Mechanical Performance of a Ballastless Track System for the Railway Bridges of High-Speed Lines: Experimental and Numerical Study under Thermal Loading

Abstract

1. Introduction

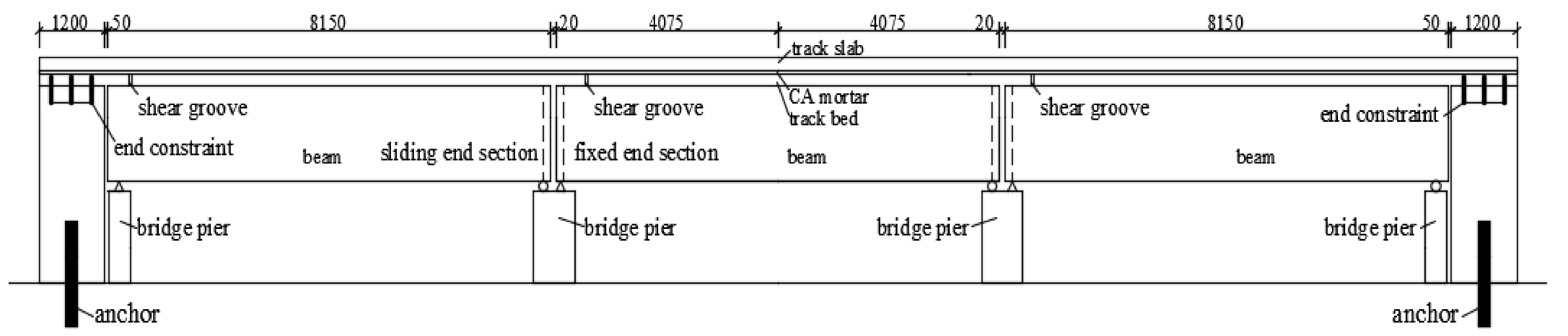

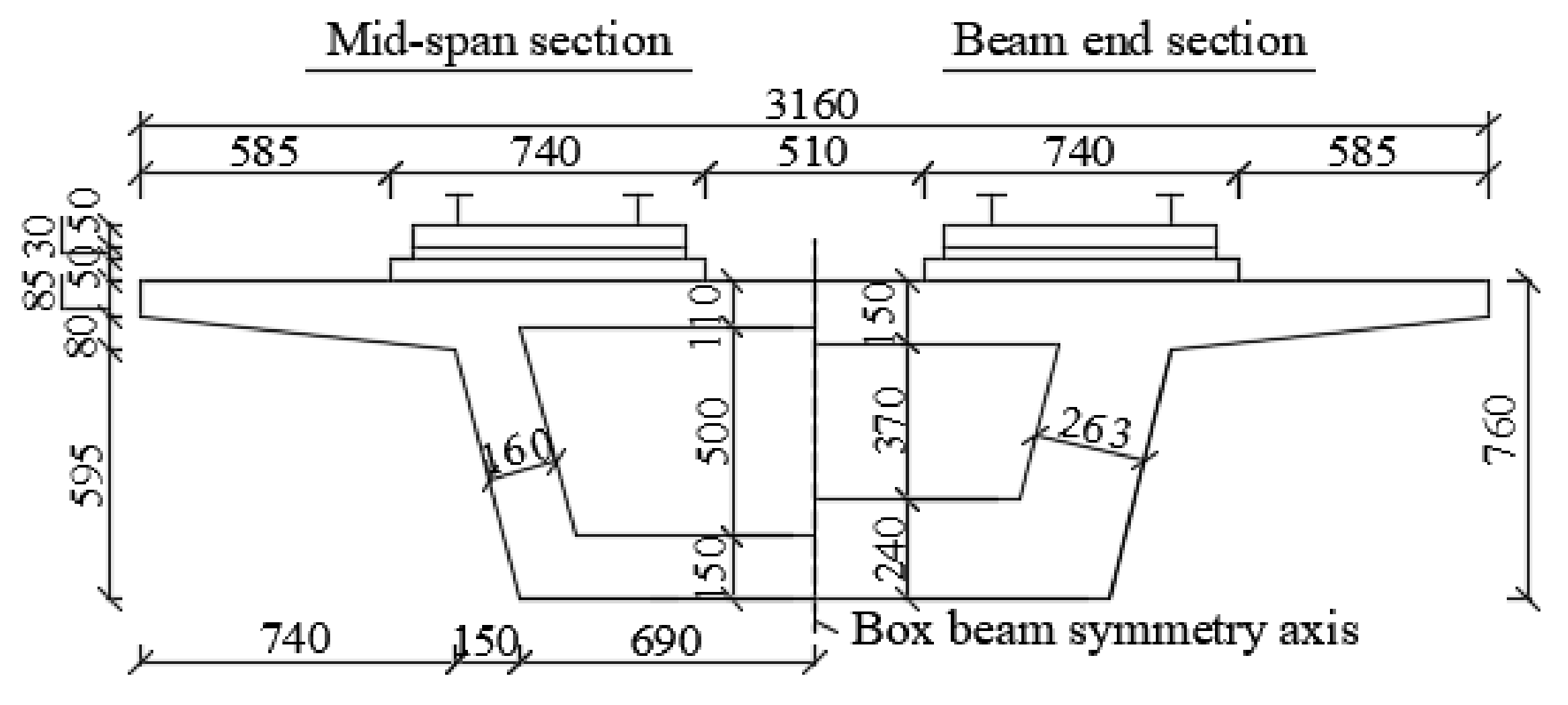

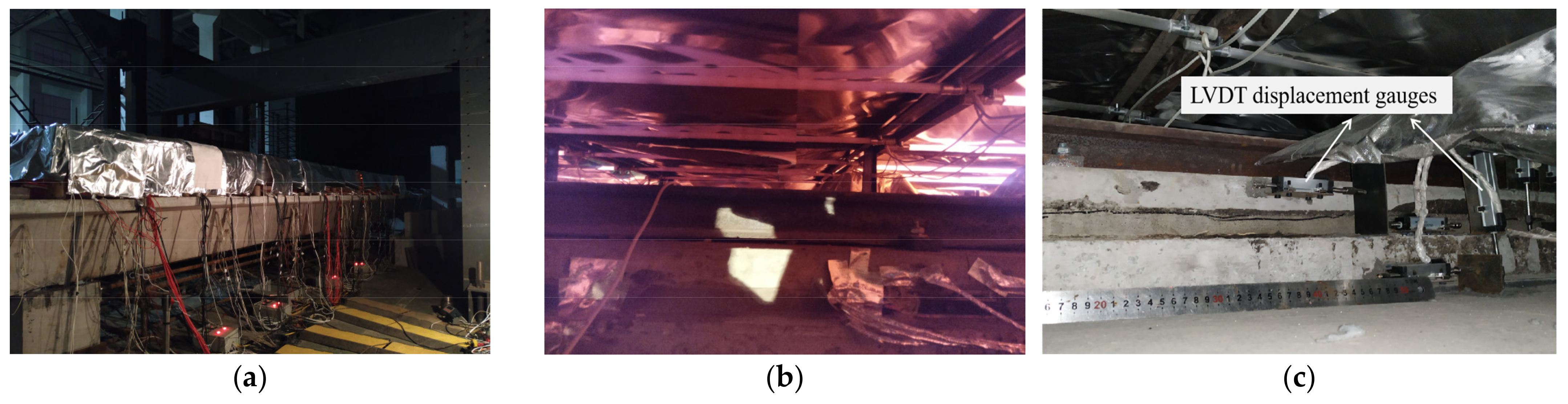

2. Test Overview

2.1. Similarity Theory

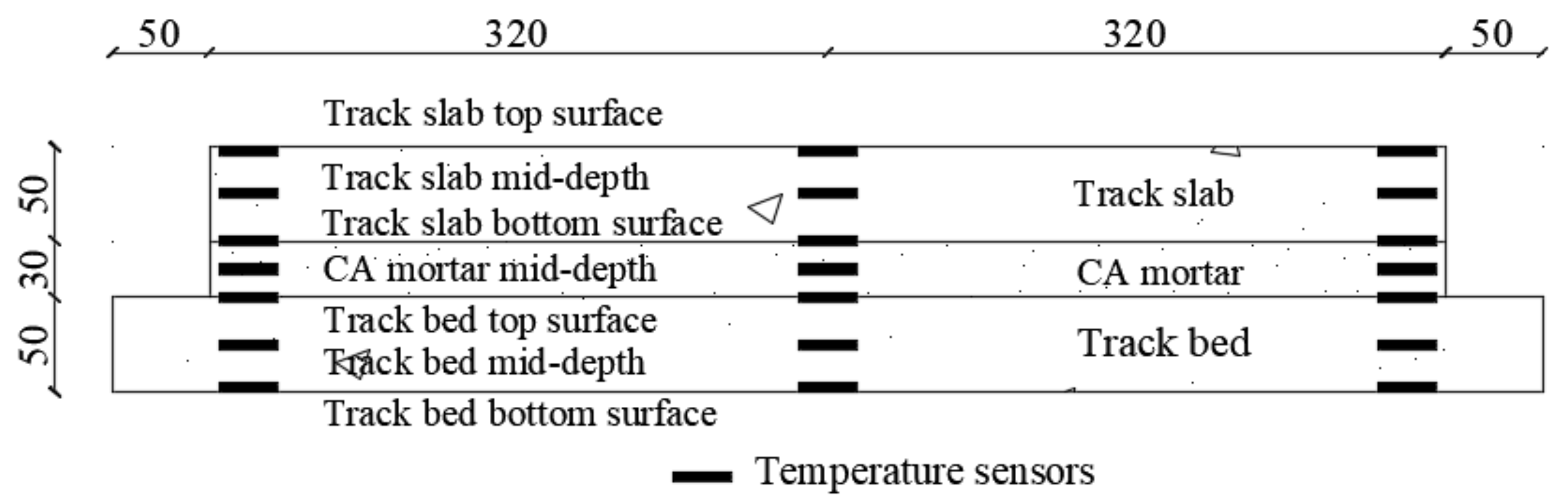

2.2. Temperature Sensors

2.3. Arrangement of Strain Sensors

