Experimental Investigation of the Friction Stir Weldability of AA8006 with Zirconia Particle Reinforcement and Optimized Process Parameters

Abstract

1. Introduction

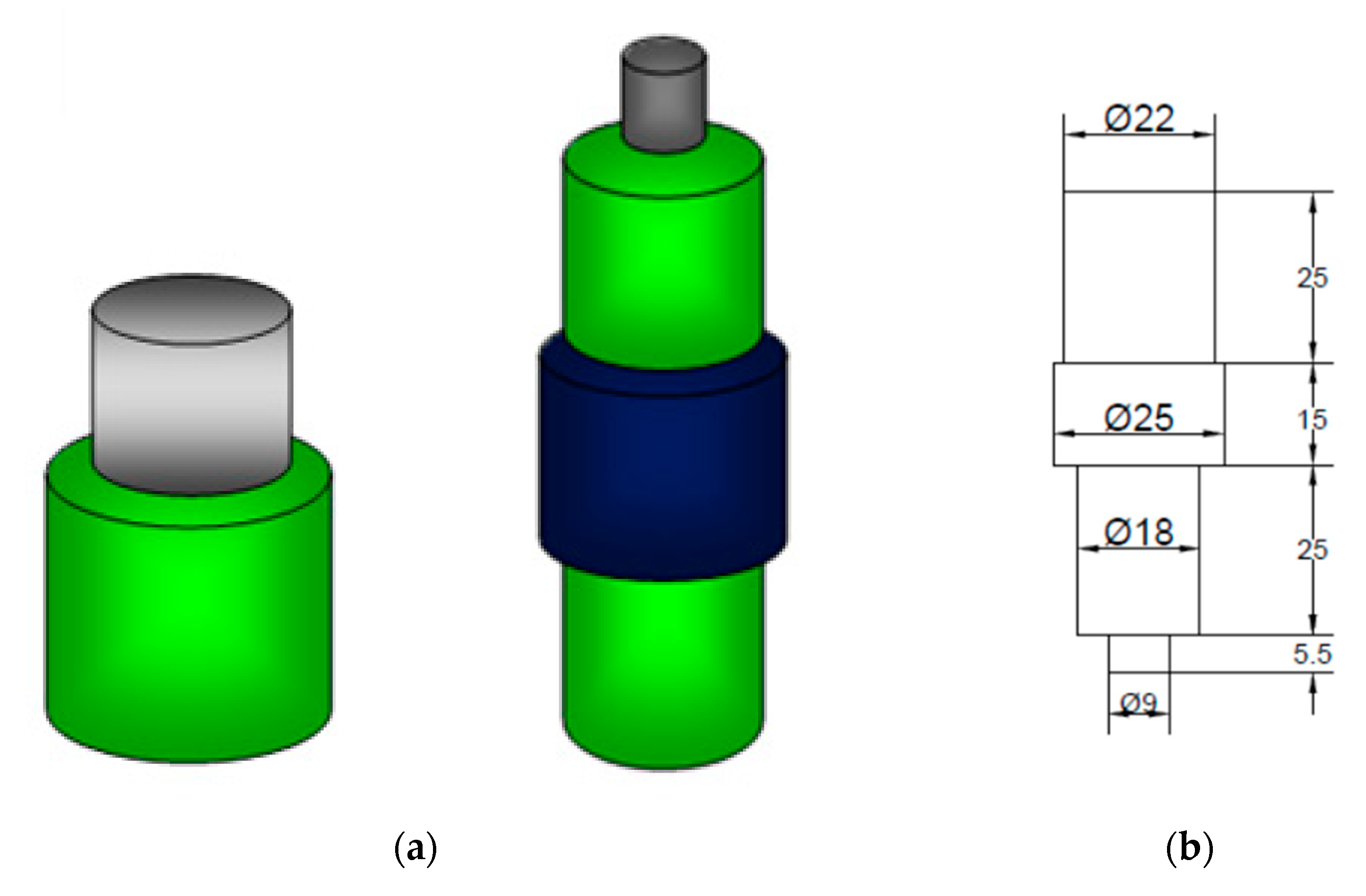

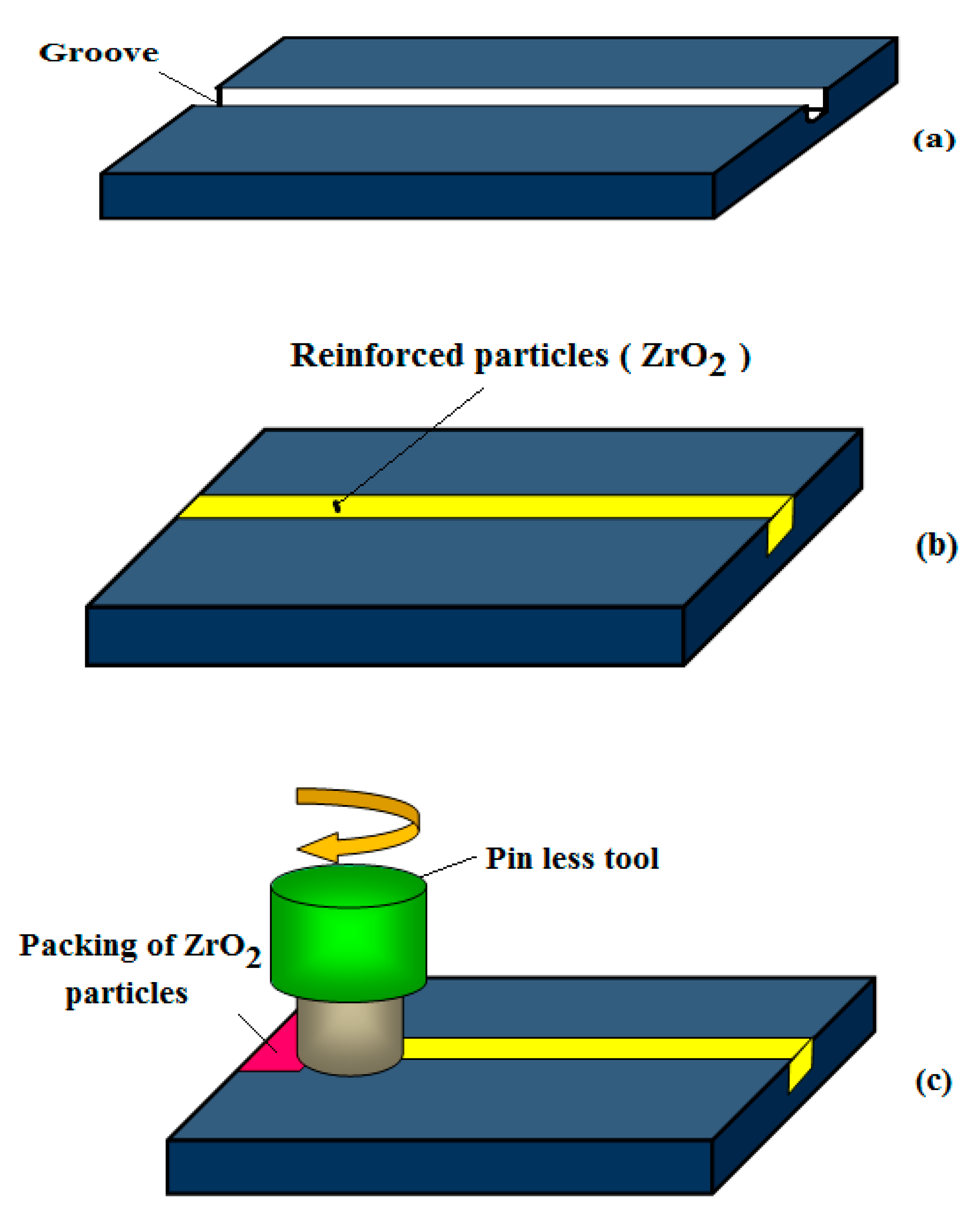

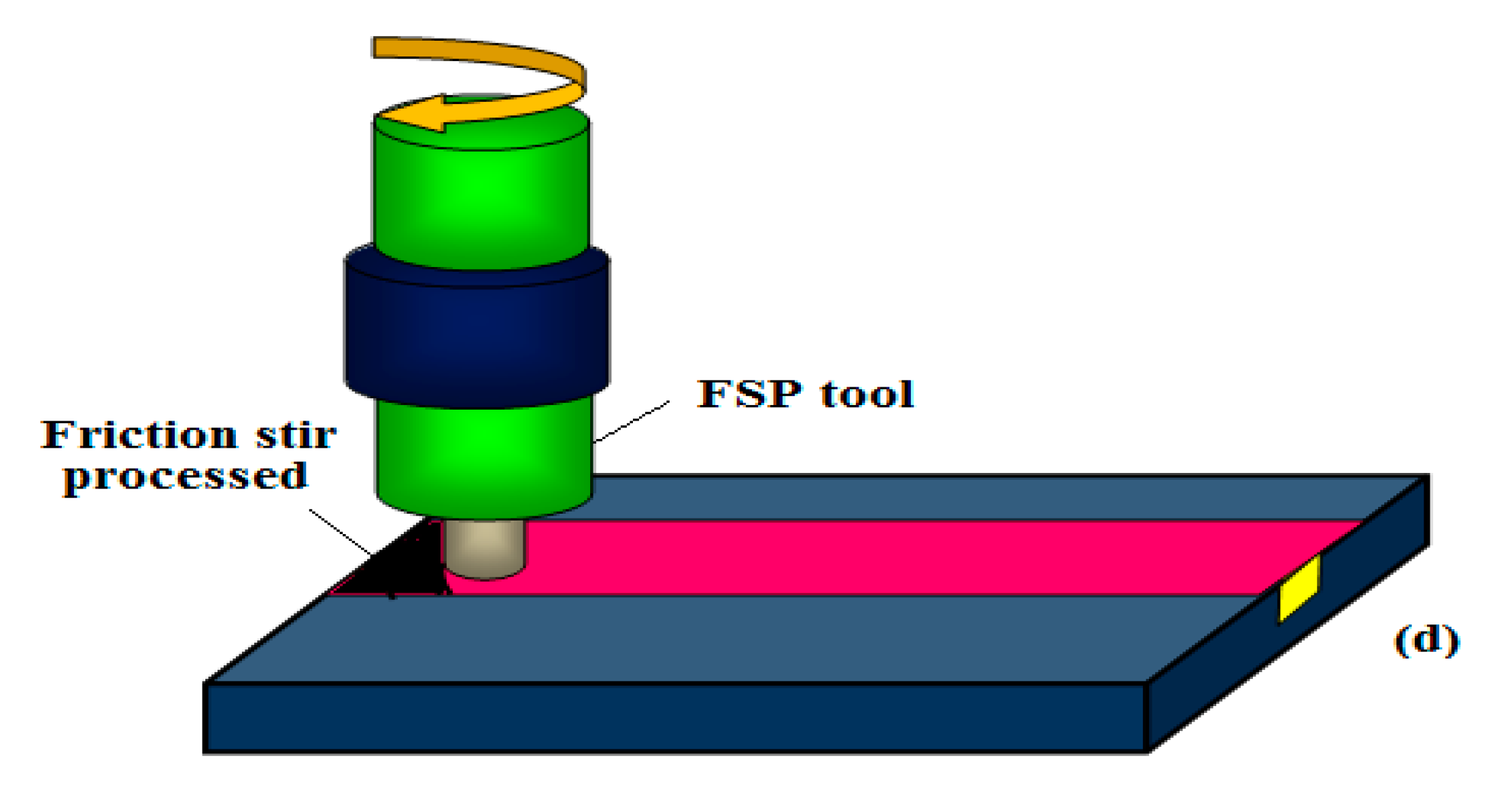

2. Materials and Methods

2.1. Base Material

2.2. Reinforcement Agent

2.3. Experimentation

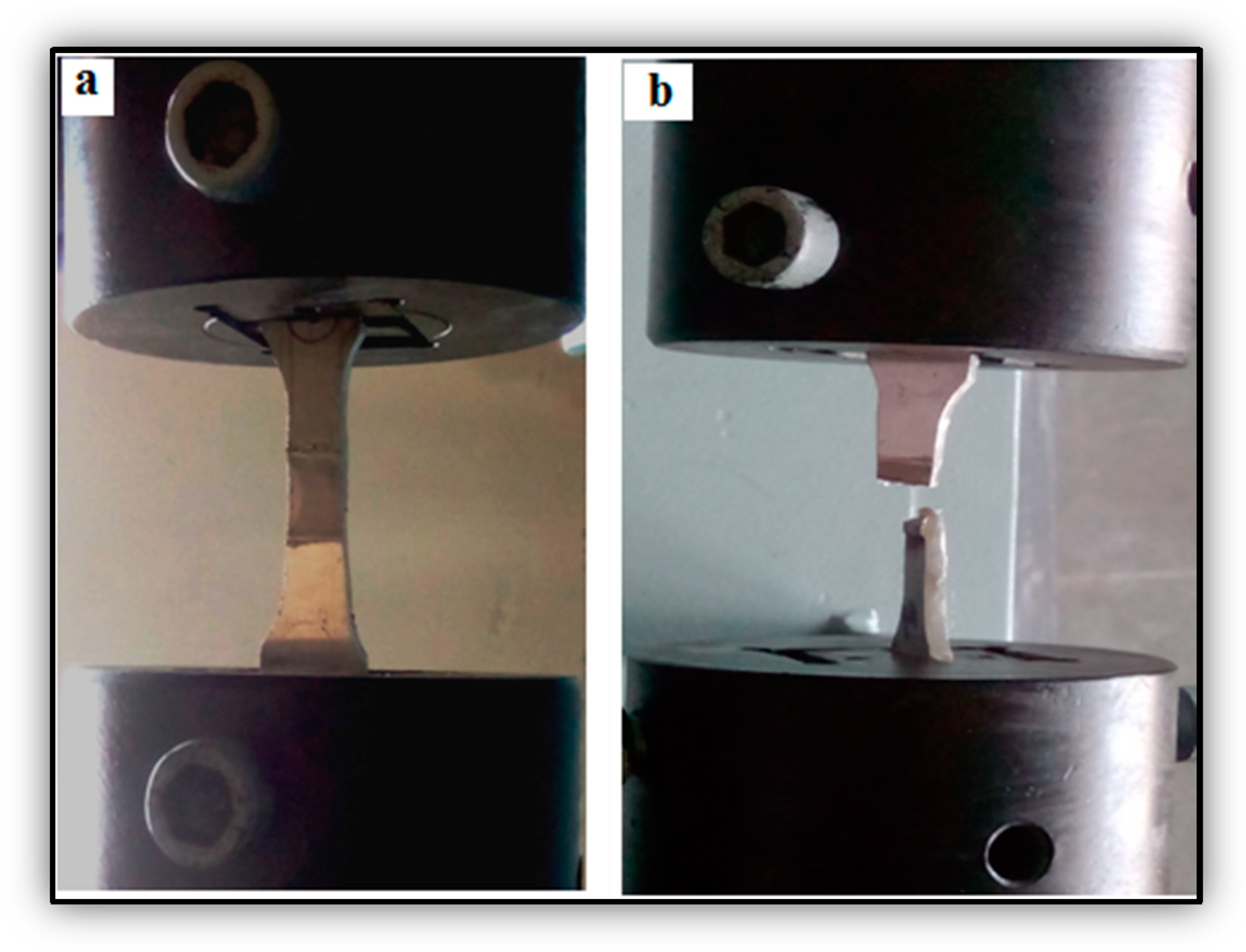

2.4. Characterization for Tensile Strength of Welded Samples

