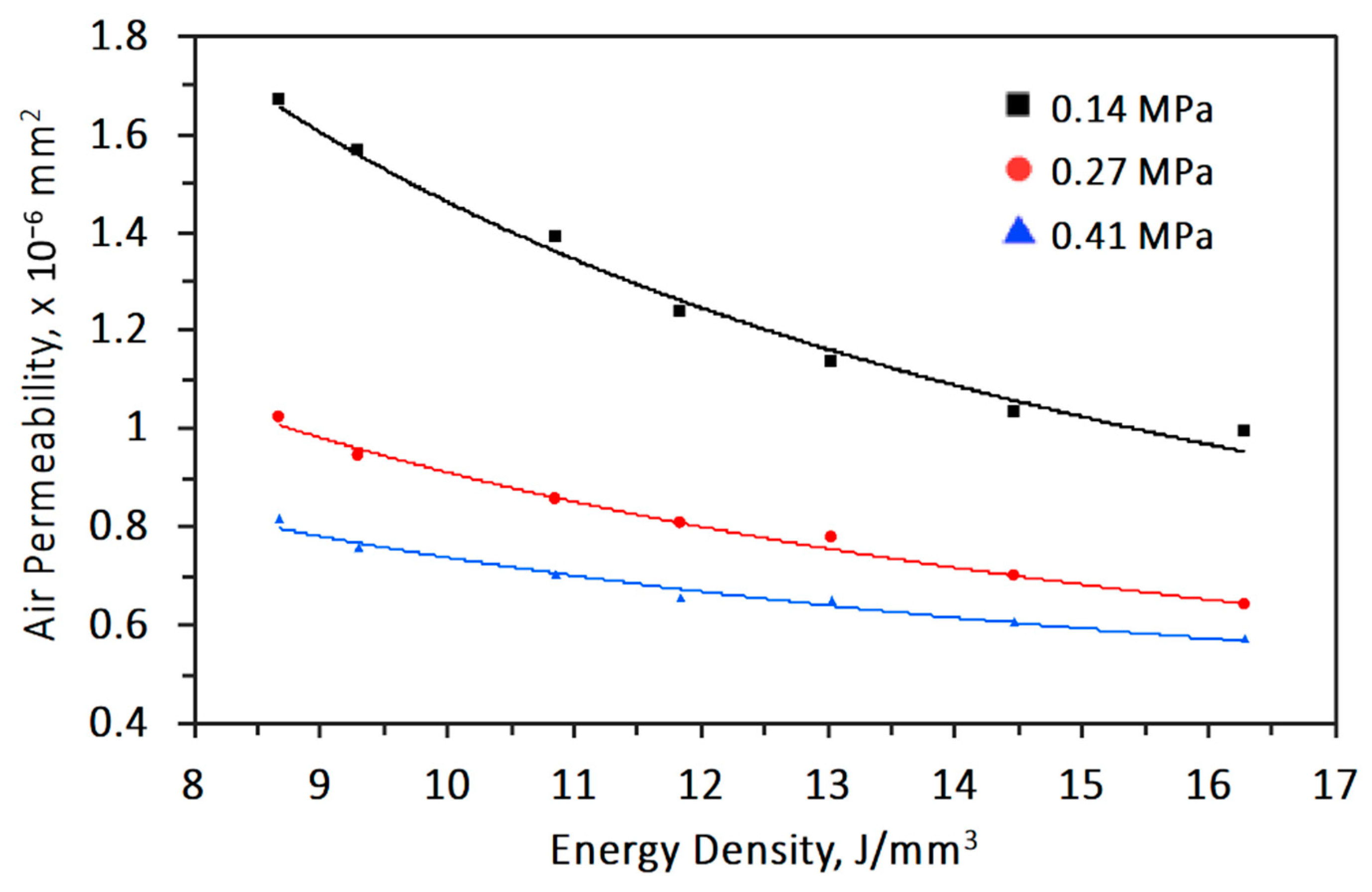

3.2. Effects of Porosity and Inlet Air Pressure on Air Permeability

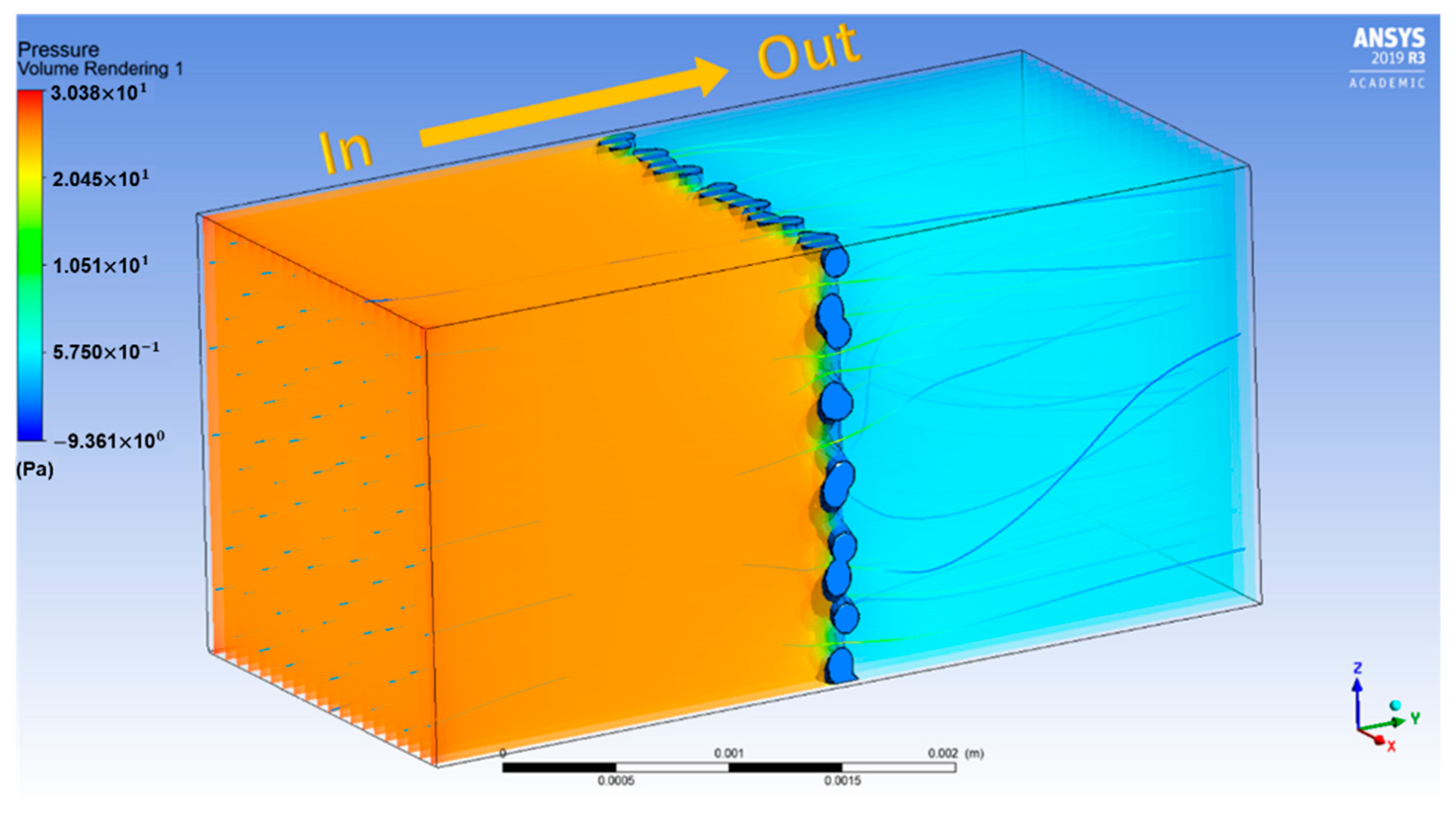

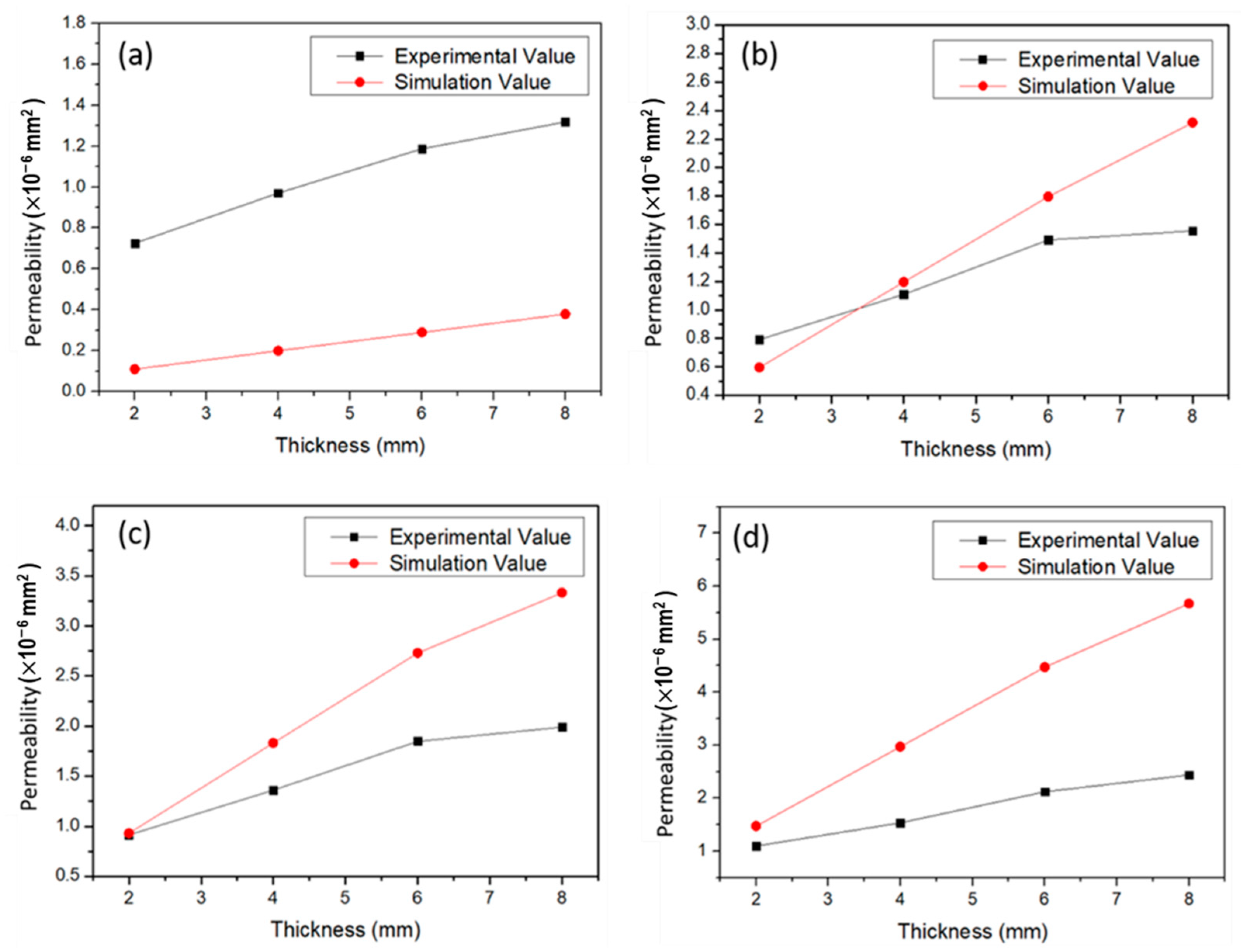

3.3. Simulation for Air Permeability

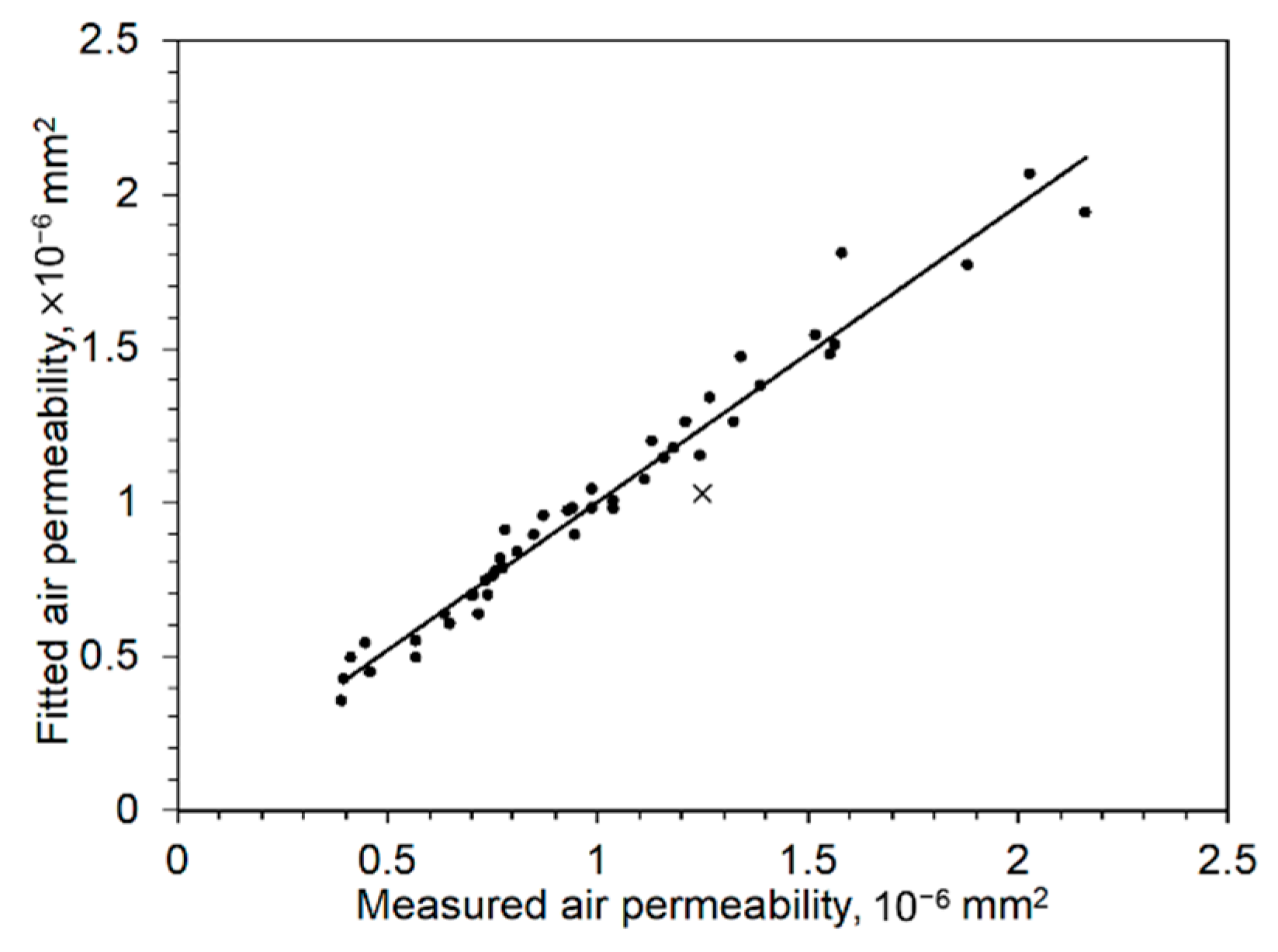

3.4. Empirical Expression of Permeability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davies, G.J.; Zhen, S. Review metallic foams: Their production, properties