Evaluation of Dynamic Properties of Sodium-Alginate-Reinforced Soil Using A Resonant-Column Test

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Resonant Column Test

2.3. Viscosity Measurement and Shear-Failure-Characteristics Test

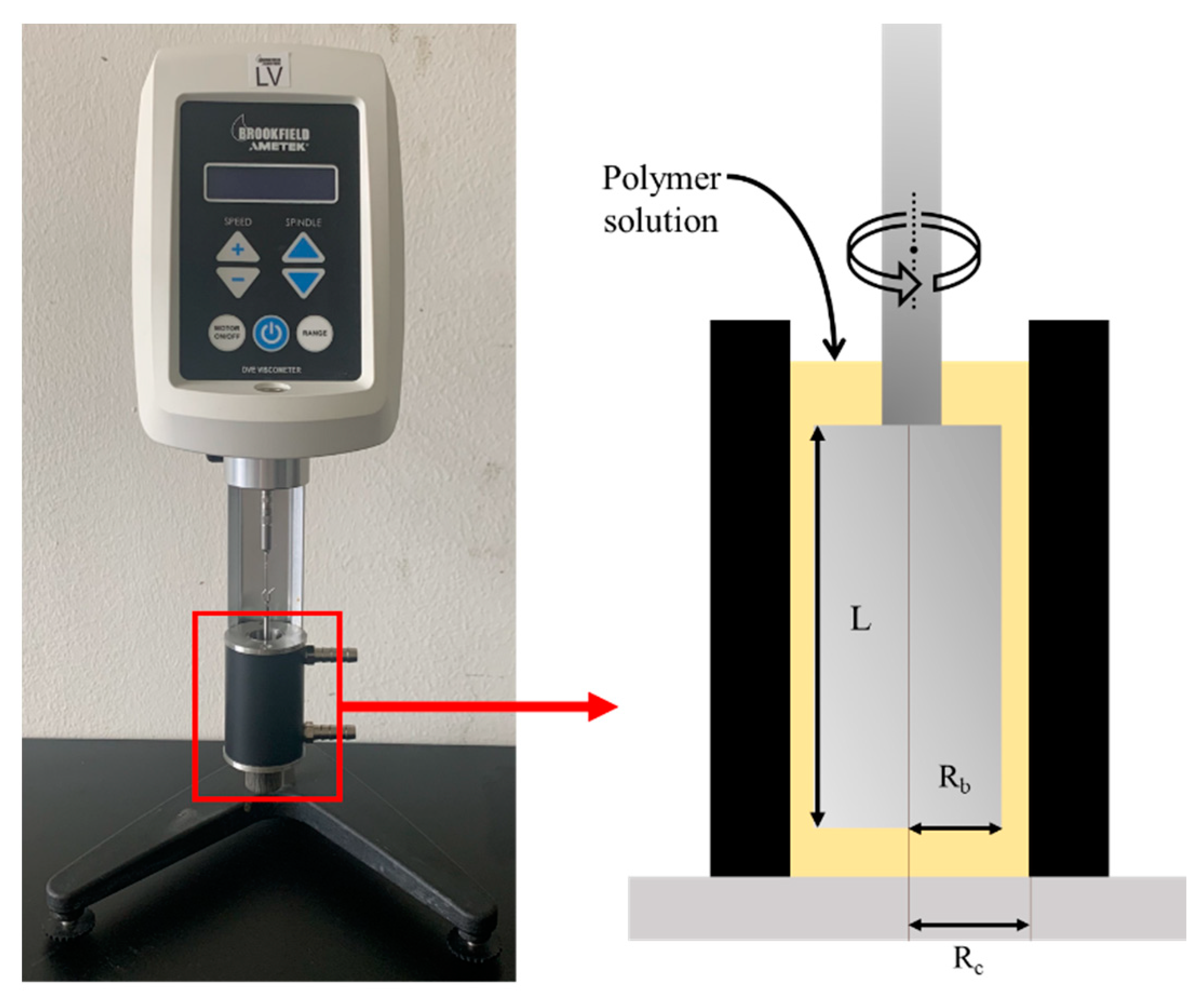

2.3.1. Viscosity Measurement Test

2.3.2. Shear-Failure-Characteristics Test

3. Results and Discussion

3.1. Resonant-Column Test

3.2. Viscosity Measurement Test

3.3. Shear-Failure-Mode Test

4. Conclusions

- (1)

