Impact of Annealing on Magnetic Properties and Structure of Co40Fe40W20 Thin Films on Si(100) Substrate

Abstract

1. Introduction

2. Materials and Methods

3. Results

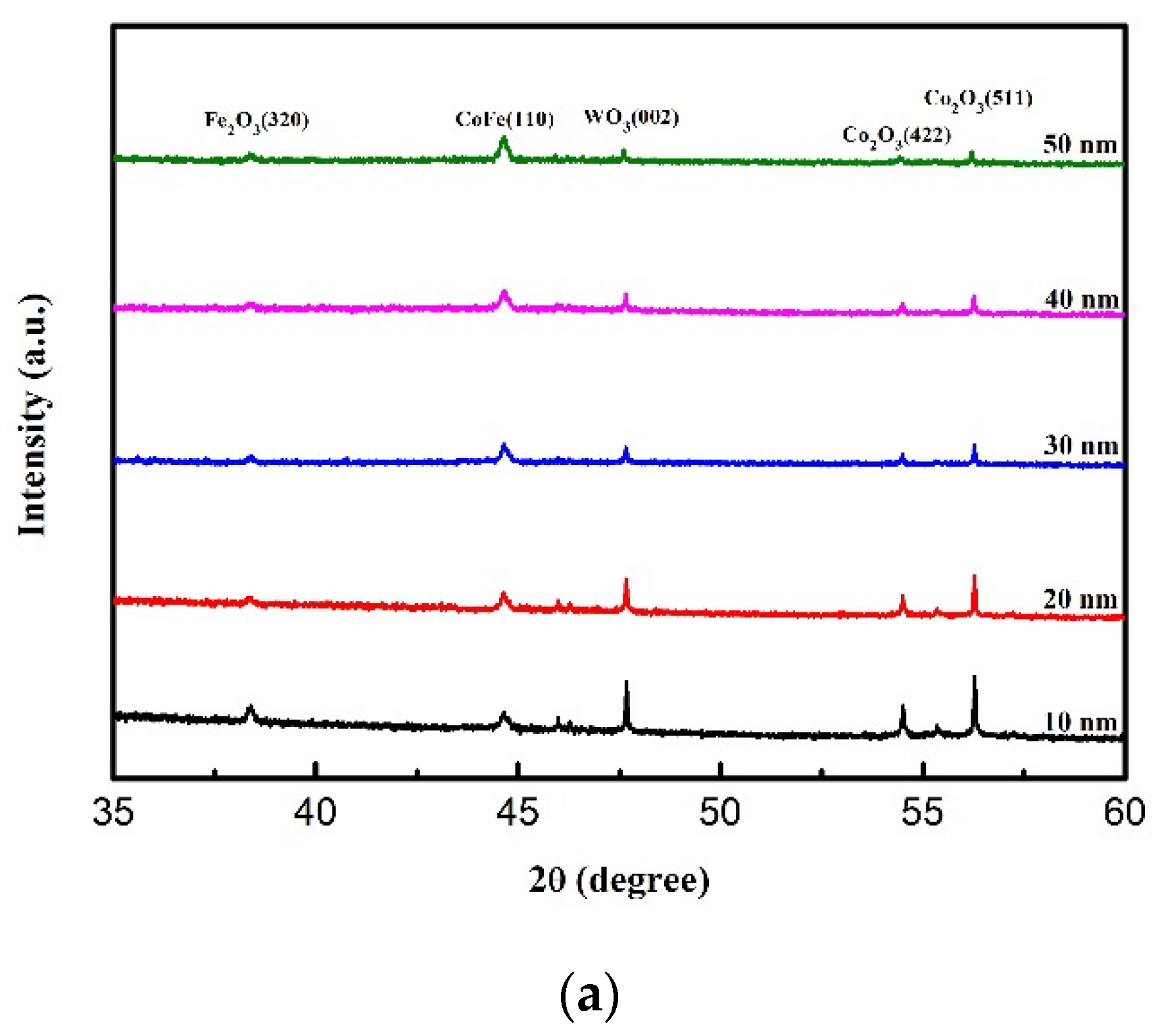

3.1. X-ray Diffraction

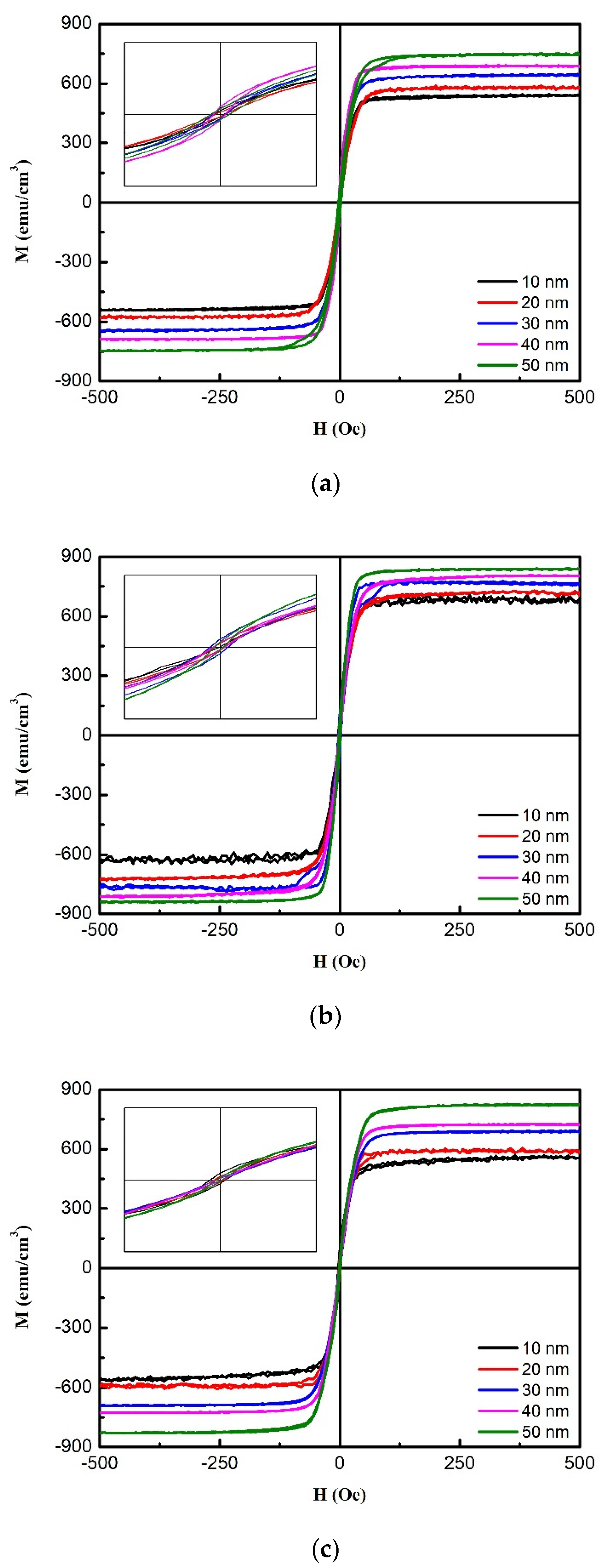

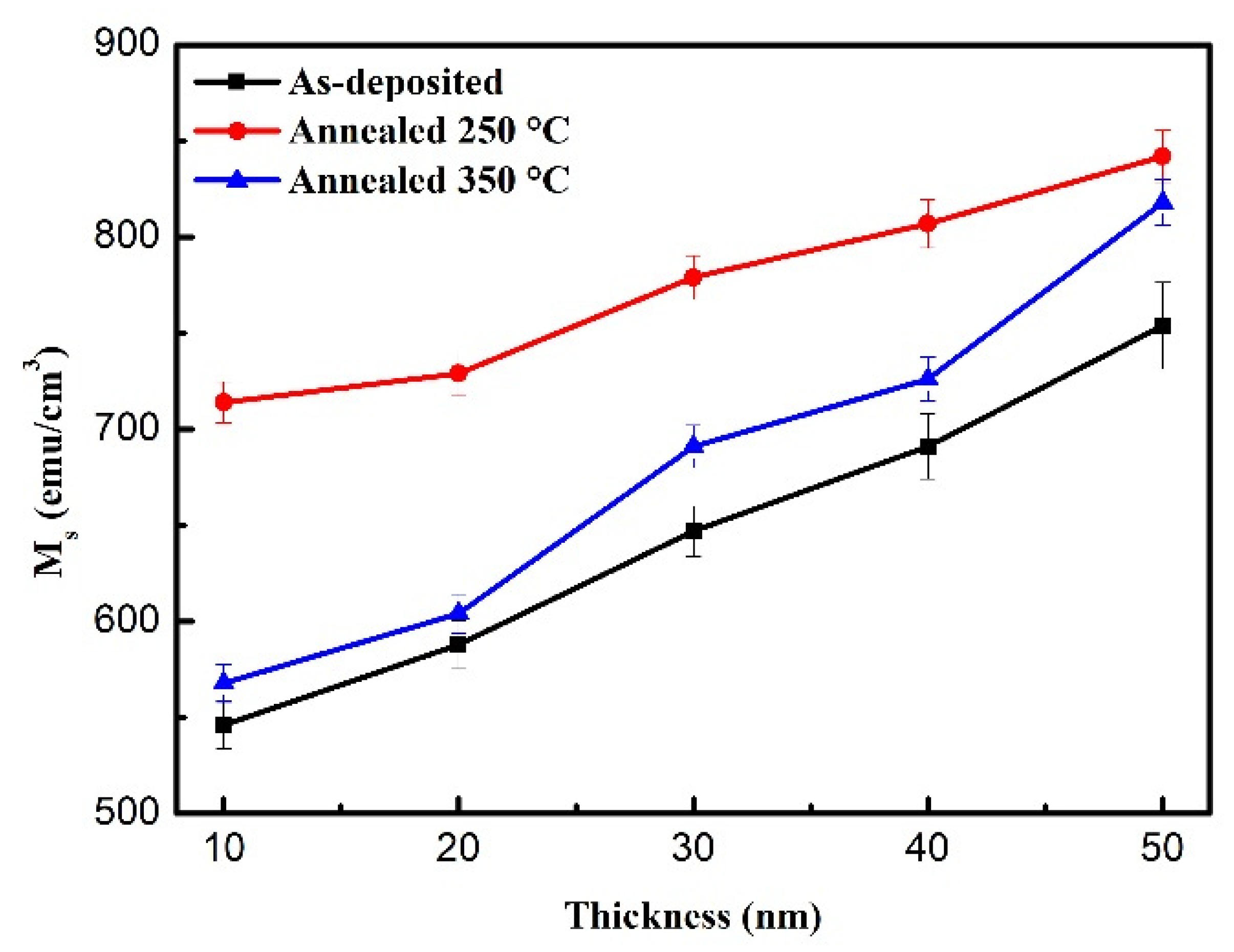

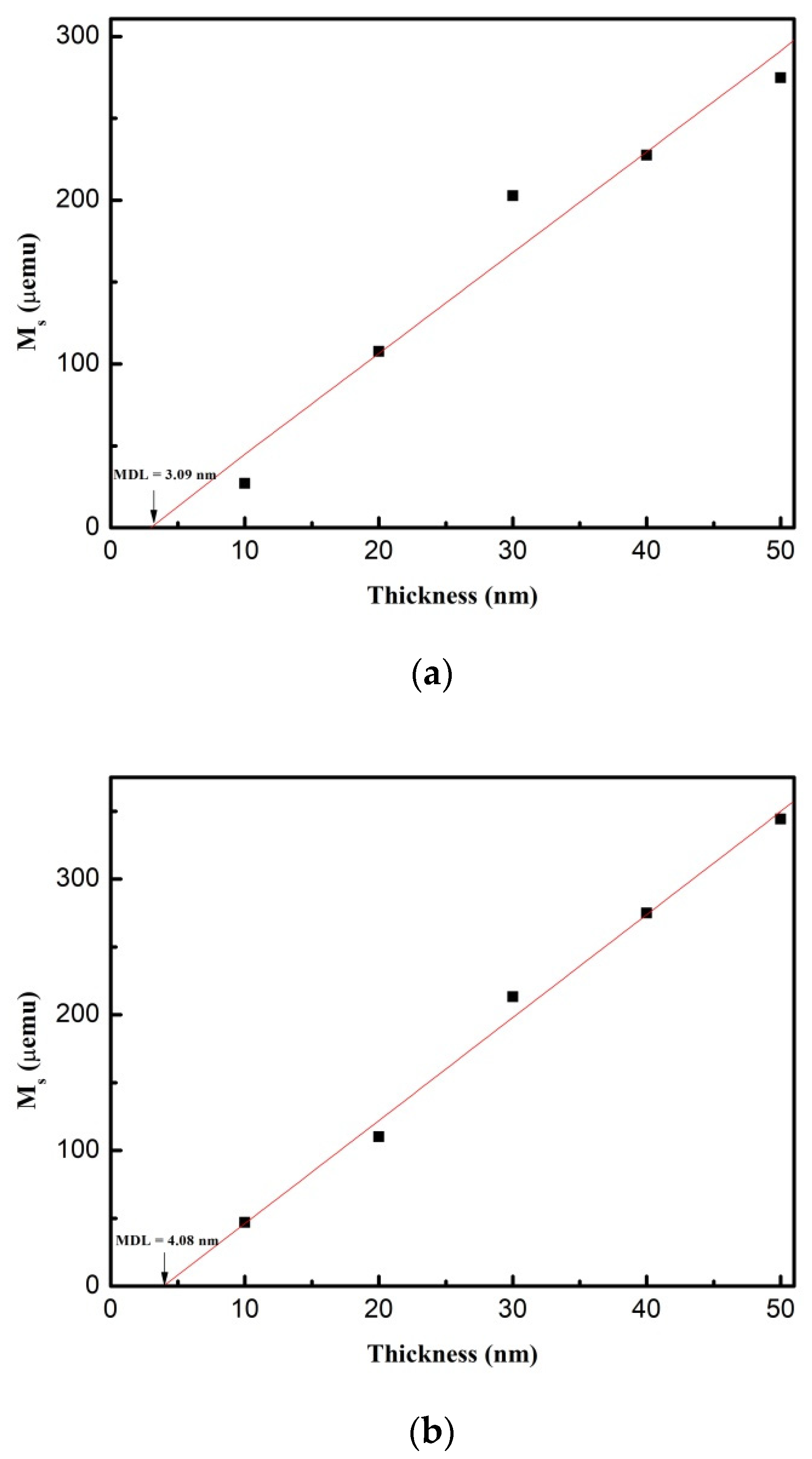

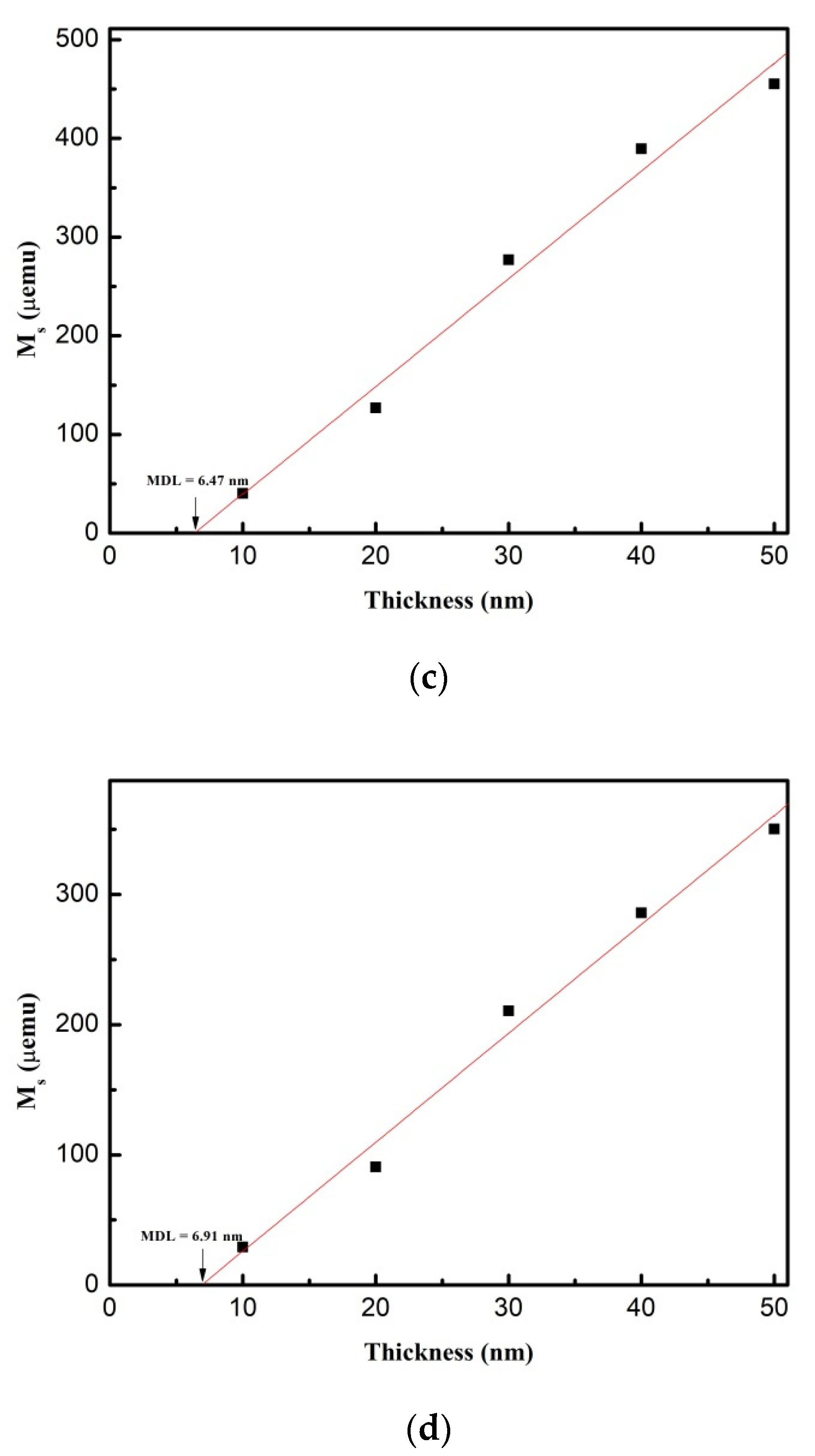

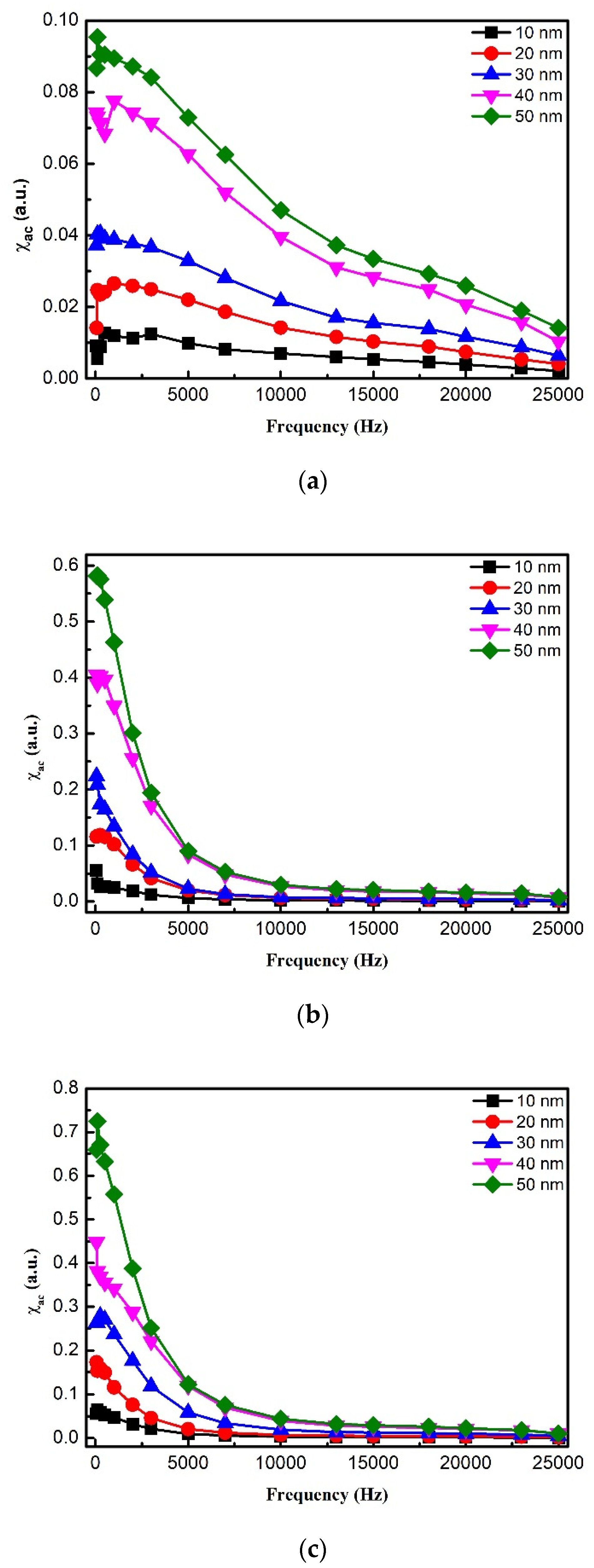

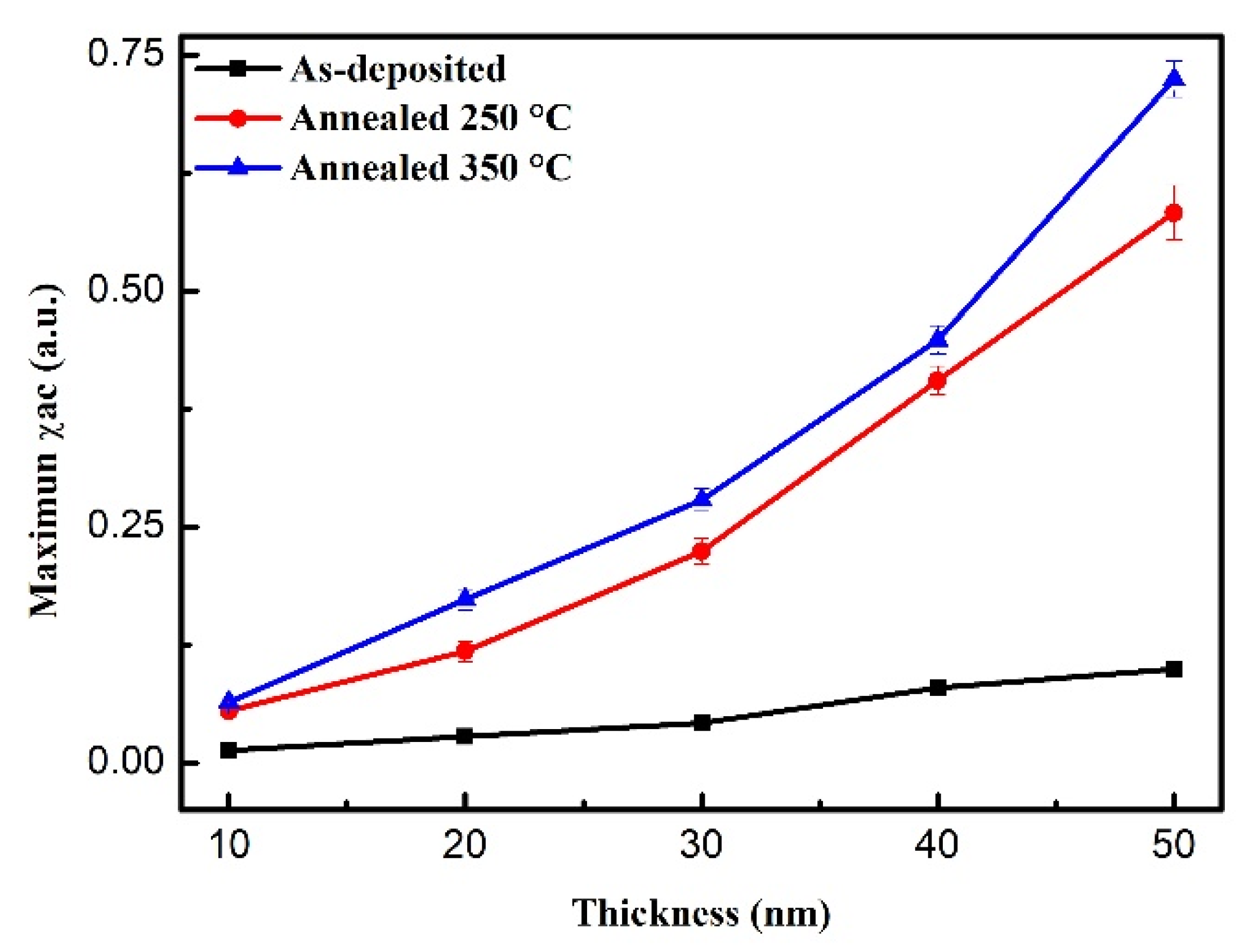

3.2. Magnetic Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Elmen, G.W. Magnetic alloys of iron, nickel, and cobalt. J. Frankl. Inst. 1929, 207, 583–617. [Google Scholar] [CrossRef]