and application. J. Mater. Sci. 1993, 18, 1899–1911. [Google Scholar] [CrossRef]

- Mariotto, S.F.; Guido, V.; Cho, L.Y.; Soares, C.P.; Cardoso, K.R. Porous stainless steel for biomedical applications. Mater. Res. 2011, 14, 146–154. [Google Scholar] [CrossRef]

- Chen, H.; Han, Q.; Wang, C.; Liu, Y.; Chen, B.; Wang, J. Porous scaffold design for additive manufacturing in orthopedics: A review. Front. Bioeng. Biotechnol. 2020, 8, 609. [Google Scholar] [CrossRef]

- Pelanconi, M.; Barbato, M.; Zavattoni, S.; Vignoles, G.L.; Ortona, A. Thermal design, optimization and additive manufacturing of ceramic regular structures to maximize the radiative heat transfer. Mater. Des. 2019, 163, 107539. [Google Scholar] [CrossRef]

- Lu, T.J.; Stone, H.A.; Ashby, M.F. Heat transfer in open-cell metal foams. Acta Mater. 1998, 46, 3619–3635. [Google Scholar] [CrossRef]

- Paris, H.; Mokhtarian, H.; Coatanea, E.; Museau, M.; Ituarte, I.F. Comparative environmental impacts of additive and subtractive manufacturing technologies. CIRP Ann. Manuf. Tech. 2016, 65, 29–32. [Google Scholar] [CrossRef]

- Kuo, C.C.; Zhu, Y.J.; Wu, Y.Z.; You, Z.Y. Development and application of a large injection mold with conformal cooling channels. Intern. J. Adv. Manuf. Technol. 2019, 103, 689–701. [Google Scholar] [CrossRef]

