3.1. Microhardness Profiles

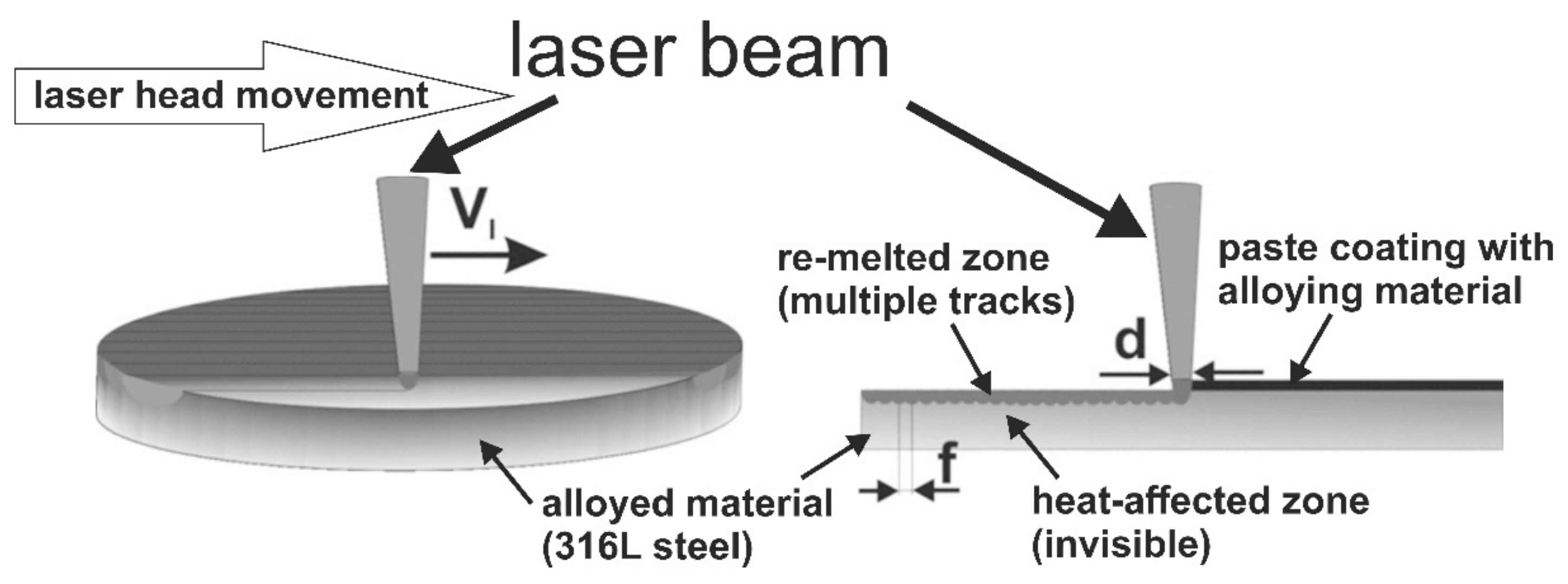

It was found that the parameters of LSA of 316L austenitic stainless steel, e.g., the type of alloying material and its thickness (

tC), laser beam diameter (

d), scanning rate (

vl), overlapping (

O) and laser beam power (

P) strongly influenced the quality of the produced surface layers [

63]. Summarizing the results of the paper [

63], it could be concluded that the fabricated laser-alloyed layers were characterized by a composite microstructure, which was composed of the hard ceramic phases (iron, chromium and nickel borides) in a soft austenitic matrix. Due to this composite microstructure, the microhardness indents included both the hard metal borides and the soft austenitic matrix. Hence, the measurements of microhardness usually represented the averaging value of this property, depending on the fraction of hard as well as soft phases, occurring on the penetrated surface. It caused some fluctuations of microhardness in the re-melted zone (MZ), despite the general trend of its diminished value by increasing the distance from the surface. The microhardness profiles along the axes of selected multiple track after LSA with boron and some metallic elements are shown in

Figure 5. The results are compared to the laser-alloyed layers with boron only (also called laser-borided layers), fabricated with a dilution ratio (

DR) of 0.54 during the present study and with

DR equal to 0.37 [

60].

Figure 5a shows the microhardness profiles across the two laser-alloyed layers with boron and Stellite-6, produced with the use of laser beam power (

P) of 1.43 kW and 1.56 kW and resulted in the dilution ratio (

DR) of 0.41 and 0.48, respectively (according to the data from the paper [

63]). The composite microstructure of the re-melted zone (MZ) was composed of the hard iron, chromium and nickel borides (Fe

2B, Cr

2B, Ni

2B) in a soft austenitic matrix (FeCrNiCoCγ phase) [

63]. The cobalt borides were not detected. Probably, all the cobalt from the alloying material (Stellite-6 powder) dissolved in the alloyed austenite. The microhardness was measured along the axes of multiple laser tracks, and the determined profiles were compared to the profiles after LSA with boron only, resulting in the dilution ratio of 0.37 [

60] and 0.54 (present work). The hardness of the re-melted zone (MZ), i.e., laser-alloyed layer, strongly depended on the type of alloying material and laser processing parameters (in this case—laser beam power used), causing the differences in the dilution ratio and, as a consequence, the various percentages of hard borides in the microstructure.

The higher hardness close to the surface (about 800 HV) of laser-alloyed layer with boron and Stellite-6 was measured in the case of the use of lower laser beam power (

P = 1.43 kW). In general, the microhardness profile in laser-alloyed zone (re-melted zone) was in this case comparable to the profile which was obtained after LSA with boron only at a dilution ratio

DR = 0.37 [

60]. Only the depth of MZ was slightly higher because of the higher value of dilution ratio (0.41). However, the composite microstructure of laser-alloyed layer with boron consisted of hard iron, chromium and nickel borides ((Fe

2B, Cr

2B, Ni

2B) and, additionally, M

23(C,B)

6 borocarbides in a soft austenitic matrix (FeCrNiCγ phase). The presence of borocarbides could cause the worsened corrosion resistance [

60] due to the diminished concentration of chromium in austenitic matrix. Whereas the microhardness profile, obtained at higher laser beam power (

P = 1.56 kW) was closer to the profile designated for laser boriding resulting in a dilution ratio of 0.54, with a slightly lower depth of re-melted zone due to the lower

DR value (0.48) and slightly higher hardness in the re-melted zone. The laser-alloyed layer with boron (i.e., laser-borided layer) at

DR = 0.54 did not contain M

23(C,B)

6 borocarbides in MZ. It should advantageously influence its corrosion behavior. In the substrate, microhardness fell to the values which were characteristic of 316L austenitic steel (160–210 HV).

Figure 5b shows the microhardness profiles of laser-alloyed layers with boron and nickel using a laser beam power of 1.43 and 1.56 kW, resulting in a dilution ratio of 0.42 and 0.48, respectively (according to the paper [

63]). In the re-melted zone, the presence of a composite microstructure was confirmed. The hard iron, chromium and nickel borides (Fe

2B, Cr

2B, Ni

2B) occurred in a soft FeCrNiCγ phase (austenitic matrix) [

63]. The results were compared with microhardness profiles of 316L austenitic steel, laser-alloyed with boron only using the laser beam power of

P = 1.82 kW at different dilution ratios

DR (0.37 [

60] and 0.54). As in previous cases, the microhardness was measured along the axes of selected multiple laser tracks. The higher values of microhardness close to the surface (approx. 690–740 HV) were measured after LSA with boron and nickel using the lower laser beam power (

P = 1.43 kW). In the case of laser treatment using a laser beam of higher power (

P = 1.56 kW), the surface hardness reached 600–680 HV and the depth of the re-melted zone (laser-alloyed zone) increased. In general, the hardness of the re-melted zone was in both cases between the values measured across the laser-alloyed layers with boron only at a dilution ratio (

DR) of 0.37 [

60] and 0.54. They differed slightly in the depth of MZ, resulting from various dilution ratios. The hardness of the substrate below the re-melted zone reached 160–210 HV, i.e., the values characteristic of 316L austenitic steel.

The microhardness profiles of laser-alloyed layers with boron, nickel and chromium at laser beam powers of 1.43 kW and 1.56 kW are shown in

Figure 5c. These profiles were compared to the microhardness profiles after laser boriding (LSA with boron exclusively) at various dilution ratios

DR = 0.37 [

60] and

DR = 0.54 (present work). The composite microstructure of laser-alloyed layers with B, Ni and Cr also consisted of hard iron, chromium and nickel borides (Fe

2B, Cr

2B, Ni

2B) in a soft FeCrNiCγ matrix [

63]. Probably, the percentage of chromium borides was increased in this case, resulting in the relatively high hardness of re-melted zone. The higher microhardness of the MZ, up to 940 HV, was obtained in the case of laser-alloyed layer with boron, nickel and chromium using a 1.43 kW laser beam power, resulting in a dilution ratio of 0.43. This was probably due to the appearance in the microstructure of a greater percentage of very hard chromium borides. Slightly lower hardness (670–850 HV) was characteristic of the laser-alloyed layer with boron, nickel and chromium at laser beam of higher power (

P = 1.56 kW) and a dilution ratio of 0.49. In this case, the obtained hardness of the re-melted zone was comparable to that of the laser-borided layer with a dilution ratio

DR = 0.37 [

60]. Both laser-alloyed layers with boron, nickel and chromium had a microhardness higher than the laser-borided layer with a dilution ratio of 0.54. In the substrate, the hardness was typical of 316L austenitic stainless steel (160–210 HV).

It was quite easy to compare the hardness of the surface layers, produced in the austenitic steel using the various techniques. The maximal hardnesses and averaging depths of the surface layers, fabricated using physical as well as conventional thermochemical techniques, were specified in the

Table 1 and

Table 2, respectively. The hardness was usually measured using the Vickers method at the various loads both in the case of physical (see

Table 1) and thermochemical (see

Table 2) techniques used. The Knoop method was rarely applied [

10,

35]. The hardness was reported more often in GPa [

19,

26,

31,

37,

38,

39,

42,

49,

53,

54]. In such cases, the hardness was measured using a nanoindenter with a Berkovich diamond tip [

19,

26,

31,

37,

39,

49,

53] or with Vickers diamond tip [

54] as well as Vickers microindenter [

38,

42]. Sometimes Vickers hardness (HV

IT) was calculated based on the indentation hardness (H

IT), expressed in GPa and measured by nanoindenter [

40].

The various physical techniques of surface treatment of austenitic steel were compared in

Table 1, taking into account the maximal hardness and averaging depths of the produced surface layers. The maximal hardness of laser-alloyed layers with boron (595–796 HV0.1) or with boron and selected metallic elements (675–911 HV0.1) ([

60] and this work) was relatively low in comparison with the surface layers, produced on the austenitic stainless steel using other physical techniques such as LTPGN processes (572–2175 HV or 720–1100 HK at different loads) [

2,

3,

5,

7,

8,

9,

10,

23], LTPGNC process (962 HV) [

7], HTPGN processes (1060–1340 HV) [

3,

5,

14,

15], LTPGC process (11–11.8 GPa) [

26] or PPB process (28.093 GPa) [

31]. Many hybrid treatments with the use of plasma processes also resulted in higher hardness of the fabricated surface layers, e.g., shot peening (SP) followed by LTPGN or sequential LTPGC and LTPGN (1615–1662 HV or 7.5–11.5 GPa, respectively) [

17,

19], cold spraying (CS) of 316L steel followed by LTPGN, LTPGC and LTPGNC processes or their various combinations (800–1350 HV) [

21], LTPGN process followed by a multi-arc ion plating (MAIP) (2280 HV) [

23] as well as TiN coatings produced by PVD technique (18.7–26 GPa) [

23,

24]. Only some of the surface layers, produced using the plasma processes, were characterized by comparable or lower hardness, e.g., the layer fabricated using LTPGN (5–9 GPa) [

19], LTPGC (570–930 HV) [

27,

28] or CPEN (438 HV) [

16]. The previously used laser surface alloying of austenitic steel [

57,

59] resulted in diminished hardness (410–480 HV) in comparison with the LSA processes presented in this study. However, the laser-alloyed layers with boron as well as with boron and selected metallic elements obtained significantly higher depths which were in the range of 338–432 μm (see

Table 1). Only the LSA with NiCoCrB powder [

59] resulted in comparable depth of the produced surface layer (260–740 μm). The depths of hardened surface layers, fabricated using the plasma or PVD techniques, ranged from 1.4 μm [

53] to 90 μm [

19] and were much thinner.

