Test and Numerical Simulation Investigation on Seismic Performance of Different Types of Expansive Polystyrene Granule Cement Latticed Concrete Walls

Abstract

1. Introduction

2. Materials and Methods

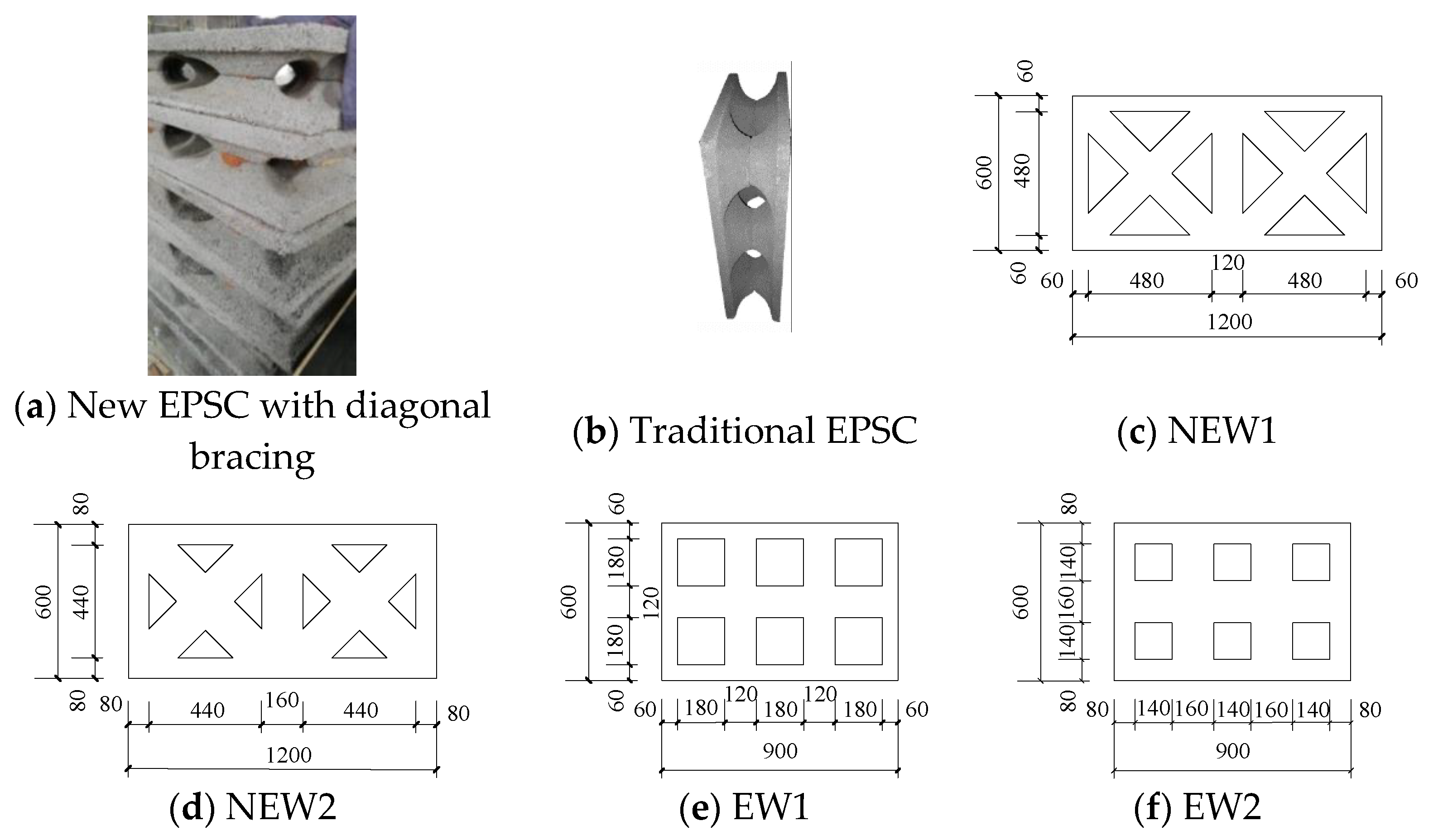

2.1. Design and Materials of Test Specimens

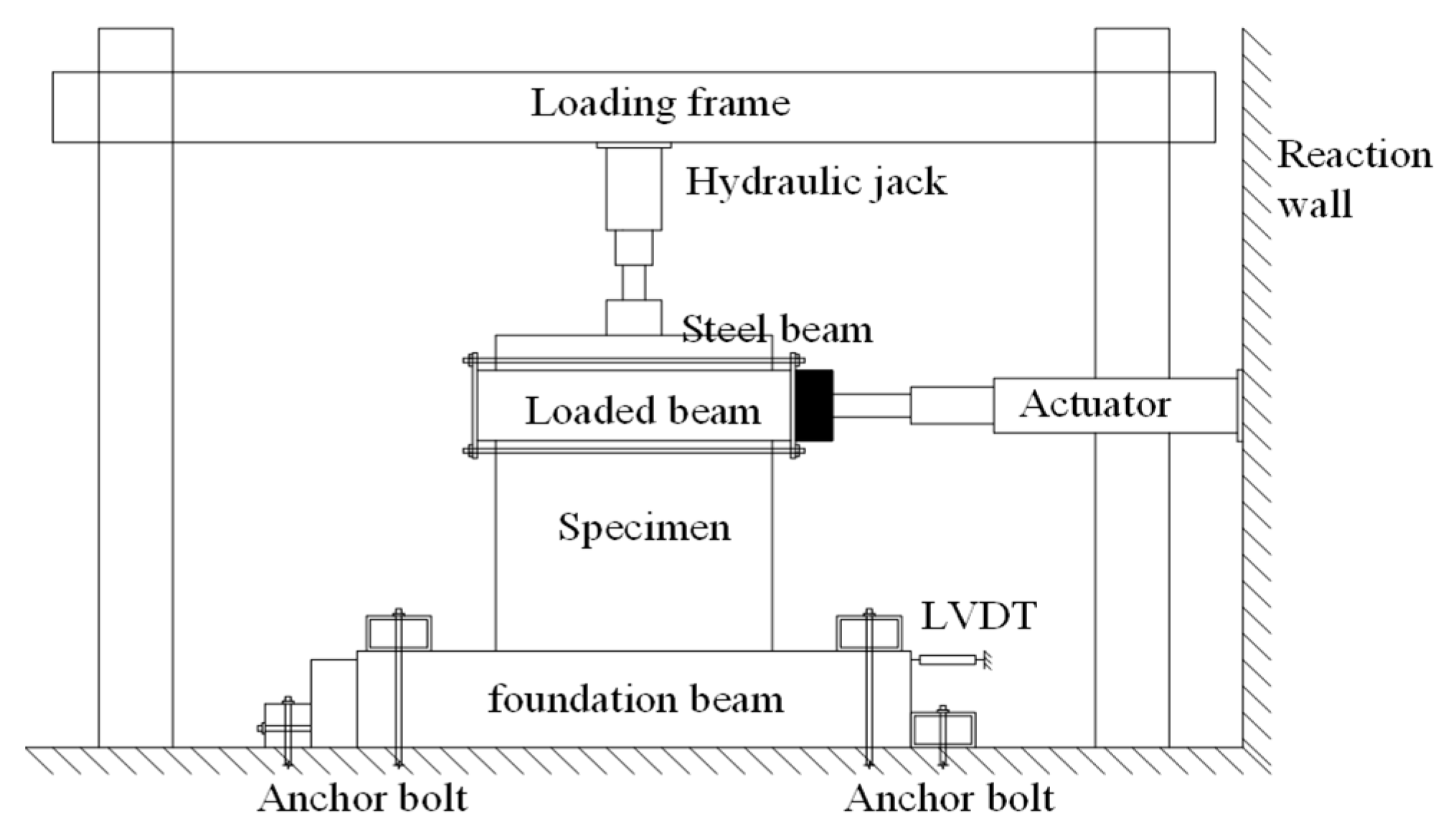

2.2. Test Setup

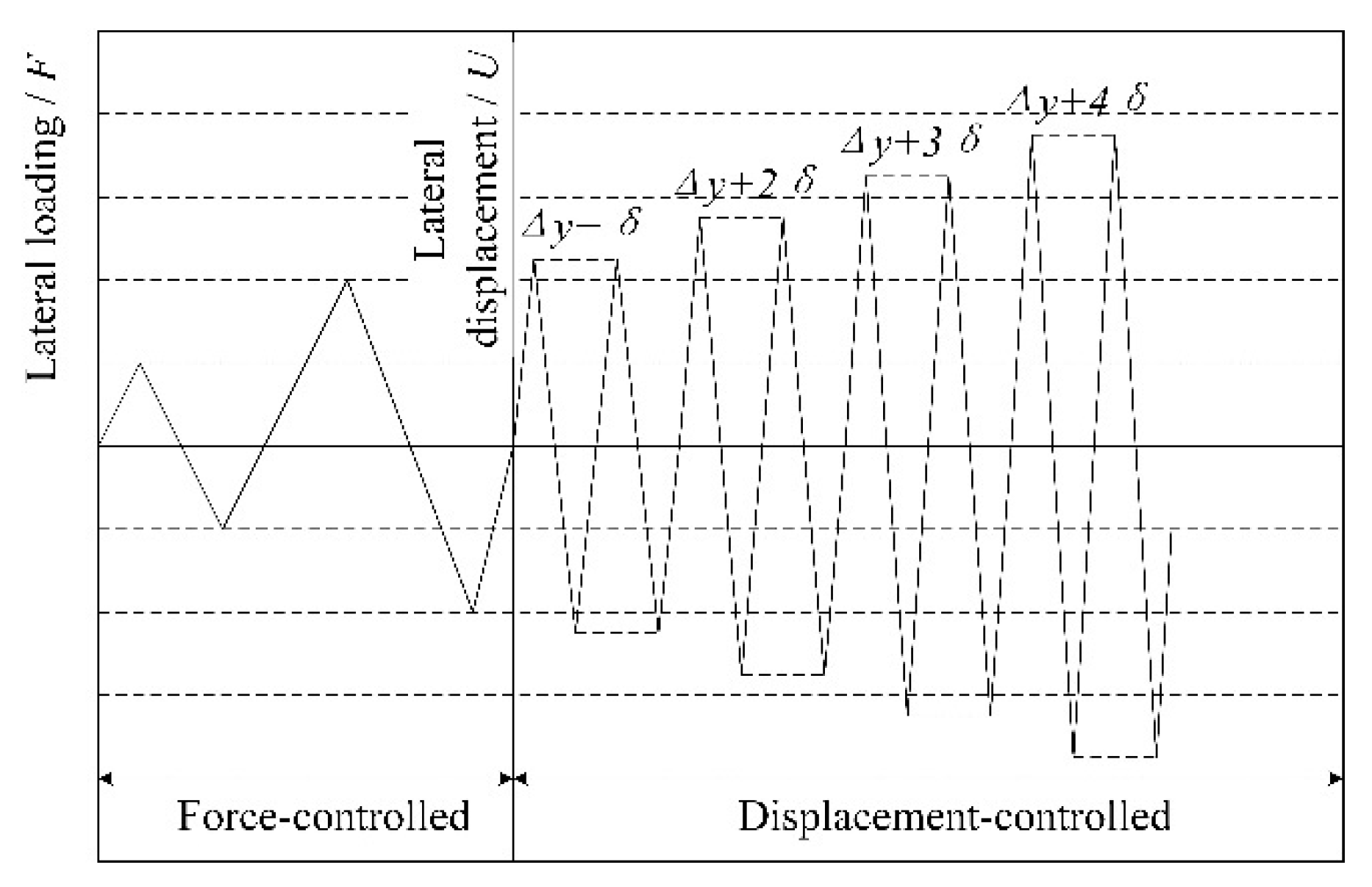

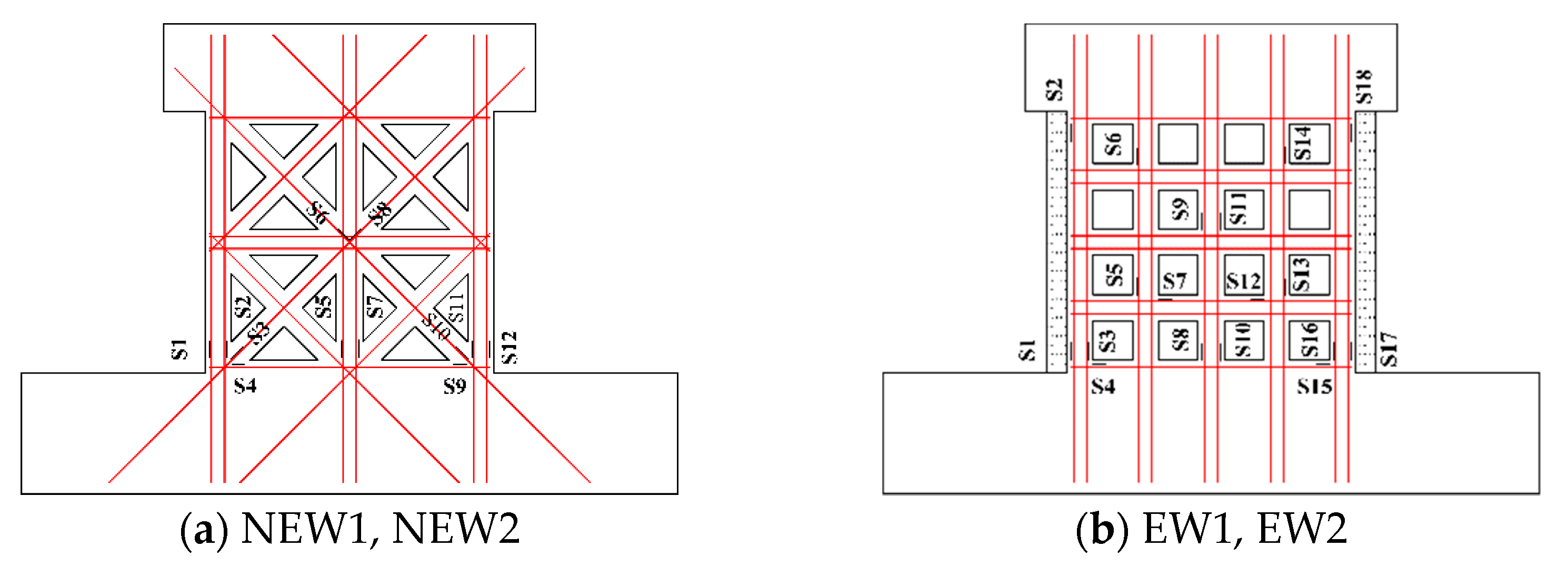

2.3. Test Program and Instrumentation

3. Results and Discussion

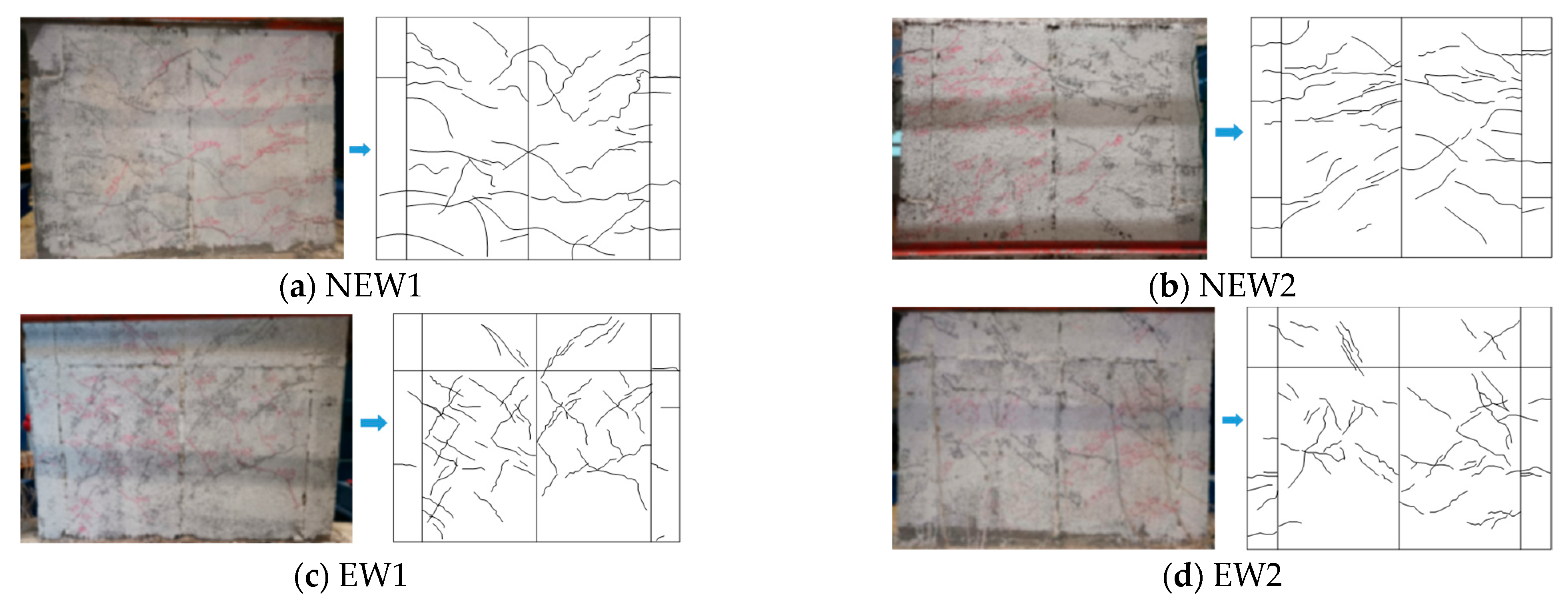

3.1. Failure Mode and Crack Distribution