- As the cement content in the soil pores increases to 7.5%, the shear modulus of the cement reinforced specimens increases. As the concentration of sodium alginate solution increases to 0.67%, the shear modulus of the soil specimen mixed with sodium alginate increases. As the concentration of sodium alginate solution increases (0.5~3.0%), the viscosity increases (66~6030 cp). Sodium alginate is observed to form a matrix between the pores of the soil, which is believed to be the cause of the increase in strength of the specimen.

- (2)

- When comparing the sodium alginate solution mixed specimen and the cement mixed specimen, the maximum shear modulus was higher than that of the 5.05 cement content specimen at sodium alginate solution concentration of 0.67%. This confirmed the possibility of sodium alginate as an eco-friendly ground reinforcement material replacing cement.

- (3)

- After that, at a concentration of 3.34%, the shear modulus tends to decrease. The cause of the increase and decrease of the shear modulus of the soil sample can be explained by the distribution pattern of sodium alginate in the pores of the soil. Up to 2% of the sodium alginate solution concentration, the matrix is evenly dispersed in the pores of the specimen, and the shear modulus increases as the concentration increases. However, at concentrations above 3.34%, the matrix is partially agglomerated with the soil in the pores. Rather, it shows a shape of local destruction, so the shear modulus decreases.

- (4)

- When mixing the reinforcement material into the soil, there is a difference in the change of the dynamic properties of the ground according to the characteristics of the reinforcement material. When mixing cement and polymer, the maximum shear modulus increases, but it becomes a hardening material that decreases the shear modulus more rapidly as the strain increases. When mixing rubber, clay type, as the shear strain increases, the shear modulus decreases slowly, showing a softening material characteristic. In this study, when cement was mixed, the hardening material characteristics were shown, and sodium alginate also showed the characteristics of the hardening material.

- (5)

- The damping increases as the soil pores within the cement content increases to 7.5%. When the sodium alginate solution is mixed, the damping ratio increases, but there is no difference between the concentrations of 0.67% and 3.34%. As the confining pressure increases, the pores between the soil particles are compressed, so that the sodium alginate solution adheres to the soil particles better. Therefore, the shear modulus exhibits a hardening characteristic as the strain increases, and the amount of energy reduction decreases through more energy transfer paths.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASCE. Minimum Design Loads for Buildings and Other Structures; American Society of Civil Engineers: Reston, VA, USA, 2010; pp. 57–80, ASCE/SEI7–10. [Google Scholar]

- Im, J.; Tran, A.T.P.; Chang, I.; Cho, G.-C. Dynamic properties of gel-type biopolymer-treated sands evaluated by Resonant Column (RC) Tests. Geomech. Eng. 2017, 12, 815–830. [Google Scholar] [CrossRef]

- Im, J.; Chang, I.; Cho, G.-C. Dynamic properties of gellan treated sands using resonant column tests. In Proceedings of the 2016 world Congress on Advances in Civil, Environmental, and Materials Research(ACEM16), Jeju Island, Korea, 28 August–1 September 2016. [Google Scholar]

- Lee, S.; Chang, I.; Chung, M.-K.; Kim, Y.; Kee, J. Geotechnical shear behavior of Xanthan Gum biopolymer treated sand from direct shear testing. Geomech. Eng. 2017, 12, 831–847. [Google Scholar] [CrossRef] [Green Version]

- Havlica, J.; Sahu, S. Mechanism of ettringite and monosulphate formation. Cem. Concr. Res. 1992, 22, 671–677. [Google Scholar] [CrossRef]

- Malekpoor, M.; Poorebrahim, G. Comparative study on the behavior of lime-soil columns and other types of stone columns. Geomech. Eng. 2014, 7, 133–148. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Impacts of booming concrete production on water resources worldwide. Nat. Sustain. 2018, 1, 69–76. [Google Scholar] [CrossRef]