- Klahn, C.; Bechmann, F.; Hofmann, S.; Dinkel, M.; Emmelmann, C. Laser additive manufacturing of gas permeable structures. Phys. Proc. 2013, 41, 873–880. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti-6Al-4V parts fabricated by selective laser melting and electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Chen, C.; Li, Y.; Zhang, M.; Wang, X.; Zhang, C.; Fing, H. Effect of laser processing parameters on mechanical properties of porous tantalum fabricated by laser multilayer microcladding. Rap. Prototyp. J. 2017, 23, 758–770. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Tucho, W.M.; Lysne, V.H.; Austbo, H.; Atle, S.K.; Hansen, V. Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L. J Alloys Comp. 2018, 740, 910–925. [Google Scholar] [CrossRef]

- Wu, T.; Tovar, A. Multiscale, Thermomechanical topology optimization of self-supporting cellular structures for porous injection molds. Rapid Prototyp. J. 2019, 25, 1482–1492. [Google Scholar] [CrossRef]

- Zhang, S.X.; Chandrasekaran, M.; Li, Q.F.; Ho, M.K.; Yong, M.S. Studies on the fabrication of tool steel components with micro-features by PIM. Intern. J. Adv. Manuf. Technol. 2008, 38, 278–284. [Google Scholar] [CrossRef]

- Banhart, J. Manufacture, characterization and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Zhao, L.; Ha, S.; Sharp, K.W.; Geltmacher, A.B.; Fonda, R.W.; Kinsey, A.H.; Zhang, Y.; Ryan, S.M.; Erdeniz, D.; Dunad, D.C.; et al. Permeability measurement and modeling of topology-optimised metallic 3-D woven lattices. Acta Mater. 2014, 81, 326–336. [Google Scholar] [CrossRef]

- Narahara, H.; Takeshita, S.; Fukumaru, H.; Koresawa, H.; Suzuki, H. Permeability performance on porous structure of injection mold fabricated by metal laser sintering combined with high-speed milling. Intern. J. Autom. Technol. 2012, 6, 576–583. [Google Scholar] [CrossRef]

- Dehgahi, S.; Sanjaria, M.; Ghoncheh, M.H.; Amirkhiz, B.S.; Mohammadi, M. Concurrent improvement of strength and ductility in heat-treated C300 maraging steels produced by laser powder bed fusion technique. Add. Manuf. 2021, 39, 101847. [Google Scholar]

- Hu, Z.; Bruno, N.; Mathew, B.; Gavin, T.; Hao, L.; Irene, T.; Yang, L. On modelling bio-scaffolds: Structural and fluid transport characterization based on 3-D imaging data. Tsinghua Sci. Technol. 2009, 14, 20–23. [Google Scholar] [CrossRef]

- Klucynski, J.; Sniezek, L.; Grzelak, K.; Mierzynski, J. The influence of exposure energy Density on porosity and microhardness of the SLM additive manufactured elements. Materials 2018, 11, 2304. [Google Scholar] [CrossRef]

- Becker, T.H.; Dimitrov, D. The achievable mechanical properties of SLM produced maraging steel 300 components. Rap. Prototyp. J. 2016, 22, 487–494. [Google Scholar] [CrossRef]

- Niu, Z.; Suzuki, H.; Ohtake, Y.; Michiawa, T. Mesh generation of porous metals from X-ray computed tomography volume data. J. Mech. Sci. Technol. 2014, 28, 2445–2451. [Google Scholar] [CrossRef]

- Habiby, F.; Haq, A.; Khan, A.Q. The properties and application of 18% nickel maraging steels. Mater. Technol. 1994, 9, 2429–2442. [Google Scholar] [CrossRef]

- Westhoff, D.; Skibinski, J.; Šedivý, O.; Wysocki, B. Investigation of the relationship between morphology and permeability for open-cell foams using virtual materials testing. Mater. Des. 2018, 147, 1–10. [Google Scholar] [CrossRef]

- Mahdavi, A.; Balaji, R.; Frecker, M.; Mockenstrum, E.M. Topology optimization of 2D continua for minimum compliance using parallel computing. Struct. Multidiscip. Opt. 2006, 32, 121–132. [Google Scholar] [CrossRef]

- Jafari, D.; Wits, W.W.; Vanekar, T.H.J.; Demir, A.G.; Previtali, B.; Geurts, B.J.; Gibson, I. Pulsed mode selective laser melting of porous structures: Structural and thermo physical characterization. Add. Manuf. 2020, 35, 101263. [Google Scholar]