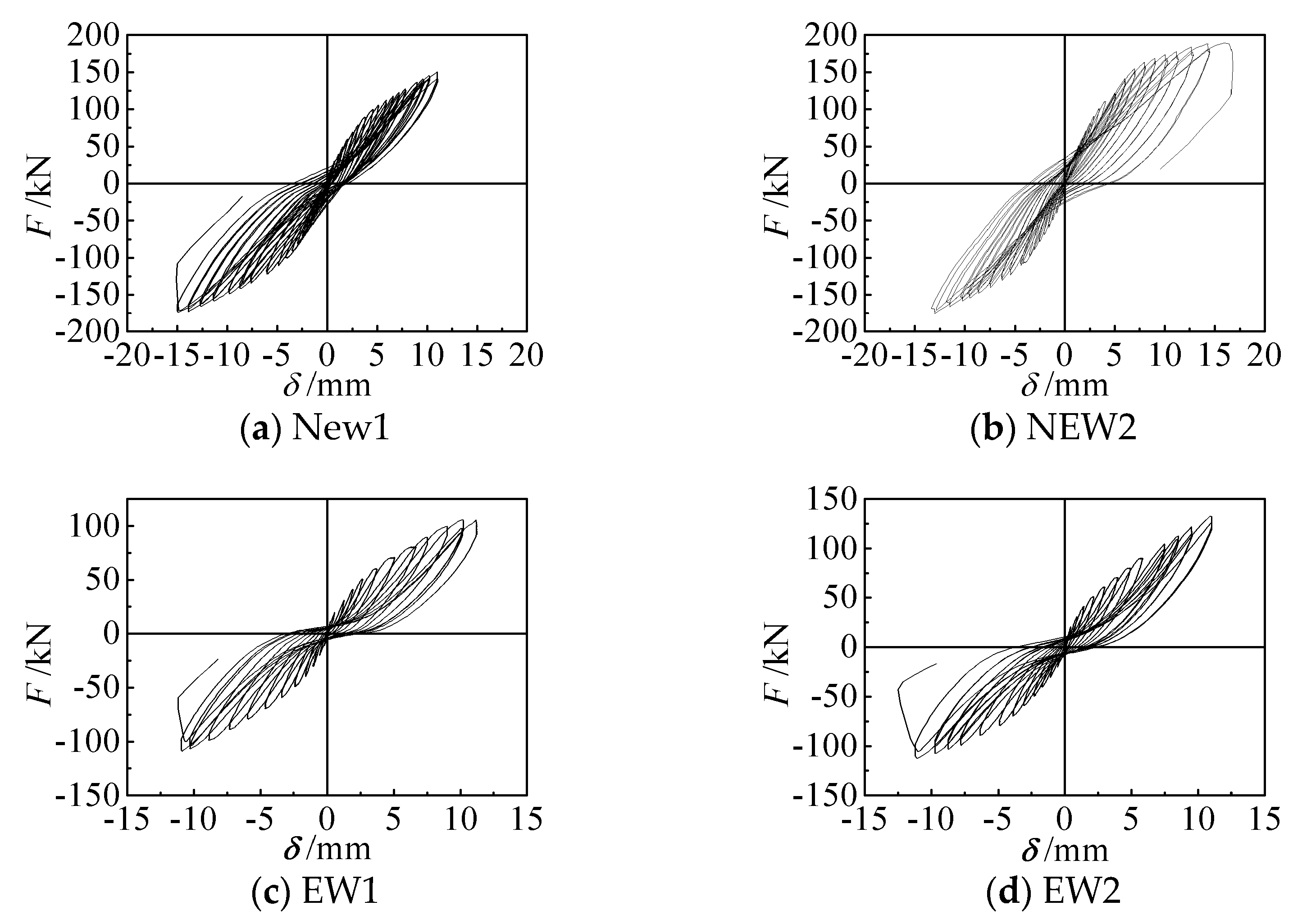

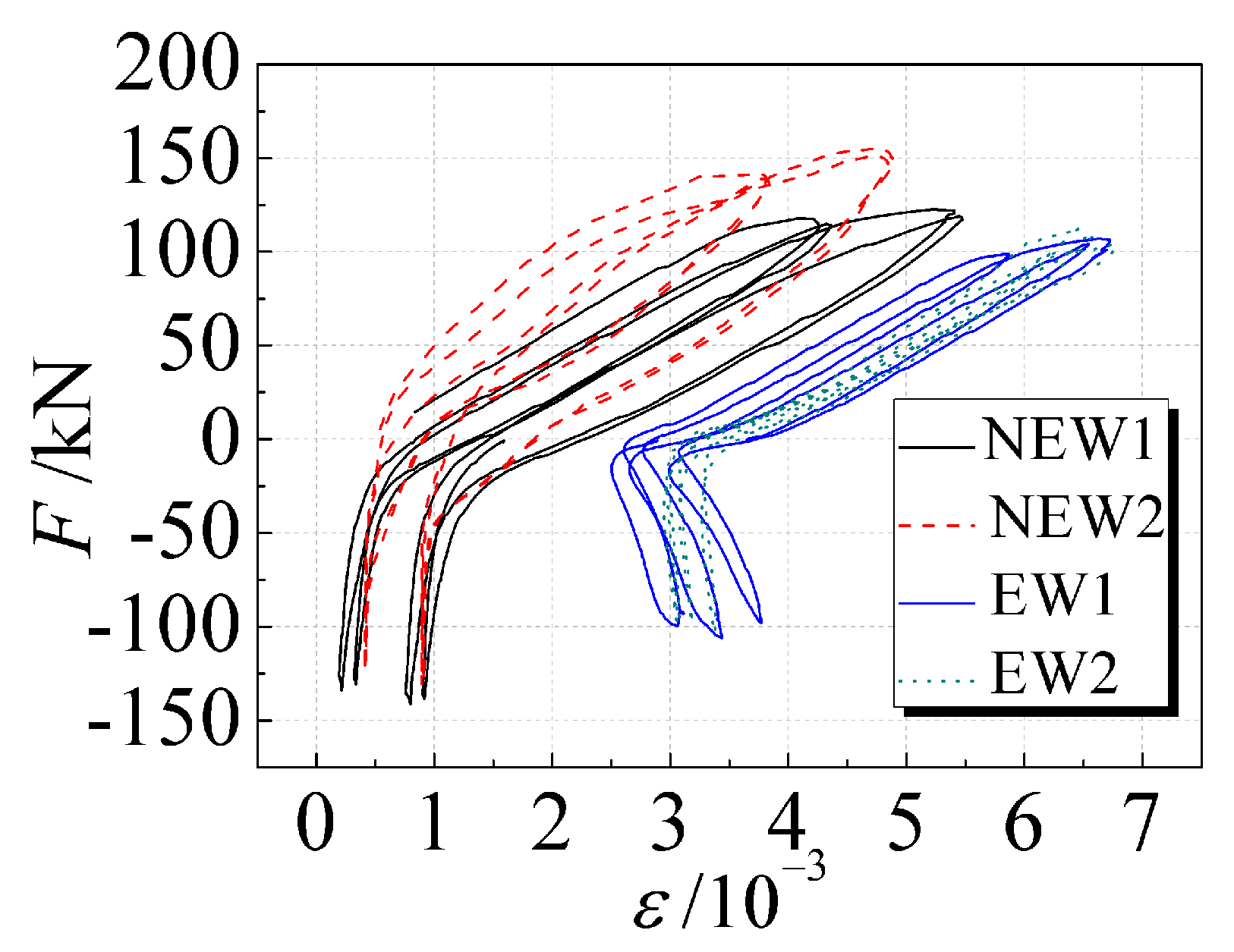

3.2. Hysteretic Response

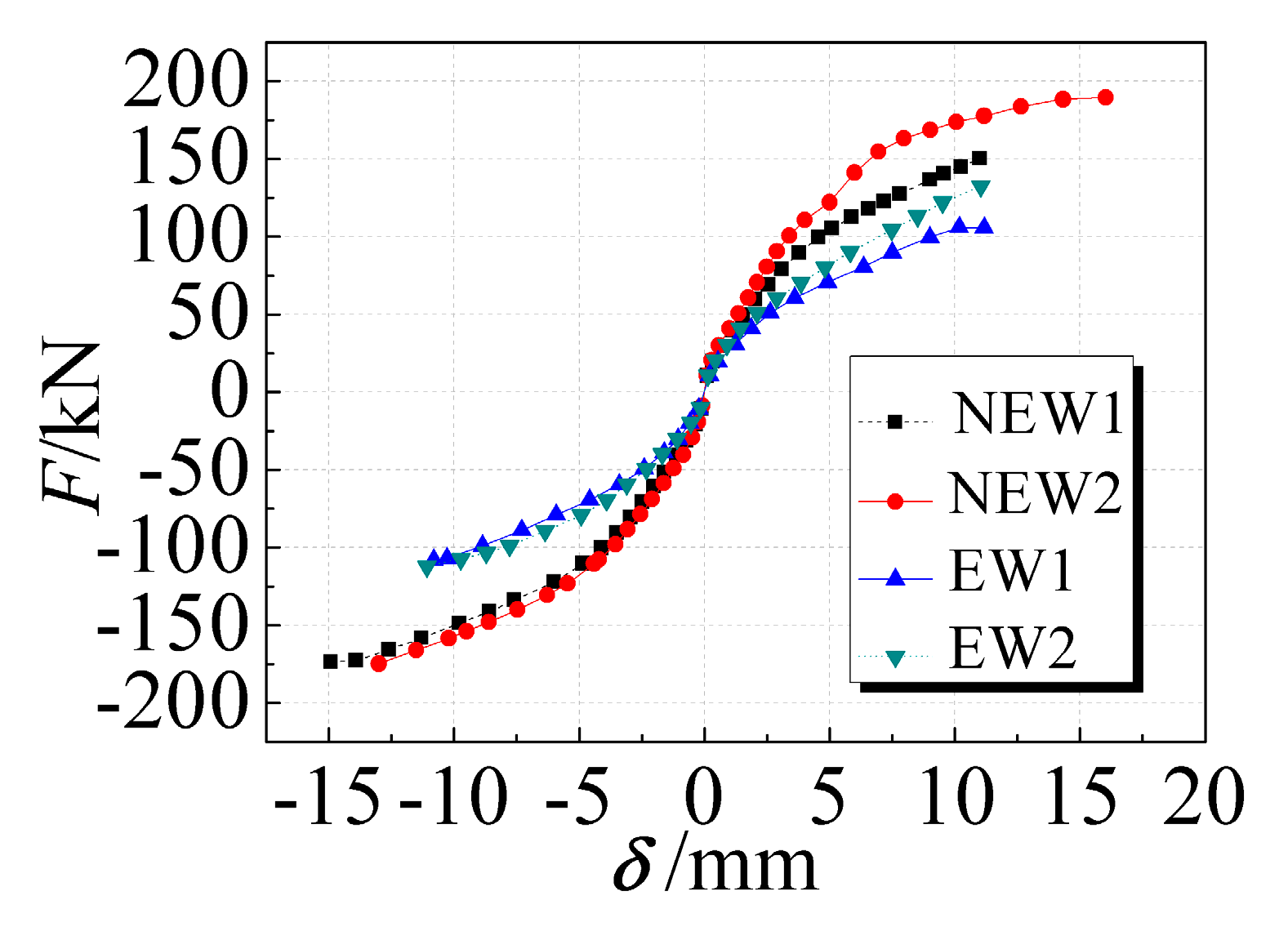

3.3. Skeleton Curves

3.4. Deformability

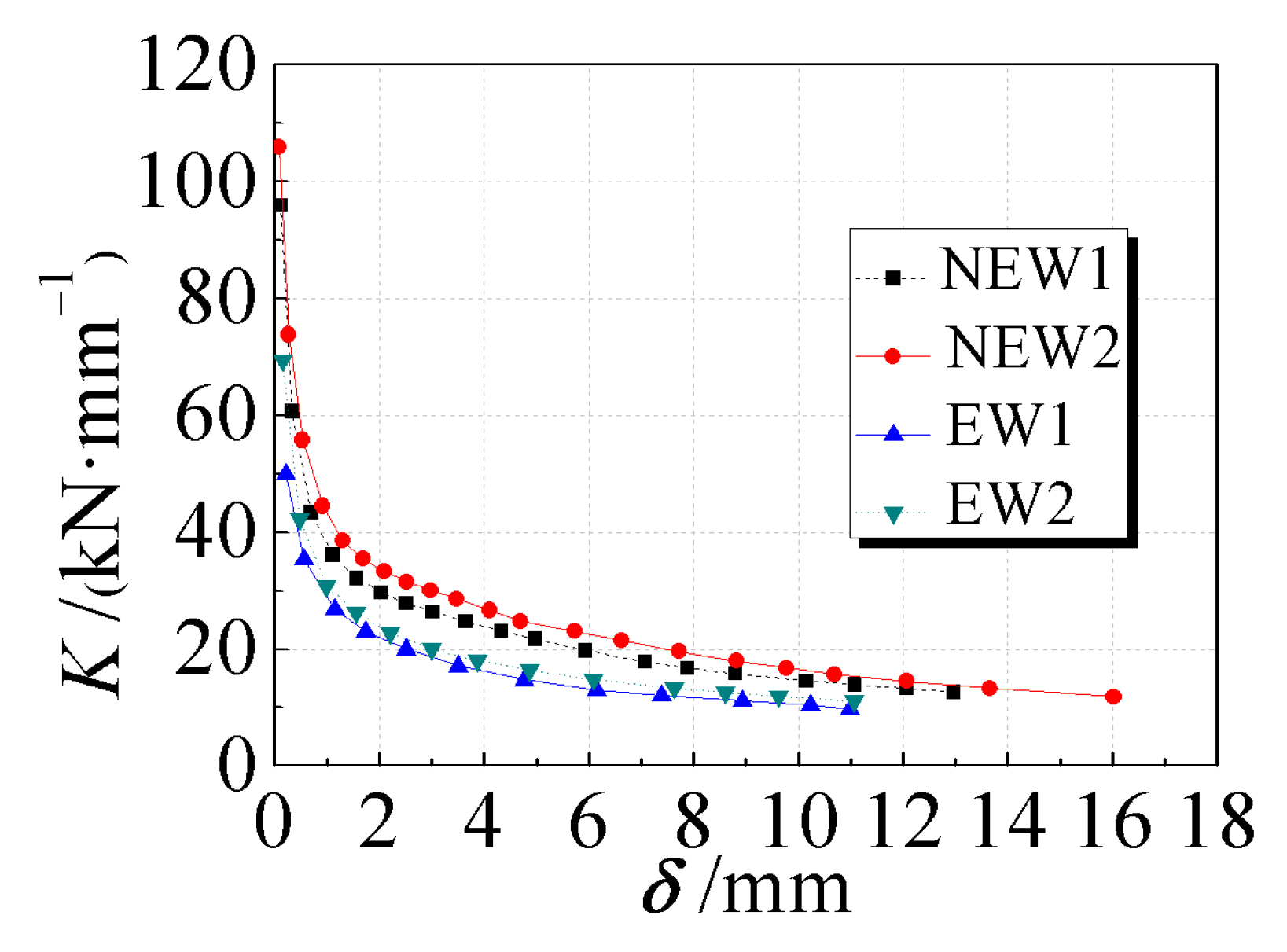

3.5. Stiffness Degradation

3.6. Energy Dissipation Capacity

3.7. Reinforcement Strain

4. Numerical Simulations

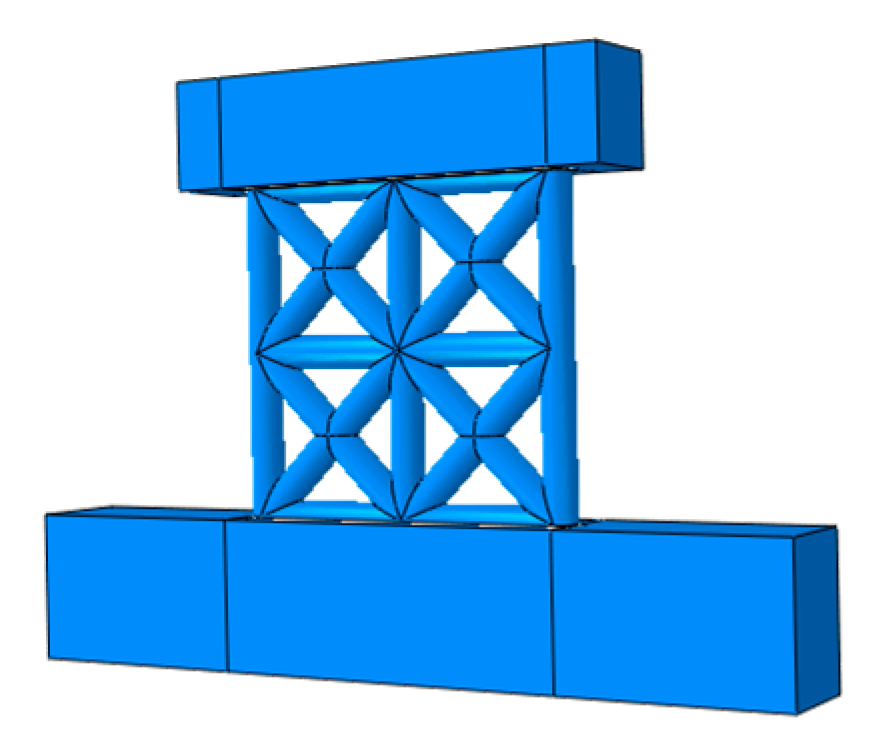

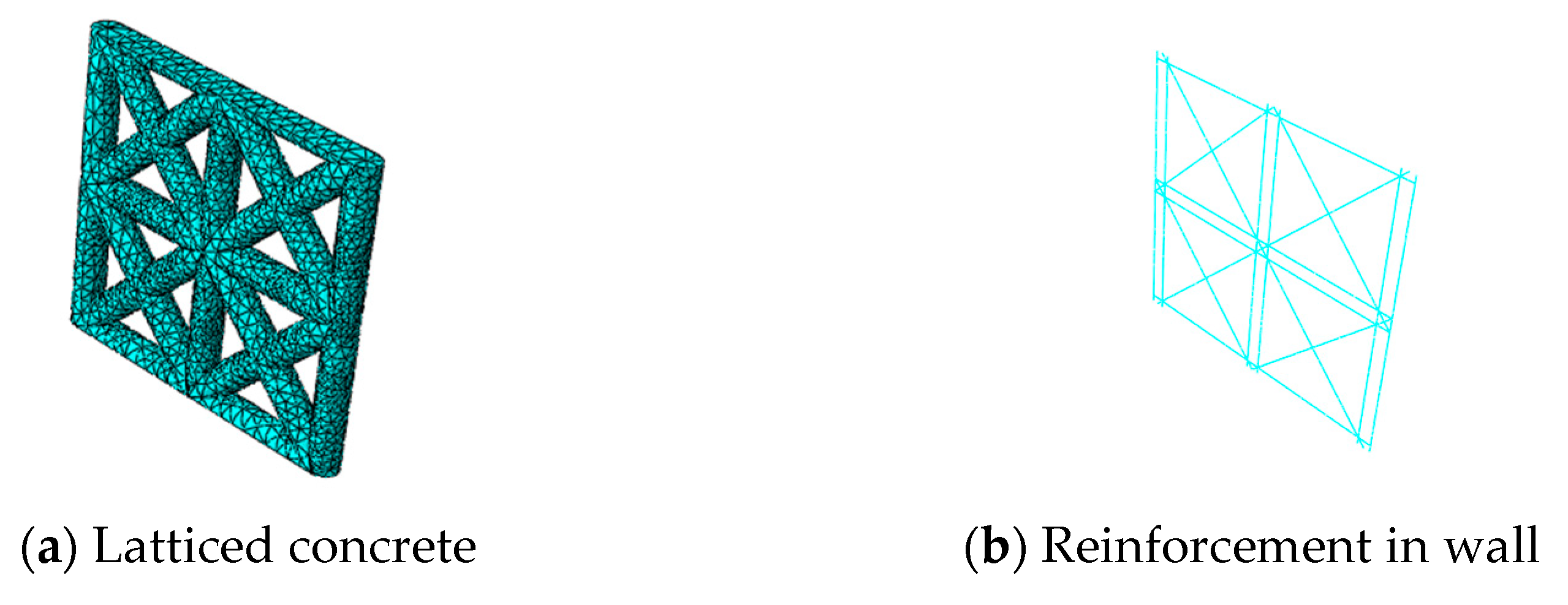

4.1. Numerical Model

4.2. Simulation Results and Comparative Analysis

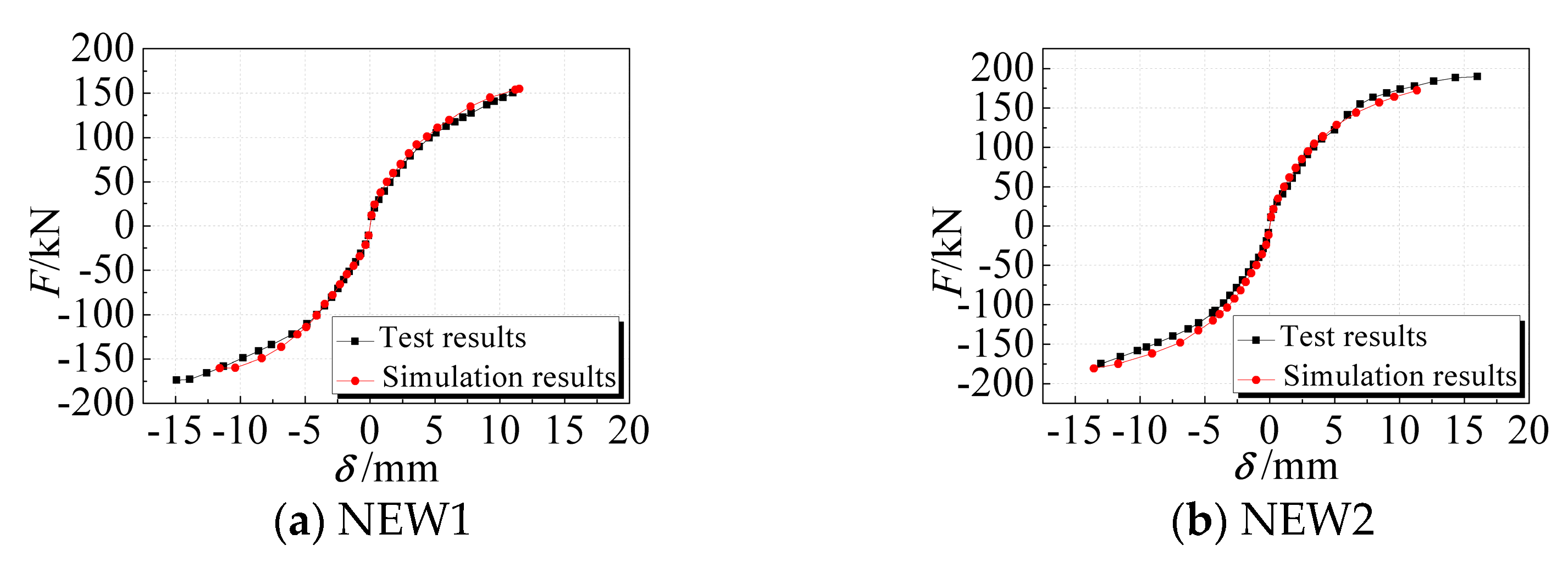

4.2.1. Skeleton Curve