The maximal hardness values and averaging depths of the surface layers measured after the surface treatment of austenitic steel using various thermochemical techniques were specified in

Table 2. All the typical thermochemical processes resulted in a hardness, which was significantly higher than that-measured after laser surface alloying presented in this study, i.e., LSA with boron as well as with boron and selected metallic elements. The extremely high hardness of the surface layers, produced on austenitic steel, was obtained after powder-pack boriding (P-PB). The borided layers were characterized by a maximal hardness in the range of: 1580–2000 HV [

33,

40,

41], 1836–2227 HK [

35] or 18–24 GPa [

37,

38,

39]. The comparable hardness (22 GPa) was measured after boriding in liquid medium [

42]. Surface mechanical attrition treatment (SMAT) followed by P-PB process resulted in a hardness of about 2000 HV [

34], whereas the diffusion annealing process after P-PB provided the borided layer with a diminished hardness (15 GPa) due to the elimination of the hard FeB phase from the microstructure [

37]. The hybrid surface layers, produced by powder-pack boriding (P-PB) followed by powder-pack chromizing (P-PCr), were characterized by a maximal hardness of 1800 HV [

41]. The same processes, carried out in reverse order (P-PCr + P-PB), resulted in a formation of the layers with a maximal hardness of 1610 HV [

41]. The hardness of nitride layers was slightly higher than-those produced using LSA. LTGN (low-temperature gas nitriding) provided the surface layer of maximal hardness of 1300 HV [

44]. The same process, carried out after HVOF-spraying of 316L steel [

45], provided the hardness in the range of 874–1005 HV. The comparable maximal hardness (11.5 GPa) was obtained after nitriding in liquid medium [

49]. Low-temperature carburizing (LTC) [

52] resulted in a maximal hardness of 1100 HV. However, the averaging depths (1.8–87 μm) of the surface layers, fabricated using the typical thermochemical techniques, were considerably lower in comparison with the laser-alloyed layers (338–432 μm).

Summarizing, although the hardness of laser-alloyed layers with boron as well as with boron and selected metallic elements was lower, their averaging depths were significantly higher than the depths of the surface layers produced on austenitic stainless steels using other physical techniques and thermochemical treatments (see

Table 1 and

Table 2). These relatively high depths of the hardened surface layers could be important under conditions of appreciable mechanical wear.

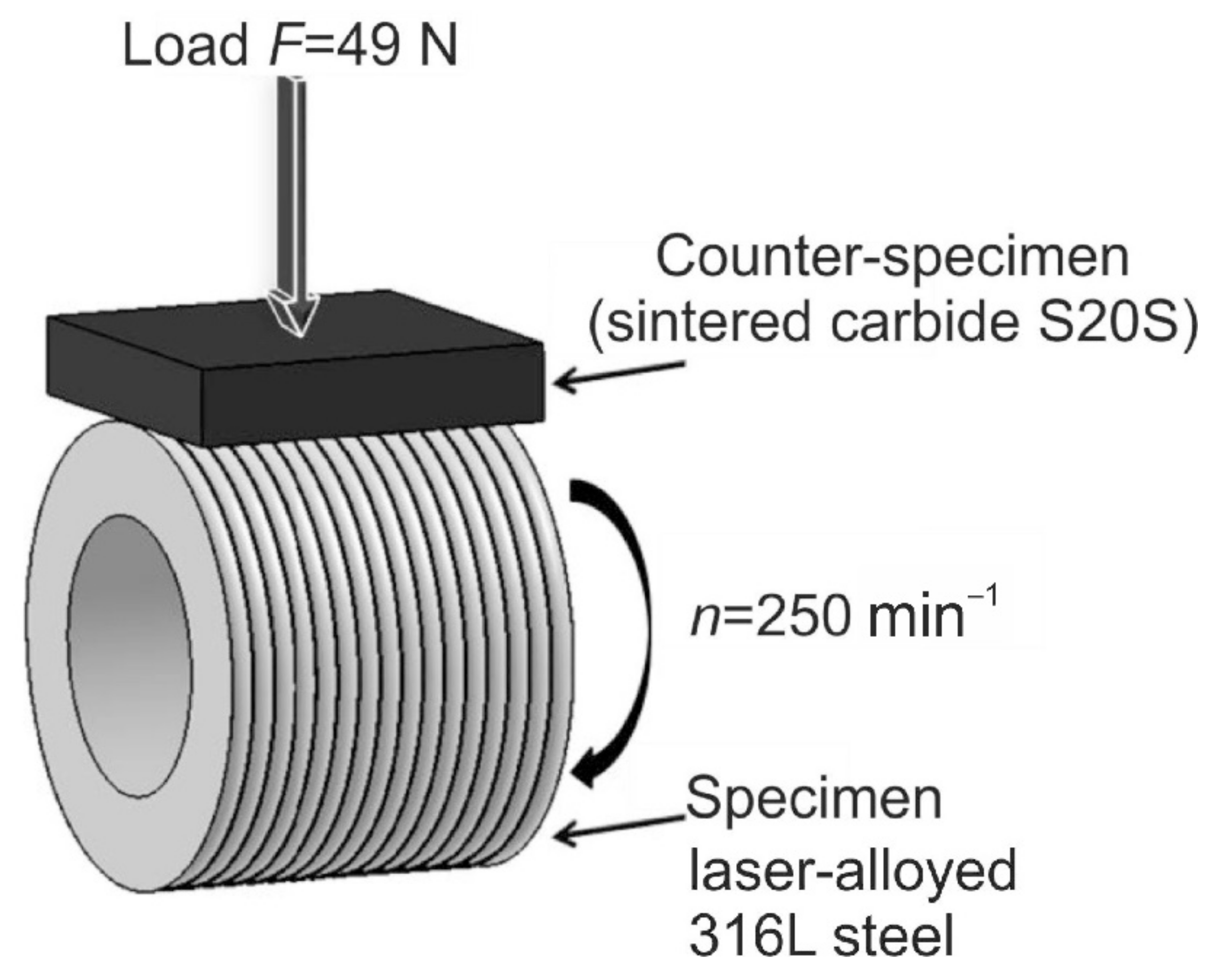

3.2. Wear Resistance

The wear resistance was studied for all the produced laser-alloyed layers with boron and with boron and selected metallic elements. Their wear behavior was investigated for 2 h with a change in the counter-specimen every 0.5 h. The results are presented in

Figure 6 and

Figure 7 and are compared to the laser-alloyed layer with boron only, reported in the previous study [

60]. The mass loss was measured every half hour and the measurement result was divided by the sample surface (friction surface,

S). This way calculated values were shown vs. the time of friction in order to determine the mass wear intensity factors. The mass wear intensity factor (

Imw) is defined as a mass loss of the specimen per unit of friction surface during a unit of time. It corresponds to the slope of a straight line in the Δ

m/

S-time (

t) coordinate system and represents the wear behavior during the mid-age period when a steady rate of wear occurs (

Figure 6). Simultaneously, the values of relative mass loss Δ

m/

mi of laser-alloyed specimens as well as counter-specimens (made of S20S sintered carbide) were measured and compared (

Figure 7).

Based on the previous study [

60], the untreated 316L austenitic stainless steel was characterized by a relatively high mass wear intensity factor

Imw = 26.12 mg·cm

−2·h

−1. In the case of all the laser-alloyed layers, the values of

Imw were significantly lower (

Figure 6). In general, the wear of the 316L steel, subjected to LSA processes, was approximately 15–26-times lower. The mass wear intensity factor, measured during the wear test of laser-alloyed layer with boron at a dilution ratio

DR = 0.37 [

60] was approximately 15-times lower, obtaining the value of 1.70 mg·cm

−2·h

−1. The similar layer, produced in the present study at higher dilution ratio (0.54), was characterized by

Imw value of 1.32 mg·cm

−2·h

−1, which was approximately 20-times lower compared to the factor of untreated 316L steel. The reduction in

Imw value was achieved despite the lower hardness of this surface layer. The LSA process of 316L steel with boron only required the relatively high laser beam power (

P = 1.82 kW) in order to produce the surface layers without such defects as microcracks or gas pores. Summarizing, the evaluation of the wear behavior using mass wear intensity factors indicated the considerable increase in wear resistance of laser-alloyed layers with boron in comparison with untreated 316L steel.

The laser-alloyed layers with boron and Stellite-6 (B and Stellite-6) were fabricated on the surface of 316L steel using the two various laser beam powers:

P = 1.43 kW and

P = 1.56 kW. It was found that the use of alloying material, consisting of amorphous boron and Stellite-6 powders, allowed the obtainment of a surface layer without defects in the form of micro-cracks or gas pores with lower power of the laser beam [

63]. The lower melting point of Stellite-6 powder (1285 °C) compared to boron (2076 °C) made the alloying material easier to melt with the substrate (316L steel) than the alloying material consisting only of boron. Hence, the laser beam power could be lower than-that applied during laser alloying with boron only. Simultaneously, at the mass ratio of boron to Stellite-6 equal to 1:1, the volume percentage of boron (about 78.3 vol%) predominated, taking into account its considerably lower density (2.34 g·cm

−3) compared to Stellite-6 powder (8.44 g·cm

−3). The wear resistance was analyzed based on the values of mass wear intensity factors in the mid-age period, when the steady rate of wear occurs. These values after two-hour wear tests with a change in the counter-specimen every 0.5 h were calculated for the two used laser beam powers:

P = 1.43 kW (

Figure 6a) and

P = 1.56 kW (

Figure 6b). The results of wear tests provided the lower mass wear intensity factors (

Imw = 0.97 mg·cm

−2·h

−1 and

Imw = 1.31 mg·cm

−2·h

−1, respectively) in comparison with the both laser-alloyed layers with boron only. When compared to the untreated 316L steel, the calculated values of

Imw were about 26-times and 20-times lower, respectively. The diminished hardness of the remelted zone, produced at higher laser beam power with the increased dilution ratio (0.48) [

63], could be the reason for the higher

Imw value.

The relatively low melting point of nickel (1455 °C) compared to boron (2076 °C) also facilitated the remelting of the alloying material together with the substrate (316L steel). Hence, as in the previous case, the use of the modified laser alloying material (a mixture of boron and nickel powders) allowed obtainment of the layer without the defects such as micro-cracks or gas pores using a diminished laser beam power [

63]. Therefore, the laser-alloyed layers with boron and nickel (B and Ni) were produced using the same values of laser beam power (

P = 1.43 kW and

P = 1.56 kW) as the laser-alloyed layers with B and Stellite-6. The mass ratio of boron to nickel powder was equal to 1:1. This meant that the volume percentage of boron in the alloying material (about 79.2 vol%) still predominated, taking into account its considerably lower density (2.34 g·cm

−3) compared to nickel powder (8.908 g·cm

−3). The values of mass wear intensity factors were analyzed in the mid-age period for the samples which were laser-alloyed using the two used laser beam powers:

P = 1.43 kW (

Figure 6a) and

P = 1.56 kW (

Figure 6b). The calculated values of

Imw (1.04 mg·cm

−2·h

−1 and 1.18 mg·cm

−2·h

−1, respectively) were approximately 25-times and 22-times lower in comparison with the untreated 316L steel and considerably lower than the values characteristic of the laser-alloyed layers solely with boron, reported in the previous study at

DR = 0.37 (1.70 mg·cm

−2·h

−1) [

60] as well as in the present work using

DR = 0.54 (1.32 mg·cm

−2·h

−1). Probably, the lower hardness of the re-melted zone (due to the higher dilution ratio

DR = 0.48 [

63]), was the reason for the increased

Imw value for the laser-alloyed layer which was formed at higher laser beam power (

P = 1.56 kW).

The use of an alloying material, consisting of boron and Ni-Cr powders, also facilitated its remelting with the substrate material (316L steel) due to the low melting point of nickel (1455 °C) as well as chromium (1857 °C) in comparison with boron (2076 °C). Hence, this modified alloying material resulted in the formation of the laser-alloyed layers without microcracks and gas pores using the diminished laser beam power (

P = 1.43 kW or

P = 1.56 kW) [

63]. It should be noted that the ratio of nickel to chromium in Ni-Cr powder was equal to 4:1. Therefore, the percentage of nickel was predominating. The mass ratio of the constituents of the alloying material (B:Ni-Cr) was equal to 1:1 and meant that the volume percentage of boron was still predominant (approximately 78.5%) due to its much lower density (2.34 g·cm

−3) compared to nickel powder (8908 g·cm

−3) or chromium powder (7.14 g·cm

−3). Similar to the previous cases, the laser-alloyed austenitic 316L steel with boron and Ni-Cr was subjected to two-hour wear tests with a change in the counter-specimen every 0.5 h. The measured Δ

m/

S values vs. time of friction (

t) are shown in

Figure 6a,b for the laser-alloyed layers produced using the laser beam power of 1.43 kW and 1.56 kW, respectively. The calculated values of mass wear intensity factors during the steady rate of wear were equal to 1.10 and 1.64 mg·cm

−2·h

−1, respectively. Hence, the values of

Imw were approximately 24-times and 16-times diminished in comparison with the untreated 316L steel. In the case of laser-alloyed layer, produced using the lower laser beam power (1.43 kW), the value of

Imw was considerably lower in comparison with the both laser-alloyed layers with boron only. However, the use of laser beam power of 1.56 kW resulted in

Imw value which was only slightly lower in comparison with the laser-alloyed layer with boron, produced with a dilution ratio of 0.37 [

60]. The diminished hardness of re-melted zone due to the higher dilution ratio (

DR = 0.49 [

63]) could be the probable reason for the increased mass wear intensity factor of the laser-alloyed layer, fabricated using the laser beam power of 1.56 kW. However, this hardness was still relatively high compared to other laser-alloyed layers analyzed. A thorough analysis of the wear process (

Figure 6b) showed that the running-in period was probably longer than in previous cases. If the test period from 1 to 2 h was taken into account for the calculation, the value of

Imw would be equal to 1.36 mg·cm

−2·h

−1, being already closer to the mass wear intensity factors of other laser-alloyed layers.

