Investigation of Compression and Buckling Properties of a Novel Surface-Based Lattice Structure Manufactured Using Multi Jet Fusion Technology

Abstract

1. Introduction

2. Material and Methodology

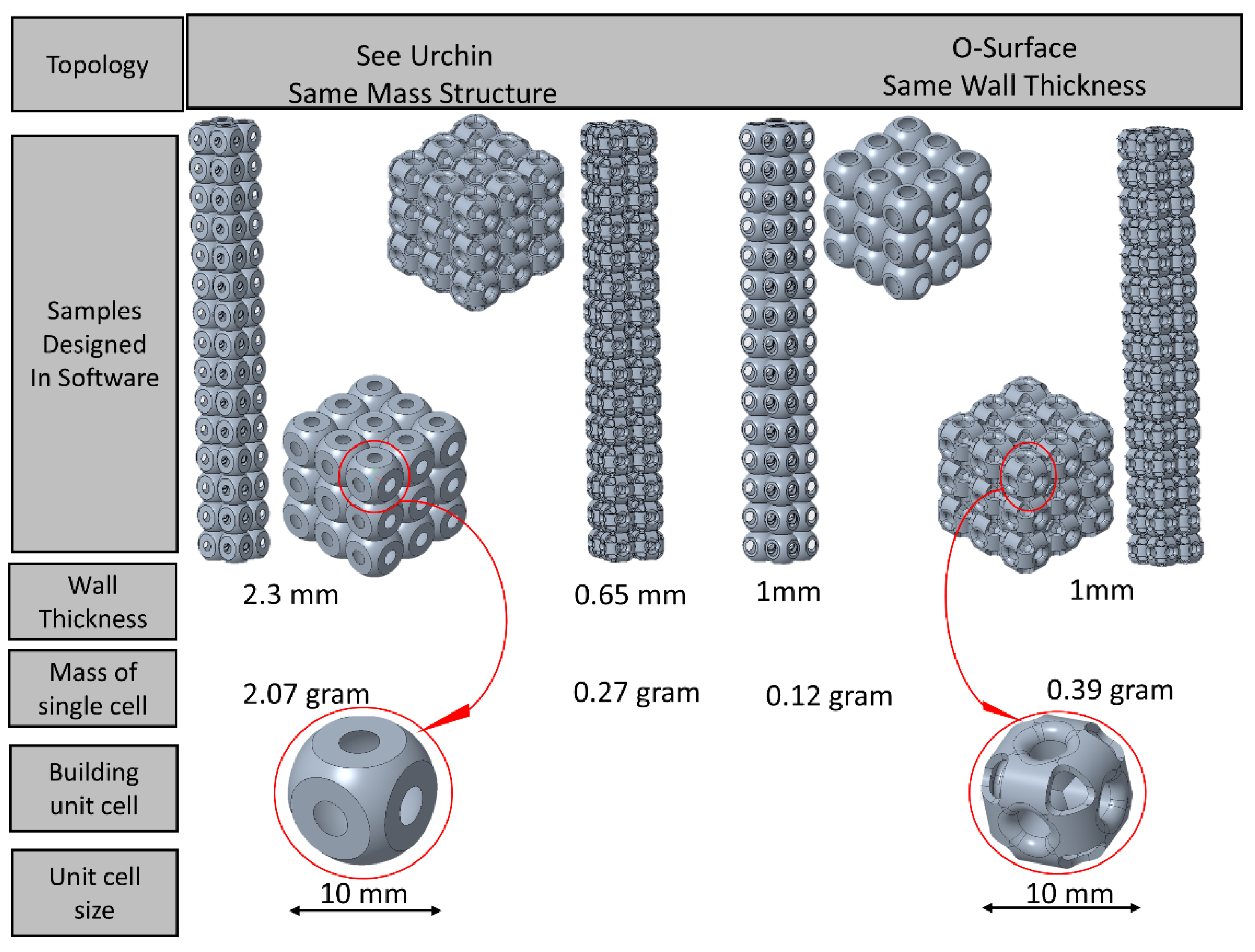

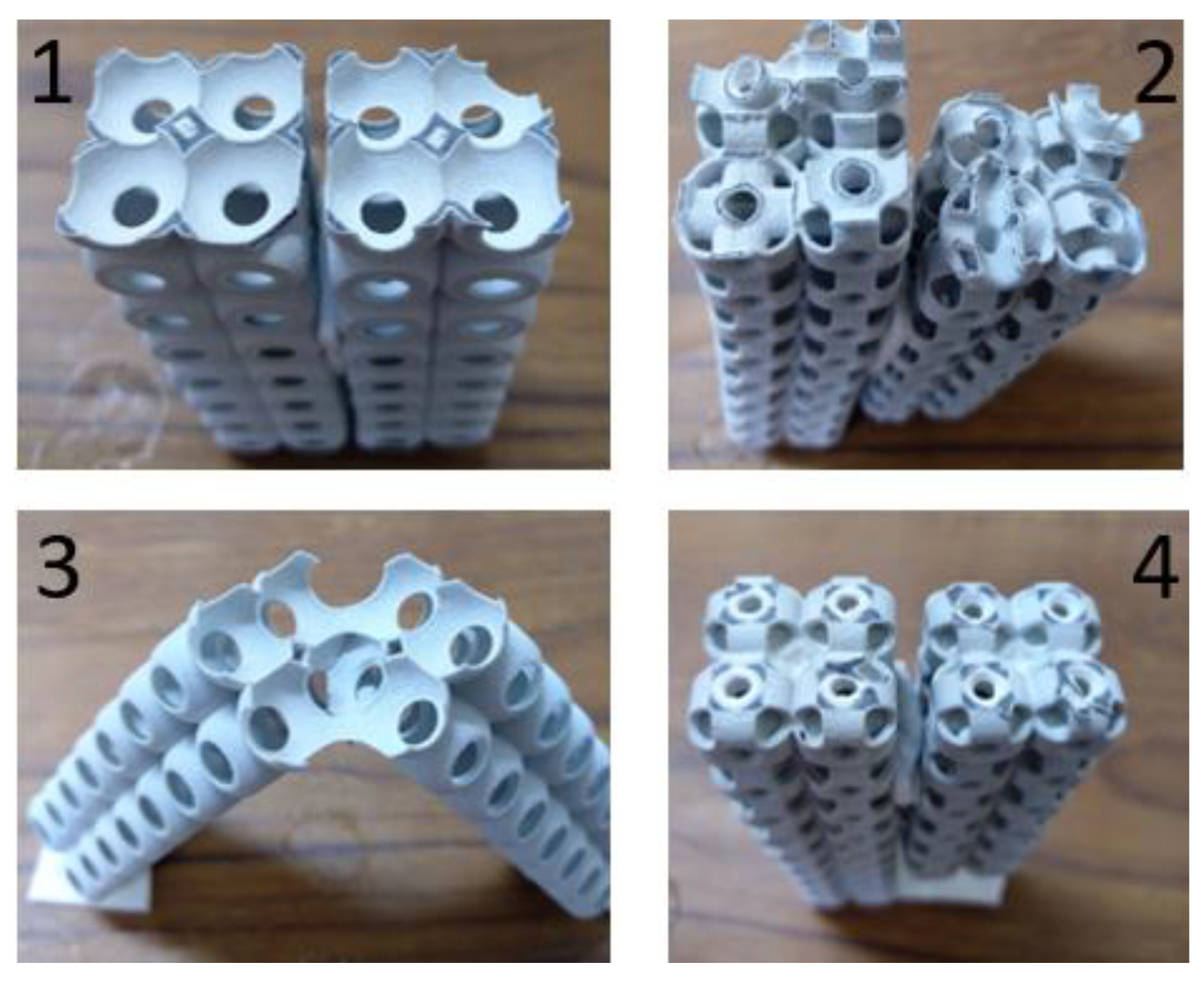

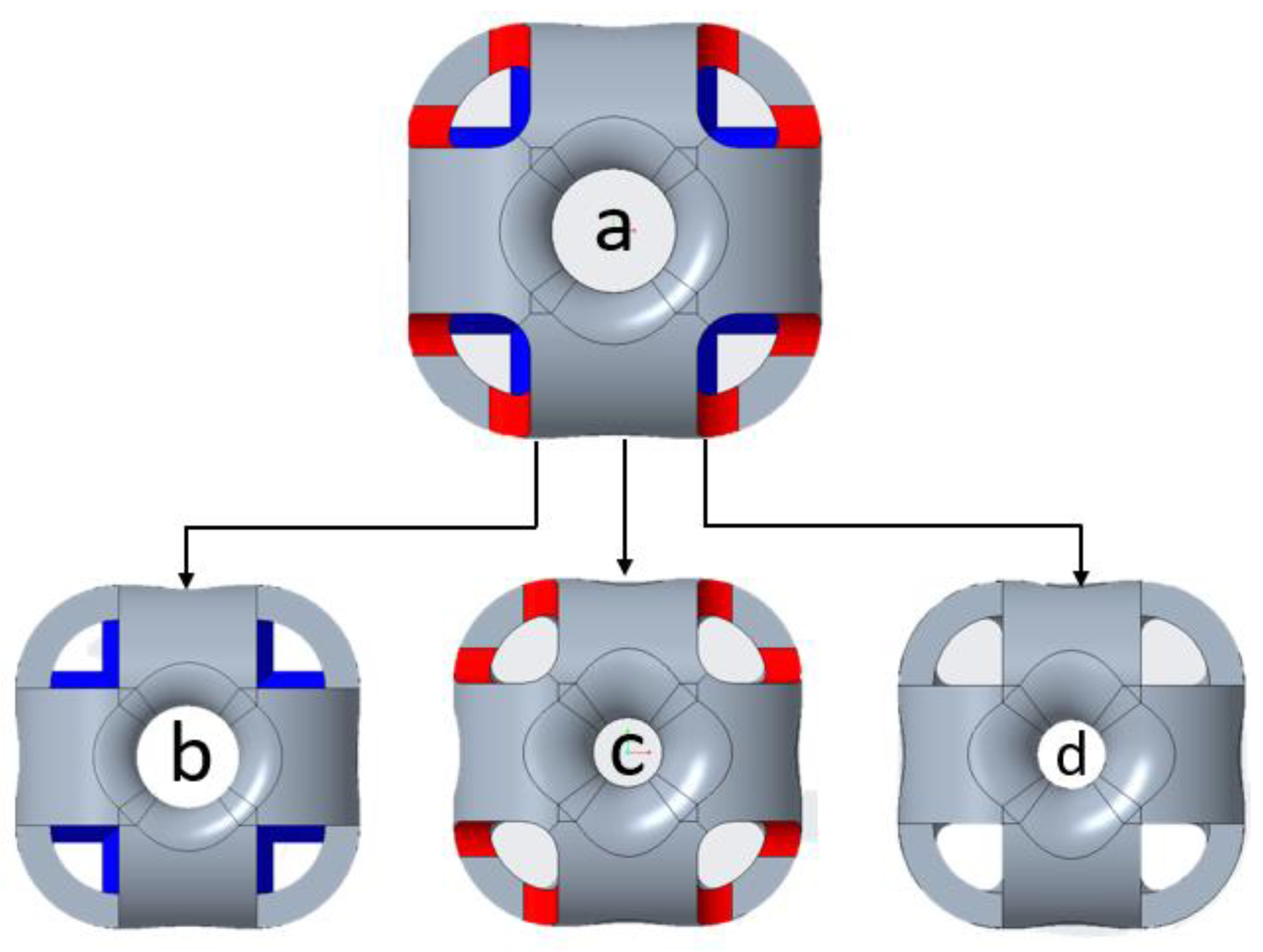

2.1. Samples Design

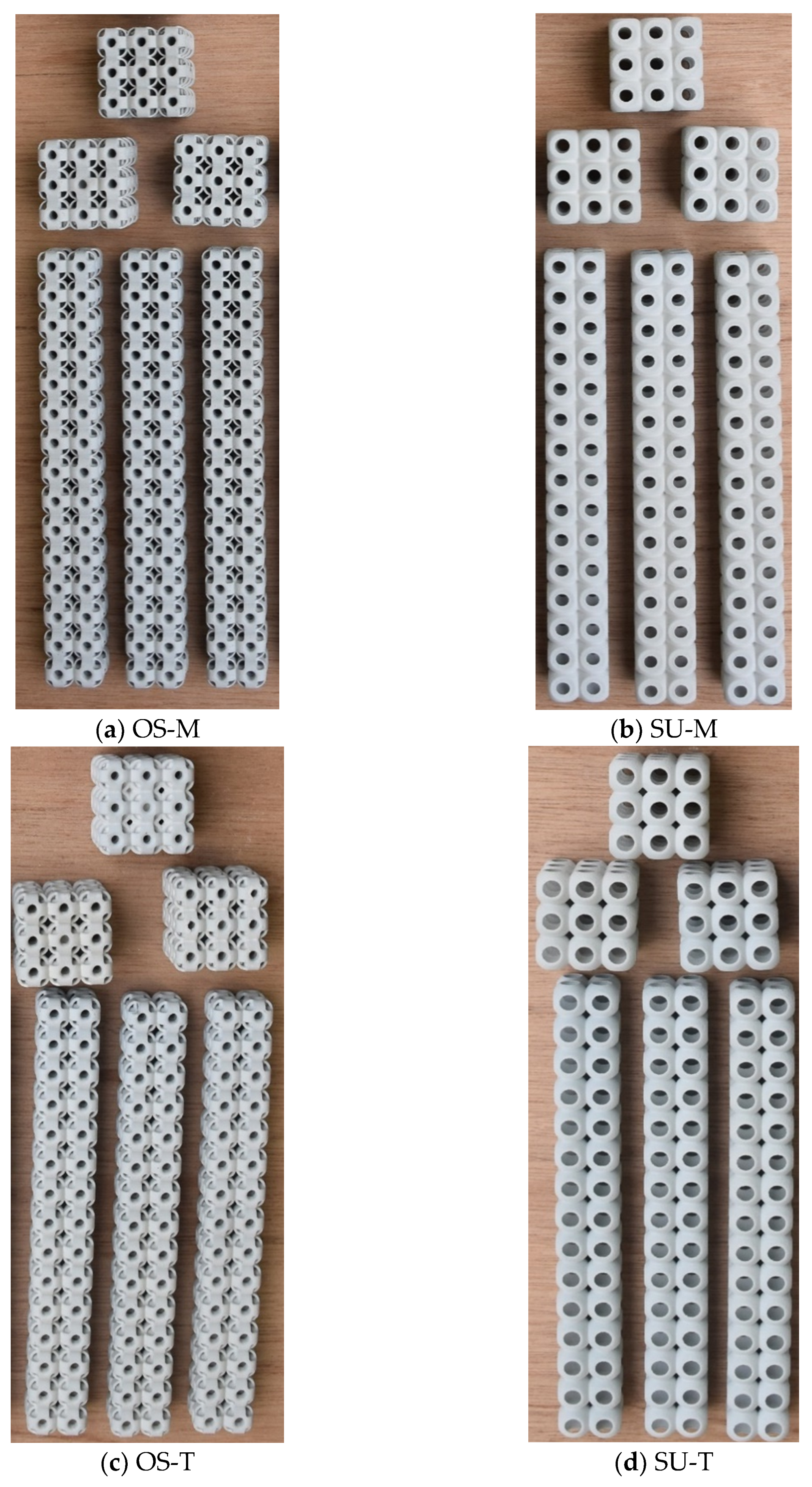

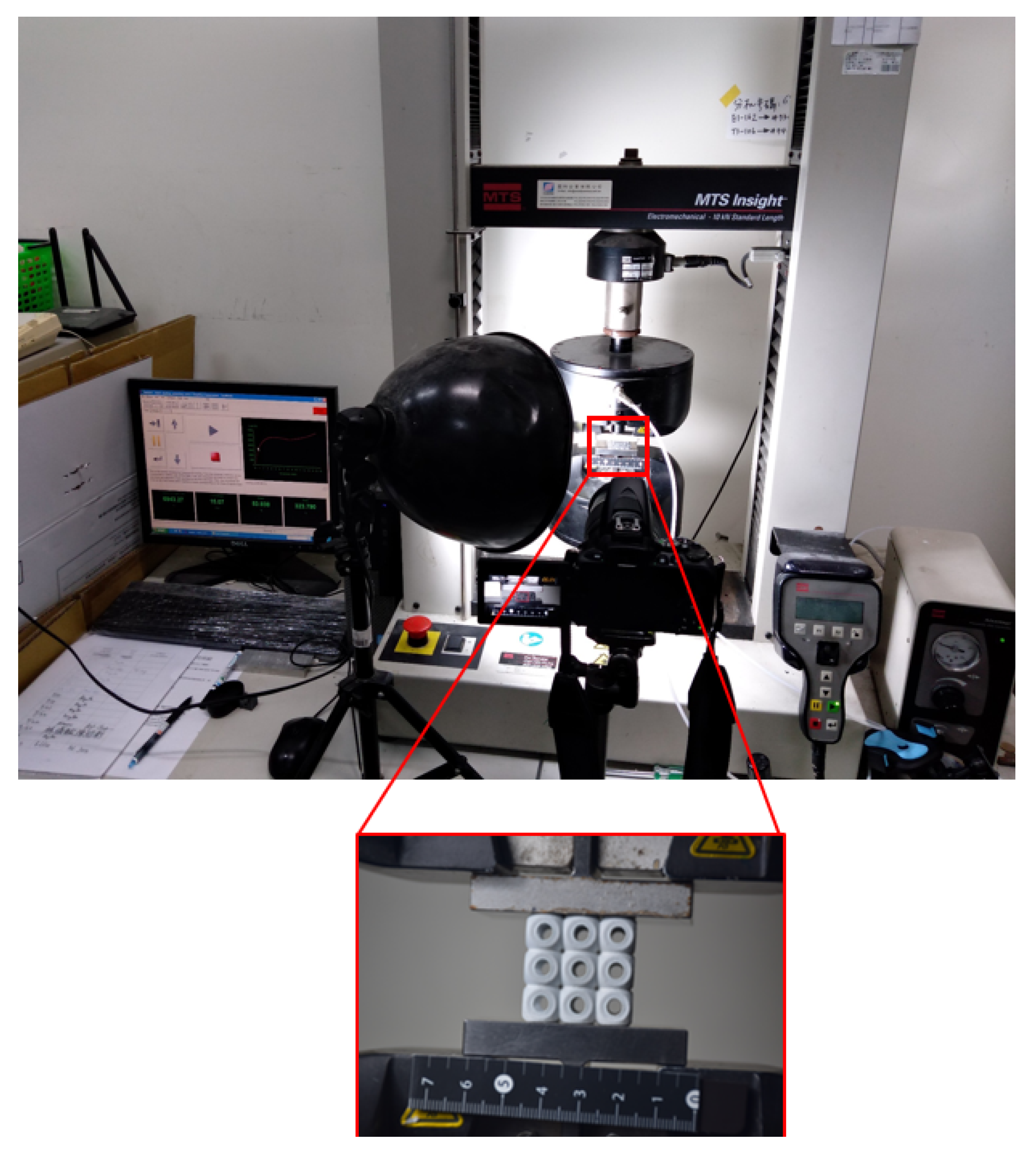

2.2. Additive Manufacturing and Testing

3. Results and Discussion

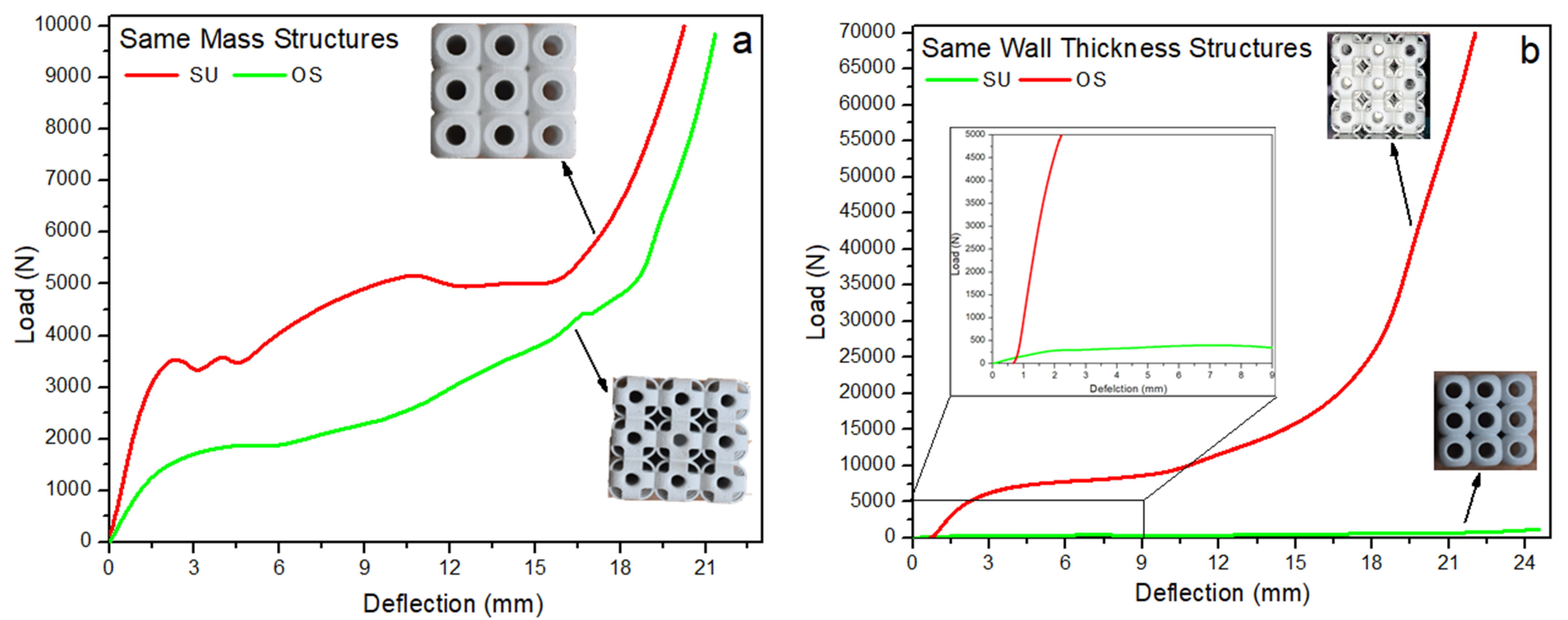

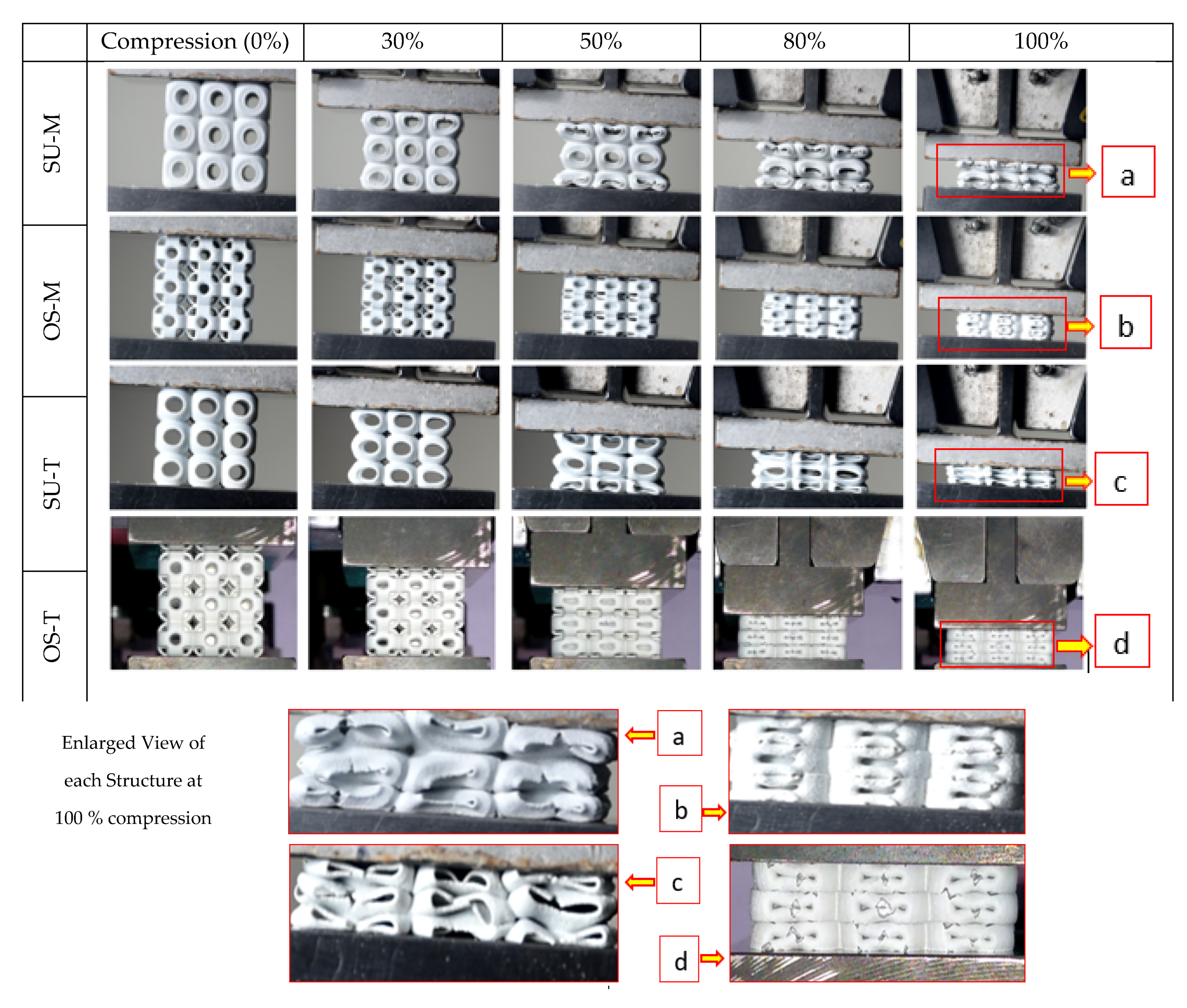

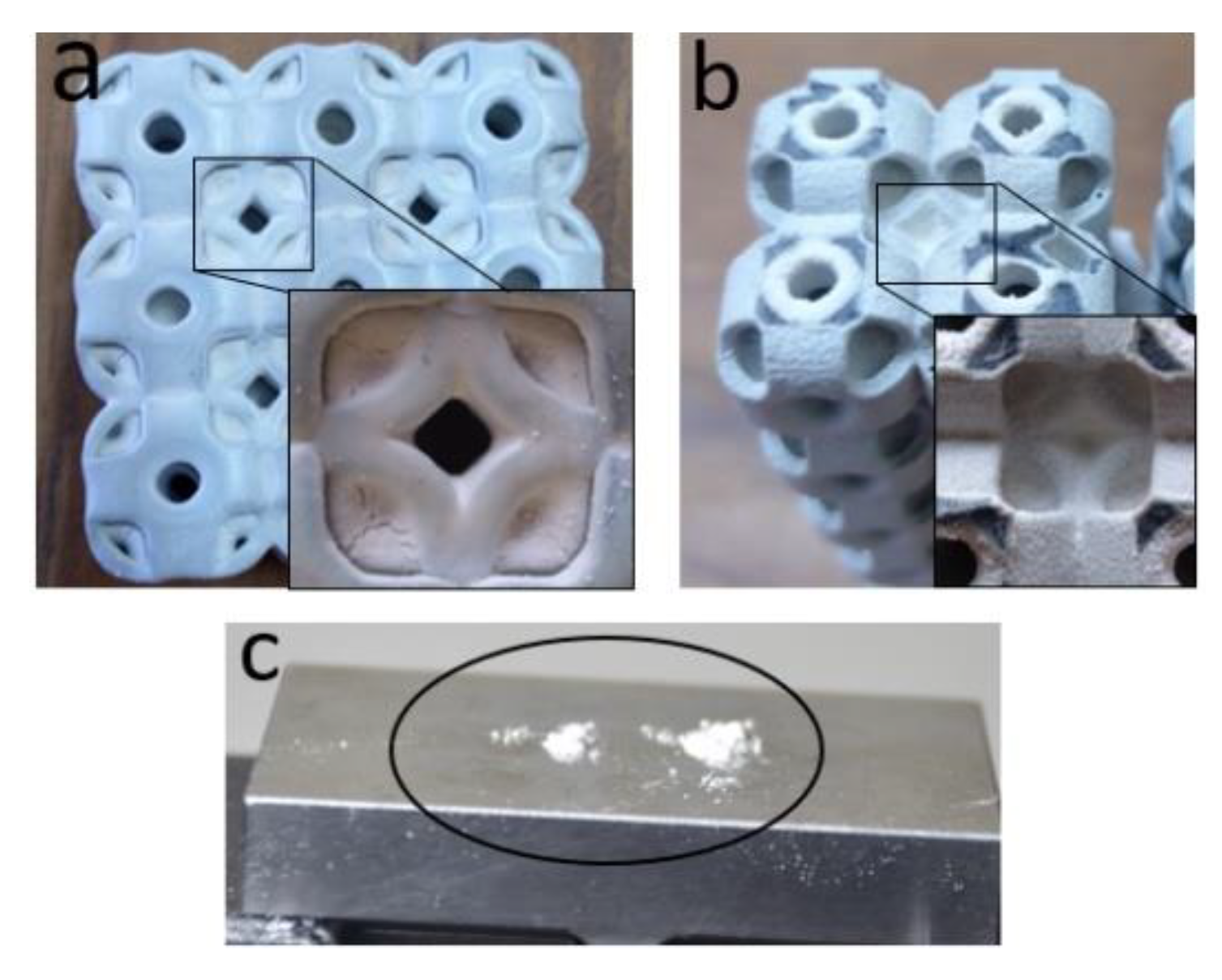

3.1. Deformation and Fracture of 3 × 3 × 3 Structures

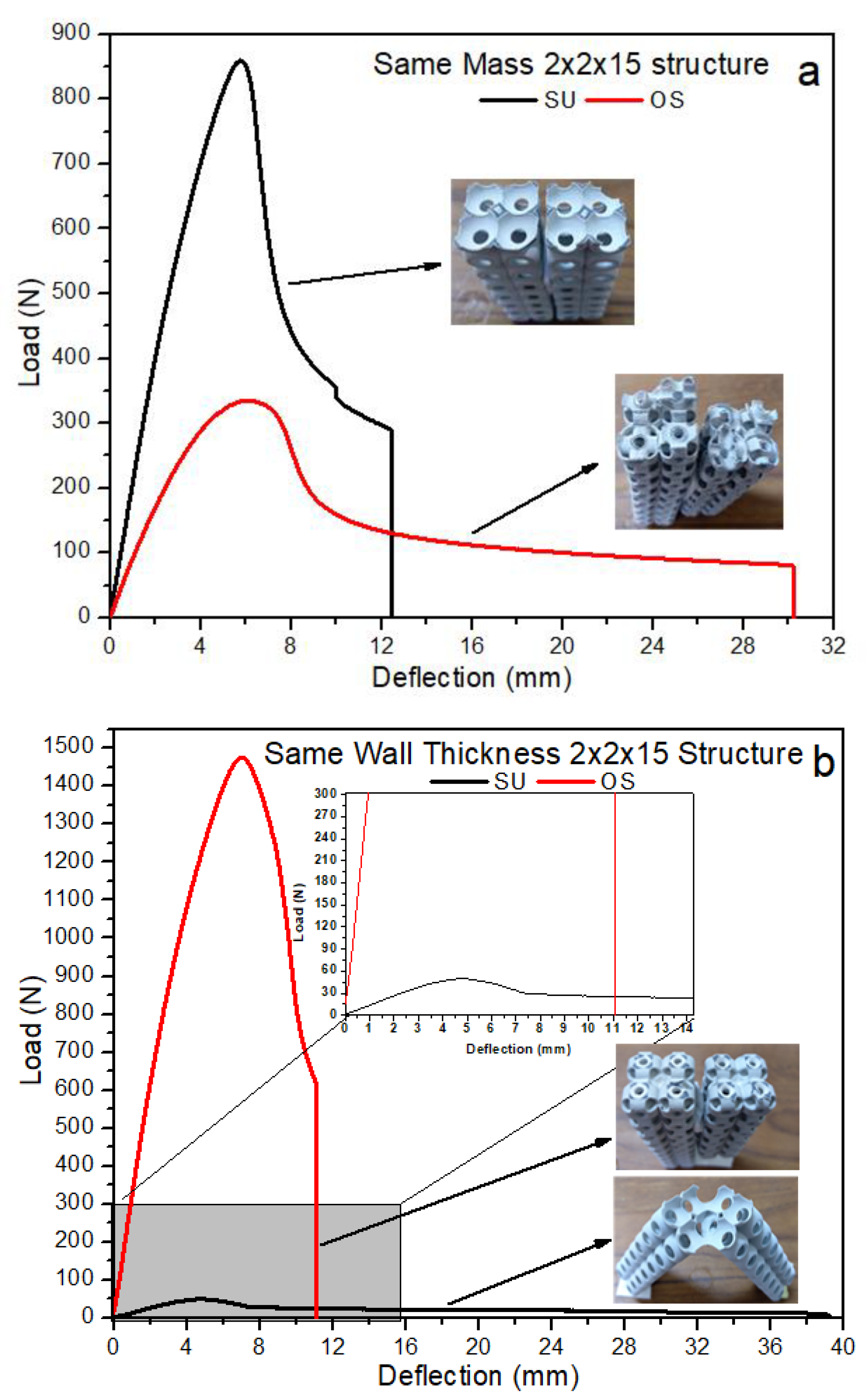

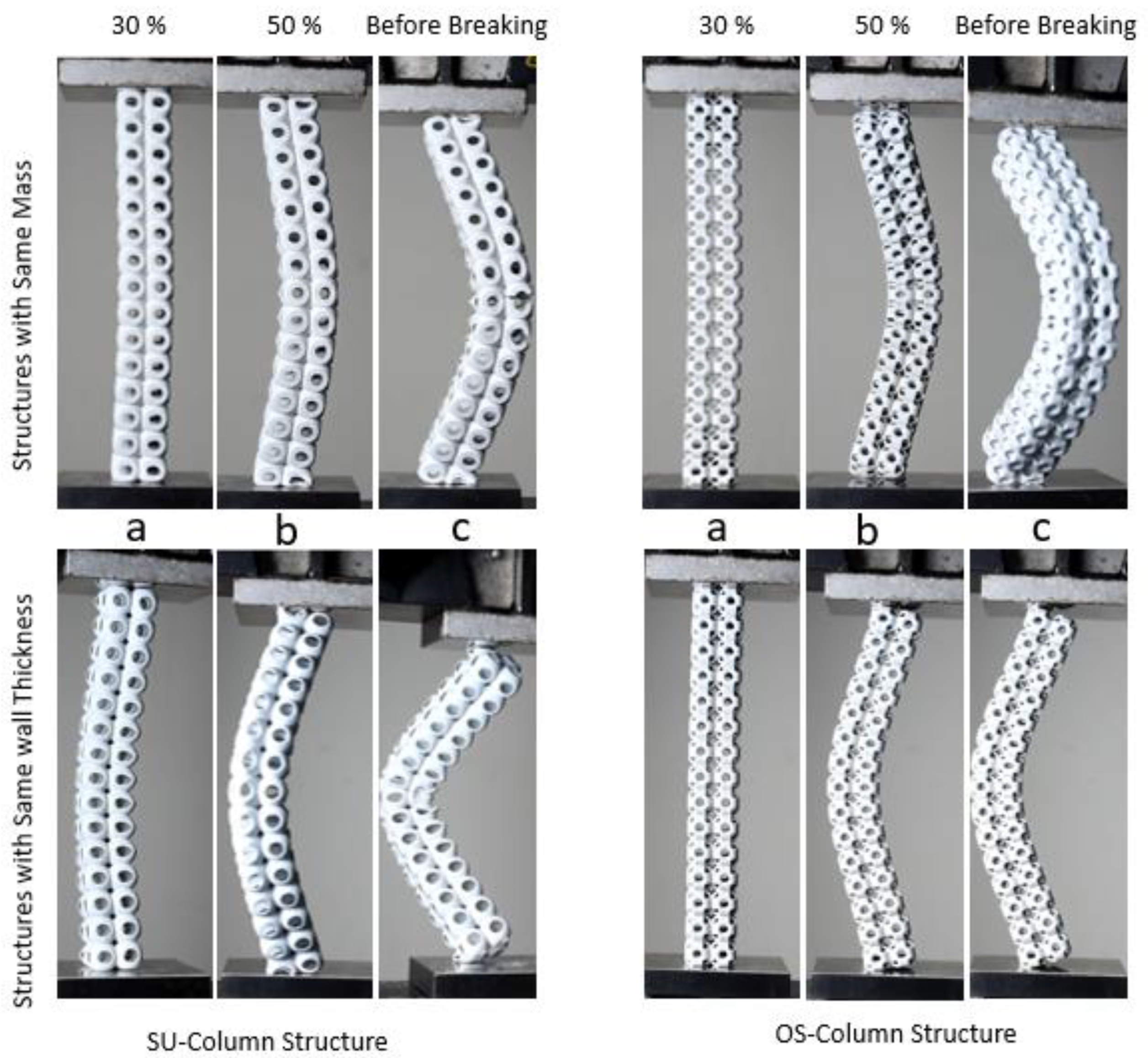

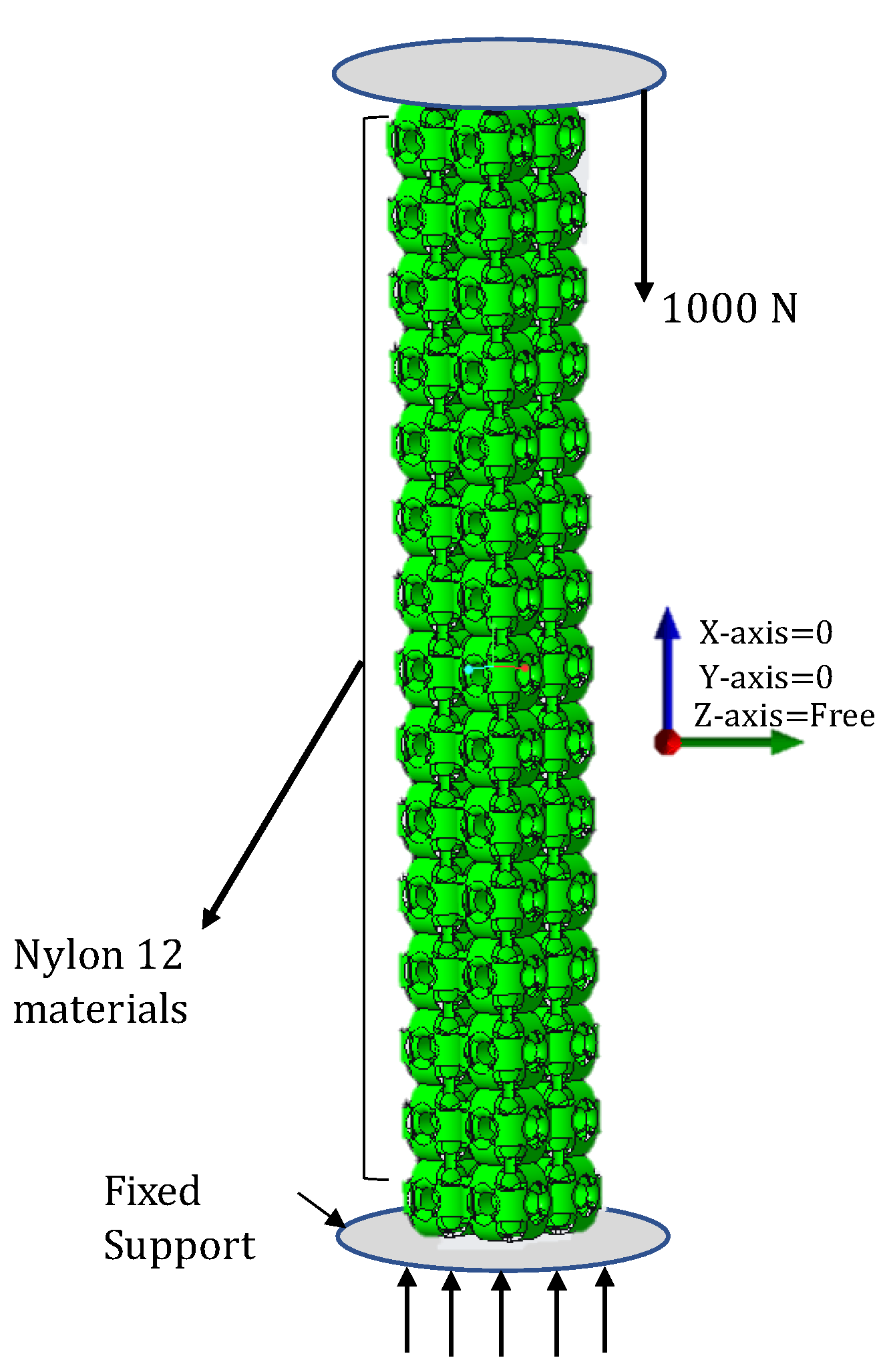

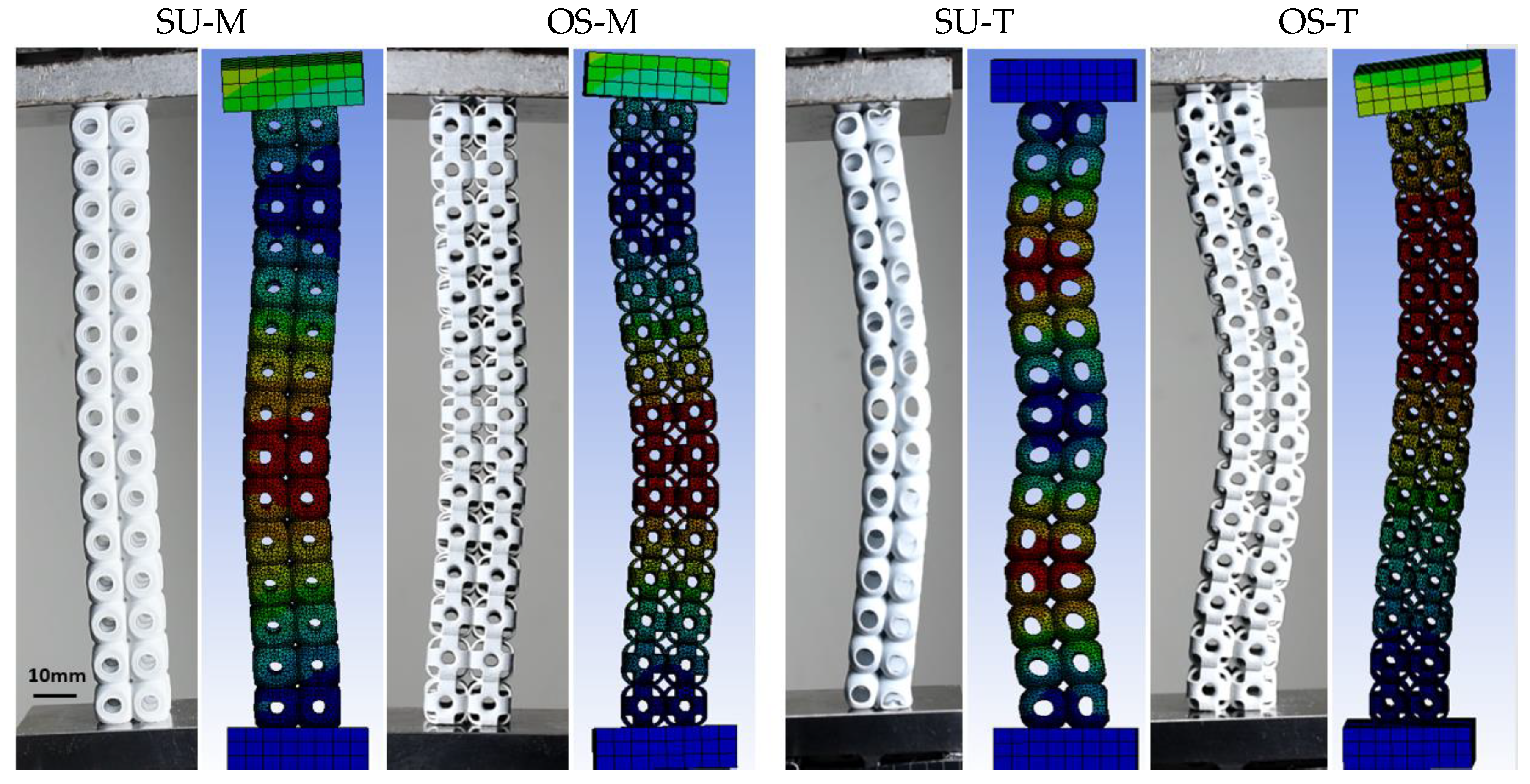

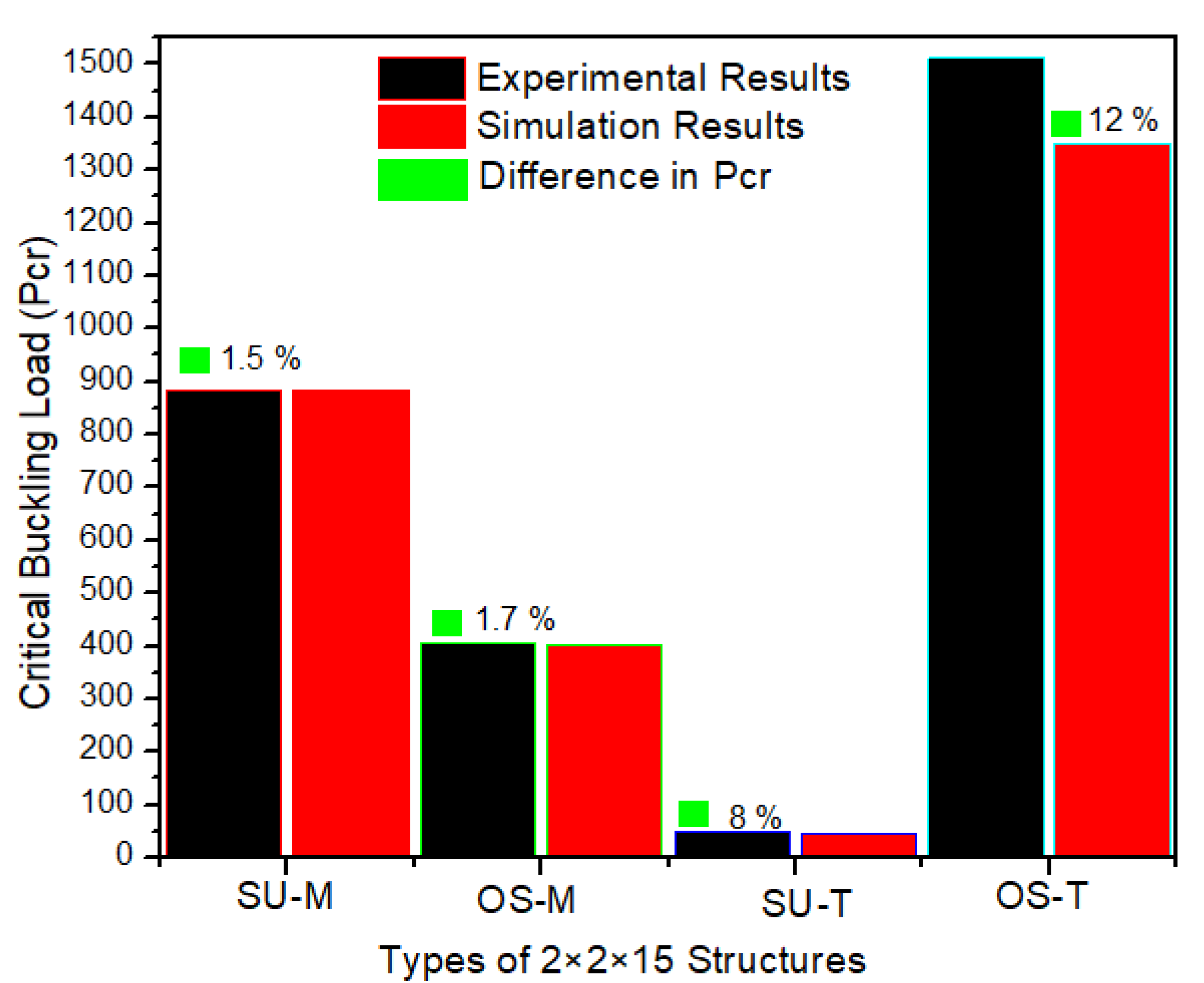

3.2. Buckling and Fracture of 2 × 2 × 15 Structure

3.3. Specific Strength

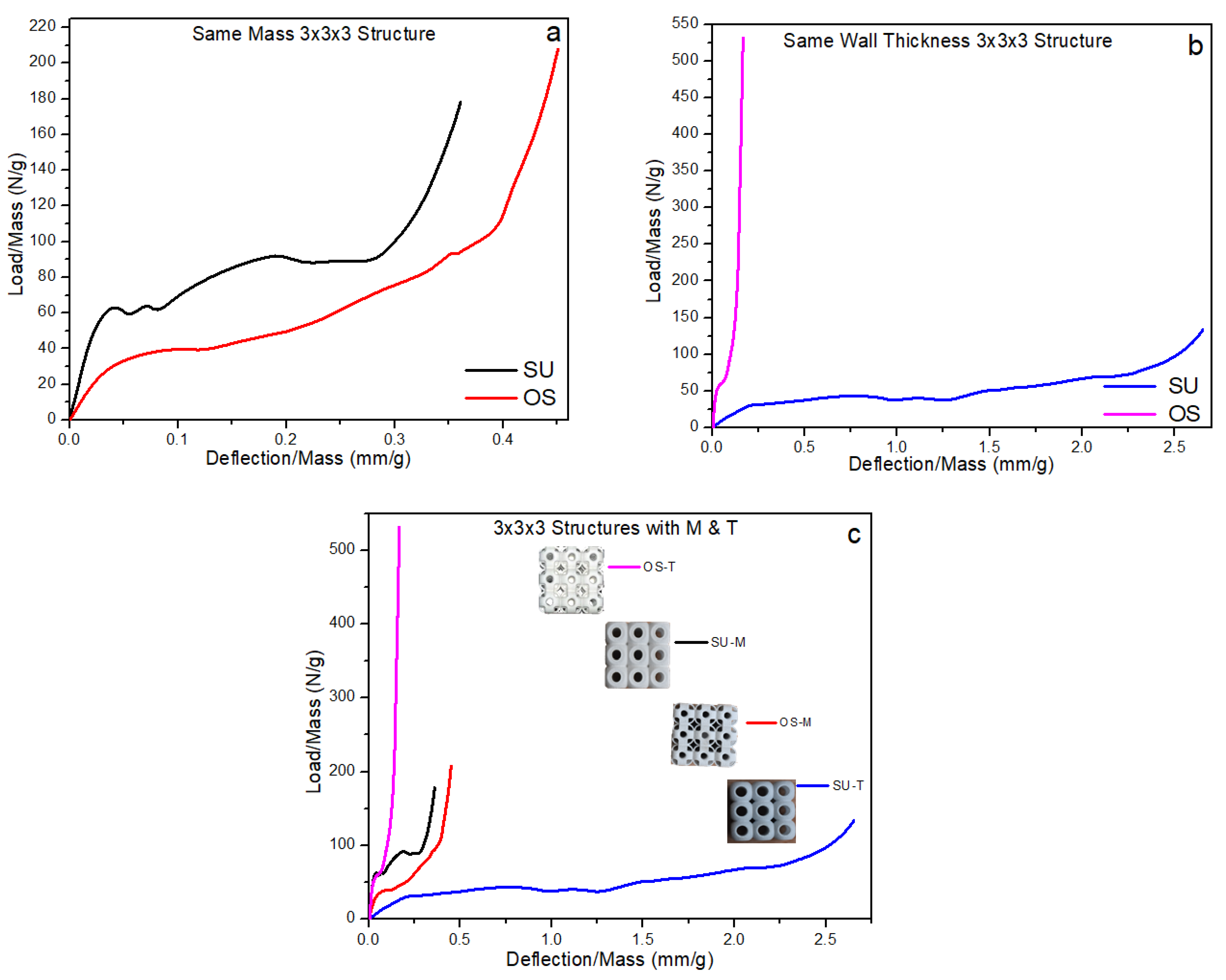

3.3.1. Specific Strength of 3 × 3 × 3 Structure

3.3.2. Specific Strength of 2 × 2 × 15 Structure