4.2.2. Mises Stress

5. Conclusions

- (1)

- In the traditional EPSC latticed concrete wall, the horizontal lattice beam and the vertical lattice column were coordinated to bear the force. After adding diagonal bracing, the wall became a new type of EPSC latticed concrete wall with diagonal bracing. The horizontal lattice beams, vertical lattice columns, and diagonal ribs were coordinated to bear the force, and the compression resistance of the concrete could be fully utilized in the new type wall with diagonal bracing.

- (2)

- The four specimens (traditional type and new type with diagonal bracing) all showed shear failure mode. For the traditional specimens, the wall cracks were relatively short and dense, especially for specimen EW1, and the distribution of “X”-shaped cracks was extremely regular. With the addition of diagonal bracing, the cracking and damage process of the composite wall was slowed down.

- (3)

- Compared with the traditional specimens, the new specimens with diagonal bracing had different degrees of improvement of the bearing capacity, elastoplastic deformation capacity, initial stiffness, and energy dissipation capacity. Initial stiffness and cumulative energy consumption were improved more than 52% and 180%, respectively. In the case of the nearly same amount of concrete, the bearing capacity of the new specimens increased by more than 12%. This indicated that the addition of diagonal bracing could improve the seismic performance of the latticed concrete composite wall.

- (4)

- Different lattice types and core hole diameters had different effects on the seismic performance of the EPSC latticed concrete walls. As the core hole diameter increased 20 mm, the bearing capacity and initial stiffness were improved more than 12% and 10%, respectively. For the same lattice type, the reinforcement was the same, and the increase in the core hole diameter led to a decrease in the reinforcement ratio of the specimen with a larger core hole diameter. The combined effect of the lattice type and the reinforcement ratio might have led to different degrees of improvement in the seismic performance of the composite wall. The study of the change in the core hole diameter could provide a basis for the definition of the use range of walls with different thicknesses in actual projects.

