The Strength and Delamination of Graphene/Cu Composites with Different Cu Thicknesses

Abstract

1. Introduction

2. Methodology and Modeling

2.1. Methodology

2.1.1. MD Analysis

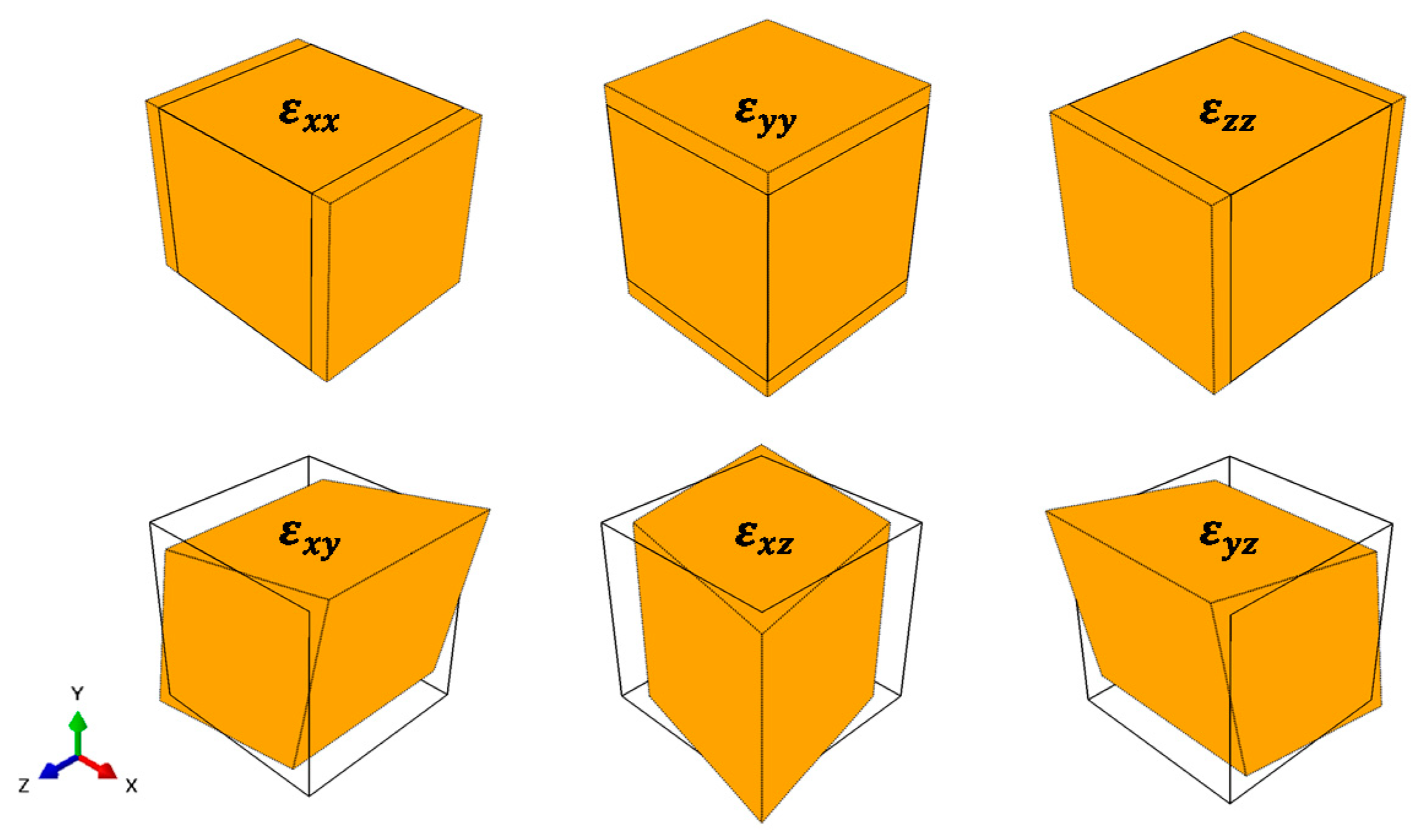

2.1.2. RVE Analysis

2.2. Modeling