- Achal, V.; Mukherjee, A.; Zhang, Q. Unearthing ecological wisdom from natural habitats and its ramifications on development of biocement and sustainable cities. Landsc. Urban Plan. 2016, 155, 61–68. [Google Scholar] [CrossRef]

- Cole, D.; Ringelberg, D.; Reynolds, C. Small-Scale Mechanical Properties of Biopolymers. J. Geotech. Geoenviron. Eng. 2012, 138, 1063–1074. [Google Scholar] [CrossRef]

- Choi, S.-G.; Chang, I.; Lee, M.; Lee, J.-H.; Han, J.-T.; Kwon, T.-H. Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

- Chang, I.; Lee, M.; Tran, A.T.P.; Lee, S.; Kwon, Y.-M.; Im, J.; Cho, G.-C. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- Khatami, H.R.; O’Kelly, B.C. Improving Mechanical Properties of Sand Using Biopolymers. J. Geotech. Geoenviron. Eng. 2013, 139, 1402–1406. [Google Scholar] [CrossRef] [Green Version]

- Nakamatsu, J.; Kim, S.; Ayarza, J.; Ramírez, E.; Elgegren, M.; Aguilar, R. Eco-friendly modification of earthen construction with carrageenan: Water durability and mechanical assessment. Constr. Build. Mater. 2017, 139, 193–202. [Google Scholar] [CrossRef]

- Jung, J.-W.; Grau, F.; Ahn, J. Characteristerization of Environment-Friendly Soils Stabilized with Biomass Wood Ash. J. Korean Soc. Hazard. Mitig. 2014, 14, 143–149. [Google Scholar] [CrossRef] [Green Version]

- Chang, I.; Cho, G.-C. Strengthening of Korean residual soil with β-1,3/1,6-glucan biopolymer. Constr. Build. Mater. 2012, 30, 30–35. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.-C. Geotechnical behavior of a beta-1,3/1,6-glucan biopolymer-treated residual soil. Geomech. Eng. 2014, 7, 633–647. [Google Scholar] [CrossRef] [Green Version]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.-C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Kim, D.-S.; Choo, Y.-W. Dynamic Deformation Characteristics of Cohesionless Soils in Korea Using Resonant Column Tests. Korean Geotech. Soc. 2001, 17, 115–128. [Google Scholar]

- Hardin, B.O.; Black, W.L. Vibration Modulus of Normally Consolidated Clay. J. Soil Mech. Found. Div. 1968, 94, 353–369. [Google Scholar] [CrossRef]

- Seed, H.B.; Idriss, I.M. Soil Moduli and Damping Factors for Dynamic Response Analyses; Report EERC 70-10; Earthquake Engineering Research Center, University of California: Berkeley, CA, USA, 1970. [Google Scholar]

- Kim, D.-S.; Ko, D.-H.; Youn, J.-U. Dynamic Deformation Characteristics of Granite Weathered Soils Using RC/TS Tests. Korean Geotech. Soc. 2004, 5, 35–46. [Google Scholar]

- Lee, C.; Shin, H.; Lee, J.-S. Behavior of sand-rubber particle mixtures: Experimental observations and numerical simulations. Int. J. Numer. Anal. Methods Geomech. 2014, 38, 1651–1663. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Cho, G.-C. Introduction of Microbial Biopolymers in Soil Treatment for Future Environmentally-Friendly and Sustainable Geotechnical Engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef] [Green Version]

- El Mohtar, C.S.; Bobet, A.; Drnevich, V.P.; Johnston, C.T.; Santagata, M.C. Pore pressure generation in sand with bentonite: From small strains to liquefaction. Géotechnique 2014, 64, 108–117. [Google Scholar] [CrossRef] [Green Version]

- Hsiao, D.-H.; Phan, V.T.-A.; Huang, C.-C. An experimental investigation on dynamic properties of various grouted sands. Geomech. Eng. 2016, 10, 77–94. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, Z.; Jin, Y.; Li, Q.; Chen, X. Experimental study on dynamic properties of sand-rubber mixtures in a small range of shearing strain amplitudes. J. Vibroeng. 2017, 19, 4378–4393. [Google Scholar] [CrossRef]