3.4. Experimental Data Validation

3.5. Challenges and Recommendation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Pan, C.; Han, Y.; Lu, J. Design and optimization of lattice structures: A review. Appl. Sci. 2020, 10, 6374. [Google Scholar] [CrossRef]

- Seharing, A.; Azman, A.H.; Abdullah, S. A review on integration of lightweight gradient lattice structures in additive manufacturing parts. Adv. Mech. Eng. 2020, 12, 168781402091695. [Google Scholar] [CrossRef]

- Du, Y.; Gu, D.; Xi, L.; Dai, D.; Gao, T.; Zhu, J.; Ma, C. Laser additive manufacturing of bio-inspired lattice structure: Forming quality, microstructure and energy absorption behavior. Mater. Sci. Eng. A 2020, 773, 138857. [Google Scholar] [CrossRef]

- Wang, R.; Shang, J.; Li, X.; Wang, Z.; Luo, Z. Novel topological design of 3D Kagome structure for additive manufacturing. Rapid Prototyp. J. 2018, 24, 261–269. [Google Scholar] [CrossRef]

- Han, Y.; Lu, W.F. A novel design method for nonuniform lattice structures based on topology optimization. J. Mech. Des. Trans. ASME 2018, 140. [Google Scholar] [CrossRef]

- Jang, K.I.; Chung, H.U.; Xu, S.; Lee, C.H.; Luan, H.; Jeong, J.; Cheng, H.; Kim, G.T.; Han, S.Y.; Lee, J.W.; et al. Soft network composite materials with deterministic and bio-inspired designs. Nat. Commun. 2015, 6, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Ha, N.S.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B Eng. 2020, 181, 107496. [Google Scholar] [CrossRef]

- Ashby, M.F. Cellular Solids: Structure and Properties; Lorna, J., Gibson, M., Ashby, F., Eds.; Cambridge Univ. Press: Cambridge, UK, 1997. [Google Scholar]

- Chu, C.; Graf, G.; Rosen, D.W. Design for Additive Manufacturing of Cellular Structures. Comput. Aided Des. Appl. 2008, 5, 686–696. [Google Scholar] [CrossRef]

- Rosen, D.W. Computer-aided design for additive manufacturing of cellular structures. Comput. Aided Des. Appl. 2007, 4, 585–594. [Google Scholar] [CrossRef]

- Nguyen, D.S.; Vignat, F. A method to generate lattice structure for Additive Manufacturing. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management. IEEE Computer Society, Singapore, 13–16 September 2016; pp. 966–970. [Google Scholar]

