The Impact of a Mobile Shading System and a Phase-Change Heat Store on the Thermal Functioning of a Transparent Building Partition

Abstract

1. Introduction

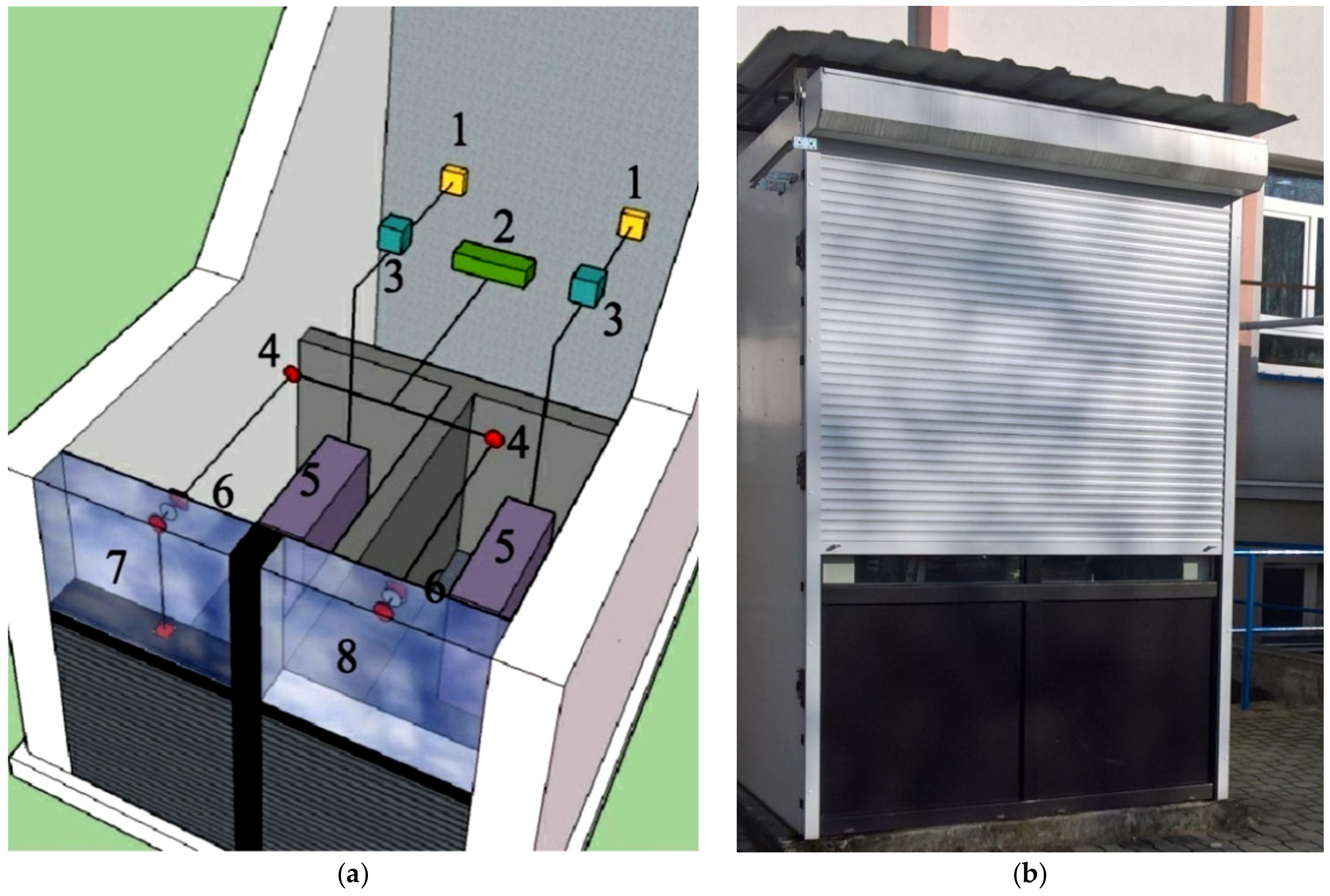

2. Materials and Methods

2.1. Materials

- Proprietary phase change material, in the form of a eutectic mixture of propyl palmitate and butyl stearate [25],

- a rectangular container made of 2 mm thick aluminium sheet, dimensions 650 mm × 100 mm × 50 mm, covered with a black matt paint coating,

- triple-glazed units of the termoflottype: Ug = 0.5 W/m2·K, containing a low-emission coating of the structure /4/16Ar/4/16Ar/4/,

- double-glazed units of the termoflottype: Ug = 0.7W/m2·K, with a low-emission coating, of the structure /4/16Ar/4/.

2.2. Apparatus

- Thermocouple LT 019008 (Ahlborn, Holzkirchen, Germany), (measurement error ±0.1 °C),

- Heat flux density sensor: type FQA020 C (Ahlborn, Holzkirchen, Germany), (measuring error ±2%),

- Almemo 2890-9 recorder (Ahlborn, Holzkirchen, Germany),

- Almemo FLA 613 GS pyarometer (Ahlborn, Holzkirchen, Germany), (measurement error ±5%),

- Thermoregulator Esco (Ahlborn, Holzkirchen, Germany), 4-channel with a hysteresis of 1 °C.

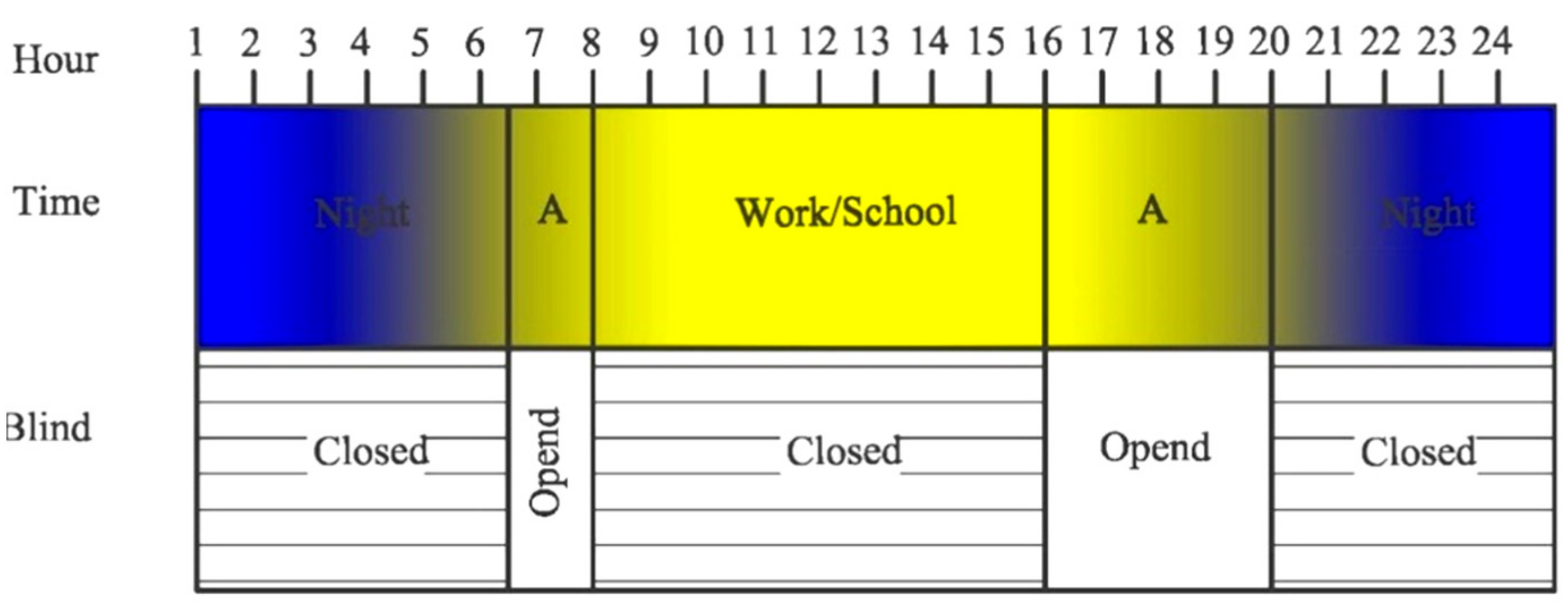

2.3. Research Method

- nature of the external climate,

- cardinal direction of the transparent barrier,

- light and heat demand profiles of the building.