2.5. Characterization for Hardness of Welded Samples

2.6. Characterization for Corrosion on Welded Samples

3. Results and Discussion

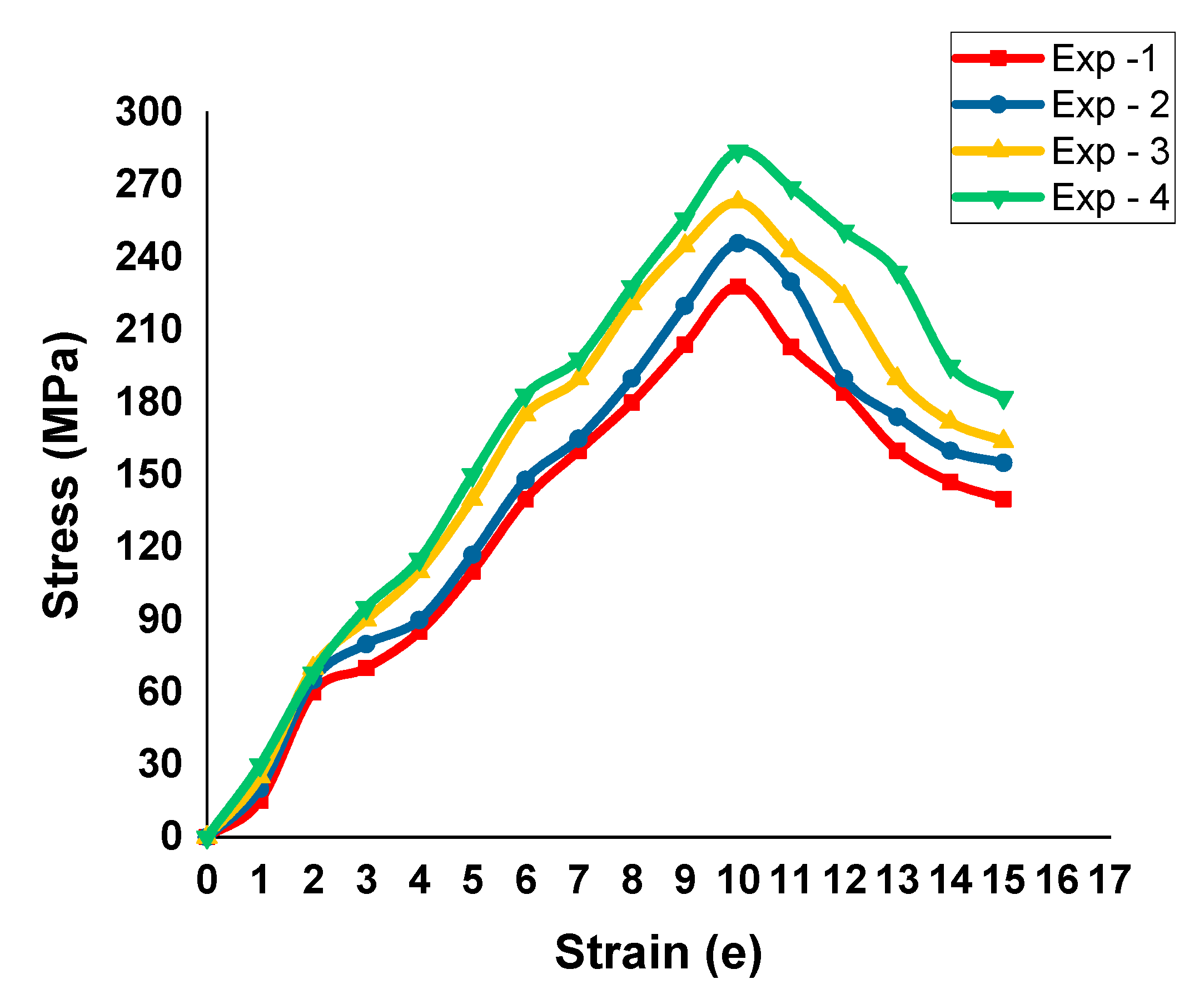

3.1. Tensile Strength of Friction Stir Processed Samples

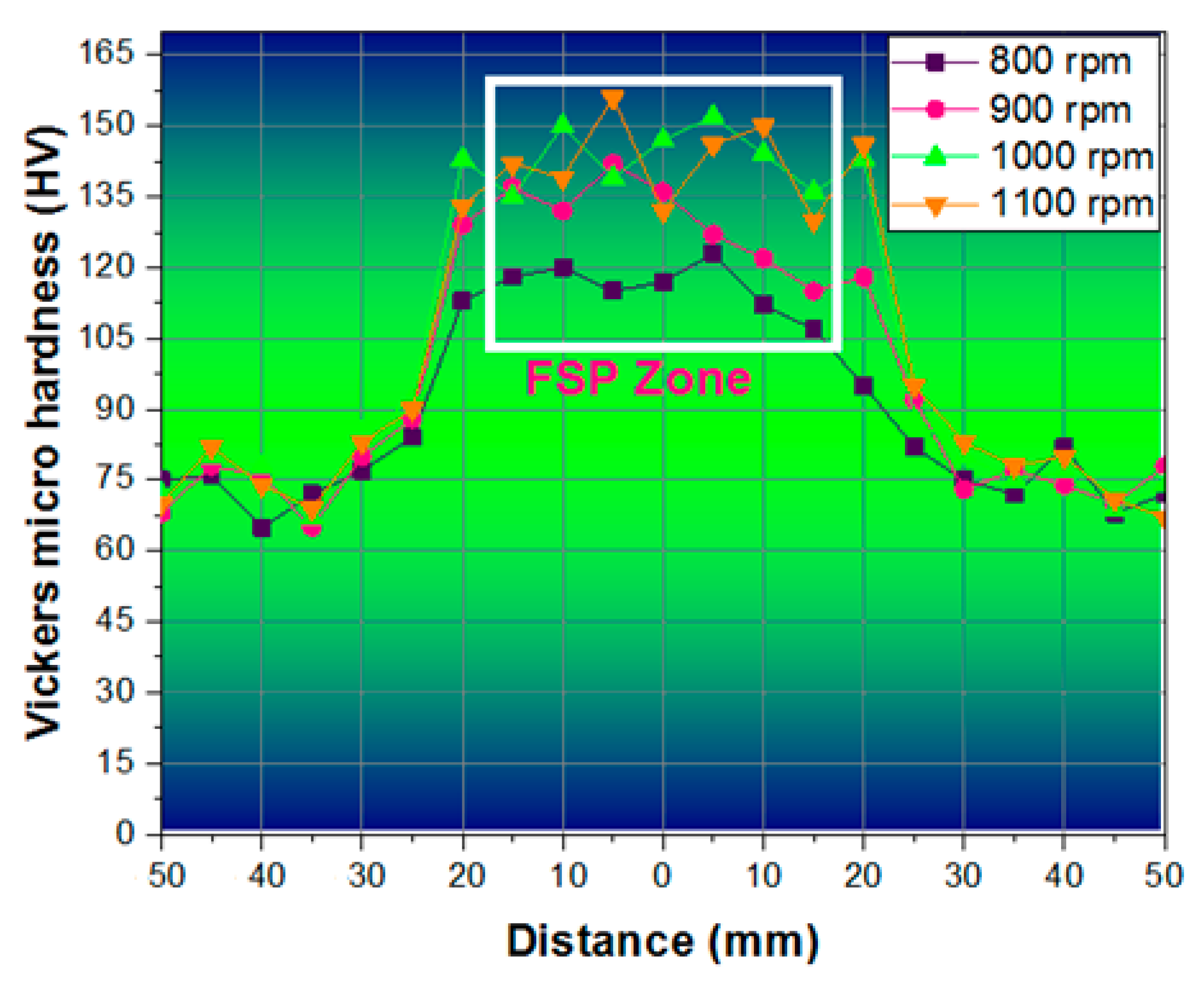

3.2. Hardness on Friction Stir Processed Samples

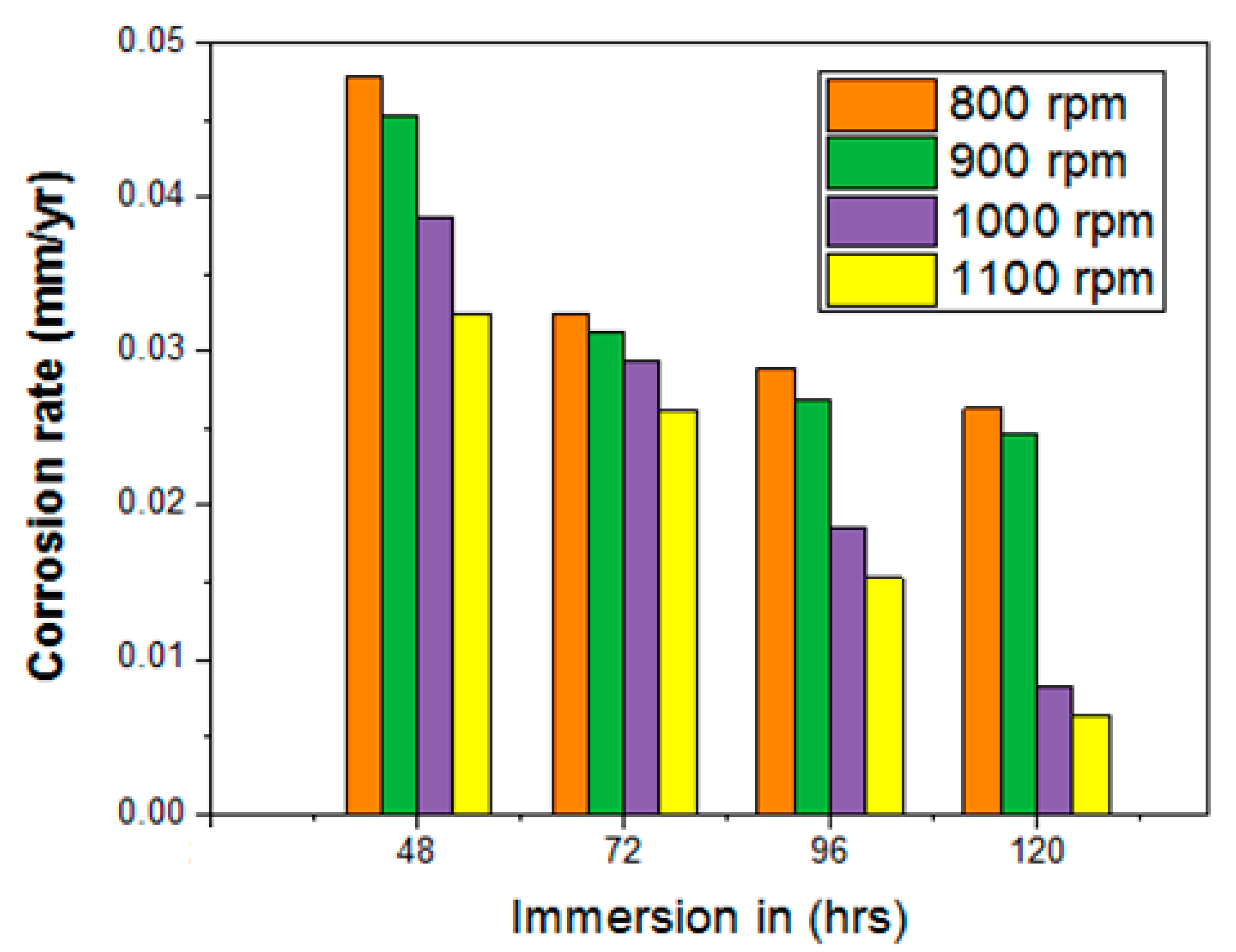

3.3. Corrosion Test Results of Friction Stir Processed Samples

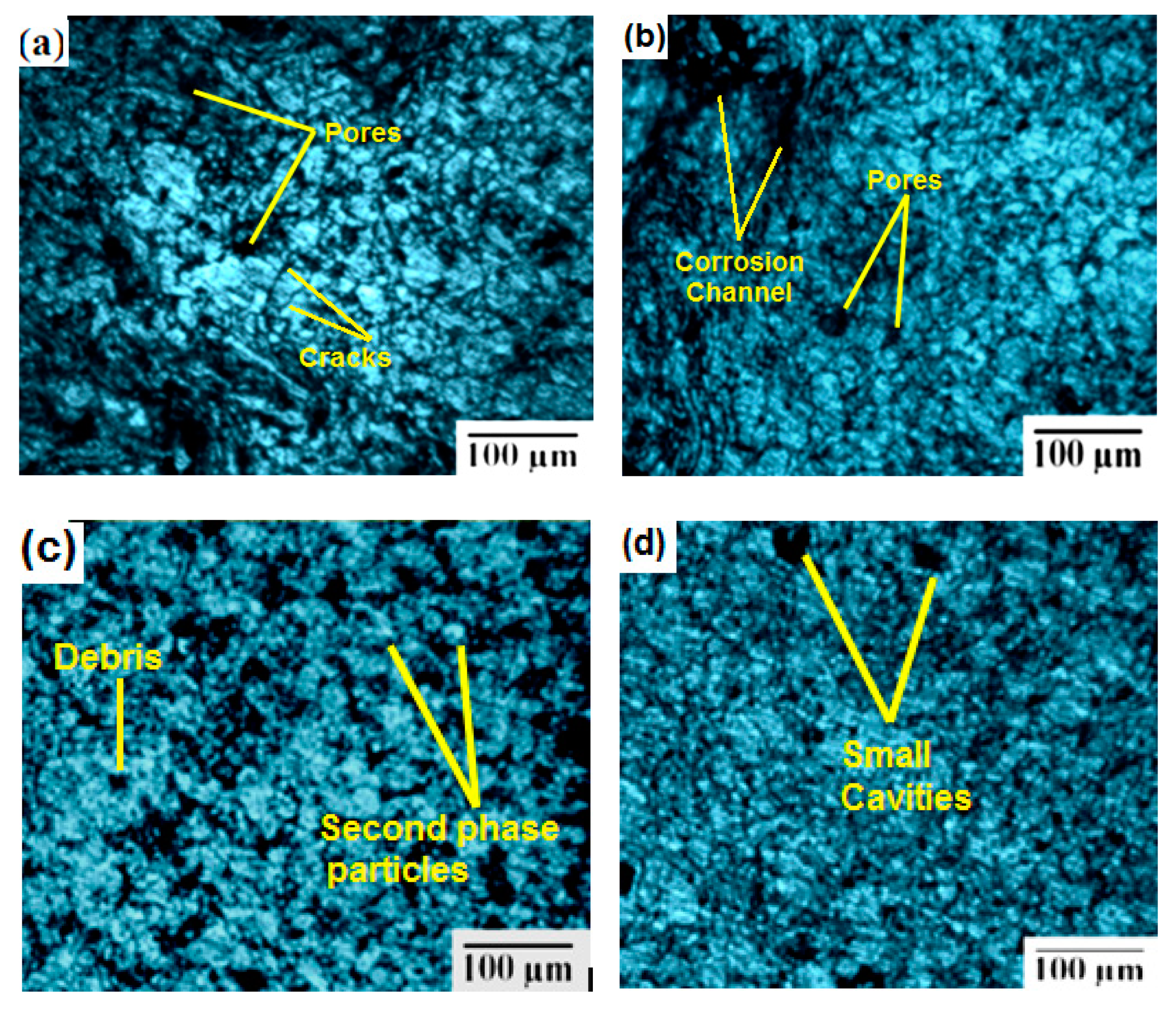

3.4. Results of Optical Microscopic Analysis on Friction Stir Processed Samples