2.2.1. MD Modeling

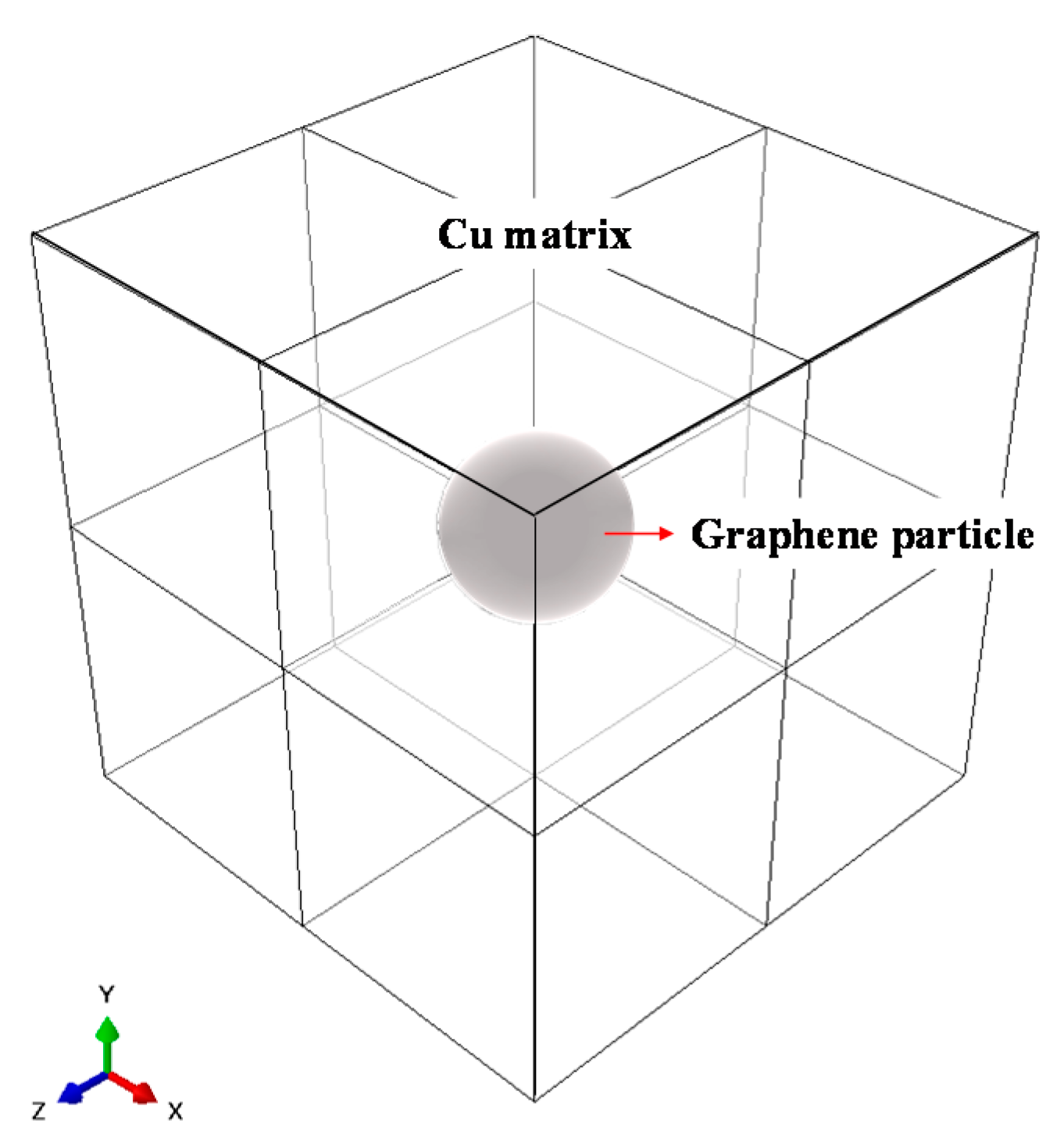

2.2.2. RVE Modeling

3. Results and Discussion

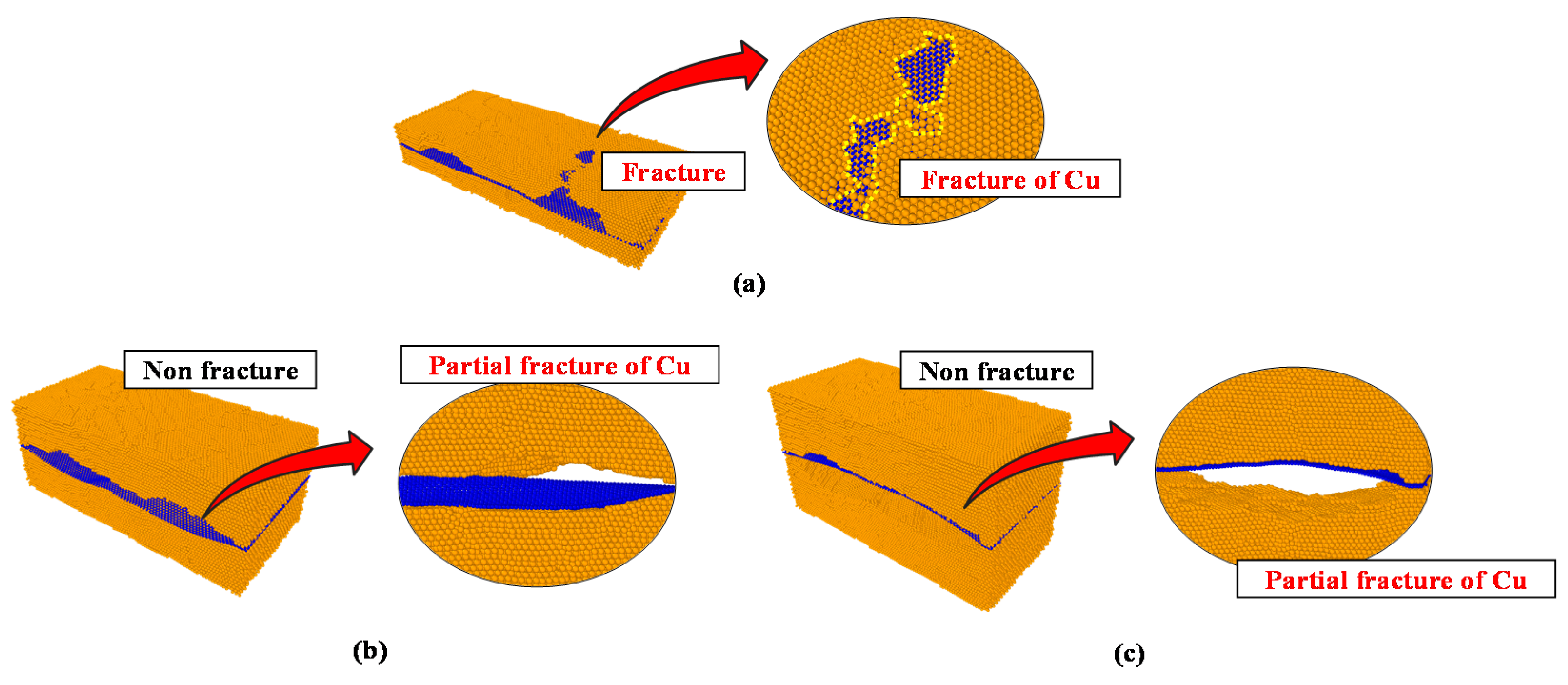

3.1. Results of the MD Analysis

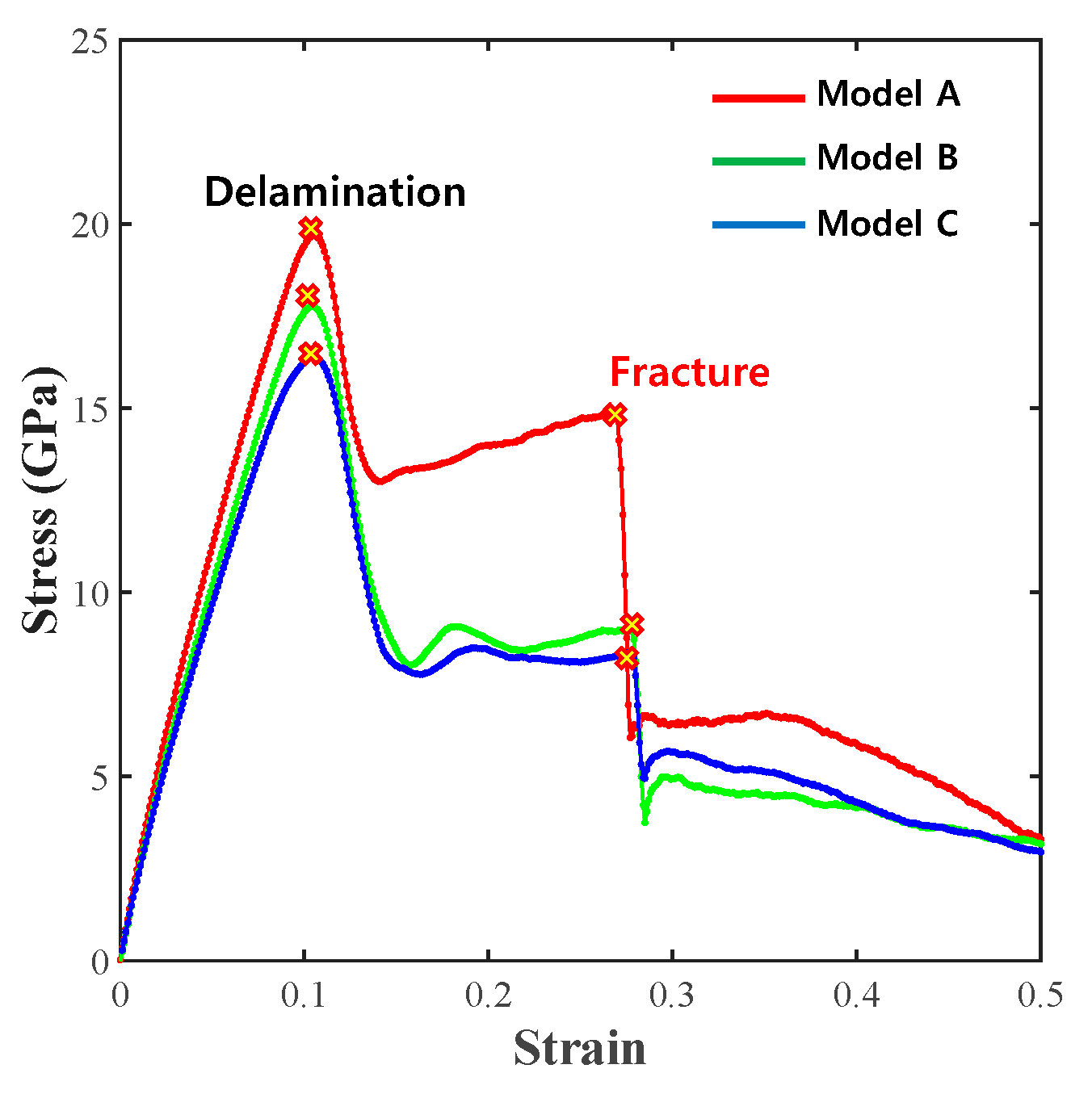

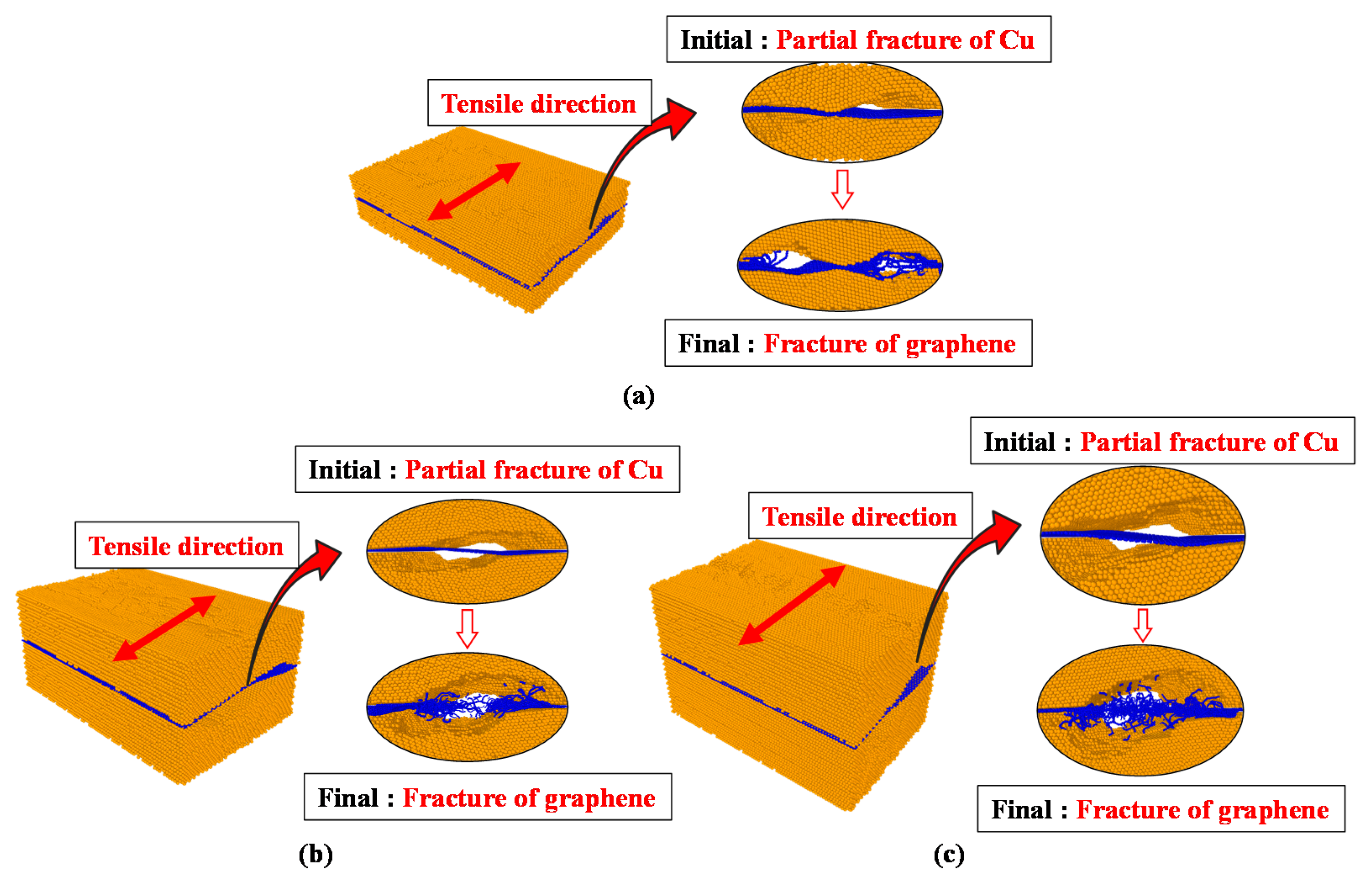