- Li, M.; Wang, S.; Zhang, S.; Fang, S.; Yu, G. The perpendicular magnetic anisotropies of CoFeB/MgO films with Nb buffer layers. J. Magn. Magn. Mater. 2019, 485, 187–192. [Google Scholar] [CrossRef]

- Manos, O.; Bougiatioti, P.; Dyck, D.; Huebner, T.; Rott, K.; Schmalhorst, J.M.; Reiss, G. Correlation of tunnel magnetoresistance with the magnetic properties in perpendicular CoFeB-based junctions with exchange bias. J. Appl. Phys. 2019, 125, 023905. [Google Scholar] [CrossRef]

- Sun, J.Z.; Trouilloud, P.L.; Lauer, G.P.; Hashemi, P. Bias dependent conductance in CoFeB-MgO-CoFeB magnetic tunnel junctions as an indicator for electrode magnetic condition at barrier interfaces. AIP Adv. 2019, 9, 015002. [Google Scholar] [CrossRef]

- Ota1, S.; Ono, M.; Matsumoto, H.; Ando, A.; Sekitani, T.; Kohno, R.; Iguchi, S.; Koyama, T.; Chiba, D. CoFeB/MgO-based magnetic tunnel junction directly formed on a flexible substrate. Appl. Phys. Express 2019, 12, 053001. [Google Scholar] [CrossRef]

- Huang, S.X.; Chen, T.Y.; Chien, C.L. Spin polarization of amorphous CoFeB determined by point-contact Andreev reflection. Appl. Phys. Lett. 2008, 92, 242509. [Google Scholar] [CrossRef]