Summarizing, the addition of selected metallic elements to the alloying material usually resulted in the reduction in the mass wear intensity factor Imw, especially, if the laser beam power was lower (1.43 kW). This could be understandable, taking into consideration the higher hardness of the re-melted zone in such a case, resulting in a smaller dilution ratio. However, there was no simple relationship between the hardness of the re-melted zone and the value of Imw. Some laser-alloyed layers with a relatively high hardness, e.g., laser-alloyed layer with boron only (produced using DR = 0.37) or both laser-alloyed layers with boron and Ni-Cr, were not at all characterized by the highest resistance to wear, that is, the lowest mass wear intensity factors. To explain these dependencies, the wear mechanisms of these layers should be analyzed. They will be described later. Based on the presented results, the highest wear resistance, i.e., the lowest Imw values, was obtained in the case of laser-alloyed layer with boron and Stellite-6 and laser-alloyed layer with boron and nickel, produced using the laser beam power of 1.43 kW.

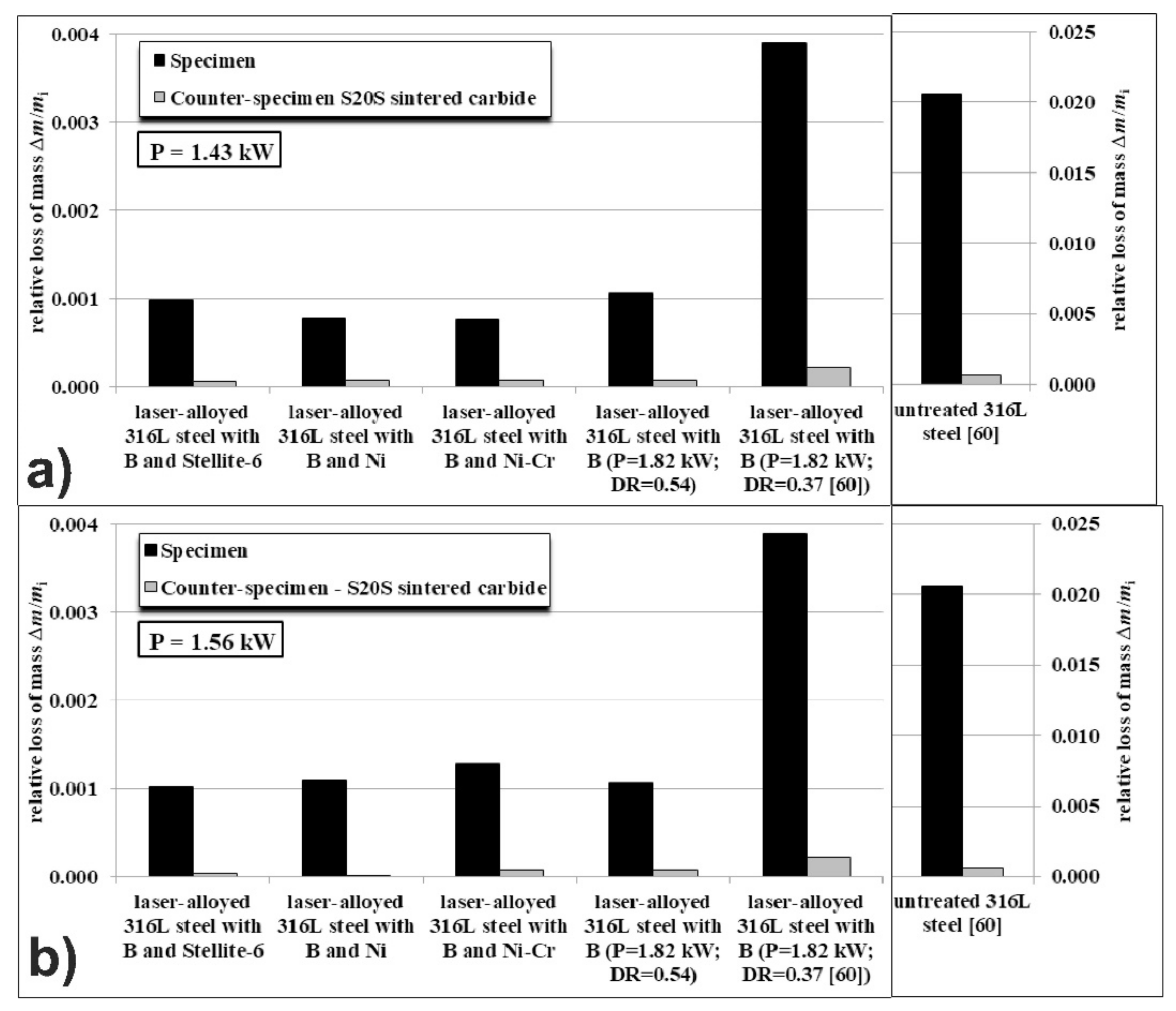

The second method of wear resistance evaluation consisted in the measurements of relative mass loss Δ

m/

mi of laser-alloyed specimens as well as counter-specimens (made of S20S sintered carbide). The results are shown in

Figure 7 for all the laser-alloyed layers compared to the untreated austenitic 316L steel. They indicated the significant increase in wear resistance of laser-borided layers (laser-alloyed layers with boron) in comparison with untreated 316L steel. Based on the previous study [

60], the value of Δ

m/

mi of the laser-alloyed layer with boron, produced using a dilution ratio of 0.37, was equal to 0.0039 and was approximately 5-times lower than the relative mass loss of the untreated 316L steel (0.0206). An even greater decrease in the relative mass loss was observed for a laser-alloyed layer with boron, which was produced in the present study and was characterized by a dilution ratio of 0.54. In this case, the value of Δ

m/

mi = 0.0011 was obtained. This meant a 19-fold reduction in relative mass loss compared to 316L steel without surface layer. Simultaneously, the relative mass loss of the counter-specimens (made of S20S sintered carbide) was equal to approximately 0.000217 and 0.000072 in the case of the mating parts made of laser-borided specimens at

DR = 0.37 [

60] or

DR = 0.54, respectively. Such values were considerably smaller than that of the counter-specimen, which mated with the untreated 316L steel (0.000651) [

60].

The relative mass losses of the laser-alloyed specimens with boron and selected metallic elements using the laser beam power 1.43 kW and 1.56 kW as well as corresponding counter-specimens are shown in

Figure 7a,b, respectively. The Δ

m/

mi values of the laser-alloyed specimens with boron and Stellite-6 (B and Stellite-6) as well as of their counter-specimens were slightly smaller than those-obtained for laser-borided 316L steel with a dilution ratio of 0.54 and significantly smaller than those-characteristic of the second laser-borided sample (DR = 0,37) [

60]. The relative mass loss of the laser-alloyed specimens was equal to about 0.0010 regardless of the laser beam power used. This meant an approximately 21-fold reduction in relative mass loss compared to the untreated 316L steel. In the case of the counter-specimens, their Δ

m/

mi values ranged from 0.000036 to 0.000065, depending on the laser beam power used in producing the specimens (1.56 kW and 1.43 kW, respectively). These values were considerably lower in comparison with 316L steel without the surface layer (0.000651) [

60].

The relative mass loss of the sample, laser-alloyed with boron and nickel (B and Ni) using laser beam power of 1.43 kW (

Figure 7a), was considerably lower compared to the values obtained for the laser-borided 316L steel with a dilution ratio of 0.37 [

60] or 0.54. To some extent, this was influenced by a smaller mass loss during the running-in stage (

Figure 7a). The value of Δ

m/

mi was equal to about 0.0008, and this meant an approximately 26-fold reduction in relative mass loss compared to the untreated 316L steel (0.0206) [

60]. The counter-specimen, which mated with laser-alloyed specimen, had a similar Δ

m/

mi value (0.000078) to the counter-specimen that mated with a laser-borided layer with a dilution ratio of 0.54 (0.000072). In the case of the laser-alloyed specimen using the higher laser beam power (1.56 kW), its relative mass loss was significantly lower compared to a laser-borided sample with a dilution ratio of 0.37 [

60] and comparable to the value measured for a laser-borided sample with a dilution ratio of 0.54 (

Figure 7b). This resulted from the slightly higher mass loss of the considered sample during the running-in stage. The obtained value of Δ

m/

mi (0.0011) was approximately 19-times diminished in comparison with the untreated 316L steel. The relative mass loss of the counter-specimen (0.000016) was exceptionally low and considerably lower than the Δ

m/

mi values characteristic of the counter-specimens that mated with the both laser-borided specimens with a dilution ratio of 0.37 and 0.54.

Using the same way, the relative mass losses of laser-alloyed specimens with boron, nickel and chromium (B and Ni-Cr) and their counter-specimens were analyzed. The specimen, produced by laser surface alloying using laser beam power of 1.43 kW, was characterized by Δ

m/

mi value (0.0008) that was significantly lower than those of laser-borided specimens with a dilution ratio of 0.37 [

60] or 0.54. The relatively low mass loss during the running-in stage could cause such a situation. This meant an approximately 26-fold reduction in relative mass loss compared to the untreated 316L steel (0.0206) [

60]. In the case of the specimen, which was fabricated using higher laser beam power (1.56 kW), the relative mass loss (0.0013) was significantly lower compared to the laser-borided specimen with a dilution ratio of 0.37 [

60] and slightly higher than the value measured for laser-borided specimen with

DR = 0.54. Undoubtedly, this may have been influenced by a slightly longer duration of the running-in stage. Hence, the relative mass loss of this specimen was approximately 16-times lower than that of the 316L steel without surface layer. The relative mass losses of the counter-specimens, which mated with the laser-alloyed specimens using the laser beam powers of 1.43 and 1.56 kW, were equal to 0.000072 and 0.000075, respectively. These values were comparable to the relative mass loss of the counter-specimen, which mated with the laser-borided specimen with a dilution ratio of 0.54.

Summarizing, the lowest relative mass losses of the specimens were obtained in the case of the treatment, consisting in laser surface alloying with boron and nickel (B and Ni) as well as with boron, nickel and chromium (B and Ni-Cr) using the laser beam power of 1.43 kW. This indicated the high wear resistance of these layers. In the case of laser-alloyed specimen with boron and nickel, its high resistance to wear was also confirmed by the relatively low value of mass wear intensity factor

Imw (

Figure 6a).

