Graphene Infused Ecological Polymer Composites for Electromagnetic Interference Shielding and Heat Management Applications

Abstract

1. Introduction

2. Methods and Materials

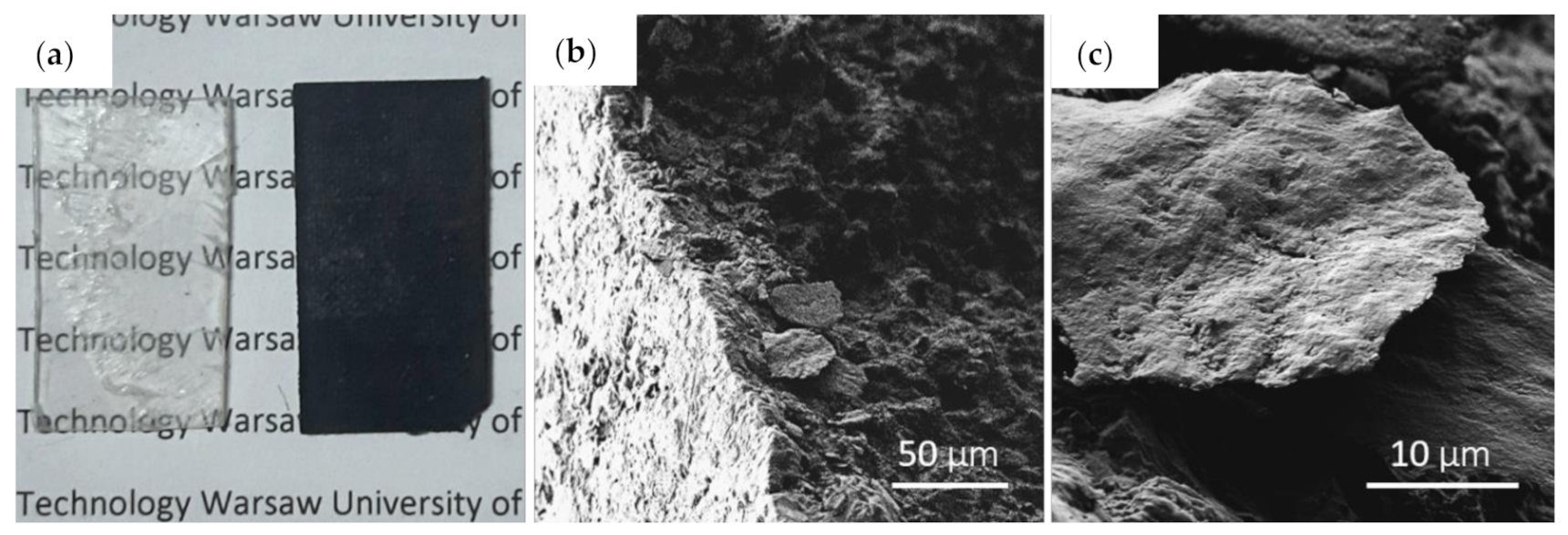

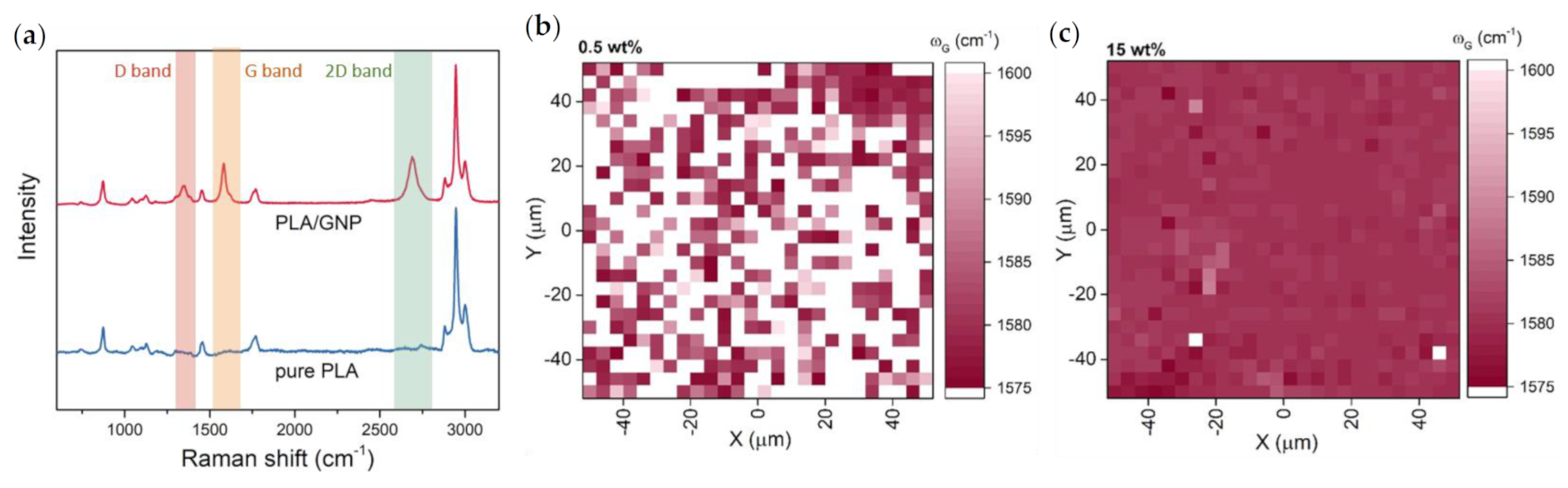

2.1. Material: PLA/GNP Composites