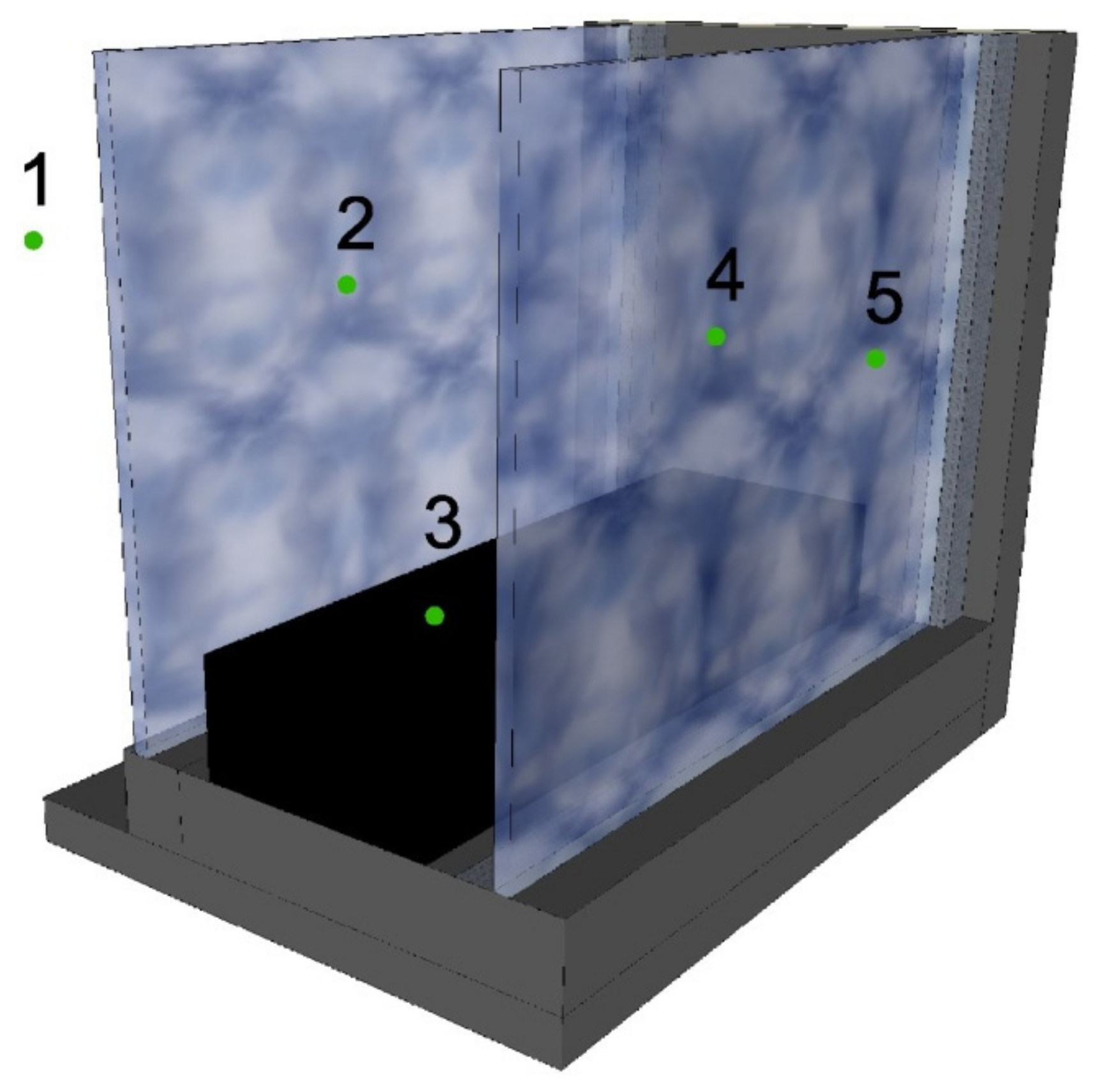

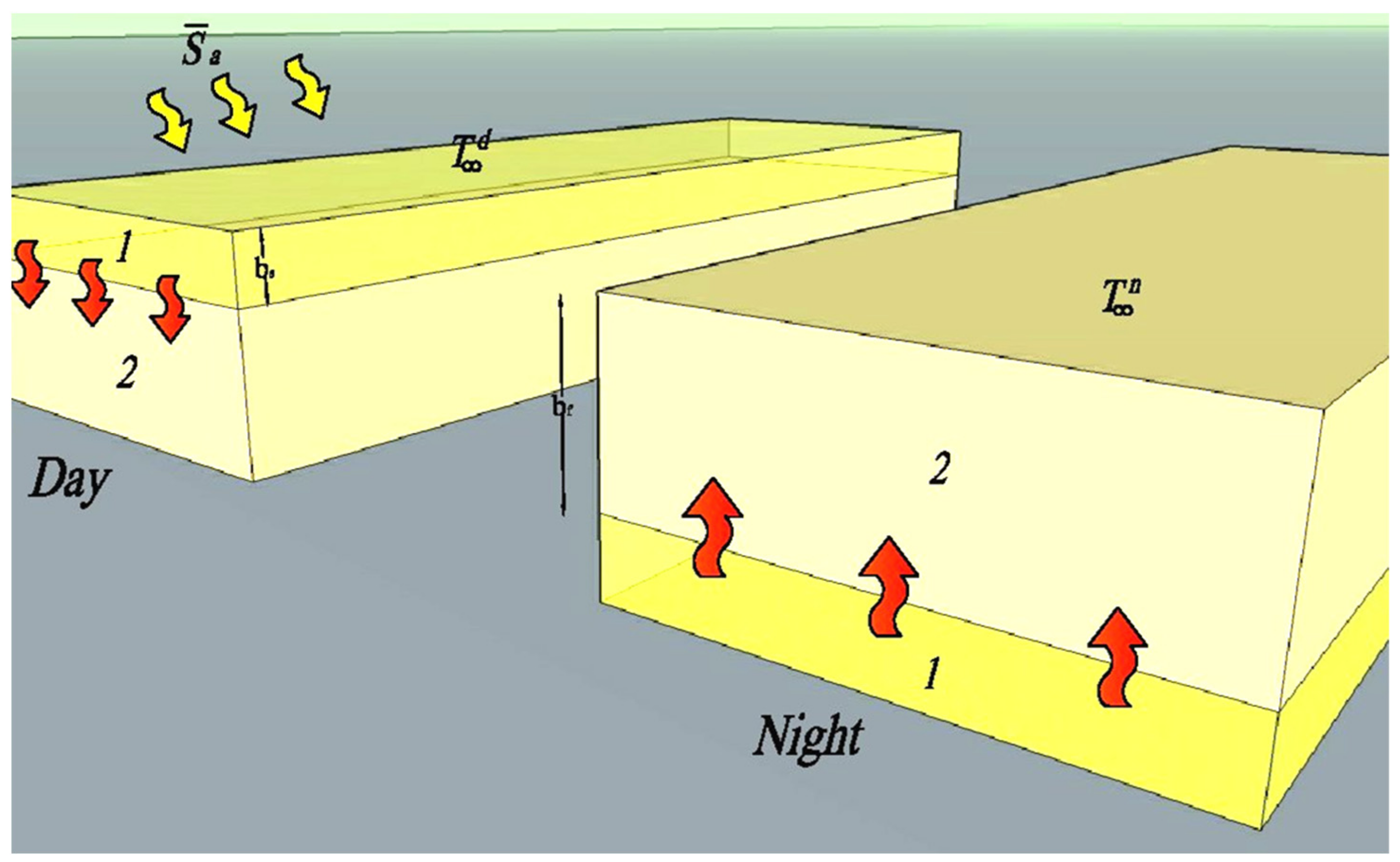

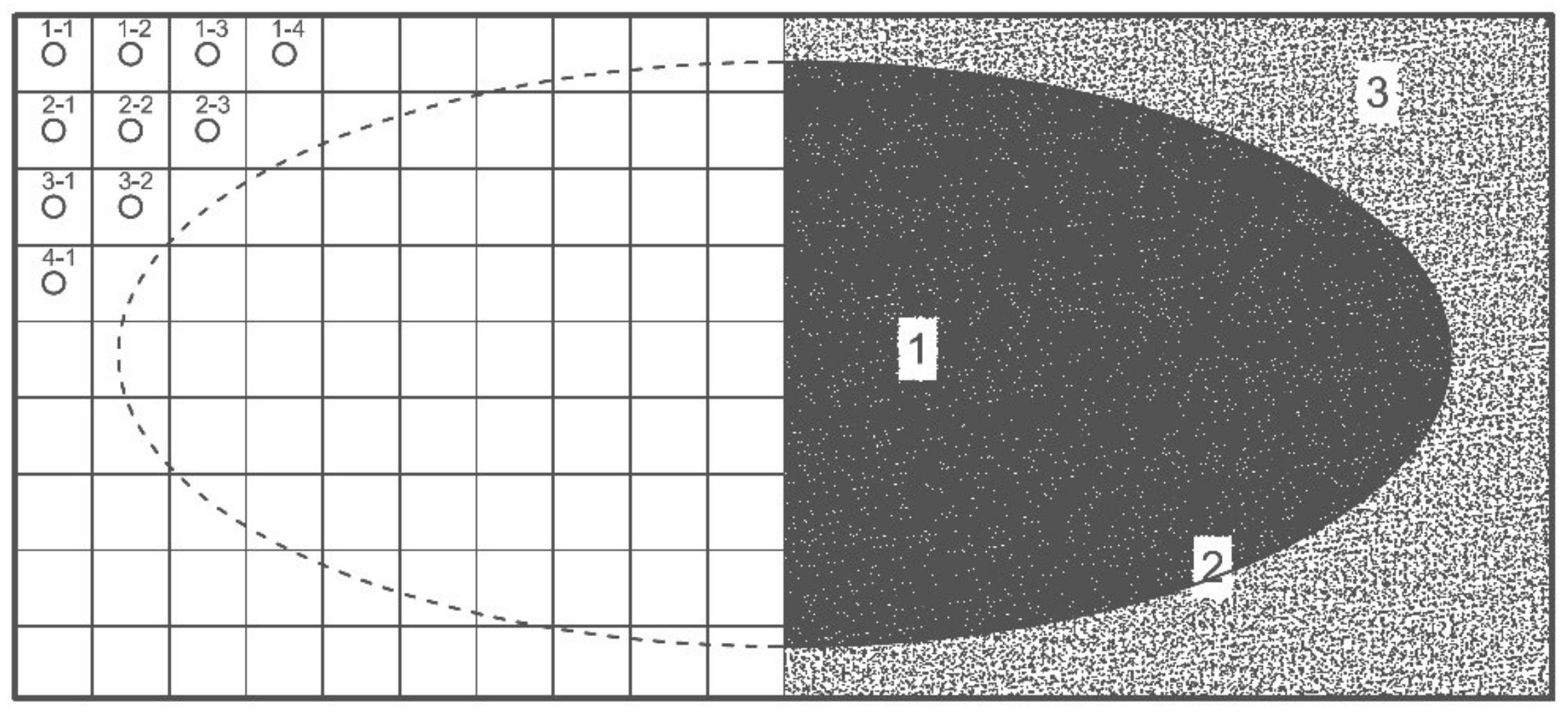

2.3.1. Numerical Model

2.3.2. Field Tests

3. Results

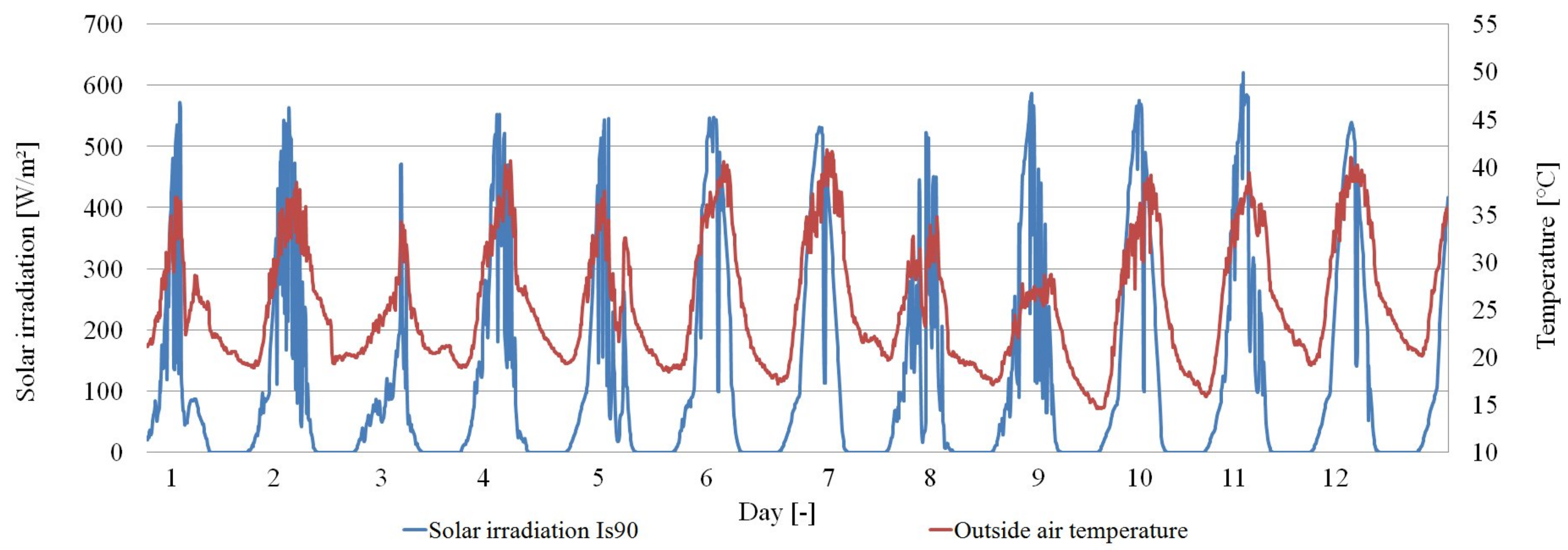

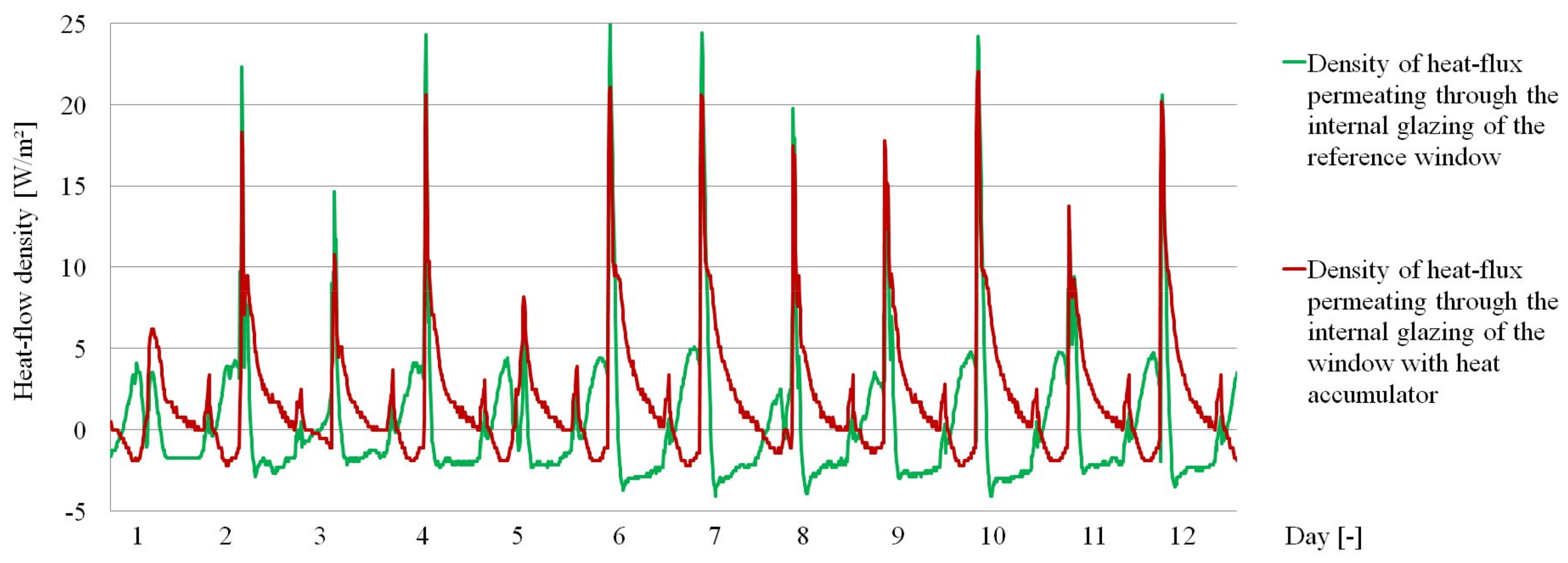

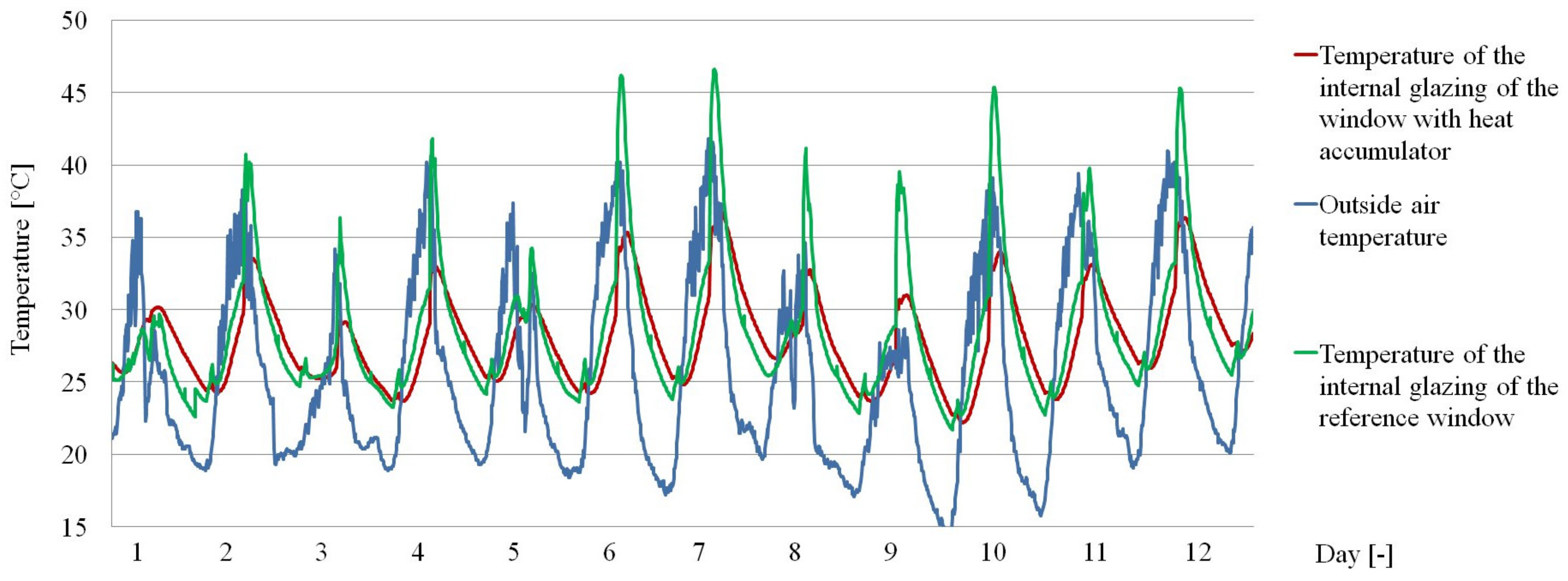

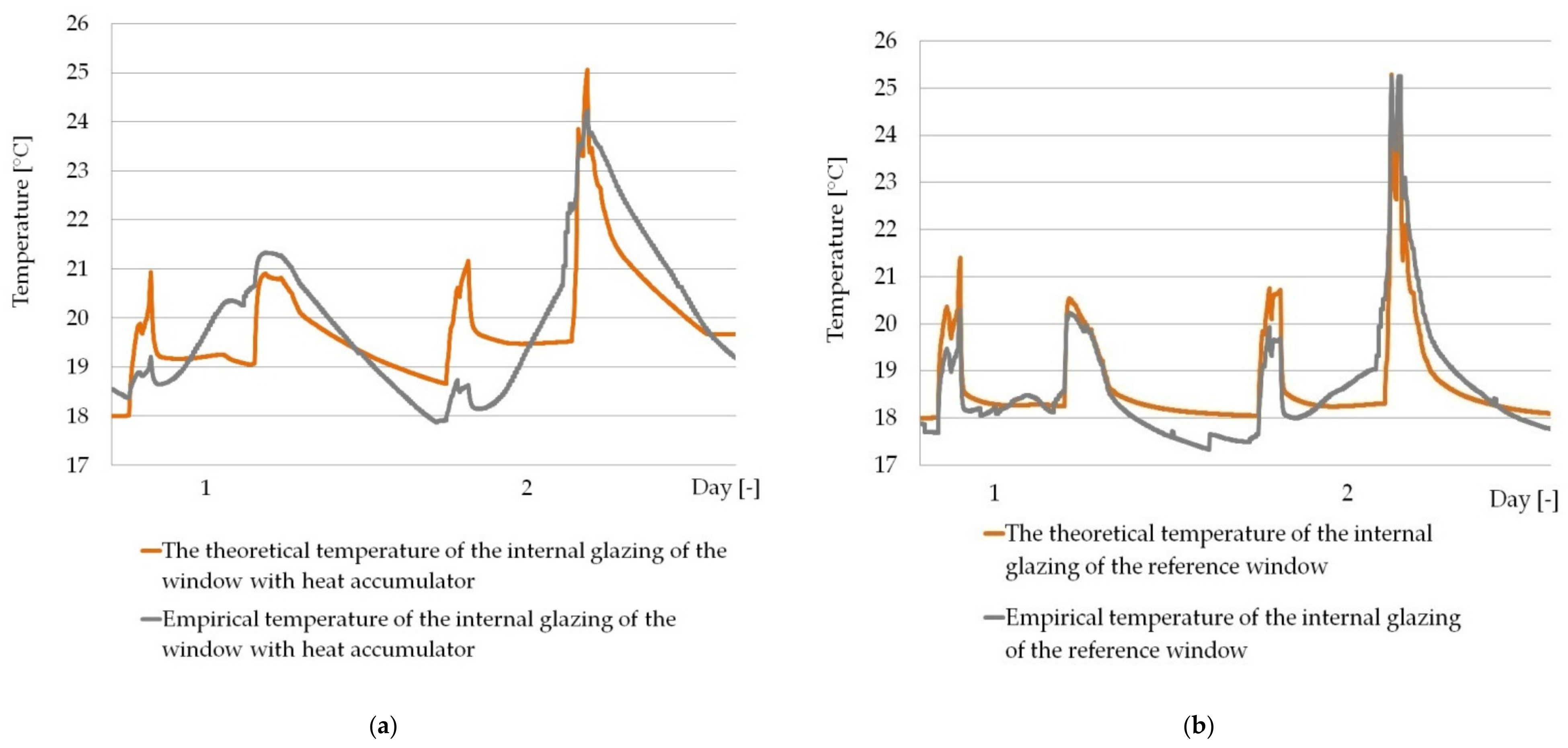

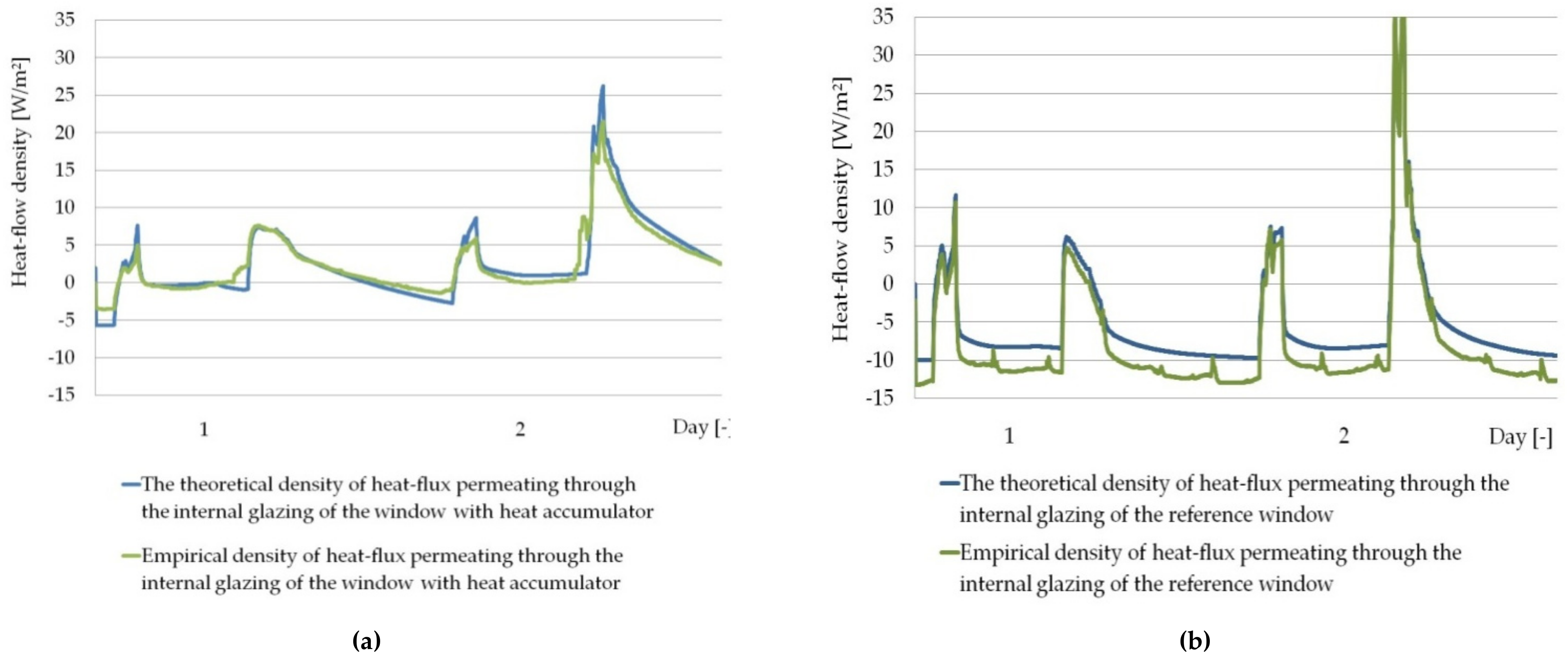

3.1. Empirical Results

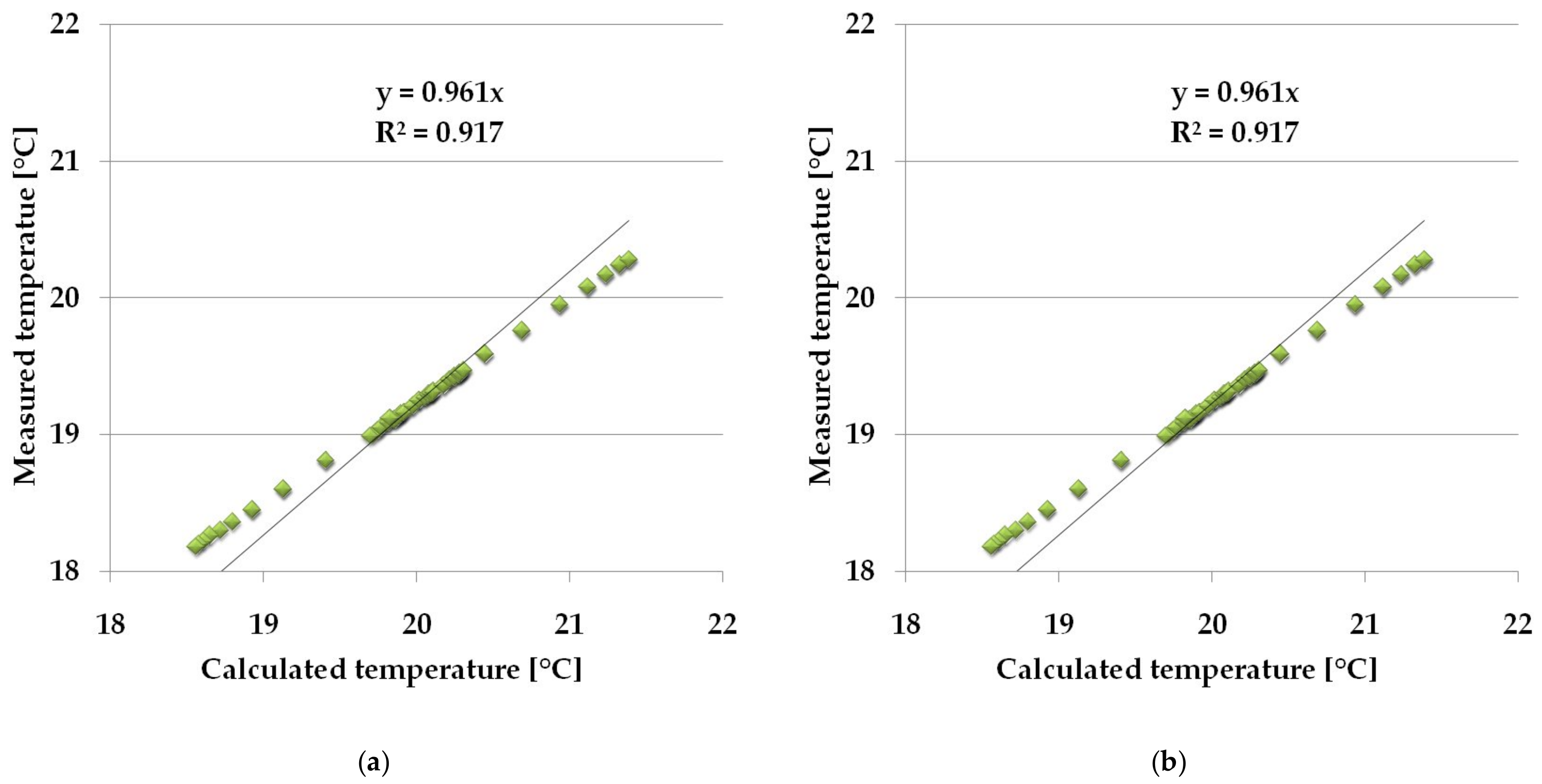

3.2. Results of Mathematical Analysis

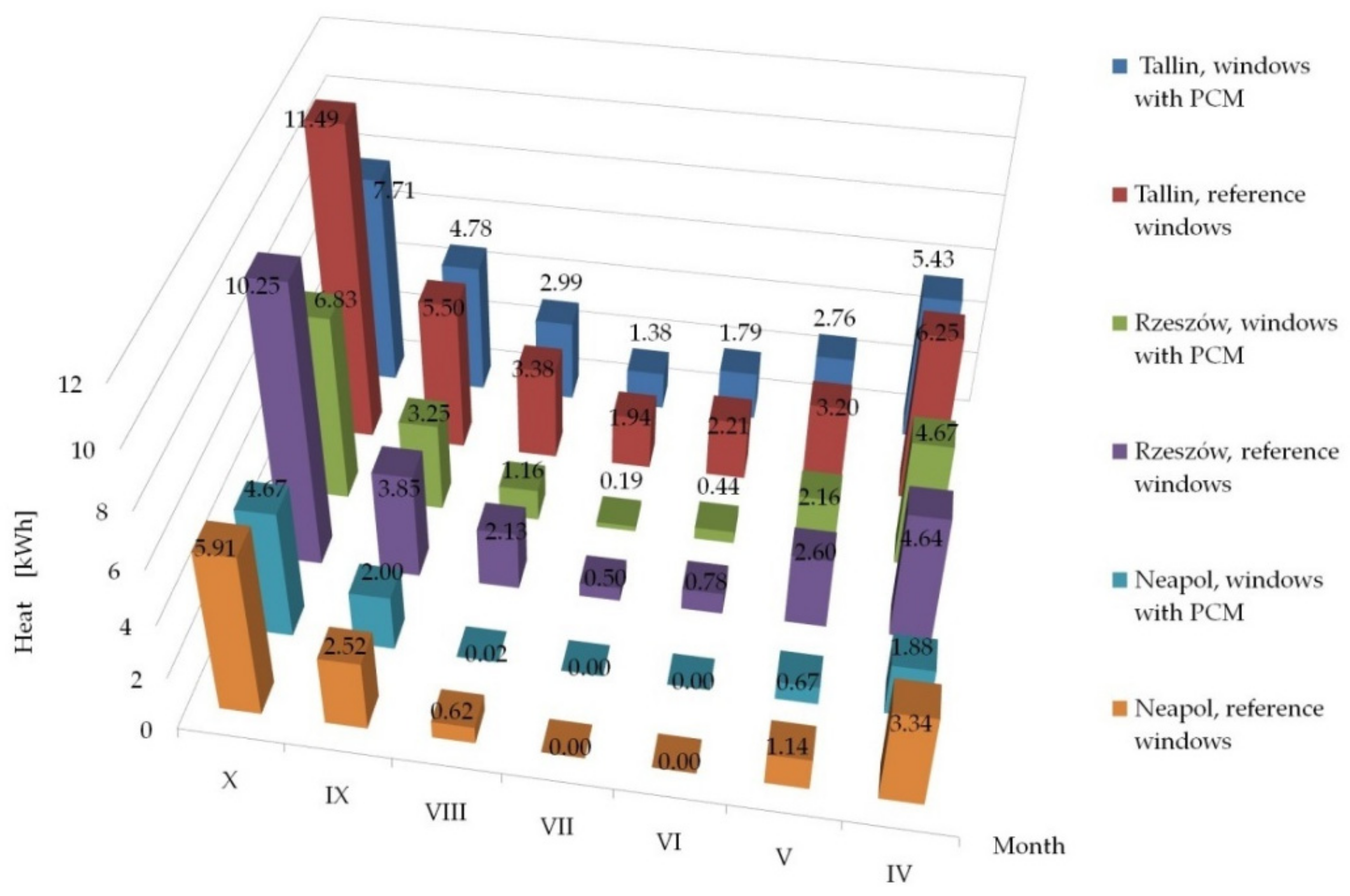

3.3. Assessment of the Impact of PCM Shading Systems in Various Climatic Conditions

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Meaning | Units |

|---|---|---|

| A | surface | m2 |

| bf | thickness of the melted PCM layer | m |

| bs | thickness of the solidified PCM layer | m |

| Cf | thermal capacity of the PCM | W/kg·K |

| Cw | specific heat of the material | W/kg·K |

| Cwi,PCM | specific heat of the PCM | W/kg·K |