The different techniques and methods of wear evaluation were reported in literature data regarding the wear behavior of the surface layers produced in austenitic steels. The samples, subjected to LTPGN process, were tested using the “block-on-ring” technique with AISI 52100 steel as a ring-shaped counter-sample [

2,

3], “ball-on-disc” method using AISI 52100 steel [

5,

9] or Al

2O

3 [

7] in the shape of ball as a counter-sample or “pin-on-disc” technique using AISI 1045 steel as a counter-sample in the shape of pin [

8]. Unfortunately, in the case of very interesting technique of LTPGN using an active screen [

10,

11,

12,

13] the wear resistance of the layers was not studied. The effects of HTPGN process on the tribological properties of austenitic steel were tested using “block-on-ring” [

3] or “ball-on-disc” [

5,

15] techniques using the counter-specimen made of AISI 52100 steel in the shape of ring [

3] or ball [

5] as well as sapphire ball [

15], respectively. After the similar process, reported in the paper [

14], the wear resistance was not investigated. The wear tests after cathodic plasma electrolytic nitriding (CPEN) were carried out using the “ball-on-disc” technique with a ball composed of Al

2O

3 [

16]. The similar wear tests were used after hybrid treatment using the plasma nitriding [

7,

13,

17,

18,

19,

20,

21,

22,

23,

24]. The wear behavior after simultaneous low-temperature plasma gas nitrocarburizing (LTPGNC) [

7] was studied by the same “ball-on-disc” method with the use of Al

2O

3 ball as a counter-sample. The wear resistance of the layer, produced by deposition of Au coating followed by LTPGN using active screen was not provided [

13]. The shot peening (SP) process was often used before LTPGN [

17,

18] or sequential LTPGC (low-temperature plasma gas carburizing) and LTPGN processes [

19]. However, the study of wear behavior was provided only in the paper [

19] in which the “ball-on-disc’ tests using WC-Co balls were performed. In the paper [

20], the laser powder bed fusion (L-PBF), one of the selective laser melting (SLM) methods, was used to create untextured and microtextured surfaces and samples. The samples, fabricated using the 316L steel powder, were tested by the “pin-on-disc” technique with the use of Al

2O

3 as a counterpart. Al

2O

3 ball was applied as a counter-sample during the wear tests of cold-sprayed 316L powder and LTPGN or low-temperature plasma gas carburizing (LTPGC), cold spraying (CS) of such a powder followed by LTPGC and LTPGN or followed by a simultaneous low-temperature plasma gas nitrocarburizing (LTPGNC) process [

21]. The same technique of wear test was used in the case of laser metal deposition (LMD) of 316L steel and nickel powders on the surface of AISI 304 austenitic steel prior to LTPGN [

22]. The plasma gas-nitrided layers followed by a multi-arc ion plating (MAIP), producing the WCrTiAlN coatings [

23], were tested using “ball-on-disc” method with the GCr15 bearing steel balls as counter-specimens. The wear behavior of physical vapor deposited (PVD) (CrWAlTiSi)N multilayer coating on plasma gas-nitrided AISI 316L steel was not studied [

24]. The influence of LTPGC process on the wear resistance of the layers produced was studied using “ball-on-disc” technique with alumina (Al

2O

3) ball as a counter-sample [

26] or by tribocorrosion test integrating the similar “ball-on-disc” tester with an electrochemical potentiostat [

27]. Whereas the papers [

25,

28] did not study the wear behavior of low-temperature gas carburized layers. The plasma gas borided layer became the interlayer between the austenitic substrate and the thin nanostructured diamond film [

29], and its wear resistance was not investigated. Only the microstructures and growth kinetics of the plasma paste borided (PPB) layers were analyzed in the paper [

30]. The advantageous influence of the PPB process on the wear resistance of austenitic steel was confirmed using “block-on-ring” technique in which a ring-shaped counter-specimen, made of quench-hardened and low-temperature tempered 100CrMnSi6-4 bearing steel, was used [

31]. Despite the difficulties with surface activation of the austenitic steels, many typical thermo-chemical processes also resulted in the formation of wear resistant surface layers. The sintered WC-Co ball [

35], Al

2O

3 ball [

38] or WC (tungsten carbide) ball [

40] became the counter-samples during the wear tests of powder-pack borided (P-PB) layers using “ball-on-disc” methods. The scratch test [

37] was employed to assess the wear behavior of boride layers based on the obtained coefficient of friction (CoF). The three-body abrasion tests were also performed after P-PB [

39]. In this case, AISI 52100 steel balls rotated against a flat borided sample in the presence of abrasive slurry. The “pin-on-disc” method with AISI 52100 steel pins was used to evaluate the wear resistance of powder-pack borided layer [

41]. The hybrid layers fabricated using P-PB followed by powder-pack chromizing (P-PCr) or P-PCr followed by P-PB were also studied [

41]. Whereas the wear behavior of some powder-pack borided layers [

33,

34,

36] as well as the layers borided in liquid media [

42,

43] was not studied. During the tribocorrosion tests of low-temperature gas nitrided layers, the “ball-on-disc” technique was applied using alumina ball as a counter-sample [

44]. The similar tests were also carried out after low-pressure and low-temperature gas nitriding (LTGN) of high-velocity oxy-fuel (HVOF) sprayed 316L coating [

45] in order to investigate the wear resistance of the layers produced. The nitrided layers, produced by high-temperature gas nitriding (HTGN) [

46,

47] as well as by nitriding in liquid media [

48,

49] were not subjected to wear tests. The wear behavior of powder-pack carburized austenitic steel was not provided [

50,

51]. The wear tests of low-temperature carburized layer, produced on 316L steel in unknown medium [

52], were carried out using the “block-on-ring” method with the two various ring-shaped counter-specimens: untreated 316L steel and the same way carburized 316L steel. The “ball-on-disc” technique was employed in order to evaluate the wear behavior of thin TiN coatings, fabricated on the 316L substrate by PVD technique, using WC-Co [

53] and silicon nitride (Si

3N

4) [

54] balls as counter-specimens. Some of the surface layers, produced on austenitic 316L steel by laser surface alloying (LSA), were also subjected to wear tests [

57,

60,

61,

62]. The “pin-on-disc” method with WC-Co drill as counter-specimen was used in order to assess the wear behavior of laser-alloyed layers with Cr

3C

2 chromium carbides [

57,

61], TiC titanium carbides [

61], a mixture of Cr

3C

2 and Cr or mixture of Ti and SiC silicon carbide [

57]. The wear resistance of laser-alloyed layer with boron was studied using “block-on-ring” technique in which the counter-sample was composed of S20S (WC-Co) sintered carbide [

60]. The “ball-on-disc” method with the use of ZrO

2 ball as a counter-specimen was applied in the paper [

62], in which the alloying material consisted of 80 wt.% Cr and 20 wt.% CrB

2 powders.

It was difficult to compare the results of wear tests of the surface layers, produced in austenitic steel using the various techniques, because of the differences in the techniques of wear behavior investigation, the methods of its evaluation as well as the load used. Therefore, the most appropriate method of comparing the effects of different surface treatment seemed to be the indication how many times the wear resistance had increased in comparison with untreated austenitic steel using specific evaluation method. The results of such considerations are shown in

Table 3 for physical techniques of formation of surface layers on austenitic steel. Volumetric wear simply meant a loss of the specimen volume during the wear test. The specific wear rate was usually measured by the ratio of the sample volume loss to the product of the applied load and sliding distance. The coefficient of friction (CoF) was defined as the ratio of applied load to the frictional force. By mass loss, the mass loss of the specimen during the wear test was understood. The mass wear intensity factor and relative mass loss were defined previously in the present study.

The laser-alloyed layers, presented in this study, were characterized by 15–26-times lower mass wear intensity factors and 5–26-times lower relative mass loss in comparison with untreated 316L steel. The wear tests were carried out using “block-on-ring” technique in which ring-shaped specimens and block-shaped counter-specimens were used. It seemed that the more comparable results could be obtained in the case of the surface layers examined with the use of the same “block-on-ring” technique, i.e., low-temperature plasma gas-nitrided [

2,

3], high-temperature plasma gas-nitrided [

3] or plasma paste borided [

31] layers. However, some differences characterized these wear tests in comparison with the tests, reported by the present work. First of all, the samples were prepared in the shape of “blocks”, and the ring-shaped counter-samples were made of 100CrMnSi6-4 bearing steel of a hardness of 60 HRC [

2,

3] or 64 HRC [

31]. The differences in the load occurred. Plasma paste borided specimens [

31] were investigated using lower load (19.6 N) in comparison with the present study (49 N). In this case, the same methods of evaluation of wear resistance were used, i.e., mass wear intensity factor (

Imw) and relative mass loss. PPB process resulted in 4-fold reduction in the

Imw value and 6-fold reduction in relative mass loss compared to the untreated 316L steel [

31]. The effect of PPB on the wear was diminished in comparison with laser-alloyed layers. In the case of the specimens, subjected to LTPGN [

2,

3] or HTPGN [

3] processes, only the load per unit of the friction surface (400 MPa) was provided. However, it was difficult to determine what area was taken into account when calculating this value. Additionally, the oil Lux 10 was used as a lubricant, and the effect on the wear was analyzed using the volumetric wear. The increase in wear resistance of these layers was extremely high, obtaining the volumetric wear up to 371 (LTPGN) or even 920-times lower (HTPGN) than that of untreated austenitic 316L steel [

2,

3].

In the case of wear tests of the surface layers, produced by LTPGN, LTPGNC, HTPGN, CPEN and LTPGC processes, the “ball-on-disc” technique was most popular [

5,

7,

9,

15,

16,

23,

26,

27]. The volumetric wear, measured after LTPGN and HTPGN under the load of 8.3 N, was 40-times and 2.5-times lower, respectively, when compared to 316L steel without surface treatment [

5]. The values of specific wear rate and coefficient of friction, measured at the load of 10 N, were used in order to evaluate the wear behavior of the surface layers, produced by LTPGN or LTPGNC processes [

7]. The results confirmed 29-fold and 23-fold reduction in specific wear rate of low-temperature plasma gas nitrided and low-temperature plasma gas nitrocarburized layers, respectively. However, the effect of such processes on coefficient of friction was ambiguous and relatively slight in comparison with untreated steel, obtaining values 1.015-times higher or 1.063-times lower after LTPGN and LTPGNC, respectively. The values of volumetric wear and CoF, measured at a load of 20 N in the case of low-temperature plasma gas nitrided layer [

9], were 13.5-times and 1.063-times lower, respectively, than the values characteristic of the austenitic steel without surface treatment. The same methods of wear evaluation were used after LTPGN process, reported in the paper [

23]. In this case, at the load of 10 N, the volumetric wear was 1.47-times lower, and coefficient of friction was 1.26-times lower compared to the untreated steel. The tribocorrosion tests at a load of 20 N indicated the 10-fold reduction in volumetric wear after LTPGC process [

27]. The specific wear rate was determined in order to evaluate the effect of various HTPGN processes on wear using the load of 3 N [

15]. Its measured values were from 175- to 650-times lower in comparison with the untreated austenitic steel. Whereas the coefficient of friction, measured after CPEN (cathodic plasma electrolytic nitriding) at load of 3 N, was only 1.6-times lower [

16]. The particular method of wear evaluation was used in the case of LTPGC process, reported by the paper [

26]. The percentage of volume removed was defined as the ratio of the volume loss per unit of length of carburized sample to the volume loss per unit of length of untreated sample. The percentage of volume removed, thus calculated, was equal to 1 for the material without surface treatment, and 10-times lower for the carburized layer [

26].

The “ball-on-disc” technique was also used during the wear tests of hybrid layers, produced by hybrid treatment [

19,

21,

22,

23] and TiN coatings [

53,

54]. LTPGN followed by MAIP (multi-arc ion plating) resulted in the greater effect on wear at the same load (10 N) than only LTPGN process, obtaining 11.2-times lower volumetric wear and 2.25-times lower friction coefficient compared to the untreated steel [

23]. The wear evaluation of the combined processes consisting in SP (shot peening) followed by LTPGC and LTPGN processes at 475 °C was performed using the volumetric wear [

19]. Its value, measured at a load of 15 N, was up to 65-times lower than that characteristic of the austenitic steel without surface treatment. Although the volumetric wear of the surface layers, produced by SP process followed by LTPGN, was not specified in

Table 3, it was reduced up to 39-times [

19]. The specific wear was measured at a load of 1.96 N during the wear tests of other hybrid processes that consisted of: CS (cold spraying) of 316L powder and LTPGN or LTPGC, CS of such a powder followed by LTPGC and LTPGN or followed by a simultaneous low-temperature plasma gas nitrocarburizing (LTPGNC) process [

21]. Among these processes, two of them were characterized by the greatest effect on reducing the wear. In the case of CS of 316L steel followed by LTPGN or CS of 316L steel followed by LTPGC and LTPGN, the values of specific wear rate were 10–26- or 9–26-times lower when compared to the untreated 316L steel, respectively. The same method of wear evaluation was reported in the paper [

22] regarding the combined processes consisting in LMD (laser metal deposition) of 316L steel and nickel powders on the surface of AISI 304 austenitic steel prior to LTPGN [

22]. The values of specific wear rate were from 56 to 175-times lower in comparison with this steel without surface treatment. TiN coating, produced by PVD technique, was characterized by 2.52-fold reduction in mass loss per friction distance and 1.37-fold reduction in coefficient of friction at a load of 5 N [

53]. Similar TiN coating, reported in the paper [

54], indicated the specific wear rate up to 13.67-times lower and CoF values 1.11–5-times lower than the values characteristic of the untreated 316L steel.