2.2. Characterization Methods

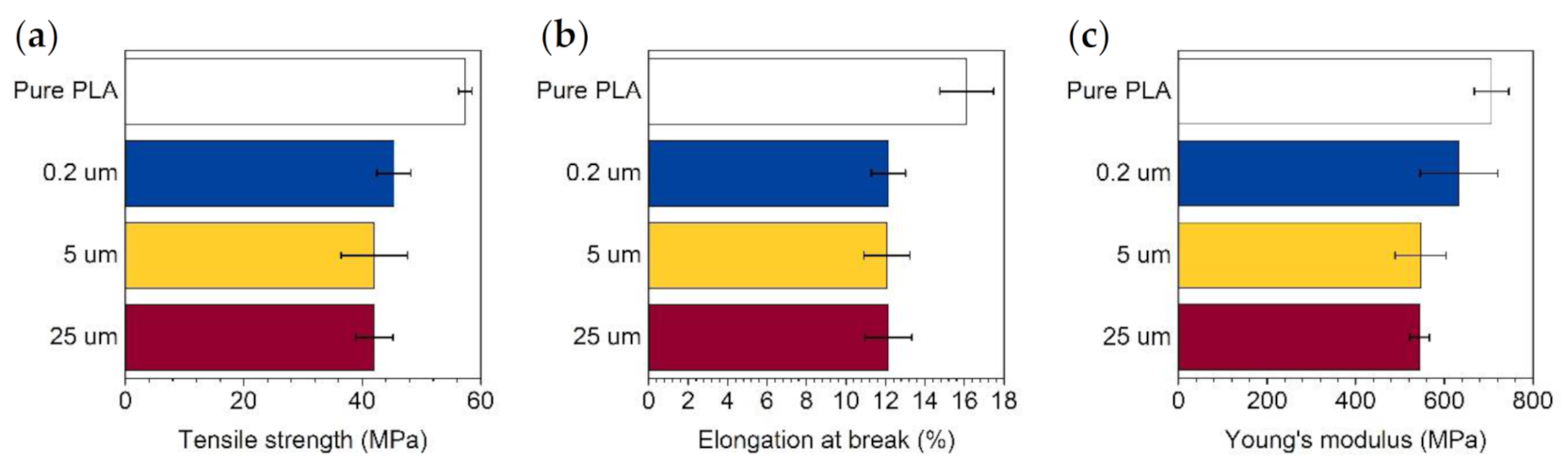

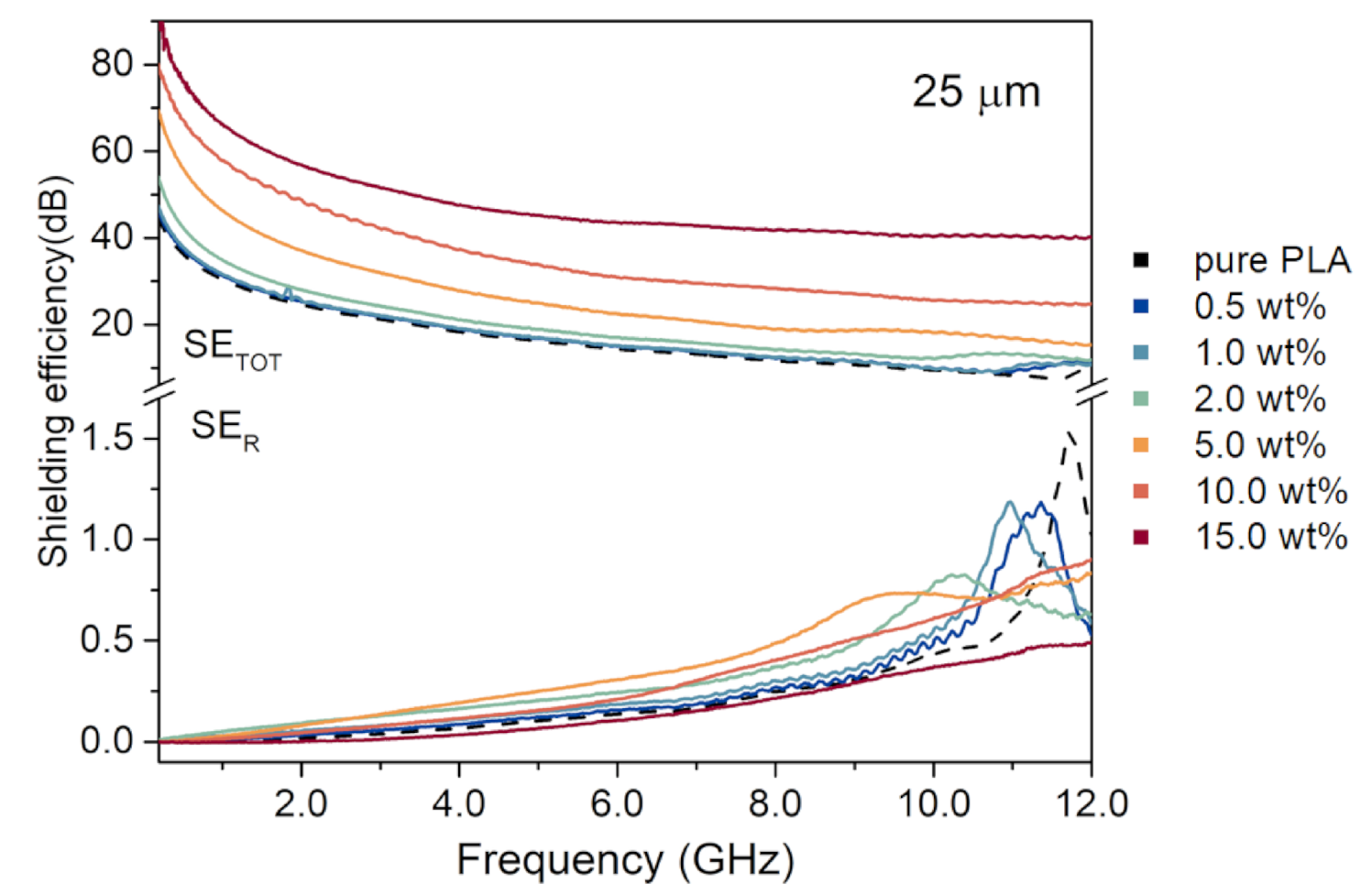

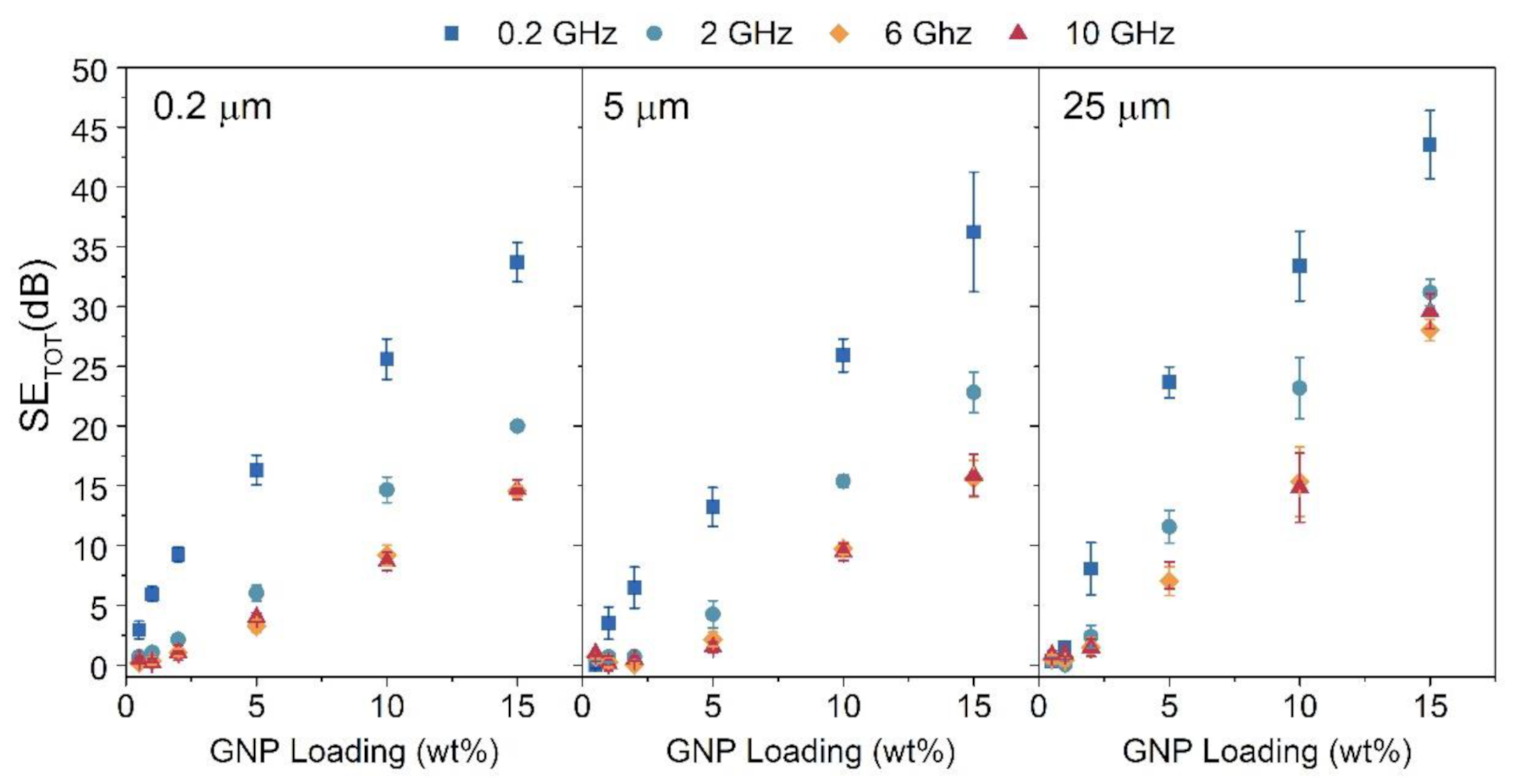

