Mechanical Characterization and Thermodynamic Analysis of Laser-Polished Landscape Design Products Using 3D Printing

Abstract

1. Introduction

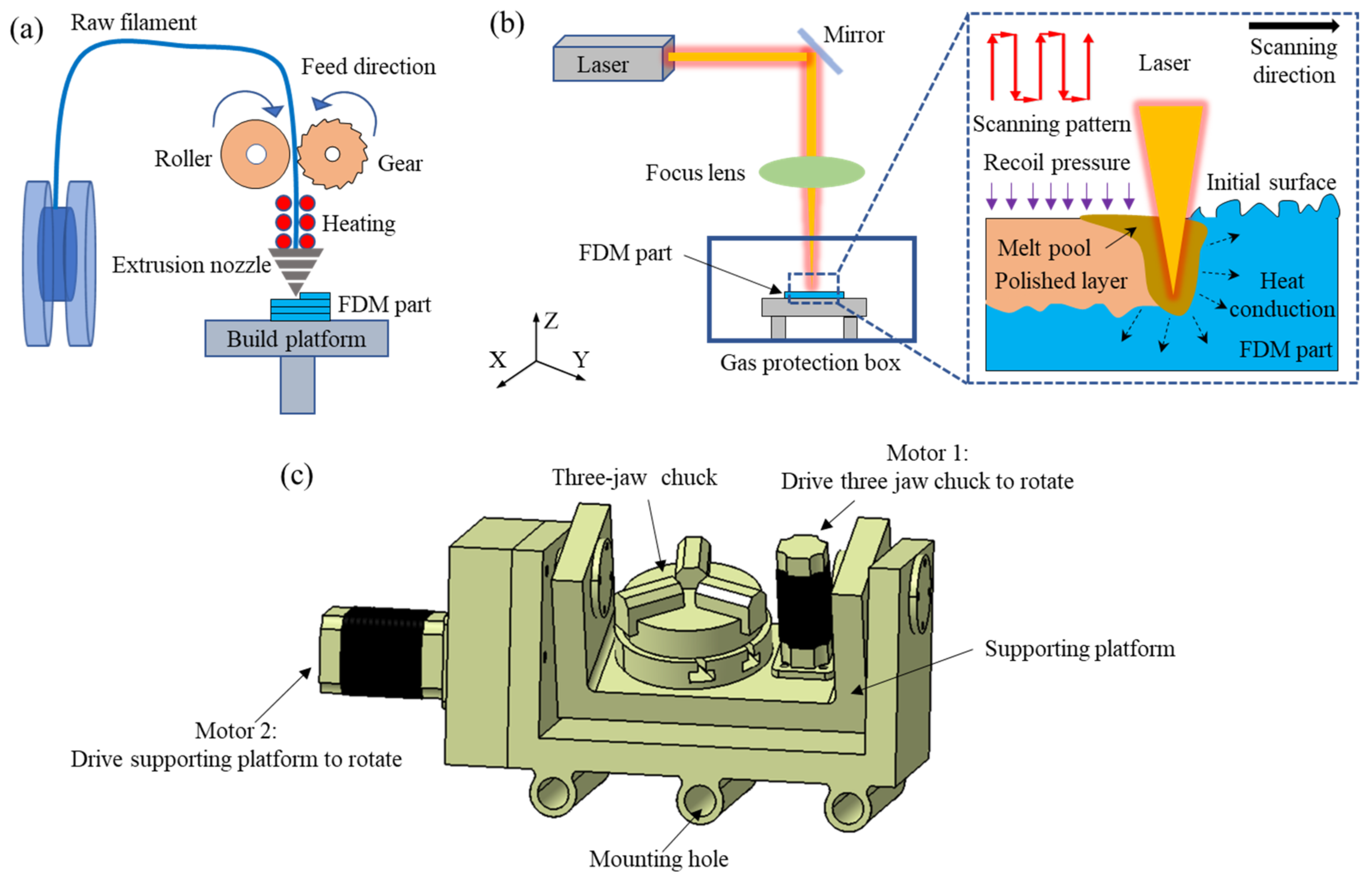

2. Materials and Methods

3. Results and Discussion

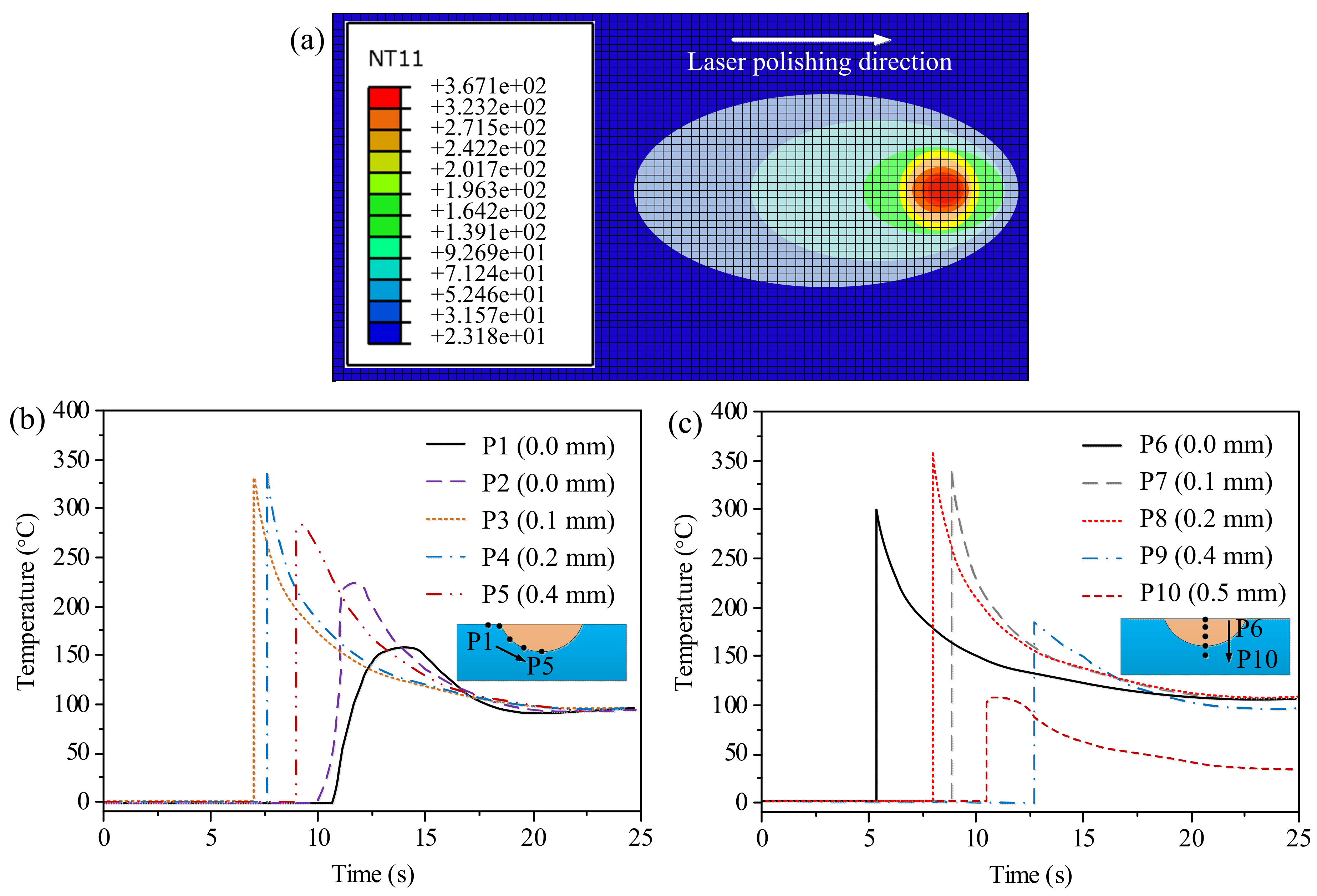

3.1. Simulation Results for the Temperature Distribution

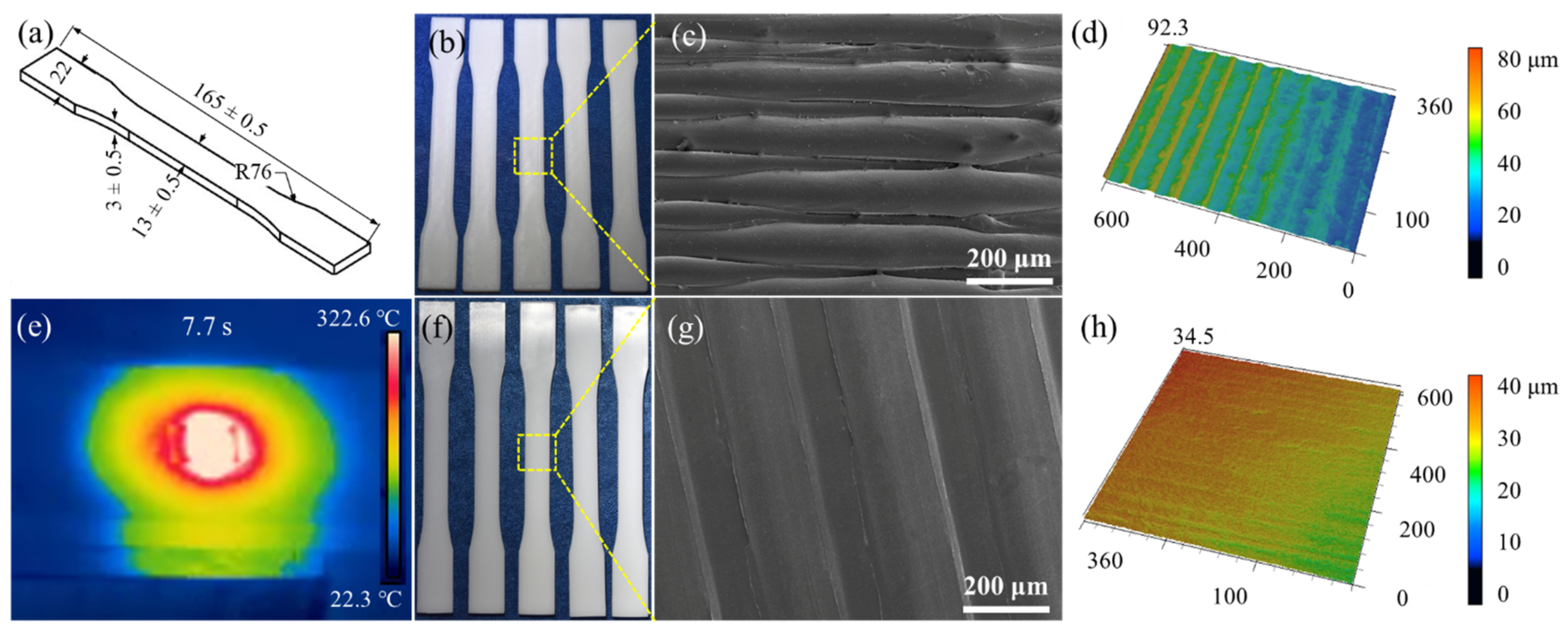

3.2. Laser Polishing of Tensile Specimen

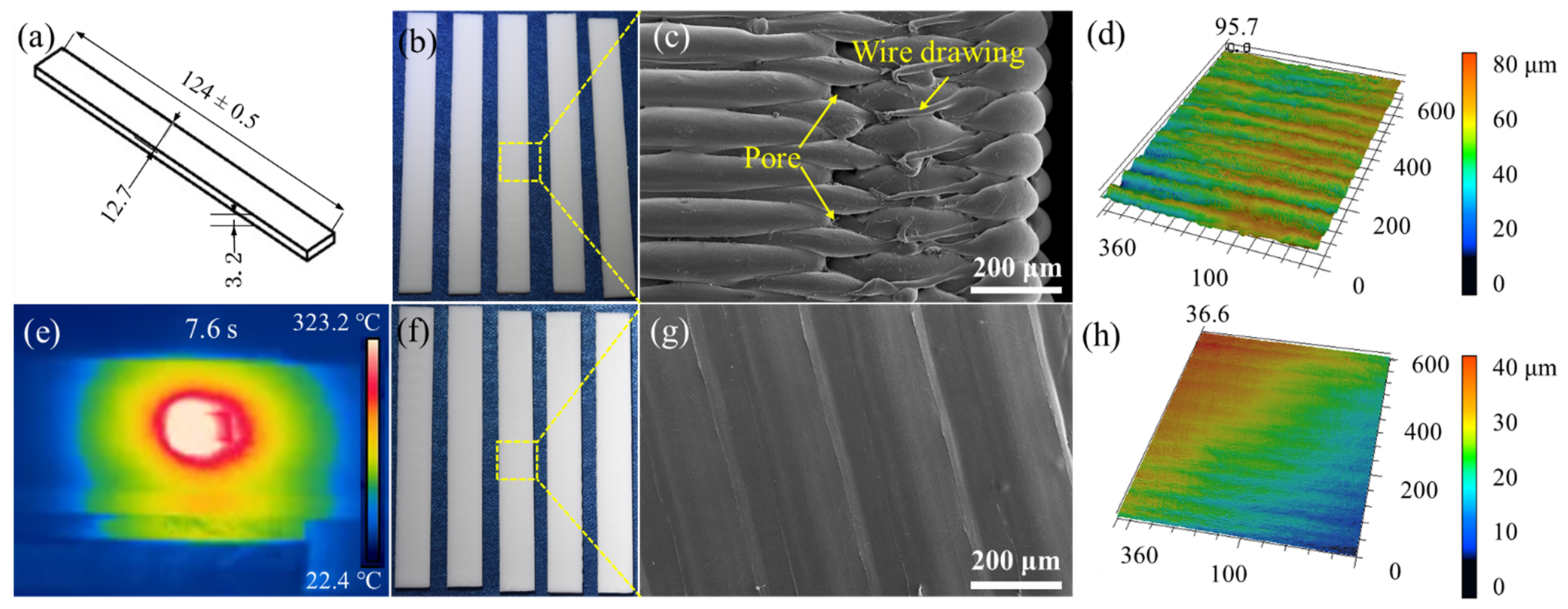

3.3. Laser Polishing of Flexural Specimen

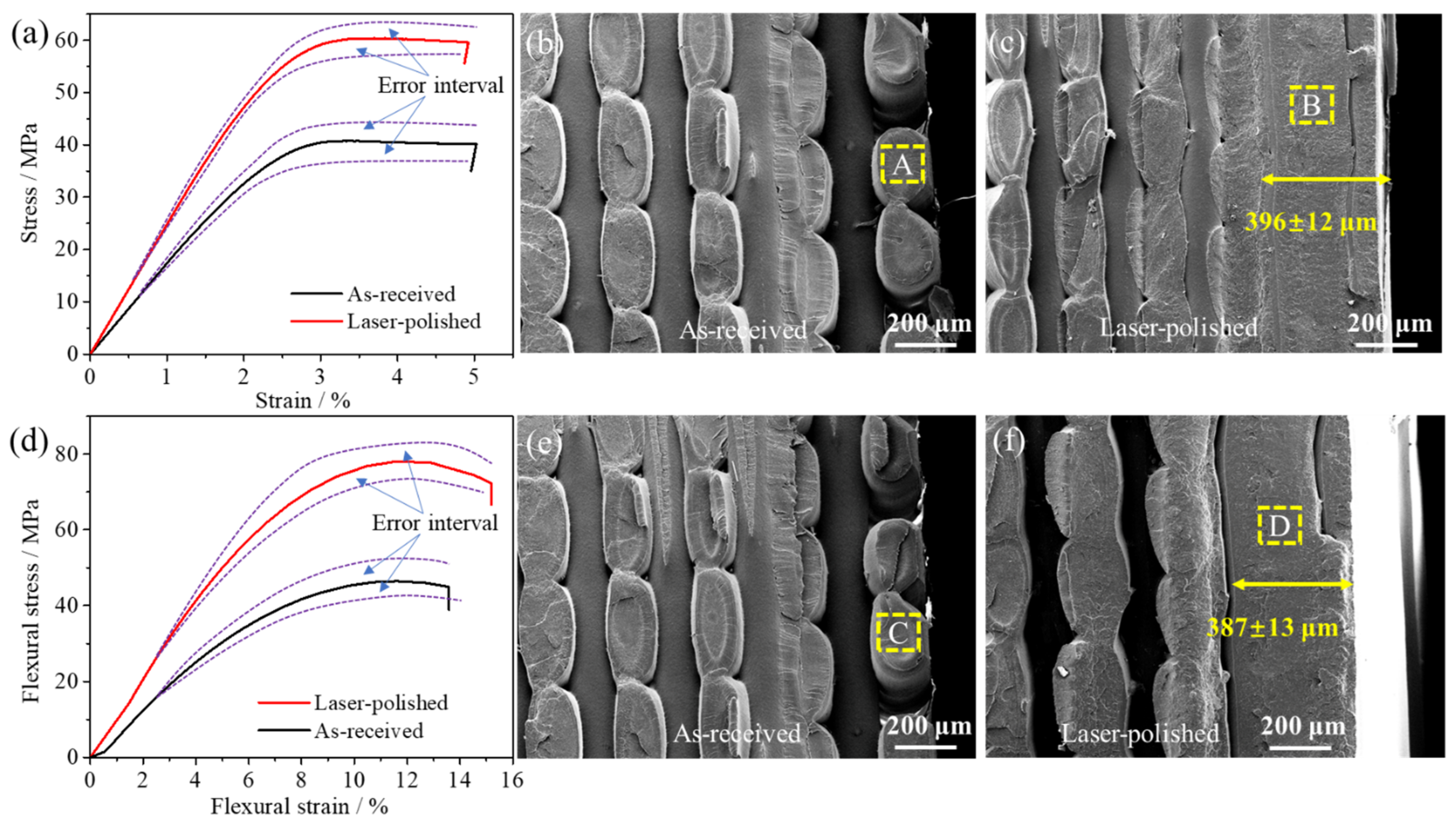

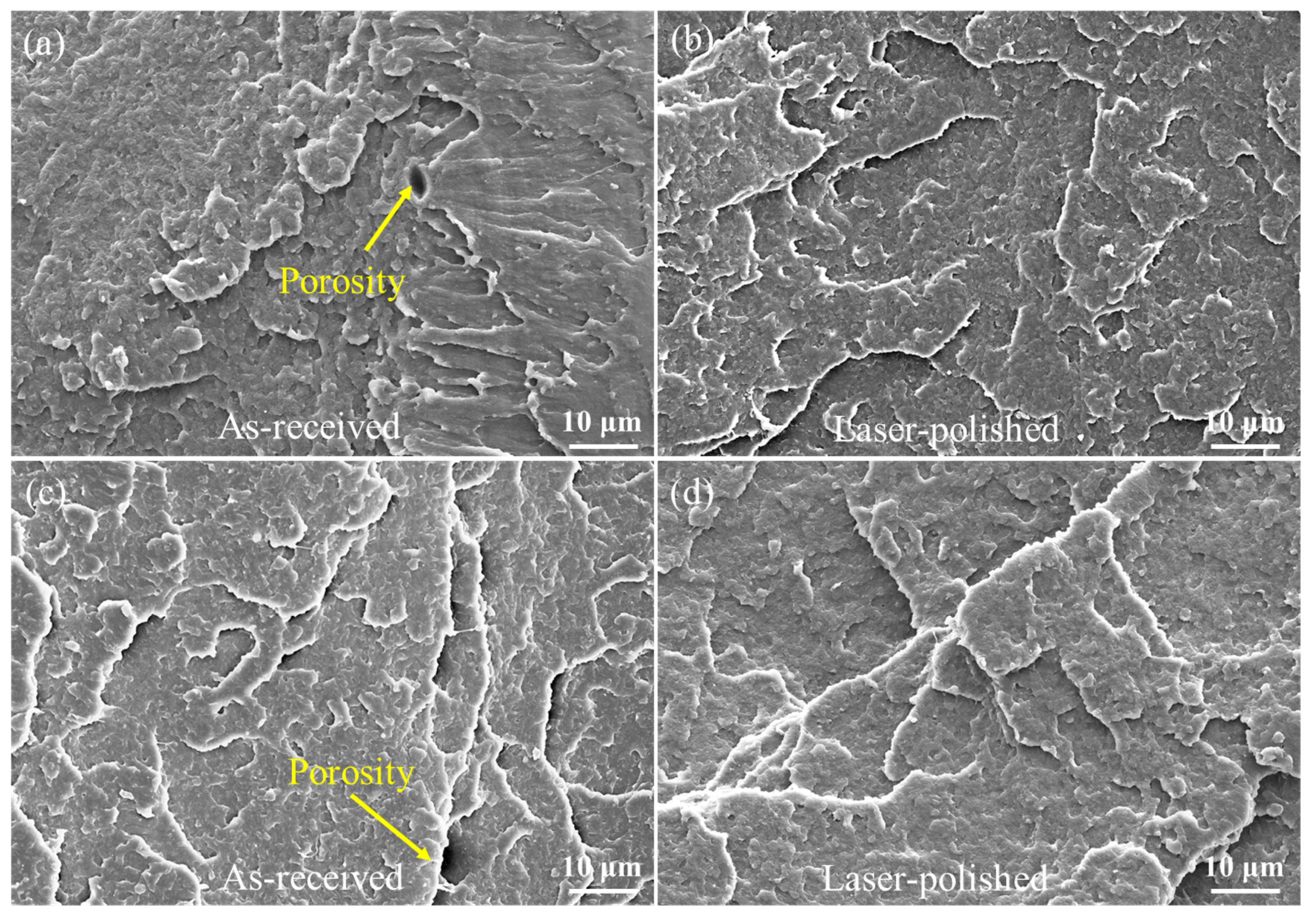

3.4. Mechanical Properties and Fracture Interface

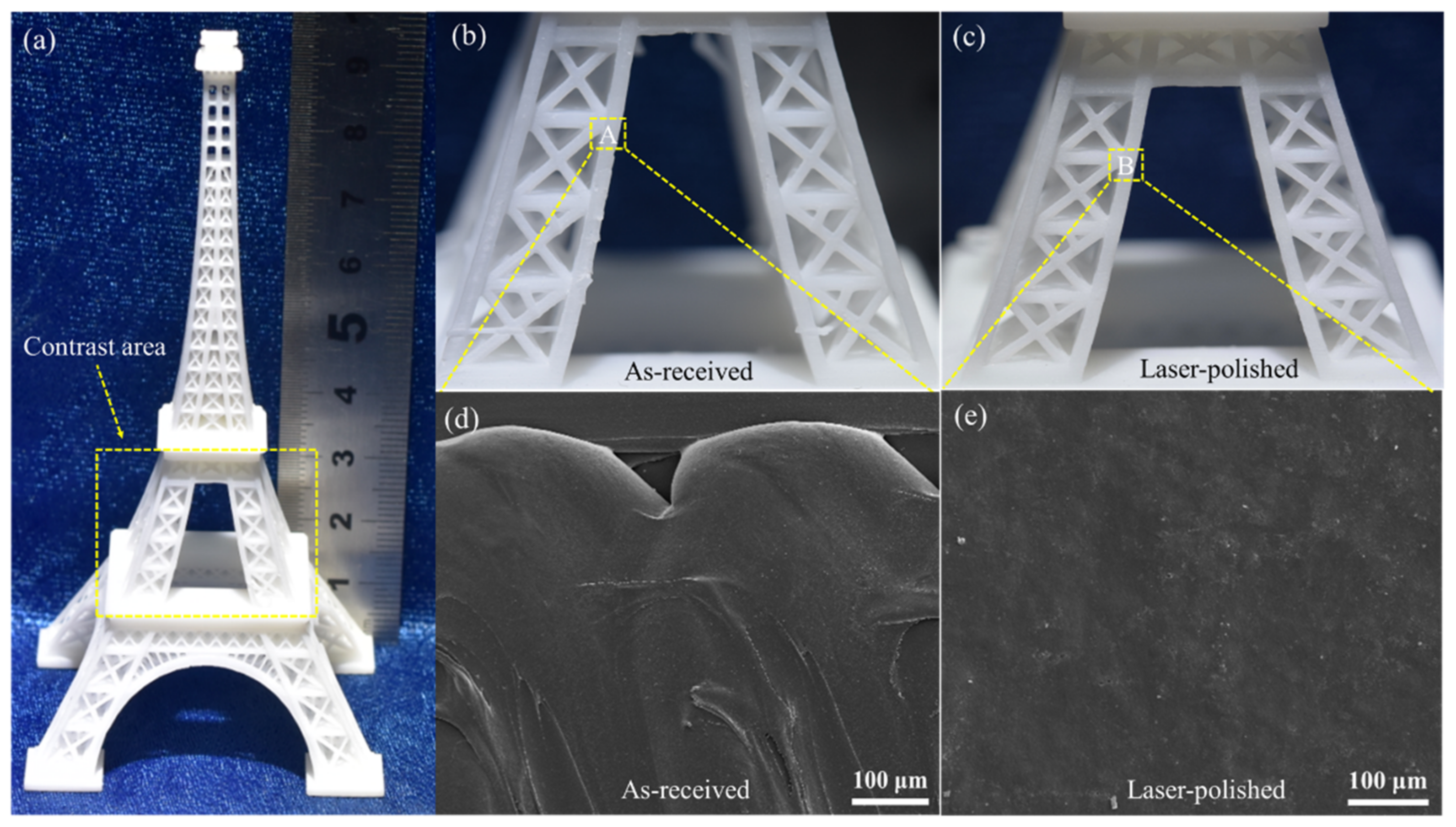

3.5. Examples of Laser Polishing on Landscape Design Products