The “pin-on-disc” technique was used less often for layers or coatings produced on austenitic steel by physical methods. In the

Table 3, only two of the physical techniques of the surface layers formation were taken into account. The wear of the low-temperature gas nitrided layer was examined under the highest load of 100 N [

8]. The effect of this surface treatment on the wear was ambiguous. The mas loss was 4.6–91-times lower, and the coefficient of friction was 1.075–1.47-times higher in comparison with the untreated 316L steel [

8]. In the case of LSA with the mixture of Cr

3C

2 and Cr powders, specific wear rate in deionized water was characterized by 1.29-fold reduction compared to the untreated 316L steel. Whereas the coefficient of friction did not change significantly during the wear tests at a load of 5 N [

57]. In the paper [

61] that was published by the same authors, the wear behavior of the laser-alloyed layers with Cr

3C

2 or TiC was studied at the same load (5 N). The specific wear rate was up to 1.66 and 5.93-times lower, respectively, and CoF values were slightly higher or lower in comparison with untreated 316L steel. The wear behavior after the hybrid process, consisting in SLM followed by LTPGN, was evaluated using the specific wear rate and coefficient of friction [

20]. In this case, the “pin-on-disc” technique was also applied under a load of 10 N. However, the results were not compared to the 316L steel without surface treatment. Unfortunately, among the physical techniques analyzed were those for which no wear tests were carried out. Therefore, it was not possibility to compare the wear behavior of the surface layers produced by LTPGN and LTPGN with active screen [

10], HTPGN [

14], SP + LTPGN [

17], LTPGC [

28] or LSA with NiCoCrB [

59].

The thermochemical techniques of producing surface layers on austenitic steel were compared in a similar way (

Table 4). For similar reasons, the amount of times the wear resistance of the layers increased compared to the untreated steel was also analyzed. Simultaneously, the wear test technique, load and methods of wear evaluation were indicated in

Table 4. As was the case with the physical techniques for the formation of the surface layers, among the methods of wear evaluation used, the volumetric wear, specific wear rate, coefficient of friction (CoF) and mass loss of the samples were the most commonly used. Additionally, the wear area and wear depth were used in order to evaluate the wear behavior of the surface layers [

45]. The wear area corresponded to the worn surface of the surface layer, and wear depth denoted the maximal depth of the wear scar formed on the investigated surface.

The surface layers, fabricated by powder-pack boriding (P-PB), were usually subjected to wear tests using the “ball-on-disc” technique [

3,

38,

39,

40] or “pin-on-disc” technique [

41]. The specific wear rate and coefficient of friction were measured at a load of 5 N after the P-PB process, as reported in the paper [

35], obtaining the values which were 4–9-times lower and 1.31–4.13-times lower, respectively, when compared to the untreated 316L steel. The same methods of wear evaluation were used in the paper [

38] at loads of 5 N or 20 N. However, in this case only the specific wear rate was compared to the 316L steel without surface treatment. Its values were 38–62-times lower, depending on the load and sliding distance used. The coefficients of friction were measured only for the borided layer, obtaining values of 0.55 and 0.65 at load of 5 N and 20 N, respectively. Micro-abrasion wear resistance of powder-pack borided 316L steel was studied in the paper [

39] using abrasive slurry, consisting of SiC particles (4–5 μm) dissolved in a 20% volume proportion with deionized water. The specific wear rate of borided layer, measured at the load of 0.2 N, was 1.53-times lower than that of the austenitic steel without surface treatment. The wear resistance of powder-pack borided 316L steel [

40] was 15–59-times lower, taking into consideration the values of specific wear rate at a load of 5 N. Whereas the CoF values were 2.03–2.68-times lower, depending on the boriding parameters (temperature and time). The volumetric wear was not compared to the untreated 316L steel [

40].

The “pin-on-disc” technique at loads of 95 N and 125 N was used in order to evaluate the wear behavior of powder-pack borided layer as well as the hybrid layers, produced by P-PB followed by P-PCr or P-PCr followed by P-PB [

41]. In this case, the two methods of wear evaluation were used: mass loss and coefficient of friction. The greatest increase in wear resistance was recorded for the borided and then chromized samples. Their mass loss indicated 11-fold and 3.71-fold reduction in the mass loss at loads of 95 and 125 N, respectively. The only borided layer was characterized by 4.75-times and 3-times diminished mass loss in comparison with the untreated 316L steel at the same loads. The effect of P-PCr followed by P-PB on the wear was smaller. The values of mass loss were 2- or 1.81-times lower, compared to the austenitic steel without surface treatment. The influence of the surface treatment used on the coefficient of friction was ambiguous [

41]. In the case of powder-pack borided layer, the values of CoF, measured at loads of 95 N and 125 N, were 1.055-times and 1.15-times higher, respectively, when compared to untreated 316L steel. The P-PCr process followed by P-PB influenced the coefficient of friction this way that its value was 1.22-times higher at a load of 95 N and nearly the same, if it was measured at a load of 125 N. It seemed that the more advantageous effect on CoF values was obtained after the hybrid treatment, consisting in P-PB followed by P-PCr. Although the coefficient of friction was 1.17-times higher at a load of 95 N, its value was 1.08-times lower at a load of 125 N compared to the untreated 316L steel [

41].

The “ball-on-disc” technique was used during the tribocorrosion tests of low-temperature gas nitrided layers in 3.5% NaCl solution [

44]. The total mass loss of the specimens resulted from the chemical and mechanical wear. If the specimens were subjected to the load of 2 N, the LTGN process caused 5–70-times the lower mass loss in comparison to the untreated 316L steel, depending on the applied potential. At the load of 10 N, its value was even 1.56-times higher when compared to the austenitic steel without surface treatment. This effect was observed because the S-phase layer was worn through at increased load. However, the coefficient of friction, measured at 10 N, was approximately 1.11-times lower than that of untreated steel [

44]. The effects of LTGN process on the wear of previously HVOF-sprayed 316L steel were studied using the “ball-on-disc” technique and “reciprocating ball-on-plane” technique [

45]. The wear areas and wear depths were measured after “ball-on-disc” test under a load of 20 N. When compared to the untreated austenitic steel, their values were 2.07–9-times lower and 1.74–5.53-times lower, respectively. During the “reciprocating ball-on-plane” tests, the volumetric wear and wear depth were used in order to evaluate the wear behavior of the specimens. The low-temperature gas nitrided specimens were characterized by 1.75–2.92 and 1.42–2.16-times diminished volumetric wear and wear depth, respectively.

The effect of low-temperature carburizing on the wear of austenitic steel was studied using the “block-on-ring” technique at a load in the range from 5 to 25 N [

52]. The volumetric wear of the specimens, subjected to LTC process, was up to 2-times lower in comparison with untreated 316L steel. Some of the previously mentioned surface layers, produced using P-PB [

33], SMAT (surface mechanical attrition treatment) followed by P-PB [

34], boriding in liquid medium [

42] or nitriding in liquid medium [

49], were not subjected to wear tests. The results of very-interesting scratch tests, carried out after P-PB or P-PB followed by diffusion annealing [

37], were difficult to compare to the other techniques of wear behavior evaluation.

Summarizing, the laser-alloyed layers, studied in the present work at a relatively high load of 49 N, were characterized by the relatively significant increase in wear resistance, measured by mass wear intensity factor (

Imw) and relative mass loss (Δ

m/

mi), when compared to the majority of the other physical and thermochemical techniques of the surface treatment. The use of a relatively high load was possible due to the high depths of the laser-alloyed layers produced. In the case of other techniques of surface treatment, the greater effect on wear reduction was usually obtained at much lower load [

5,

7,

15,

19,

22,

38,

40] or at the load which was difficult to determine [

2,

3]. The higher load was reported only during the wear tests of low-temperature plasma gas nitrided layer [

8] and the surface layers which were fabricated by P-PB, P-PB followed by P-PCr or P-PCr followed by P-PB [

41]. Only the results of the paper [

8] indicated the comparable or even greater effect of the surface layer on the wear behavior of austenitic steel.

3.3. Wear Mechanisms

The wear mechanism of laser-alloyed layers with boron as well as with boron and selected metallic elements was studied based on the SEM observations of the worn surfaces of the specimens and counter-specimens (S20S sintered carbides) and EDS patterns of selected elements on these surfaces. The same techniques were previously used in order to identify the wear mechanism of laser-borided layer and untreated 316L steel [

60]. The worn surface of the laser-borided layer with a dilution ratio of 0.37 indicated, firstly, the intensive abrasive wear represented by the characteristic shallow grooves. Simultaneously, the EDS patterns of selected elements on the worn surfaces indicated the obvious signs of oxidative wear of laser-borided specimen as well as the effects of adhesive wear on the worn surface of the counter-specimen [

60]. On the other hand, the worn surface of austenitic steel 316L without surface treatment was characterized by obvious signs of strong plastic deformation as well as abrasive and adhesive wear, as indicated by deep grooves and adhesive craters. The effects of adhesion were confirmed by the EDS patterns of selected elements on the worn surface of the counter-specimen after the wear test of untreated 316L steel [

60].

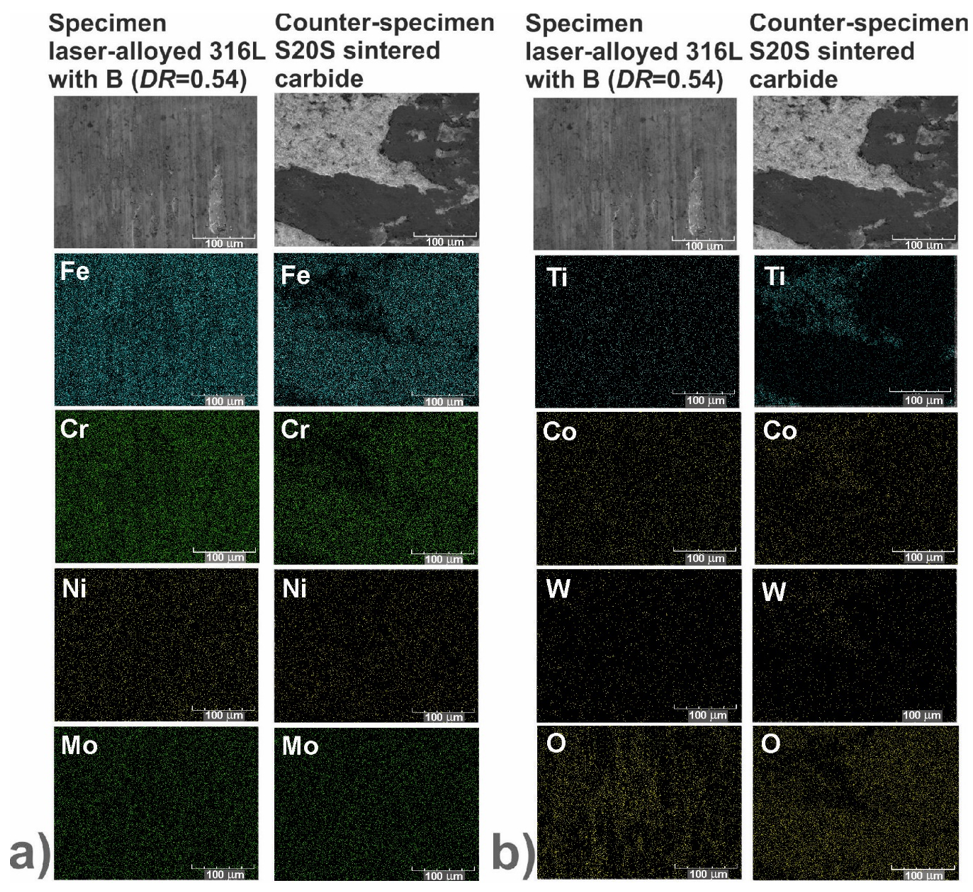

The worn surfaces of the laser-borided specimen with a dilution ratio of 0.54 and counter-specimen, made of S20S sintered carbide, are presented in

Figure 8. Simultaneously, the EDS patterns of selected elements characteristic of a specimen (

Figure 8a) and counter-specimen (

Figure 8b) are shown. Additionally, the EDS patterns of oxygen were taken into account in

Figure 8b. The worn surface of the laser-borided layer with a higher dilution ratio (0.54) revealed intensive abrasive wear, as indicated by the characteristic shallow grooves (

Figure 8). In this case, the reduced concentrations of iron and chromium (

Figure 8a) were observed in some darker areas of the sample, which corresponded to a considerably increased oxygen content (

Figure 8b). This may indicate the oxidative wear. The light areas with predominant abrasive wear and dark areas with reduced concentrations of titanium, cobalt and tungsten (

Figure 8b) as well as increased iron, chromium and oxygen concentrations (

Figure 8a) were visible on the surface of mating counter-specimen. This indicated the possibility of adhesive and oxidative wear. The areas of the worn surfaces of the counter-samples with relatively high iron and chromium concentrations overlapped.