- Hecht, H.; Srebnik, S. Structural Characterization of Sodium Alginate and Calcium Alginate. Biomacromolecules 2016, 17, 2160–2167. [Google Scholar] [CrossRef]

- Arab, M.G.; Mousa, R.A.; Gabr, A.R.; Azam, A.M.; El-Badawy, S.M.; Hassan, A.F. Resilient Behavior of Sodium Alginate–Treated Cohesive Soils for Pavement Applications. J. Mater. Civ. Eng. 2019, 31, 04018361. [Google Scholar] [CrossRef]

- Pathak, T.S.; Kim, J.S.; Lee, S.-J.; Baek, D.-J.; Paeng, K.-J. Preparation of Alginic Acid and Metal Alginate from Algae and their Comparative Study. J. Polym. Environ. 2008, 16, 198–204. [Google Scholar] [CrossRef]

- Solovieva, A.B.; Kopylov, A.S.; Savko, M.A.; Zarkhina, T.S.; Lovskaya, D.D.; Lebedev, A.E.; Menshutina, N.V.; Krivandin, A.V.; Shershnev, I.V.; Kotova, S.L.; et al. Photocatalytic Properties of Tetraphenylporphyrins Immobilized on Calcium Alginate Aerogels. Sci. Rep. 2017, 7, 12640. [Google Scholar] [CrossRef] [Green Version]

- Drnevich, V.P.; Hardin, B.O.; Shippy, D.J. Modulus and Damping of Soils by the Resonant-Column Method; Silver, M.L., Tiedemann, D., Eds.; ASTM International: West Conshohocken, PA, USA, 1978; pp. 91–125. [Google Scholar]

- Lenormand, R.; Zarcone, C. Capillary Fingering: Percolation and fractal dimension. Transp. Porous Media 1989, 4, 599–612. [Google Scholar] [CrossRef]

- Jung, J.-W.; Cao, S.; Ahn, J. Characteristerization of Biopolymer Solution Used for Soil Remediation and Petroleum Production. J. Korean Soc. Hazard. Mitig. 2014, 14, 109–114. [Google Scholar] [CrossRef] [Green Version]

- Cao, S.; Bate, B.; Hu, J.; Jung, J. Engineering Behavior and Characteristics of Water-Soluble Polymers: Implication on Soil Remediation and Enhanced Oil Recovery. Sustainability 2016, 8, 205. [Google Scholar] [CrossRef] [Green Version]

- Jung, J.; Jang, J.; Ahn, J. Characterization of a Polyacrylamide Solution Used for Remediation of Petroleum Contaminated Soils. Materials 2016, 9, 16. [Google Scholar] [CrossRef] [Green Version]

- Belalia, F.; Djelali, N.E. Rheological properties of sodium alginate solutions. Rev. Roum. Chim. 2014, 59, 135–145. [Google Scholar]

- Saxena, S.K.; Avramidis, A.S.; Reddy, K.R. Dynamic moduli and damping ratios for cemented sands at low strains. Can. Geotech. J. 1988, 25, 353–368. [Google Scholar] [CrossRef]

- Darendeli, M. Development of New Family of Normalized Modulus Reduction and Material Damping Curves. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2001. [Google Scholar]

- Yu, H.-t.; Wang, J.-h.; Yuan, Y. An improved dynamic hysteretic model for soils. J. Shanghai Jiaotong Univ. (Sci.) 2013, 18, 655–659. [Google Scholar] [CrossRef]