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahern, J. Urban landscape sustainability and resilience: The promise and challenges of integrating ecology with urban planning and design. Landsc. Ecol. 2013, 28, 1203–1212. [Google Scholar] [CrossRef]

- Marques, B.; Grabasch, G.; McIntosh, J. Fostering Landscape Identity Through Participatory Design With Indigenous Cultures of Australia and Aotearoa/New Zealand. Space Cult. 2021, 24, 37–52. [Google Scholar] [CrossRef]

- Zhang, Z.; Meerow, S.; Newell, J.P.; Lindquist, M. Enhancing landscape connectivity through multifunctional green infrastructure corridor modeling and design. Urban For. Urban Green. 2019, 38, 305–317. [Google Scholar] [CrossRef]

- Lovell, S.T.; DeSantis, S.R.; Nathan, C.A.; Olson, M.B.; Mendez, V.E.; Kominami, H.C.; Erickson, D.L.; Morris, K.S.; Morris, W.B. Integrating agroecology and landscape multifunctionality in Vermont: An evolving framework to evaluate the design of agroe-cosystems. Agric. Syst. 2010, 103, 327–341. [Google Scholar] [CrossRef]

- Gagne, S.A.; Eigenbrod, F.; Bert, D.G.; Cunnington, G.M.; Olson, L.T.; Smith, A.C.; Fahrig, L. A simple landscape design framework for biodiversity conservation. Landsc. Urban Plan. 2015, 136, 13–27. [Google Scholar] [CrossRef]

- Singh, A.; Kapil, S.; Das, M. A comprehensive review of the methods and mechanisms for powder feedstock handling in directed energy deposition. Addit. Manuf. 2020, 35, 101388. [Google Scholar] [CrossRef]