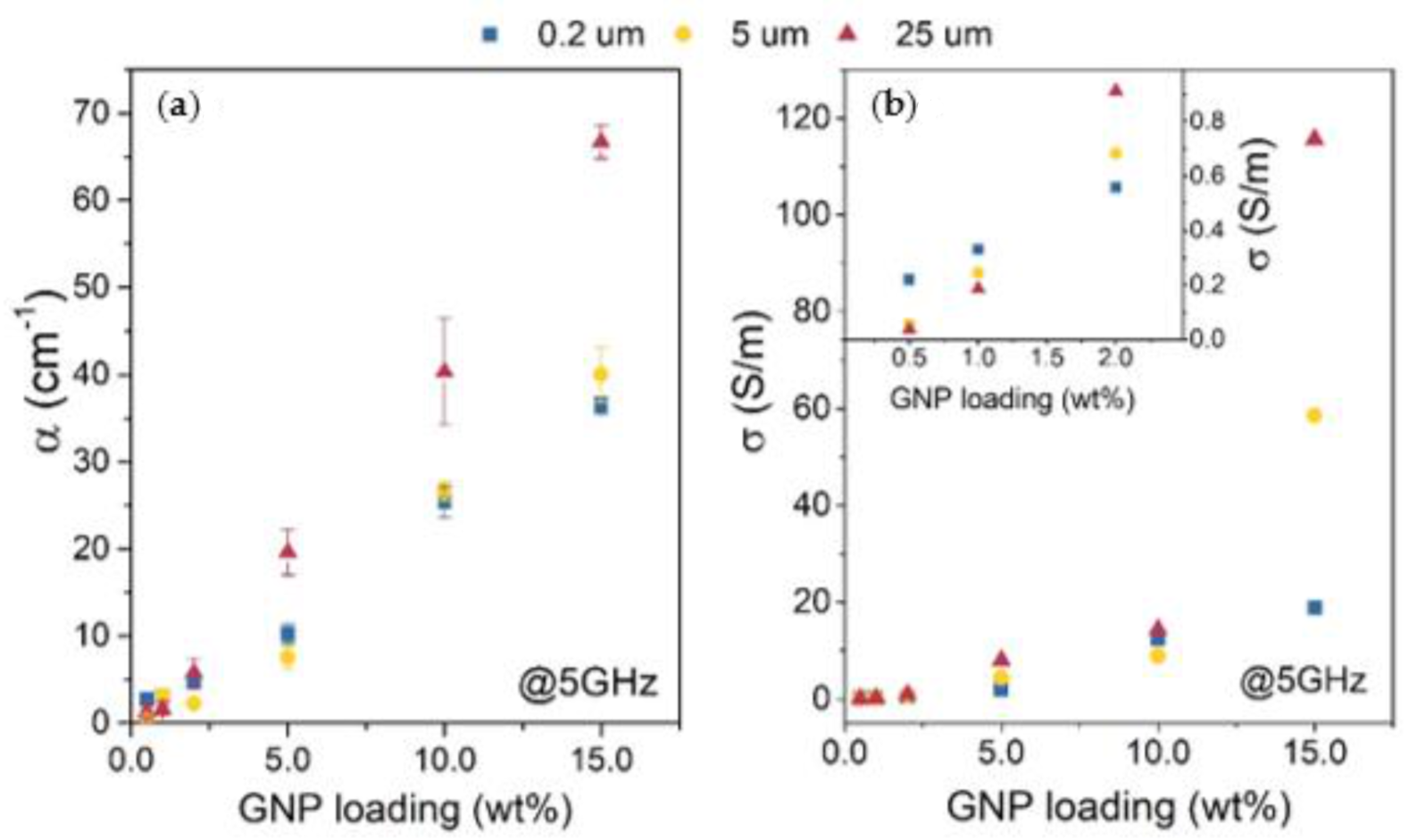

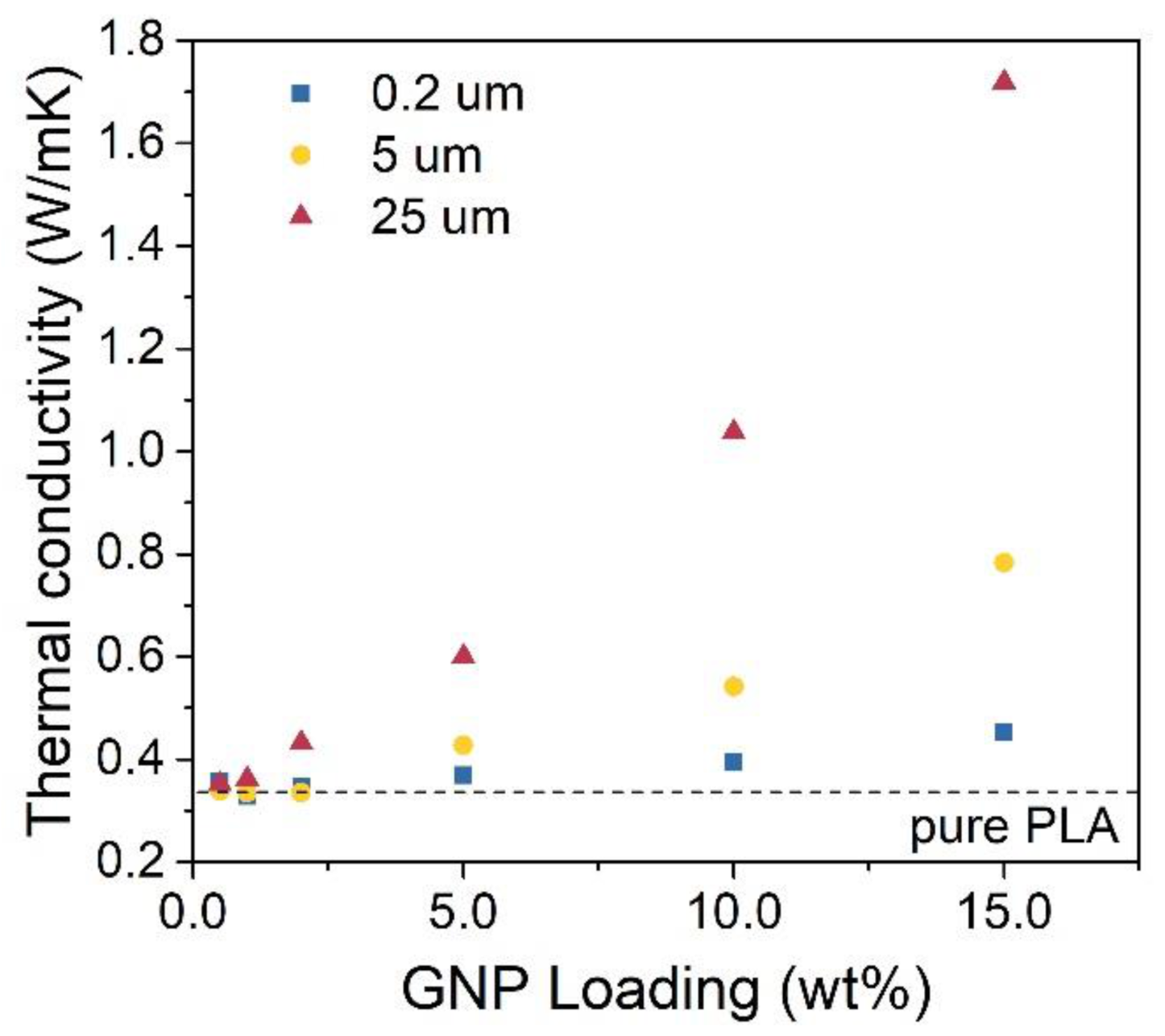

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferreira, A.D.B.L.; Nóvoa, P.R.O.; Marques, A.T. Multifunctional Material Systems: A state-of-the-art review. Compos. Struct. 2016, 151, 3–35. [Google Scholar] [CrossRef]