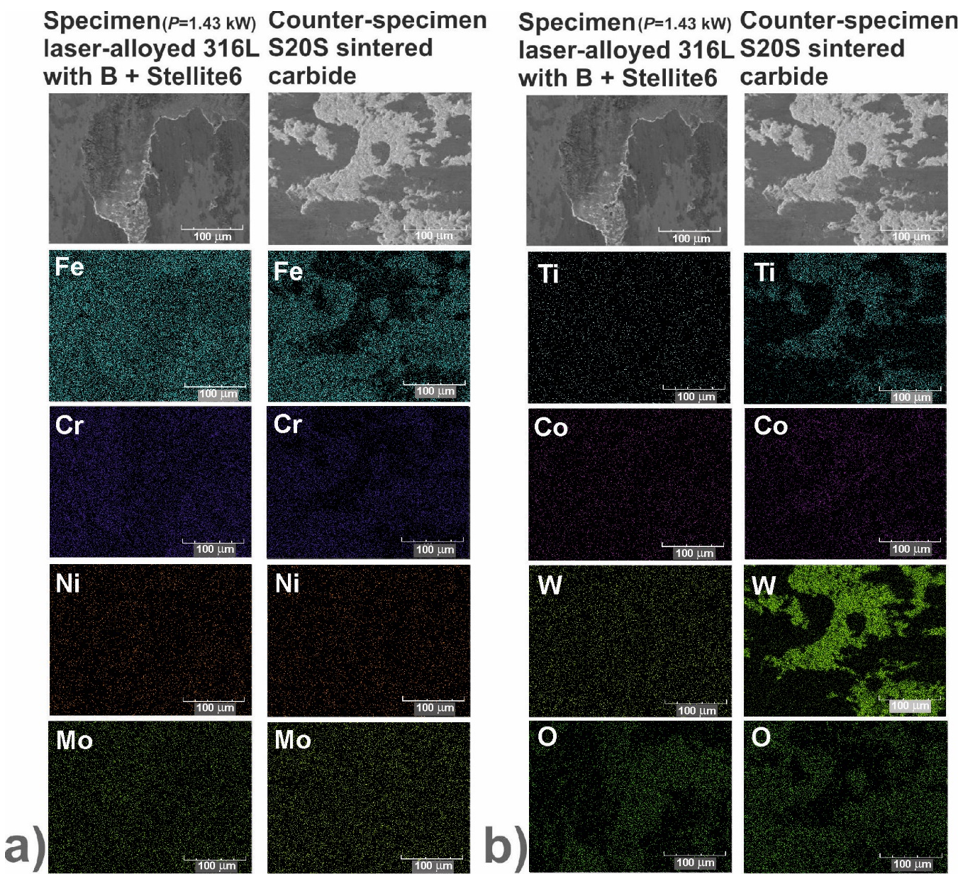

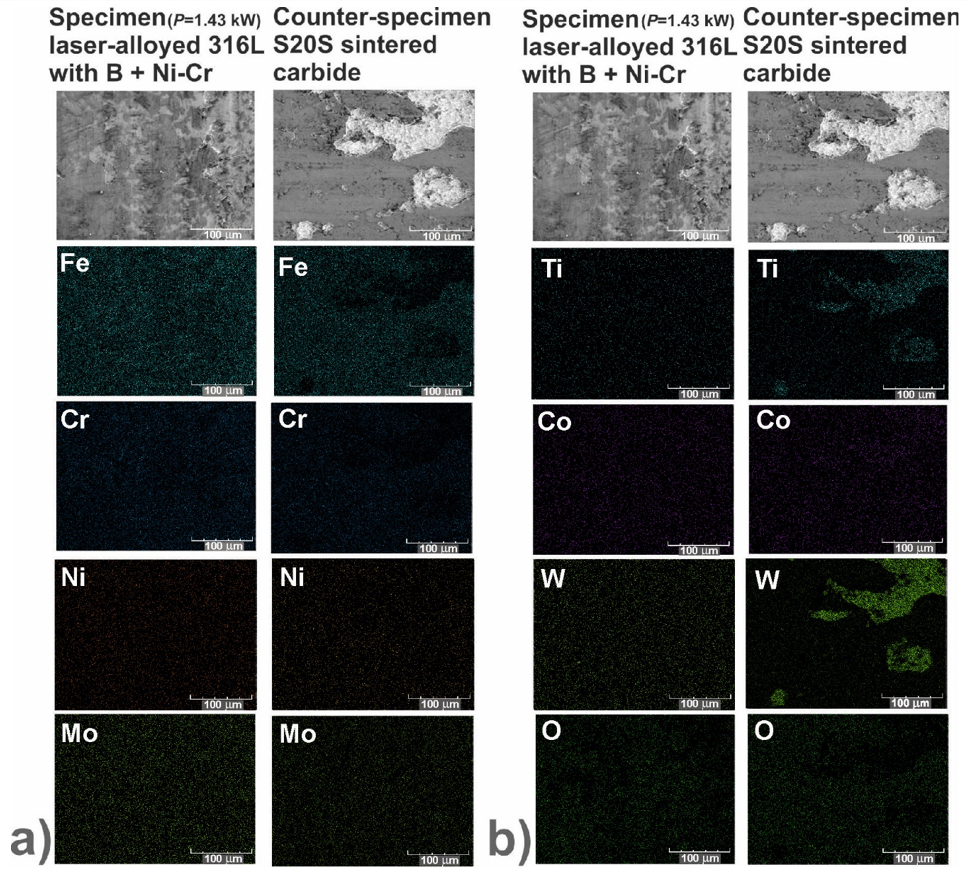

The worn surfaces of the laser-alloyed specimen with boron and Stellite-6 at a dilution ratio of 0.41 and counter-specimen, made of S20S sintered carbide, were also observed using SEM (

Figure 9). The EDS patterns of selected elements characteristic of a specimen and counter-specimen are shown in

Figure 9a,b, respectively. Shallow grooves, indicating abrasive wear, as well as small adhesive craters were observed on the worn surface of the laser-alloyed sample. The increased oxygen content in some darker areas of the sample and counter-sample (

Figure 9b) demonstrated possible oxidative wear. The increased iron concentration in some areas of the counter-specimen was due to the probable adhesive wear. Usually, it was accompanied by an increased oxygen content, which in turn would confirm oxidative wear. Significantly lower concentrations of tungsten, cobalt and titanium were also observed in the areas where oxides appeared on the worn surface of the counter-specimen. A relatively low concentration of chromium was observed on the worn surface of the specimen. Chromium was also not detected in more quantities on the worn surface of the counter-specimen. This may have indicated its reduced contents close to the surface of the laser-alloyed layer produced.

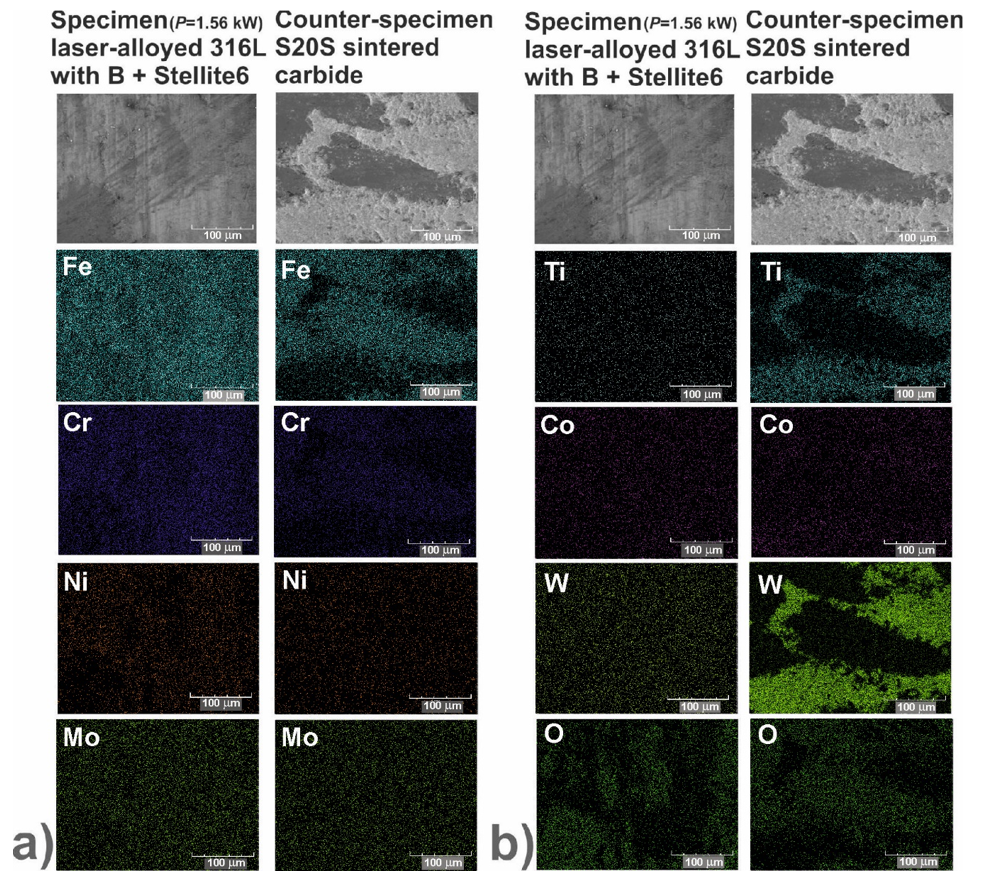

SEM observations and X-ray microanalysis on the worn surfaces of 316L steel, laser-alloyed with boron and Stellite-6 alloy at higher laser beam power (1.56 kW), and mating counter-specimen (S20S), led to similar conclusions as those formulated with the use of a lower laser beam power (1.43 kW). The worn surfaces of the sample and counter-sample, together with the EDS patterns of distribution of selected elements, are shown in

Figure 10. Shallow grooves on the worn surface of the laser-alloyed sample indicated its obvious abrasive wear. Small adhesive craters were also visible. It was likely that oxidative wear also occurred, as evidenced by the increased oxygen content in some darker areas of the specimen and counter-specimen (

Figure 10b), as well as by the increased iron concentration on the worn surface of the counter-specimen in these areas (

Figure 10a) that could also result from the adhesive wear. As in the previous case, relatively low concentrations of tungsten, titanium and cobalt were observed on the worn surfaces of the counter-samples in the areas in which the oxides appeared. Simultaneously, relatively low chromium concentrations were detected on the worn surfaces of the sample and counter-sample. It was characteristic of both laser-alloyed specimens with boron and Stellite-6 that the increase in cobalt content was not visible on their worn surfaces, despite the presence of cobalt in the alloying material.

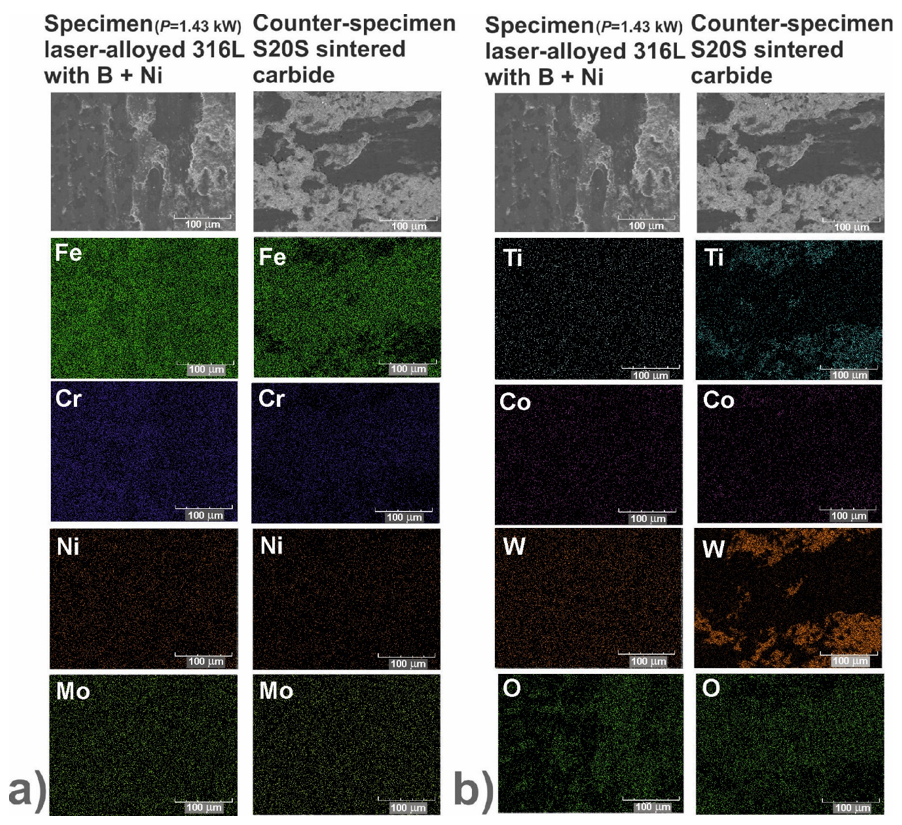

Figure 11 shows the worn surfaces of the laser-alloyed specimen with boron and nickel at a dilution ratio of 0.41 and the counter-specimen with distribution of the analyzed elements by the EDS method. Similar wear mechanisms have been observed as in previous cases. Shallow grooves on the worn surface of the laser-alloyed sample showed abrasive wear and small craters indicated adhesive wear. The increased oxygen content was observed in darker areas of the sample and counter-sample (

Figure 11b). Together with the increased iron concentrations on the worn surface of the counter-specimen, it indicated likely wear by oxidation. Such an increased iron content on the counter-sample may also have been partly due to adhesive wear. Simultaneously, the areas with oxides on the worn surface of the sample indicated a diminished iron content. In the probable areas of occurring oxides, significantly reduced concentrations of tungsten, titanium and cobalt were also visible on the worn surface of the counter-sample. There was a relatively low concentration of chromium on the worn surface of the specimen as well as counter-specimen. As in previous cases, this could indicate its reduced content in the surface zone of the laser-alloyed layer produced.