- Wang, X.; Guo, Q.; Cai, X.; Zhou, S.; Kobe, B.; Yang, J. Initiator-integrated 3D printing enables the formation of complex metallic architectures. ACS Appl. Mater. Interfaces 2014, 6, 2583–2587. [Google Scholar] [CrossRef]

- Zuo, Z.; Gong, J.; Huang, Y.; Zhan, Y.; Gong, M.; Zhang, L. Experimental research on transition from scale 3D printing to full-size printing in construction. Constr. Build. Mater. 2019, 208, 350–360. [Google Scholar] [CrossRef]

- Alhumayani, H.; Gomaa, M.; Soebarto, V.; Jabi, W. Environmental assessment of large-scale 3D printing in construction: A comparative study between cob and concrete. J. Clean. Prod. 2020, 270, 122463. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Kapetaniou, C.; Rieple, A.; Pilkington, A.; Frandsen, T.; Pisano, P. Building the layers of a new manufacturing taxonomy: How 3D printing is creating a new landscape of production eco-systems and competitive dynamics. Technol. Forecast. Soc. Chang. 2018, 128, 22–35. [Google Scholar] [CrossRef]

- Li, Y.; Gao, S.; Dong, R.; Ding, X.; Duan, X. Additive Manufacturing of PLA and CF/PLA Binding Layer Specimens via Fused Deposition Modeling. J. Mater. Eng. Perform. 2018, 27, 492–500. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Lee, K.-M.; Park, H.; Kim, J.; Chun, D.-M. Fabrication of a superhydrophobic surface using a fused deposition modeling (FDM) 3D printer with poly lactic acid (PLA) filament and dip coating with silica nanoparticles. Appl. Surf. Sci. 2019, 467–468, 979–991. [Google Scholar] [CrossRef]

- Karimi, D.; Crawford, B.; Milani, A.S. Manufacturing process and mechanical properties of a novel acrylonitrile butadiene styrene-based composite, with recycled natural granite micro-particles. Manuf. Lett. 2020, 23, 79–84. [Google Scholar] [CrossRef]

- Krishna, A.V.; Faulcon, M.; Timmers, B.; Reddy, V.V.; Barth, H.; Nilsson, G.; Rosén, B.G. Influence of different post-processing methods on surface topography of fused deposition modelling samples. Surf. Topogr. Metrol. Prop. 2020, 8, 014001. [Google Scholar] [CrossRef]

- Sajan, N.; John, T.D.; Sivadasan, M.; Singh, N.K. An investigation on circularity error of components processed on Fused Deposition Modeling (FDM). Mater. Today Proc. 2018, 5, 1327–1334. [Google Scholar] [CrossRef]