- Markham, D. Shielding: Quantifying the shielding requirements for portable electronic design and providing new solutions by using a combination of materials and design. Mater. Des. 1999, 21, 45–50. [Google Scholar] [CrossRef]

- Kargar, F.; Barani, Z.; Balinskiy, M.; Magana, A.S.; Lewis, J.S.; Balandin, A.A. Dual-Functional Graphene Composites for Electromagnetic Shielding and Thermal Management. Adv. Electron. Mater. 2019, 5, 1800558. [Google Scholar] [CrossRef]

- Lee, H.; Yu, S.; Shahzad, F.; Kim, W.N.; Park, C.; Hong, S.M.; Koo, C.M. Density-tunable lightweight polymer composites with dual-functional ability of efficient EMI shielding and heat dissipation. Nanoscale 2017, 9, 13432–13440. [Google Scholar] [CrossRef]

- Secor, E.B.; Prabhumirashi, P.L.; Puntambekar, K.; Geier, M.L.; Hersam, M.C. Inkjet Printing of High Conductivity, Flexible Graphene Patterns. J. Phys. Chem. Lett. 2013, 4, 1347–1351. [Google Scholar] [CrossRef]

- Cooper, D.R.; D’Anjou, B.; Ghattamaneni, N.; Harack, B.; Hilke, M.; Horth, A.; Majlis, N.; Massicotte, M.; Vandsburger, L.; Whiteway, E.; et al. Experimental Review of Graphene. ISRN Condens. Matter Phys. 2012, 1–56. [Google Scholar] [CrossRef]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine Structure Constant Defines Visual Transparency of Graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef]

- Zhang, L.; Alvarez, N.T.; Zhang, M.; Haase, M.; Malik, R.; Mast, D.; Shanov, V. Preparation and characterization of graphene paper for electromagnetic interference shielding. Carbon 2015, 82, 353–359. [Google Scholar] [CrossRef]

- Hong, S.K.; Kim, K.Y.; Kim, T.Y.; Kim, J.H.; Park, S.W.; Kim, J.H.; Cho, B.J. Electromagnetic interference shielding effectiveness of monolayer graphene. Nanotechnology 2012, 23, 455704. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Ghosh, S.; Calizo, I.; Teweldebrhan, D.; Pokatilov, E.P.; Nika, D.L.; Balandin, A.A.; Bao, W.; Miao, F.; Lau, C.N. Extremely high thermal conductivity of graphene: Prospects for thermal management applications in nanoelectronic circuits. Appl. Phys. Lett. 2008, 92, 151911. [Google Scholar] [CrossRef]

- Xu, Y.L.; Uddin, A.; Estevez, D.; Luo, Y.; Peng, H.X.; Qin, F.X. Lightweight microwire/graphene/silicone rubber composites for efficient electromagnetic interference shielding and low microwave reflectivity. Compos. Sci. Technol. 2020, 189, 108022. [Google Scholar] [CrossRef]

- Bansala, T.; Joshi, M.; Mukhopadhyay, S.; Doong, R.; Chaudhary, M. Electrically conducting graphene-based polyurethane nanocomposites for microwave shielding applications in the Ku band. J. Mater. Sci. 2017, 52, 1546–1560. [Google Scholar] [CrossRef]

- Khasim, S. Polyaniline-Graphene nanoplatelet composite films with improved conductivity for high performance X-band microwave shielding applications. Results Phys. 2019, 12, 1073–1081. [Google Scholar] [CrossRef]

- Kargar, F.; Barani, Z.; Salgado, R.; Debnath, B.; Lewis, J.S.; Aytan, E.; Lake, R.K.; Balandin, A.A. Thermal Percolation Threshold and Thermal Properties of Composites with High Loading of Graphene and Boron Nitride Fillers. Acs Appl. Mater. Interfaces 2018, 10, 37555–37565. [Google Scholar] [CrossRef]

- Kim, S.Y.; Noh, Y.J.; Yu, J. Thermal conductivity of graphene nanoplatelets filled composites fabricated by solvent-free processing for the excellent filler dispersion and a theoretical approach for the composites containing the geometrized fillers. Compos. Part A Appl. Sci. Manuf. 2015, 69, 219–225. [Google Scholar] [CrossRef]