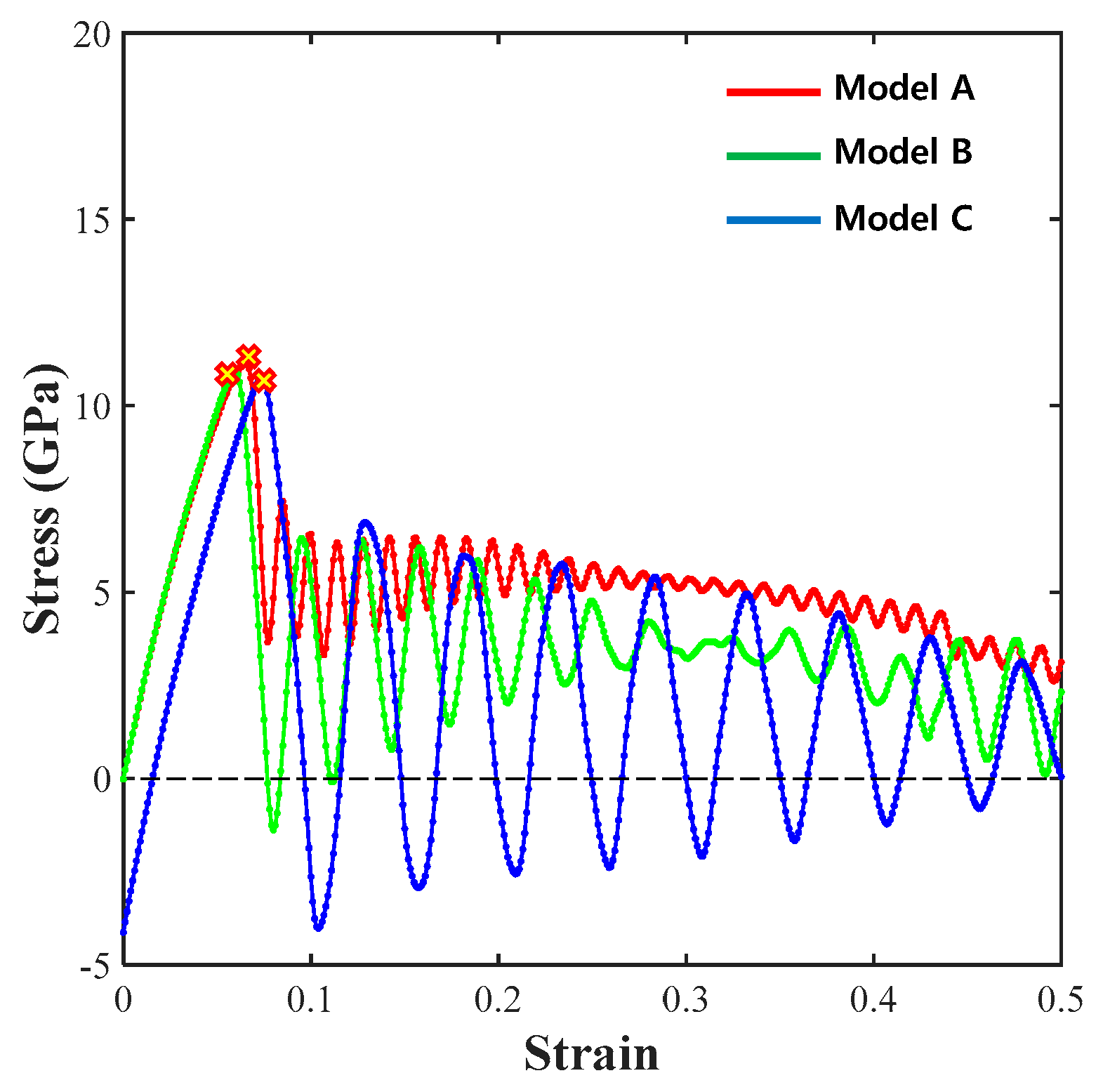

3.1.1. Results of the Zigzag-Direction Tensile Analysis

3.1.2. Results of the Armchair-Direction Tensile Analysis

3.1.3. Results of the Z-Direction Tensile Analysis

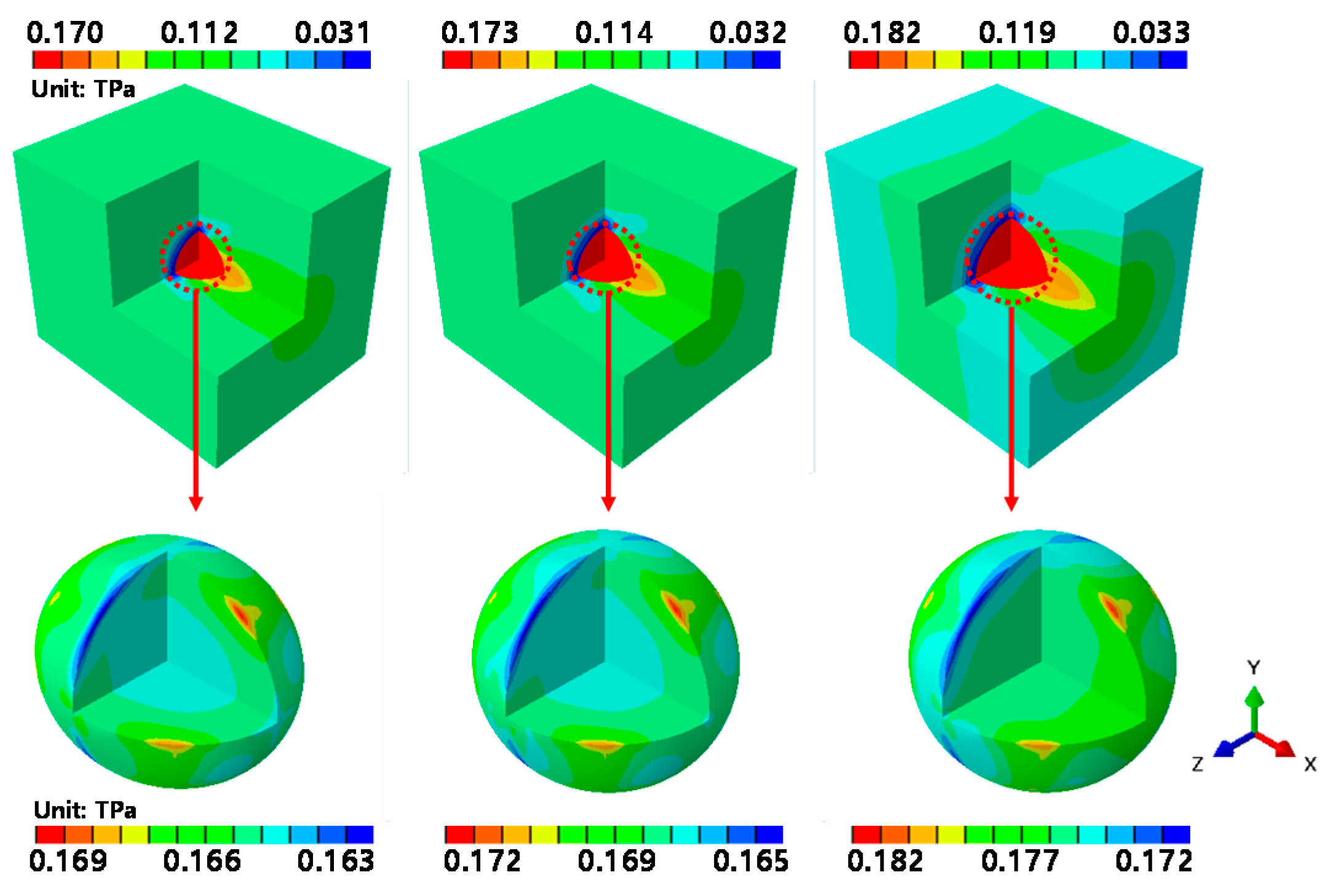

3.2. Results of the RVE Analysis

3.2.1. Results of the -Direction Tensile Analysis

3.2.2. Results of the -Direction Tensile Analysis

3.2.3. Results of the -Direction Tensile Analysis

3.2.4. Stress Variations of the Graphene/Cu Interface

3.2.5. Variation in the Macroscopic Properties of the Graphene/Cu Composites According to the Graphene Size

4. Conclusions

- In the MD analysis results for graphene/Cu composites, the strength performance of the graphene/Cu composites is influenced by whether the graphene maintains its bonds. The strength of the graphene/Cu composites does not increase if the Cu thickness increases. Rather, an increase in Cu thickness in the same tensile direction reduces the strength performance of the graphene/Cu composites.