- Vyavahare, S.; Teraiya, S.; Panghal, D.; Kumar, S. Fused deposition modelling: A review. Rapid Prototyp. J. 2020, 26, 176–201. [Google Scholar] [CrossRef]

- Mohammad Reza Khosravani, T.R. Effects of raster layup and printing speed on strength of 3D-printed structural components. Procedia Struct. Integr. 2020, 28, 720–725. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S.; Leone, C. Laser finishing of 3D printed parts produced by material extrusion. Opt. Lasers Eng. 2020, 124, 105801. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, X.; Wang, Y.; Osswald, T.A. Laser polishing of Cu/PLA composite parts fabricated by fused deposition modeling: Analysis of surface finish and mechanical properties. Polym. Compos. 2020, 41, 1356–1368. [Google Scholar] [CrossRef]

- Deng, T.; Li, J.; Zheng, Z. Fundamental aspects and recent developments in metal surface polishing with energy beam irradiation. Int. J. Mach. Tools Manuf. 2020, 148, 103472. [Google Scholar] [CrossRef]

- Zhu, W.-L.; Beaucamp, A. Compliant grinding and polishing: A review. Int. J. Mach. Tools Manuf. 2020, 158, 103634. [Google Scholar] [CrossRef]

- Krishnan, A.; Fang, F. Review on mechanism and process of surface polishing using lasers. Front. Mech. Eng. 2019, 14, 299–319. [Google Scholar] [CrossRef]

- Wang, W.J.; Yung, K.C.; Choy, H.S.; Xiao, T.Y.; Cai, Z.X. Effects of laser polishing on surface microstructure and corrosion resistance of additive manufactured CoCr alloys. Appl. Surf. Sci. 2018, 443, 167–175. [Google Scholar] [CrossRef]

- Yung, K.C.; Xiao, T.Y.; Choy, H.S.; Wang, W.J.; Cai, Z.X. Laser polishing of additive manufactured CoCr alloy components with complex surface geometry. J. Mater. Process. Technol. 2018, 262, 53–64. [Google Scholar] [CrossRef]

- Yung, K.C.; Wang, W.J.; Xiao, T.Y.; Choy, H.S.; Mo, X.Y.; Zhang, S.S.; Cai, Z.X. Laser polishing of additive manufactured CoCr components for controlling their wettability characteristics. Surf. Coat. Technol. 2018, 351, 89–98. [Google Scholar] [CrossRef]

- Temmler, A.; Pirch, N.; Luo, J.; Schleifenbaum, J.H.; Häfner, C.L. Numerical and experimental investigation on formation of surface structures in laser remelting for additive-manufactured Inconel 718. Surf. Coat. Technol. 2020, 403, 126370. [Google Scholar] [CrossRef]

- Marimuthu, S.; Triantaphyllou, A.; Antar, M.; Wimpenny, D.; Morton, H.; Beard, M. Laser polishing of selective laser melted components. Int. J. Mach. Tools Manuf. 2015, 95, 97–104. [Google Scholar] [CrossRef]

- Tian, Y.; Gora, W.S.; Cabo, A.P.; Parimi, L.L.; Hand, D.P.; Tammas-Williams, S.; Prangnell, P.B. Material interactions in laser polishing powder bed additive manufactured Ti6Al4V components. Addit. Manuf. 2018, 20, 11–22. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, X.; Guan, Y. Ultrafine microstructure development in laser polishing of selective laser melted Ti alloy. J. Mater. Sci. Technol. 2021, 83, 1–6. [Google Scholar] [CrossRef]

- Rosa, B.; Mognol, P.; Hascoët, J.-Y. Modelling and optimization of laser polishing of additive laser manufacturing surfaces. Rapid Prototyp. J. 2016, 22, 956–964. [Google Scholar] [CrossRef]

- Bhaduri, D.; Penchev, P.; Batal, A.; Dimov, S.; Soo, S.L.; Sten, S.; Harrysson, U.; Zhang, Z.; Dong, H. Laser polishing of 3D printed mesoscale components. Appl. Surf. Sci. 2017, 405, 29–46. [Google Scholar] [CrossRef]

- Taufik, M.; Jain, P.K. Laser assisted finishing process for improved surface finish of fused deposition modelled parts. J. Manuf. Process. 2017, 30, 161–177. [Google Scholar] [CrossRef]

- Chai, Y.; Li, R.W.; Perriman, D.M.; Chen, S.; Qin, Q.-H.; Smith, P.N. Laser polishing of thermoplastics fabricated using fused deposition modelling. Int. J. Adv. Manuf. Technol. 2018, 96, 4295–4302. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, X.; Gan, S. Effects of laser polishing on surface quality and mechanical properties of PLA parts built by fused deposition modeling. J. Appl. Polym. Sci. 2019, 137, 48288. [Google Scholar] [CrossRef]

- Inkinen, S.; Hakkarainen, M.; Albertsson, A.C.; Sodergard, A. From lactic acid to poly(lactic acid) (PLA): Characterization and analysis of PLA and its precursors. Biomacromolecules 2011, 12, 523–532. [Google Scholar] [CrossRef]