- Parthasarathy, J.; Starly, B.; Raman, S. A design for the additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. J. Manuf. Process. 2011, 13, 160–170. [Google Scholar] [CrossRef]

- Wong, M.; Owen, I.; Sutcliffe, C.J.; Puri, A. Convective heat transfer and pressure losses across novel heat sinks fabricated by Selective Laser Melting. Int. J. Heat. Mass. Transf. 2009, 52, 281–288. [Google Scholar] [CrossRef]

- Shen, Y.; Mckown, S.; Tsopanos, S.; Sutcliffe, C.J.; Mines, R.A.W.; Cantwell, W.J. The Mechanical Properties of Sandwich Structures Based on Metal Lattice Architectures. J. Sandw. Struct. Mater. 2010, 12, 159–180. [Google Scholar] [CrossRef]

- Plocher, J.; Panesar, A. Effect of density and unit cell size grading on the stiffness and energy absorption of short fibre-reinforced functionally graded lattice structures. Addit. Manuf. 2020. [Google Scholar] [CrossRef]

- Du, Y.; Li, H.; Luo, Z.; Tian, Q. Topological design optimization of lattice structures to maximize shear stiffness. Adv. Eng. Softw. 2017. [Google Scholar] [CrossRef]

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; Deotte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, ultrastiff mechanical metamaterials. Science 2014, 344, 1373–1377. [Google Scholar] [CrossRef]

- Kumar, A.; Collini, L.; Daurel, A.; Jeng, J.Y. Design and additive manufacturing of closed cells from supportless lattice structure. Addit. Manuf. 2020, 33, 101168. [Google Scholar] [CrossRef]

- Maskery, I.; Aremu, A.O.; Parry, L.; Wildman, L.D.; Tuck, C.J.; Aschcroft, I.A. Effective design and simulation of surface-based lattice structures featuring volume fraction and cell type grading. Mater. Des. 2018, 155, 220–232. [Google Scholar] [CrossRef]

- Ashby, M. The properties of foams and lattices. Philos. Trans. R Soc. A Math. Phys. Eng. Sci. 2006, 364, 15–30. [Google Scholar] [CrossRef]

- Arshad, A.B.; Nazir, A.; Jeng, J.Y. The effect of fillets and crossbars on mechanical properties of lattice structures fabricated using additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 111, 931–943. [Google Scholar] [CrossRef]

- Beyer, C.; Figueroa, D. Design and Analysis of Lattice Structures for Additive Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2016, 138. [Google Scholar] [CrossRef]