- Kumar, P.; Topin, F. Investigation of fluid flow properties in open cell foams: Darcy and weak inertia regimes. Chem. Eng. Sci. 2014, 116, 793–805. [Google Scholar] [CrossRef]

- Dallago, M.; Zanini, F.; Carmingnato, S.; Pasini, D.; Beneditti, M. Effect of the geometrical defectiveness on the mechanical properties of SLM biomedical Ti6Al4V lattices. Procedia Struct. Integr. 2018, 13, 161–167. [Google Scholar] [CrossRef]

- Suard, M.; Martin, G.; Lhuissier, P.; Dendievel, R.; Vignat, F.; Blandin, J.J.; Villeneuve, F. Mechanical equivalent diameter of single struts for the stiffness prediction of lattice structures produced by electron beam melting. Add. Manuf. 2015, 8, 124–131. [Google Scholar] [CrossRef]

- Yasa, E.; Kempen, K.; Kruth, J.P. Microstructure and mechanical properties of maraging steel 300 after selective laser melting. In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference (SFF 2010), Austin, TX, USA, 9–11 August 2010; pp. 383–396. [Google Scholar]

- Hommel, J.; Coltman, E.; Class, H. Porosity-permeability relations for evolving pore space: A review with a focus on (bio-)geochemically altered porous media. Transp. Porous Med. 2018, 124, 589–629. [Google Scholar] [CrossRef]

- Dukhan, N.; Minjeur, C.A., II. A two-permeability approach for assessing flow properties in metal foam. J. Porous Mater. 2011, 18, 417–424. [Google Scholar] [CrossRef]

- Chan, A.K.T.; Pelton, R.H.; Zhu, S.; Baird, M.H.I. The effects of polystyrene beads and nylon fibres on the permeability of compressed wood fibre and pads. Can. J. Chem. Eng. 1996, 74, 229–235. [Google Scholar] [CrossRef]

- Sabet, S.; Barisik, M.; Mobedi, M.; Beskok, A. An extended Kozeny-Carman-Klinkenberg model or gas permeability in micro/nano-porous media. Phys. Fluids 2019, 31, 112001. [Google Scholar] [CrossRef]

| C | Ni | Co | Mo | Ti | Al | Mn | Si | Fe |

|---|---|---|---|---|---|---|---|---|

| <0.03 | 17–19 | 8.5–9.5 | 4.2–5.2 | 0.6–0.8 | 0.05–0.15 | <0.1 | <0.1 | balance |

| Sample | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 |

|---|---|---|---|---|---|---|---|---|---|

| Hatch distance (mm) | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.55 | 0.6 | 0.7 | 0.75 |

| Energy density (J/mm3) | 21.7 | 18.6 | 16.2 | 14.4 | 13.1 | 11.8 | 10.8 | 9.3 | 8.6 |

| Porosity (%) | 21.5 | 22.3 | 26.6 | 29.3 | 36.2 | 38.3 | 39.9 | 44.9 | 49.5 |

| Projected area fraction of pores (%) | 25.9 | 28.6 | 38.1 | 41.5 | 45.4 | 49.6 | 54.2 | 56.5 | 57.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhinakar, A.; Li, B.-E.; Chang, Y.-C.; Chiu, K.-C.; Chen, J.-K. Air Permeability of Maraging Steel Cellular Parts Made by Selective Laser Melting. Materials 2021, 14, 3118. https://doi.org/10.3390/ma14113118

Dhinakar A, Li B-E, Chang Y-C, Chiu K-C, Chen J-K. Air Permeability of Maraging Steel Cellular Parts Made by Selective Laser Melting. Materials. 2021; 14(11):3118. https://doi.org/10.3390/ma14113118

Chicago/Turabian StyleDhinakar, Annadurai, Bai-En Li, Yo-Cheng Chang, Kuo-Chi Chiu, and Jhewn-Kuang Chen. 2021. "Air Permeability of Maraging Steel Cellular Parts Made by Selective Laser Melting" Materials 14, no. 11: 3118. https://doi.org/10.3390/ma14113118

APA StyleDhinakar, A., Li, B.-E., Chang, Y.-C., Chiu, K.-C., & Chen, J.-K. (2021). Air Permeability of Maraging Steel Cellular Parts Made by Selective Laser Melting. Materials, 14(11), 3118. https://doi.org/10.3390/ma14113118