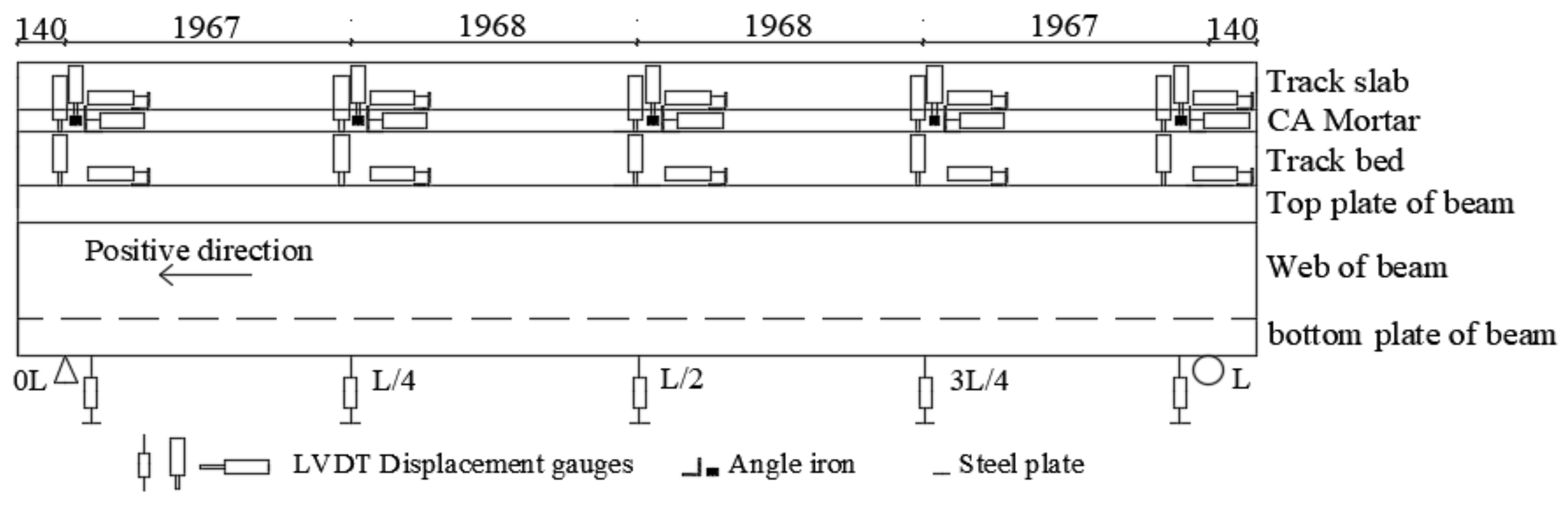

2.4. Arrangement of Displacement Monitoring Points

3. Test Results and Analysis

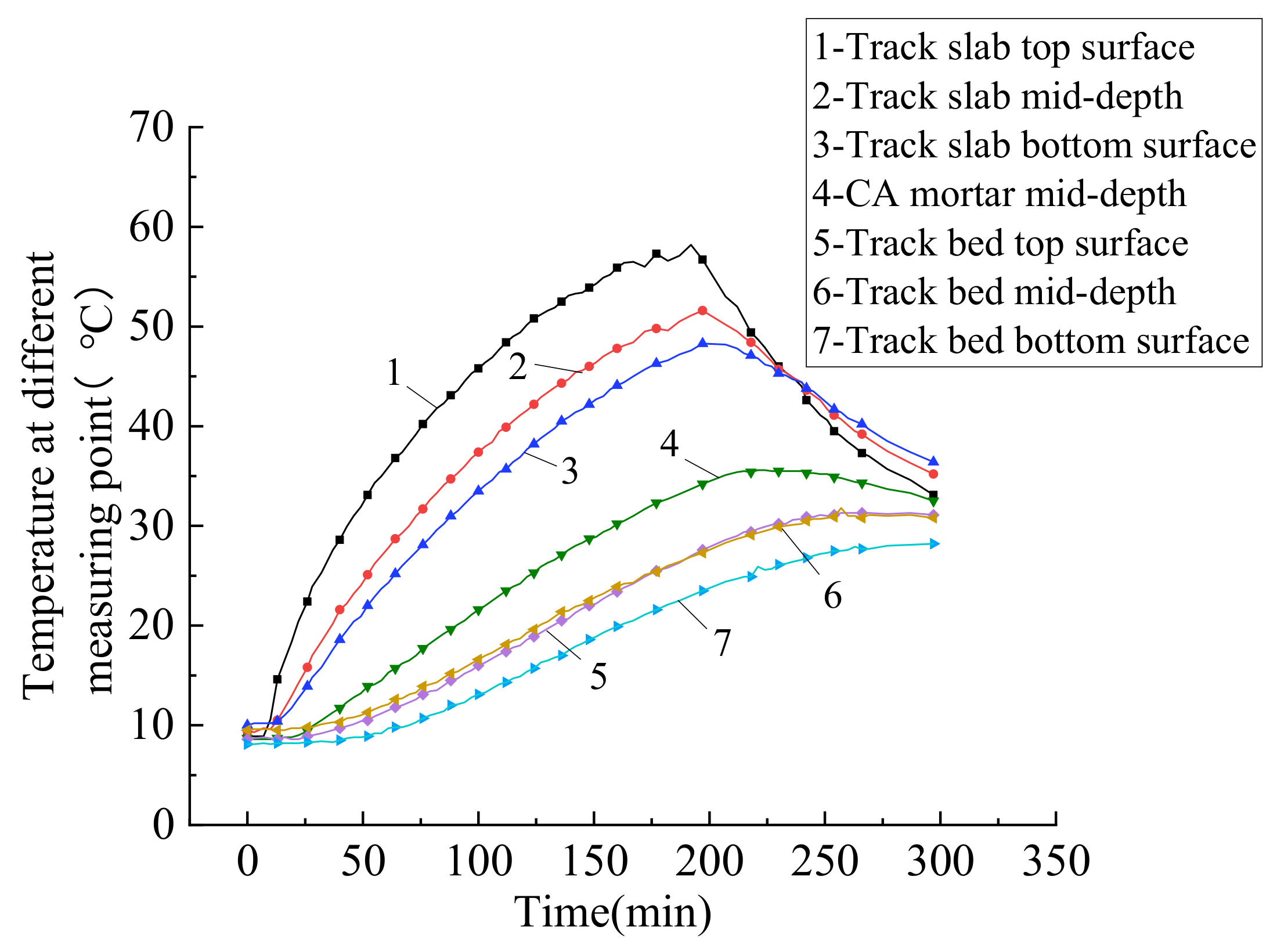

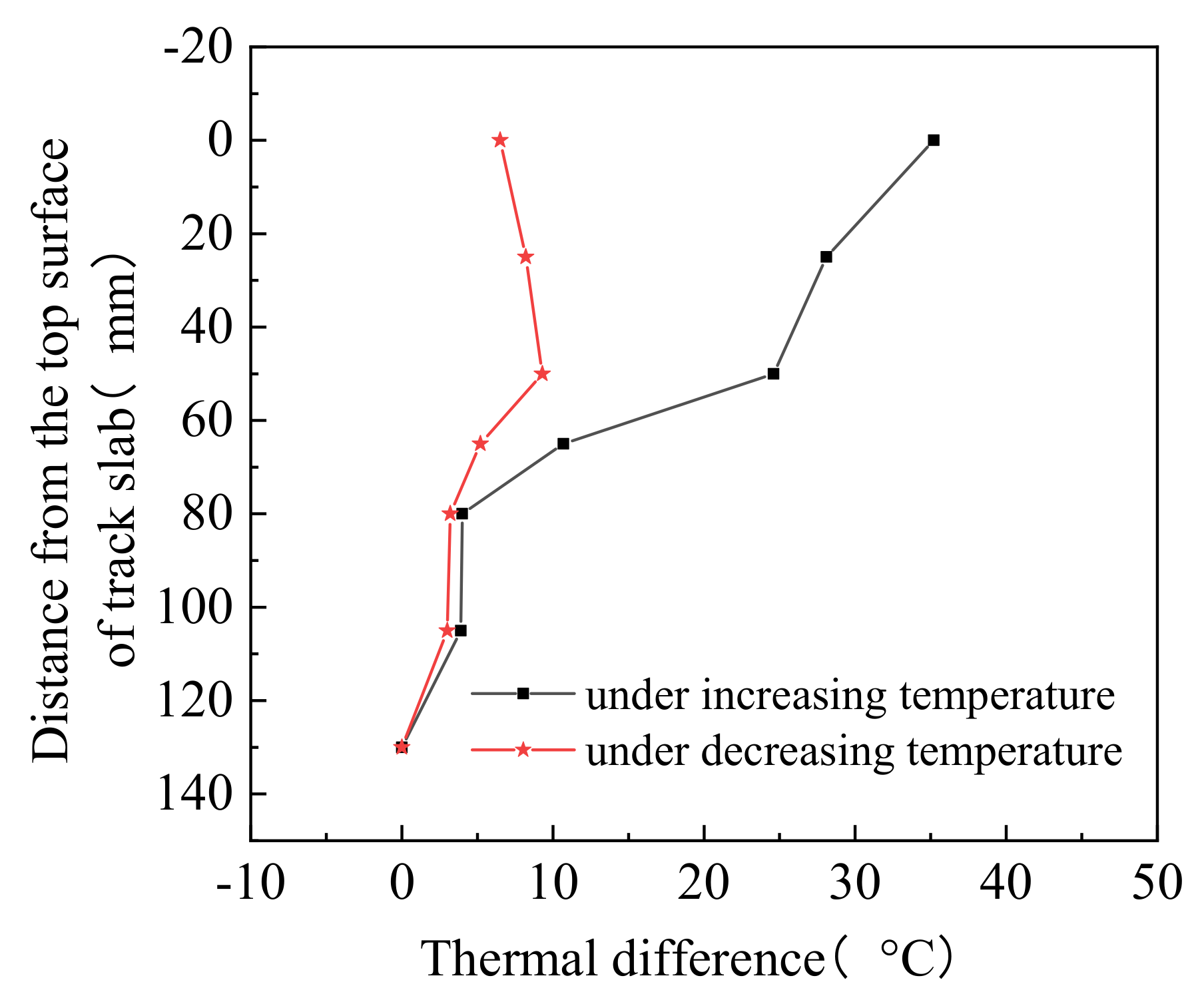

3.1. Distribution of Thermal Difference

3.2. Strain Analysis

4. Displacement Analysis

4.1. Relative Displacements between Track Layers

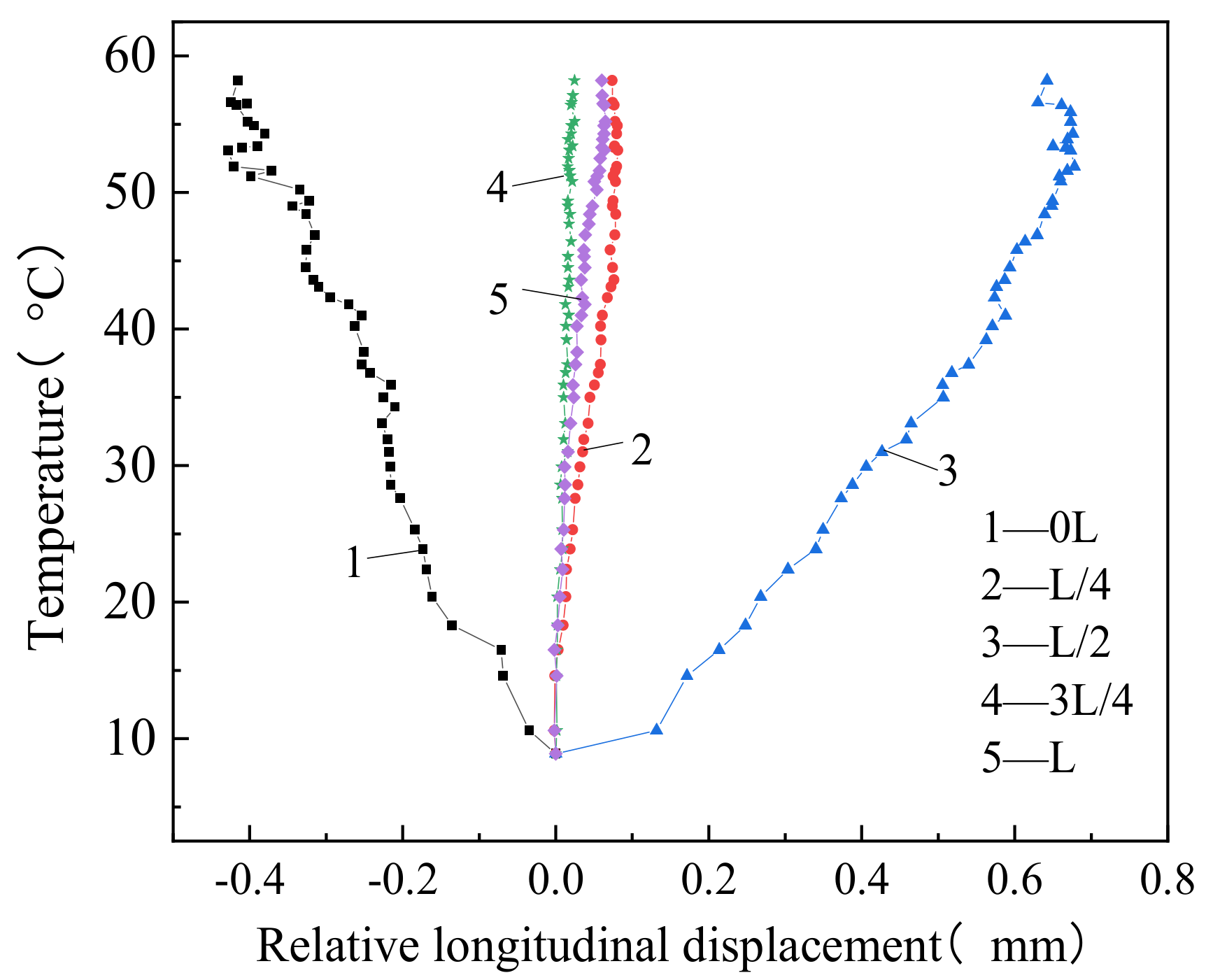

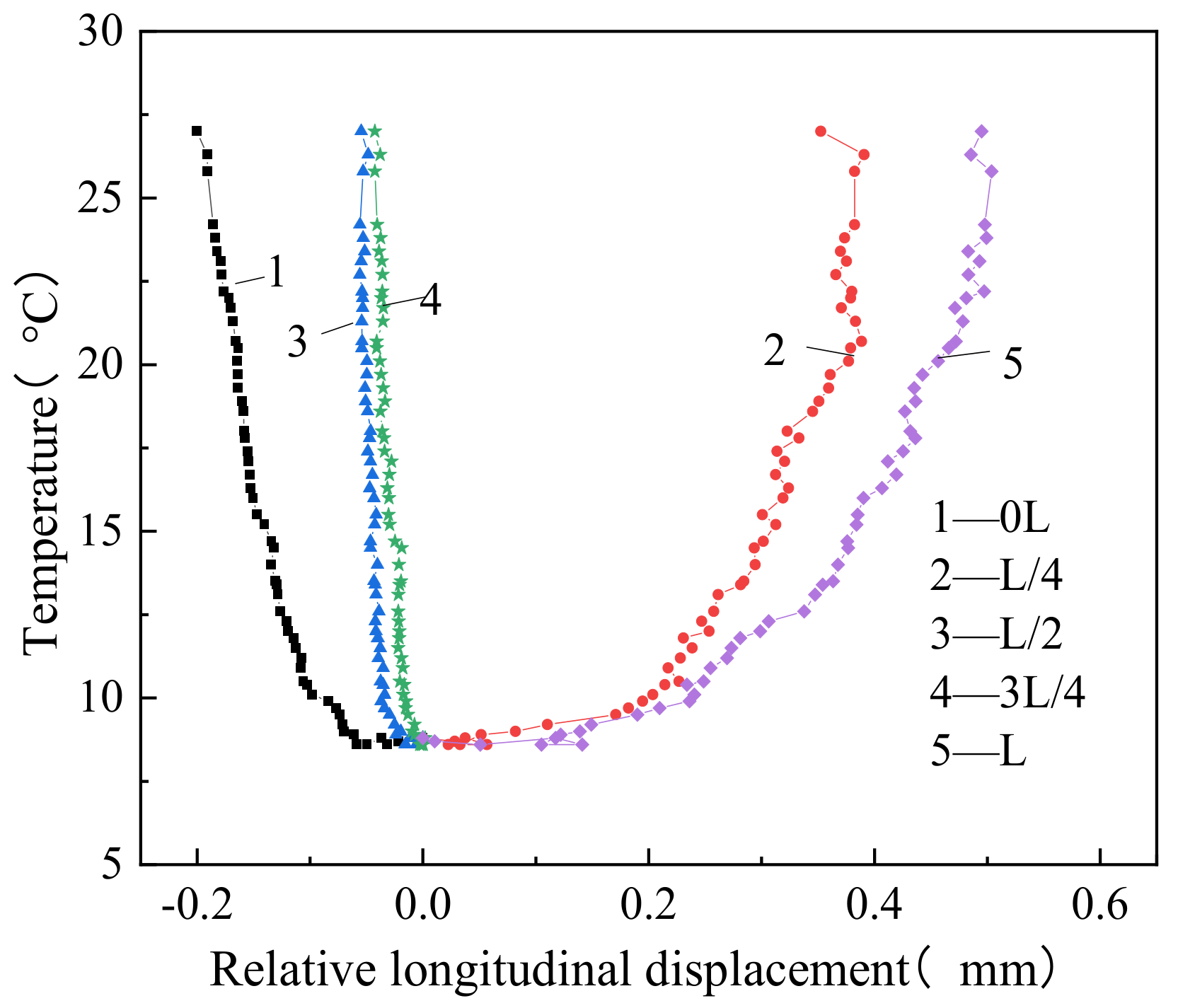

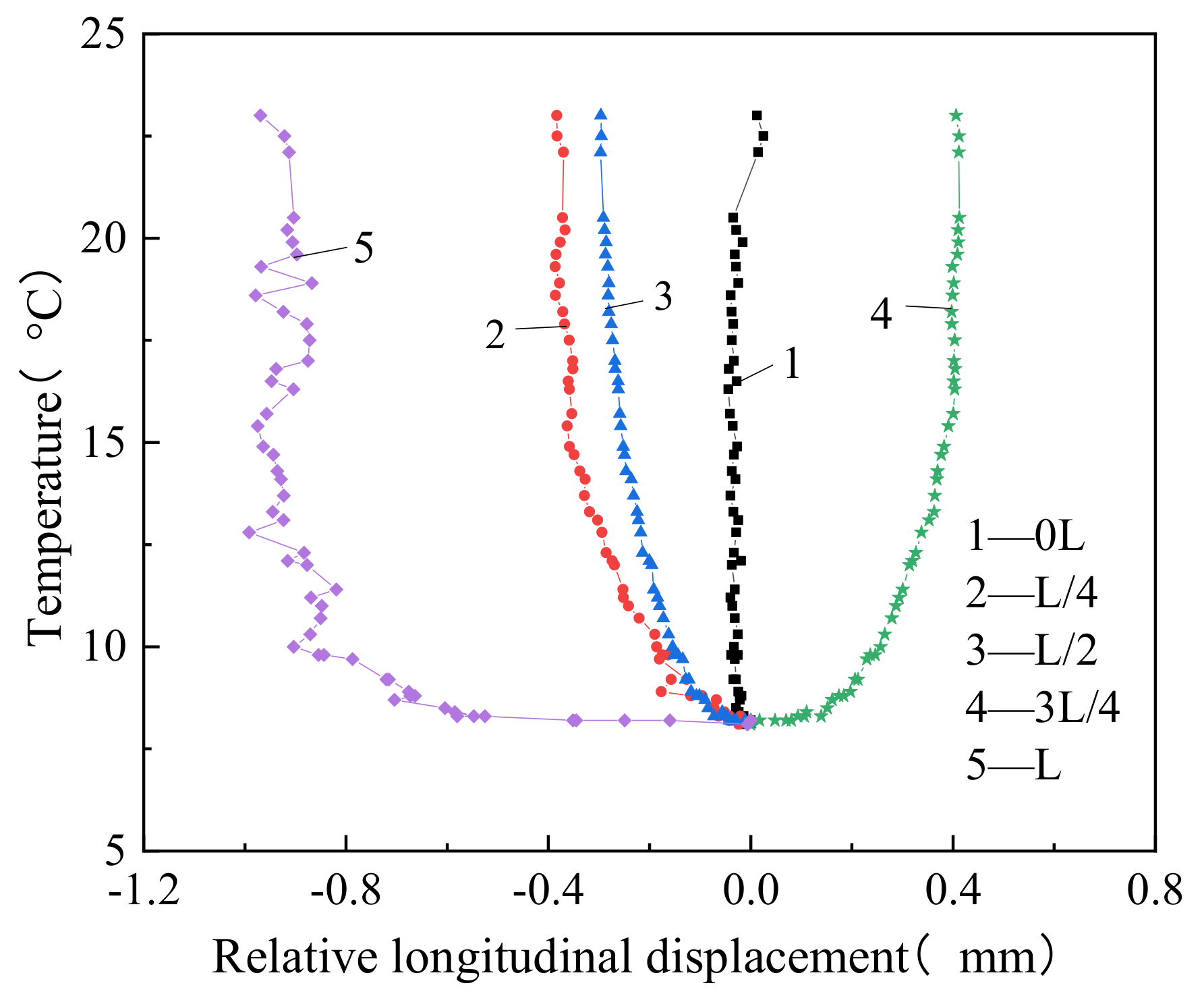

4.1.1. Relative Longitudinal Displacements between Layers

- (1)

- Displacements between track slab and track bed in the longitudinal direction

- (2)

- Displacements between the CA mortar and track bed in the longitudinal direction.

- (3)

- Displacements between the track bed and support beam in the longitudinal direction

4.1.2. Relative Vertical Displacement between Layers

- (1)

- Relative vertical displacement between the track slab and the track bed

- (2)