- Saghaian, S.; Amerinatanzi, A.; Moghaddam, N.; Majumdar, A.; Nematollahi, M.; Saedi, S. Mechanical and shape memory properties of triply periodic minimal surface (TPMS) NiTi structures fabricated by selective laser melting. Biol. Eng. Med. 2018, 3. [Google Scholar] [CrossRef]

- Primo, T.; Calabrese, M.; Del Prete, A.; Anglani, A. Additive manufacturing integration with topology optimization methodology for innovative product design. Int. J. Adv. Manuf. Technol. 2017, 93, 467–479. [Google Scholar] [CrossRef]

- Ye, X.C.; Lin, X.C.; Xiong, J.Y.; Wu, H.H.; Zhao, G.W.; Fang, D. Electrical properties of 3D printed graphite cellular lattice structures with triply periodic minimal surface architectures. Mater. Res. Express 2019, 6, 125609. [Google Scholar] [CrossRef]

- Femmer, T.; Kuehne, A.J.C.; Wessling, M. Estimation of the structure dependent performance of 3-D rapid prototyped membranes. Chem. Eng. J. 2015, 273, 438–445. [Google Scholar] [CrossRef]

- Wieding, J.; Jonitz, A.; Bader, R. The Effect of Structural Design on Mechanical Properties and Cellular Response of Additive Manufactured Titanium Scaffolds. Materials 2012, 5, 1336–1347. [Google Scholar] [CrossRef]

- Almeida, H.A.; Bártolo, P.J. Design of tissue engineering scaffolds based on hyperbolic surfaces: Structural numerical evaluation. Med. Eng. Phys. 2014, 36, 1033–1040. [Google Scholar] [CrossRef] [PubMed]

- Latture, R.M.; Rodriguez, R.X.; Holmes, L.R.; Zok, F.W. Effects of nodal fillets and external boundaries on compressive response of an octet truss. Acta Mater. 2018, 149, 78–87. [Google Scholar] [CrossRef]

- Gümrük, R.; Mines, R.A.W. Compressive behaviour of stainless steel micro-lattice structures. Int. J. Mech. Sci. 2013, 68, 125–139. [Google Scholar] [CrossRef]

- Sui, Q.; Lai, C.; Fan, H. Buckling failure modes of one-dimensional lattice truss composite structures. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2018, 232, 2565–2583. [Google Scholar] [CrossRef]

- Weeger, O.; Boddeti, N.; Yeung, S.K.; Kaijima, S.; Dunn, M.L. Digital design and nonlinear simulation for additive manufacturing of soft lattice structures. Addit. Manuf. 2019, 25, 39–49. [Google Scholar] [CrossRef]