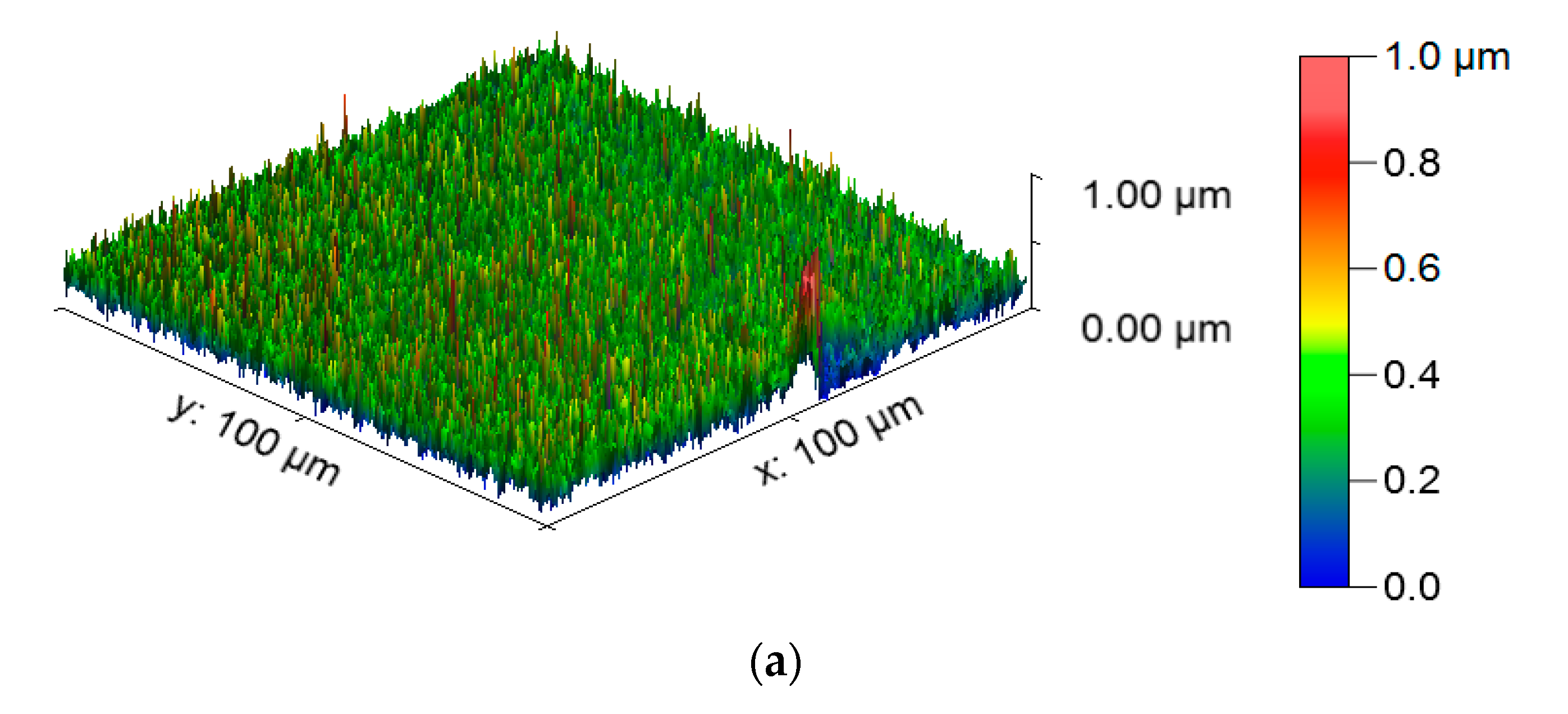

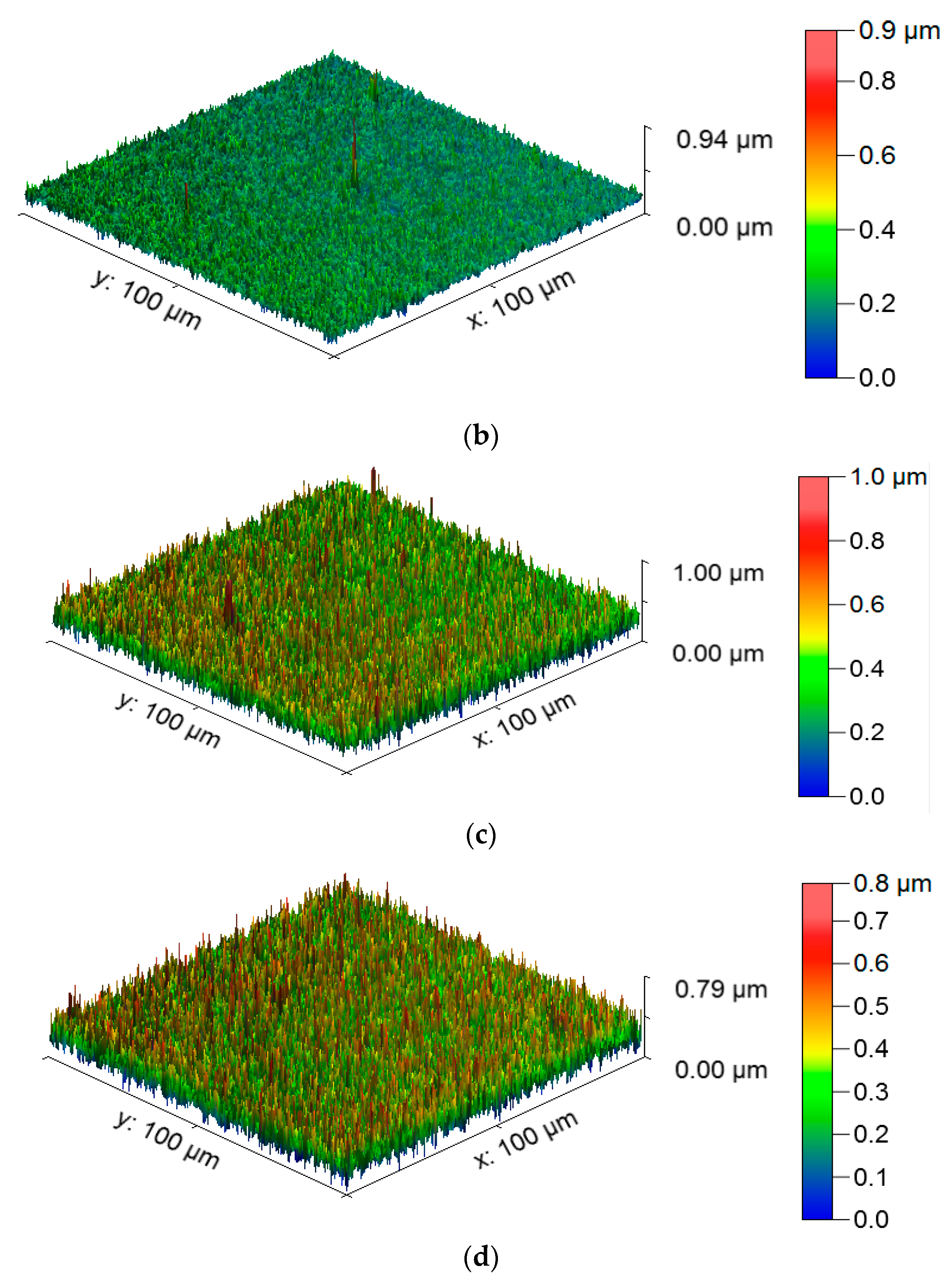

3.5. Surface Morphological Investigation on Samples with 2D Profilometry Images

3.6. Surface Morphological Investigation on Samples with 3D Profilometry Images

4. Conclusions

- In the tensile test, all four specimens were tested, and all the specimens’ tensile strength increased with the increase in the stirring (tool rotational) speed. The maximum tensile strength obtained was 284 MPa with a stirring speed of 1100 rpm. This clearly confirms that an increased speed and high temperature modify the grains in the surface structure.

- The hardness development in the FSP samples revealed an improved Vickers microhardness of 156 HV at the friction stir processing zone for a higher stirring speed of 1100 rpm. The investigation results show that there was an increase in the Vickers microhardness at the friction stir processing zone with an increase in the stirring speed. The microhardness of the base materials also improved a little.

- The investigation of corrosion resistance in the friction stir processed samples revealed that the corrosion resistance could be altered by altering the stirring speed. The corrosion rate increased then gradually decreased when the length of immersion increased. The minimum corrosion rate achieved was 0.0064 mm/yr with a 1100 rpm stirring speed.

- OM and SEM images of the 2D and 3D profilometry were taken to see whether the corrosion resistance of the all specimens was improved by the friction stir processing, It was found that using a lower stirring speed causes small holes in the friction stir-processed specimens.

- Our findings are that the AA8006 material is friction stir weldable. The quality of the weld can be improved by friction stir processing. The rate of stirring decides the corrosion resistance, tensile strength, and microhardness in the welded zone. That is, the process can be controlled by altering the stirring speed to obtain the desired corrosion resistance, tensile strength, and microhardness.