- Additionally, graphene/Cu composites are more vulnerable to armchair-direction tensile forces than zigzag-direction tensile forces. In graphene/Cu composites, it is necessary to consider the direction of graphene to prevent sudden fracture after delamination.

- In the RVE analysis results for the graphene/Cu composites, a large stress occurred in graphene, which resulted in a large stress difference between graphene and Cu. This means that the interface of graphene/Cu composites is most vulnerable to external loads. The difference according to the volume fraction change was that when the volume fraction of graphene increased, the stress distribution of Cu also increased.

- In the RVE analysis results for graphene where the stress is most concentrated, even within graphene, various stress distributions were observed. These results disprove the necessity of RVE multiscale analysis for graphene/Cu composites. In this study, it was found that higher stress appeared at the interface than at the center of graphene.

- Further work should be performed with the aim of evaluating graphene/Cu composites that laminated multi-layer graphene rather than single-layer graphene. This further work will validate the usage specifications and performance of graphene/Cu composites in practical applications such as semiconductor wiring and electronic devices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cooper, D.R.; D’Anjou, B.; Ghattamaneni, N.; Harack, B.; Hilke, M.; Horth, A.; Massicotte, M.; Vandsburger, L.; Whiteway, E. Experimental Review of Graphene. Int. Sch. Res. Not. 2012, 2012, 1–56. [Google Scholar] [CrossRef]

- Verma, D.; Gope, P.C.; Shandilya, A.; Gupta, A. Mechanical-Thermal-Electrical and Morphological properties of Graphene Reinforced Polymer Composites: A Review. Trans. Indian Inst. Met. 2014, 67, 803–816. [Google Scholar] [CrossRef]

- Castro Neto, A.H.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The Electronic Properties of Graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef]

- Zhuo, Q.; Mao, Y.; Lu, S.; Cui, B.; Yu, L.; Tang, J.; Sun, J.; Yan, C. Seed-Assisted Synthesis of Graphene Films on Insulation Substrate. Materials 2019, 12, 1376. [Google Scholar] [CrossRef] [PubMed]

- Kamedulski, P.; IInicka, A.; Lukaszewica, J.P.; Skorupska, M. Highly effective three-dimensional functionalization of graphite to graphene by wet chemical exfoliation methods. Adsorption 2019, 25, 631–638. [Google Scholar] [CrossRef]

- Choi, W.B.; Lee, J.W. Graphene Synthesis and Applications; CRC Press: Boca Raton, FL, USA, 2012; p. 188. [Google Scholar]

- Jung, H.; Kang, W. Three-Dimensional Nanoporous Graphene-Based Materials and their Applications. Ceramist 2019, 22, 243–255. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J.; Yeom, M.S.; Shin, J.W.; Kim, H.; Cui, Y.; Kysar, J.W.; Hone, J.; Jung, Y.; Jeon, S.; et al. Strengthening Effect of Single-Atomic-Layer Graphene in Metal–Graphene Nanolayered Composites. Nat. Commun. 2013, 4, 2114–2120. [Google Scholar] [CrossRef] [PubMed]

- Boostani, F.; Tahamtan, S.; Jiang, Z.Y.; Wei, D.; Yazdani, S.; Khosroshahi, R.A.; Mousavian, R.T.; Xu, J.; Zhang, X.; Gong, D. Enhanced Tensile Properties of Aluminium Matrix Composites Reinforced with Graphene Encapsulated SiC Nanoparticles. Compos. Part A 2015, 68, 155–163. [Google Scholar] [CrossRef]

- Trana, T.Q.; Lee, J.K.Y.; Chinnappana, A.; Loc, N.H.; Tran, L.T.; Ji, D.; Jayathilakaa, W.A.D.M.; Kumar, V.V.; Ramakrishnaa, S. High-Performance Carbon Fiber/Gold/Copper Composite Wires for Lightweight Electrical Cables. J. Mater. Sci. Technol. 2020, 42, 46–53. [Google Scholar] [CrossRef]

- Rezaei, R. Tensile mechanical characteristics and deformation mechanism of metal-graphene nanolayered composites. Comput. Mater. Sci. 2018, 151, 181–188. [Google Scholar] [CrossRef]

- Kim, S.J.; Shin, D.H.; Choi, Y.S.; Rho, H.; Moon, B.J.; Kim, Y.; Lee, S.K.; Lee, D.S.; Kim, T.W.; Lee, S.H.; et al. Ultrastrong Graphene-Copper Core-Shell Wires for High-Performance Electrical Cables. ACS Nano 2018, 12, 2803–2808. [Google Scholar] [CrossRef] [PubMed]