- Relative vertical displacement between track bed and support beam

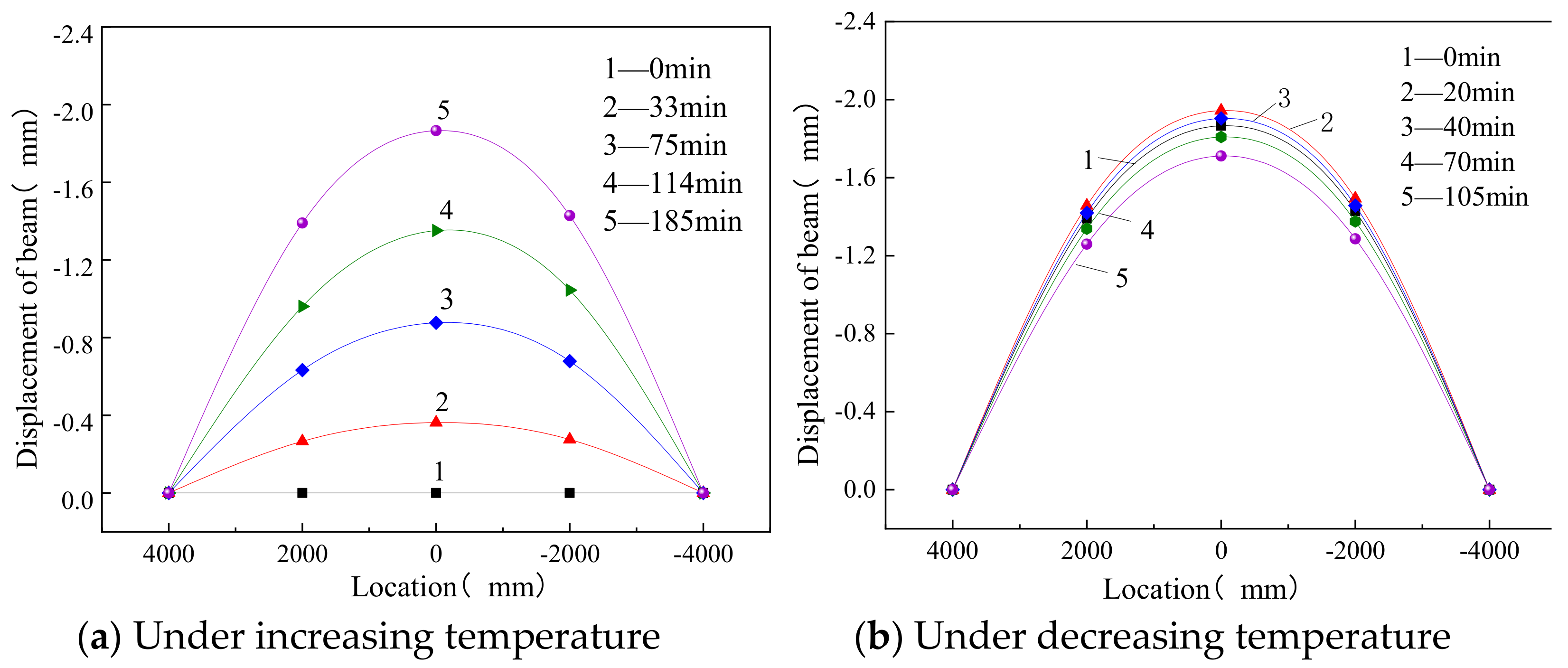

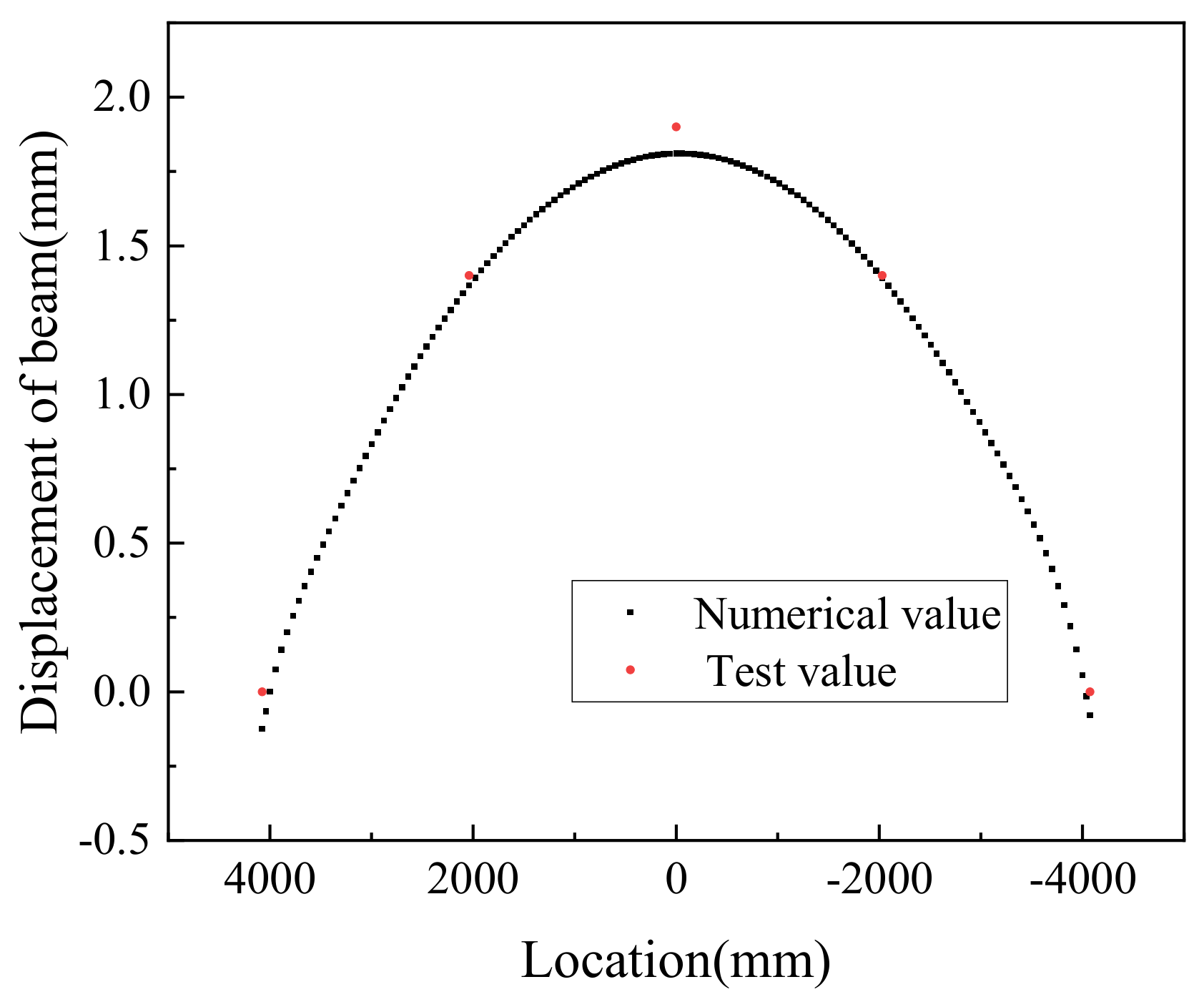

4.2. Overall Displacement of the Support Beam

5. Stress Analysis

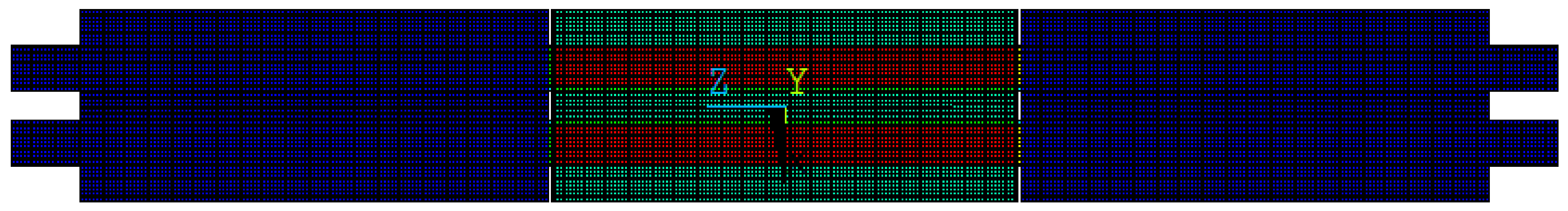

5.1. Formulation and Validation of the Numerical Model

5.1.1. Model Formulation

5.1.2. Model Validation

5.2. Comments on the Results

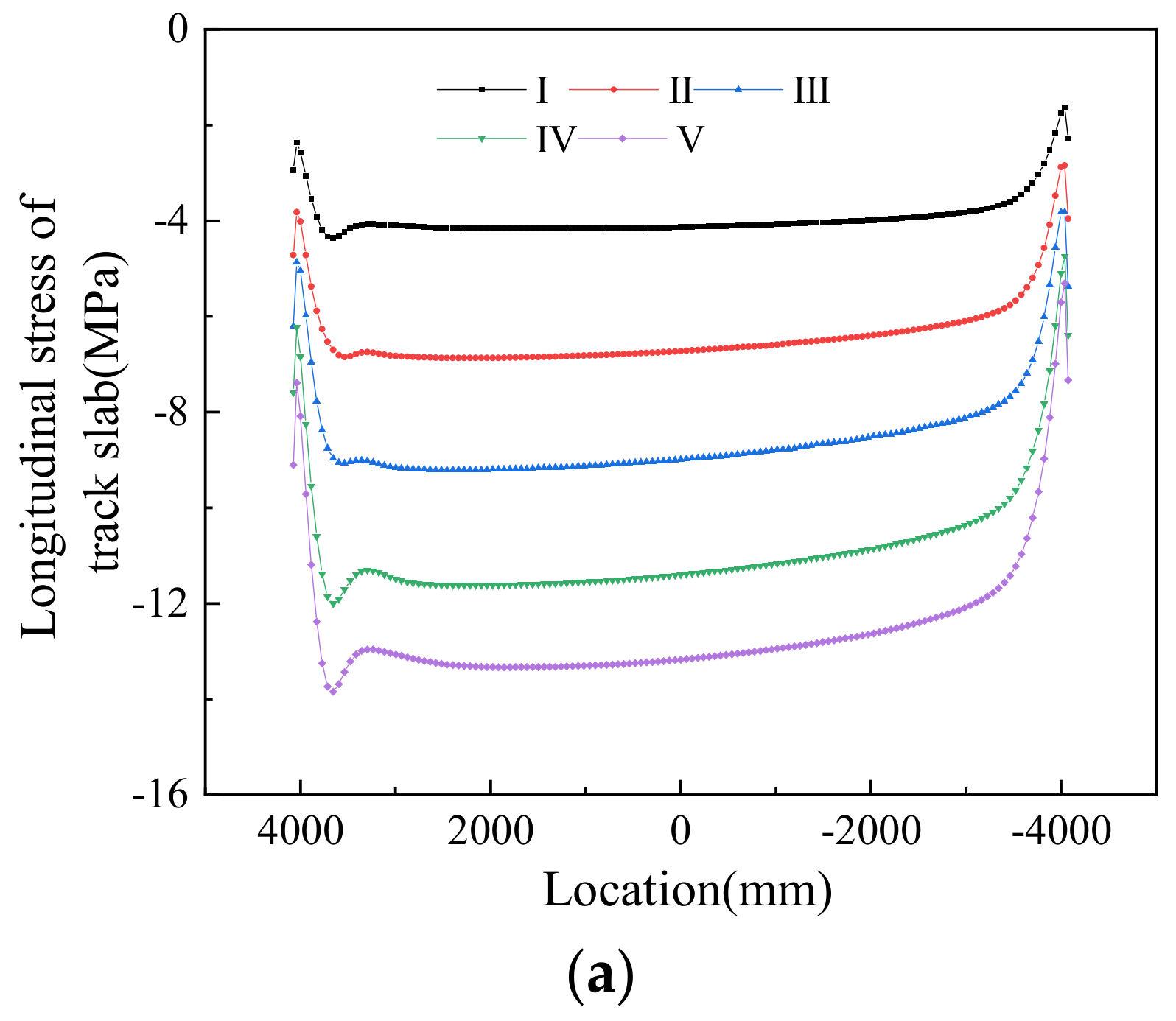