- Kalu, E.E.; Bell, R.; Dupree, M. Improvement of the corrosion behavior of electrodeposited CoFeCu thin films. Mater. Chem. Phys. 2010, 124, 689–693. [Google Scholar] [CrossRef]

- Kumari, T.P.; Raja, M.M.; Kumar, A.; Srinath, S.; Kamat, S.V. Effect of thickness on structure, microstructure residual stress and soft magnetic properties of DC sputtered Fe65Co35 soft magnetic thin films. J. Magn Magn. Mater. 2014, 365, 93–99. [Google Scholar] [CrossRef]

- Gottwald, M.; Lee, K.; Kan, J.J.; Ocker, B.; Wrona, J.; Tibus, S.; Langer, J.; Kang, S.H.; Fullerton, E.E. Ultra-thin Co-Pd multilayers with enhanced high-temperature annealing stability. Appl. Phys. Lett. 2013, 102, 052405. [Google Scholar] [CrossRef]

- An, G.G.; Lee, J.B.; Yang, S.M.; Kim, J.H.; Chung, W.S.; Yoon, K.S.; Hong, J.P. Correlation between Pd metal thickness and thermally stable perpendicular magnetic anisotropy features in [Co/Pd]n multilayers at annealing temperatures up to 500 °C. AIP Adv. 2015, 5, 027137. [Google Scholar] [CrossRef]

- Kawahara, T.; Ito, K.; Takemura, R.; Ohno, H. Spin-transfer torque RAM technology: Review and prospect. Microelectron. Reliab. 2012, 52, 613–627. [Google Scholar] [CrossRef]

- Wang, S.; Li, M.; Zhang, S.; Fang, S.; Wang, D.; Yu, G. High annealing tolerance and the microstructure study in perpendicular magnetized MgO/CoFeB/MgO structures with thin W spacer layer. J. Magn. Magn. Mater. 2019, 479, 121–125. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, T.; Zhu, Z.; Zhong, H.; Khamis, K.M.; Zhu, K. High thermal stability in W/MgO/CoFeB/W/CoFeB/W stacks via ultrathin W insertion with perpendicular magnetic anisotropy. J. Magn. Magn. Mater. 2016, 410, 123–127. [Google Scholar] [CrossRef]

- Miyakawa, N.; Worledge, D.C.; Kita, K. Impact of Ta Diffusion on the Perpendicular Magnetic Anisotropy of Ta/CoFeB/MgO. IEEE Magn. Lett. 2013, 4, 1000104. [Google Scholar] [CrossRef]