| ΔHT | PCM phase change enthalpy | J/g |

| Q | Heat | Wh |

| qt | heat flux density as a function of time | W/m2 |

| R | heat resistance | m2·K/W |

| R2 | determination coefficients | [-] |

| additional heat flux | W/m2 | |

| Sth | number of degree hours | Kh |

| t | time | h |

| T | temperature | °C |

| Tpf | melting/freezing points of the PCM | °C |

| TT | phase change temperature of the PCM | °C |

| Δt | time step | h |

| Uu | storage unit heat loss factor | W/m2·K |

| Δxi | thickness of the element i, | m |

| y | arithmetic mean of the value of the independent variable | [-] |

| theoretical value of the explanatory variable | [-] | |

| yt | actual value of variable y at time t | [-] |

| λ | thermal conductivity | W/m·K |

| λf | PCM heat transfer rate | W/m·K |

| ϱ | surface density | kg/m2 |

| ϱmzf | PCM density | kg/m3 |

References

- Hu, Y.; Heiselberg, P.K.; Guo, R. Ventilation cooling/heating performance of a PCM enhanced ventilated window—An experimental study. Energy Build. 2020, 214, 109903. [Google Scholar] [CrossRef]

- Smolec, W. Photothermal Solar Energy Conversion; Polish Scientific Publisher: Warsaw, Poland, 2000; In Polish. [Google Scholar]

- Lee, E.S.; Pang, X.; McNeil, A.; Hoffmann, S.; Thanachareonkit, A.; Li, Z.; Ding, Y. Assessment of the Potential to Achieve very Low Energy Use in Public Buildings in China with Advanced Window and Shading Systems. Buildings 2015, 5, 668–699. [Google Scholar] [CrossRef]

- Kim, S.-H.; Shin, K.-J.; Choi, B.-E.; Jo, J.-H.; Cho, S.; Cho, Y.-H. A Study on the Variation of Heating and Cooling Load According to the Use of Horizontal Shading and Venetian Blinds in Office Buildings in Korea. Energies 2015, 8, 1487–1504. [Google Scholar] [CrossRef]

- Setiawan, A.F.; Huang, T.-L.; Tzeng, C.-T.; Lai, C.-M. The Effects of Envelope Design Alternatives on the Energy Consumption of Residential Houses in Indonesia. Energies 2015, 8, 2788–2802. [Google Scholar] [CrossRef]