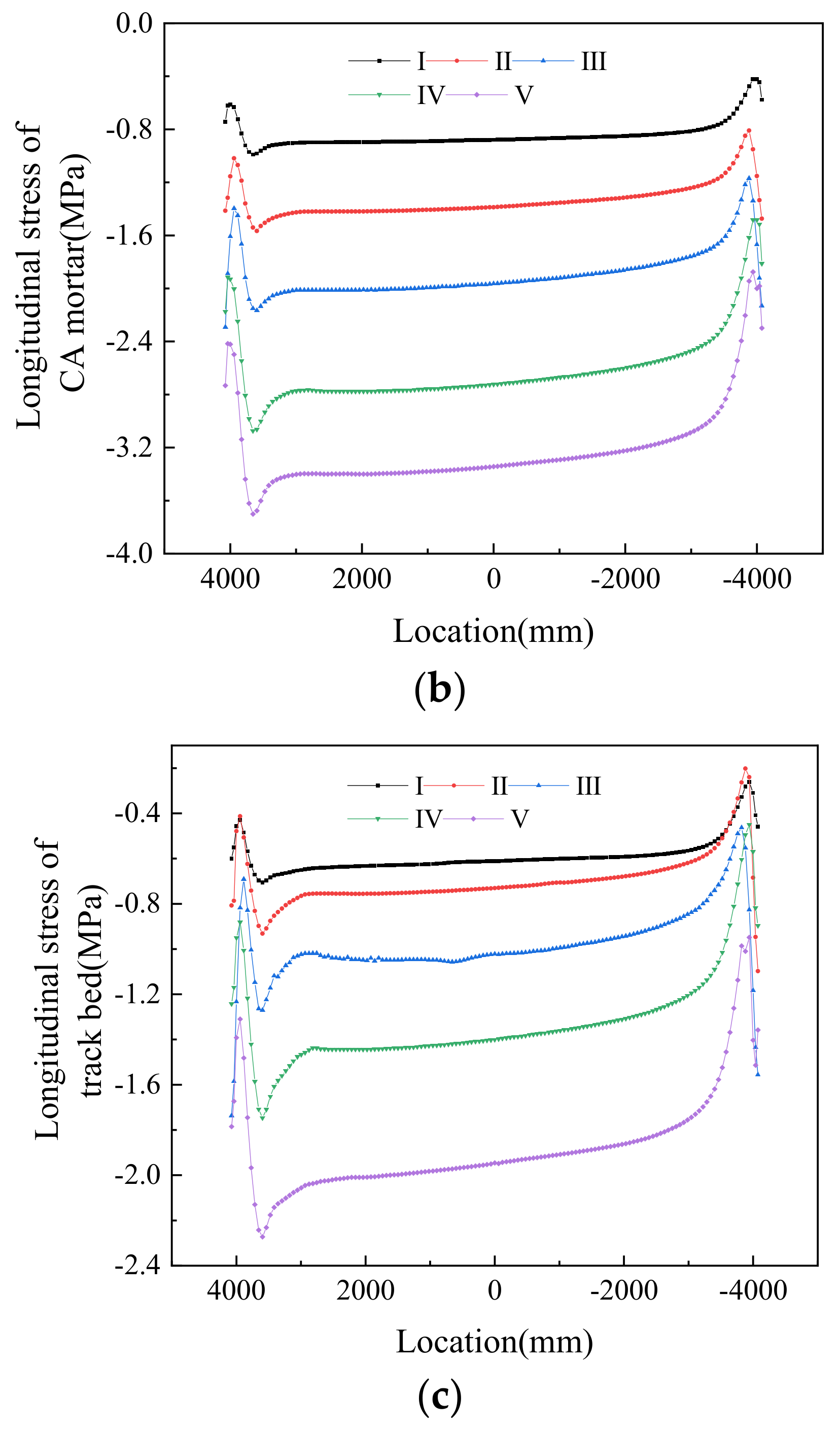

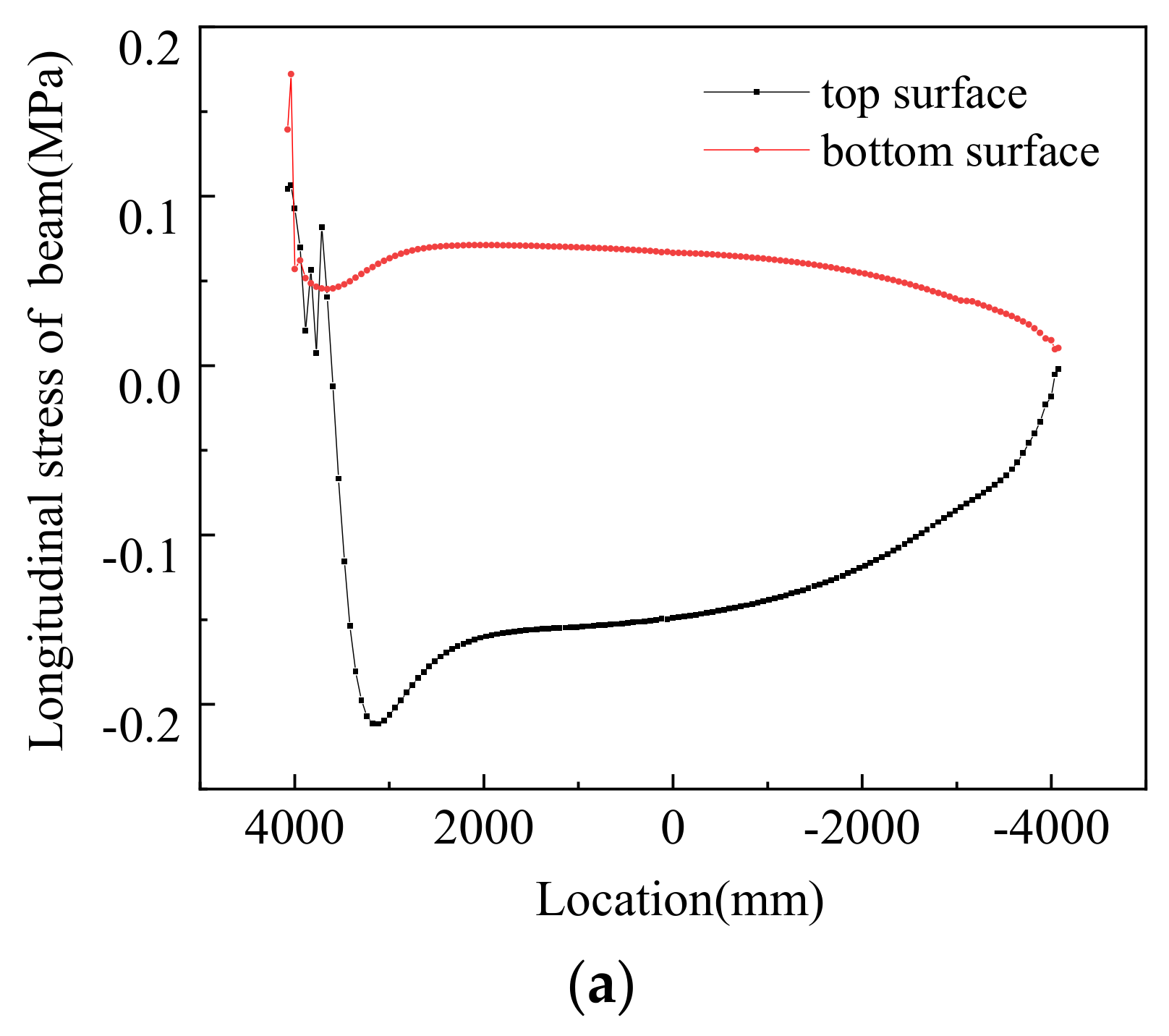

5.2.1. Positive Thermal Gradients

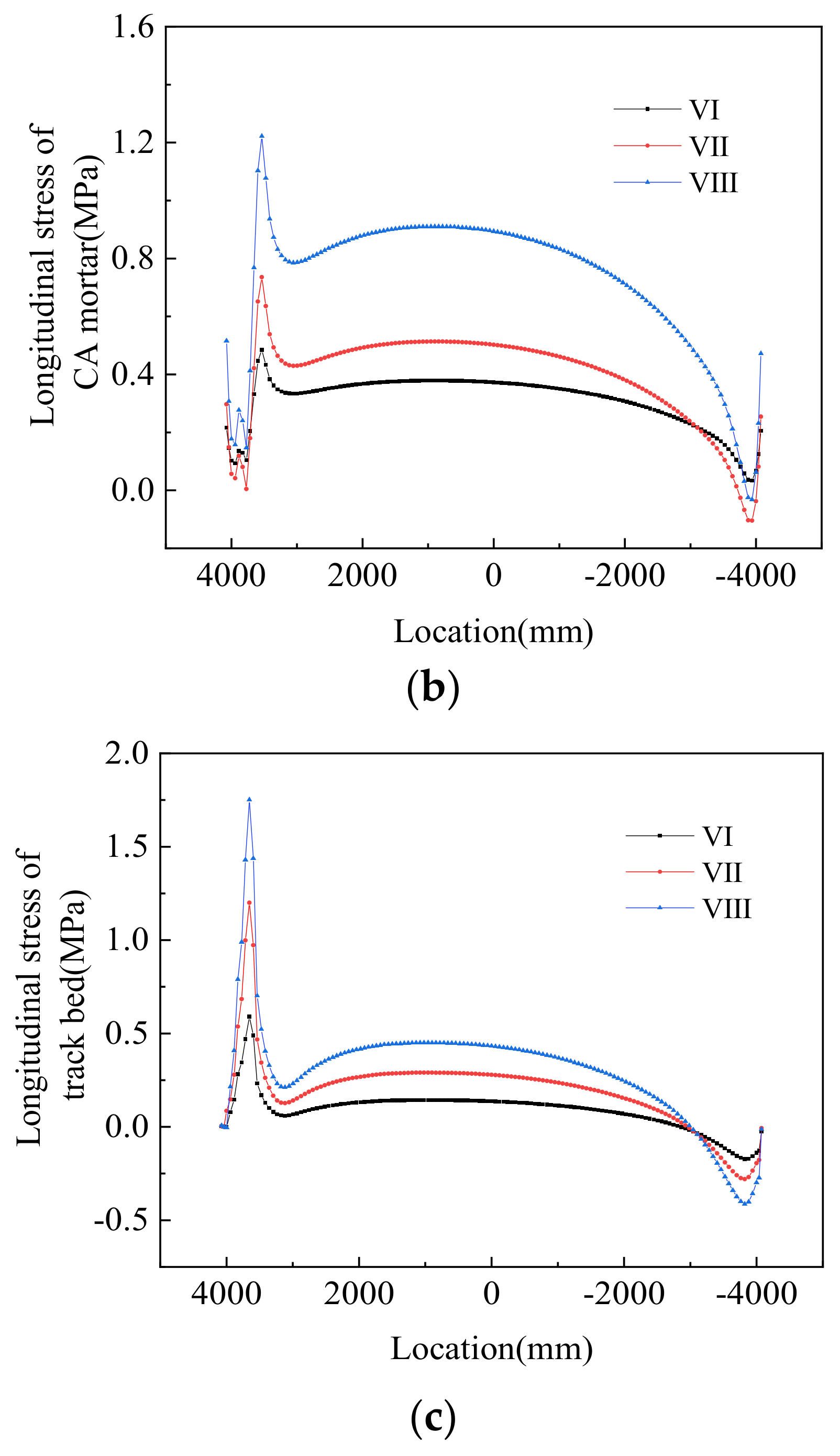

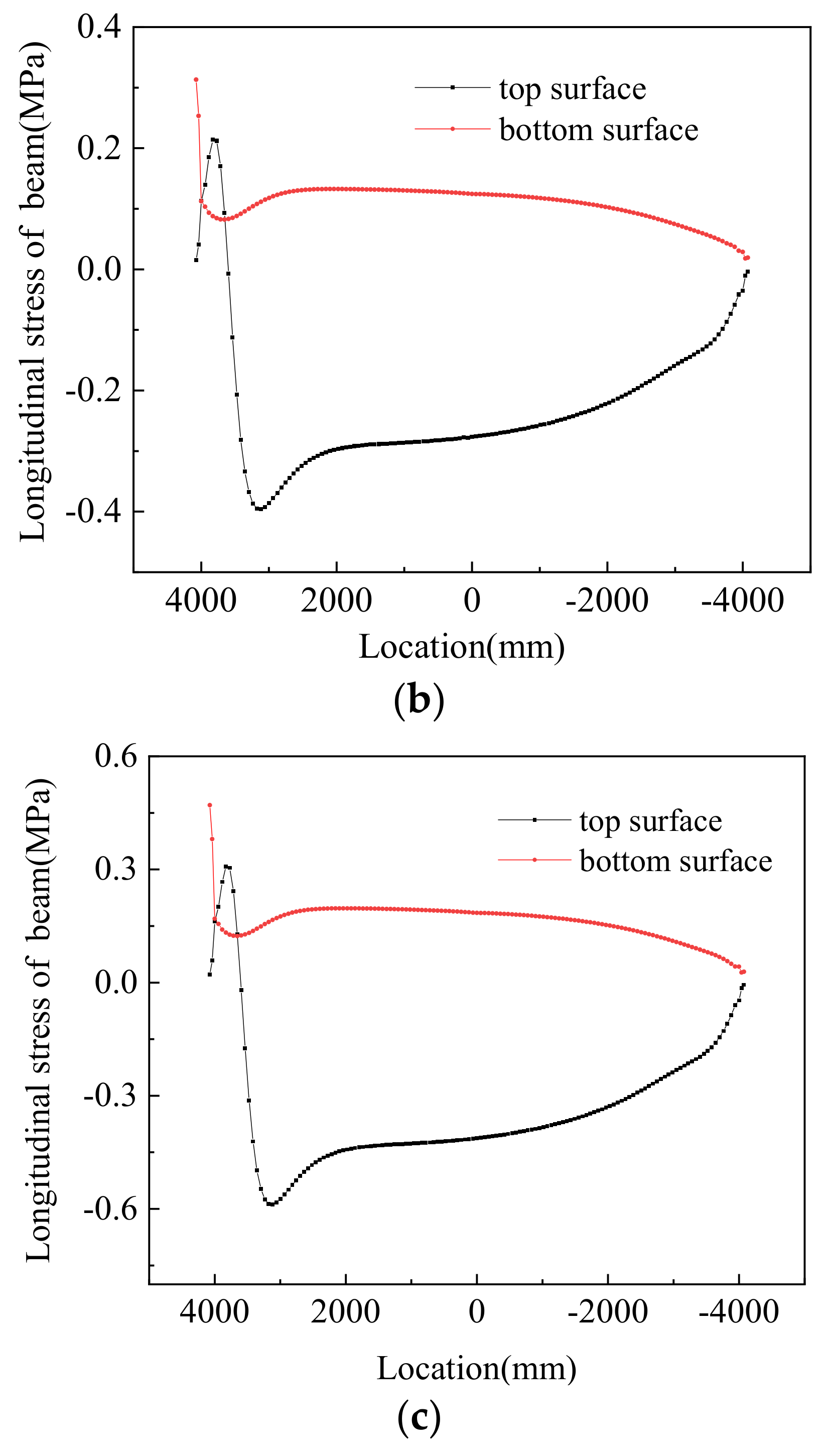

5.2.2. Negative Thermal Gradients

6. Conclusions

- The experimental and numerical study carried out in this project regarding thermal loads in a ballastless track system for the railway bridges of high-speed railway lines makes it possible to draw the following conclusions: the strains in the track layers increase nonlinearly with temperature; the higher the temperature, the larger the tensile strain, and the maximum tensile strain in the track slab is higher than the other layers; the relative displacements between track slab and cement-emulsified asphalt (CA) mortar is the driving force behind heat-induced gap initiation;