- An, G.G.; Lee, J.B.; Yang, S.M.; Kim, J.H.; Chung, W.S.; Hong, J.P. Highly stable perpendicular magnetic anisotropies of CoFeB/MgO frames employing W buffer and capping layers. Acta Mater. 2015, 87, 259–265. [Google Scholar] [CrossRef]

- Sun, J.; Li, H.; Huang, Y.; Zhuang, Z. CoFeW ternary oxides nanoparticles for oxygen evolution reaction. Mater. Lett. 2018, 223, 246–249. [Google Scholar] [CrossRef]

- Meng, H.; Lum, W.H.; Sbiaa, R.; Lua, S.Y.H.; Tan, H.K. Annealing effects on CoFeB-MgO magnetic tunnel junctions with perpendicular anisotropy. J. Appl. Phys. 2011, 110, 033904. [Google Scholar] [CrossRef]

- Kaidatzis, A.; Bran, C.; Psycharis, V.; Vázquez, M.; Martín, J.M.G.; Niarchos, D. Tailoring the magnetic anisotropy of CoFeB/MgO stacks onto W with a Ta buffer layer. Appl. Phys. Lett. 2015, 106, 262401. [Google Scholar] [CrossRef]

- Ghaferi, Z.; Sharafi, S.; Bahrololoom, M.E. The role of electrolyte pH on phase evolution and magnetic properties of CoFeW codeposited films. Appl. Surf. Sci. 2016, 375, 35–41. [Google Scholar] [CrossRef]

- Pai, C.F.; Liu, L.; Li, Y.; Tseng, H.W.; Ralph, D.C.; Buhrman, R.A. Spin transfer torque devices utilizing the giant spin Hall effect of tungsten. Appl. Phys. Lett. 2012, 101, 122404. [Google Scholar] [CrossRef]

- Almasi, H.; Sun, C.L.; Li, X.; Newhouse-Illige, T.; Bi, C.; Price, K.C.; Nahar, S.; Grezes, C.; Hu, Q.; Amiri, P.K.; et al. Perpendicular magnetic tunnel junction with W seed and capping layers. J. Appl. Phys. 2017, 121, 153902. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, J.B.; An, G.G.; Yang, S.M.; Chung, W.S.; Park, H.S.; Hong, J.P. Ultrathin W space layer-enabled thermal stability enhancement in a perpendicular MgO/CoFeB/W/CoFeB/MgO recording frame. Sci. Rep. 2015, 5, 16903. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.J.; Chang, Y.H.; Ou, S.L.; Chen, Y.T.; Li, W.H.; Jhou, T.Y.; Chu, C.L.; Wu, T.H.; Tseng, S.W. Effect of annealing on the structural, magnetic, surface energy and optical properties of Co32Fe30W38 films deposited by direct-current magnetron sputtering. Coatings 2020, 10, 1028. [Google Scholar] [CrossRef]

- Kim, D.H.; Park, K.W.; Park, B.G. Enhanced tunnel magnetoresistance and electric field effect in CoFeB/MgO/CoFeB perpendicular tunnel junctions with W under layer. Curr. Appl. Phys. 2017, 17, 962–965. [Google Scholar] [CrossRef]

- Wang, H.; Kou, X.; Wang, S.; Zhou, J.; Zhang, X.; Li, J. Structures, magnetic properties and thermal stability of CoFeB/MgO films. Phys. Procedia 2011, 18, 267–273. [Google Scholar] [CrossRef]

- Wang, D.; Nordman, C.; Qian, Z.; Daughton, J.M.; Myers, J. Magnetostriction effect of amorphous CoFeB thin films and application in spin-dependent tunnel junctions. J. Appl. Phys. 2005, 97, 10C906. [Google Scholar] [CrossRef]

- Wang, W.X.; Yang, Y.; Naganuma, H.; Ando, Y.; Yu, R.C.; Han, X.F. The perpendicular anisotropy of Co40Fe40B20 sandwiched between Ta and MgO layers and its application in CoFeB/MgO/CoFeB tunnel junction. Appl. Phys. Lett. 2011, 99, 012502. [Google Scholar] [CrossRef]

- He, C.; Navabi, A.; Shao, Q.; Yu, G.; Wu, D.; Zhu, W.; Zheng, C.; Li, X.; He, Q.L.; Razavi1, S.A.; et al. Spin-torque ferromagnetic resonance measurements utilizing spin Hall magnetoresistance in W/Co40Fe40B20/MgO structures. Appl. Phys. Lett. 2016, 109, 202404. [Google Scholar] [CrossRef]

- Liu, W.J.; Chang, Y.H.; Chen, Y.T.; Chiang, Y.C.; Liu, Y.C.; Wu, T.H.; Chi, P.W. Effect of annealing on the structural, magnetic, surface energy of CoFeBY films on Si (100) substrate. Materials 2021, 14, 987. [Google Scholar] [CrossRef]

- Iihama, S.; Mizukami, S.; Naganuma, H.; Oogane, M.; Ando, Y.; Miyazaki, T. Gilbert damping constants of Ta/CoFeB/MgO(Ta) thin films measured by optical detection of precessional magnetization dynamics. Phys. Rev. B 2014, 89, 174416. [Google Scholar] [CrossRef]