- Amirkhani, M.; Garcia-Hansen, V.; Isoardi, G.; Allan, A. An Energy Efficient Lighting Design Strategy to Enhance Visual Comfort in Offices with Windows. Energies 2017, 10, 1126. [Google Scholar] [CrossRef]

- Kunwar, N.; Bhandari, M. A Comprehensive Analysis of Energy and Daylighting Impact of Window Shading Systems and Control Strategies on Commercial Buildings in the United States. Energies 2020, 13, 2401. [Google Scholar] [CrossRef]

- Zhong, K.; Li, S.; Sun, G.; Li, S.; Zhang, X. Simulation study on dynamic heat transfer performance of PCM-filled glass window with different thermophysical parameters of phase change material. Energy Build. 2015, 106, 87–95. [Google Scholar] [CrossRef]

- Lai, K.; Wang, W.; Giles, H. Solar shading performance of window with constant and dynamic shading function in different climate zones. Sol. Energy 2017, 147, 113–125. [Google Scholar] [CrossRef]

- Samadi, S.; Noorzai, E.; Beltrán, L.O.; Abbasi, S. A computational approach for achieving optimum daylight inside buildings through automated kinetic shading systems. Front. Arch. Res. 2020, 9, 335–349. [Google Scholar] [CrossRef]

- Ghosh, A.; Neogi, S. Effect of fenestration geometrical factors on building energy consumption and performance evaluation of a new external solar shading device in warm and humid climatic condition. Sol. Energy 2018, 169, 94–104. [Google Scholar] [CrossRef]

- Huo, H.; Xu, W.; Li, A.; Cui, G.; Wu, Y.; Liu, C. Field comparison test study of external shading effect on thermal-optical performance of ultralow-energy buildings in cold regions of China. Build. Environ. 2020, 180, 106926. [Google Scholar] [CrossRef]

- Bhatia, A.; Sangireddy, S.A.R.; Garg, V. An approach to calculate the equivalent solar heat gain coefficient of glass windows with fixed and dynamic shading in tropical climates. J. Build. Eng. 2019, 22, 90–100. [Google Scholar] [CrossRef]