- Le Duigou, A.; Chabaud, G.; Matsuzaki, R.; Castro, M. Tailoring the mechanical properties of 3D-printed continuous flax/PLA biocomposites by controlling the slicing parameters. Compos. Part B Eng. 2020, 203, 108474. [Google Scholar] [CrossRef]

- He, X.; Elmer, J.W.; DebRoy, T. Heat transfer and fluid flow in laser microwelding. J. Appl. Phys. 2005, 97, 084909. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Y.; Jiang, F.; Li, C. Experimental investigation and FEM analysis of laser cladding assisted by coupled field of electric and magnetic. Mater. Res. Express 2018, 6, 016516. [Google Scholar] [CrossRef]

- He, T.; Wei, C.; Jiang, Z.; Zhao, Y.; Shao, J. Super-smooth surface demonstration and the physical mechanism of CO2 laser polishing of fused silica. Opt. Lett. 2018, 43, 5777–5780. [Google Scholar] [CrossRef]

- Adel, M.; Abdelaal, O.; Gad, A.; Nasr, A.B.; Khalil, A. Polishing of fused deposition modeling products by hot air jet: Evaluation of surface roughness. J. Mater. Process. Technol. 2018, 251, 73–82. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters for dimensional accuracy using I-optimality criterion. Measurement 2016, 81, 174–196. [Google Scholar] [CrossRef]

- Marwah, O.M.F.; Sharif, S.; Ibrahim, M.; Mohamad, E.J.; Idris, M.H. Direct rapid prototyping evaluation on multijet and fused deposition modeling patterns for investment casting. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2016, 230, 949–958. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Object infill density | 100% |

| Layer height | 0.1 mm |

| Feed rate | 33 mm/s |

| Travel feed rate | 58 mm/s |

| Print temperature | 210 °C |

| Filament diameter | 1.75 ± 0.1 mm |

| Nozzle diameter | 0.3 mm |

| Deposition infill pattern | ±45° |

| Categories | Tensile Test | Flexural Test |

|---|---|---|

| Testing speed | 1.5 mm/min | 1.5 mm/min |

| Sampling frequency | 20 Hz | 20 Hz |

| Distance between two grips | 110 mm | / |

| Distance between two supports | / | 50 mm |

| Parameter | Value |

|---|---|

| Laser power | 5 W |

| scanning speed | 1200 mm/s |

| spot size | 100 µm |

| Density | 1280 Kg/m3 |

| Thermal conductivity | 0.025 W/m·K |

| Melting point | 450.15 K |

| Solid specific heat capacity | 1950 J/(Kg·K) |

| Liqud specific heat capacity | 2120 J/(Kg·K) |

| Categories | Tensile Specimens (Unit: g) | Flexural Specimens (Unit: g) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| As-Received | 8.4722 | 8.5262 | 8.4319 | 8.5455 | 8.5113 | 6.5322 | 6.4723 | 6.3842 | 6.4026 | 6.5899 |

| Laser-Polished | 8.4013 | 8.4237 | 8.3997 | 8.3890 | 8.3973 | 6.3545 | 6.4015 | 6.3328 | 6.3803 | 6.3992 |

| Categories | Tensile Specimens (Unit: g) | Flexural Specimens (Unit: g) | ||

|---|---|---|---|---|

| S | S | |||

| As-received | 8.4974 | 0.2130 | 6.4762 | 0.2912 |

| Laser-polished | 8.4022 | 0.1037 | 6.3737 | 0.1732 |

| Categories | Young’s Modulus (GPa) | Young’s Modulus Standard Deviation (GPa) | Tensile Strength (MPa) | Tensile Strength Standard Deviation (MPa) |

|---|---|---|---|---|

| As-received | 1.17 | 0.26 | 39.96 | 0.73 |

| Laser-polished | 1.61 | 0.05 | 58.57 | 0.52 |

| Categories | Flexural Modulus (GPa) | Flexural Modulus Standard Deviation (GPa) | Flexural Strength (MPa) | Flexural Strength Standard Deviation (MPa) |

|---|---|---|---|---|

| As-received | 17.66 | 0.46 | 43.32 | 0.65 |

| Laser-polished | 14.33 | 0.23 | 75.61 | 0.37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ba, Y.; Wen, Y.; Wu, S. Mechanical Characterization and Thermodynamic Analysis of Laser-Polished Landscape Design Products Using 3D Printing. Materials 2021, 14, 2601. https://doi.org/10.3390/ma14102601

Ba Y, Wen Y, Wu S. Mechanical Characterization and Thermodynamic Analysis of Laser-Polished Landscape Design Products Using 3D Printing. Materials. 2021; 14(10):2601. https://doi.org/10.3390/ma14102601

Chicago/Turabian StyleBa, Yue, Yu Wen, and Shibin Wu. 2021. "Mechanical Characterization and Thermodynamic Analysis of Laser-Polished Landscape Design Products Using 3D Printing" Materials 14, no. 10: 2601. https://doi.org/10.3390/ma14102601

APA StyleBa, Y., Wen, Y., & Wu, S. (2021). Mechanical Characterization and Thermodynamic Analysis of Laser-Polished Landscape Design Products Using 3D Printing. Materials, 14(10), 2601. https://doi.org/10.3390/ma14102601