- Under increasing temperature, the relative displacement of the different layers of track structure in the longitudinal direction is nonlinear. Due to the shear grooves, the relative zero-displacement point between the track slab and track bed, between the CA mortar and track bed, and between the track bed and the supporting beam changes continuously from the fixed end section to sliding end section in the longitudinal direction. The plot of vertical relative displacement in track–bridge structures with temperature is consistent with that of longitudinal relative displacement;

- The overall displacement of the beam increases gradually under increasing temperature. The overall displacement of the beam decreases slowly under decreasing temperature. The profiles of the vertical displacement in the supporting beams clearly indicate a camber due to the positive thermal gradients;

- Under positive thermal gradients, the track structure is under compression. The larger the positive thermal gradient, the greater the compressive stress in the track structure. Under negative thermal gradients, the track structure is pulled downwards by the supporting structure, and negative thermal gradients have a great influence on the internal force of the track structure, which makes the track structure layer produce larger tensile stress.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Stress | |

| Horizontal axial stress in the full-scale model | |

| Horizontal axial strain in the scale model | |

| E | Elastic modulus |

| L | Span of the specimen |

| Thermal difference in the vertical direction | |

| Thermal | |

| M | Mass |

| Stress in different directions in the scale model | |

| Strain | |

| T | Time |

| Horizontal axial strain in the full-scale model | |

| Poisson’s ratio | |

| Linear expansion coefficient | |

| Thermal gradient | |

| Similarity constant | |

| Displacement |

References

- Zheng, T. Research on Development of China’s High-speed Railway and Economy. J. China Railw. Soc. 2020, 42, 34–41. [Google Scholar]

- Kang, C.J.; Matthias, B.; Marc, W.; Steffen, M. Experimental and numerical investigations of rail behaviour under compressive force on ballastless track systems. Eng. Struct. 2019, 197, 109413. [Google Scholar] [CrossRef]

- Shan, Y.C.; Zheng, S.G.; Zhang, X.F.; Luo, W.; Mao, J.D.; Kong, D.Y. Fatigue performance of the CA mortar used in CRTS I ballastless slab track under simulated servicing condition. Materials 2018, 11, 2259. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.C.; Yu, Z.W.; Xiang, P.; Jin, C. Composite action of the track slab and the self-compacting concrete filling layer subjected to train-induced fatigue load: An experimental investigation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 580–592. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, Y.R.; Li, Q.H.; Jin, F.; Nadakatti, M.M. Analysis of the initiation and propagation of fatigue cracks in the CRTS II slab track inter-layer using FE-SAFE and XFEM. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 223, 678–690. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, X.P.; Gao, L.; Wu, K. Improvement on the mechanical properties of CA mortar and concrete composite specimens in high-speed railway by modification of interlayer bonding. Constr. Build. Mater. 2019, 228, 116758. [Google Scholar] [CrossRef]

- Wang, T.; Jia, H.Q.; Liu, Z.K.; Wei, Z.; Xie, X.; Wu, S.L.; Li, H.Y. Experimental study of the gap between track slab and cement asphalt mortar layer in CRTS I slab track. J. Mod. Transp. 2018, 26, 173–178. [Google Scholar] [CrossRef]

- Cao, S.H.; Yang, R.S.; Su, C.G.; Dai, F.; Liu, X.Y.; Jiang, X.Y. Damage mechanism of slab track under the coupling effects of train load and water. Eng. Fract. Mech. 2016, 163, 160–175. [Google Scholar] [CrossRef]

- Zeng, Z.P.; Wang, J.D.; Shen, S.W.; Li, P.; Shuaibu, A.A.; Wang, W.D. Experimental study on evolution of mechanical properties of CRTS III ballastless slab track under fatigue load. Constr. Build. Mater. 2019, 210, 639–649. [Google Scholar]

- Zhu, S.Y.; Wang, M.Z.; Zhai, W.M.; Cai, C.; Zhao, C.; Zeng, D.; Zhang, J. Mechanical property and damage evolution of concrete interface of ballastless track in high-speed railway: Experiment and simulation. Constr. Build. Mater. 2018, 187, 460–473. [Google Scholar] [CrossRef]

- Chen, X.H.; Zhu, Y.; Cai, D.G.; Xu, G.; Dong, T. Investigation on Interface Damage between Cement Concrete Base Plate and Asphalt Concrete Waterproofing Layer under Temperature Load in Ballastless Track. Appl. Sci. 2020, 10, 2654. [Google Scholar] [CrossRef]

- Chen, Z.; Xiao, J.L.; Liu, X.Y.; Qin, H.P.; Yang, R.S. Deformation behavior of slab warping for longitudinal continuous rigid slab under temperature effect. Adv. Struct. Eng. 2019, 22, 2823–2836. [Google Scholar] [CrossRef]

- Wang, J.F.; Zhou, Y.B.; Wu, T.M.; Wu, X. Performance of Cement Asphalt Mortar in Ballastless Slab Track over High-Speed Railway under Extreme Climate Conditions. Int. J. Geomech. 2019, 19, 04019037. [Google Scholar] [CrossRef]

- Liu, X.K.; Zhang, W.H.; Xiao, J.L.; Liu, X.Y.; Li, W. Damage Mechanism of Broad-narrow Joint of CRTS II Slab Track under Temperature Rise. KSCE J. Civ. Eng. 2019, 23, 2126–2135. [Google Scholar] [CrossRef]

- Song, L.; Liu, H.B.; Cui, C.X.; Yu, Z.W.; Li, Z.G. Thermal deformation and interfacial separation of a CRTS II slab ballastless track multilayer structure used in high-speed railways based on meteorological data. Constr. Build. Mater. 2020, 237, 117528. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, L.; Fan, T.J. Temperature field analysis of CRTS II ballastless track slab structure on soil subgrade. Appl. Mech. Mater. 2014, 587, 1255–1261. [Google Scholar] [CrossRef]

- Ma, T.; Xu, L. Storey-based stability of unbraced steel frames under piece-linear temperature distributions. Eng. Struct. 2019, 194, 147–160. [Google Scholar] [CrossRef]

- Yang, R.S.; Li, J.L.; Kang, W.X.; Liu, X.Y.; Cao, S.H. Temperature Characteristics Analysis of the Ballastless Track under Continuous Hot Weather. J. Transp. Eng. Part A Syst. 2017, 143, 04017048. [Google Scholar] [CrossRef]

- Gao, L.; You, M.X.; Xiao, H.; Ma, Z.; Ma, Z.; Gan, Z. Experimental Study on Relation Between Temperature Distribution in CRTS II Slab-type Ballastless Track and Ambient Temperature. Railw. Constr. 2016, 5, 6–9. (In Chinese) [Google Scholar]

- Dai, G.L.; Su, H.T.; Liu, W.S.; Yan, B. Temperature distribution of longitudinally connected ballastless track on bridge in Summer. J. Cent. South Univ. (Sci. Technol.) 2017, 48, 1073–1080. (In Chinese) [Google Scholar]

- Ou, Z.M.; Sun, L. Value of temperature loads on probability demand for ballastless track slab Ⅱ: Thermal gradient actions. J. China Railw. Soc. 2018, 40, 80–86. (In Chinese) [Google Scholar]

- Zhao, L.; Zhou, L.Y.; Zhang, G.C.; Akim, D.M.; Jiang, L.Q.; Zhang, Y.Y. Experimental Study of the Temperature Distribution in CRTS II Ballastless Tracks on a High-Speed Railway Bridge. Appl. Sci. 2020, 10, 1980. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Wei, T.Y.; Zhang, G.C.; Zhang, Y.Y.; Akim, D.M.; Zhao, L.; Guo, W. Experimental Study of the Influence of Extremely Repeated Thermal Loading on a Ballastless Slab Track-Bridge Structure. Appl. Sci. 2020, 10, 461. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Yuan, Y.H.; Zhao, L.; Akim, D.M.; Zou, L.F.; Hou, W.Q. Laboratory Investigation of the Temperature-Dependent Mechanical Properties of a CRTS-Ⅱ Ballastless Track-Bridge Structural System in Summer. Appl. Sci. 2020, 10, 5504. [Google Scholar] [CrossRef]

- Wang, P.C.; Ye, Y.S.; Zhang, Q.L.; Liu, J.Y.; Yao, J.K. Investigation on the sulfate attack-induced heave of a ballastless track railway subgrade. Transp. Geotech. 2020, 23, 100316. [Google Scholar] [CrossRef]