| Index | Value for Sample | |

|---|---|---|

| Sieve Analysis | D10 | 0.18 |

| D30 | 0.45 | |

| D60 | 1.23 | |

| Cu | 6.67 | |

| CC | 0.94 | |

| Passing No.4 sieve [%] | 100 | |

| Passing No.200 sieve [%] | 2.62 | |

| Specific gravity | 2.61 | |

| Unit weight [g/cm3] | 1.77 | |

| USCS | SP | |

| Index | Sample |

|---|---|

| Formula | (C6H7O6Na)n |

| Source | Macrocystis pyrifera |

| Moisture | 15% |

| Heavy Metals | 0.002% |

| pH | 6.5 |

| No. | Mixing Materials | Content [%] | Confining Pressure [kPa] |

|---|---|---|---|

| 1 | Cement | 0 | 100 |

| 2 | 2.5 | ||

| 3 | 5.0 | ||

| 4 | 7.5 | ||

| 5 | Sodium alginate solution | 0.67 | 100 |

| 6 | 200 | ||

| 7 | 300 | ||

| 8 | 3.34 | 100 | |

| 9 | 200 | ||

| 10 | 300 |

| Mixing Material | Content [%] | Density [g/cm3] | Gmax [MPa] Confining Pressure [kPa]: 100 | ||

| Cement | 0 | 1.77 | 39.51 | ||

| 2.5 | 1.75 | 59.10 | |||

| 5.0 | 1.77 | 67.32 | |||

| 7.5 | 1.81 | 93.51 | |||

| Mixing Material | Content [%] | Density [g/cm3] | Gmax [MPa] | ||

| Confining Pressure [kPa] | |||||

| 100 | 200 | 300 | |||

| SA solution | 0.67 | 1.69 | 78.45 | 89.99 | 102.01 |

| 3.34 | 1.79 | 46.54 | 57.13 | 69.56 | |

| Mixing Material | Content [%] | R | C | Confining Pressure [kPa] |

|---|---|---|---|---|

| Cement | 0 | 1.960 | 2.580 | 100 |

| 2.5 | 2.007 | 9.040 | 100 | |

| 5.0 | 3.341 | 1758.714 | 100 | |

| 7.5 | 3.857 | 69,150.070 | 100 | |

| SA solution | 0.67 | 2.150 | 9.686 | 100 |

| 2.103 | 5.298 | 200 | ||

| 2.200 | 5.859 | 300 | ||

| 3.34 | 2.143 | 8.611 | 100 | |

| 2.121 | 5.166 | 200 | ||

| 2.107 | 4.425 | 300 |

| Material | Concentration (%) | A (Y-Intercept) | B (Consistency Index) | n (Flow Behavior Index) | Behavior |

|---|---|---|---|---|---|

| SA | 0.5 | 0.0000 | 0.0859 | 0.9269 | Shear thinning |

| 1 | 0.0000 | 0.1665 | 0.9807 | ||

| 1.5 | 0.0000 | 0.4889 | 0.9836 | ||

| 2 | 0.0000 | 1.5759 | 0.9474 | ||

| 2.5 | 0.0000 | 3.5817 | 0.8339 | ||

| 3 | 0.0000 | 5.8144 | 0.8979 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, S.; Ryou, J.-E.; Ahn, K.; Lee, C.; Lee, J.-D.; Jung, J. Evaluation of Dynamic Properties of Sodium-Alginate-Reinforced Soil Using A Resonant-Column Test. Materials 2021, 14, 2743. https://doi.org/10.3390/ma14112743

Ahn S, Ryou J-E, Ahn K, Lee C, Lee J-D, Jung J. Evaluation of Dynamic Properties of Sodium-Alginate-Reinforced Soil Using A Resonant-Column Test. Materials. 2021; 14(11):2743. https://doi.org/10.3390/ma14112743

Chicago/Turabian StyleAhn, Seongnoh, Jae-Eun Ryou, Kwangkuk Ahn, Changho Lee, Jun-Dae Lee, and Jongwon Jung. 2021. "Evaluation of Dynamic Properties of Sodium-Alginate-Reinforced Soil Using A Resonant-Column Test" Materials 14, no. 11: 2743. https://doi.org/10.3390/ma14112743

APA StyleAhn, S., Ryou, J.-E., Ahn, K., Lee, C., Lee, J.-D., & Jung, J. (2021). Evaluation of Dynamic Properties of Sodium-Alginate-Reinforced Soil Using A Resonant-Column Test. Materials, 14(11), 2743. https://doi.org/10.3390/ma14112743