The worn surfaces of 316L steel, laser-alloyed steel with boron and nickel at a dilution ratio of 0.48, and mating with it counter-sample are shown in

Figure 12 together with EDS patterns of distribution of selected elements. The wear mechanisms of this laser-alloyed specimen were similar to the previous surface layers analyzed. Shallow grooves on the worn surface of the laser-alloyed sample indicated abrasive wear, while the presence of small craters confirmed adhesive wear. The darkest areas on the worn surfaces of the sample and counter-sample were characterized by an increased oxygen content (

Figure 12b), and an increased iron concentration was visible on the worn surface of the counter-sample in these areas (

Figure 12a). This indicated the probable oxidative wear. The relatively high iron content on the worn surface of the counter-specimen may also have been partly due to adhesive wear. Simultaneously, the diminished iron contents were detected in the areas with oxides on the worn surface of the specimen. As in the previous cases, the areas of occurring oxides were characterized by diminished tungsten, titanium and cobalt contents on the worn surface of the counter-sample (

Figure 12b), and relatively low chromium content was observed on the worn surfaces of the specimen and counter-specimen.

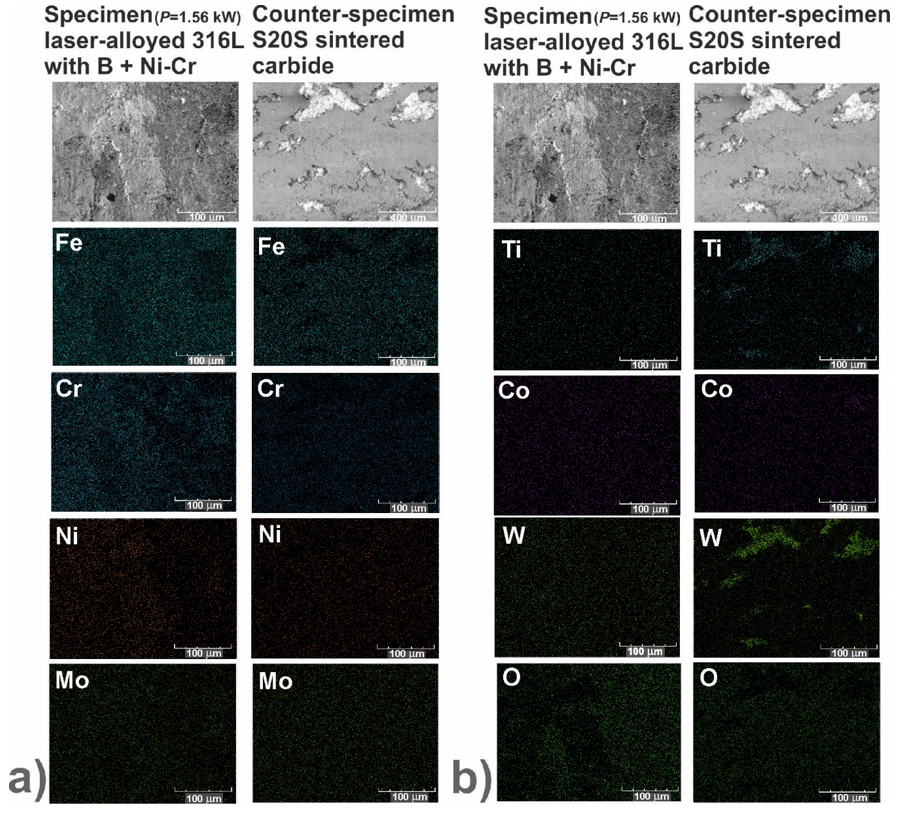

The worn surfaces of laser-alloyed specimen with boron, nickel and chromium at a dilution ratio of 0.43 and corresponding counter-specimen (S20S sintered carbide), together with EDS patterns of distribution of selected elements, are shown in

Figure 13. Similar wear mechanisms were found to be present, as those-identified for laser-alloyed only with boron, boron and Stellite-6 or with boron and nickel. Shallow grooves on the worn surface of the sample were a sign of abrasive wear, and small craters confirmed adhesive wear. The darker areas, observed on the worn surfaces of the sample and counter-sample (

Figure 13b) were characterized by an increased oxygen content. The increased iron concentration was also recorded on the worn surface of the counter-sample in these areas (

Figure 13a). This indicated a high probability of wear by oxidation. The relatively high iron content on the worn surface of the counter-specimen may also have confirmed adhesive wear. On the other hand, in the areas where oxides appeared, the relatively low iron content was detected on the worn surface of the specimen. In the areas where oxides probably occurred on the worn surface of the counter-sample, tungsten and titanium concentrations were significantly lower. In contrast to the case of laser alloying with the previous types of alloying materials, the worn surface of the sample clearly showed the relatively high chromium concentration, which was also observed on the surface of the counter-sample, probably as a result of the combined oxidative wear and adhesive wear. It is estimated that the reason for this was due to the inclusion of chromium as a part of the alloying material.

The similar analysis enabled to identify the wear mechanisms of laser-alloyed specimen with boron, nickel and chromium at a dilution ratio of 0.49. The worn surfaces of the specimen and counter-specimen after wear test as well as their EDS patterns are shown in

Figure 14. In general, the same wear mechanisms have been identified as in previous cases, i.e., abrasive wear, adhesive wear and oxidative wear, based on the SEM images of the worn surfaces and EDS patterns obtained.

Summarizing, the wear behavior of all the laser-alloyed alloyed layers, presented in this work, was characterized by a predominant abrasive wear as well as oxidative wear and to a lesser extent observed adhesive wear. The wear mechanisms of other surface layers, fabricated by physical techniques, were identified using various methods and devices, e.g., OM images [

5,

7,

9,

27], SEM images [

15,

23,

53,

54,

60], optical profilometer [

7], WDS (wavelength dispersive spectrometer) [

15], EDS (energy dispersive spectrometer) [

23,

54,

60] or confocal microscope [

16]. Many of these papers analyzed the wear mechanisms under condition of dry friction (unlubricated sliding contact) [

5,

7,

8,

9,

15,

16,

19,

20,

21,

22,

23,

26,

31,

53,

54,

60]. Some of them confirmed abrasive, adhesive as well as the oxidative wear with severe plastic deformations in the case of the untreated 316L steel [

7,

9,

15,

16,

23,

27,

53,

54,

60], irrespective of the technique of wear tests and the load used. However, in many papers the wear mechanisms of the surface layers were not studied, assuming their predominant abrasive wear [

2,

3,

8,

21,

22,

26,

31,

57]. In the case of hybrid surface treatment, consisting in SP (shot peening) followed by LTPGC and LTPGN processes at 475 °C [

19], the authors indicated that the thin layer demonstrated possible adhesive wear due to the plastic deformation in the underlying substrate. The thick layer was necessary to avoid this plastic deformation [

19].

Some of the surface layers, produced by the physical techniques, were subjected to the detailed analysis of wear mechanisms. They are specified in

Table 5. The wear mechanisms of low-temperature or high-temperature plasma gas nitrided layers [

5] were studied using optical microscope (OM). OM images of the worn surfaces revealed the craters with scratching and rolling which confirmed grooving abrasion and rolling abrasion, respectively. The same method of wear mechanism identification was used after wear tests of the specimens subjected to LTPGN and LTPGNC processes [

7]. The wear tracks were characterized by shallow grooves and adhesion craters, revealing the abrasive and adhesive wear, respectively. Additionally, the transverse cracks were observed in the wear tracks using optical profilometer what confirmed the plastic deformation of the material underneath the surface layer [

7]. OM images of the wear scars on the worn surface of low-temperature plasma gas nitrided layer [

9] indicated the shallow grooves, corresponding to abrasive wear. SEM images of wear tracks revealed the shallow grooves, confirming the abrasive wear of high-temperature plasma gas nitrided layers [

15]. Simultaneously, the WDS pattern of oxygen demonstrated the increased oxygen concentration, especially in the case of the adjacent areas to the wear tracks. It could confirm the presence of oxides and thus oxidative wear [

15].

The confocal microscope was used in order to identify the wear mechanism of the surface layer produced by CPEN [

16]. The shallow grooves were observed on its worn surface, revealing the abrasive wear. The wear mechanisms of the layers, fabricated by LTPGN process and LTPGN followed by MAIP (multi-arc ion plating), were identified using SEM images and EDS X-ray microanalysis [

23]. SEM images revealed slight scratches and craters (dark pitches) on the worn surfaces of these layers, corresponding to abrasive and adhesive wear, respectively. The increased oxygen content, measured by EDS method, confirmed the presence of oxides on the worn surfaces and thus oxidative wear [

23]. The low-temperature plasma gas carburized 316L steel was subjected to tribocorrosion tests in 1 M H

2S0

4 and 0.5 M NaCl solutions [

27]. Shallow grooves in OM images of worn surfaces confirmed the abrasive wear. Additionally, the signs of general corrosion (oxygen evolution) in 1 M H

2S0

4 and crevice corrosion in 0.5 M NaCl indicated corrosive wear. No pitting corrosion was revealed on the worn surfaces. TiN coatings, produced by PVD technique, were characterized by abrasive wear [

53] based on the SEM images of worn surface. In the case of the similar coatings, reported in the paper [

54], the SEM images of the worn surfaces revealed abrasive and adhesive wear [

54]. Simultaneously, based on the EDS X-ray microanalysis, the increased oxygen concentration was detected on the worn surfaces. It confirmed the presence of oxides and thus the oxidative wear [

54]. The wear mechanisms of laser-borided layer, reported in the previous study [

60], were the same as those-identified for the laser-alloyed layers in this work.

The wear mechanisms of the surface layers, fabricated by thermochemical treatment, are listed in

Table 6. Most of these layers were subjected to wear tests under conditions of dry friction (unlubricated sliding contact) [

35,

38,

40,

41,

45,

52], excluding the powder-pack borided layer [

39] and low-temperature gas nitrided layer [

44]. The similar methods and devices were used in order to identification of wear mechanism, e.g., SEM images of the worn surfaces [

35,

40,

44,

45], EDS analysis [

35], optical profilometer [

38,

39] or analysis of percentage of SiC particles in the abrasive slurry [

39]. SEM images of the worn surface of powder-pack borided layers revealed deep scars and adhesion craters after wear tests under conditions of dry friction as well as in simulated body fluid (SBF) [

35]. They confirmed the abrasive and adhesive wear mechanism of such a layer, respectively. The worn surfaces were substantially oxidized. The EDS analysis revealed the increased oxygen content on the worn surfaces what confirmed oxidative wear. This wear mechanism predominated, if the wear test was performed in SBF (simulated body fluid) medium [

35]. The grooves and material shedding (debris) on the worn surface of powder-pack borided layers confirmed their abrasive wear [

38]. Simultaneously, based on the paper [

64] and intergranular or surface cracks, the authors suggested pitting and cracking as well as oxidative wear. The surface layer, produced by P-PB, was subjected to the wear test in the abrasive slurry, consisting of SiC particles (4–5 μm) dissolved in a deionized water [

39]. The high percentage of abrasive SiC particles in the slurry and relatively low load favored rolling abrasion. Simultaneously, the low percentage of abrasive SiC particles in the slurry and relatively high load caused grooving abrasion. SEM images of the worn surface of powder-pack borided layer revealed micro-cutting and micro-plowing [

40]. It confirmed the abrasive wear. On the other hand, micro-cracking and micro-fatigue revealed the suffer fracture and pitting, respectively. The wear scars were also characterized by plastic deformations as well as debris-adhesion and delaminations which could indicate the adhesive wear [

40]. The tribocorrosion test in 3.5% NaCl solution was carried out after LTGN process [

44]. In the SEM images of worn surfaces of low-temperature gas nitrided layer the abrasion marks and micro-pits were clearly visible. They confirmed the abrasive and corrosive wear, respectively. The wear mechanisms of low-temperature gas nitrided layer, produced in HVOF-sprayed 316L steel, were examined using SEM images of the worn surface [

45]. The deep grooves and breakout of hardened spray particles revealed abrasive wear of such a layer.