- Chen, L.; Chen, J.J.; Wang, J.X. Study on stress transfer and interface damage of CRTS II slab ballastless track. J. China Railw. Soc. 2018, 40, 130–138. (In Chinese) [Google Scholar]

- Zhou, L.Y.; Yang, L.Q.; Shan, Z.; Peng, X.S.; Akim, D.M. Investigation of the Fatigue Behaviour of a Ballastless Slab Track–Bridge Structural System under Train Load. Appl. Sci. 2019, 9, 3625. [Google Scholar] [CrossRef]

- Wang, M.Z.; Cai, C.B.; Zhu, S.Y.; Zhai, W.M. Experimental study on dynamic performance of typical nonballasted track systems using a full-scale test rig. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2017, 231, 470–481. [Google Scholar] [CrossRef]

- Lou, P.; Zhu, J.P.; Dai, G.L.; Yan, B. Experimental study on bridge-track system temperature actions for Chinese high-speed railway. Arch. Civ. Mech. Eng. 2018, 18, 451–464. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Zhao, L.; Zhang, G.C.; Wei, T.Y.; Zeng, Y.H.; Peng, X.S. Model test study on CRTSⅡ Ballastless track under rapid temperature rise and fall on High-Speed Railway bridge. J. China Railw. Soc. 2020, 42, 90–98. (In Chinese) [Google Scholar]

- Najjar, S.; Moghaddam, A.M.; Sahaf, A.; Yazdani, M.R.; Delarami, A. Evaluation of the mixed mode (I/II) fracture toughness of cement emulsified asphalt mortar (CRTS II) using mixture design of experiments. Constr. Build. Mater. 2019, 225, 812–828. [Google Scholar] [CrossRef]

- Ren, J.J.; Wang, J.; Li, X.; Wei, K.; Li, H.L.; Deng, S.J. Influence of cement asphalt mortar debonding on the damage distribution and mechanical responses of CRTS I prefabricated slab. Constr. Build. Mater. 2020, 230, 116995. [Google Scholar] [CrossRef]

- Tian, D.M.; Deng, D.H.; Peng, J.W.; Wang, S.X.; Ai, Y.Q. Influence of Temperature on Interfacial Bonding between Cement Emulsified Asphalt Mortar Layer and Concrete Layer. J. China Railw. Soc. 2013, 35, 78–85. [Google Scholar]

- Ren, J.J.; Li, H.L.; Cai, X.P.; Deng, S.J.; Wang, J.; Du, W. Viscoelastic deformation behavior of cement and emulsified asphalt mortar in China railway track system I prefabricated slab track. J. Zhejiang Univ. Sci. A 2020, 4, 304–316. [Google Scholar] [CrossRef]

- Zhao, L.; Zhou, L.Y.; Akim, D.; Mahunon, A.D.; Zhang, Y.Y.; Li, H.Y.; Zou, L.F.; Yuan, Y.H. Experimental study on stiffness degradation of CRTSⅡ ballastless track-bridge structural system under fatigue train load. Constr. Build. Mater. 2021, 283, 122794. [Google Scholar] [CrossRef]

| Physical Quantity | Dimension | Test Structure | Prototype Structure | Similarity Ratio |

|---|---|---|---|---|

| Physical dimension | L | l/4 | 1 | 1/4 |

| Modulus of elasticity | M/(L*T2) | E | E | 1 |

| Coefficient of linear expansion | 1/θ | α | α | 1 |

| Temperature | θ | T | T | 1 |

| Thermal gradient | θ/L | ∇T | 4∇T | 1/4 |

| Physical Quantity | Dimension | Test Structure | Prototype Structure | Similarity Ratio |

|---|---|---|---|---|

| Stress | M/(L*T2) | σ | σ | 1 |

| Strain | 1 | ε | ε | 1 |

| Displacement | L | δ/4 | δ/4 | 1/4 |

| (a) Between the track slab and track bed (mm). | ||||

|---|---|---|---|---|

| 0L | L/4 | L/2 | 3L/4 | L |

| 0.030 | 0.410 | 0.370 | 0.420 | 0.180 |

| 0.040 | 0.430 | 0.410 | 0.500 | 0.420 |

| 0.300 | 0.550 | 0.180 | 0.200 | 0.250 |

| 0.470 | 0.600 | 0.550 | 0.300 | 0.310 |

| 0.400 | 0.700 | 0.500 | 0.420 | 0.400 |

| (b) Between the track bed and support beam (mm). | ||||

| 0L | L/4 | L/2 | 3L/4 | L |

| 0.010 | 0.065 | 0.077 | 1.052 | 0.049 |

| 0.086 | 0.163 | 0.366 | 1.291 | 0.066 |

| 0.012 | 0.252 | 0.670 | 1.580 | 0.273 |

| 0.031 | 0.316 | 1.031 | 1.750 | 0.352 |

| 0.247 | 0.348 | 0.687 | 1.900 | 0.418 |

| Structure | Unit Type | Modulus of Elasticity (Pa) | Poisson Ratio | Density (kg/m3) | Linear Expansivity (1/°C) |

|---|---|---|---|---|---|

| Steel rail | BEAM189 | 2.10 × 105 | 0.3 | 7800 | 1.20 × 10−5 |

| Track slab (C55) | SOLID65 | 3.60 × 104 | 0.2 | 2600 | 1.00 × 10−5 |

| CA mortar | SOLID65 | 1.17 × 104 | 0.2 | 1800 | 1.00 × 10−5 |

| Track bed (C30) | SOLID65 | 3.20 × 104 | 0.2 | 2600 | 1.00 × 10−5 |

| Beam (C50) | SOLID65 | 3.55 × 104 | 0.2 | 2600 | 1.00 × 10−5 |

| Bridge abutment | SOLID65 | 2.63 × 104 | 0.2 | 2600 | 1.00 × 10−5 |

| Tendon | LINK8 | 1.95 × 105 | 0.3 | 7800 | 1.20 × 10−5 |

| Structure | Temperature Increased by 50 °C |

|---|---|

| Top of track slab | 58.2 °C |

| Bottom of track bed | 37.6 °C |

| Bottom of CA mortar | 27 °C |

| Bottom of track bed (Top surface of beam) | 23 °C |

| 200 mm from the top of beam | 0 °C |

| Load Condition | І | Ⅱ | Ⅲ | Ⅳ |

|---|---|---|---|---|

| Thermal gradient (°C/m) | 20 °C/m | 40 °C/m | 60 °C/m | 80 °C/m |

| Load Condition | Ⅴ | Ⅵ | Ⅶ | Ⅷ |

| Thermal gradient (°C/m) | 100 °C/m | −10 °C/m | −20 °C/m | −30 °C/m |

| Load | Track Slab | CA Mortar | Track Bed | Top Surface of Beam | Bottom of Beam | |

|---|---|---|---|---|---|---|

| І | maximum | −4.366 | −0.990 | −0.706 | −1.780 | −0.420 |

| minimum | −1.634 | −0.422 | −0.262 | −0.084 | −0.089 | |

| Ⅱ | maximum | −6.699 | −1.540 | −0.931 | −1.888 | −0.800 |

| minimum | −2.844 | −0.951 | −0.240 | −0.084 | −0.105 | |

| Ⅲ | maximum | −8.968 | −2.152 | −1.270 | −2.270 | −0.622 |

| minimum | −3.819 | −1.339 | −0.825 | −0.096 | −0.006 | |

| Ⅳ | maximum | −12.008 | −3.074 | −1.746 | −3.310 | −0.881 |

| minimum | −4.742 | −1.482 | −0.450 | −0.148 | −0.067 | |

| Ⅴ | maximum | −13.845 | −3.701 | −2.273 | −5.025 | −1.220 |

| minimum | −5.309 | −1.875 | −0.949 | −0.228 | −0.064 | |

| Load | Track Slab | CA Mortar | Track Bed | Top Surface of Beam | Bottom of Beam | |

|---|---|---|---|---|---|---|

| Ⅵ | maximum | 0.760 | 0.484 | 0.590 | 0.106 | 0.172 |

| minimum | −0.044 | 0.034 | −0.172 | −0.212 | 0.010 | |

| Ⅶ | maximum | 1.469 | 0.736 | 1.120 | 0.214 | 0.313 |

| minimum | −0.078 | −0.104 | −0.280 | −0.396 | 0.018 | |

| Ⅷ | maximum | 2.156 | 1.222 | 1.752 | 0.308 | 0.470 |

| minimum | −0.096 | −0.031 | −0.413 | −0.588 | 0.027 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhou, L.; Mahunon, A.D.; Zhang, G.; Peng, X.; Zhao, L.; Yuan, Y. Mechanical Performance of a Ballastless Track System for the Railway Bridges of High-Speed Lines: Experimental and Numerical Study under Thermal Loading. Materials 2021, 14, 2876. https://doi.org/10.3390/ma14112876

Zhang Y, Zhou L, Mahunon AD, Zhang G, Peng X, Zhao L, Yuan Y. Mechanical Performance of a Ballastless Track System for the Railway Bridges of High-Speed Lines: Experimental and Numerical Study under Thermal Loading. Materials. 2021; 14(11):2876. https://doi.org/10.3390/ma14112876

Chicago/Turabian StyleZhang, Yingying, Lingyu Zhou, Akim D. Mahunon, Guangchao Zhang, Xiusheng Peng, Lei Zhao, and Yahui Yuan. 2021. "Mechanical Performance of a Ballastless Track System for the Railway Bridges of High-Speed Lines: Experimental and Numerical Study under Thermal Loading" Materials 14, no. 11: 2876. https://doi.org/10.3390/ma14112876

APA StyleZhang, Y., Zhou, L., Mahunon, A. D., Zhang, G., Peng, X., Zhao, L., & Yuan, Y. (2021). Mechanical Performance of a Ballastless Track System for the Railway Bridges of High-Speed Lines: Experimental and Numerical Study under Thermal Loading. Materials, 14(11), 2876. https://doi.org/10.3390/ma14112876