- Gu, J.; Xie, C.; Li, H.; Dang, J.; Geng, W.; Zhang, Q. Thermal percolation behavior of graphene nanoplatelets/polyphenylene sulfide thermal conductivity composites. Polym. Compos. 2014, 35, 1087–1092. [Google Scholar] [CrossRef]

- Li, A.; Zhang, C.; Zhang, Y.-F. Thermal Conductivity of Graphene-Polymer Composites: Mechanisms, Properties, and Applications. Polymers 2017, 9, 437. [Google Scholar] [CrossRef]

- Shukla, V. Review of electromagnetic interference shielding materials fabricated by iron ingredients. Nanoscale Adv. 2019, 1, 1640–1671. [Google Scholar] [CrossRef]

- Chamorro-Posada, P.; Vázquez-Cabo, J.; Rubiños-López, Ó.; Martín-Gil, J.; Hernández-Navarro, S.; Martín-Ramos, P.; Sánchez-Arévalo, F.M.; Tamashausky, A.V.; Merino-Sánchez, C.; Dante, R.C. THz TDS study of several sp2 carbon materials: Graphite, needle coke and graphene oxides. Carbon 2016, 98, 484–490. [Google Scholar] [CrossRef]

- Jia, W.; Luo, Y.; Yu, J.; Liu, B.; Hu, M.; Chai, L.; Wang, C. Effects of high-repetition-rate femtosecond laser micromachining on the physical and chemical properties of polylactide (PLA). Opt. Express 2015, 23, 26932–26939. [Google Scholar] [CrossRef] [PubMed]

- Al-Maqdasi, Z.; Gong, G.; Nyström, B.; Emami, N.; Joffe, R. Characterization of Wood and Graphene Nanoplatelets (GNPs) Re-inforced Polymer Composites. Materials 2020, 13, 2089. [Google Scholar] [CrossRef] [PubMed]

- Tamboli, S.M.; Mhaske, S.T.; Kale, D.D. Properties of high-density polyethylene filled with waste crosslinked foam. J. App. Polym. Sci. 2003, 91, 110–114. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Tensile Behavior of High-Density Polyethylene Including the Effects of Processing Tech-nique, Thickness, Temperature, and Strain Rate. Polymers 2020, 12, 1857. [Google Scholar] [CrossRef]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Kotsilkova, R.; Ivanov, E.; Menseidov, D.; Naddeo, C.; Romano, V.; Guadagno, L.; Adami, R.; et al. Nanocarbon/Poly(Lactic) Acid for 3D Printing: Effect of Fillers Content on Electromagnetic and Thermal Properties. Materials 2019, 12, 2369. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Wang, S.; Zhang, L.; Park, C.B. Injection-molded microcellular PLA/graphite nanocomposites with dramatically enhanced mechanical and electrical properties for ultra-efficient EMI shielding applications. J. Mater. Chem. C 2018, 6, 6847–6859. [Google Scholar] [CrossRef]

- Zdrojek, M.; Bomba, J.; Łapińska, A.; Dużyńska, A.; Żerańska-Chudek, K.; Suszek, J.; Stobiński, L.; Taube, A.; Sypek, M.; Judek, J. Graphene-based plastic absorber for total sub-terahertz radiation shielding. Nanoscale 2018, 10, 13426–13431. [Google Scholar] [CrossRef]

- Zeranska-Chudek, K.; Siemion, A.; Palka, N.; Mdarhri, A.; Elaboudi, I.; Brosseau, C.; Zdrojek, M. Terahertz Shielding Properties of Carbon Black Based Polymer Nanocomposites. Materials 2021, 14, 835. [Google Scholar] [CrossRef]

- Zeranska-Chudek, K.; Lapinska, A.; Siemion, A.; Jastrzębska, A.M.; Zdrojek, M. Terahertz time domain spectroscopy of graphene and MXene polymer composites. J. Appl. Polym. Sci. 2021, 138, 49962. [Google Scholar] [CrossRef]

- Kashi, S.; Gupta, R.K.; Baum, T.; Kao, N.; Bhattacharya, S.N. Morphology, electromagnetic properties and electromagnetic interference shielding performance of poly lactide/graphene nanoplatelet nanocomposites. Mater. Des. 2016, 95, 119–126. [Google Scholar] [CrossRef]

- Prashantha, K.; Roger, F. Multifunctional properties of 3D printed poly(lactic acid)/graphene nanocomposites by fused deposition modeling. J. Macromol. Sci. Part A 2017, 54, 24–29. [Google Scholar] [CrossRef]

- Lee, K.P.M.; Baum, T.; Shanks, R.; Daver, F. Graphene–polyamide-6 composite for additive manufacture of multi-functional electromagnetic interference shielding components. J. App. Polym. Sci. 2021, 138, 49909. [Google Scholar] [CrossRef]