- Hwang, J.; Yoon, T.; Jin, S.H.; Lee, J.; Kim, T.S.; Hong, S.H.; Jeon, S. Enhanced Mechanical Properties of Graphene/Copper Nanocomposites Using a Molecular-Level Mixing Process. Adv. Mater. 2013, 25, 6724–6729. [Google Scholar] [CrossRef] [PubMed]

- Peng, W.; Sun, K. Effects of Cu/graphene interface on the mechanical properties of multilayer Cu/graphene composites. Mech. Mater. 2020, 141, 103270. [Google Scholar] [CrossRef]

- Plimston, S.J. Fast Parallel Algorithms for Short-range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Bai, J.; Zhong, W.; Jiang, S.; Huang, Y.; Duan, X. Graphene nanomesh. Nat. Nanotechnol. 2010, 5, 190–194. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, X.; Zhang, L.; Lee, S.; Dai, H. Chemically Derived, Ultrasmooth Graphene Nanoribbon Semiconductors. Science 2008, 319, 1229–1232. [Google Scholar] [CrossRef] [PubMed]

- Tersoff, J. New Empirical Approach for the Structure and Energy of Covalent Systems. Phys. Rev. B 1988, 37, 6991–7000. [Google Scholar] [CrossRef] [PubMed]

- Finnis, M.W.; Sinclair, J.E. A simple empirical N-body potential for transition metals. Philos. Mag. A 1984, 50, 45–55. [Google Scholar] [CrossRef]

- Kim, M.J.; Park, S.H.; Park, J.S.; Lee, W.I.; Kim, M.S. Micro-Mechanical Failure Prediction and Verification for Fiber Reinforced Composite Materials by Miltiscale Modeling Method. Int. J. Numer. Methods Eng. 2013, 45, 17–24. [Google Scholar]

- Micromechanics for Abaqus User’s Manual. In Abaqus Version 2017; Dassault Systèmes Simulia Corp: Providence, RI, USA, 2017.

| Material | Young’s Modulus (Elastic Modulus) | Poisson’s Ratio |

|---|---|---|

| Cu | 110 GPa | 0.34 |

| Graphene | 1 TPa | 0.149 |

| Model | Stress (GPa) | |||

|---|---|---|---|---|

| Zigzag Direction | Armchair Direction | |||

| Delamination | Fracture | Delamination | Fracture | |

| Model A | 15.53 | 19.7 | 16.37 | 14.7 |

| Model B | 17.02 | 11.5 | 17.76 | 8.9 |

| Model C | 16.03 | 8.9 | 19.69 | 8.2 |

| Graphene: 1.39% | ||

| E1 (GPa) | E2 (GPa) | E3 (GPa) |

| 112.654 | 112.655 | 112.655 |

| Nu12 | Nu13 | Nu23 |

| 0.34 | 0.34 | 0.34 |

| G12 (GPa) | G13 (GPa) | G23 (GPa) |

| 42.049 | 42.049 | 42.049 |

| Graphene: 2.04% | ||

| E1 (GPa) | E2 (GPa) | E3 (GPa) |

| 113.951 | 113.953 | 113.952 |

| Nu12 | Nu13 | Nu23 |

| 0.34 | 0.34 | 0.34 |

| G12 (GPa) | G13 (GPa) | G23 (GPa) |

| 42.528 | 42.528 | 42.519 |

| Graphene: 4.16% | ||

| E1 (GPa) | E2 (GPa) | E3 (GPa) |

| 118.422 | 118.428 | 118.427 |

| Nu12 | Nu13 | Nu23 |

| 0.33 | 0.33 | 0.33 |

| G12 (GPa) | G13 (GPa) | G23 (GPa) |

| 44.050 | 44.049 | 44.051 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-M.; Park, W.-R.; Kwon, O.-H. The Strength and Delamination of Graphene/Cu Composites with Different Cu Thicknesses. Materials 2021, 14, 2983. https://doi.org/10.3390/ma14112983

Kim S-M, Park W-R, Kwon O-H. The Strength and Delamination of Graphene/Cu Composites with Different Cu Thicknesses. Materials. 2021; 14(11):2983. https://doi.org/10.3390/ma14112983

Chicago/Turabian StyleKim, Song-Mi, Woo-Rim Park, and Oh-Heon Kwon. 2021. "The Strength and Delamination of Graphene/Cu Composites with Different Cu Thicknesses" Materials 14, no. 11: 2983. https://doi.org/10.3390/ma14112983

APA StyleKim, S.-M., Park, W.-R., & Kwon, O.-H. (2021). The Strength and Delamination of Graphene/Cu Composites with Different Cu Thicknesses. Materials, 14(11), 2983. https://doi.org/10.3390/ma14112983