- This investigation utilized the well-known reinforcement agent zirconia for friction stir processing. Our investigation will be extended with some other reinforcements. This investigation considered AA8006 alloy plates with a fixed thickness for FSP. The thickness will be altered and standardized for commercial use.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| MPa | Mega Pascal |

| rpm | revolution per minute |

| Mm/min | millimeter per minute |

| FSP | Friction Stir Processing |

| FSW | Friction Stir Welding |

| SEM | Scanning Electron Microscopy |

| ON | Optical Microscopy |

| kN | kilo-Newton |

| te | Time of Exposure |

| ac | cross sectional area |

| ∆W | reduction in specimen weight |

| ρ | mass density |

| NaCl | sodium chloride |

| ASTM | American Society for Testing and Materials |

| G | Grams |

| UTM | Universal Testing Machine |

| CNC | Computer Numerical Control |

| ZrO2 | zirconia (or) zirconium dioxide |

| TIG | Tungsten Inert Gas |

| AMC | aluminum metal matrix composite |

| TiB2 | titanium diboride |

| BN | boron nitride |

| Al0.3CoCrCu0.3FeNi | a kind of high-entropy alloy |

References

- Sharma, A.; Sharma, V.M.; Mewar, S.; Pal, S.K.; Paul, J. ‘Friction stir processing of Al6061-SiC-graphite hybrid surface composites. Mater. Manuf. Process. 2017, 1–9. [Google Scholar] [CrossRef]

- Li, K.; Liu, X.; Zhao, Y. Research status and prospect of friction stir processing technology. Coatings 2019, 9, 129. [Google Scholar] [CrossRef]

- Palanivel, R.; Dinaharan, I.; Laubscher, R.F.; Davim, J.P. Influence of boron nano particles on microstructure and wear behavior of AA6082/ TiB2 hybrid aluminium composites synthesized by friction stir processing. Mater. Des. 2016, 106, 195–204. [Google Scholar] [CrossRef]

- Rana, H.; Badheka, V. Influence of Friction stir processing conditions on the manufacturing of Al Mg-Zn-Cu alloy/boron carbide surface composite. J. Mater. Process. Technol. 2018. [Google Scholar] [CrossRef]

- Saravanan, R.; Rao, M.S.; Malyadri, T.; Sunkara, N. Profile optimization in tooltip for FSW process—A numerical investigation. In Recent Trends in Mechanical Engineering. Lecture Notes in Mechanical Engineering; Narasimham, G., Babu, A., Reddy, S., Dhanasekaran, R., Eds.; Springer: Singapore, 2020; pp. 373–385. [Google Scholar] [CrossRef]

- Sivaraman, P.; Nithyanandhan, T.; Karthick, M.; Kirivasan, S.M.; Rajarajan, S.; Sundar, M.S. Analysis of tensile strength of AA 2014 and AA 7075 dissimilar metals using friction stir welding. Mater. Today Proc. 2020, 37, 187–192. [Google Scholar] [CrossRef]

- Pandiyarajan, R.; Maran, P.; Marimuthu, S.; Arumugam, K. Mechanical and metallurgical characterization of friction stir welded AA6061-ZrO2-C hybrid MMCs. Mater. Today Proc. 2019, 19, 256–259. [Google Scholar] [CrossRef]

- Sivaraman, P.; Prabhu, M.K.; Nithyanandhan, T.; Mohammed Razzaq, M.; Kousik, K.; Abraham, D.D. Development of aluminum based AA 2014 and AA 7075 dissimilar metals for aerospace applications. Mater. Today Proc. 2021, 37, 522–526. [Google Scholar] [CrossRef]

- Ramamoorthi, R.; Yuvaraj, K.P.; Gokul, C.; Eashwar, S.J.; Arunkumar, N.; Dheen, S.A.T. An investigation of the impact of axial force on friction stir-welded AA5086/AA6063 on microstructure and mechanical properties butt joints. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Mohamed, M.F.; Yaknesh, S.; Kumar, C.A.; Rajadurai, J.G.; Janarthanan, S.; Vignes, A.V. Optimization of friction stir welding parameters for enhancing welded joints strength using Taguchi based grey relational analysis. Mater. Today Proc. 2020, 39, 676–681. [Google Scholar] [CrossRef]

- Lin, P.T.; Liu, H.C.; Hsieh, P.Y.; Wei, C.Y.; Tsai, C.W.; Sato, Y.S.; Chen, S.C.; Yen, H.W.; Lu, N.H.; Chen, C.H. Heterogeneous structure-induced strength-ductility synergy by partial recrystallization during friction stir welding of a high-entropy alloy. Mater. Des. 2021, 197, 109238. [Google Scholar] [CrossRef]

- Sanusi, K.O.; Akinlabi, E.T. Friction-stir processing of a composite aluminum alloy (AA 1050) reinforced with Titanium carbide powder. Mater. Techol. 2017, 3, 427–435. [Google Scholar] [CrossRef]

- Selvakumar, S.; Dinaharan, I.; Palanivel, R.; Babu, B.G. Development of stainless steel particulate reinforced AA6082 aluminum matrix composites with enhanced ductility using friction stir processing. Mater. Sci. Eng. A 2017, 685, 317–326. [Google Scholar] [CrossRef]

- Sivanesh Prabhu, M.; Elaya Perumal, A.; Arulvel, S.; Franklin, I.R. Friction and wear measurements of friction stir processed aluminium alloy 6082/CaCO3 composite. Measurement 2019, 10–20. [Google Scholar] [CrossRef]

- Thangarasu, A.; Murugan, N.; Dinaharan, I.; Vijay, S.J. Synthesis and characterization of titanium carbide particulate reinforced AA6082 aluminium alloy composites via friction stir processing. Arch. Civil Mech. Eng. 2014. [Google Scholar] [CrossRef]

- Suvarna, R.L.; Kumar, A. Influence of Al2O3 particles on the microstructure and mechanical properties of copper surface composites fabricated by friction stir processing. Def. Technol. 2014, 10, 375–383. [Google Scholar] [CrossRef]

- Sudhakar, I.; Reddy, G.M.; Rao, K.S. Ballistic behavior of boron carbide reinforced AA7075 aluminium alloy using friction stir processing—An experimental study and analytical approach. Def. Technol. 2016, 12, 25–31. [Google Scholar] [CrossRef]

- Du, Z.; Tan, M.J.; Guo, J.F.; Bi, G.; Wei, J. Fabrication of a new Al-Al2O3-CNTs composite using friction stir processing (FSP). Mater. Sci. Eng. A 2016, 667, 125–131. [Google Scholar] [CrossRef]

- Dinaharan, I.; Akinlabi, E.T.; Hattingh, D.G. Microstructural characterization and sliding wear behavior of Cu/TiC copper matrix composites developed using friction stir processing. Metallogr. Microstruct. Anal. 2018, 7, 464–475. [Google Scholar] [CrossRef]

- Liu, D.; Xin, R.; Zhao, L.; Hu, Y.; Zhang, J. Evaluation of corrosion and wear resistance of friction stir welded ZK60 alloy. Sci. Technol. Weld. Joining 2017, 22, 601–609. [Google Scholar] [CrossRef]