- Wang, G.; Liao, X.; Yang, J.; Tang, W.; Zhang, Y.; Jiang, Q.; Li, G. Frequency-selective and tunable electromagnetic shielding effectiveness via the sandwich structure of silicone rubber/graphene composite. Compos. Sci. Technol. 2019, 184, 107847. [Google Scholar] [CrossRef]

- Zhang, H.-B.; Yan, Q.; Zheng, W.-G.; He, Z.; Yu, Z.-Z. Tough Graphene−Polymer Microcellular Foams for Electromagnetic In-terference Shielding. ACS Appl. Mater. Interfaces 2011, 3, 918–924. [Google Scholar] [CrossRef]

- Zeng, Q.; Du, Z.; Qin, C.; Wang, Y.; Liu, C.; Shen, C. Enhanced thermal, mechanical and electromagnetic interference shielding properties of graphene nanoplatelets-reinforced poly(lactic acid)/poly(ethylene oxide) nanocomposites. Mater. Today Commun. 2020, 25, 101632. [Google Scholar] [CrossRef]

- Varenik, M.; Nadiv, R.; Levy, I.; Vasilyev, G.; Regev, O. Breaking through the Solid/Liquid Processability Barrier: Thermal Conduc-tivity and Rheology in Hybrid Graphene–Graphite Polymer Composites. ACS Appl. Mater. Interfaces 2017, 9, 7556–7564. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Meng, F.; Li, D.; Tian, X.; Wang, Z.; Zhou, Z. Super-high thermal conductivity of polyamide-6/graphene-graphene oxide composites through in situ polymerization. High Perform. Polym. 2017, 29, 585–594. [Google Scholar] [CrossRef]

- Guo, W.; Chen, G. Fabrication of graphene/epoxy resin composites with much enhanced thermal conductivity via ball milling technique. J. App. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Tang, Z.; Kang, H.; Shen, Z.; Guo, B.; Zhang, L.; Jia, D. Grafting of Polyester onto Graphene for Electrically and Thermally Conductive Composites. Macromolecules 2012, 45, 3444–3451. [Google Scholar] [CrossRef]

| Type of Composite | EMI SE (dB) | Range (GHz) | Thickness (mm) | κ (W/mK) | Ref. |

|---|---|---|---|---|---|

| PLA/GNP | 16 | 8–12 | 1.2 | - | [32] |

| PA6/GNP | 16 | 8–12 | 1.0 | - | [33] |

| SR/GNP | 20 | 8–12 | 1.7 | - | [34] |

| PMMA/GNP (foam) | 13–19 | 8–12 | 4.0 | - | [35] |

| PLA + PEO/GNP | 14 | 8–12 | 1.5 | - | [36] |

| Silicone/GNP | - | - | 0.1–1.5 | 2.60 | [37] |

| PPS/GNP | - | - | - | 4.41 | [18] |

| PA6/graphene-GO | - | - | - | 2.14 | [38] |

| GNP/epoxy | - | - | - | 2.67 | [39] |

| BE/graphene | - | - | 0.54 | [40] | |

| PLA/GNP | 10.22 | 30 | 10.0 | 0.66 | [26] |

| Epoxy/FLG | 45 | 8.2–12.4 | 1.0 | 8.00 | [3] |

| PLA/GNP | 42 | 0.2–12 | 1.0 | 1.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeranska-Chudek, K.; Wróblewska, A.; Kowalczyk, S.; Plichta, A.; Zdrojek, M. Graphene Infused Ecological Polymer Composites for Electromagnetic Interference Shielding and Heat Management Applications. Materials 2021, 14, 2856. https://doi.org/10.3390/ma14112856

Zeranska-Chudek K, Wróblewska A, Kowalczyk S, Plichta A, Zdrojek M. Graphene Infused Ecological Polymer Composites for Electromagnetic Interference Shielding and Heat Management Applications. Materials. 2021; 14(11):2856. https://doi.org/10.3390/ma14112856

Chicago/Turabian StyleZeranska-Chudek, Klaudia, Anna Wróblewska, Sebastian Kowalczyk, Andrzej Plichta, and Mariusz Zdrojek. 2021. "Graphene Infused Ecological Polymer Composites for Electromagnetic Interference Shielding and Heat Management Applications" Materials 14, no. 11: 2856. https://doi.org/10.3390/ma14112856

APA StyleZeranska-Chudek, K., Wróblewska, A., Kowalczyk, S., Plichta, A., & Zdrojek, M. (2021). Graphene Infused Ecological Polymer Composites for Electromagnetic Interference Shielding and Heat Management Applications. Materials, 14(11), 2856. https://doi.org/10.3390/ma14112856