- Sun, G.; Pang, T.; Xu, C.; Zheng, G.; Song, J. Energy absorption mechanics for variable thickness thin-walled structures. Thin Walled Struct. 2017, 118, 214–228. [Google Scholar] [CrossRef]

- Nazir, A.; Arshad, A.B.; Jeng, J.-Y. Buckling and Post-Buckling Behavior of Uniform and Variable-Density Lattice Columns Fabricated Using Additive Manufacturing. Materials 2019, 12, 3539. [Google Scholar] [CrossRef] [PubMed]

- Kastratović, G.; Vidanović, N.; Grbović, A.; Rašuo, B. Approximate determination of stress intensity factor for multiple surface cracks. FME Trans. 2018, 46, 39–45. [Google Scholar] [CrossRef]

- Sui, Q.; Fan, H.; Lai, C. Failure analysis of 1D lattice truss composite structure in uniaxial compression. Compos. Sci. Technol. 2015. [Google Scholar] [CrossRef]

- Guessasma, S.; Tao, L.; Belhabib, S.; Zhu, J.; Zhang, W.; Nouri, H. Analysis of microstructure and mechanical performance of polymeric cellular structures designed using stereolithography. Eur. Polym. J. 2018, 98, 72–82. [Google Scholar] [CrossRef]

- Gautam, R.; Idapalapati, S.; Feih, S. Printing and characterisation of Kagome lattice structures by fused deposition modelling. Mater. Des. 2018, 137, 266–275. [Google Scholar] [CrossRef]

- EACPDS. Creo Software; Version 4.0, PTC’s 3D Modeling CAD Software; EACPDS: Boston, MA, USA, 1987. [Google Scholar]

- Nath, S.D.; Nilufar, S. An Overview of Additive Manufacturing of Polymers and Associated Composites. Polymers 2020, 12, 2719. [Google Scholar] [CrossRef]

- Ali, M.; Nazir, A.; Jeng, J.-Y. Mechanical performance of additive manufactured shoe midsole designed using variable-dimension helical springs. Int. J. Adv. Manuf. Technol. 2020, 1–20. [Google Scholar] [CrossRef]

- Callister, W.D.; David Rethwisch, J.G. Materials Science and Engineering, 8th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; pp. 170–171. [Google Scholar]

- HP Development Company, HP Jet Fusion 580 Color-Product Specifications-3D Printing. Available online: https://hp3d.pl/pdf/User_guide_jet_fusion_580_3d.pdf?v=v064 (accessed on 1 February 2021).

- ASTM. Standard D1621 Standard Test Method for Compressive Properties of Rigid Cellular Plastics. ASTM B Stand. 2016, 0, 1–5. [Google Scholar]

- Keller, J.B. The shape of the strongest column. Arch. Ration Mech. Anal. 1960, 5, 275–285. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Cedolin, L. Stability of Structures: Elastic, Inelastic, Fracture and Damage Theories; World Scientific Publishing Co.: London, UK, 2010. [Google Scholar]

- Overvelde, J.T.B.; Shan, S.; Bertoldi, K. Compaction Through Buckling in 2D Periodic, Soft and Porous Structures: Effect of Pore Shape. Adv. Mater. 2012, 24, 2337–2342. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.-W.; Elishakoff, I.; Starnes, J.H.; Bushnell, D. Effect of the thickness variation and initial imperfection on buckling of composite cylindrical shells: Asymptotic analysis and numerical results by BOSOR4 and PANDA2. Int. J. Solids Struct. 1997, 34, 3755–3767. [Google Scholar] [CrossRef]

- Karam, G.N.; Gibson, L.J. Elastic buckling of cylindrical shells with elastic cores-II. Experiments. Int. J. Solids Struct. 1995, 32, 1285–1306. [Google Scholar] [CrossRef]

- Peirson, B. Comparison of Specific Properties of Engineering Materials. Available online: https://www2.gvsu.edu/peirsonb/spec_prop.pdf (accessed on 2 February 2021).

- Stamping Simulation. The Strength-to-Weight Ratio of Metals. Available online: https://stampingsimulation.com/strength-to-weight-ratio-of-metals/ (accessed on 2 February 2021).

- Spadoni, A.; Ruzzene, M.; Scarpa, F. Global and local linear buckling behavior of a chiral cellular structure. Phys. Status Solidi 2005, 242, 695–709. [Google Scholar] [CrossRef]

- Pedersen, P.T.; Jensen, J.J. Buckling behaviour of imperfect spherical shells subjected to different load conditions. Thin Walled Struct. 1995, 23, 41–55. [Google Scholar] [CrossRef]

- Nazir, A.; Jeng, J.Y. Buckling behavior of additively manufactured cellular columns: Experimental and simulation validation. Mater. Des. 2020, 186. [Google Scholar] [CrossRef]

- Guo, L.; Yang, S.; Jiao, H. Behavior of thin-walled circular hollow section tubes subjected to bending. Thin Walled Struct. 2013, 73, 281–289. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11, 168781401882288. [Google Scholar] [CrossRef]

- Son, Y.K. A cost estimation model for advanced manufacturing systems. Int. J. Prod. Res. 1991, 29, 441–452. [Google Scholar] [CrossRef]

- Hopkinson, N.; Dicknes, P. Analysis of rapid manufacturing—using layer manufacturing processes for production. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2003, 217, 31–39. [Google Scholar] [CrossRef]

- Hunter, L.W.; Brackett, D.; Brierley, N.; Yang, J.; Attallah, M.A. Assessment of trapped powder removal and inspection strategies for powder bed fusion techniques. Int. J. Adv. Manuf. Technol. 2020, 106, 4521–4532. [Google Scholar] [CrossRef]

| Topology | Mass of a Unit Cell (g) | Wall Thickness (mm) | Dimensions of Structure(mm) | Relative Density of Designed Models (%) | Relative Density of AM Parts (%) | ||

|---|---|---|---|---|---|---|---|

| Height | Width | Breadth | |||||

| SU-M (3 × 3 × 3) | 0.27 | 2.3 | 30 | 30 | 30 | 28 | 29 |

| OS-M (3 × 3 × 3) | 0.27 | 0.65 | 30 | 30 | 30 | 28 | 25 |

| SU-M (2 × 2 × 15) | 0.27 | 2.3 | 149 | 20 | 20 | 28 | 27 |

| OS-M (2 × 2 × 15) | 0.27 | 0.65 | 149 | 20 | 20 | 28 | 24 |

| SU-T (3 × 3 × 3) | 0.127 | 1 | 30 | 30 | 30 | 13.5 | 10.5 |

| OS-T (3 × 3 × 3) | 0.39 | 1 | 30 | 30 | 30 | 39 | 45 |

| SU-T (2 × 2 × 15) | 0.127 | 1 | 149 | 20 | 20 | 13.5 | 10 |

| OS-T (2 × 2 × 15) | 0.39 | 1 | 149 | 20 | 20 | 39 | 40 |

| Density (g/cm3) | Young’s Modulus (MPa) | Poisson’s Ratio | Tensile Strength (MPa) | Ultimate Tensile Strength (MPa) |

|---|---|---|---|---|

| 1.01 | 1437 | 0.33 | 27 | 44 |

| True stress (MPa) | 27.12 | 30.00 | 34.09 | 37.00 | 40.01 | 43.02 | 46.00 | 48.03 | 50.00 | 52.69 |

| True plastic strain (mm/mm) | 0 | 0.002 | 0.007 | 0.011 | 0.016 | 0.023 | 0.032 | 0.040 | 0.050 | 0.077 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazir, A.; Ali, M.; Jeng, J.-Y. Investigation of Compression and Buckling Properties of a Novel Surface-Based Lattice Structure Manufactured Using Multi Jet Fusion Technology. Materials 2021, 14, 2599. https://doi.org/10.3390/ma14102599

Nazir A, Ali M, Jeng J-Y. Investigation of Compression and Buckling Properties of a Novel Surface-Based Lattice Structure Manufactured Using Multi Jet Fusion Technology. Materials. 2021; 14(10):2599. https://doi.org/10.3390/ma14102599

Chicago/Turabian StyleNazir, Aamer, Mubasher Ali, and Jeng-Ywan Jeng. 2021. "Investigation of Compression and Buckling Properties of a Novel Surface-Based Lattice Structure Manufactured Using Multi Jet Fusion Technology" Materials 14, no. 10: 2599. https://doi.org/10.3390/ma14102599

APA StyleNazir, A., Ali, M., & Jeng, J.-Y. (2021). Investigation of Compression and Buckling Properties of a Novel Surface-Based Lattice Structure Manufactured Using Multi Jet Fusion Technology. Materials, 14(10), 2599. https://doi.org/10.3390/ma14102599