- Li, M.; Wang, S.; Zhang, S.; Fang, S.; Feng, G.; Cao, X.; Zhang, P.; Wang, B.; Yu, G. The effect of interfacial oxygen migration on the PMA and thermal stability in MTJ with double MgO layers. Appl. Surf. Sci. 2019, 488, 30–35. [Google Scholar] [CrossRef]

- Jang, S.Y.; Lim, S.H.; Lee, S.R. Magnetic dead layer in amorphous CoFeB layers with various top and bottom structures. J. Appl. Phys. 2010, 107, 09C707. [Google Scholar] [CrossRef]

- Budde, T.; Gatzen, H.H. Magnetic properties of an SmCo/NiFe system for magnetic microactuators. J. Magn. Magn. Mater. 2004, 272–276, 2027–2028. [Google Scholar] [CrossRef]

- Wen, D.; Li, J.; Gan, G.; Yang, Y.; Zhang, H.; Liu, Y. Double peaks of the permeability spectra of obliquely sputtered CoFeB amorphous films. Mater. Res. Bull. 2019, 110, 107–111. [Google Scholar] [CrossRef]

- Yang, S.Y.; Chien, J.J.; Wang, W.C.; Yu, C.Y.; Hing, N.S.; Hong, H.E.; Hong, C.Y.; Yang, H.C.; Chang, C.F.; Lin, H.Y. Magnetic nanoparticles for high-sensitivity detection on nucleic acids via superconducting-quantum-interference-device-based immunomagnetic reduction assay. J. Magn. Magn. Mater. 2011, 323, 681–685. [Google Scholar] [CrossRef]

- Chen, Y.T.; Xie, S.M.; Jheng, H.Y. The low-frequency alternative-current magnetic susceptibility and electrical properties of Si(100)/Fe40Pd40B20(X Å)/ZnO(500 Å) and Si(100)/ZnO(500 Å)/Fe40Pd40B20(Y Å) systems. J. Appl. Phys. 2013, 113, 17B303. [Google Scholar] [CrossRef]

| Material | Thickness | Maximum χac (a.u.) | Optimal Resonance Frequency, fres (Hz) | Crystallinity |

|---|---|---|---|---|

| Glass/Co32Fe30W38 [23] | 10–50 nm at RT and annealed conditions | 0.02–0.52 | 50–1000 | Weak |

| Si(100)/Co40Fe40W20 | 10–50 nm at RT and annealed conditions | 0.055–0.745 | 50–1000 | Strong |

| Thickness (nm) | As-Deposited (emu/cm3) | Post-Annealing at 250 °C (emu/cm3) | Post-Annealing at 350 °C (emu/cm3) |

|---|---|---|---|

| 10 | 546 | 714 | 568 |

| 20 | 588 | 729 | 604 |

| 30 | 647 | 779 | 691 |

| 40 | 691 | 807 | 726 |

| 50 | 754 | 842 | 818 |

| Thickness (nm) | As-Deposited Optimal Resonance Frequency (Hz) | Post-Annealing at 250 °C of Optimal Resonance Frequency (Hz) | Post-Annealing at 350 °C of Optimal Resonance Frequency (Hz) |

|---|---|---|---|

| 10 | 500 | 50 | 100 |

| 20 | 1000 | 250 | 50 |

| 30 | 250 | 50 | 250 |

| 40 | 1000 | 50 | 50 |

| 50 | 100 | 100 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.-J.; Chang, Y.-H.; Chen, Y.-T.; Jhou, T.-Y.; Chen, Y.-H.; Wu, T.-H.; Chi, P.-W. Impact of Annealing on Magnetic Properties and Structure of Co40Fe40W20 Thin Films on Si(100) Substrate. Materials 2021, 14, 3017. https://doi.org/10.3390/ma14113017

Liu W-J, Chang Y-H, Chen Y-T, Jhou T-Y, Chen Y-H, Wu T-H, Chi P-W. Impact of Annealing on Magnetic Properties and Structure of Co40Fe40W20 Thin Films on Si(100) Substrate. Materials. 2021; 14(11):3017. https://doi.org/10.3390/ma14113017

Chicago/Turabian StyleLiu, Wen-Jen, Yung-Huang Chang, Yuan-Tsung Chen, Tian-Yi Jhou, Ying-Hsuan Chen, Te-Ho Wu, and Po-Wei Chi. 2021. "Impact of Annealing on Magnetic Properties and Structure of Co40Fe40W20 Thin Films on Si(100) Substrate" Materials 14, no. 11: 3017. https://doi.org/10.3390/ma14113017

APA StyleLiu, W.-J., Chang, Y.-H., Chen, Y.-T., Jhou, T.-Y., Chen, Y.-H., Wu, T.-H., & Chi, P.-W. (2021). Impact of Annealing on Magnetic Properties and Structure of Co40Fe40W20 Thin Films on Si(100) Substrate. Materials, 14(11), 3017. https://doi.org/10.3390/ma14113017