In some papers, reporting the wear behavior of the surface layers produced by thermochemical treatment, the wear mechanisms were not studied in more details [

41,

52]. In the case of P-PB processes and hybrid treatment, consisting in P-PB followed by P-PCr or P-PCr followed by P-PB, the wear mechanisms were not identified [

41]. In general, the abrasive wear was assumed. It was observed that the mass loss of the counterpart pins increased with the applied load. This happened due to more sever engagements at the contact surfaces, and subsequently heat accumulated locally at the contact surfaces. This situation increased the possibility of adhesive wear [

41]. The wear mechanism of low-temperature carburized layer was also not identified [

52]. It was concluded that only the carburized layer resulted in the improved resistance of the surface to plastic deformation and abrasion, as well as to limit adhesion between the mating surfaces.

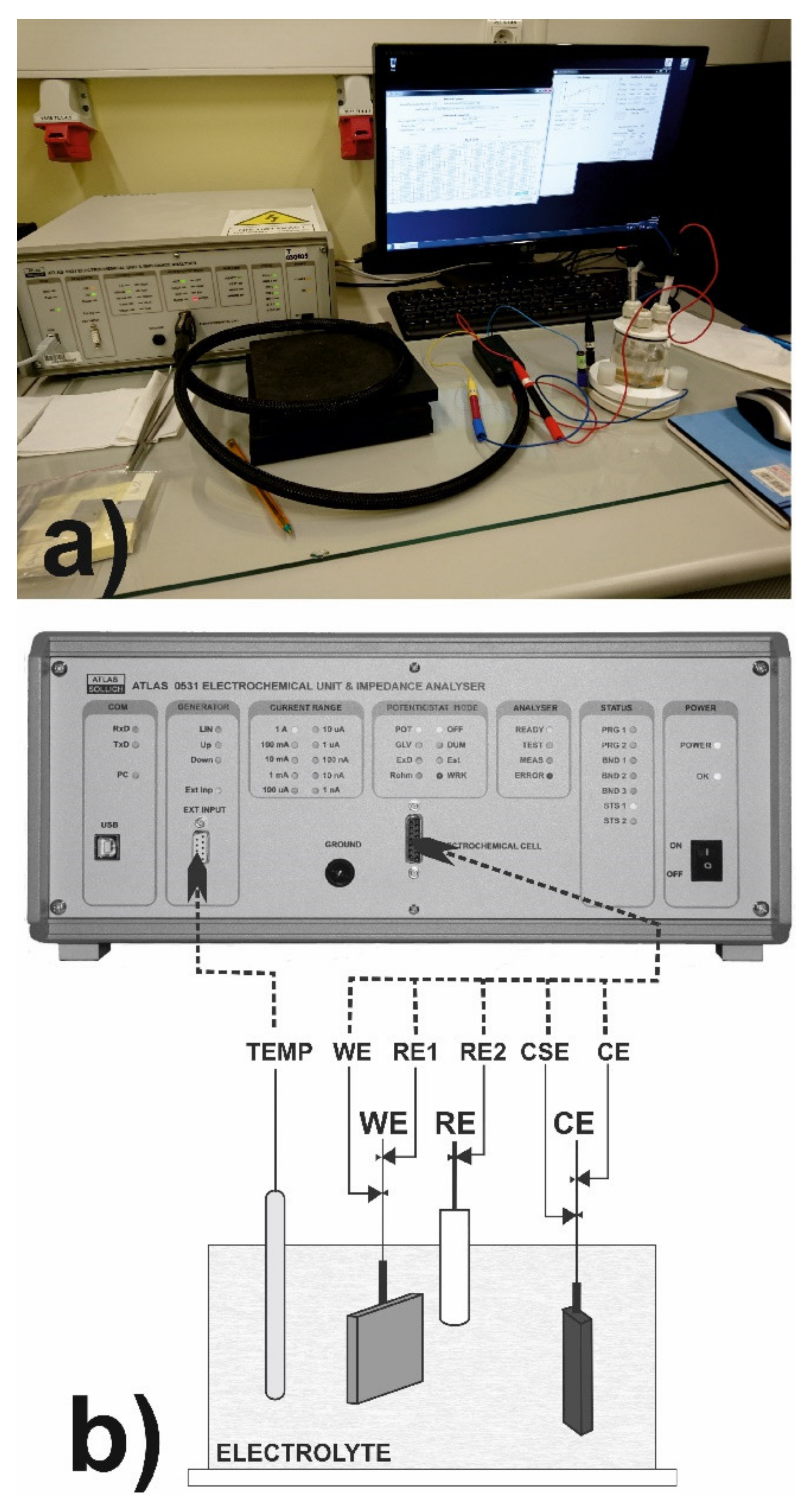

3.4. Corrosion Resistance

Corrosion resistance tests were conducted using ATLAS 0531 electrochemical unit and impedance analyzer in 3.5% NaCl and 0.5 M H

2SO

4 solutions on the flat samples (

Figure 1) which were laser-alloyed with boron and selected metallic elements (Stellite-6, Ni, Ni-Cr) at laser beam power of 1.43 kW and laser-alloyed with boron only at laser beam power of 1.82 kW. The test results of the laser-alloyed layers were compared with those-obtained from untreated 316L steel. The corrosion tests were conducted at 22 °C (295 K) in two corrosive media: 3.5% aqueous NaCl solution and 1 M H

2SO

4 solution. The potential ranged from −2 to 2 V, with a potential change rate of 0.5 mV/s.

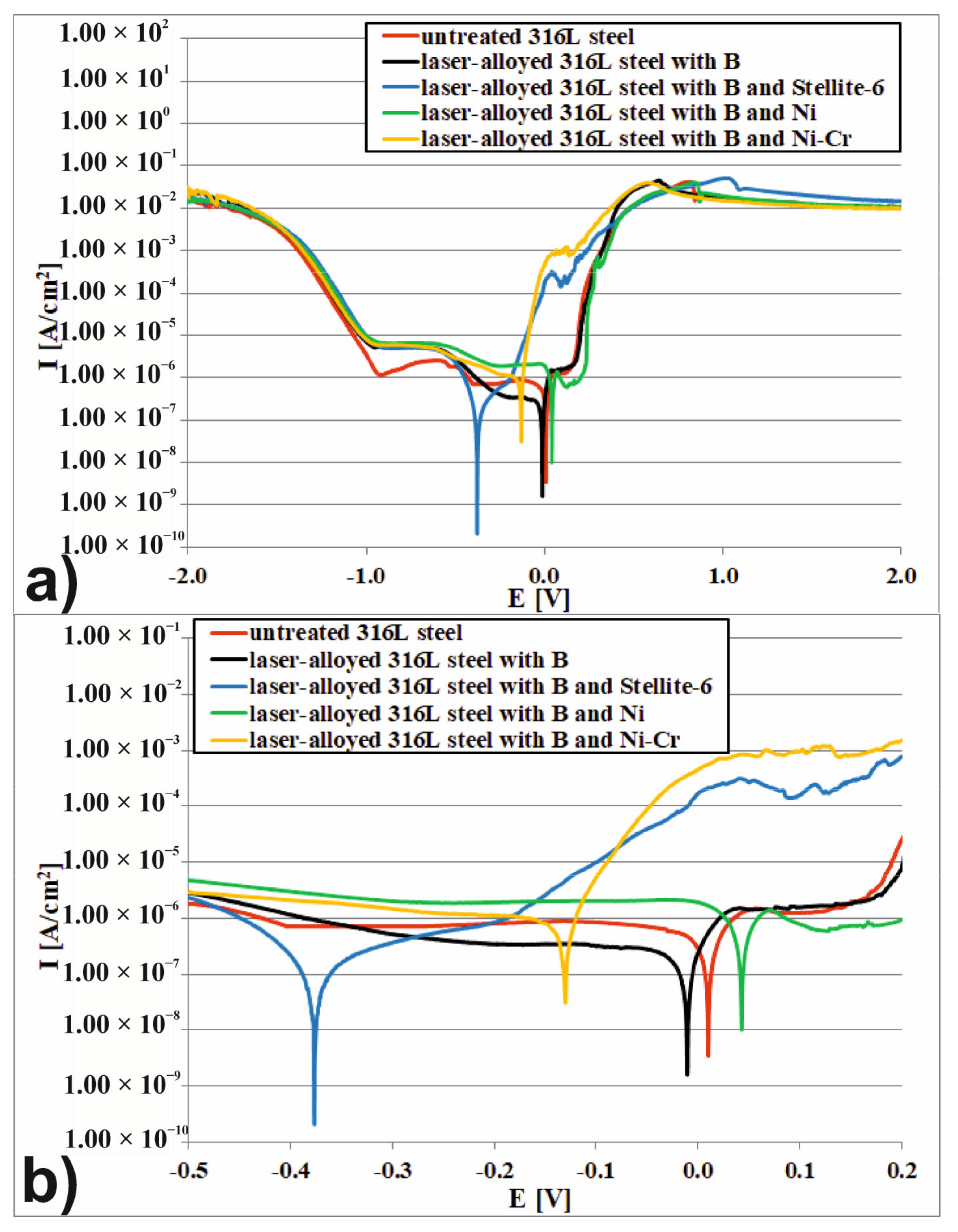

The polarization curves in 1 M H

2SO

4 solution are shown in

Figure 15, and the calculated values of corrosion potential

Ecorr and corrosion current density

Icorr are specified in

Table 7. It was expected that the single-phase austenitic structure of untreated 316L steel will be characterized by the greatest corrosion resistance, while the composite boride layers produced by laser alloying would have a slightly lower corrosion resistance due to their multiphase microstructure. The laser-alloyed layer with boron and Stellite-6 was undoubtedly characterized by a worst corrosion resistance, because the corrosion potential for this sample was the most negative (

Ecorr = −356.88 mV) and at the same time the corrosion current density was the highest (

Icorr = 15.6 × 10

−6 A/cm

2), indicating that the largest amount of ions of this material was being digested into the electrolyte. It turned out that the other laser-alloyed layers showed a very-similar corrosion potential (between −286.89 mV and −279.59 mV), which with also a slight difference in the corrosion current density (from 4.5 × 10

−6 to 9 × 10

−6 A/cm

2) showed that their corrosion resistance was comparable. The untreated 316L steel was characterized by a slightly more negative corrosive potential (−304.11 mV) and a slightly higher corrosion current density (10.1 × 10

−6 A/cm

2) compared to laser-alloyed layers with boron, boron and nickel or boron, nickel and chromium.

However, significant differences in the course of polarization curves were visible. For the 316L steel without surface treatment, the region of active digestion was much smaller compared to the laser-alloyed samples, indicating better corrosion resistance. Simultaneously, the region of primary passivation for untreated 316L steel was approximately twice as wide (within the range of potentials) compared to all the laser-alloyed samples. It was also important that for untreated material, the passive region was accompanied by a very low current density (2.5 × 10−6 A/cm2) compared to all the laser-alloyed layers, which were characterized by the current density in passive region from approximately 3 × 10−4 A/cm2 for the laser-alloyed layer with boron and Stellite-6 up to about 2 × 10−3 A/cm2 for the laser-alloyed layer with boron, nickel and chromium. This confirmed the very good corrosion resistance of 316L steel in 1 M sulfuric acid environment. The relatively narrow passive region, observed in the case of laser-alloyed specimens, could be related to the resistance of borides to oxidation. Analysis of the surfaces of the specimens after corrosion tests revealed clear pits in all the laser-alloyed layers, while the surface of untreated 316L steel indicated more uniform corrosion. In conclusion, as expected, the untreated 316L austenitic steel was characterized by the best corrosion resistance in 1 M H2SO4. The slightly less corrosion resistance was revealed for laser-alloyed layers with boron, boron and nickel as well as boron, nickel and chromium. By far the worst corrosion resistance was demonstrated by the laser-alloyed layer with boron and Stellite-6.

The results of the studies in 3.5% NaCl water solution are shown in

Figure 16 and

Table 8. Undoubtedly, the laser-alloyed layer with boron and Stellite-6 was characterized by the least corrosive resistance. Its corrosion potential was the most negative (

Ecorr = −371.19 mV) and the region f active digestion was the widest, although at the same time the corrosion current density was quite low (

Icorr = 64.6 × 10

−8 A/cm

2). The sample after laser-alloying with boron, nickel and chromium had the second negative value of corrosive potential (−132.84 mV) and the highest value of corrosion current density (22.5 × 10

−7 A/cm