- Abreu, C.M.; Acuña, R.; Cabeza, M.; Cristóbal, M.J.; Merino, P.; Verdera, D. Microstructure and mechanical properties of Al/SiC composite surface layer produced by friction stir processing. Ciencia Tecnol. Mater. 2017, 29, e82–e86. [Google Scholar] [CrossRef]

- Rana, H.G.; Badheka, V.J.; Kumar, A. Fabrication of Al7075 / B4C surface composite by novel Friction Stir Processing (FSP) and investigation on wear properties. Proc. Technol. 2016, 23, 519–528. [Google Scholar] [CrossRef]

- Chaluvaraju, B.V.; Afzal, A.; Vinnik, D.A.; Kaladgi, A.R.; Alamri, S.; Tirth, V. Mechanical and corrosion studies of friction stir welded nano Al2O3 reinforced Al-Mg matrix composites: RSM-ANN modelling approach. Symmetry 2021, 13, 537. [Google Scholar] [CrossRef]

- Nagaraja, S.; Nagegowda, K.U.; Kumar, V.A.; Alamri, S.; Afzal, A.; Thakur, D.; Kaladgi, A.R.; Panchal, S.; Saleel, C.A. Influence of the fly ash material inoculants on the tensile and impact characteristics of the aluminum AA 5083/7.5SiC composites. Materials 2021, 14, 2452. [Google Scholar] [CrossRef]

- Sharath, B.N.; Venkatesh, C.V.; Afzal, A.; Ahmed, M.; Baig, A.; Kumar, A.P. Study on effect of ceramics on dry sliding wear behaviour of Al-Cu-Mg based metal matrix composite at different temperature. Mater. Today Proc. 2021. [CrossRef]

- Sharath, B.N.; Jeevan, T.P.; Baig, M.A.; Ashrith, H.S.; Afzal, A.; Reddy, A.R. Machinability studies on boron carbide and graphite reinforced aluminium hybrid composites. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Guggari, G.S.; Shivakumar, S.; Nikhil, R.; Manjunath, G.A.; Afzal, A.; Saleel, C.A. Experimental investigation of mechanical properties of Acrylonitrile Butadiene Styrene ( ABS ) based polymer for Submersible pumps Experimental investigation of mechanical properties of Acrylonitrile Butadiene Styrene ( ABS ) based polymer for Submersible. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1065, 12035. [Google Scholar] [CrossRef]

- Kaladgi, A.R.; Rehman, K.F.; Afzal, A.; Baig, M.A.; Soudagar, M.E.; Bhattacharyya, S. Fabrication characteristics and mechanical behaviour of aluminium alloy reinforced with Al2O3 and coconut shell particles synthesized by stir casting Fabrication characteristics and mechanical behaviour of aluminium alloy reinforced with Al2O3 and c. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1057. [Google Scholar] [CrossRef]

| Name of the Constituent in AA8006 Alloy | Chemical Symbol | Percentage of Contribution |

|---|---|---|

| Zinc | Zn | 0.75% |

| Magnesium | Mg | 0.69% |

| Copper | Cu | 0.27% |

| Silicon | Si | 0.36% |

| Iron | Fe | 1.60% |

| Manganese | Mn | 0.58% |

| Aluminum | Al | 95.60% |

| Other Elements Each | - | 0.04% |

| Total Sum of Others | - | 0.11% |

| Experimental. Index. | Stirring (Tool Pin Rotational) Speed (rpm) | Traverse Speed of Tool Head (mm per min) | Compressive Force on Tool (kN) | Tool Tilt Angle in Degree |

|---|---|---|---|---|

| 1 | 800 | 40 | 3 | 2 |

| 2 | 900 | 40 | 3 | 2 |

| 3 | 1000 | 40 | 3 | 2 |

| 4 | 1100 | 40 | 3 | 2 |

| Experimental. Index | Stirring (Tool Pin Rotational) Speed (rpm) | Traverse Speed of Tool Head (mm per min) | Compressive Force on Tool (kN) | Tool Tilt Angle in Degrees |

|---|---|---|---|---|

| 1 | 800 | 40 | 3 | 2 |

| 2 | 900 | 40 | 3 | 2 |

| 3 | 1000 | 40 | 3 | 2 |

| 4 | 1100 | 40 | 3 | 2 |

| Average Microhardness Values in Various Zones | |||||

|---|---|---|---|---|---|

| Expt. Index | Tool Pin Rotational Speed (rpm) | Unaffected Zone | Heat-Affected Zone | Thermo-Mechanically Affected Zone | FSP Zone |

| 1 | 800 | 75 | 109 | 114 | 115 |

| 2 | 900 | 77 | 120 | 122 | 124 |

| 3 | 1000 | 80 | 133 | 138 | 141 |

| 4 | 1100 | 84 | 142 | 145 | 148 |

| Specimen No. | Tool Pin Rotational Speed (rpm) | Corrosion Rate (mm/yr) | |||

|---|---|---|---|---|---|

| 48 h | 72 h | 96 h | 120 h | ||

| 1 | 800 | 0.0478 | 0.0324 | 0.0289 | 0.0263 |

| 2 | 900 | 0.0453 | 0.0312 | 0.0268 | 0.0247 |

| 3 | 1000 | 0.0387 | 0.0294 | 0.0186 | 0.00821 |

| 4 | 1100 | 0.0324 | 0.0262 | 0.0153 | 0.0064 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sathish, T.; Kaladgi, A.R.R.; Mohanavel, V.; Arul, K.; Afzal, A.; Aabid, A.; Baig, M.; Saleh, B. Experimental Investigation of the Friction Stir Weldability of AA8006 with Zirconia Particle Reinforcement and Optimized Process Parameters. Materials 2021, 14, 2782. https://doi.org/10.3390/ma14112782

Sathish T, Kaladgi ARR, Mohanavel V, Arul K, Afzal A, Aabid A, Baig M, Saleh B. Experimental Investigation of the Friction Stir Weldability of AA8006 with Zirconia Particle Reinforcement and Optimized Process Parameters. Materials. 2021; 14(11):2782. https://doi.org/10.3390/ma14112782

Chicago/Turabian StyleSathish, Thanikodi, Abdul Razak R. Kaladgi, V. Mohanavel, K. Arul, Asif Afzal, Abdul Aabid, Muneer Baig, and Bahaa Saleh. 2021. "Experimental Investigation of the Friction Stir Weldability of AA8006 with Zirconia Particle Reinforcement and Optimized Process Parameters" Materials 14, no. 11: 2782. https://doi.org/10.3390/ma14112782

APA StyleSathish, T., Kaladgi, A. R. R., Mohanavel, V., Arul, K., Afzal, A., Aabid, A., Baig, M., & Saleh, B. (2021). Experimental Investigation of the Friction Stir Weldability of AA8006 with Zirconia Particle Reinforcement and Optimized Process Parameters. Materials, 14(11), 2782. https://doi.org/10.3390/ma14112782