- Chi, F.; Zhu, Z.; Jin, L.; Bart, D. Calculation method of shading area covering southerly orientated windows for the Tangwu building in Sizhai village. Sol. Energy 2019, 180, 39–56. [Google Scholar] [CrossRef]

- Musiał, M. Analysis of the impact of selected factors on the effectiveness of using PCM in mobile window insulation 2018. E3S Web Conf. SOLINA 2018, 49, 00073. [Google Scholar] [CrossRef]

- Musiał, M. Evaluation of the energy efficiency of an internal blind containing PCM 2018. E3S Web Conf. SOLINA 2018, 49, 00074. [Google Scholar] [CrossRef]

- Park, J.H.; Yun, B.Y.; Chang, S.J.; Wi, S.; Jeon, J.; Kim, S. Impact of a passive retrofit shading system on educational building to improve thermal comfort and energy consumption. Energy Build. 2020, 216, 109930. [Google Scholar] [CrossRef]

- Sherif, A.; Sabry, H.; Arafa, R.; Wagdy, A. The Impact of Alternative Window Glazing Types and a Shading System on the Daylighting of Hospital Patient Rooms: Simulation Analysis under a Desert Clear Sky. Energy Procedia 2015, 78, 1805–1810. [Google Scholar] [CrossRef][Green Version]

- Abazari, T.; Mahdavinejad, M. Integrated Model for Shading and Airflow Window in BSk. Energy Procedia 2017, 122, 571–576. [Google Scholar] [CrossRef]

- Zheng, X.; Dai, T.; Tang, M. An experimental study of vertical greenery systems for window shading for energy saving in summer. J. Clean. Prod. 2020, 259, 120708. [Google Scholar] [CrossRef]

- Invidiata, A.; Ghisi, E. Life-cycle energy and cost analyses of window shading used to improve the thermal performance of houses. J. Clean. Prod. 2016, 133, 1371–1383. [Google Scholar] [CrossRef]

- Vigna, I.; Bianco, L.; Goia, F.; Serra, V. Phase Change Materials in Transparent Building Envelopes: A Strengths, Weakness, Opportunities and Threats (SWOT) Analysis. Energies 2018, 11, 111. [Google Scholar] [CrossRef]

- Musiał, M. Untersuchung des Einflusses der Geometrie von PCM-Elementen auf ihre Wärme speicher effizienz. Bauphysik 2019, 41, 324–330. [Google Scholar] [CrossRef]

- Szyszka, J.; Starakiewicz, A. A quasi-box window concept to improve the thermal-insulation property of old windows—Case study. E3S Web Conf. 2018, 49, 00115. [Google Scholar] [CrossRef]

- Musiał, M. Wykorzystanie organicznych estrów alifatycznych do otrzymania korzystnej energetycznie mieszaniny eutektycznej. PRZEMYSŁ CHEMICZNY 2018, 1, 69–70. [Google Scholar] [CrossRef]

- Lichołai, L.; Musiał, M. Experimental Analysis of the Function of a Window with a Phase Change Heat Accumulator. Materials 2020, 13, 3647. [Google Scholar] [CrossRef] [PubMed]

- Qiu, S.; Solomon, L.; Fang, M. Study of Material Compatibility for a Thermal Energy Storage System with Phase Change Material. Energies 2018, 11, 572. [Google Scholar] [CrossRef]

- Sá, A.V.; Azenha, M.; Guimarães, A.; Delgado, J. FEM Applied to Building Physics: Modeling Solar Radiation and Heat Transfer of PCM Enhanced Test Cells. Energies 2020, 13, 2200. [Google Scholar] [CrossRef]

- Lundström, L.; Akander, J.; Zambrano, J. Development of a Space Heating Model Suitable for the Automated Model Generation of Existing Multifamily Buildings—A Case Study in Nordic Climate. Energies 2019, 12, 485. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, P.-F.; Tzeng, C.-T.; Lai, C.-M. Thermal Performance of Microencapsulated Phase Change Material (mPCM) in Roof Modules during Daily Operation. Energies 2018, 11, 679. [Google Scholar] [CrossRef]

- Hu, Y.; Heiselberg, P.K. A new ventilated window with PCM heat exchanger—Performance analysis and design optimization. Energy Build. 2018, 169, 185–194. [Google Scholar] [CrossRef]

- Li, C.; Lyu, Y.; Li, C.; Qiu, Z. Energy performance of water flow window as solar collector and cooling terminal under adaptive control. Sustain. Cities Soc. 2020, 59, 102152. [Google Scholar] [CrossRef]

- Lyu, Y.-L.; Liu, W.-J.; Su, H.; Wu, X. Numerical analysis on the advantages of evacuated gap insulation of vacuum-water flow window in building energy saving under various climates. Energy 2019, 175, 353–364. [Google Scholar] [CrossRef]

- Li, D.; Zhang, C.; Li, Q.; Liu, C.; Arıcı, M.; Wu, Y. Thermal performance evaluation of glass window combining silica aerogels and phase change materials for cold climate of China. Appl. Therm. Eng. 2020, 165, 114547. [Google Scholar] [CrossRef]

- Zastawna-Rumin, A.; Kisilewicz, T.; Berardi, U. Novel Simulation Algorithm for Modeling the Hysteresis of Phase Change Materials. Energies 2020, 13, 1200. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, R.; Heiselberg, P.K. Performance and control strategy development of a PCM enhanced ventilated window system by a combined experimental and numerical study. Renew. Energy 2020, 155, 134–152. [Google Scholar] [CrossRef]

- Fang, T.; Lahdelma, R. Optimization of combined heat and power production with heat storage based on sliding time window method. Appl. Energy 2016, 162, 723–732. [Google Scholar] [CrossRef]

- Li, D.; Wang, B.; Li, Q.; Liu, C.; Arıcı, M.; Wu, Y. A numerical model to investigate non-gray photothermal characteristics of paraffin-containing glazed windows. Sol. Energy 2019, 194, 225–238. [Google Scholar] [CrossRef]

- Sun, C.; Giles, H.; Lian, Z. The dynamic impact of window characteristics on shading factor and energy consumption. Sol. Energy 2014, 102, 1–13. [Google Scholar] [CrossRef]

- Synthos Properties of Copolymers. Available online: https://www.synthosgroup.com/grupy-produktowe/synthos-specialties (accessed on 21 July 2020).

- Lichołai, L. Zastosowanie kopolimerów octanu winylu i akrylanów alkilowych do powlekania organicznych materiałów zmiennofazowych. PRZEMYSŁ CHEMICZNY 2018, 1, 66–68. [Google Scholar] [CrossRef]

- Musiał, M.M. Experimental and Numerical Analysis of the Energy Efficiency of Transparent Partitions with a Thermal Storage Unit. J. Ecol. Eng. 2020, 21, 201–211. [Google Scholar] [CrossRef]

- Hu, Y.; Heiselberg, P.K.; Johra, H.; Guo, R. Experimental and numerical study of a PCM solar air heat exchanger and its ventilation preheating effectiveness. Renew. Energy 2020, 145, 106–115. [Google Scholar] [CrossRef]

- Shabgard, H.; Zhu, W.; Faghri, A. Integral Solution of Two-Region Solid–Liquid Phase Change in Annular Geometries and Application to Phase Change Materials–Air Heat Exchangers. Energies 2019, 12, 4474. [Google Scholar] [CrossRef]

- Kisilewicz, T. Glazed building wall as a solar thermal collector. Arch. Civ. Mech. Eng. 2009, 9, 83–99. [Google Scholar] [CrossRef]

- Pogorzelski, J.A. Building Thermal Physics; Polish Scientific Publisher: Warsaw, Poland, 1976; In Polish. [Google Scholar]

- Photovoltaic Geographical Information System Europe. Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/tools.html (accessed on 21 July 2020).