- (5)

- The addition of diagonal bracing could delay the strain development process of the vertical reinforcement at the bottom of the lattice side columns. The numerical simulation results obtained with the simplified modeling method were in good agreement with the experimental results, which indicated that the simplified modeling method is suitable for analyzing the seismic performance of the EPSC latticed concrete wall, and provides useful insights for subsequent parametric research on latticed concrete walls.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, L.H.; Fan, Y.Z.; Xu, M.L.; Sun, C.W. A decomposition analysis of embodied energy consumption in China’s construction industry. Sustainability 2017, 9, 1583. [Google Scholar] [CrossRef]

- Zhou, D.Q.; Zhang, L.; Zha, D.L.; Wu, F.; Wang, Q.W. Decoupling and decomposing analysis of construction industry’s energy consumption in China. Nat. Hazards 2019, 95, 39–53. [Google Scholar] [CrossRef]

- Liu, B.; Wang, D.D.; Xu, Y.Q.; Liu, C.L.; Luther, M. Vertical specialisation measurement of energy embodied in international trade of the construction industry. Energy 2018, 165, 689–700. [Google Scholar] [CrossRef]

- Hong, J.K.; Shen, G.Q.; Guo, S.; Xue, F.; Zheng, W. Energy use embodied in China’s construction industry: A multi-regional input–output analysis. Renew. Sustain. Energy Rev. 2016, 53, 1303–1312. [Google Scholar] [CrossRef]

- Liu, B.; Wang, D.D.; Xu, Y.Q.; Liu, C.L.; Luther, M. Embodied energy consumption of the construction industry and its international trade using multi-regional input–output analysis. Energy Build 2018, 173, 489–501. [Google Scholar] [CrossRef]

- Hong, J.K.; Shen, Q.P.; Xue, F. A multi-regional structural path analysis of the energy supply chain in China’s construction industry. Energy Policy 2016, 92, 56–68. [Google Scholar] [CrossRef]

- Zhang, X.H.; Zhang, E.Y.; Xu, M.; Wang, R.C. Anti-seismic Experimental Study on Composite Wall with One-Sided Cladding of Strawboard. J. Build Mater. 2019, 22, 908–916. [Google Scholar]

- Lai, X.D.; Lu, C.; Liu, J.X. A synthesized factor analysis on energy consumption, economy growth, and carbon emission of construction industry in China. Environ. Sci. Pollut. Res. 2019, 26, 13896–13905. [Google Scholar] [CrossRef] [PubMed]

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Hao, Y.; Zhao, J.B. A Research on Green and Energy-saving Architectural Strategies of the Zero Carbon Living ZedPavilion at 2010 Shanghai Expo; Destech Publicat Inc: Shenzhen, China, 2015; pp. 4116–4120. [Google Scholar]

- Dominguez-Santos, D.; Mora-Melia, D.; Pincheira-Orellana, G.; Ballesteros-Pérez, P.; Retamal-Bravo, C. Mechanical properties and seismic performance of wood-concrete composite blocks for building construction. Materials 2019, 12, 1500. [Google Scholar] [CrossRef]

- Choi, I.; Kim, J.H.; You, Y.-C. Effect of cyclic loading on composite behavior of insulated concrete sandwich wall panels with GFRP shear connectors. Compos. Part B Eng. 2016, 96, 7–19. [Google Scholar] [CrossRef]

- Kim, J.H.; You, Y.-C. Composite Behavior of a Novel Insulated Concrete Sandwich Wall Panel Reinforced with GFRP Shear Grids: Effects of Insulation Types. Materials 2015, 8, 899–913. [Google Scholar] [CrossRef]

- Liu, J.J.; Wang, C.K.; Xiao, C.Z.; Zhang, L.C.; Zhi, H.L.; Wang, W.X.; Zhang, H.B. Study on Seismic Performance of EPSC Form Latticed Concrete Wall with Testing Method. Build Struct 2006, 36 (Suppl. S1), 46–50. [Google Scholar]

- State Council of the PRC. 13th Five-Year Plan for Comprehensive Work Plan for Energy Conservation and Emission Reduction. China Build Mater. 2017, 3, 42–53. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the PRC. “Basic Safety Technical Guidelines for the Reconstruction of Rural Dangerous Houses” issued. Constr. Wall Innov. Build Energy Sav. 2018, 6, 69. [Google Scholar]

- Fu, X.D.; Ma, F.; Ma, Y.Z. Experimental Study of Lattice Composing Shear Walls on Seismic Performance. J. Tianjin Univ. 2000, 03, 336–340. [Google Scholar]

- Lu, Y.Q.; Hu, L.; Ma, K.J.; Zhang, H.G. Test research on the wall of new type RC grid frame structure. Hunan Univ. (Nat. Sci.) 2013, 40, 8–14. [Google Scholar]

- Ma, S.C.; Jiang, N. Seismic Experimental Study on New-Type Composite Exterior Wallboard with Integrated Structural Function and Insulation. Materials 2015, 8, 3732–3753. [Google Scholar] [CrossRef]

- Jiang, N.; Liang, Z. Restoring Force Model of New Type Gypsum-Concrete Composite Exterior Wallboard. J. Tianjin Univ. Sci. Technol. 2018, 51, 977–987. [Google Scholar]

- Wang, Q.; Qian, J.R.; Ma, B.M.; Hu, Q.C.; Feng, B.C. Experimental study on seismic behavior of concrete grillage walls. J. Build Struct 2004, 04, 15–25. [Google Scholar]

- Sun, J.C.; Qian, J.R.; Fang, E.H.; Hu, Q.C.; Femg, B.C. Experimental study on seismic behavior of concrete grill wall with small shear span ratio. J. Build. Struct. 2002, 02, 19–26. [Google Scholar]

- Zhang, W.J.; Du, Y.N.; Kang, H.A.; Qian, J.R.; Feng, B.C. Experimental study on seismic behavior of large grid size RC shear walls. J. Build. Struct. 2011, 32, 116–124. [Google Scholar]

- Zhao, X.Y. Study on Energy Conservation, R.C. Grid Frame Structure with Insulating Form. Ph.D. Thesis, TianJin University, Tianjing, China, 2010. (In Chinese). [Google Scholar]

- Han, W.L.; Qian, J.R.; Zhang, W.J.; Zhao, Z.Z.; Zhang, B.Y.; Ma, T.; Zhang, Y.Z. Experimental study on seismic behavior of precast concrete hollow shear walls. J. Build. Struct. 2020, 41, 32–41. [Google Scholar]

- Dusicka, P.; Kay, T. In-Plane Lateral Cyclic Behavior of Insulated Concrete Form Grid Walls. J Struct Eng 2011, 137, 1075–1084. [Google Scholar] [CrossRef]

- Asadi, P.; Madandoust, R.; Zahrai, S. Mehd. Response modification factor due to ductility of screen-grid ICF wall system in high seismic risk zones. KSCE J. Civ. Eng. 2017, 21, 258–264. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Cao, W.L.; Zhang, Y.B. Study on seismic performance of low-rise shear wall with thermal insulation blocks of single-row steel reinforcement and L-shaped frame. China Civ. Eng. J. 2016, 49, 35–44. [Google Scholar]

- Cao, W.L.; Cheng, J.; Zhang, Y.B.; Dong, H.Y. Experiment of seismic behavior of low-rise recycled aggregate concrete shear wall with insulation blocks and single layer of reinforcement. J. Build. Struct. 2015, 36, 51–58. [Google Scholar]

- Zhang, Y.B.; Cao, W.L.; Zhou, Z.Y.; Dong, H.Y.; Cheng, J. Experimental study on seismic behavior of mid-rise recycled aggregate concrete shear wall with insulation blocks. J. Build. Struct. 2015, 36, 29–36. [Google Scholar]

- Cao, Q.K.; Zhang, J.X.; Bao, Y.Y. Experimental on shear resistance of EPSC lattice concrete wall. J. Liaoning Tech. Univ. 2019, 38, 530–535. [Google Scholar]

- Tang, B.Z.; Xiong, L.H.; Li, X.J.; Chen, S.; Chen, H.P.; Huang, D.W. Experimental study on seismic behavior of full-scale reinforced concrete frame with EPSC latticed concrete infill wall. J. Build. Struct. 2020, 41, 13–23. [Google Scholar]

- Tang, B.Z.; Chen, S.; Li, X.J.; Xiong, L.H.; Chen, H.P.; Feng, Q.S. Seismic performance of RC frames with EPSC latticed concrete infill walls. Eng. Struct. 2019, 197, 109437. [Google Scholar] [CrossRef]

- Tang, B.Z.; Li, X.J.; Chen, S.; Xiong, L.H. Shaking Table Test of a RC Frame with EPSC Latticed Concrete Infill Wall. Shock Vib. 2017, 2017, 1–18. [Google Scholar] [CrossRef]

- GB-T 50081-2019. Standard for Test Methods of Concrete Physical and Mechanical Properties; China Architecture & Build Press: Beijing, China, 2019. [Google Scholar]

- JGJ/T 101—2015. Specification for Seismic Test of Buildings; China Architecture & Build Press: Beijing, China, 2015. [Google Scholar]

- Guo, Z.H. Principles of Reinforced Concrete; Butterworth-Heinnemann: Oxford, UK, 2014; p. 415. [Google Scholar]

- ABAQUS. Analysis User’s Manual; Dassault Systems Simulia Corp: Providence, RI, USA, 2014. [Google Scholar]

- GB50010-2010. Code for Design of Concrete Structures (2015); China Architecture & Build Press: Beijing, China, 2010. [Google Scholar]

- Lee, J.; Fenves, G.L. A plastic-damage concrete model for earthquake analysis of dams. Earthq. Eng. Struct. Dyn. 1998, 27, 937–956. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-damage model for cyclic loading of concrete structures. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- Shakeel, S.; Fiorino, L.; Landolfo, R. Numerical modelling of lightweight steel drywall partitions for in-plane seismic performance evaluations. Ing. Sismica 2020, 37, 64–83. [Google Scholar]

- Ahmadi, H.M.; De Matteis, G. Seismic performance of steel shear panels with butterfly-shaped links. Ing. Sismica 2020, 37, 84–101. [Google Scholar]

| Apparent Density/(kg/m3) | Thermal Conductivity /(W·m−1·K−1) | Compressive Strength/MPa | Splitting Tensile Strength/MPa | Fire Resistance/h |

|---|---|---|---|---|

| ≤380 | ≤0.08 | ≥0.40 | ≥0.10 | ≥3 |

| Specimen | Dimension (Height × Width × Thickness)/mm | Core Hole Diameter/mm | Reinforcement | Reinforcement Ratio (%) | Cube Compressive Strength of Concrete fcu/MPa | Latticed Form | ||

|---|---|---|---|---|---|---|---|---|

| Latticed Beams, Columns | Diagonal Bracing | Latticed Beams, Columns | Diagonal Bracing | |||||

| NEW1 | 1200 × 1500 × 210 | 120 | 2B8 | 1B8 | 0.890 | 0.445 | 20.8 | New type with diagonal bracing |

| NEW2 | 1200 × 1500 × 250 | 160 | 0.500 | 0.250 | ||||

| EW1 | 1200 × 1500 × 210 | 120 | — | 0.890 | — | Traditional type | ||

| EW2 | 1200 × 1500 × 250 | 160 | 0.500 | |||||

| Specimen | Crack Width at Peak Load/mm |

|---|---|

| NEW1 | 5 |

| NEW2 | 6 |

| EW1 | 5 |

| EW2 | 6 |

| Specimen | Cracking Point | Yield Point | Yield Point | ||||

|---|---|---|---|---|---|---|---|

| Fcr/kN | Fy/kN | Average Value of Fy/kN | Relative Value of Fy | Fu/kN | Average Value of Fu/kN | Relative Value of Fu | |

| NEW1 | +49.34 | +100.90 | 108.05 | 1.000 | +150.33 | 162.00 | 1.000 |

| −115.20 | −173.66 | ||||||

| NEW2 | +40.89 | +128.98 | 120.74 | 1.117 | +189.58 | 182.21 | 1.125 |

| −112.50 | −174.84 | ||||||

| EW1 | +30.70 | +71.17 | 71.59 | 1.000 | +106.11 | 107.06 | 1.000 |

| −72.01 | −108.00 | ||||||

| EW2 | +40.85 | +84.50 | 81.25 | 1.135 | +132.46 | 122.38 | 1.143 |

| −78.00 | −112.30 | ||||||

| Specimen | δy/mm | Relative Value of δy | δu/mm | Relative Value of δu | μ | Relative Value of μ |

|---|---|---|---|---|---|---|

| NEW1 | 5.08 | 1.000 | 12.96 | 1.000 | 2.55 | 1.000 |

| NEW2 | 5.12 | 1.008 | 14.51 | 1.120 | 2.83 | 1.110 |

| EW1 | 4.99 | 1.000 | 10.99 | 1.000 | 2.20 | 1.000 |

| EW2 | 5.01 | 1.004 | 11.06 | 1.006 | 2.21 | 1.005 |

| Specimen | Cumulative Energy Dissipation E/(kN·mm) | Relative Value of Cumulative Energy Dissipation |

|---|---|---|

| NEW1 | 23,282 | 1.000 |

| NEW2 | 25,848 | 1.110 |

| EW1 | 7923 | 1.000 |

| EW2 | 9030 | 1.140 |

| Material Parameters | Wall Concrete | Wall Reinforcement | Material Parameters | Wall Concrete |

|---|---|---|---|---|

| Elastic modulus E (GPa) | 26.00 | 200 | Initial yield compressive stress σco (MPa) | 8.60 |

| Poisson’s ratio υ | 0.20 | 0.3 | Compression variable ωc | 1.00 |

| Density ρ (kg/m3) | 2500 | 7800 | Stretch variable ωt | 0.00 |

| Divergence angle ψ (°) | 30 | Damping ratio ξ | 0.05 |

| Specimen | VE (kN) | VN (kN) | VE/VN |

|---|---|---|---|

| NEW1 | 162.00 | 157.50 | 1.02 |

| NEW2 | 182.21 | 176.45 | 1.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, X.; Li, X.; Tang, B. Test and Numerical Simulation Investigation on Seismic Performance of Different Types of Expansive Polystyrene Granule Cement Latticed Concrete Walls. Materials 2021, 14, 3082. https://doi.org/10.3390/ma14113082

Cao X, Li X, Tang B. Test and Numerical Simulation Investigation on Seismic Performance of Different Types of Expansive Polystyrene Granule Cement Latticed Concrete Walls. Materials. 2021; 14(11):3082. https://doi.org/10.3390/ma14113082

Chicago/Turabian StyleCao, Xinyu, Xiaojun Li, and Baizan Tang. 2021. "Test and Numerical Simulation Investigation on Seismic Performance of Different Types of Expansive Polystyrene Granule Cement Latticed Concrete Walls" Materials 14, no. 11: 3082. https://doi.org/10.3390/ma14113082

APA StyleCao, X., Li, X., & Tang, B. (2021). Test and Numerical Simulation Investigation on Seismic Performance of Different Types of Expansive Polystyrene Granule Cement Latticed Concrete Walls. Materials, 14(11), 3082. https://doi.org/10.3390/ma14113082