| Month | Tallinn | Rzeszów | Naples | |||

|---|---|---|---|---|---|---|

| Window with PCM [kWh] | Reference Window [kWh] | Window with PCM [kWh] | Reference Window [kWh] | Window with PCM [kWh] | Reference Window [kWh] | |

| IV | −5.43 | −6.25 | −4.67 | −4.64 | −1.88 | −3.34 |

| V | −2.76 | −3.20 | −2.16 | −2.60 | −0.67 | −1.14 |

| VI | −1.79 | −2.21 | −0.44 | −0.78 | 0 | 0 |

| VII | −1.38 | −1.94 | −0.19 | −0.50 | 0 | 0 |

| VIII | −2.99 | −3.38 | −1.16 | −2.13 | −0.02 | −0.62 |

| IX | −4.78 | −5.50 | −3.25 | −3.85 | −2.00 | −2.52 |

| X | −7.71 | −11.45 | −6.83 | −8.25 | −4.67 | −5.91 |

| Sum | −26.85 | −33.97 | −18.67 | −22.74 | −7.36 | −13.52 |

| Month | Tallinn | Rzeszów | Naples | |||

|---|---|---|---|---|---|---|

| Window with PCM [kWh] | Reference Window [kWh] | Window with PCM [kWh] | Reference Window [kWh] | Window with PCM [kWh] | Reference Window [kWh] | |

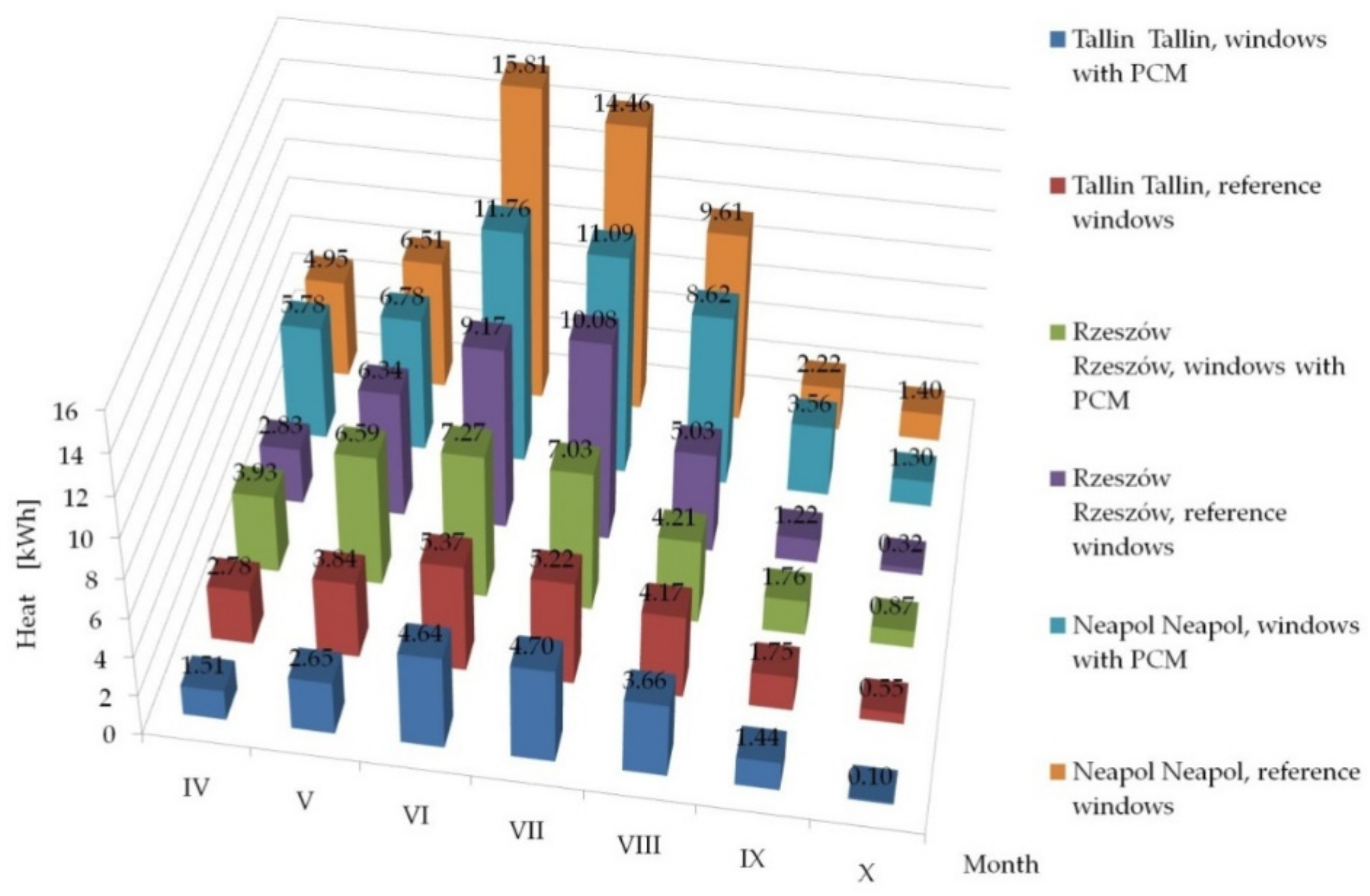

| IV | 1.51 | 2.78 | 3.93 | 2.83 | 5.78 | 4.95 |

| V | 2.65 | 3.84 | 6.59 | 6.34 | 6.76 | 6.51 |

| VI | 4.64 | 5.37 | 7.27 | 9.17 | 11.76 | 15.81 |

| VII | 4.70 | 5.22 | 7.03 | 10.08 | 11.09 | 14.46 |

| VIII | 3.66 | 4.17 | 4.21 | 5.03 | 8.62 | 9.61 |

| IX | 1.44 | 1.75 | 1.76 | 1.22 | 3.56 | 2.22 |

| X | 0.10 | 0.55 | 0.87 | 0.32 | 1.30 | 1.40 |

| Sum | 18.71 | 23.68 | 31.65 | 34.99 | 48.89 | 54.96 |

| Month | Tallinn | Rzeszów | Naples | |||

|---|---|---|---|---|---|---|

| Window with PCM [kWh] | Reference Window [kWh] | Window with PCM [kWh] | Reference Window [kWh] | Window with PCM [kWh] | Reference Window [kWh] | |

| IV | −3.92 | −3.47 | −0.74 | −1.81 | 3.90 | 1.61 |

| V | −0.11 | 0.64 | 4.43 | 3.75 | 6.10 | 5.37 |

| VI | 2.86 | 3.16 | 6.83 | 8.39 | 11.76 | 15.81 |

| VII | 3.32 | 3.27 | 6.84 | 9.57 | 11.09 | 14.46 |

| VIII | 0.67 | 0.79 | 3.05 | 3.90 | 8.60 | 8.99 |

| IX | −3.35 | −3.75 | −1.49 | −2.63 | 1.56 | −0.30 |

| X | −7.61 | −10.94 | −5.96 | −7.93 | −3.37 | −4.52 |

| Sum | −8.14 | −10.29 | 12.95 | 13.26 | 39.64 | 41.44 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musiał, M.; Lichołai, L. The Impact of a Mobile Shading System and a Phase-Change Heat Store on the Thermal Functioning of a Transparent Building Partition. Materials 2021, 14, 2512. https://doi.org/10.3390/ma14102512

Musiał M, Lichołai L. The Impact of a Mobile Shading System and a Phase-Change Heat Store on the Thermal Functioning of a Transparent Building Partition. Materials. 2021; 14(10):2512. https://doi.org/10.3390/ma14102512

Chicago/Turabian StyleMusiał, Michał, and Lech Lichołai. 2021. "The Impact of a Mobile Shading System and a Phase-Change Heat Store on the Thermal Functioning of a Transparent Building Partition" Materials 14, no. 10: 2512. https://doi.org/10.3390/ma14102512

APA StyleMusiał, M., & Lichołai, L. (2021). The Impact of a Mobile Shading System and a Phase-Change Heat Store on the Thermal Functioning of a Transparent Building Partition. Materials, 14(10), 2512. https://doi.org/10.3390/ma14102512